Patents

Literature

86results about How to "Increase vaporization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

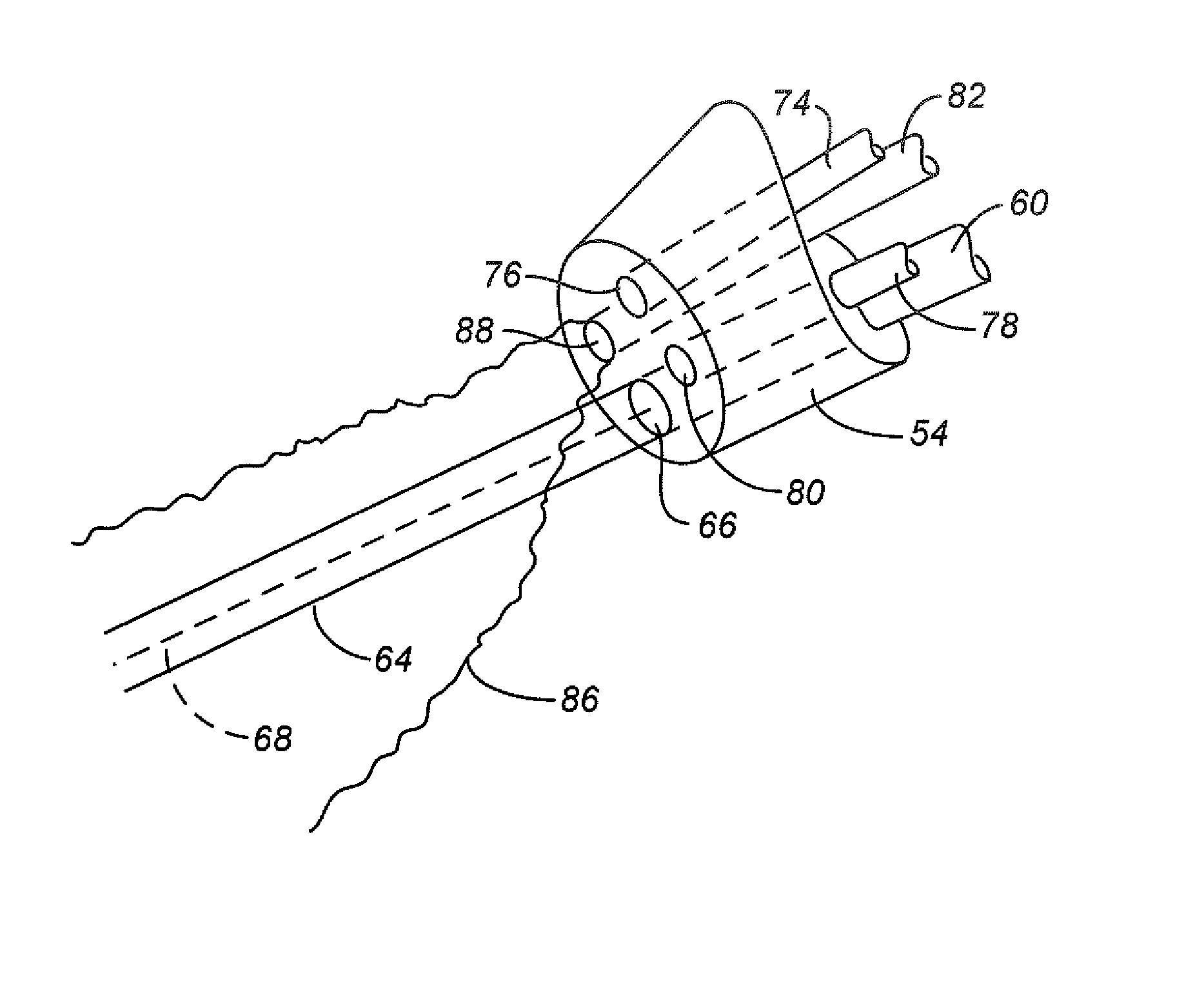

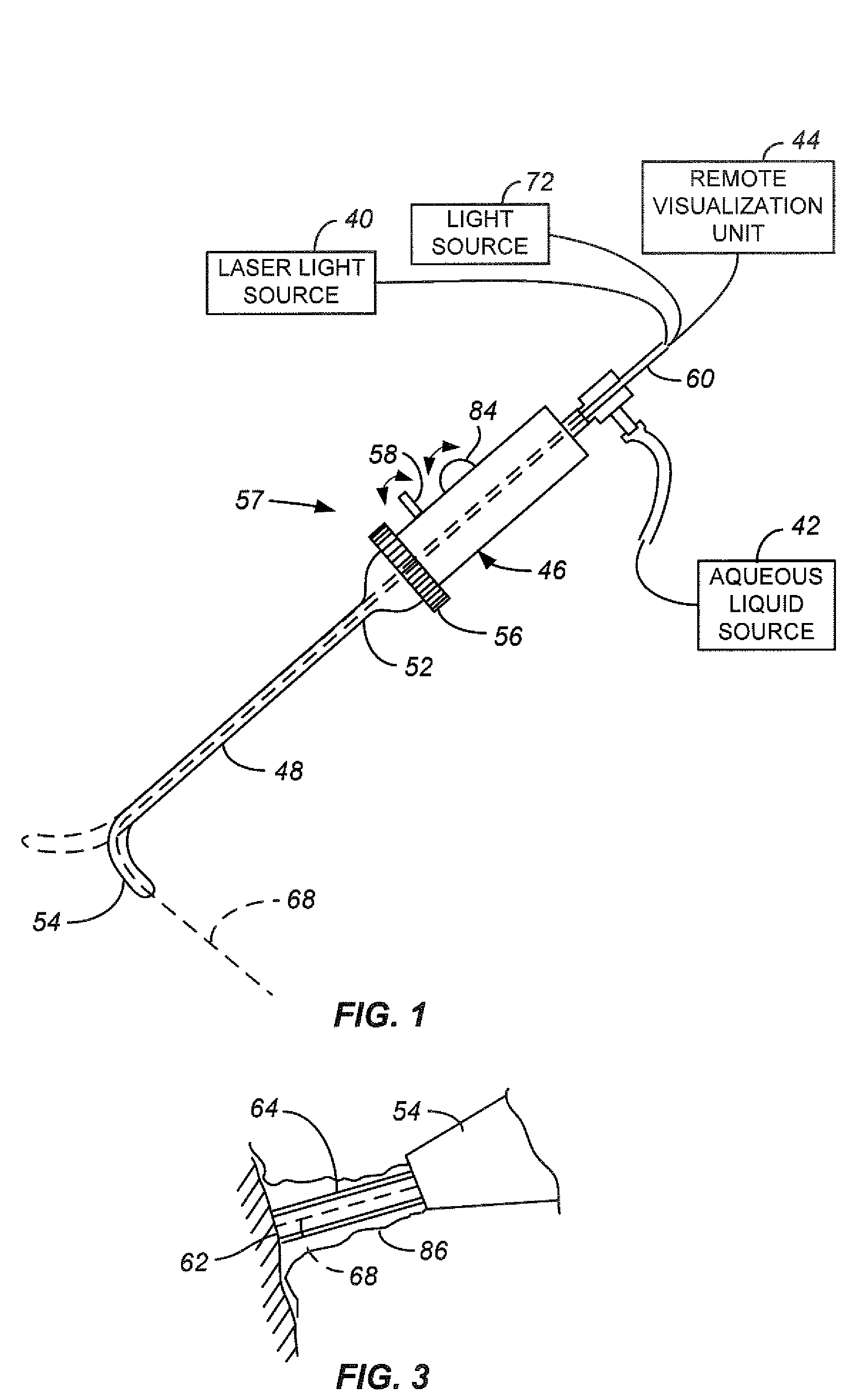

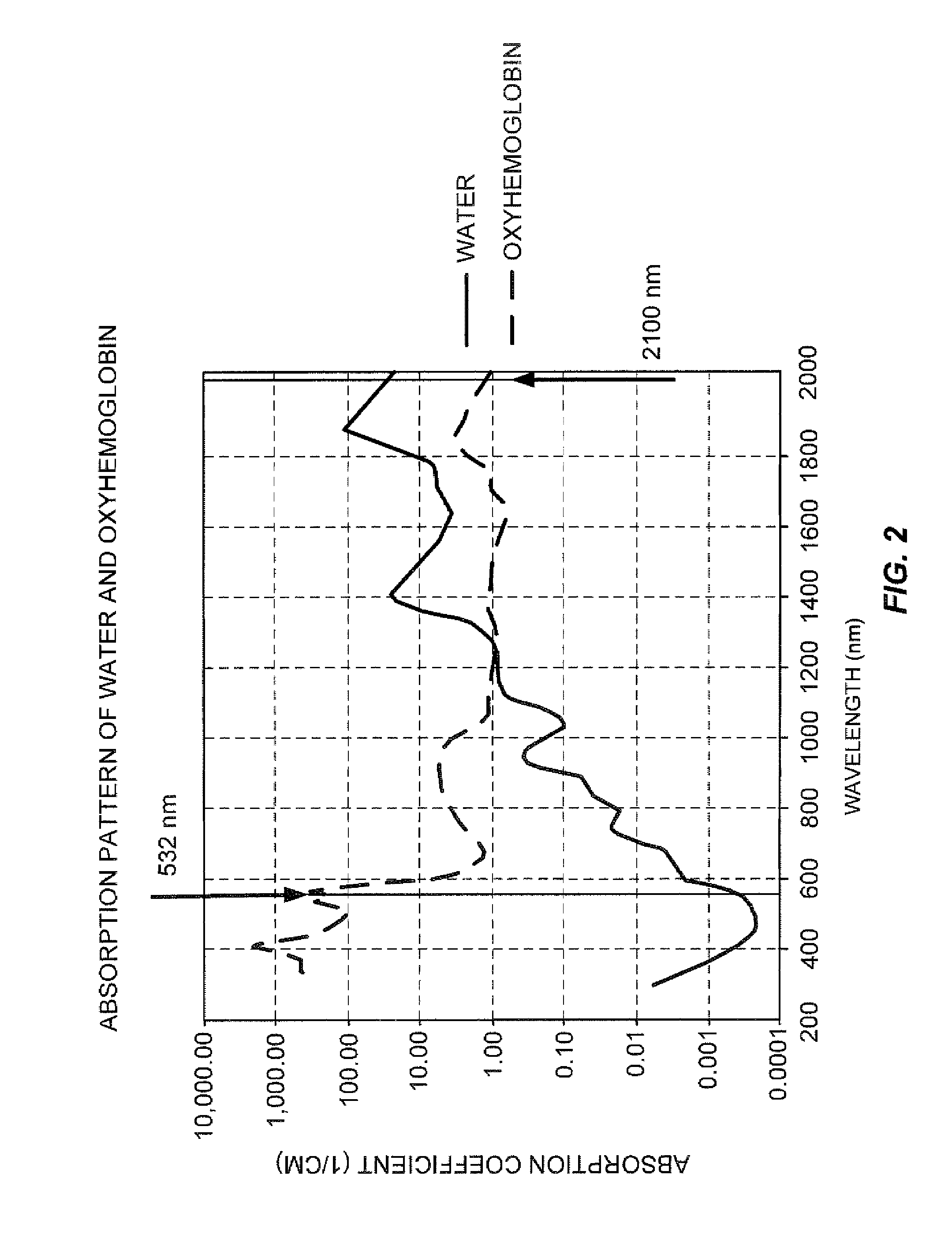

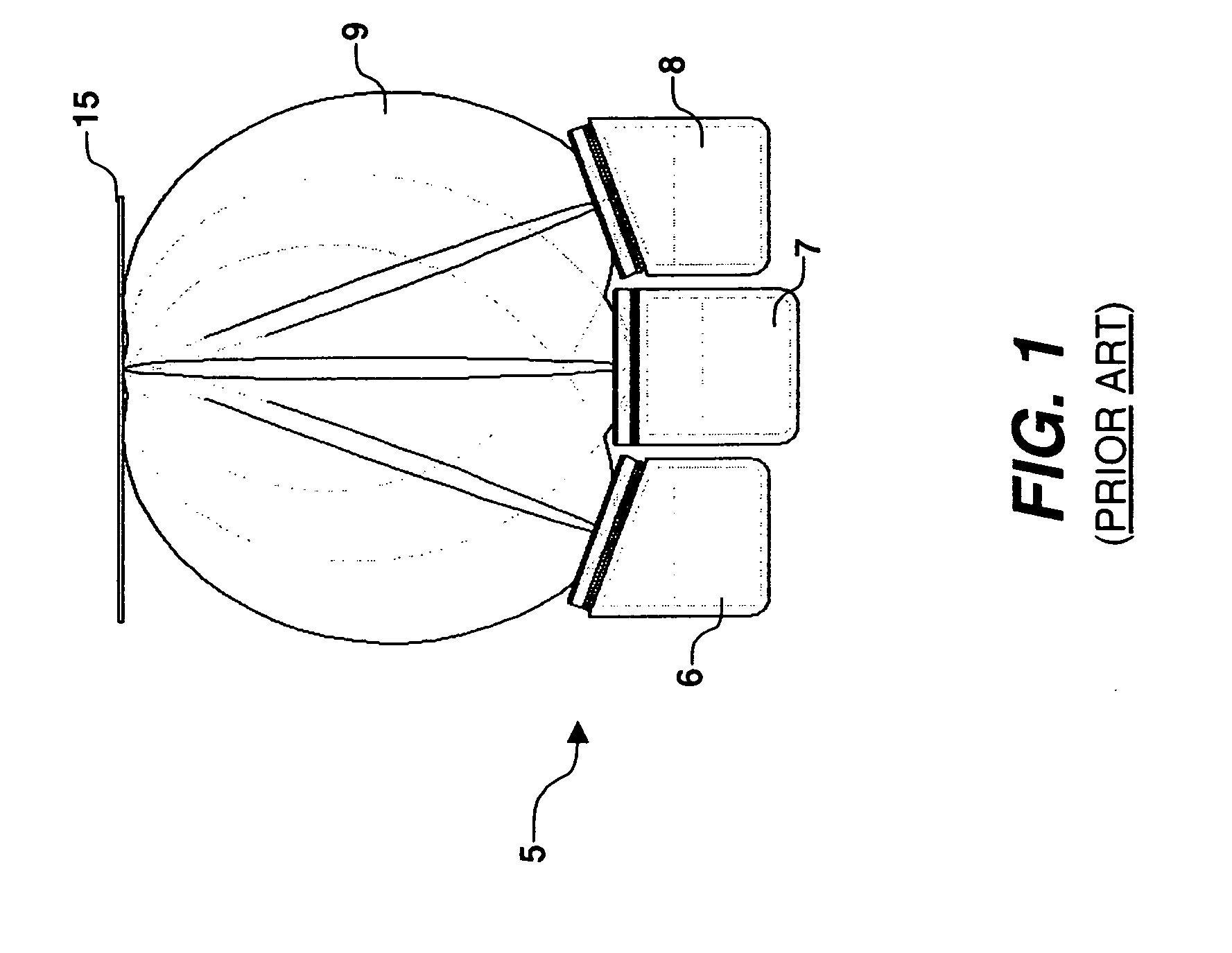

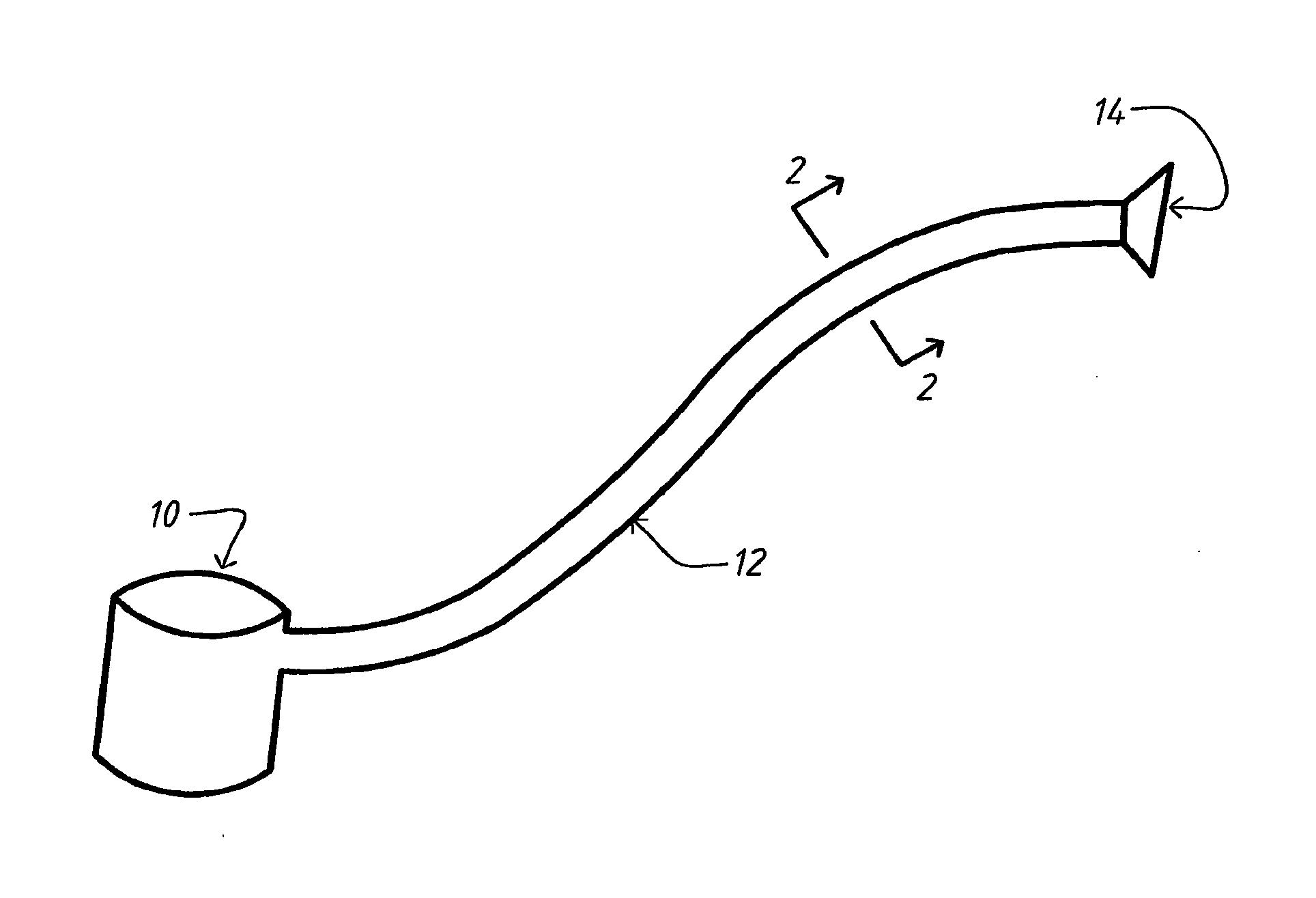

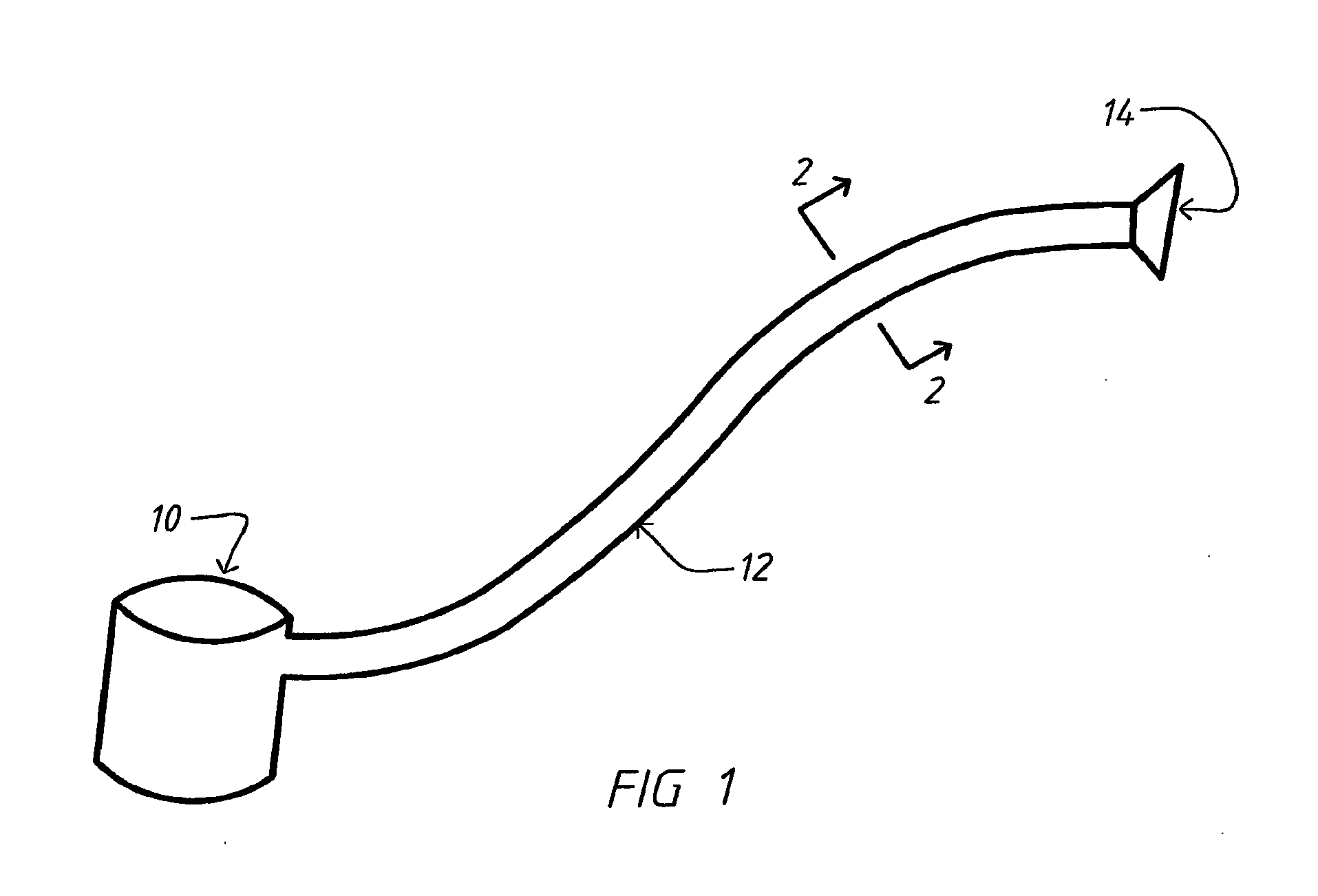

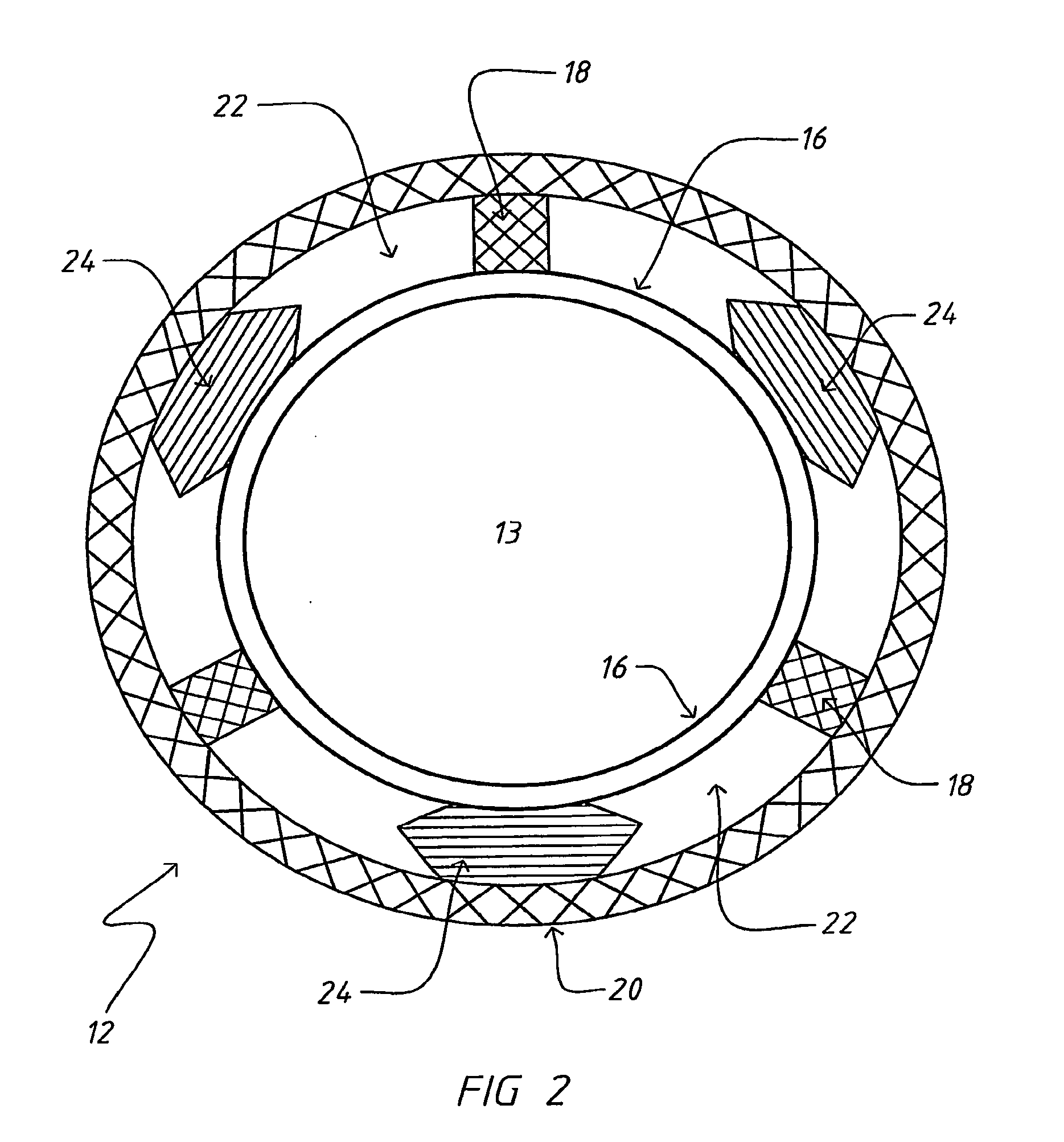

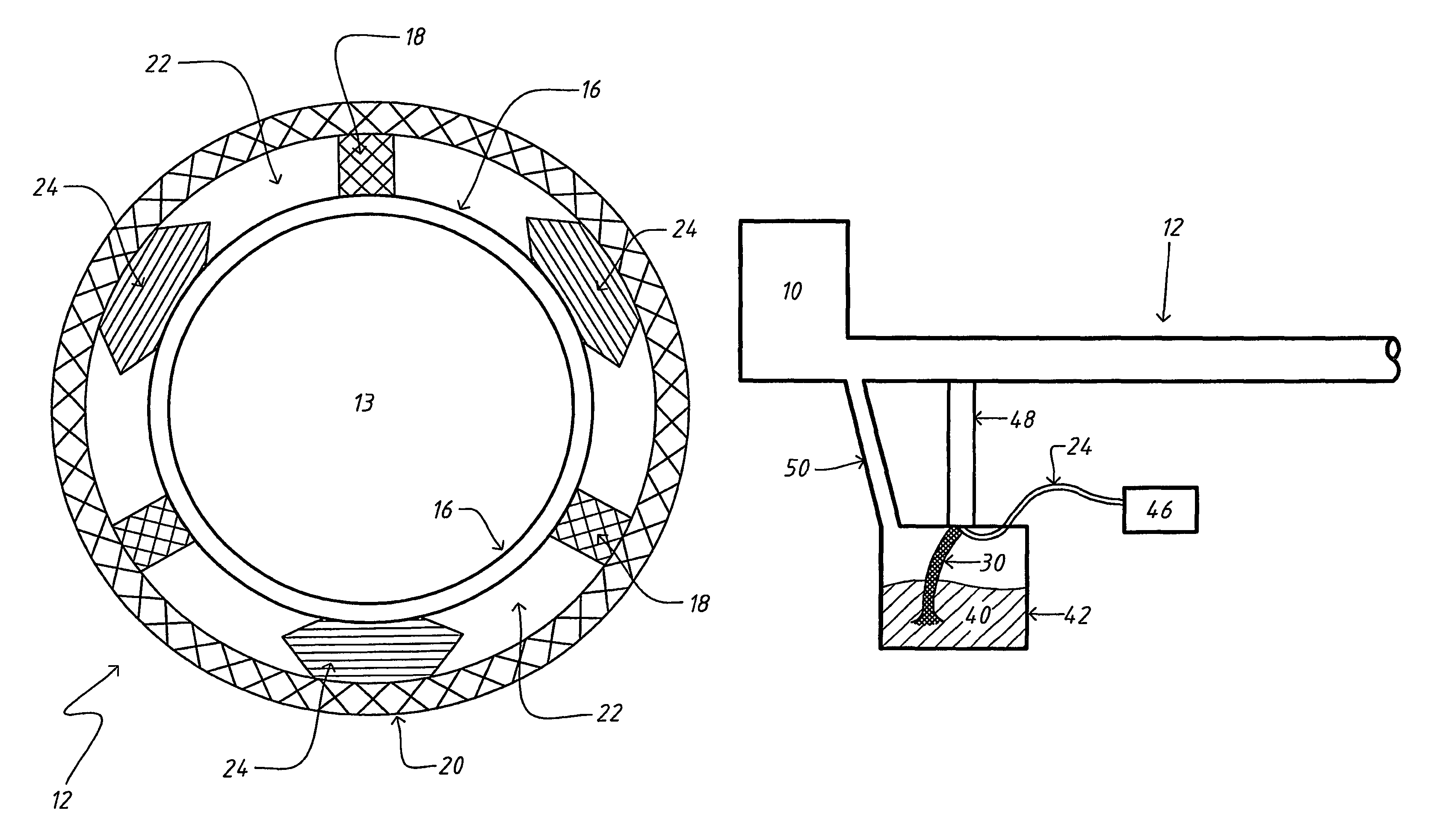

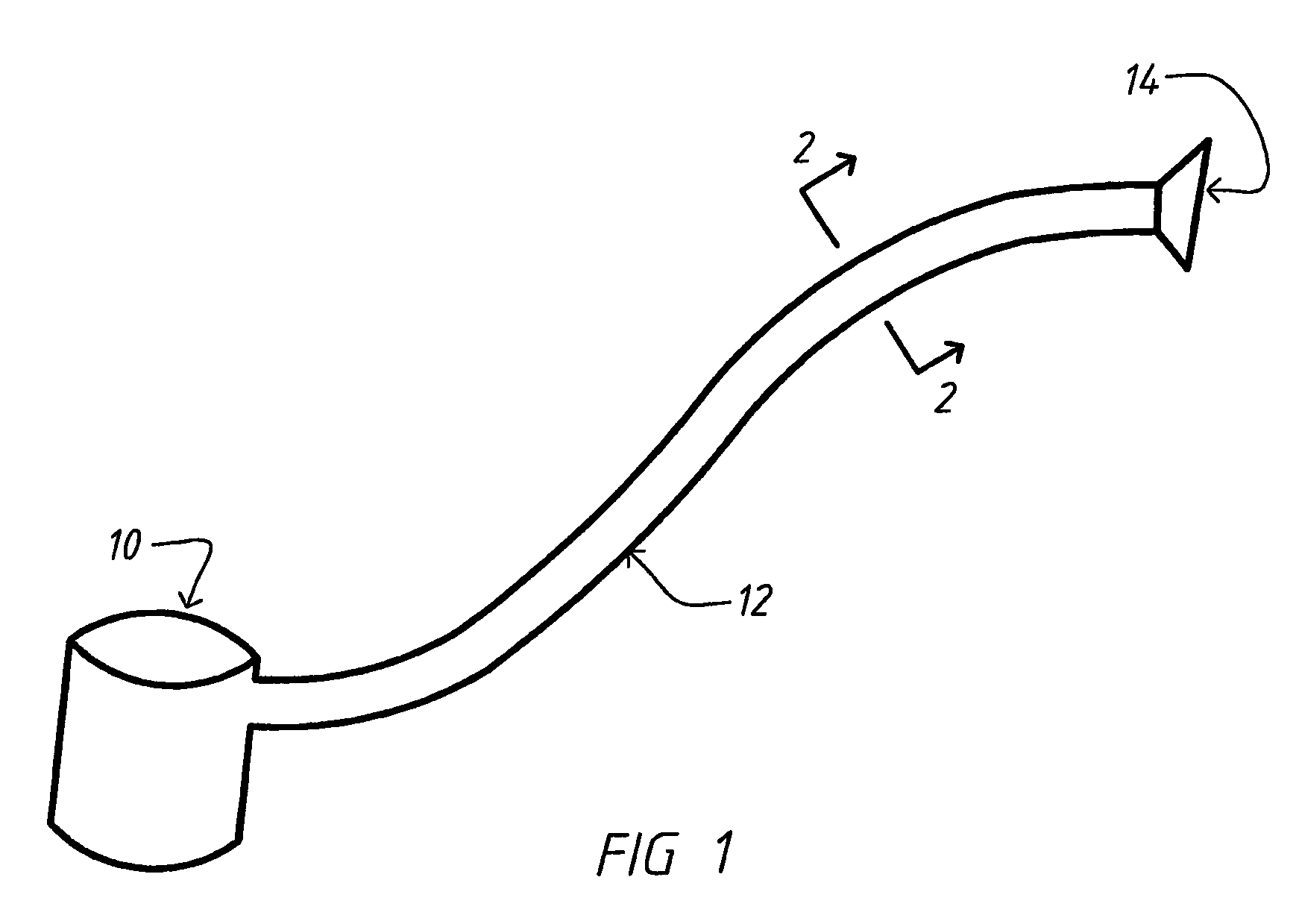

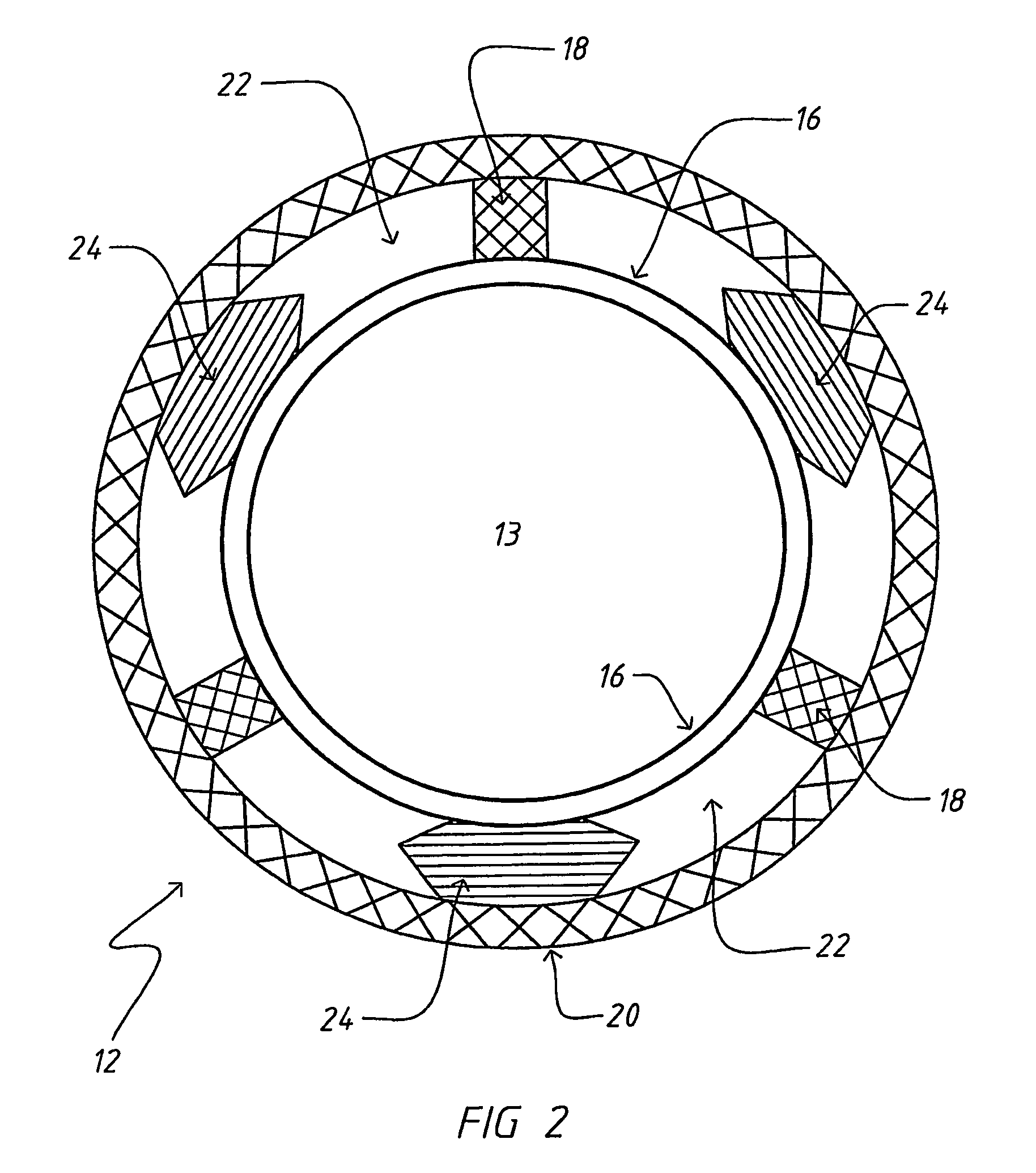

Laparoscopic Laser Device and Method

InactiveUS20070185474A1Reduce heatProtect from preventable damageLaser detailsEndoscopesMedicineVaporization

Laser radiation delivered to a treatment area causes vaporization of a substantially greater volume of tissue than the volume of residual coagulated tissue. The laser radiation may have a wavelength of about 300 nm to about 700 nm, may be used with a smoke suppressing irrigant, may have an average irradiance greater than about 5 kilowatts / cm2, and may have a spot size of at least 0.05 mm2. A laparoscopic laser device, for use with an insufflated bodily cavity, may include an elongate body adapted for insertion into an insufflated bodily cavity. A laser energy delivery element, at the distal end of the elongate body, may be coupleable to a source of tissue-vaporization-capable laser energy and capable of delivering laser energy along a laser energy path extending away from the laser energy delivery element. A smoke-suppressing liquid pathway, extending along the elongate body to an exit opening at the distal end, may be coupleable to a source of a smoke-suppressing liquid. The smoke-suppressing liquid is directed generally along the laser energy path. A remote visualization device may be used to view along the laser energy path.

