Coking wastewater strong brine recycling method

A technology for coking wastewater and concentrated brine, applied in the field of water treatment, can solve the problems of no coking wastewater reverse osmosis concentrated brine treatment and reuse reports, etc., and achieve good social and environmental benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

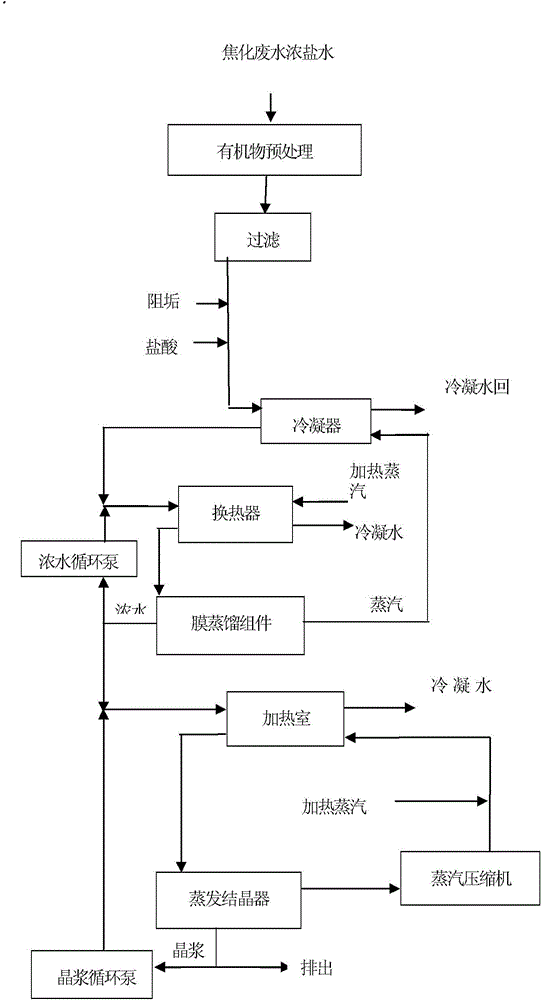

Image

Examples

Embodiment Construction

[0040] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

[0041] The invention provides a method for reusing concentrated brine of coking wastewater, comprising the following steps:

[0042] (1) Organic matter pretreatment

[0043] First use O 3 / H 2 o 2 Oxidize the concentrated brine, the reaction time is 10-20min, the dosage of O3 is 5-30mg / L, the H 2 o 2 The dosage is 30~100mg / L, and the removal rate of COD after oxidation is 20~40%. At the same time, B / C(BOD 5 / COD) increased from 0.05 to 0.4~0.6; the chemically oxidized effluent enters the biological contact oxidation reactor for further treatment, the hydraulic retention time of the biological contact oxidation is 2~10h, and the effluent COD is below 80mg / L.

[0044] (2) filter

[0045] The effluent from the bioreactor enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com