Owner:AMS RES CORP

Polystyrene reclamation process

InactiveUS20020062054A1Avoid lostEasy to reuseHydrocarbon by hydrogenationPlastic recyclingPropyl bromideBoiling point

This disclosure concerns a process and apparatus for reclamation of waste polystyrene-type materials for reuse within the specification ranges of the input polystyrene-type material. The disclosed process and apparatus include dissolution of the waste polystyrene-type materials in a dissolve section utilizing a reusable solvent having a low boiling point and high vaporization rate, removal of solid contaminants in one or more filter sections, devolatilization of the dissolved polystyrene and recovery of the polystyrene-type material in a solid form in a recovery section. Preferably the process and apparatus provide a closed system and include recycling and reuse in the process of the vaporized solvent. The maximum temperature in the recovery section is 190° C. The reusable solvent is preferably environmentally safe and has a low boiling point and high vaporization rate. n-Propyl bromide, or environmentally safe mixtures thereof, including mixtures with isopropyl alcohol, is the preferred reusable solvent.

Owner:RESOURCE RECOVERY TECH

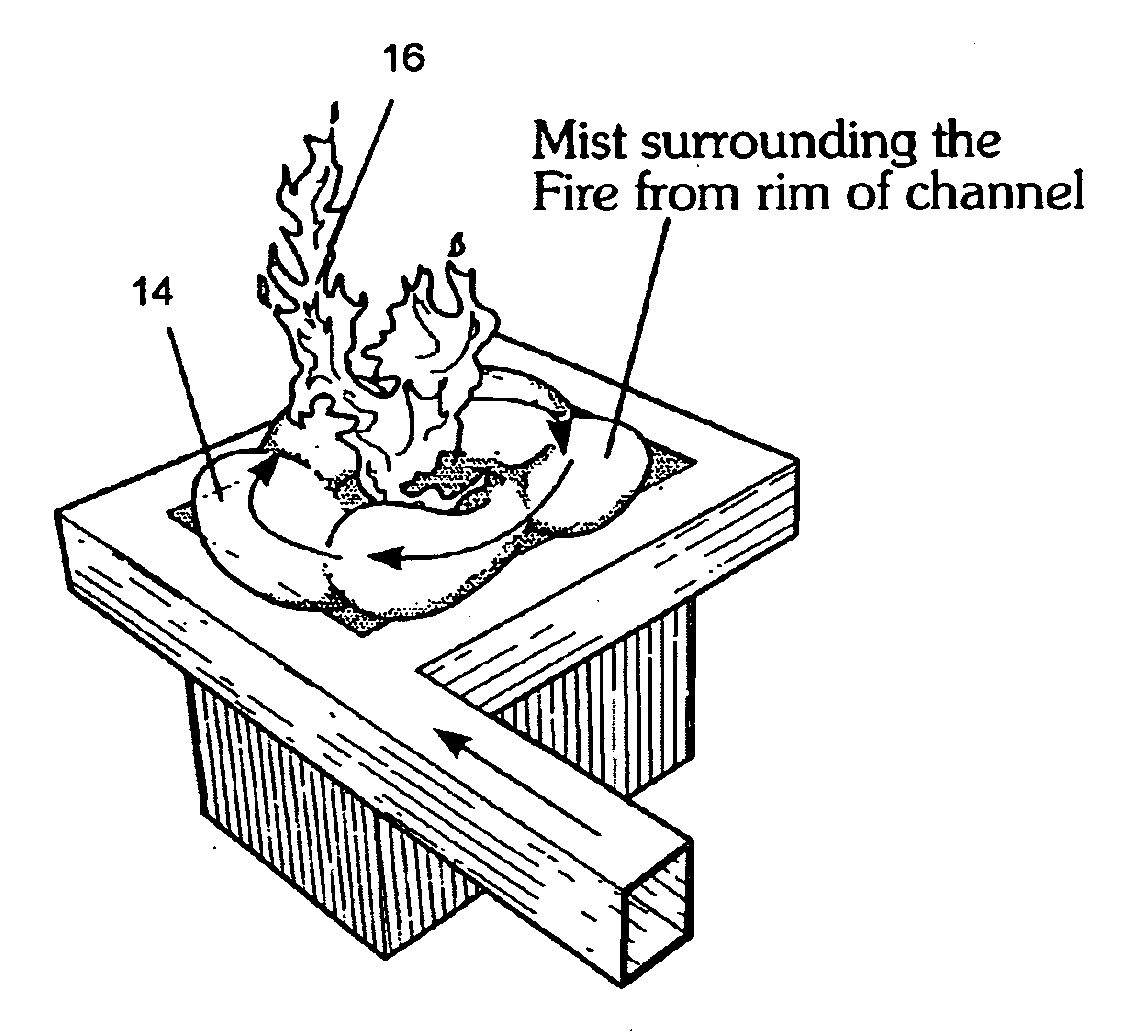

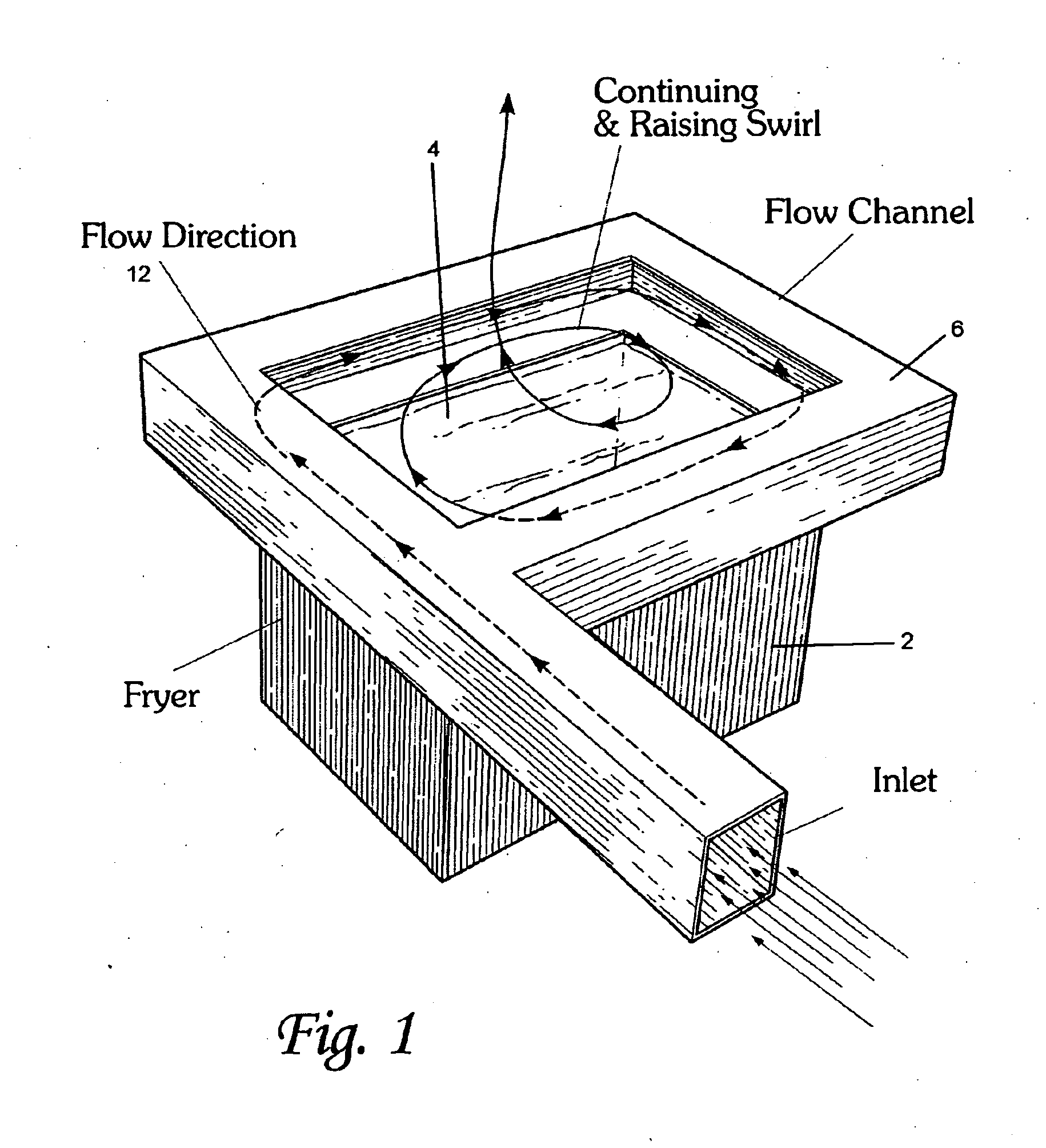

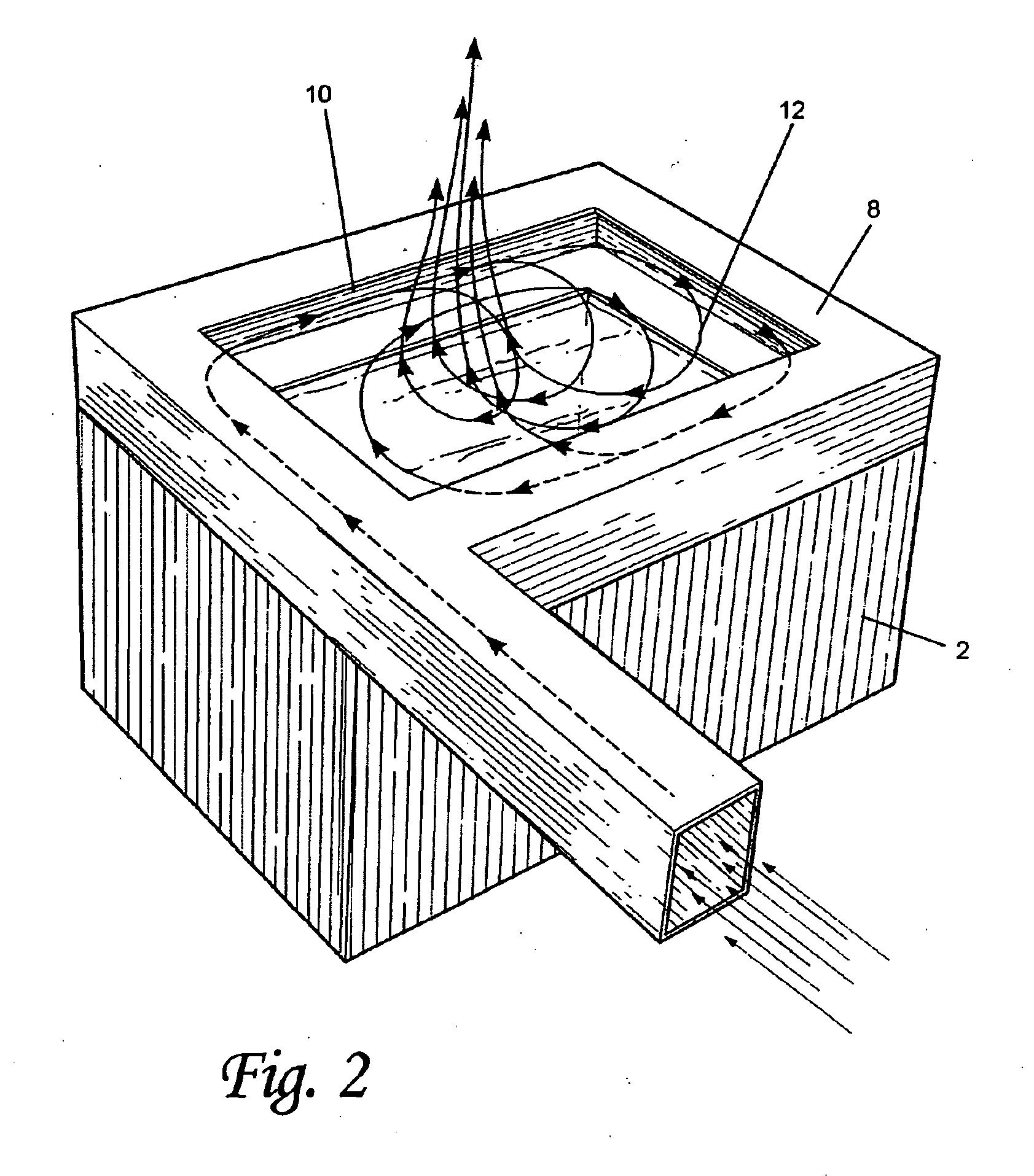

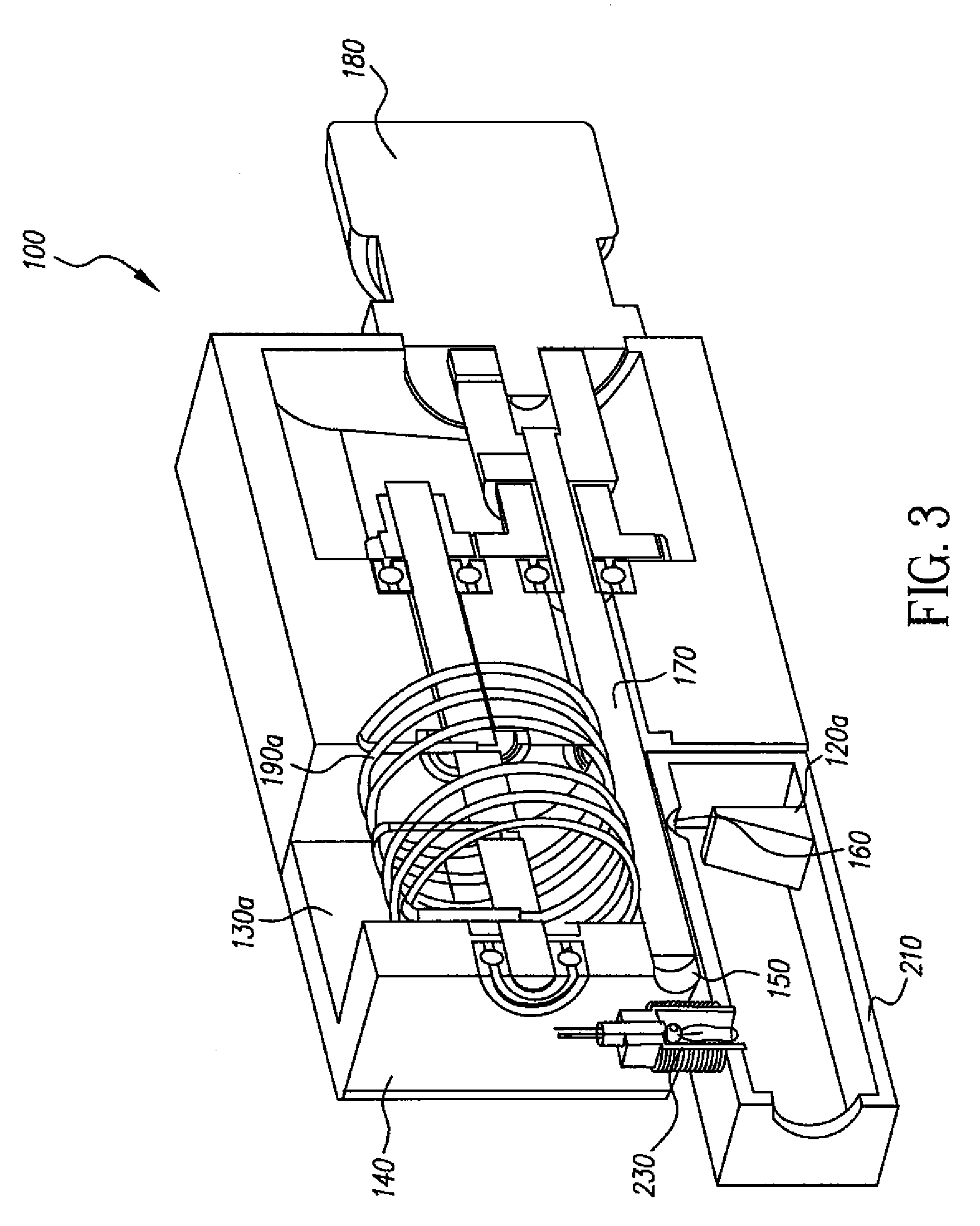

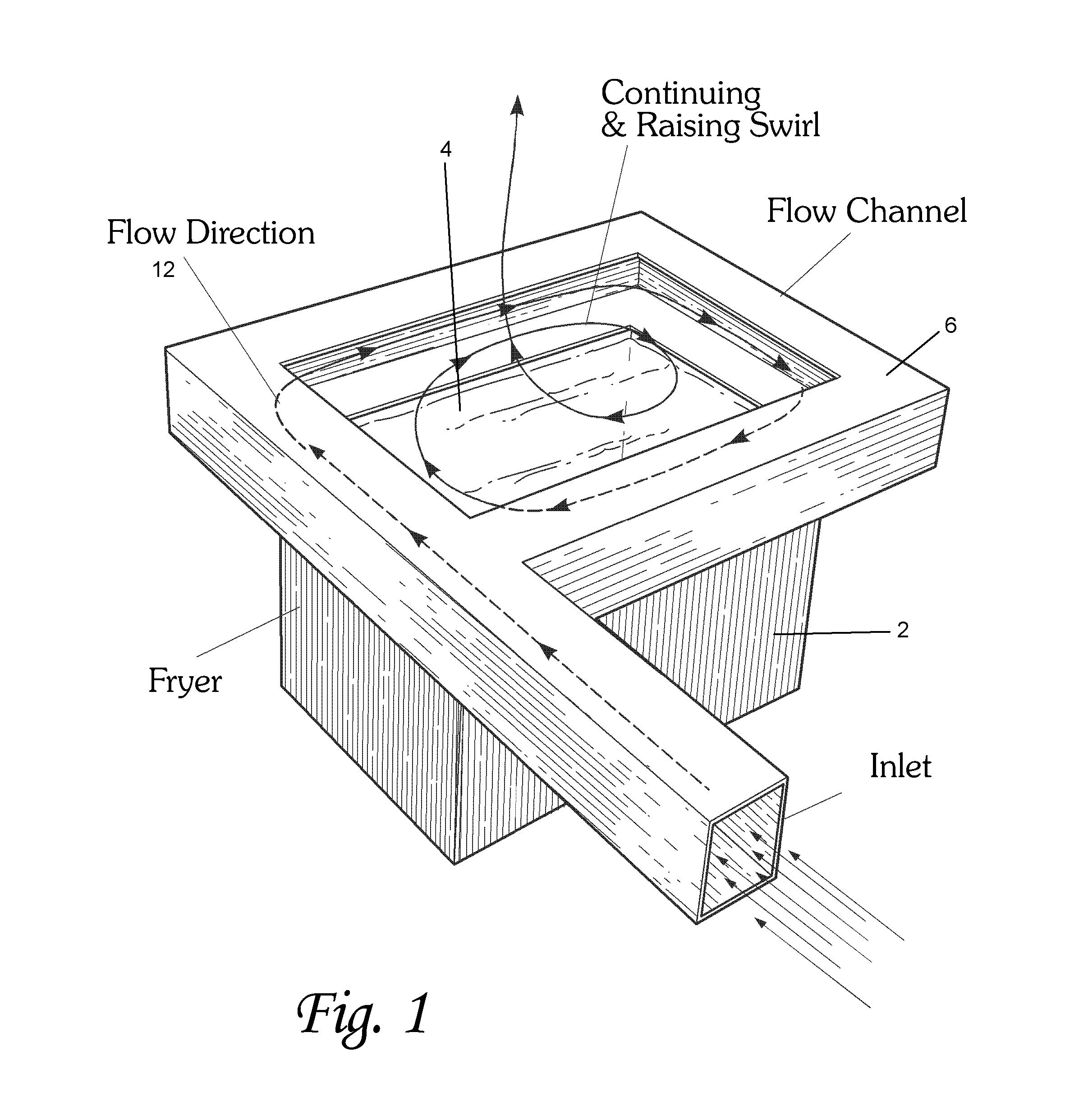

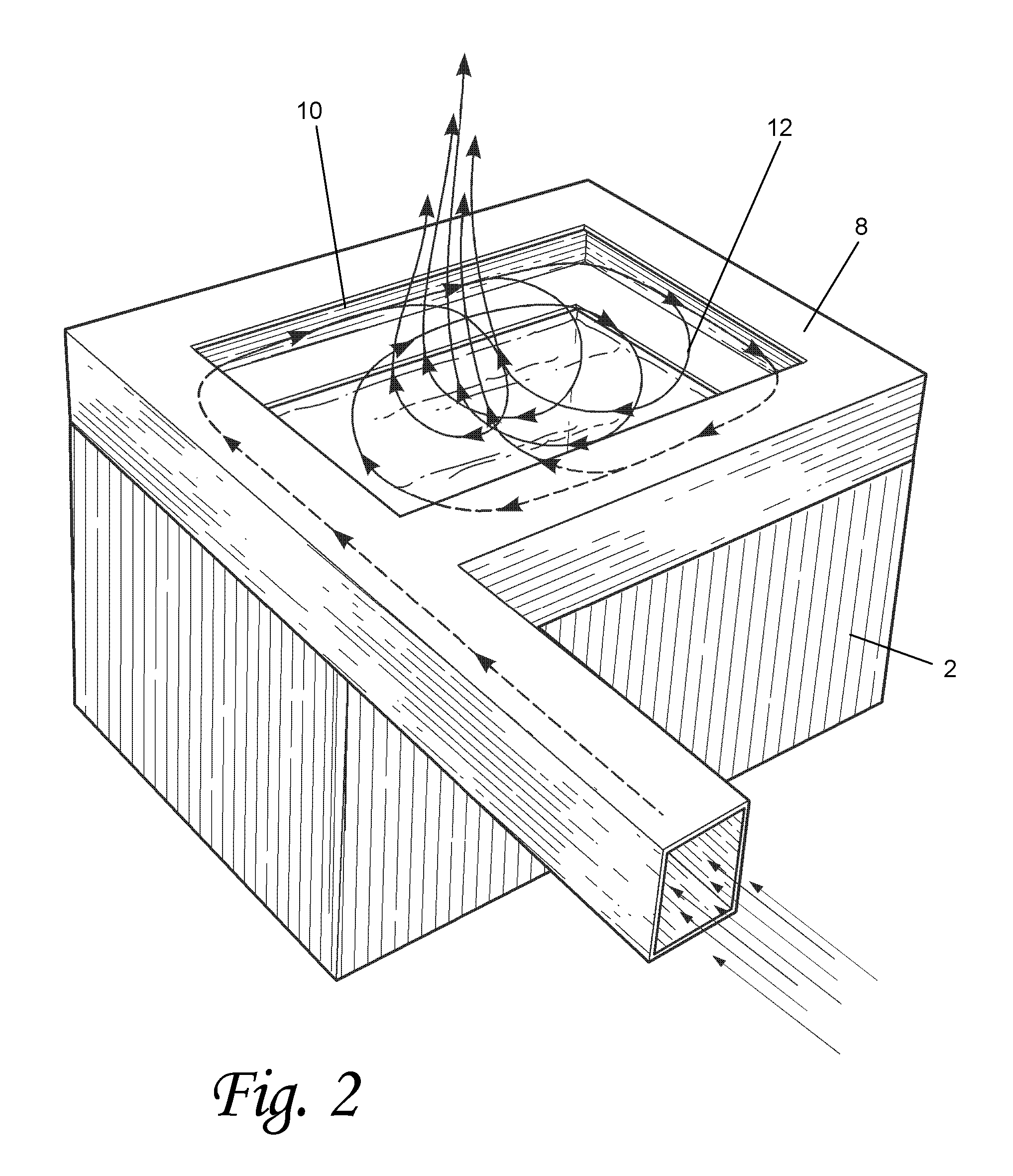

A method and device for suppression of fire by local flooding with ultra-fine water mist

InactiveUS20070193753A1Small sizeExtract heat from the firebaseFire rescueBoring toolsUltra fineEngineering

A method and device for suppression of fires related to heating appliances, vent hoods and work benches through deployment of very fine mist droplets, preferably less 100 micron diameter, into the firebase. A low momentum, high mist loading fine mist stream is introduced about the firebase. Mist is discharged to the firebase through diffusers or swirl channels so that the mist surrounding the firebase will be entrained into the firebase to secure and suppress the fire. After the fire is suppressed, the fine mist is further discharged to the hot oil surface for cooling.

Owner:ADIGA KAYYANI C +2

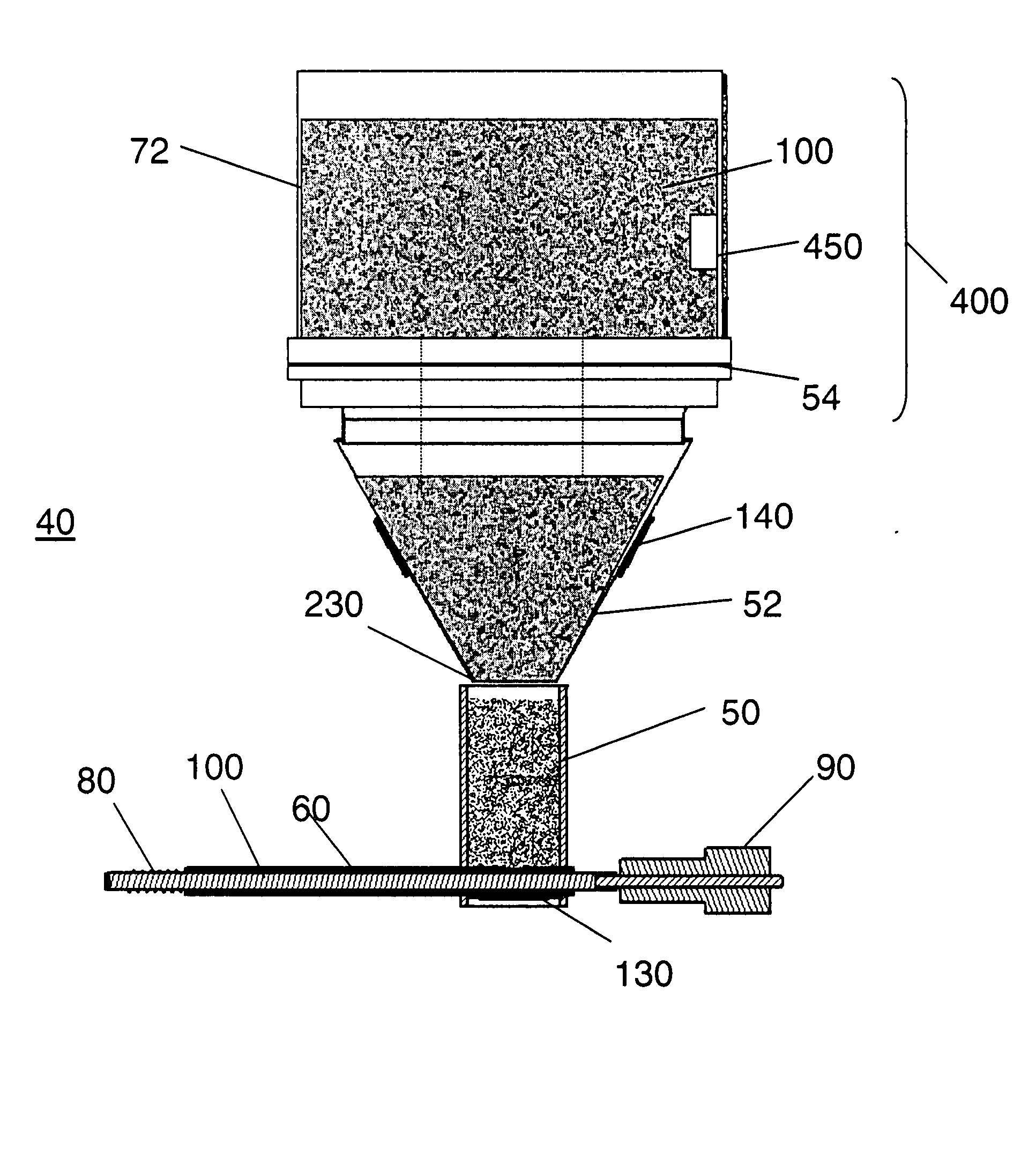

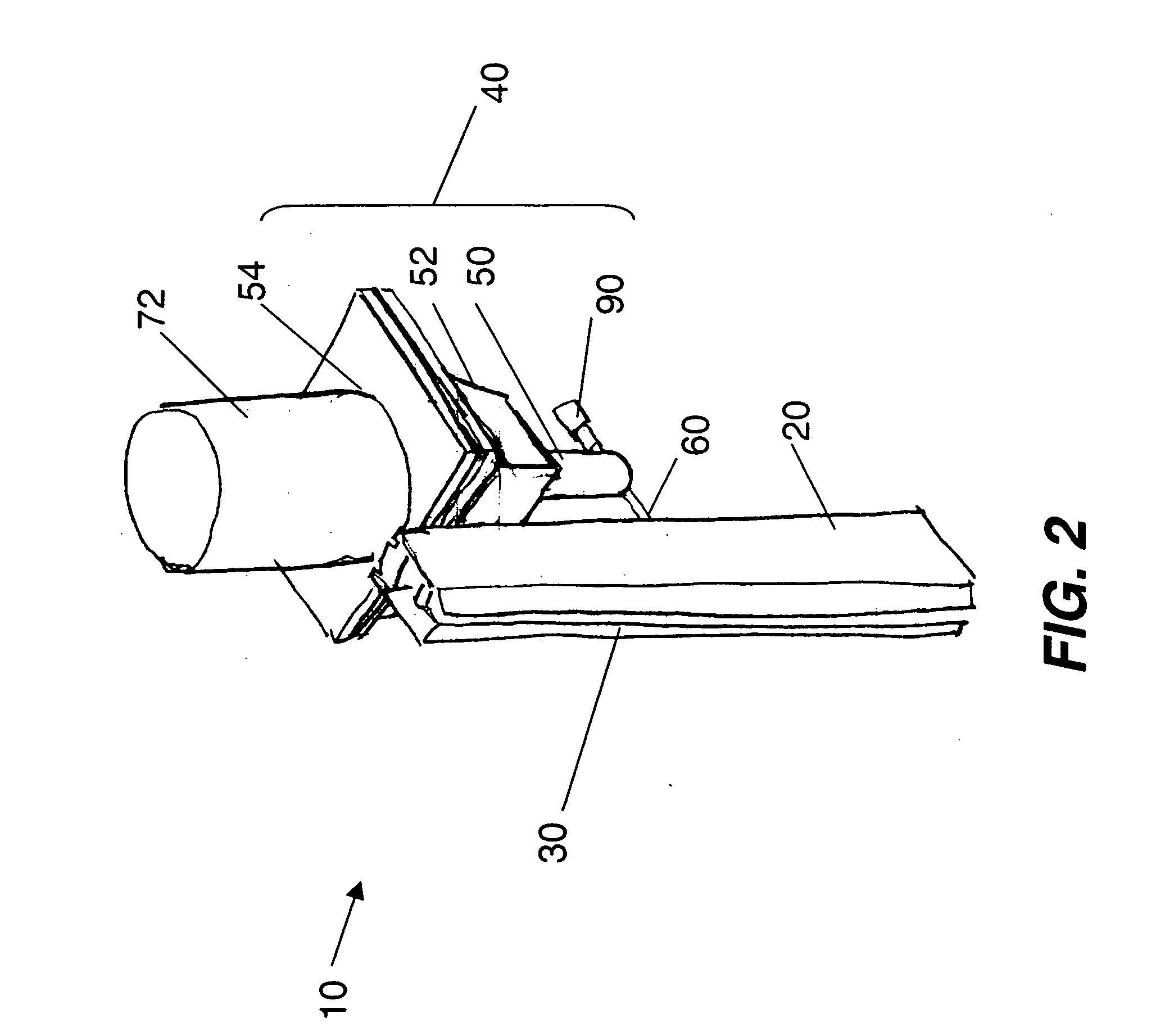

Deposition system using sealed replenishment container

ActiveUS20070104864A1Steady vaporization rateReduce riskVacuum evaporation coatingSolid-state devicesEngineeringVaporization

A method for vaporizing particulate material and depositing it onto a surface to form a layer, includes providing a supply of particulate material in a replenishment container, the replenishment container having a sealed interface fitting; mounting the replenishment container to a supply hopper defining at least one feed opening, and breaking the seal at the interface fitting; transferring particulate material from the replenishment container to the supply hopper; and transferring such particulate material through the feed opening along a feeding path to a vaporization zone where at least a component portion of the particulate material is vaporized and delivered to the surface to form the layer.

Owner:GLOBAL OLED TECH

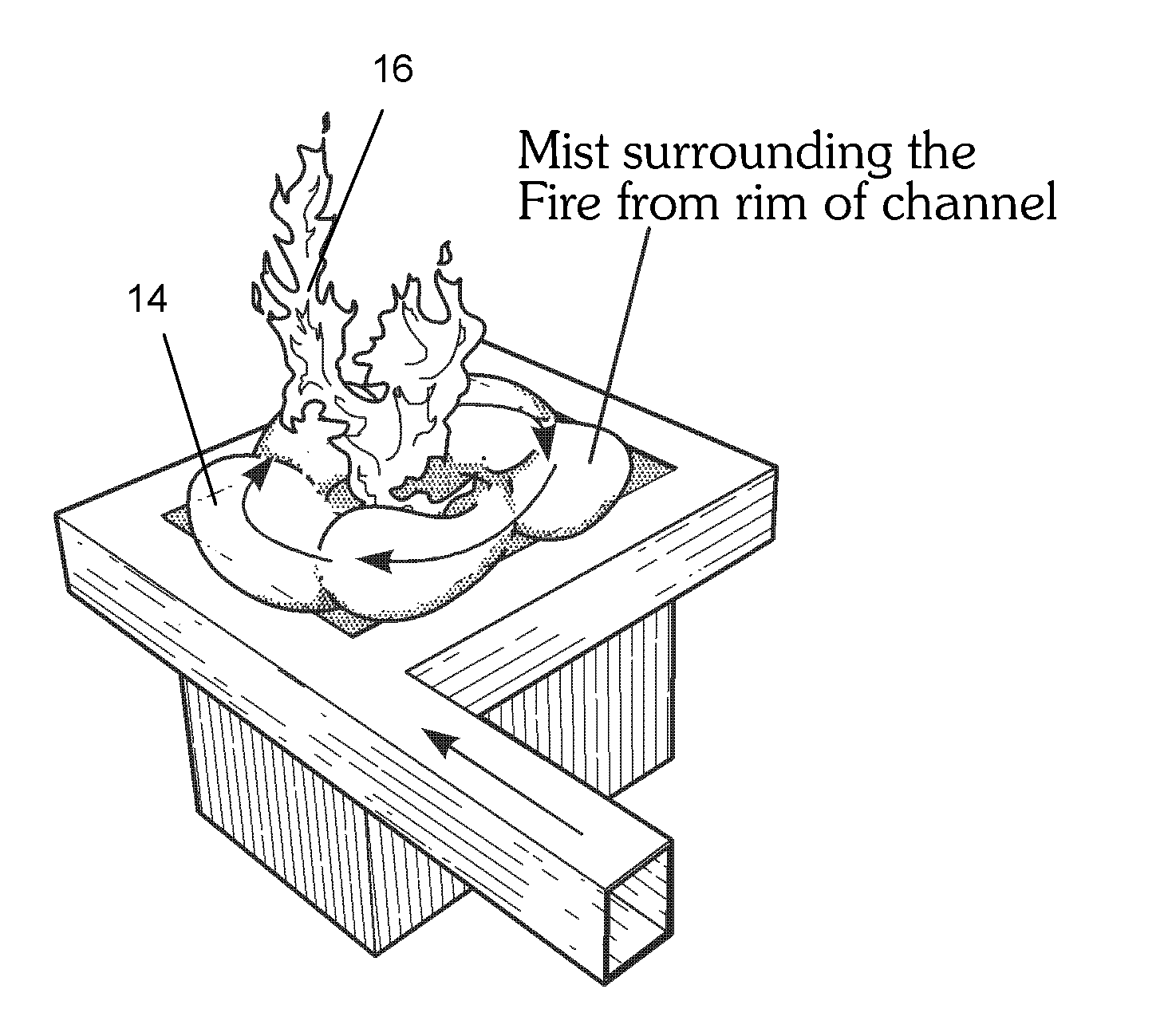

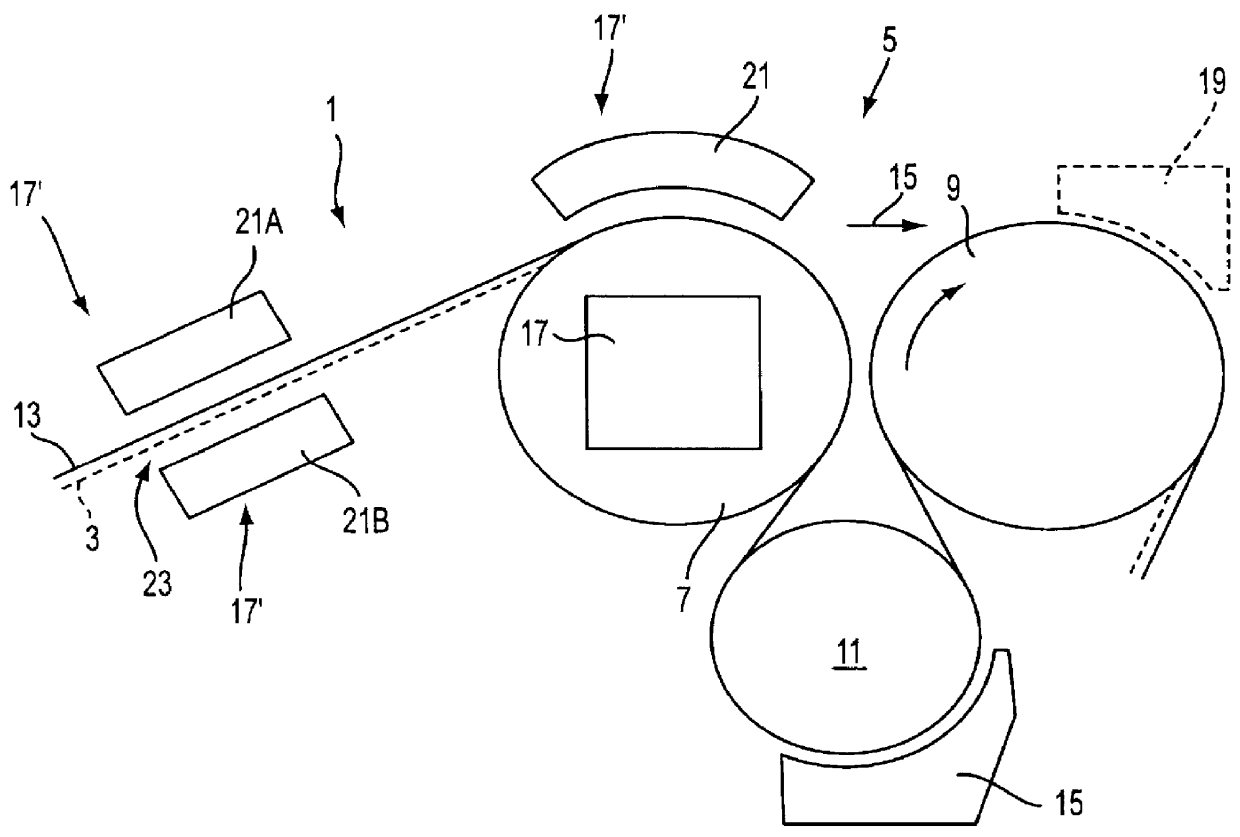

Vaporization apparatus with precise powder metering

ActiveUS20090176016A1Reduce riskQuick start and stopVacuum evaporation coatingSputtering coatingSmooth surfaceEvaporator

Apparatus for vaporizing a particulate material, comprising a metering apparatus including: a reservoir; a housing having an internal volume and first and second openings for respectively receiving and discharging the particulate material; a rotatable shaft disposed in the internal volume, the shaft having a smooth surface and a circumferential groove for receiving particulate material from the reservoir and for discharging the particulate material; the rotatable shaft and the internal volume cooperating such that the particulate material is transported by the circumferential groove and not along the remainder of the rotatable shaft; a scraper disposed in relation to the second opening, having at its end substantially the same cross section as the groove in the rotating shaft, the scraper cooperating with the groove to dislodge particulate material retained therein, and in response to the shaft rotating, delivers metered amounts of particulate material through the second opening; to the flash evaporator.

Owner:GLOBAL OLED TECH

Method and device for suppression of fire by local flooding with ultra-fine water mist

InactiveUS20100218959A1Small sizeExtract heat from the firebaseFire rescueBoring toolsEngineeringUltra fine

A method and device for suppression of fires related to heating appliances, vent hoods and work benches through deployment of very fine mist droplets, preferably less 100 micron diameter, into the firebase. A low momentum, high mist loading fine mist stream is introduced about the firebase. Mist is discharged to the firebase through diffusers or swirl channels so that the mist surrounding the firebase will be entrained into the firebase to secure and suppress the fire. After the fire is suppressed, the fine mist is further discharged to the hot oil surface for cooling.

Owner:NANOMIST SYST

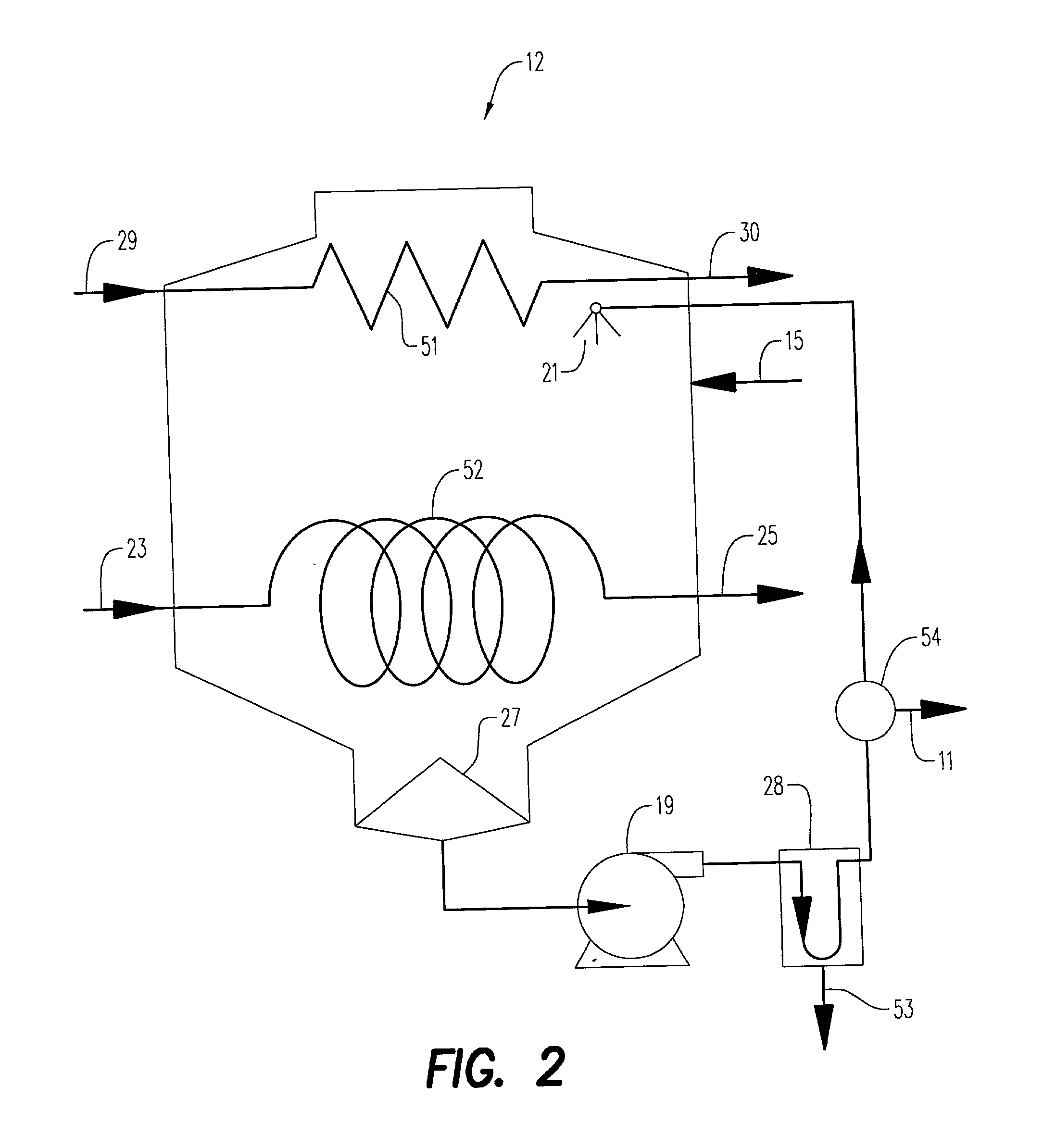

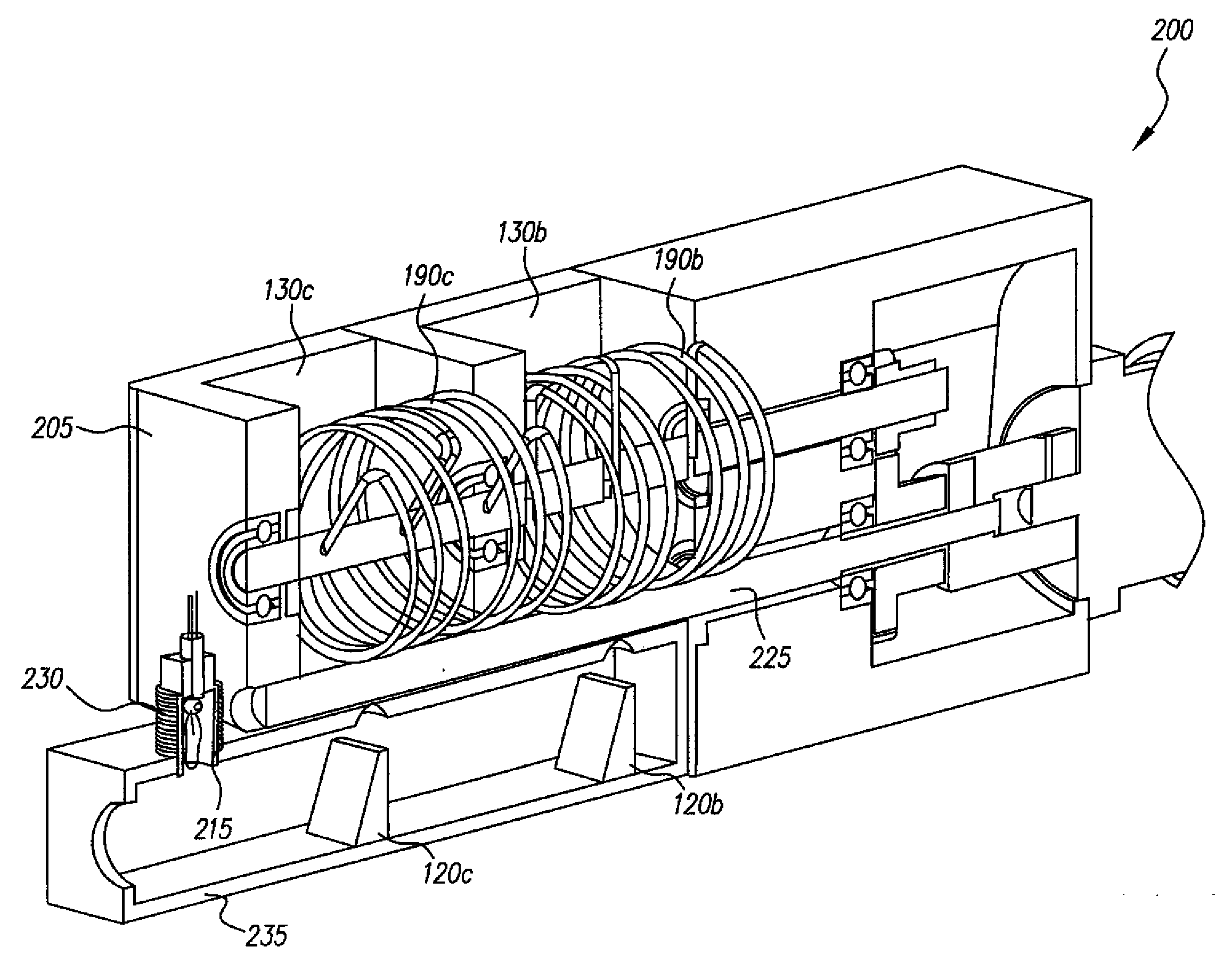

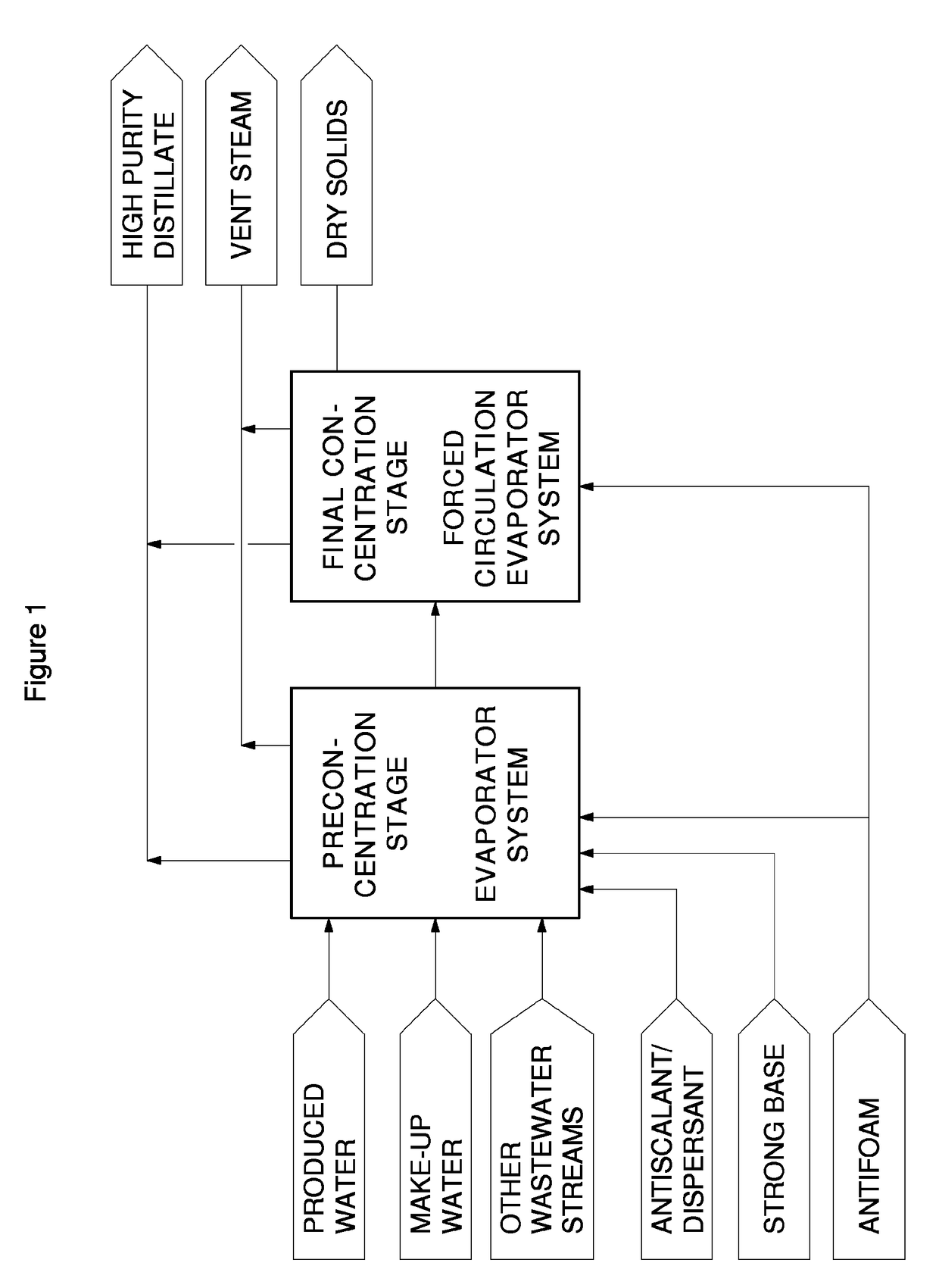

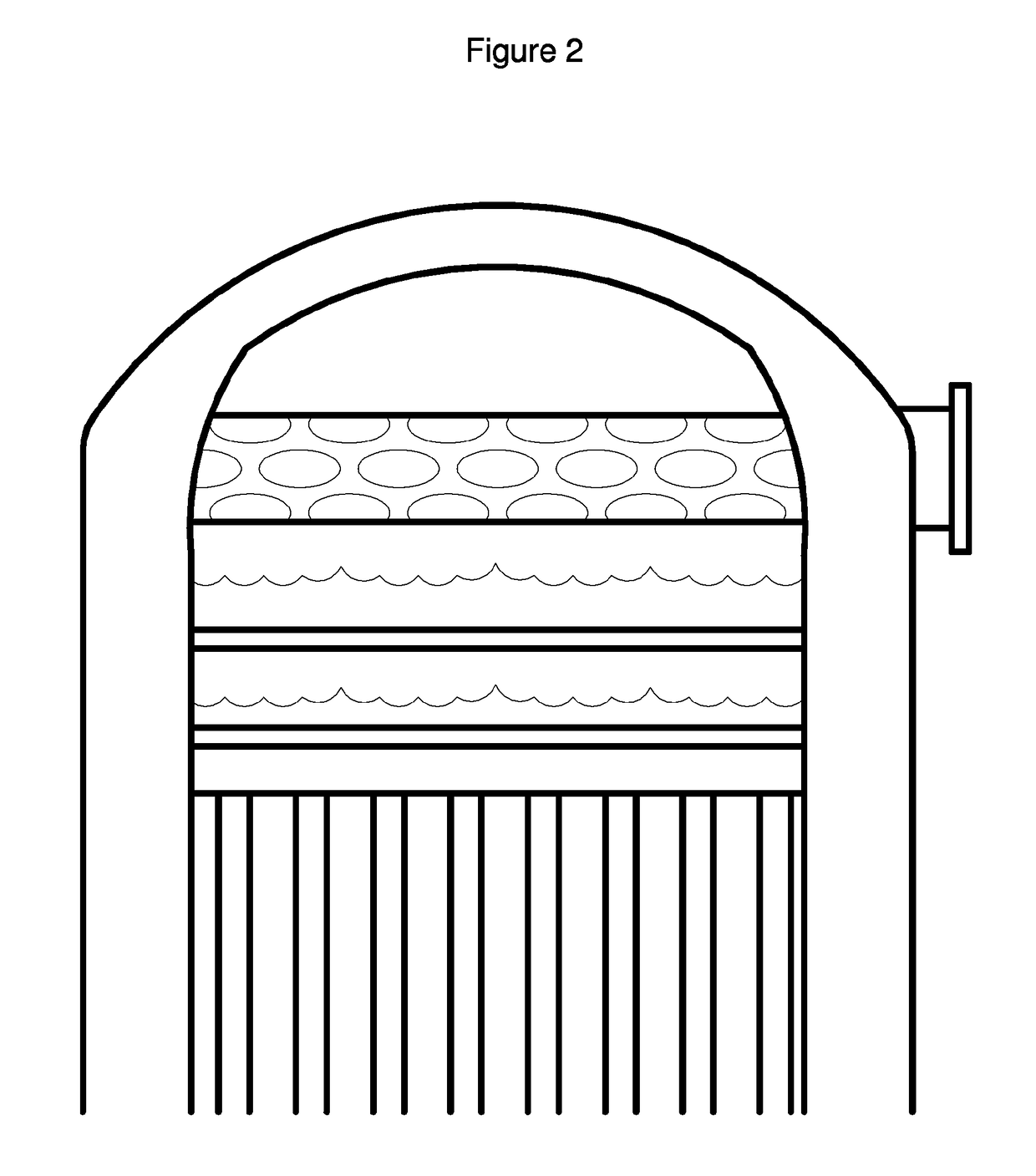

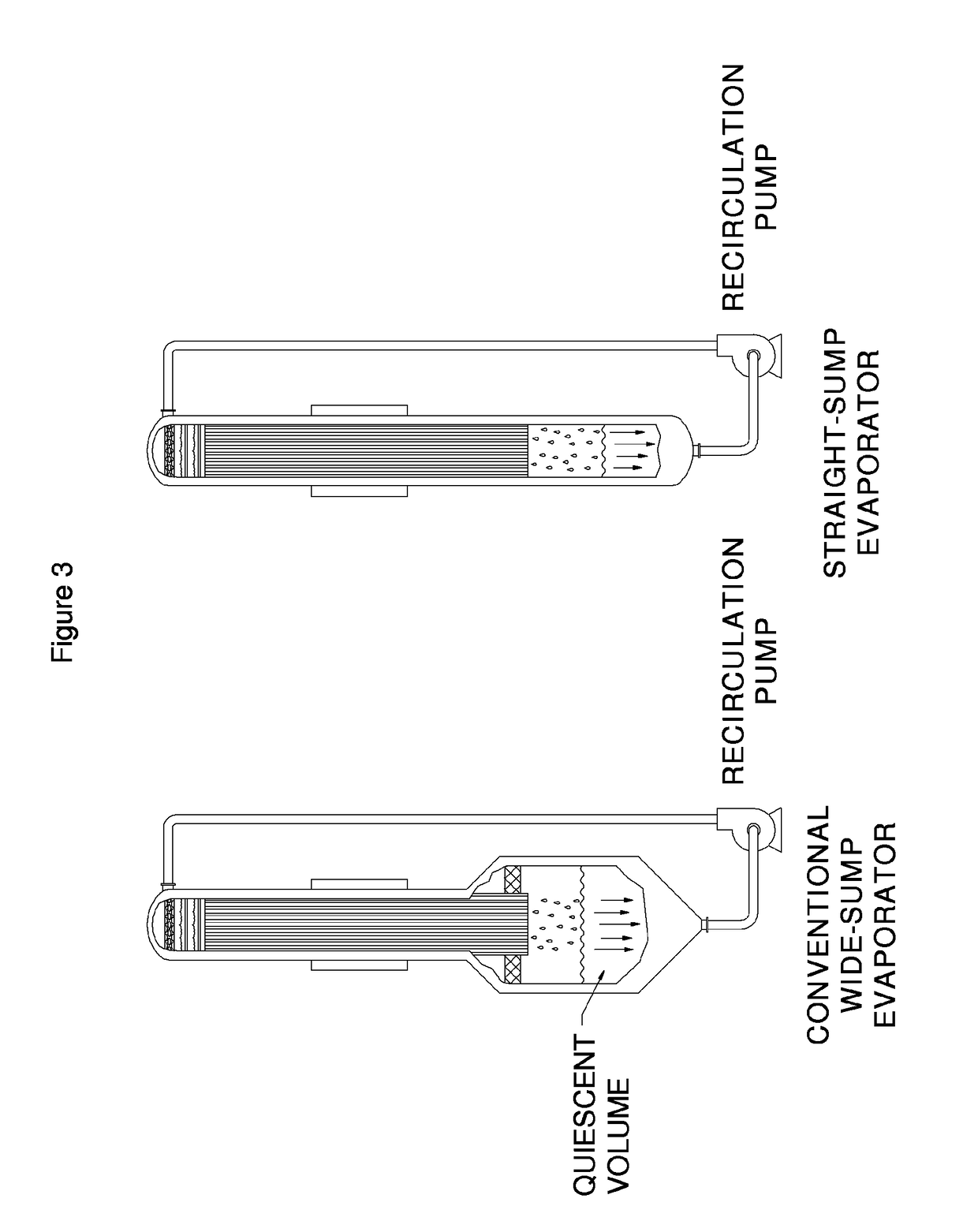

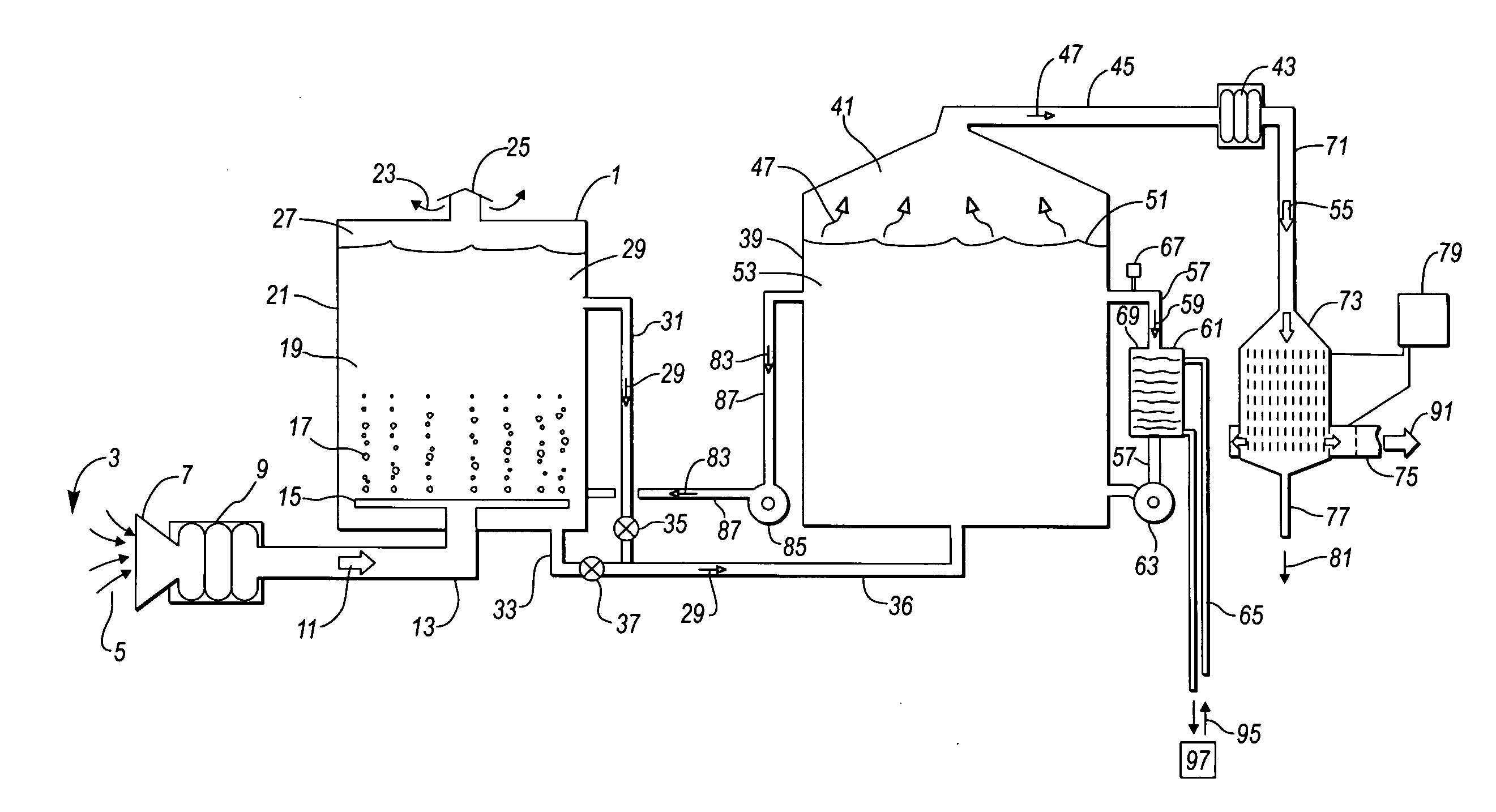

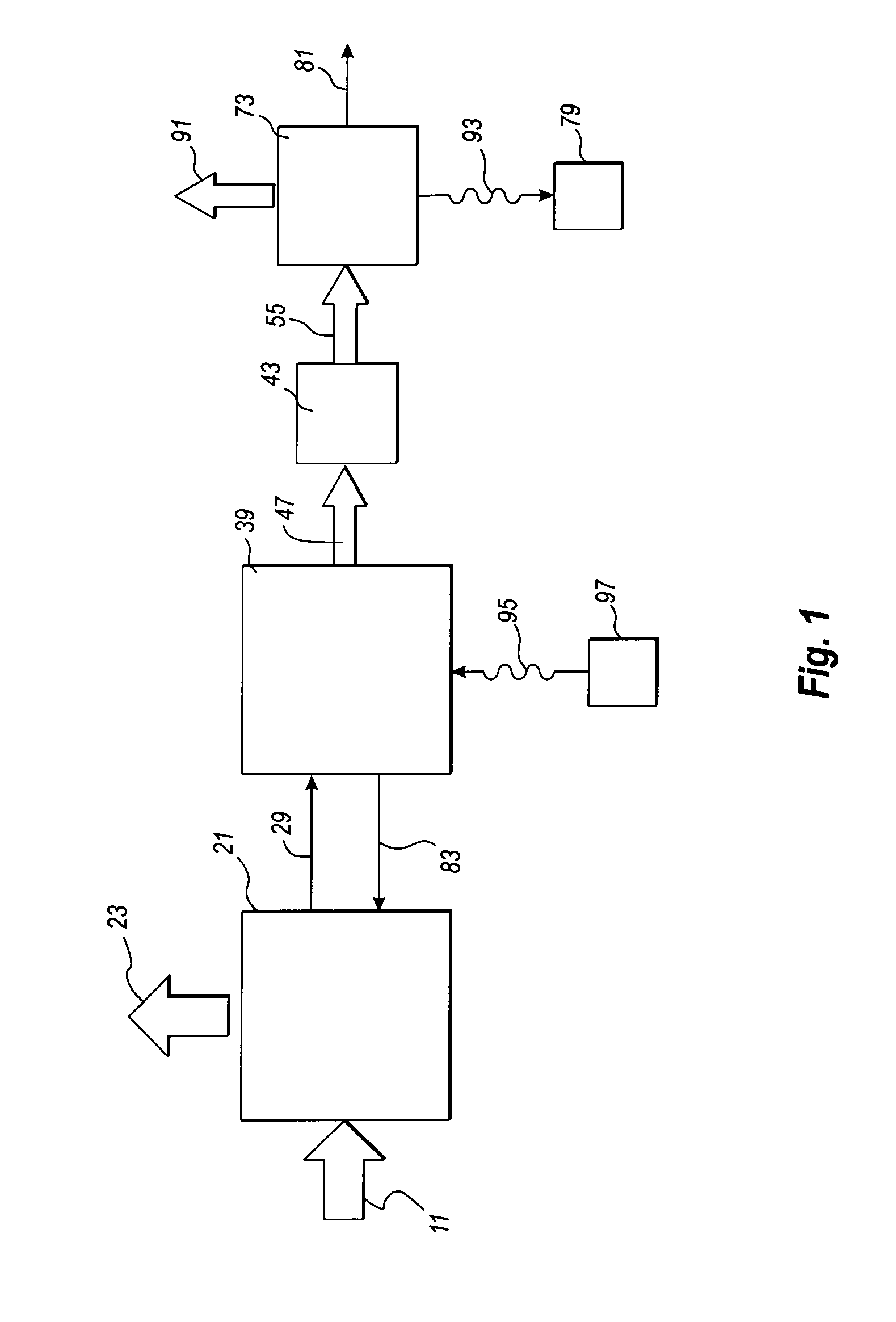

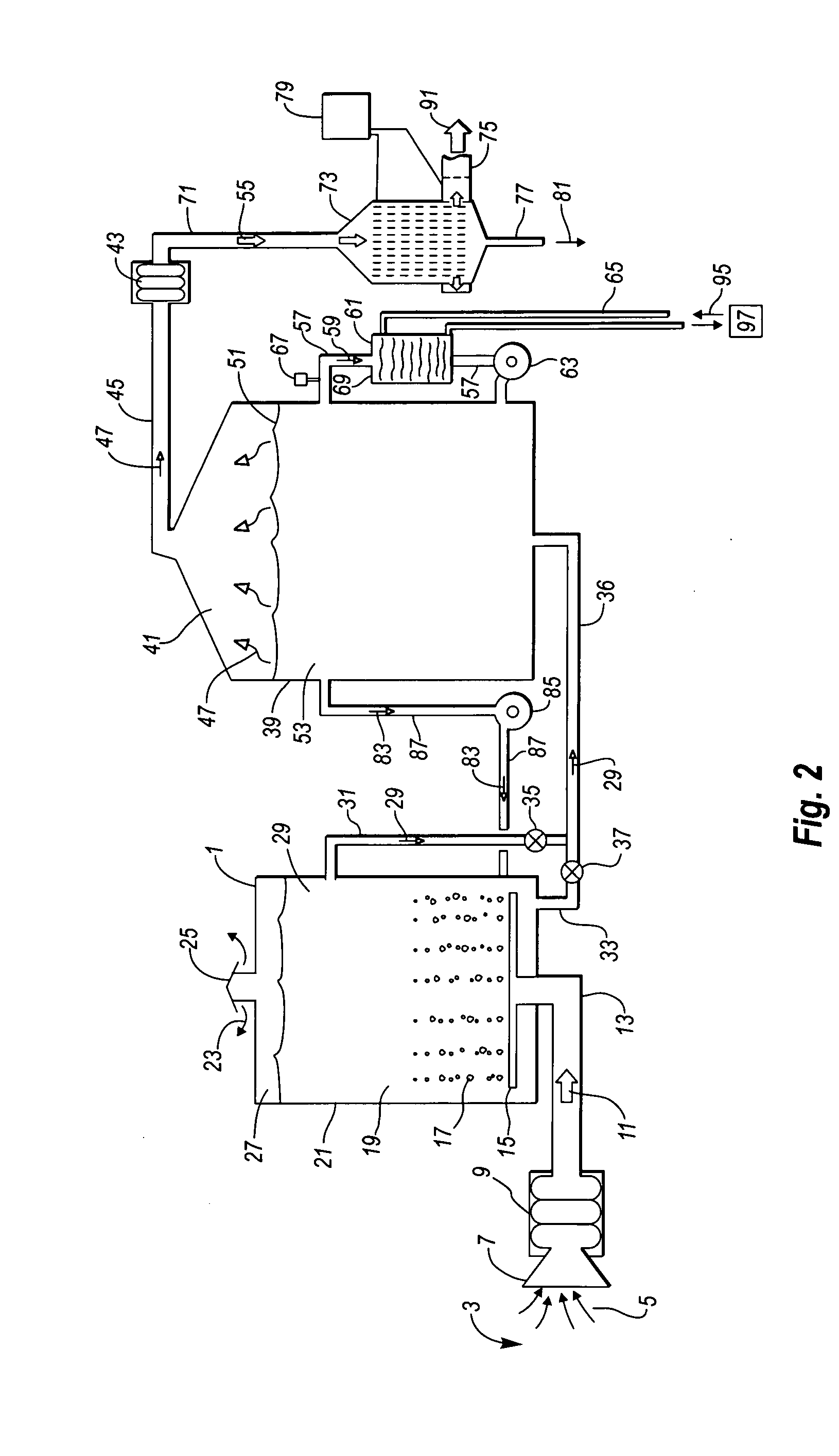

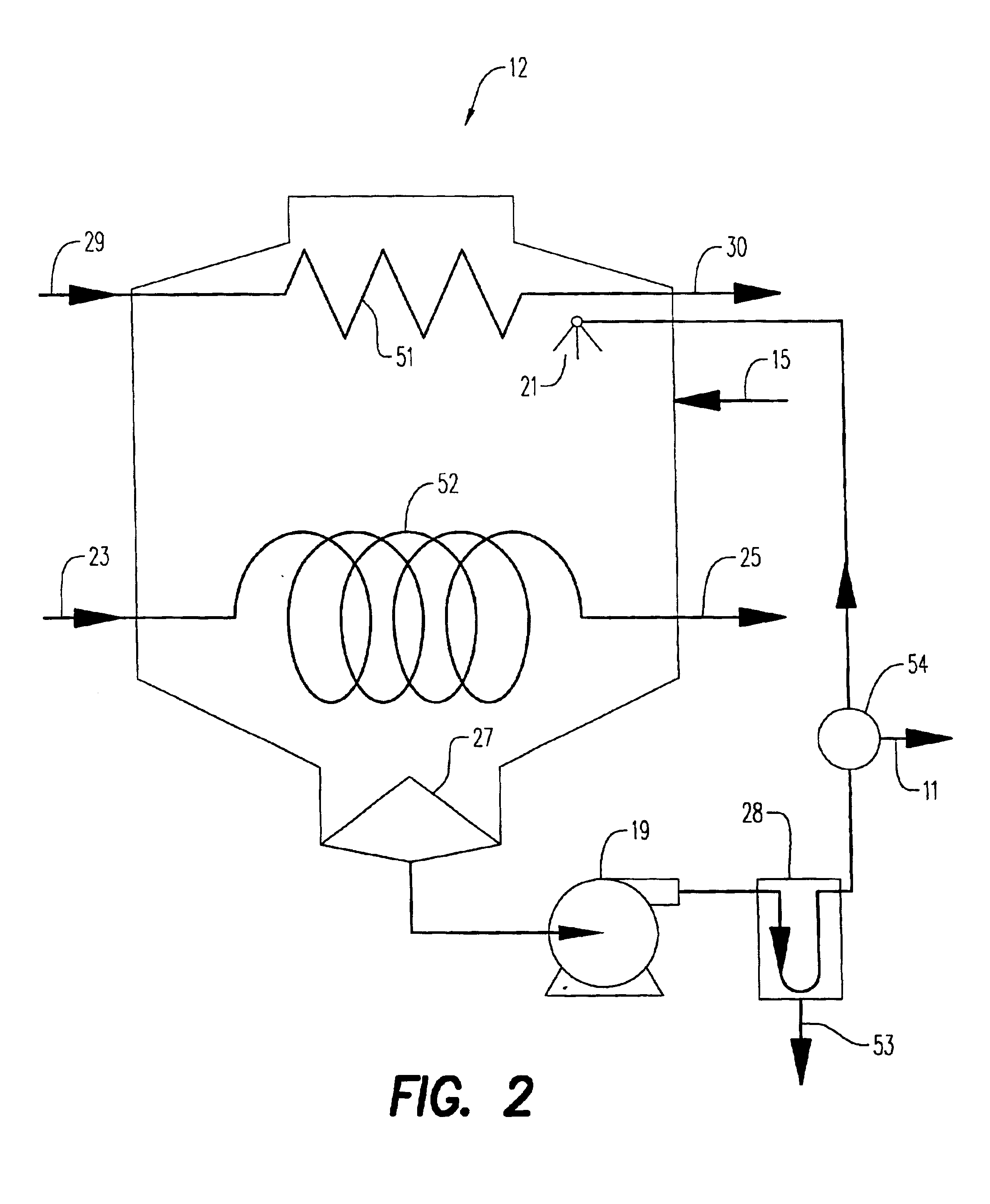

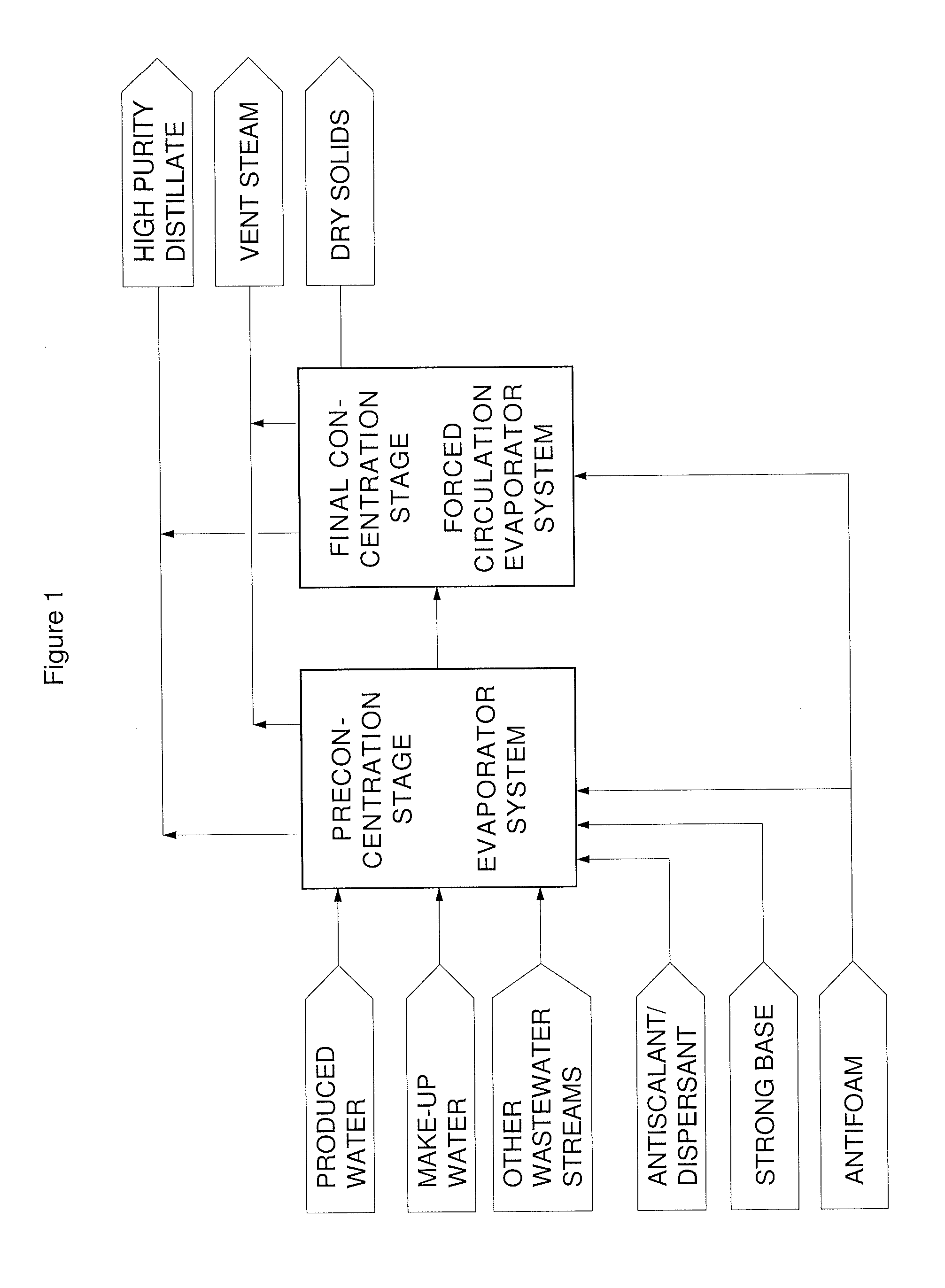

Method for production of high purity distillate from produced water for generation of high pressure steam

ActiveUS8469091B2High work pressureIncrease vaporization rateUsing liquid separation agentInsulationEngineeringFuel oil

Embodiments presented herein provide an evaporation based zero liquid discharge method for generation of up to 100% quality high pressure steam from produced water in the heavy oil production industry. De-oiled water is processed in an evaporation system producing a distillate that allows steam to be generated with either drum-type boilers operating at higher pressures or once-through steam generators (OTSGs) operating at higher vaporization rates. Evaporator blowdown is treated in a forced-circulation evaporator to provide a zero liquid discharge system that could recycle >98% of the deoiled water for industrial use. Exemplary embodiments of the invention provide at least one “straight sump” evaporator and at least one hybrid external mist eliminator. Embodiments of the evaporation method operate at a higher overall efficiency than those of the prior art by producing distillate at a higher enthalpy which minimizes the high pressure boiler preheating requirement.

Owner:AQUATECH INT LLC

Vacuum drying method for lithium battery cell

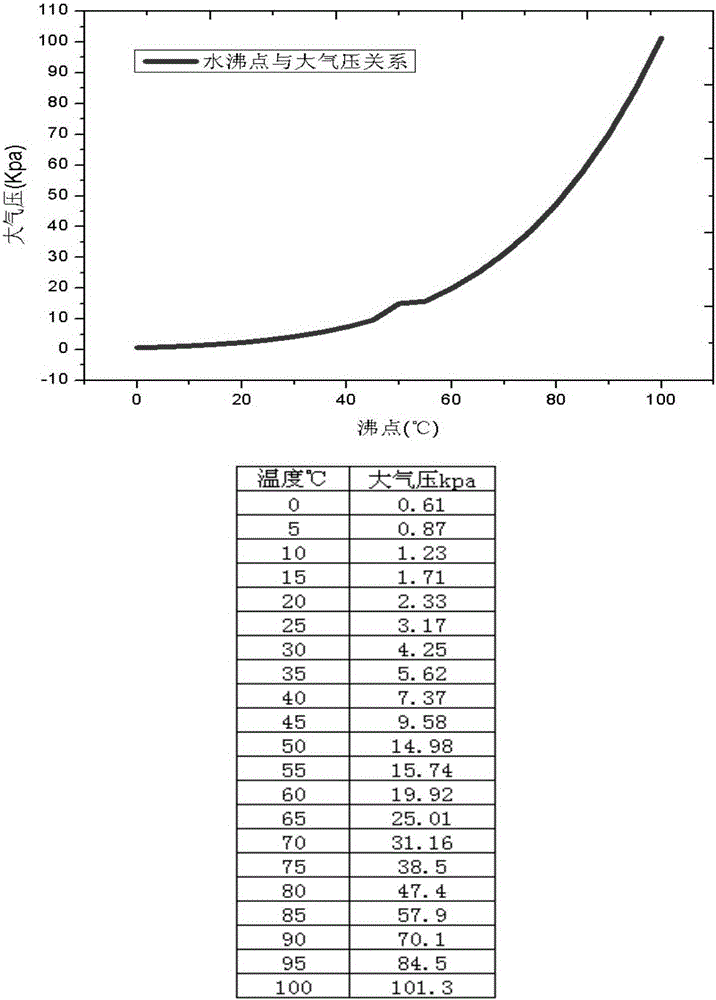

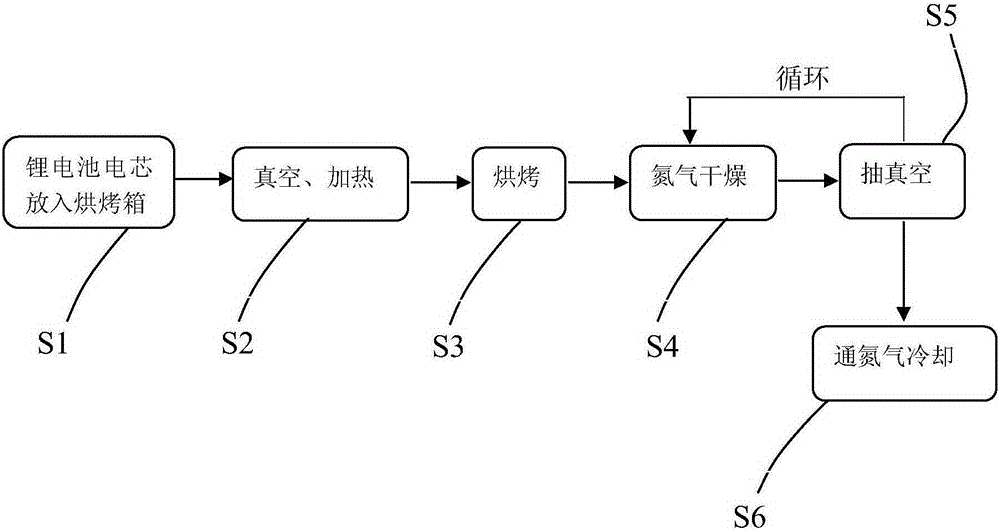

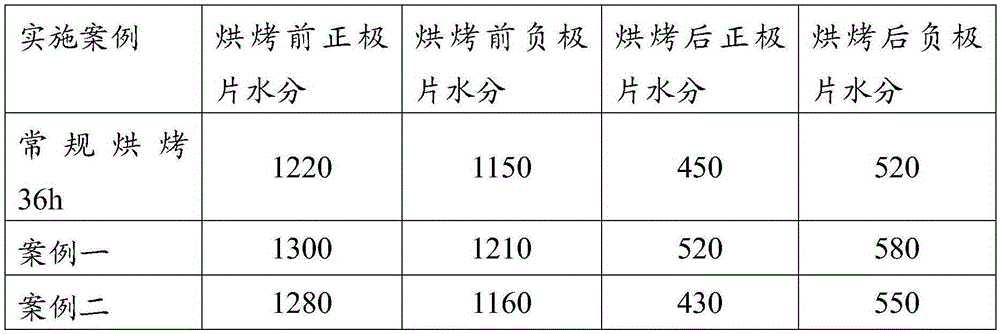

InactiveCN106643003AIncrease the baking vacuumIncrease vaporization rateDrying using combination processesDrying solid materials without heatProcess engineeringVacuum drying

The invention provides a vacuum drying method for a lithium battery cell. The vacuum drying method comprises the following steps that S1, the lithium battery cell is put into a vacuum baking oven, and the vacuum baking oven is closed; S2, a heating switch of the vacuum baking oven is turned on, and the temperature rises to 85 DEG C; a vacuum pump is opened, and the vacuum baking oven is vacuumized to 0.5 Kpa below; S3, the constant vacuum degree and temperature of the vacuum baking oven are kept, and baking is conducted for 1 hour to 3 hours; S4, dry nitrogen is introduced into the vacuum baking oven, vacuum-unloading is conducted on the vacuum baking oven to the normal pressure, and the nitrogen is kept being introduced for 2 min-3 min; S5, the vacuum baking oven is vacuumized to 0.5 Kpa below again, and baking is conducted for 1 hour to 3 hours; and S6, the dry nitrogen is introduced to the baking oven, vacuum-unloading is conducted on the vacuum baking oven to the normal pressure, and cooling is conducted.

Owner:OPTIMUM BATTERY CO LTD

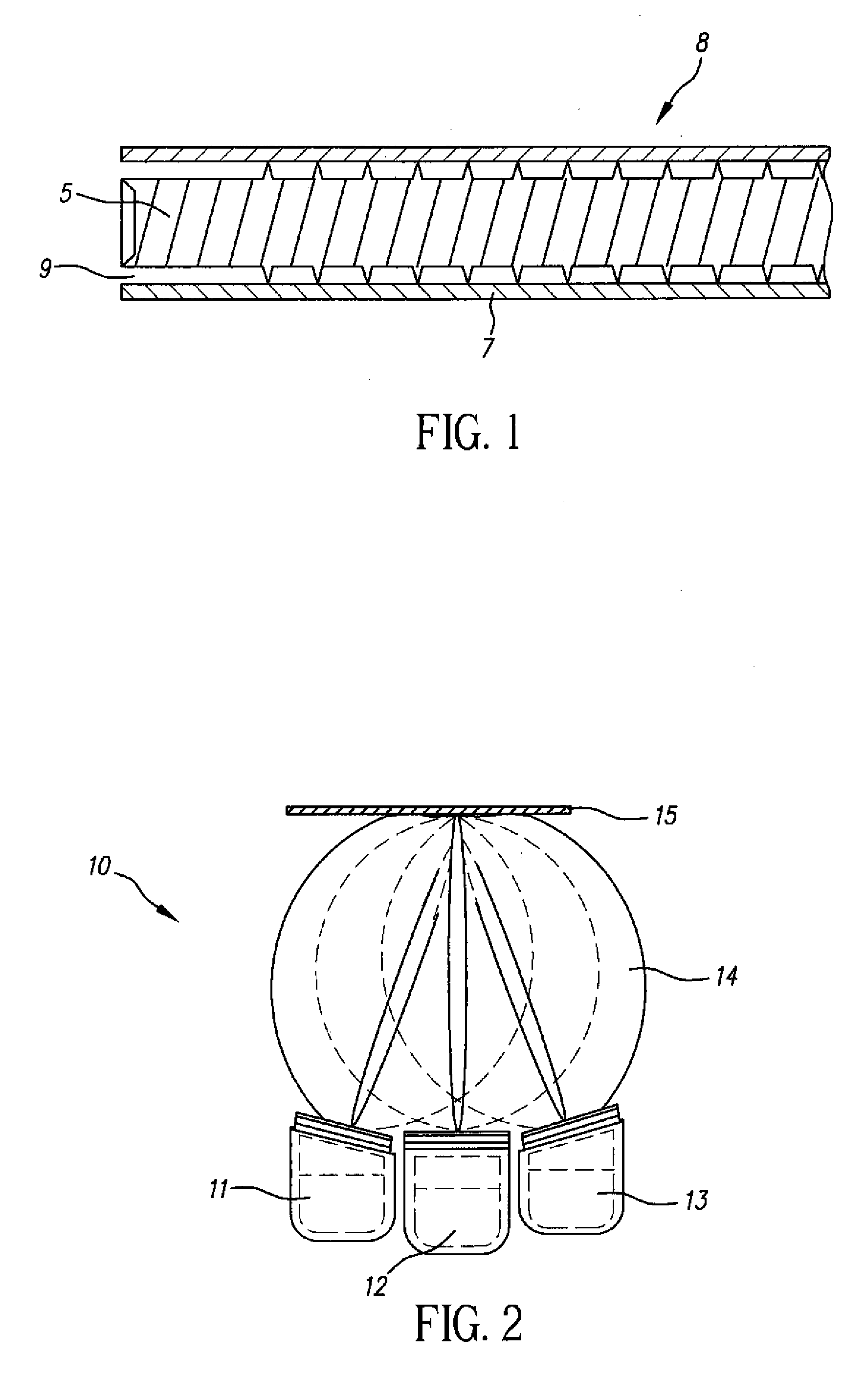

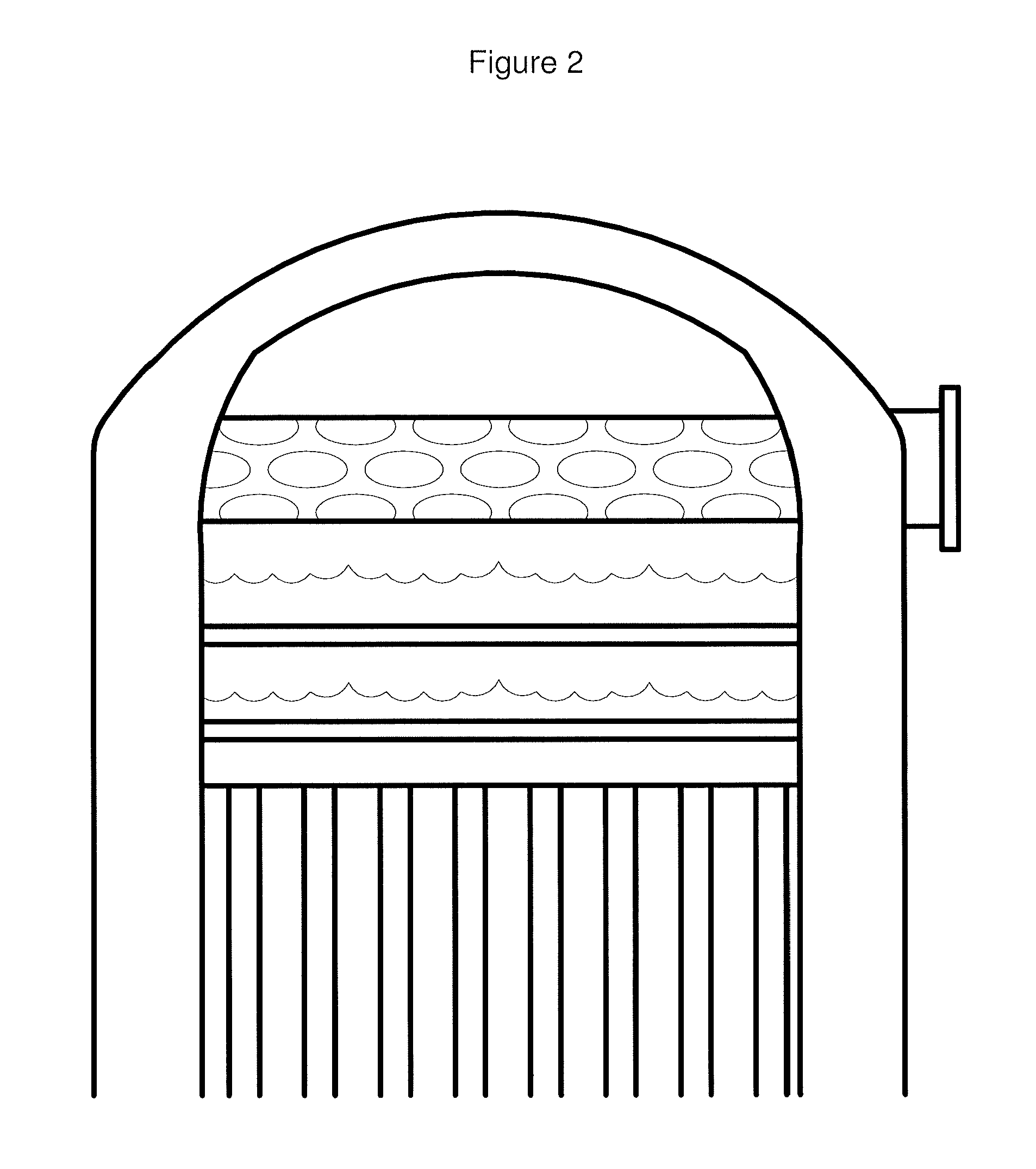

Machine and process for manufacturing or treating a material web

InactiveUS6098309AKeep dryWeaken energyDrying using combination processesDrying solid materials with heatCombustionProduct gas

Apparatus and process for manufacturing or treating a material web that includes at least one heatable cylinder and a combustion unit. The combustion unit is adapted to heat the at least one heatable cylinder with at least one of combustion gases and infrared radiation and the material web is adapted to be guided one of alone and with a transport belt over the at least one heatable cylinder. The apparatus also includes at least one blower box positioned to direct a hot gas onto the material web. The hot gas is at least one of the combustion gas and heated by the combustion gases. The process includes heating the at least one heatable cylinder with at least one of combustion gases and infrared radiation of the combustion unit, guiding the material web, one of alone and with a transport belt, over the at least one heated cylinder, and directing a hot gas from the blower box onto the material web, the hot gas being at least one of the combustion gas and heated by the combustion gases.

Owner:VOITH PATENT GMBH

Water extraction apparatus and method

InactiveUS20060191411A1Improve water absorptionLow costUsing liquid separation agentLiquid waterLiquid state

Apparatus and method for extracting water from air containing water vapor. A feed air assembly supplies air containing water vapor to a diff-user assembly in a reactive tank containing a reagent, preferably sulfuric acid, which absorbs the water vapor from the feed air. The reactive tank vents the dried air. A reagent solution line transmits reagent solution from the reactive tank to a recovery tank. A vacuum pump evaporates concentrated water vapor from the recovery tank and an extraction energy exchanger condenses the concentrated water vapor to liquid water.

Owner:N P JOHNSON FAMILY PARTNERSHIP

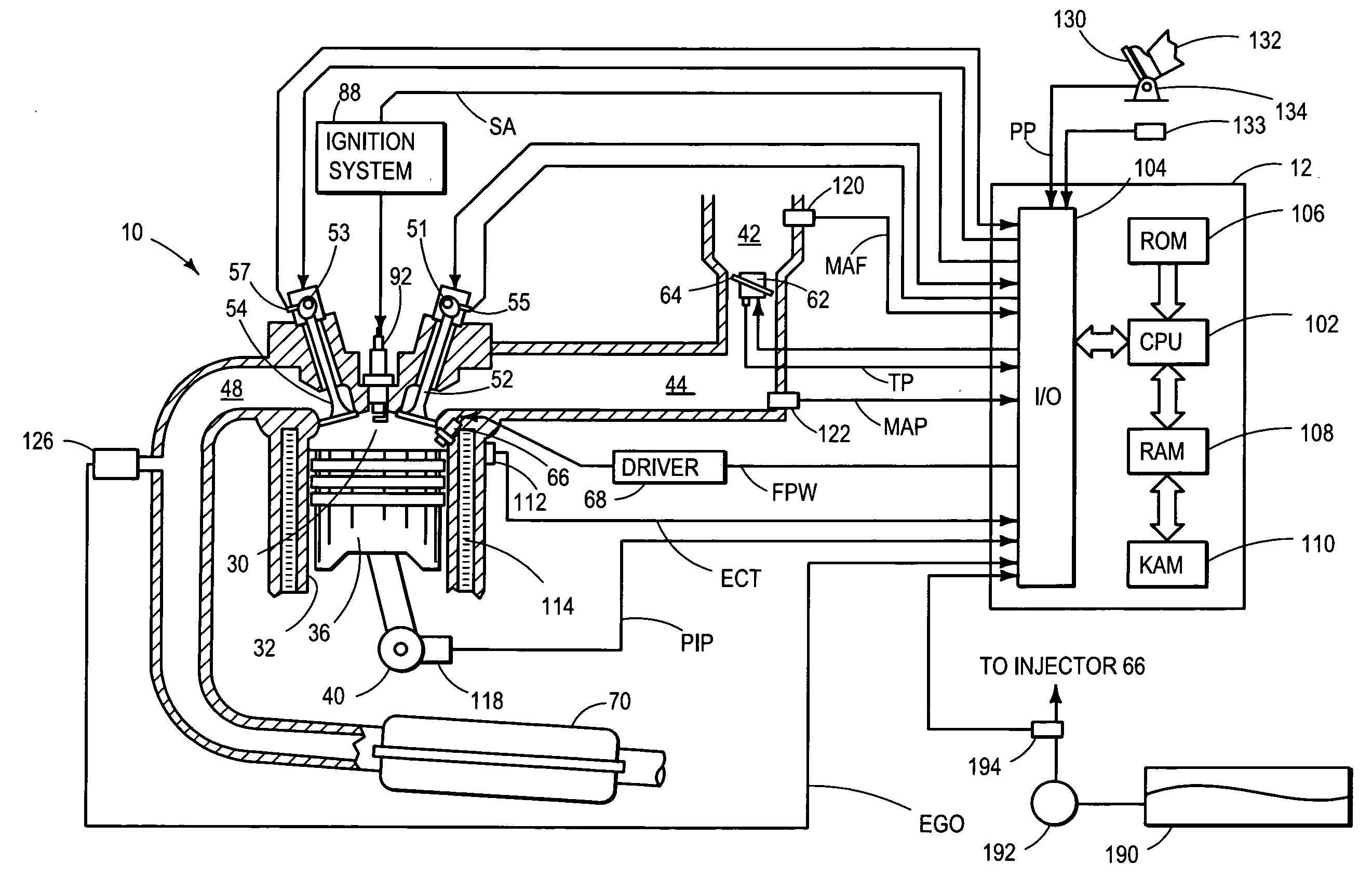

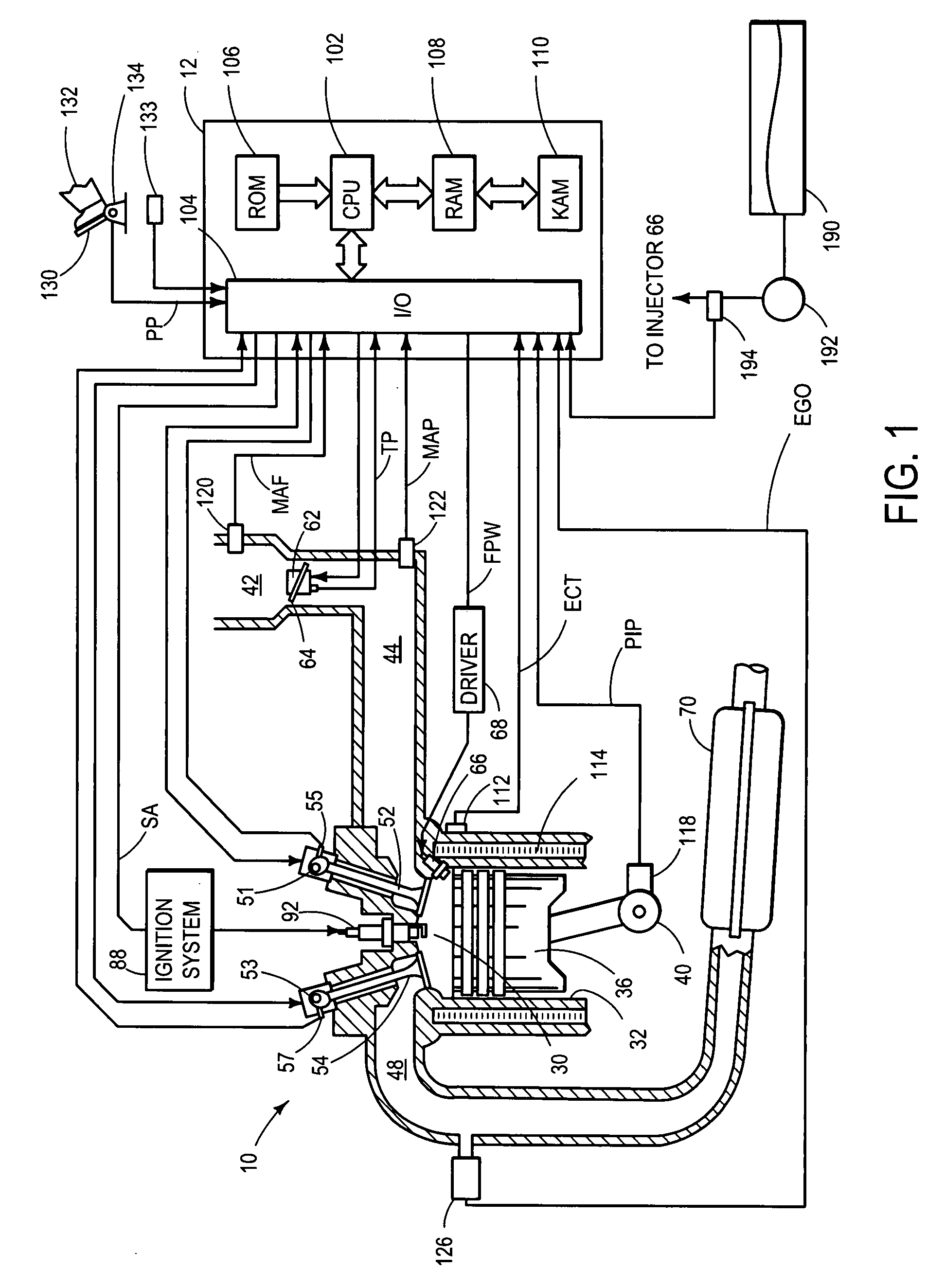

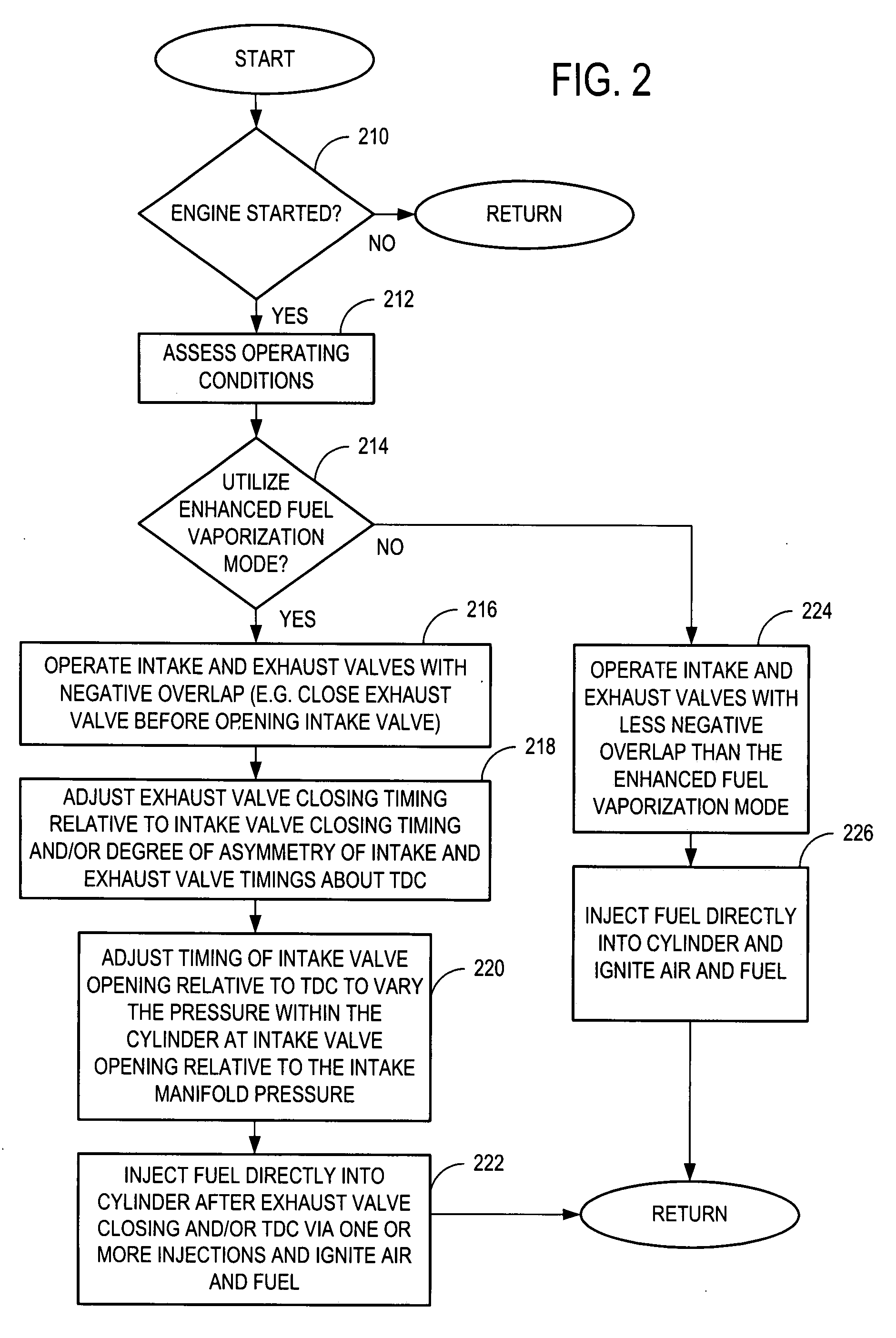

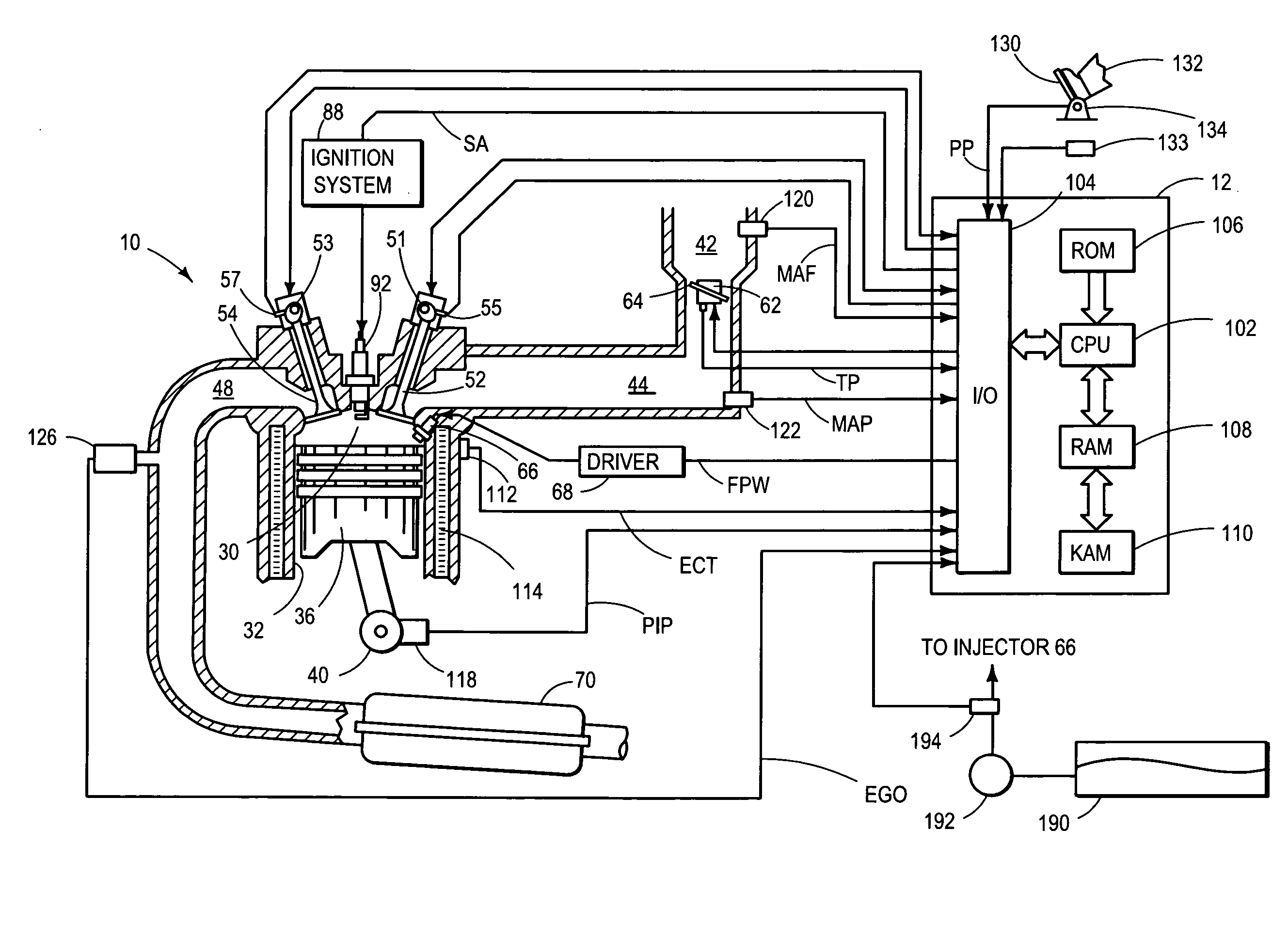

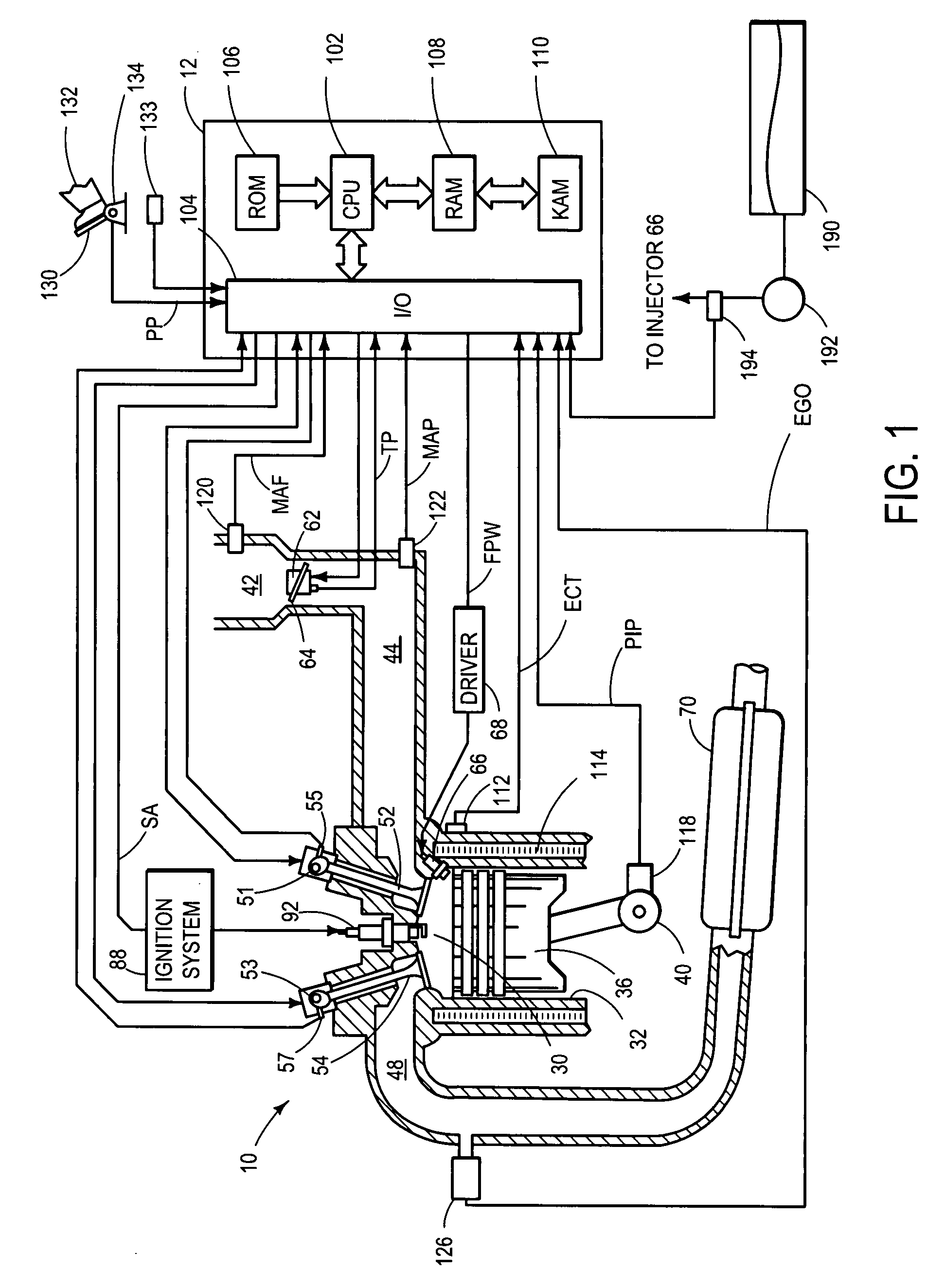

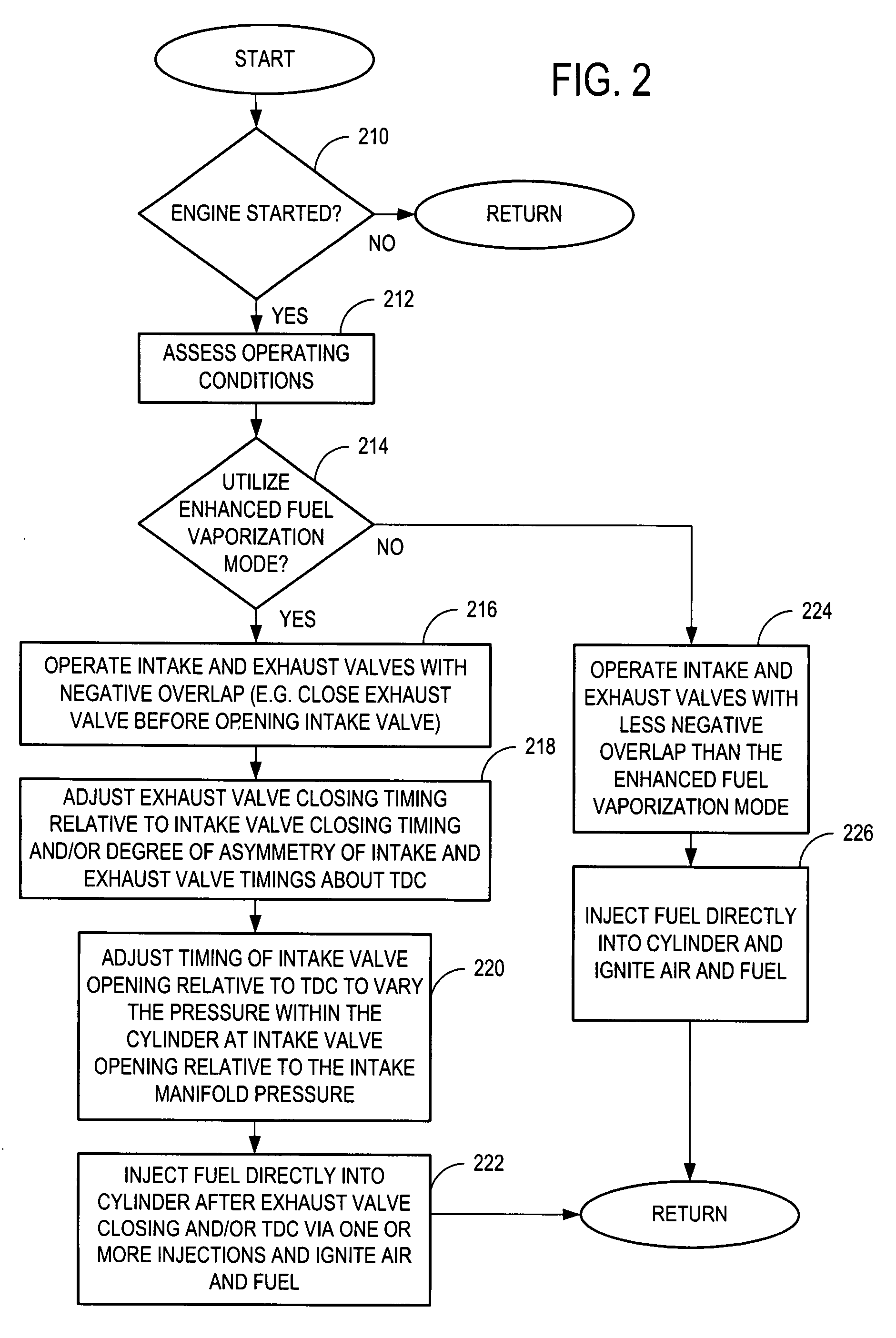

Approach for Improved Fuel Vaporization in a Directly Injected Internal Combustion Engine

InactiveUS20090093950A1Reduce vaporization rateRate of vaporization is lowElectrical controlInternal combustion piston enginesExhaust valveTop dead center

A system and a method of facilitating fuel vaporization in a directly injected internal combustion engine are provided. As one example, the method comprises: closing an exhaust valve of the cylinder; opening an intake valve after the exhaust valve has closed; moving a piston of the cylinder away from top dead center between the closing of the exhaust valve and the opening of the intake valve to expand the cylinder volume and reduce a pressure within the cylinder to below a pressure of an air intake manifold of the cylinder; and initiating an injection of fuel directly into the cylinder via an in-cylinder injector after the exhaust valve has closed.

Owner:FORD GLOBAL TECH LLC

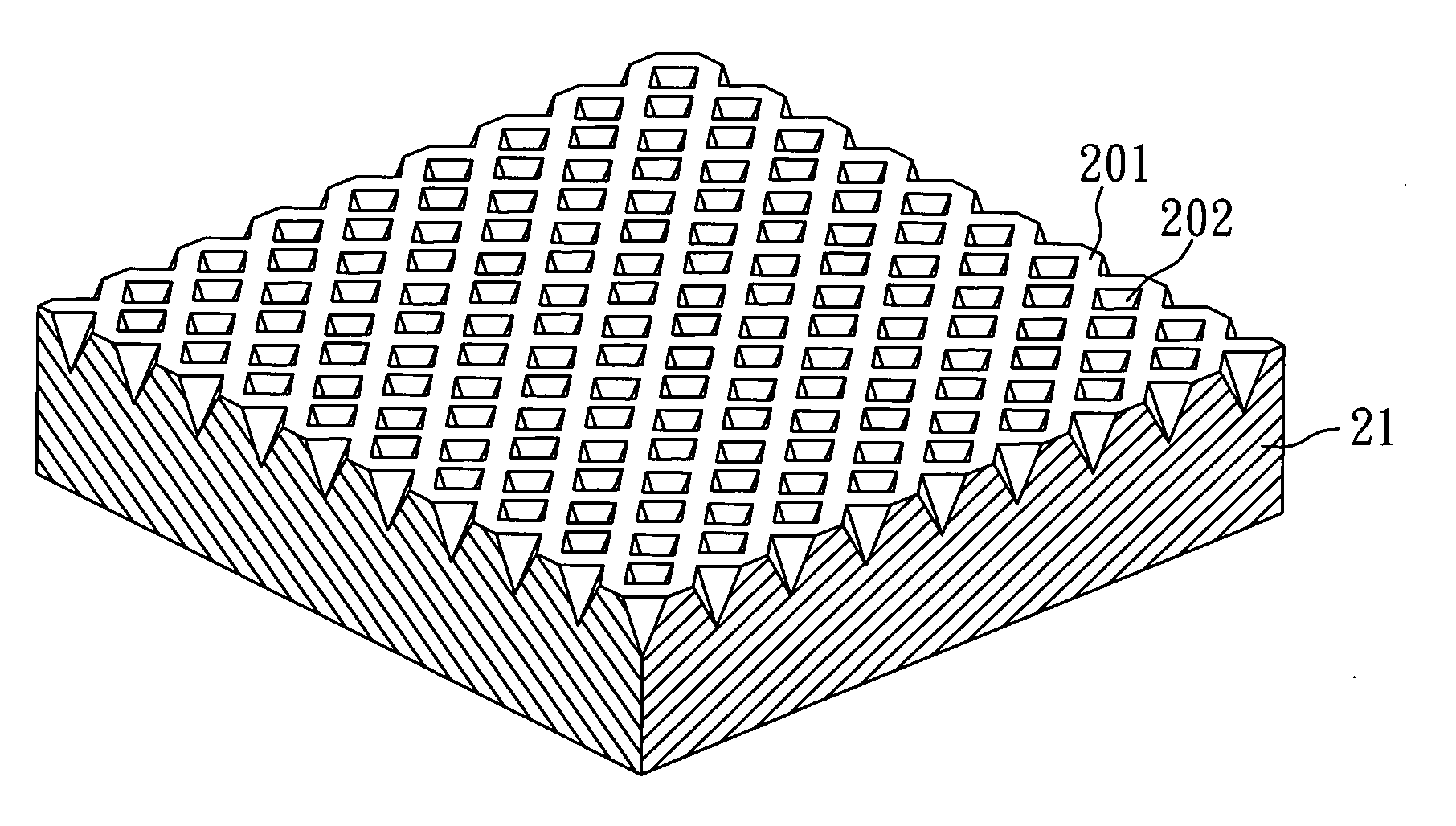

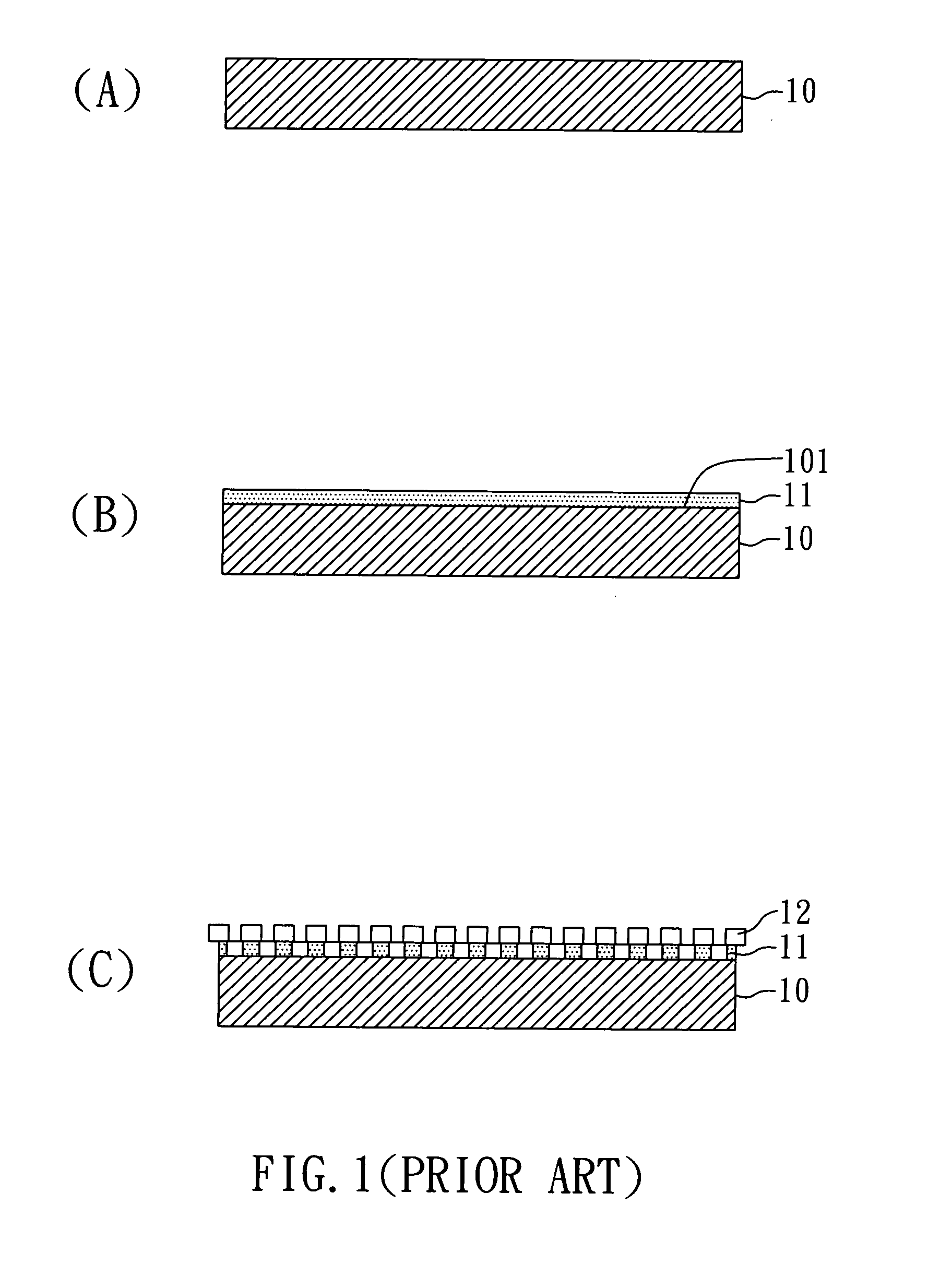

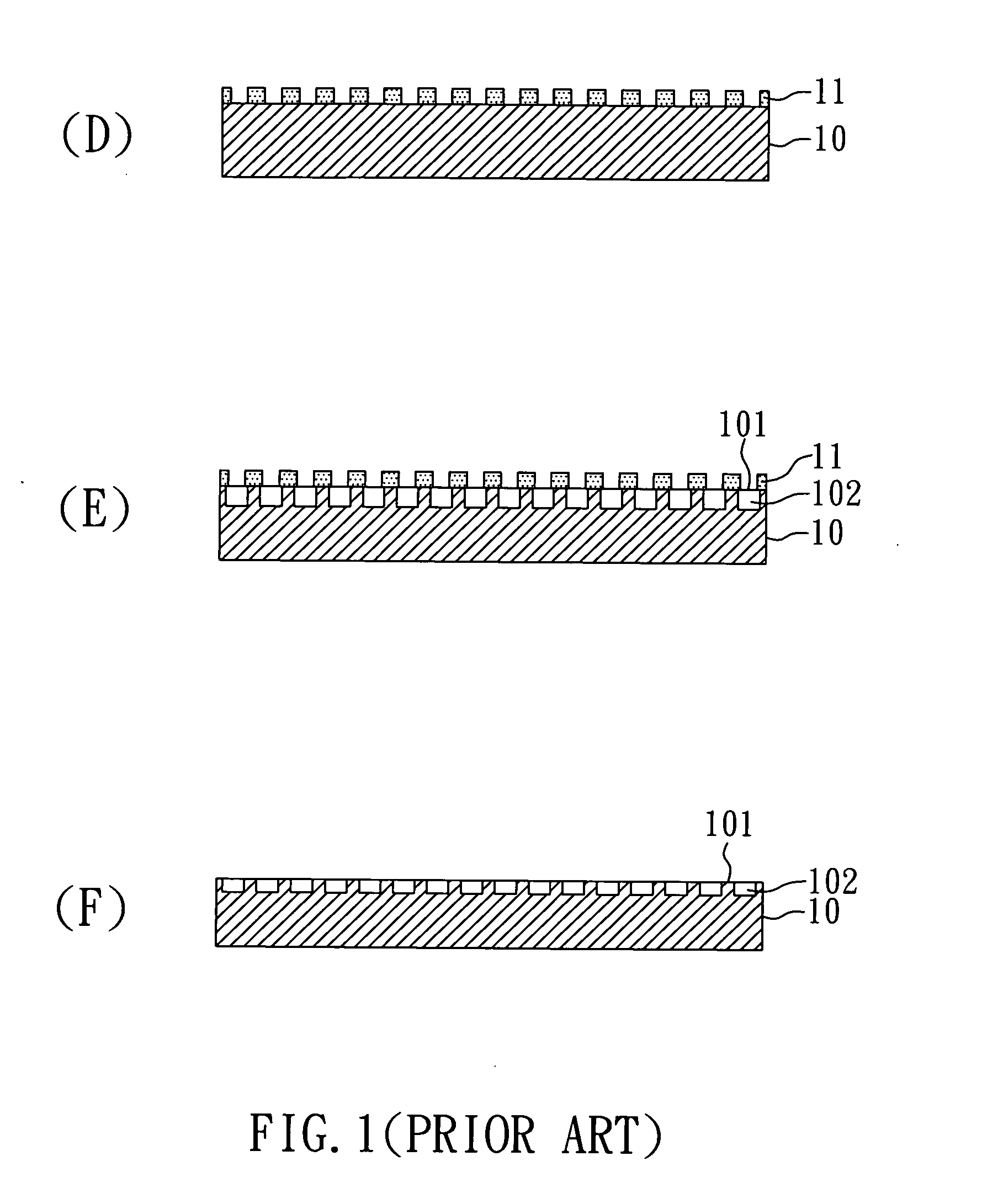

Method for preparing substrate with periodical structure

InactiveUS20100270263A1Reduce probabilityUniform periodical structureDecorative surface effectsNanoopticsLithographyNano sized

A method for preparing a substrate with periodical structure, comprising the following steps: (A) providing a substrate and plural nano-sized balls, wherein the nano-sized balls are arranged on the surface of the substrate; (B) depositing a cladding layer on partial surface of the substrate and the gaps between the nano-sized balls; (C) removing the nano-sized balls; (D) etching the substrate by using the cladding layer as a mask; and (E) removing the mask to form a periodical structure on the surface of the substrate. In the present invention, the nano-sized balls are used as a template for forming the mask. Hence, compared with the lithography, when the method of the present invention is used to prepare a substrate with a periodical structure, the duration of the process and the manufacturing cost can be decreased.

Owner:AUROTEK CORP

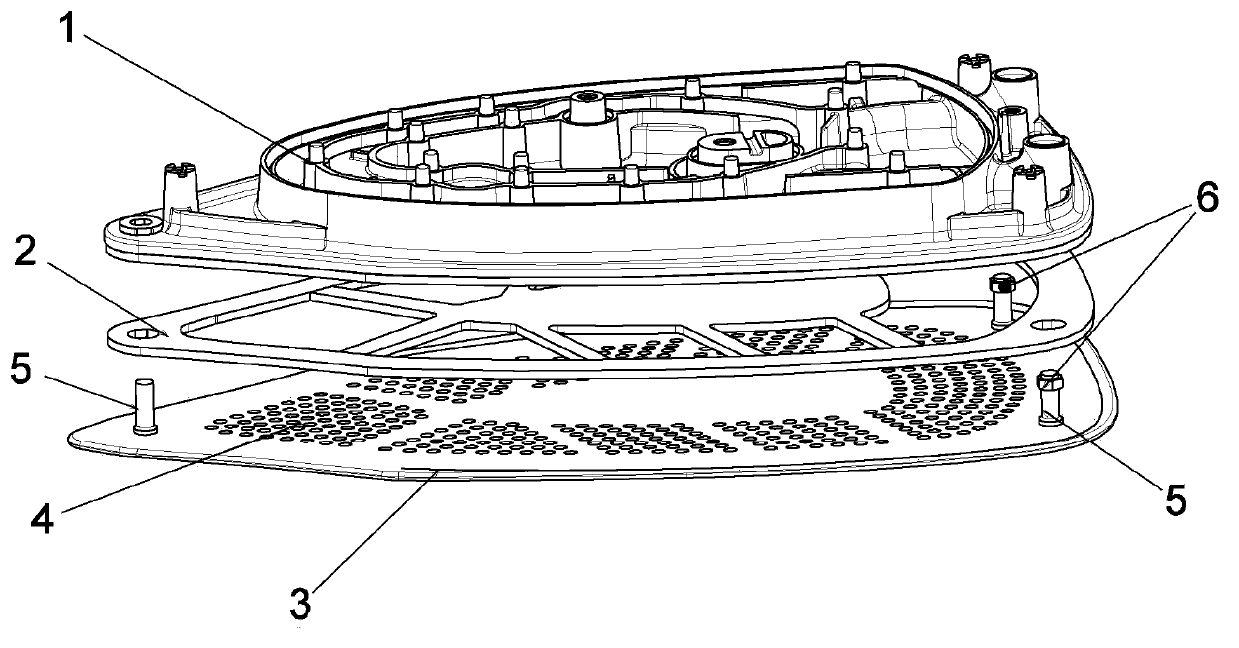

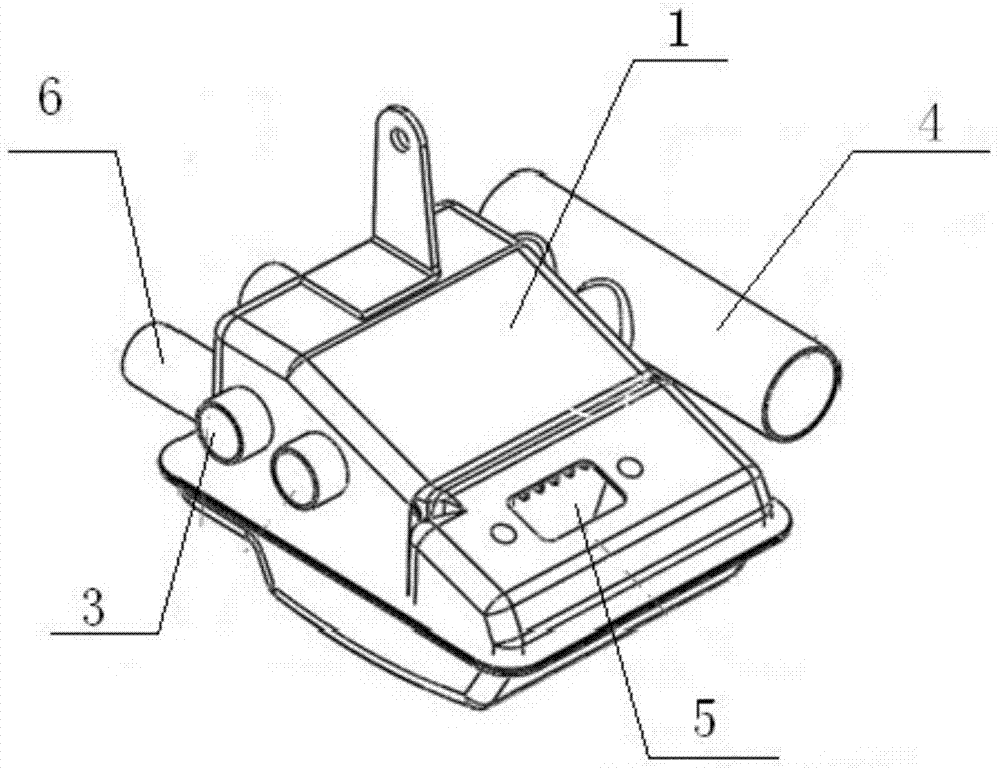

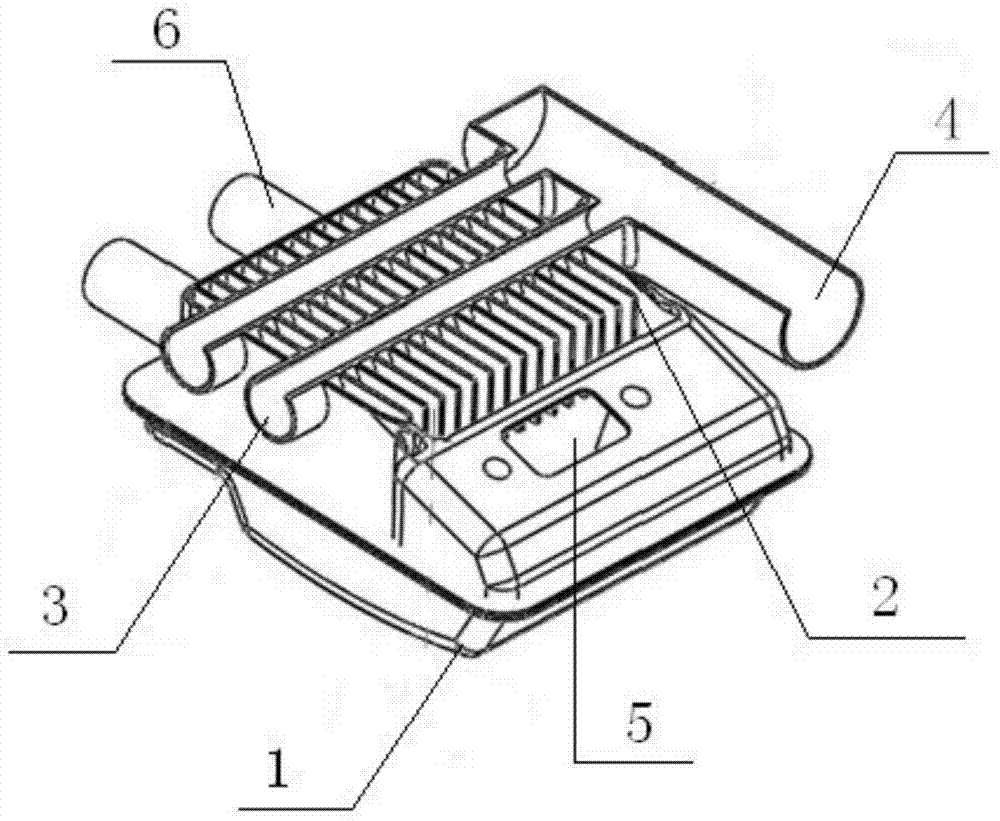

Steam iron

InactiveCN103966823AAvoid drippingReduce the temperatureHand ironTextiles and paperEngineeringSurface plate

Owner:活力科研有限公司

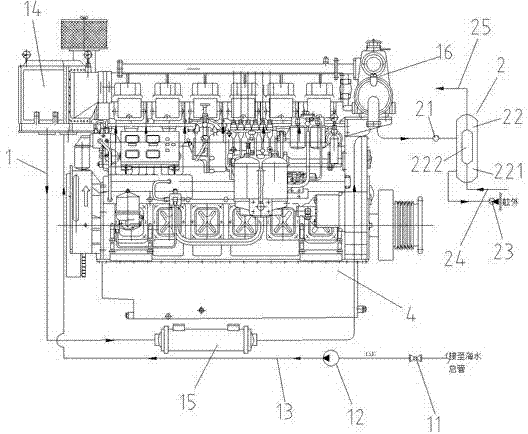

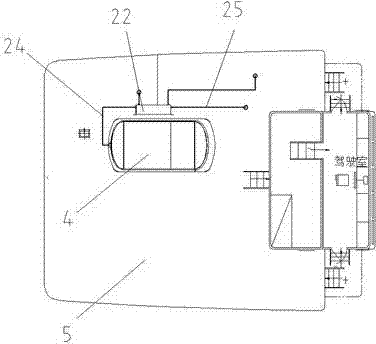

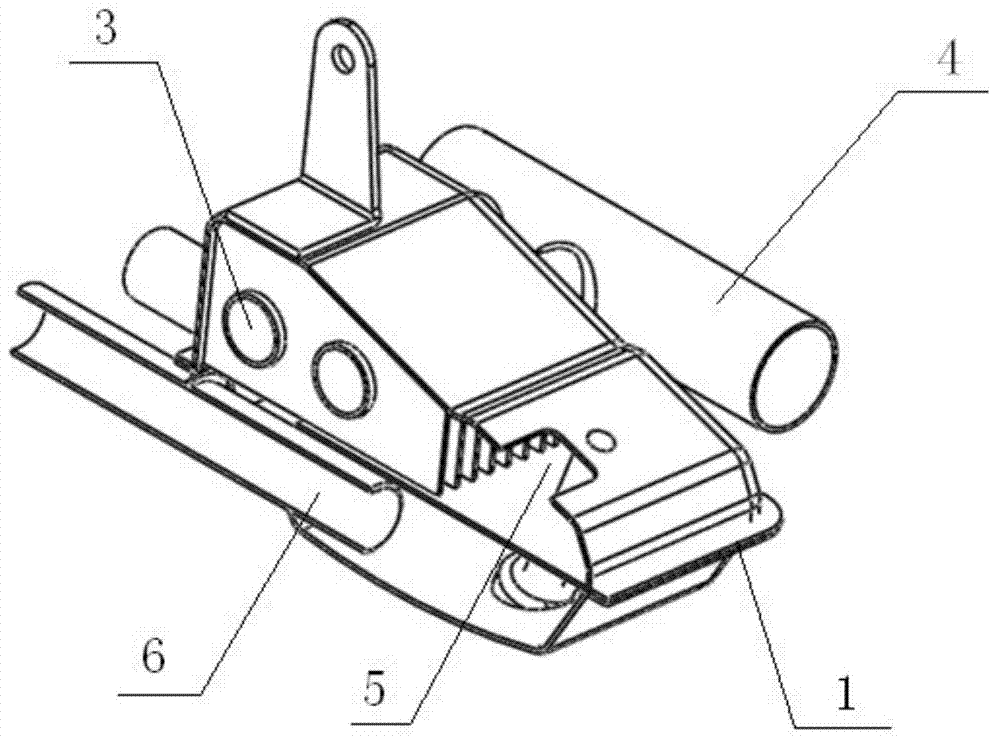

Diesel oil-LNG (liquefied natural gas) dual-fuel hybrid power ship LNG vaporizing device

InactiveCN102926894AIncrease vaporization rateEnsure normal gas supplyInternal combustion piston enginesFuel supply apparatusCheck valveDiesel engine

The invention discloses a diesel oil-LNG (liquefied natural gas) dual-fuel hybrid power ship LNG vaporizing device which comprises a diesel engine sea water opening type cooling circuit and an LNG vaporizing loop, wherein one end of a stop valve of the diesel engine sea water opening type cooling circuit is communicated with a sea water main pipe, and the other end of the stop valve is communicated to a sea water pump through a sea water pipeline; an output end of the sea water pump is connected with an input end of a fresh water cooler through a middle cooler and a lubricating oil cooler; the LNG vaporizing loop comprises a liquid stream observer and a water bath vaporizer, the water bath vaporizer comprises an outer tank and an inner container, the output end of the fresh water cooler is communicated to the outer tank of the water bath vaporizer by passing through the sea water pipeline and the liquid stream observer and then passes through the output end of the outer tank and a check valve to be lead to the outside of a ship board; and the output end of an LNG gas storage tank is communicated with the inner container of the water bath vaporizer, natural gas after being heated and vaporized is lead to the air main pipe of a dual-fuel diesel engine from the inner container of the vaporizer, and the vaporizing rate of the natural gas is improved by more than 20%. The normal gas supply quantity of the diesel engine is guaranteed, and the diesel oil-LNG dual-fuel hybrid power ship LNG vaporizing device has obvious economical efficiency and favorable vaporization efficiency.

Owner:JIANGSU MODERN SHIPBUILDING TECH

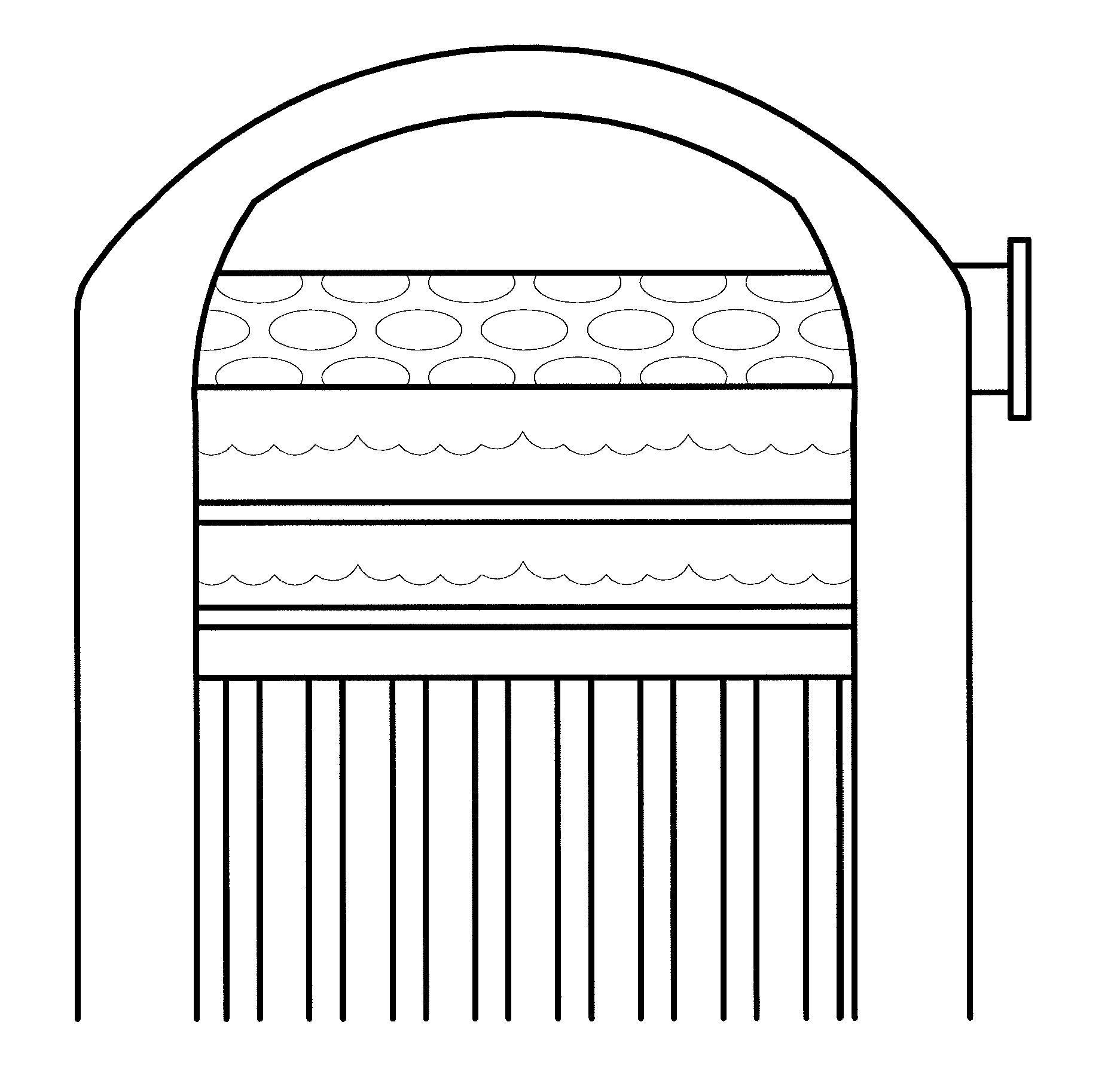

Humidification arrangement for a respiratory apparatus

ActiveUS20150101607A1Increase vaporization rateRespiratory masksMedical devicesWater channelSemipermeable membrane

A humidifying apparatus utilizing a semi-permeable membrane portion within a gas conduit where the direction of gas flow within a central lumen is given by an arrow. The humidification apparatus has a helical configuration for the semi-permeable membrane portion, a structural reinforcing member or members, a water channel and a heating element. The helical configuration of an outer wall may be similar to conventional conduits that are in common use in respiratory apparatus. Thus the humidification apparatus may be readily substituted into existing respiratory device by exchanging the gas conduit.

Owner:RESMED LTD

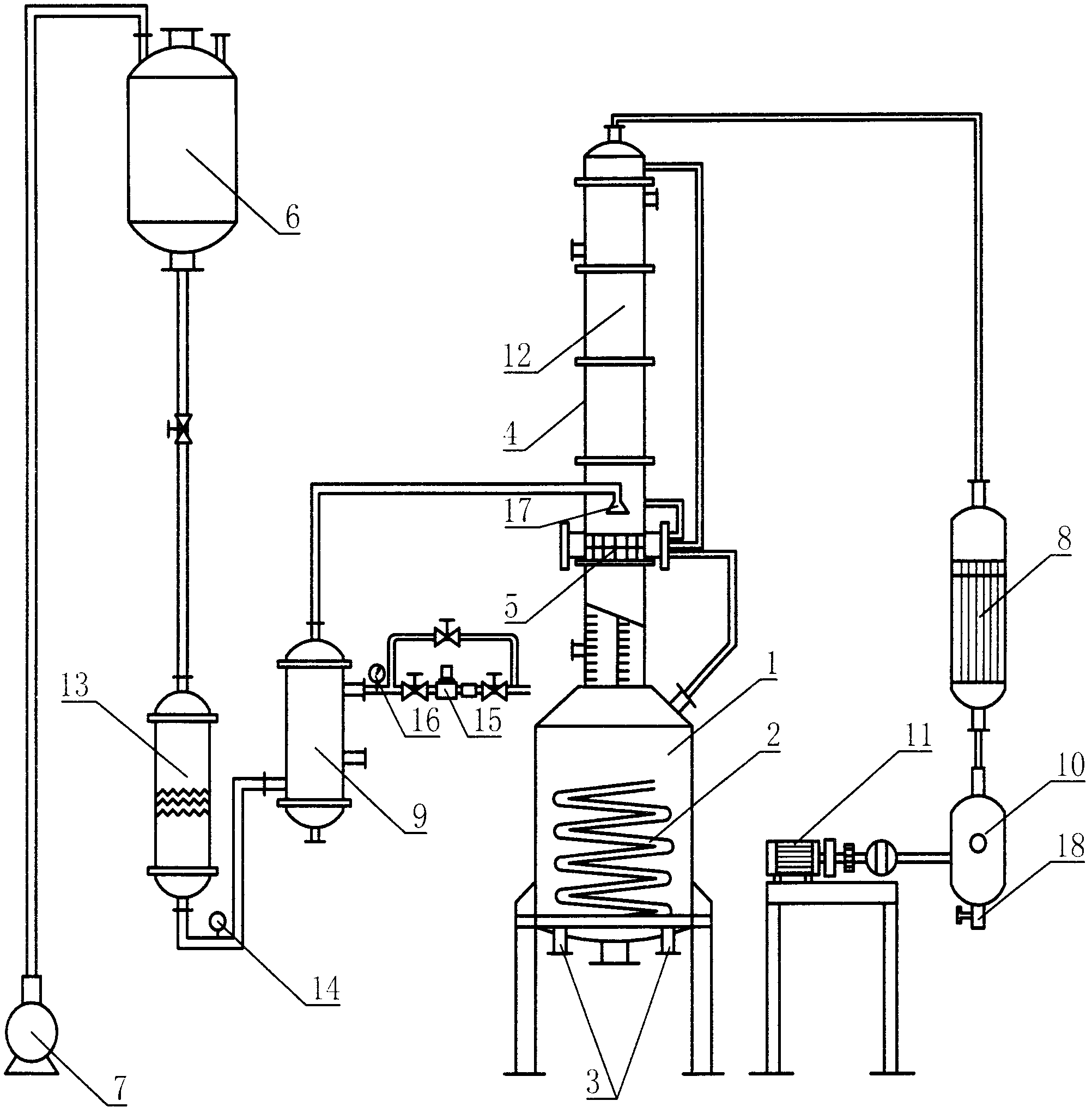

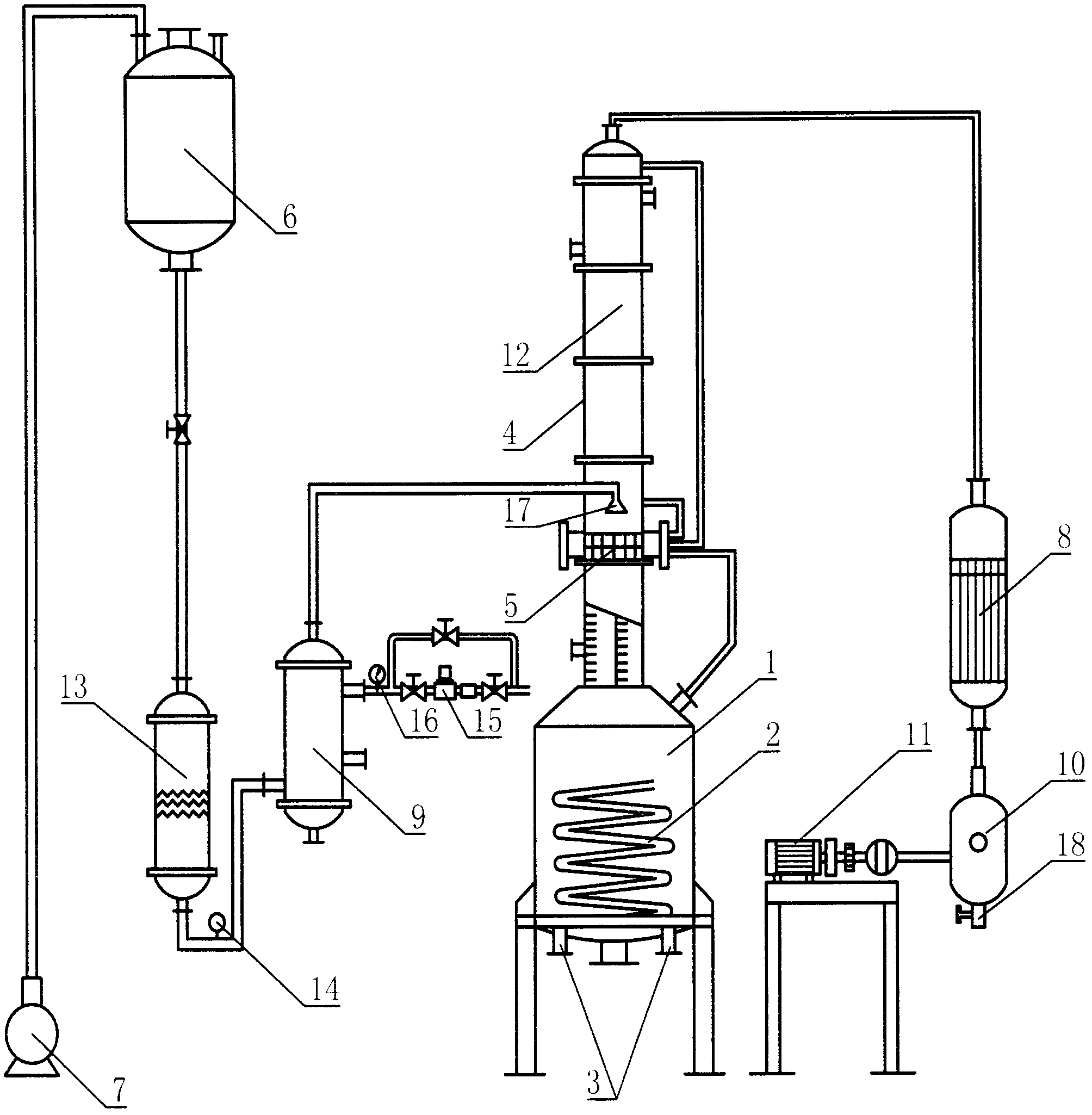

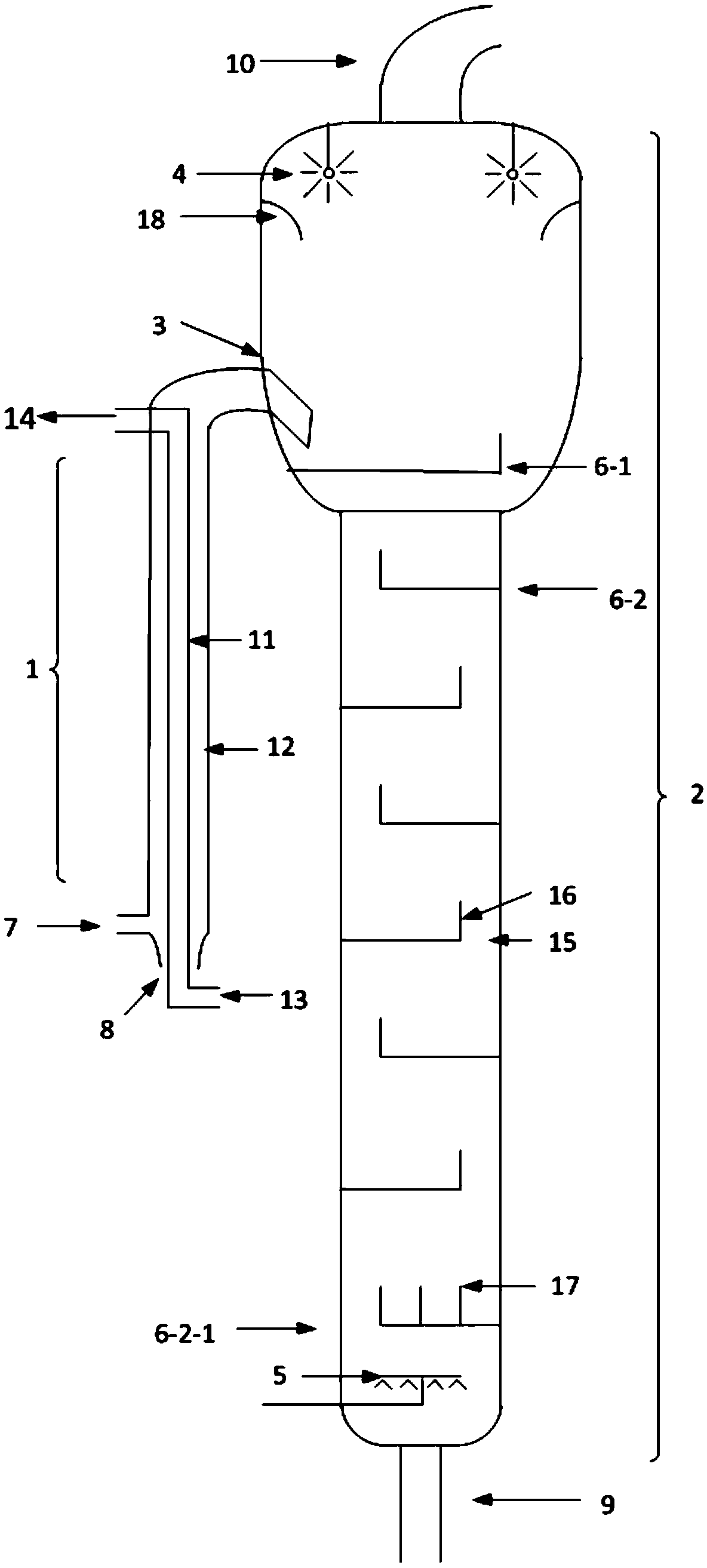

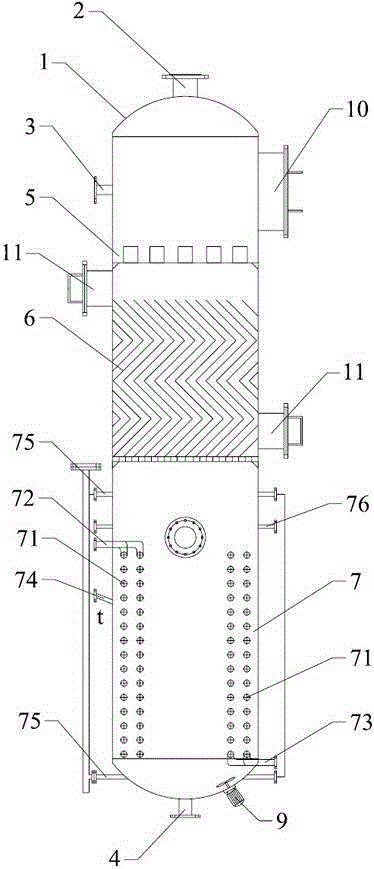

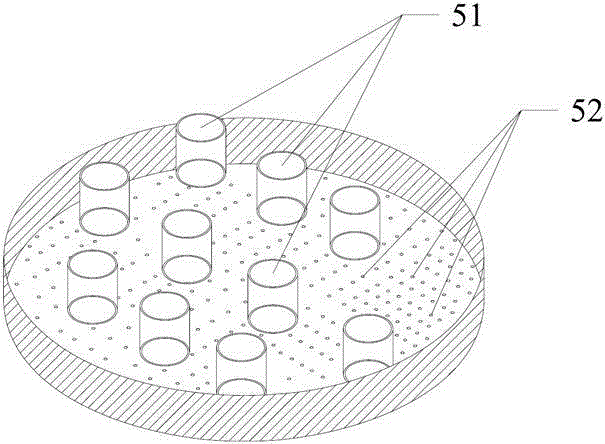

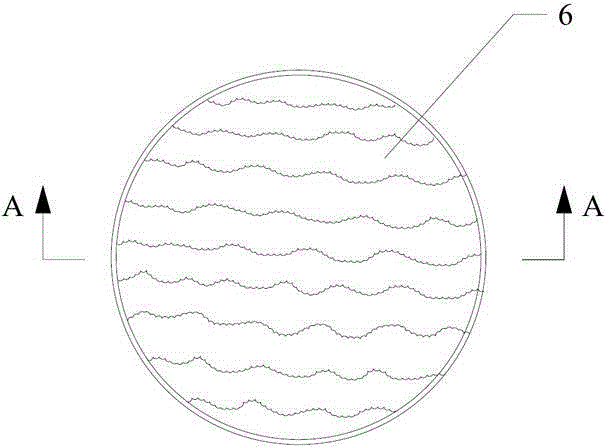

Alcohol recovery tower

InactiveCN102584524AEffective primary filtrationHigh recovery purityOrganic compound preparationHydroxy compound preparationAqueous alcoholDistillation

The invention relates to an alcohol recovery device, in particular to an alcohol recovery tower, which has a high recovery speed and high recovery purity and is economical and durable. The alcohol recovery tower comprises a distillation tower kettle (1), a distillation tower body (4), a high-level storage tank (6), a centrifugal pump (7), a condensation cooler (8), a filter (13), a preheater (9) and a vacuum storage tank (10), wherein the distillation tower body (4) is arranged above the distillation tower kettle (1); a heating pipe (2) is arranged inside the distillation tower kettle (1); two steam inlets (3) are symmetrically formed at the bottom of the distillation tower kettle (1); a filler (5) is arranged in the distillation tower body (4); one side of the distillation tower body (4) is connected with the high-level storage tank (6) provided with the centrifugal pump (7) through a pipeline; the other side of the distillation tower body (4) is connected with the condensation cooler (8) through a pipeline; the preheater (9) is arranged between the high-level storage tank (6) and the distillation tower body (4), and a steam heating way is adopted for the preheater (9); the vacuum storage tank (10) is arranged below the condensation cooler (8); one side of the vacuum storage tank (10) is provided with a vacuum pump (11); and the bottom of the vacuum storage tank (10) is provided with an alcohol outlet (18).

Owner:付顺林

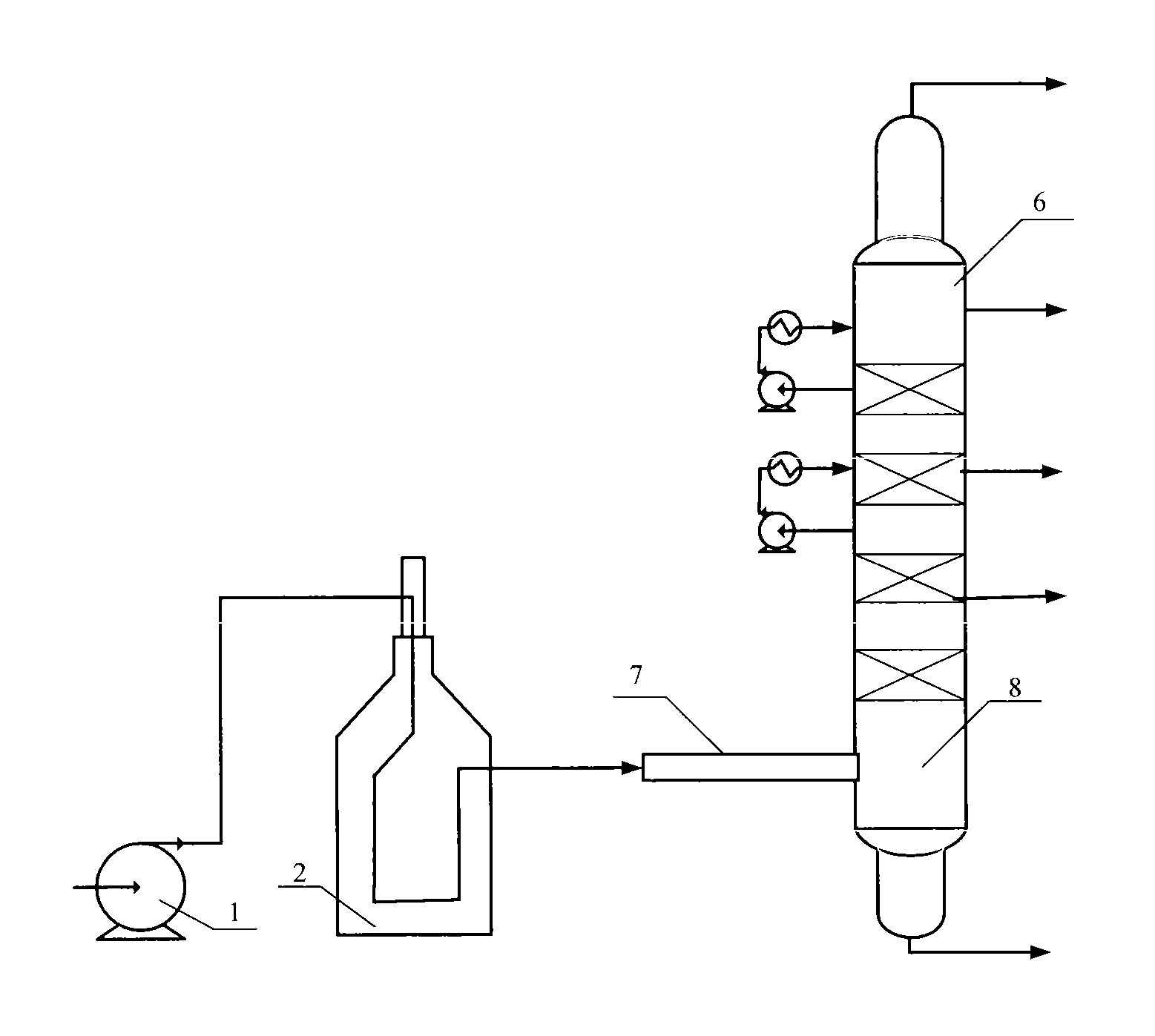

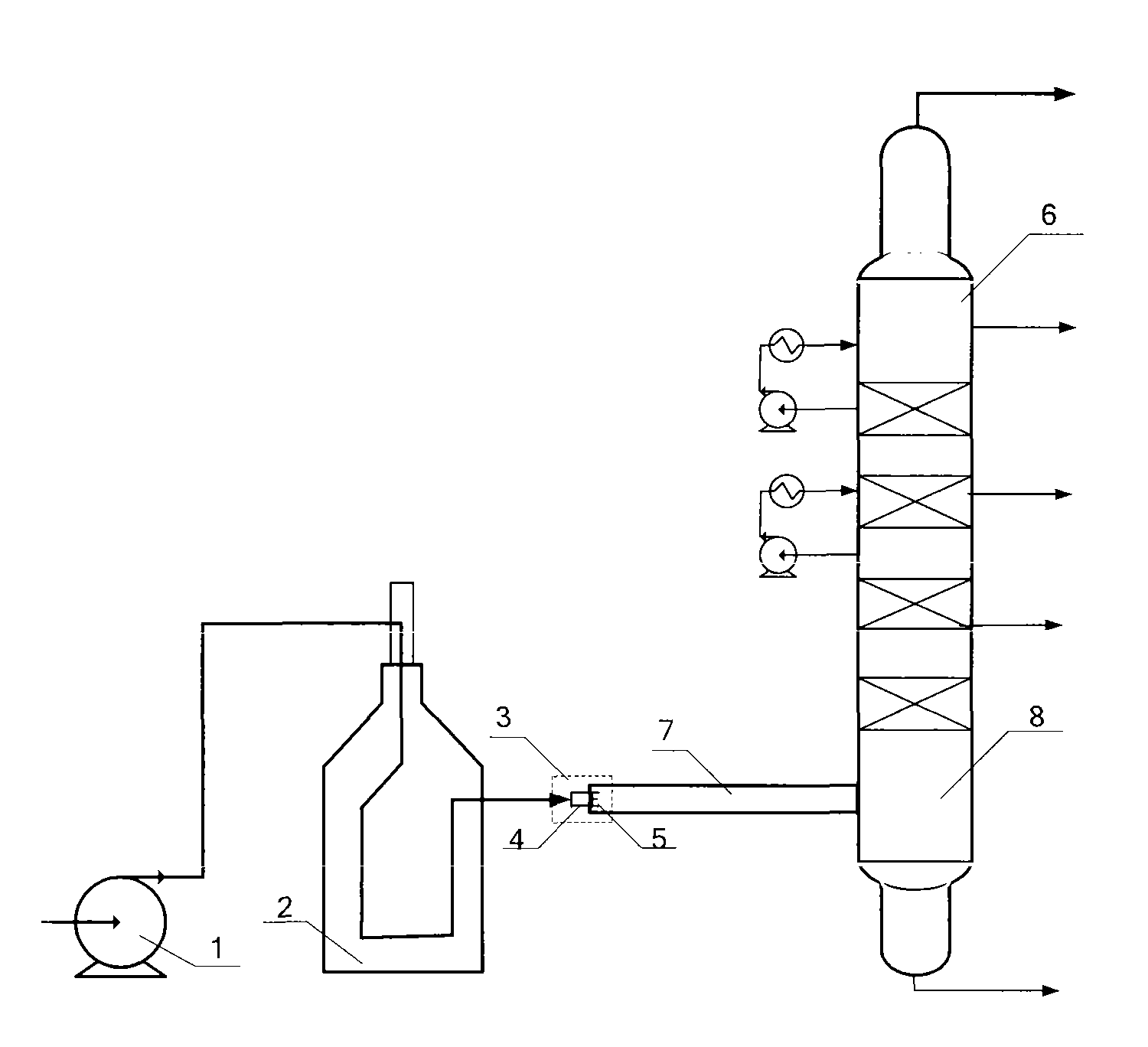

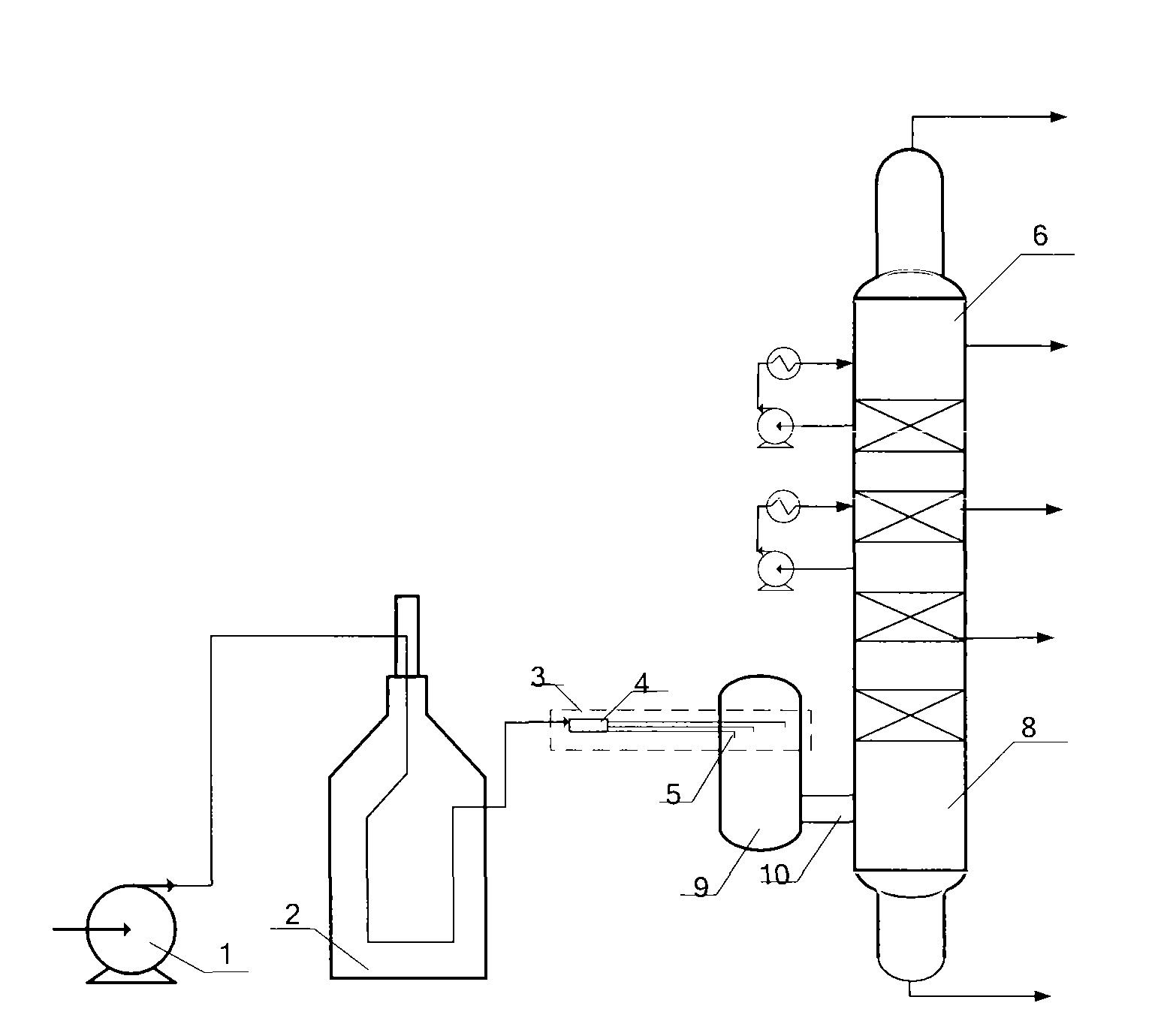

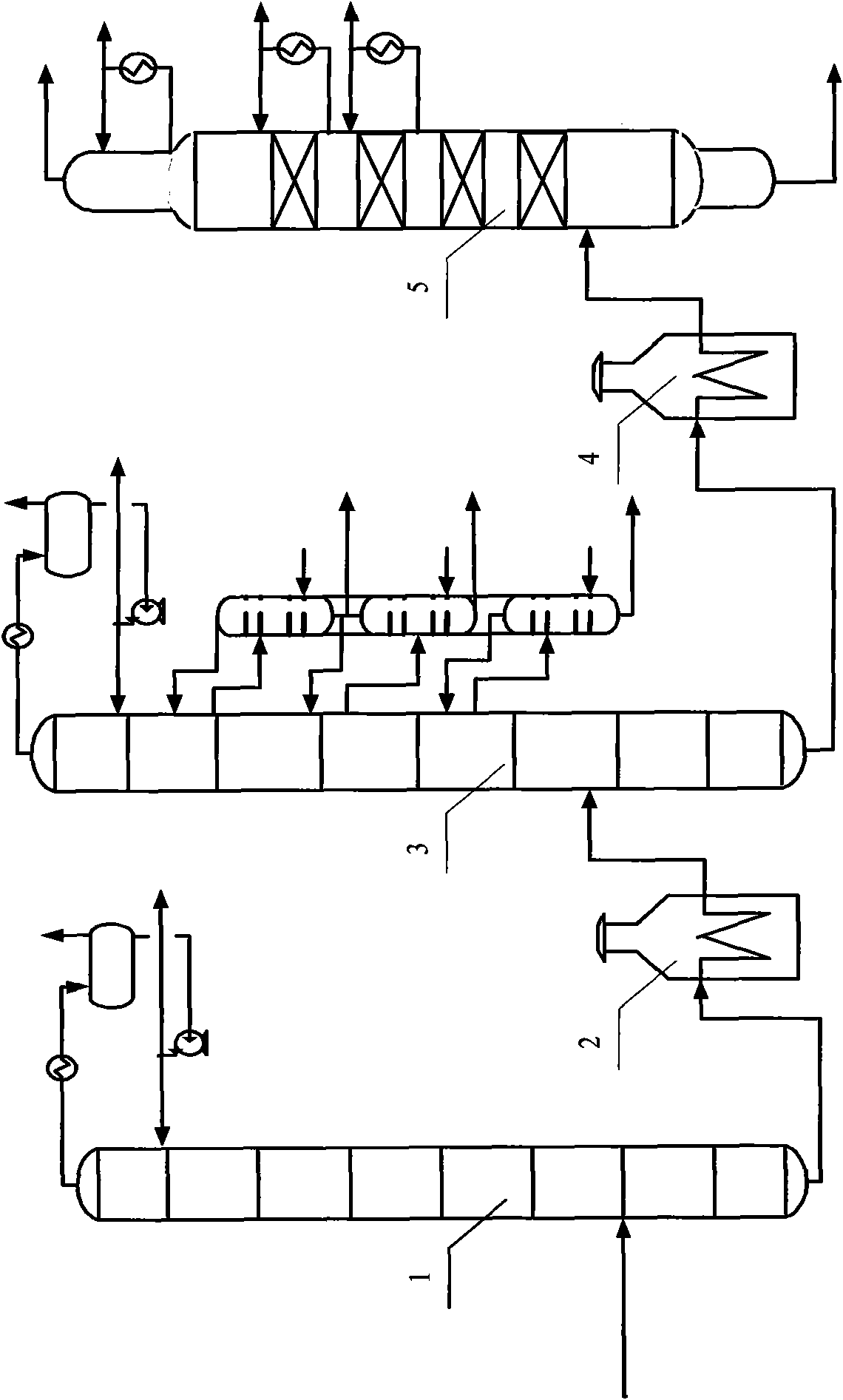

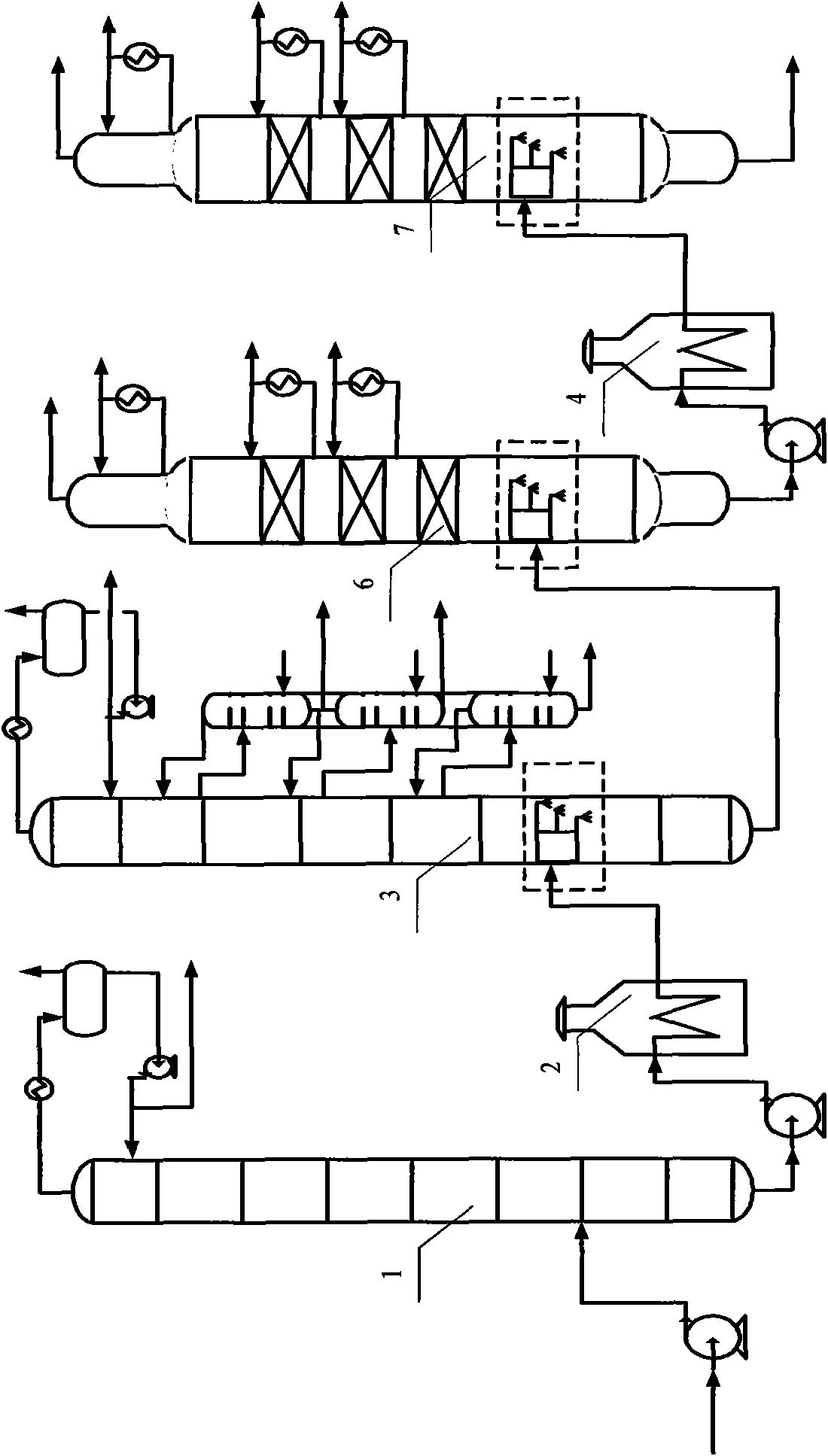

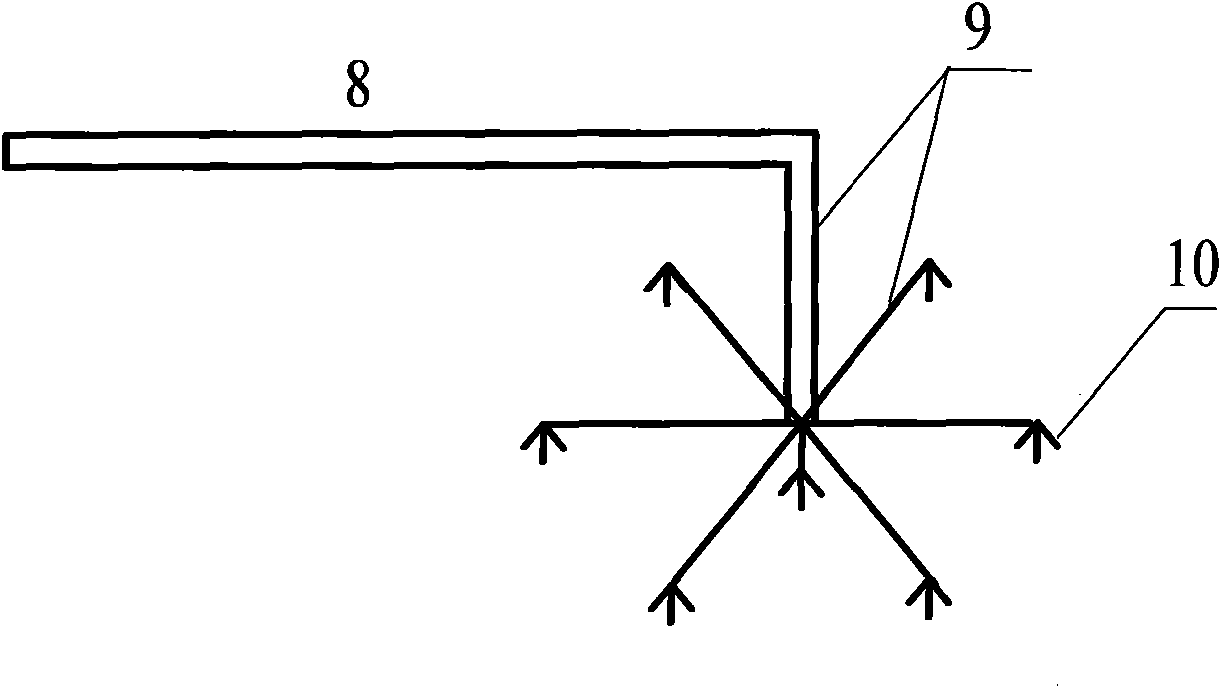

Fractionating column feed method for improving distillate yield

ActiveCN102079984AImprove distillate yieldHigh yieldHydrocarbon distillationSmall dropletFractionating column

Disclosed is a fractionating column feed method for improving distillate yield, which comprises the following steps: preheating petroleum hydrocarbon raw oil to be fractionated by a heating furnace; spraying the preheated raw oil into a atomization container under the pressure of 100.0-1000.0kPa higher than the pressure of the atomization container and atomizing into small droplets with the particle size of 0.0001-10 millimeters and vaporizing partly; and introducing the small droplets into a fractionating column for distillation separation; leading out the distillate products from the top ofthe fractionating tower and / or the lateral line and the residues from the bottom. In the method provided by the invention, the vaporization process of the raw oil is accelerated through atomization in order to fully vaporize the distillate in an extreme short period of time, minimize the distillate content in the residual oil to the great extent and increase the yield of distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and method for removing VOC (voltaic organic compound) in emulsion

ActiveCN108654124AEfficient removalIncrease vaporization rateLiquid degasification with auxillary substancesEvaporationBenzeneEmulsion

The invention discloses a device and a method for removing VOC (voltaic organic compound) in an emulsion. The device body comprises a steam and liquid mixer and a VOC removal tower, wherein the steamand liquid mixer is of a multi-layer sleeve tube type structure or a tube type structure with a perforated plate; a tower body of the VOC removal tower is separated into an upper part and a lower part, the inner diameter of the upper part is greater than the inner diameter of the lower part, the upper part is provided with a rotary spraying device at the top part of the VOC removal tower, and thelower part is provided with a gas distributor at the bottom part of the VOC removal tower; a screen plate is arranged between the rotary spraying device and the gas distributor. The method using the device to remove the VOC in multiple emulsions has the advantages that the foaming and crusting are avoided in the treatment process; especially for hydrophobic VOC of BA, St, benzene series and the like, the continuous and high-efficiency effects are realized, and the like; the method has great application and popularization prospect in the fields of ultralow VOC, clean-odor emulsions.

Owner:WANHUA CHEM GRP CO LTD +1

Approach for improved fuel vaporization in a directly injected internal combustion engine

InactiveUS7992537B2Reduce vaporization rateRate of vaporization is lowElectrical controlInternal combustion piston enginesExhaust valveExternal combustion engine

A system and a method of facilitating fuel vaporization in a directly injected internal combustion engine are provided. As one example, vaporization may be improved by coordinating the timing of the directly injected fuel with intake valve opening while also utilizing negative valve overlap between the intake and exhaust valves to generate reduced pressures within the cylinder.

Owner:FORD GLOBAL TECH LLC

Polystyrene reclamation process

InactiveUS6720467B2Avoid lostEasy to reuseHydrocarbon by hydrogenationPlastic recyclingPropyl bromideBoiling point

This disclosure concerns a process and apparatus for reclamation of waste polystyrene-type materials for reuse within the specification ranges of the input polystyrene-type material. The disclosed process and apparatus include dissolution of the waste polystyrene-type materials in a dissolve section utilizing a reusable solvent having a low boiling point and high vaporization rate, removal of solid contaminants in one or more filter sections, devolatilization of the dissolved polystyrene and recovery of the polystyrene-type material in a solid form in a recovery section. Preferably the process and apparatus provide a closed system and include recycling and reuse in the process of the vaporized solvent. The maximum temperature in the recovery section is 190° C. The reusable solvent is preferably environmentally safe and has a low boiling point and high vaporization rate. n-Propyl bromide, or environmentally safe mixtures thereof, including mixtures with isopropyl alcohol, is the preferred reusable solvent.

Owner:RESOURCE RECOVERY TECH

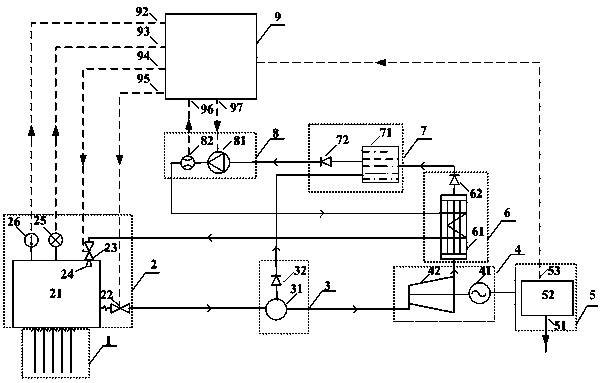

System and method for water spray injection type pulse steam electric power generation

ActiveCN103422919AEfficient and feasible thermoelectric conversionImprove conversion efficiencyFrom solar energySteam engine plantsThermal energyControl line

The invention discloses a system and method for water spray injection type pulse steam electric power generation. A temperature sensor (26), a pressure sensor (25) and a flow meter (82) are respectively connected with a signal transmission line of a main control unit (9), a control line of the main control unit (9) is connected with a water injection valve (23), a steam release valve (22) and a water pump (81). Water is injected by force in a quantitative mode, the quantitative water is subjected to instant vaporization to be steam in the high-temperature environment of a steam generator, the steam pushes a turbine to do work and drives an electric generator to generate electricity to complete pulse work, and efficienct and feasible thermoelectric conversion is achieved. A circulation pulse working mode is adopted, and the system and method break through the tradition that a great amount of water is heated in a one-time mode for doing work, reduce water consumption and effectively improve conversion efficiency from thermal energy to steam potential energy. Under the control of a controller, the quantitative water is injected by force and rapidly and completely is vaporized in the high-temperature environment of the steam generator, the vaporization rate of the water is improved, and therefore the conversion efficiency from the thermal energy to the steam potential energy is further improved.

Owner:圣辉(上海)能源科技有限公司

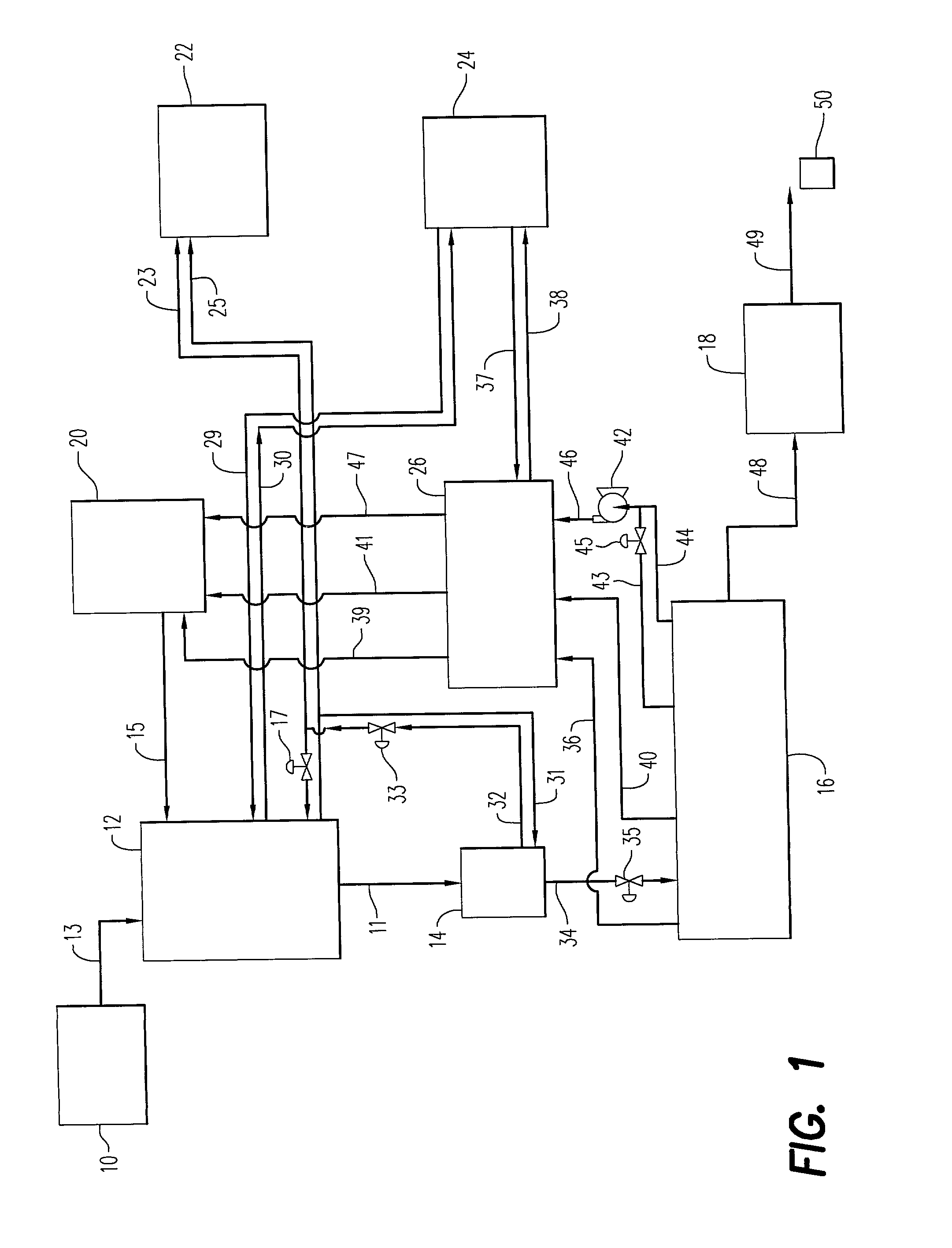

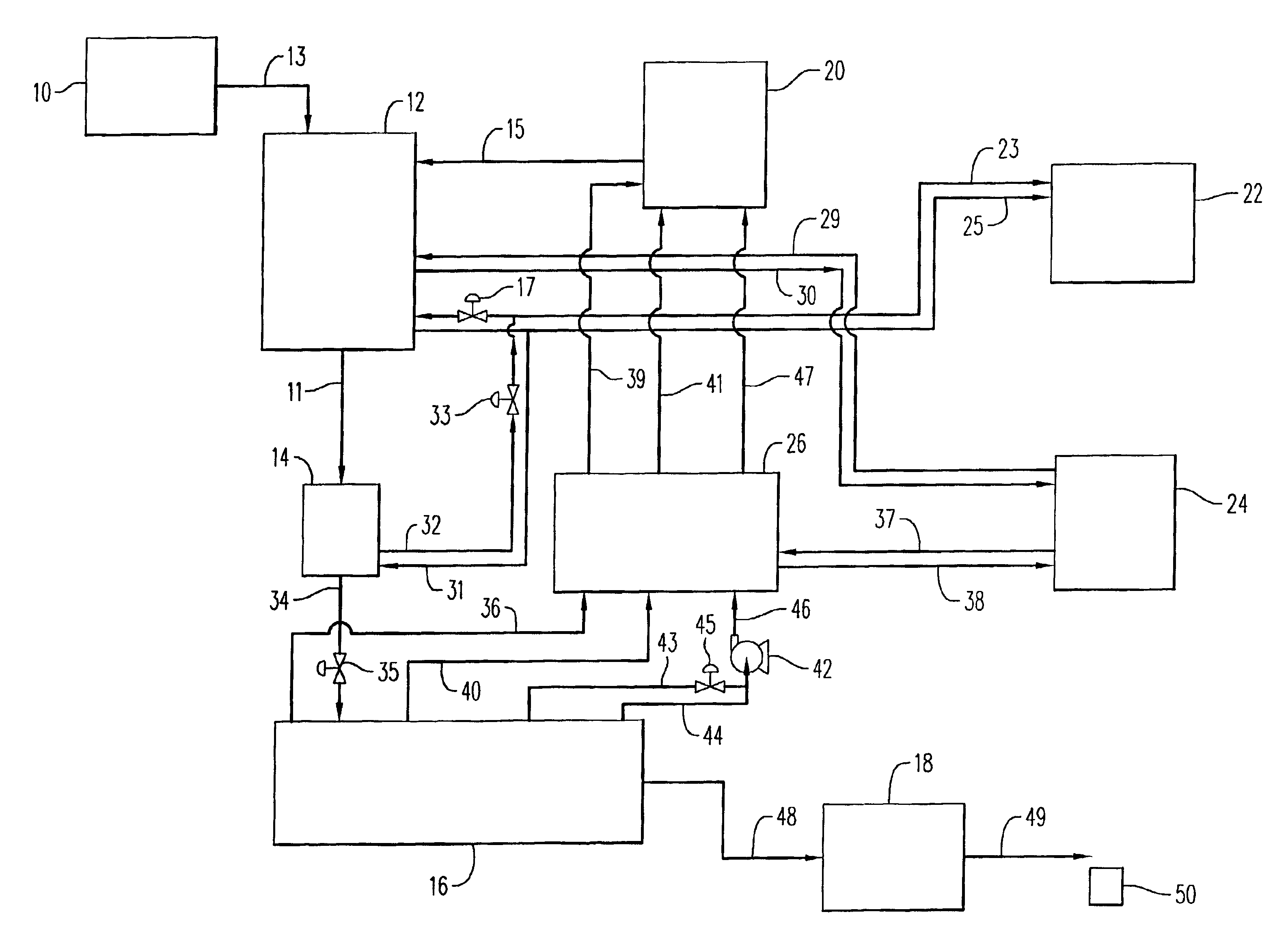

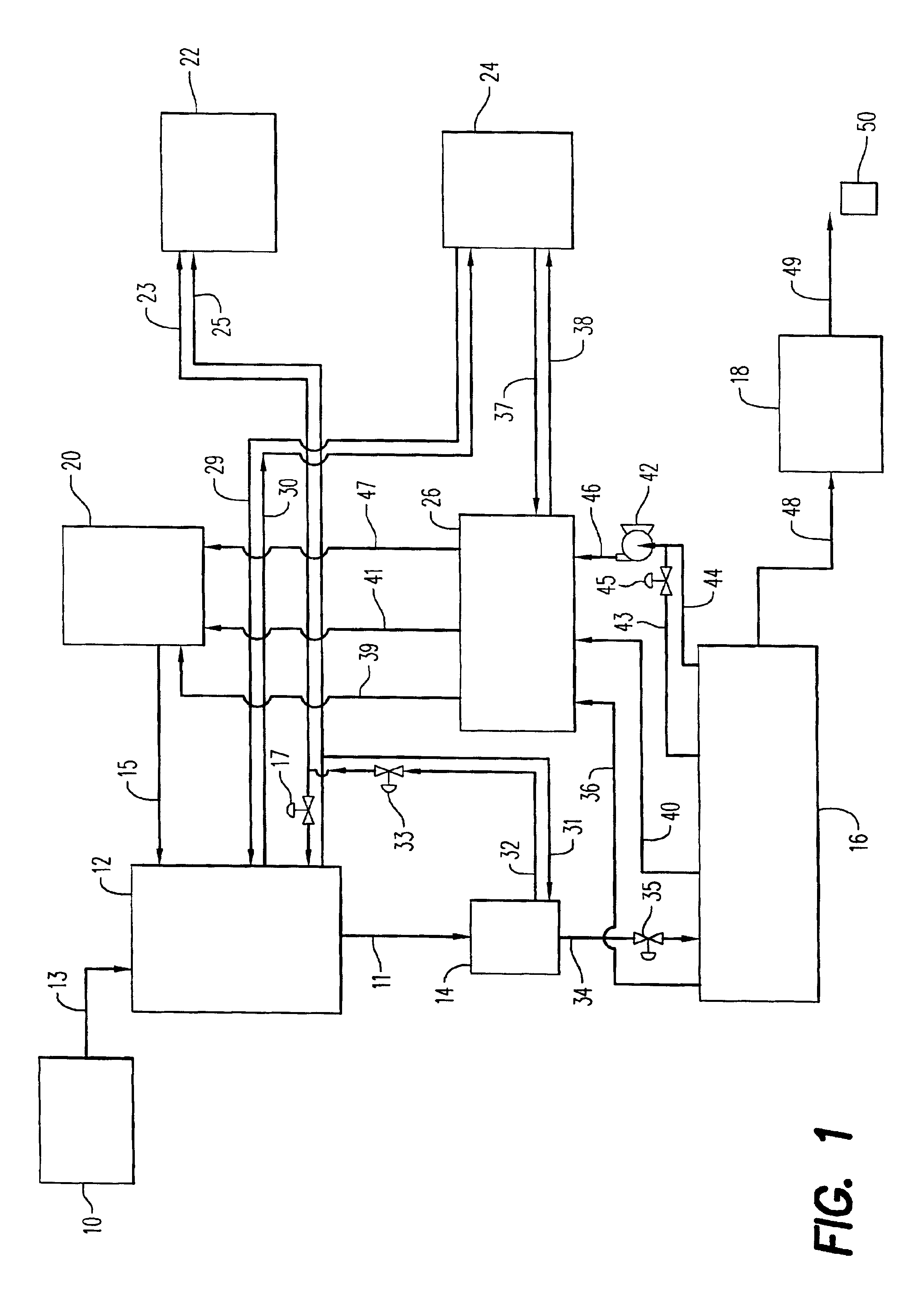

Method for production of high purity distillate from produced water for generation of high pressure steam

ActiveUS20130269934A1High work pressureIncrease vaporization rateEnergy industryFluid removalFuel oilProcess engineering

Embodiments presented herein provide an evaporation based zero liquid discharge method for generation of up to 100% quality high pressure steam from produced water in the heavy oil production industry. De-oiled water is processed in an evaporation system producing a distillate that allows steam to be generated with either drum-type boilers operating at higher pressures or once-through steam generators (OTSGs) operating at higher vaporization rates. Evaporator blowdown is treated in a forced-circulation evaporator to provide a zero liquid discharge system that could recycle >98% of the deoiled water for industrial use. Exemplary embodiments of the invention provide at least one “straight sump” evaporator and at least one hybrid external mist eliminator. Embodiments of the evaporation method operate at a higher overall efficiency than those of the prior art by producing distillate at a higher enthalpy which minimizes the high pressure boiler preheating requirement.

Owner:AQUATECH INT LLC

Humidification arrangement for a respiratory apparatus

InactiveUS8944056B2Increase vaporization rateOther heat production devicesRespiratory masksWater channelBiomedical engineering

A humidifying apparatus utilizing a semi-permeable membrane portion within a gas conduit where the direction of gas flow within a central lumen is given by an arrow. The humidification apparatus has a helical configuration for the semi-permeable membrane portion, a structural reinforcing member or members, a water channel and a heating element. The helical configuration of an outer wall may be similar to conventional conduits that are in common use in respiratory apparatus. Thus the humidification apparatus may be readily substituted into existing respiratory device by exchanging the gas conduit.

Owner:RESMED LTD

Crude oil distilling method and device for pressure type feeding

ActiveCN102559251ALarge mass transfer areaIncrease vaporization rateTreatment with plural serial refining stagesVacuum furnaceProcess engineering

Provided is a crude oil distilling method and a device for pressure type feeding. The device comprises an atmospheric distillation portion and a reduced pressure distillation portion. A primary vacuum tower is arranged in front of a vacuum furnace, and tower bottom oil of the primary vacuum tower is heated and wormed by the vacuum furnace and then led into a secondary vacuum distillation tower to be distilled, wherein all of an atmospheric tower, the primary vacuum tower and the secondary vacuum tower adopt a pressure type feeding system to atomize raw materials into liquid droplets to be sprayed into the distillation towers. By means of the method, the raw materials are atomized into the liquid droplets to be sprayed into the distillation towers, thereby increasing vapor-liquid interphase mass transfer area and improving vaporization ratio of a fractionating tower vaporized section. The primary vacuum tower is arranged in front of the vacuum furnace, an extracted portion comprises light components, and the heat load of a heating furnace and the device loss can be reduced under the condition that processing amounts at the reduced pressure distillation portion are the same.

Owner:CHINA PETROLEUM & CHEM CORP +1

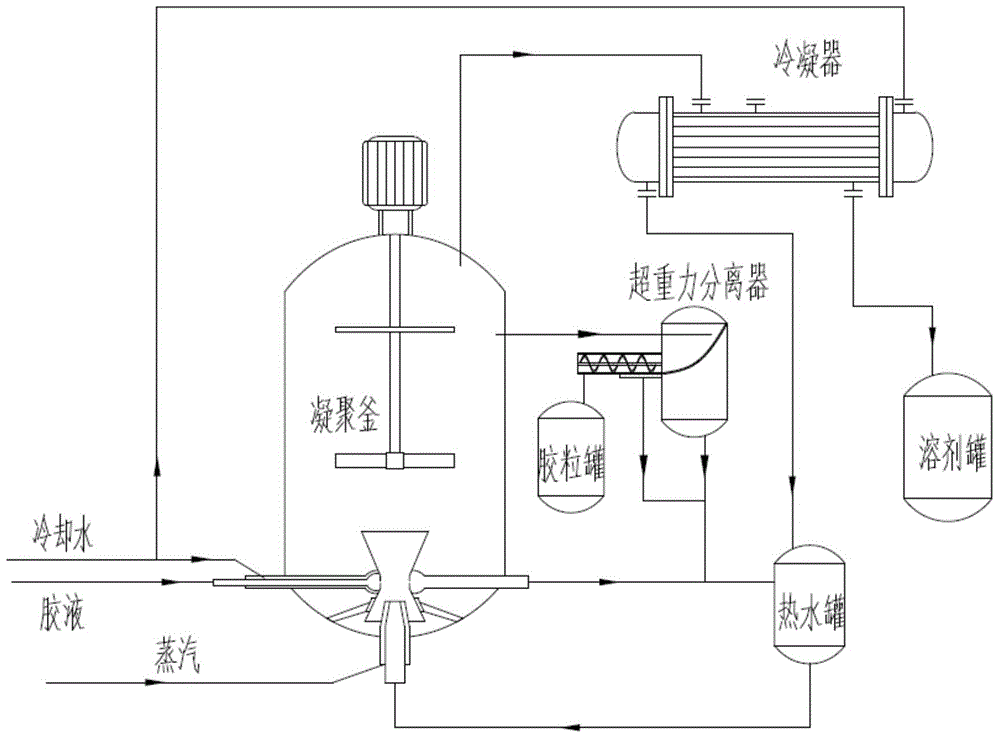

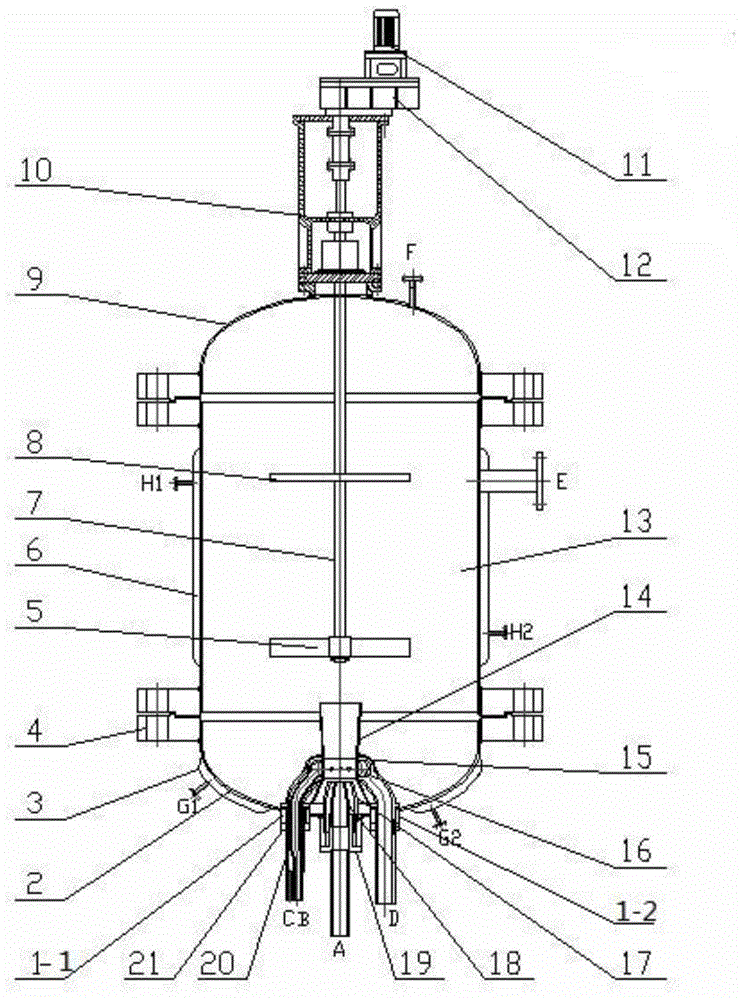

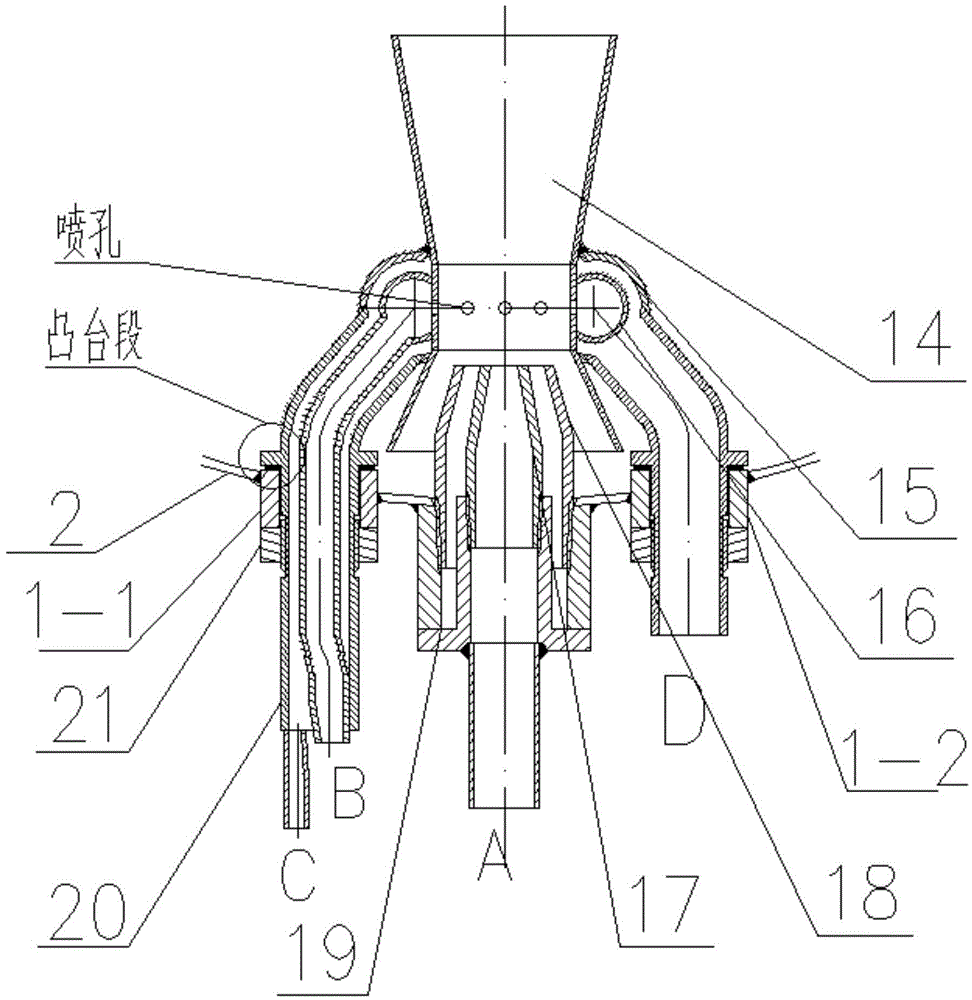

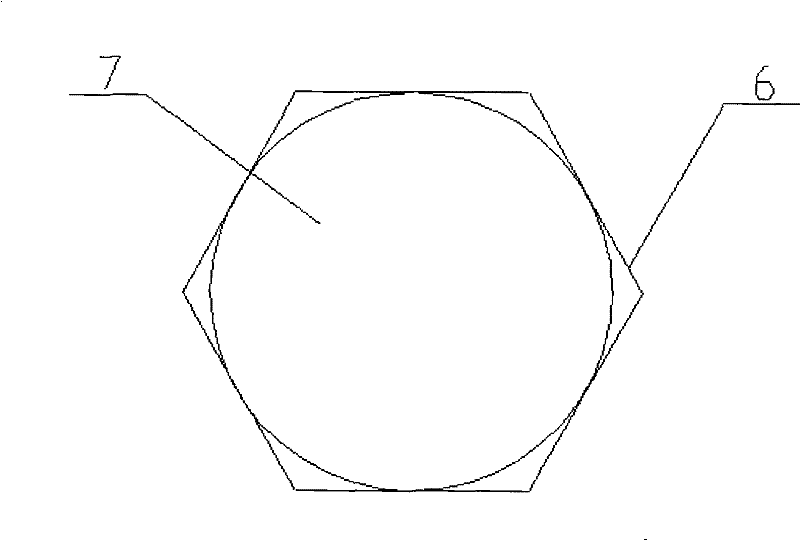

Jet flow flash condensation pot for continuous preparation of hydrogenated nitrile rubber

ActiveCN104941558AImprove effective utilizationImprove cohesionMixer accessoriesChemical/physical/physico-chemical stationary reactorsCondensation processNitrile rubber

The invention relates to a jet flow flash condensation pot for continuous preparation of hydrogenated nitrile rubber. The jet flow flash condensation pot mainly comprises a cylinder body with a jacket, a motor-driven stirring device and a Venturi jet flow device, wherein an upper head of the cylinder body with the jacket is connected with the motor-driven stirring device; a lower head of the cylinder body is connected with the Venturi jet flow device; a cooling water inlet pipe and a cooling water outlet pipe are fixed to the lower head through a cooling water inlet pipe platform and a cooling water outlet platform of the Venturi jet flow device; a Venturi jet flow device cylinder body, as well as a ring pipe and a cooling water ring pipe which are welded with the Venturi jet flow device cylinder body, is fixed on the lower head by the cooling water inlet pipe and the cooling water outlet pipe; a steam nozzle and a hot water nozzle are mounted on a base; a steam pipe is horizontally and directly inserted into the outer side pipe of the base to be perpendicular to the plane of both the cooling water inlet pipe and the cooling water outlet pipe. The jet flow flash condensation pot can improve the solvent vaporization rate and the steam effective utilization ratio, realizes the continuous condensation process, and is simple and convenient to operate, short in condensation time and favorable for large-scale rubber condensation production.

Owner:TIANJIN UNIV

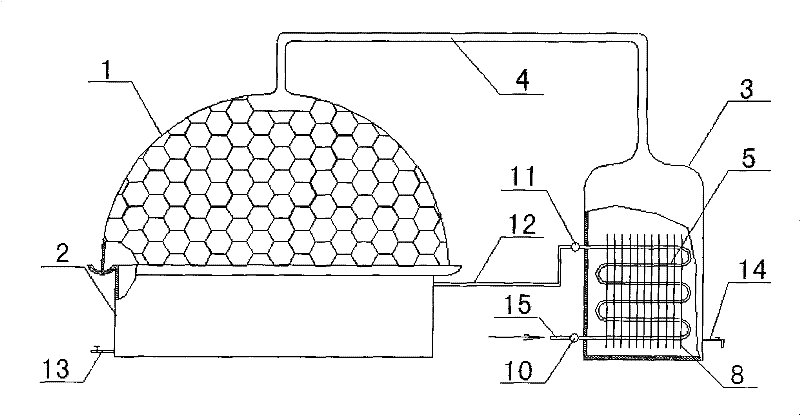

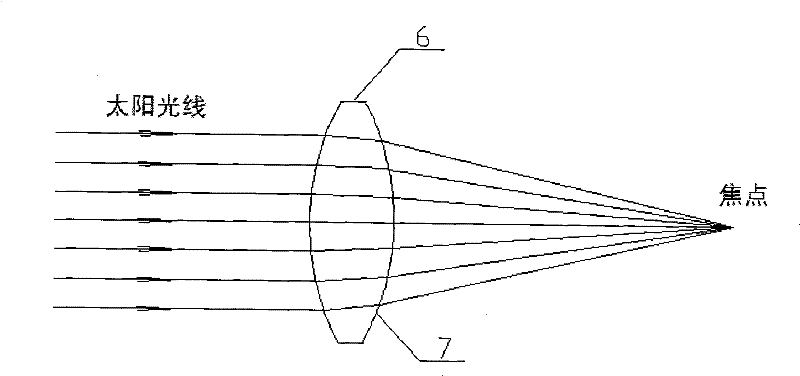

Solar energy sea water desalinating device

InactiveCN101538070BIncrease vaporization rateIncrease radiant heatGeneral water supply conservationSeawater treatmentWater vaporFresh water

The invention discloses a solar energy sea water desalinating device which comprises a sea water heater and a condensing heat exchanger. The solar energy sea water desalinating device is characterized in that the sea water heater is composed of a sea water collection tank and a crown solar heat collector covered on the sea water collection tank, the condensing heat exchanger leads in sea water by a sea water inlet and leads the sea water into the sea water collection tank by a sea water supply pipe communicated with the sea water collection tank; the crown solar heat collector is composed of a plurality of transmitting glass; each transmitting glass is a biconvex mirror, and sunlight projecting the surface of each transmitting glass is respectively focused on sea water in the circular seawater collection tank, the top of the crown solar heat collector is connected with the condensing heat exchanger by a communicating pipe, and stream evaporated by the sea water collection tank is guided into the condensing heat exchanger to be output through a fresh water pipe after being condensed into fresh water.

Owner:CHANGAN UNIV

Epoxy soybean oil drying device and drying method thereof

InactiveCN105289017ALarge specific surface areaTroubleshoot issues that don't keep runningOrganic chemistryFatty-oils/fats refiningEpoxyFilling materials

The invention discloses an epoxy soybean oil drying device and a drying method thereof. The apparatus comprises a drying tank, a steam outlet and a feed inlet are arranged on the drying tank, a discharge hatch is arranged below the drying tank, a material distributor connected to the feed inlet is arranged on an upper segment of the drying tank, a vacuum pipeline used for dewatering the material under negative pressure is connected with the steam outlet, a filling device connected with the material distributor is arranged on an intermediate segment in the drying tank and is used for dispersing the material; and a heater is used for heating and drying the material, which is positioned below the filling device and arranged at a lower segment in the drying tank. The drying device is capable of uniformly distributing the materials through the material distributor, so that a vaporization rate can be increased by heating the material, a problem that equipment cannot continuously operate due to material coking and filling material obstruction can be solved, equipment maintenance cost is reduced, production efficiency is obviously enhanced, product quality is stabilized, and energy can be saved.

Owner:佛山市高明晟俊塑料助剂有限公司

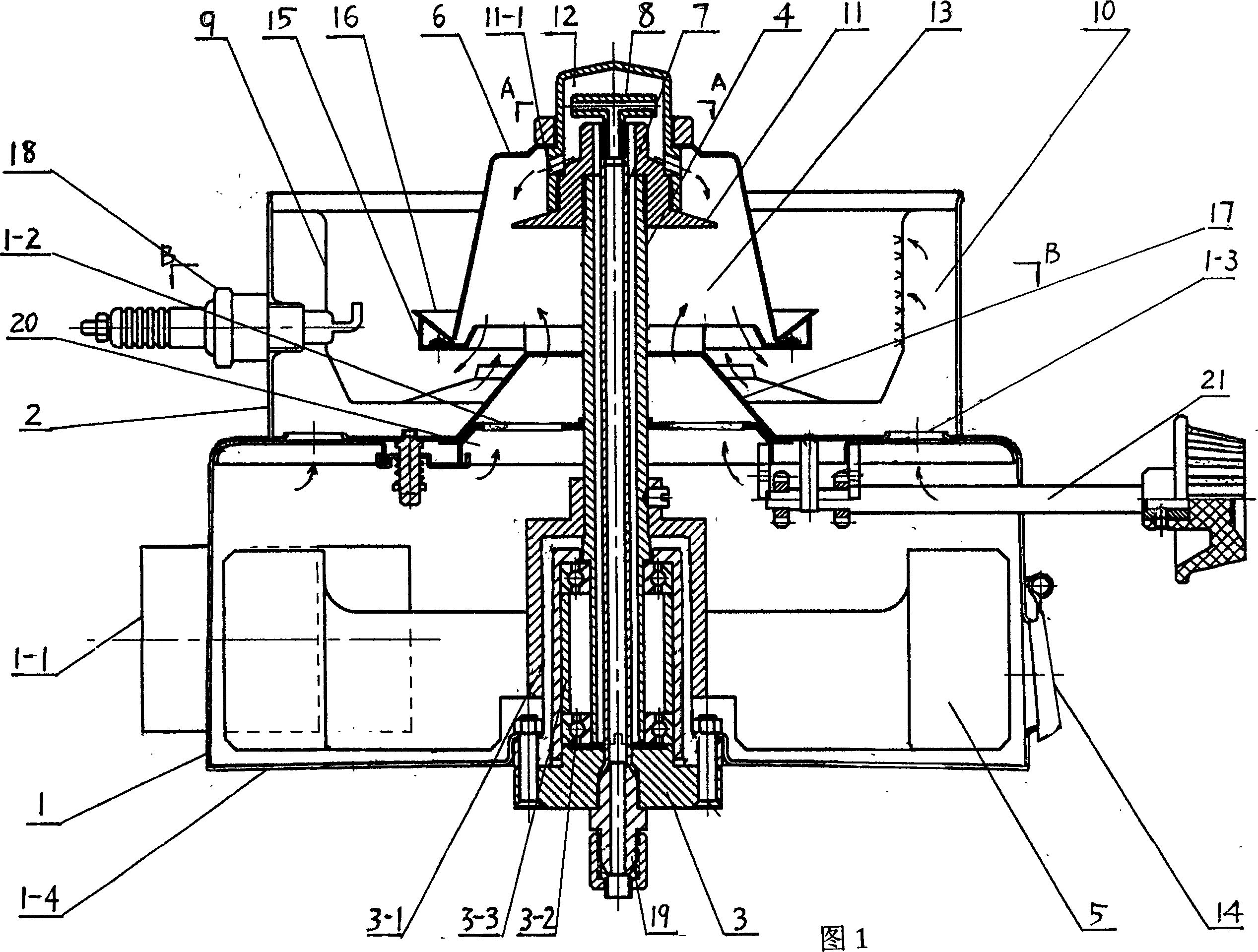

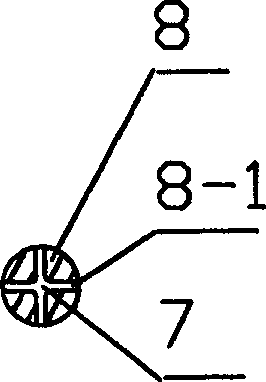

Spindle central oil feeding burner

The rotation shaft oil / gas supplying burner consist sof air chamber caisng and combustor on the casing, which are communicated via gas channel. One rotating shaft supported with the bearing part in the bottom of the air chamber stretches through the channel to the combustor and has vaporizing rotary cap connected to its upper part and oil pipe and oil nozzle onside it. The combustor has burning bowl with small holes or meshes and circular air chamber formed into between. The present invention features that the oil pipe inside the rotation shaft is fixed and the evaporizing top cap with side hole in the top of the rotation shaft separates the rotary cap space into vaporizing chamber and mixing chamber. The present invention has the advantages of homogeneous rotation speed, high oil vaporizing rate and high homogeneity.

Owner:王战勇

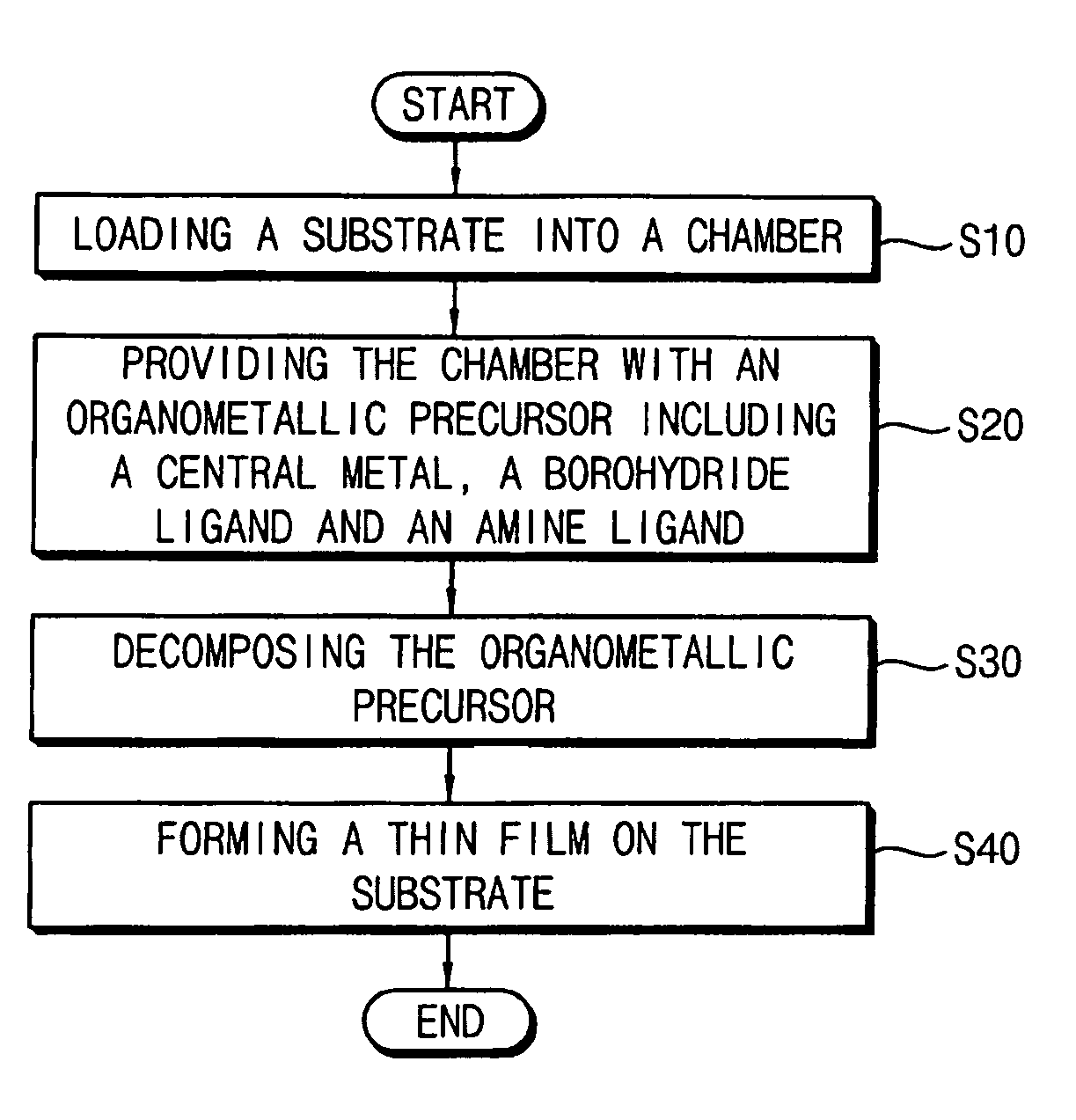

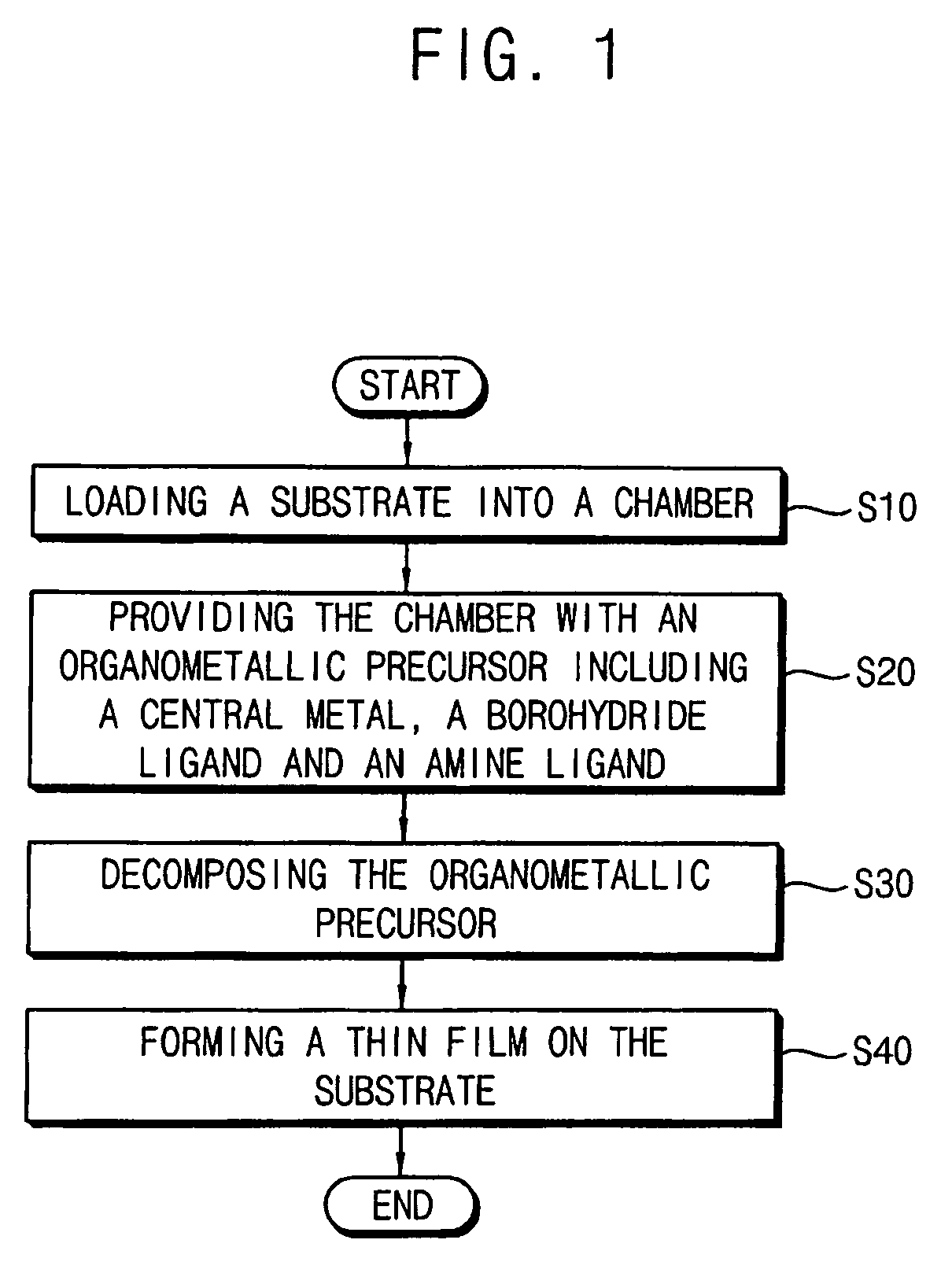

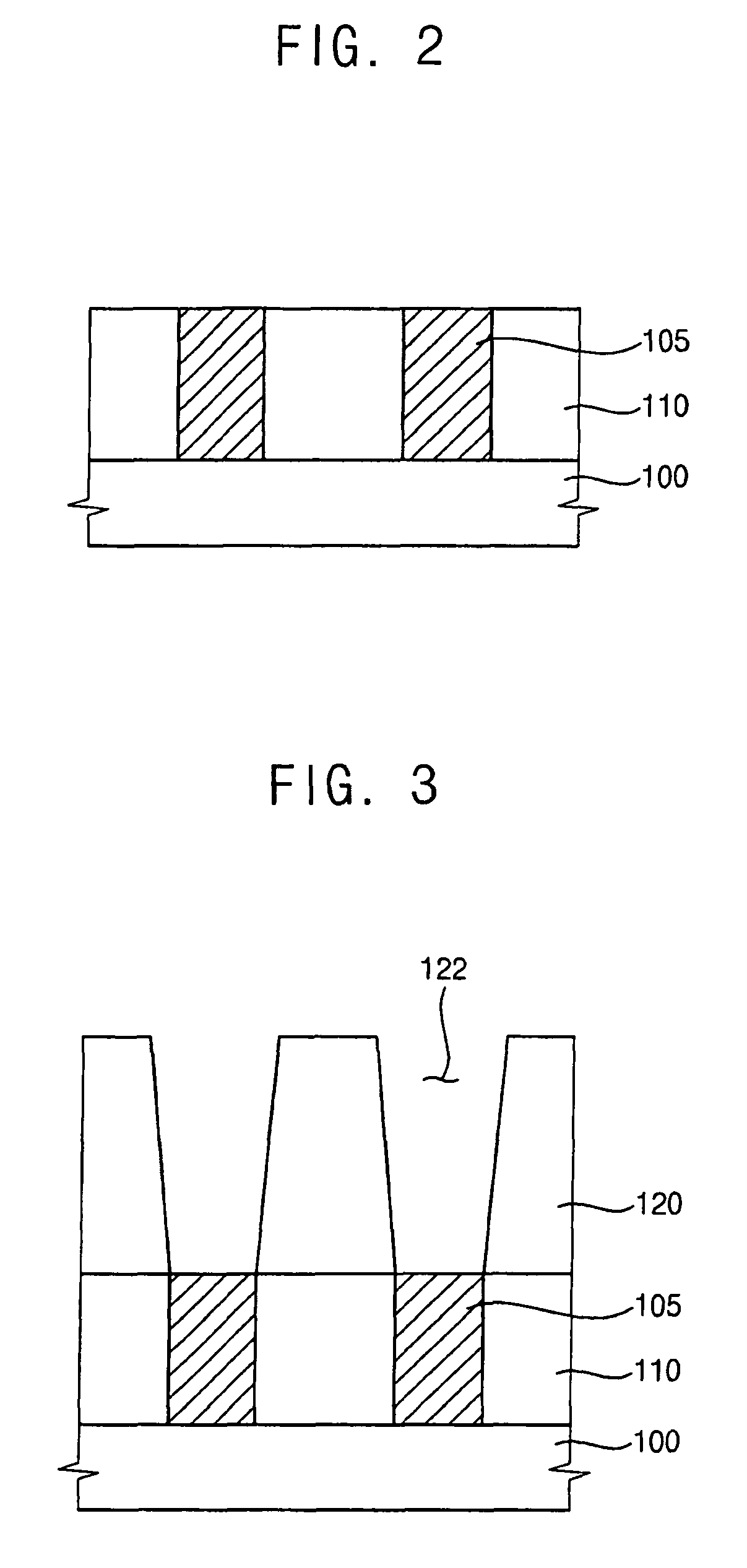

Organometallic precursor, thin film having the same, metal wiring including the thin film, method of forming a thin film and method of manufacturing a metal wiring using the same

ActiveUS8268397B2Reduce polarityInteractionVacuum evaporation coatingSputtering coatingDevice materialHydride ligands

Disclosed are an organometallic precursor that may be used in manufacturing a semiconductor device, a thin film having the same, a metal wiring including the thin film, a method of forming a thin film and a method of manufacturing a metal wiring. An organometallic precursor including a central metal, a borohydride ligand and an amine ligand for reducing a polarity of the organometallic precursor may be provided onto a substrate, and may be thermally decomposed to form a thin film on the substrate. The organometallic precursor having a reduced polarity may be provided to a chamber with a constant flow rate, and thus stability and / or efficiency of a semiconductor manufacturing process may be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

Low temperature ignition guaranteeing device of small gasoline engine of unmanned aerial vehicle

ActiveCN103790739AImprove efficiencyImprove work efficiencyInternal combustion piston enginesThermal treatment of fuelWater vaporGasoline

The invention relates to a low temperature ignition guaranteeing device of a small gasoline engine of an unmanned aerial vehicle. An emission of a small piston type engine of an unmanned aerial vehicle is mainly composed of un-combusted components, combustion products and excess air. Except N2, O2, H2, water vapour and the like are harmless, the rest is harmful components which are mainly composed of NOx, CO, HC, SO2, combustion particles and the like; in addition, energy which can be used also exists in tail gas. Power output of the small piston type engine of the unmanned aerial vehicle occupies 25%-42% of the total heat of fuel combustion, and the rest of the heat is discharged in the form of waste heat from cooling and the tail gas. Not only is energy waste caused, but also a certain degree of atmosphere heat pollution will be caused. According to the low temperature ignition guaranteeing device of the small gasoline engine of the unmanned aerial vehicle, the waste gas of the small piston type engine of the unmanned aerial vehicle is used for heating air entering the small piston type engine of the unmanned aerial vehicle, so that the purposes of energy conservation and emission reduction are achieved, and meanwhile the problem that the small piston type engine of the unmanned aerial vehicle works difficultly under the climate conditions of subzero low temperature and high altitudes is solved.

Owner:天津市联创蔚莱科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com