Alcohol recovery tower

A technology of alcohol recovery tower and tower body, which is applied in the direction of distillation and separation, preparation of organic compounds, chemical instruments and methods, etc. It can solve the problem that the dilute alcohol stock solution is not further filtered, the dilute alcohol stock solution cannot be evenly distributed, and the recovery efficiency is affected and effects, etc., to achieve good recycling effects, speed up recycling, and improve recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

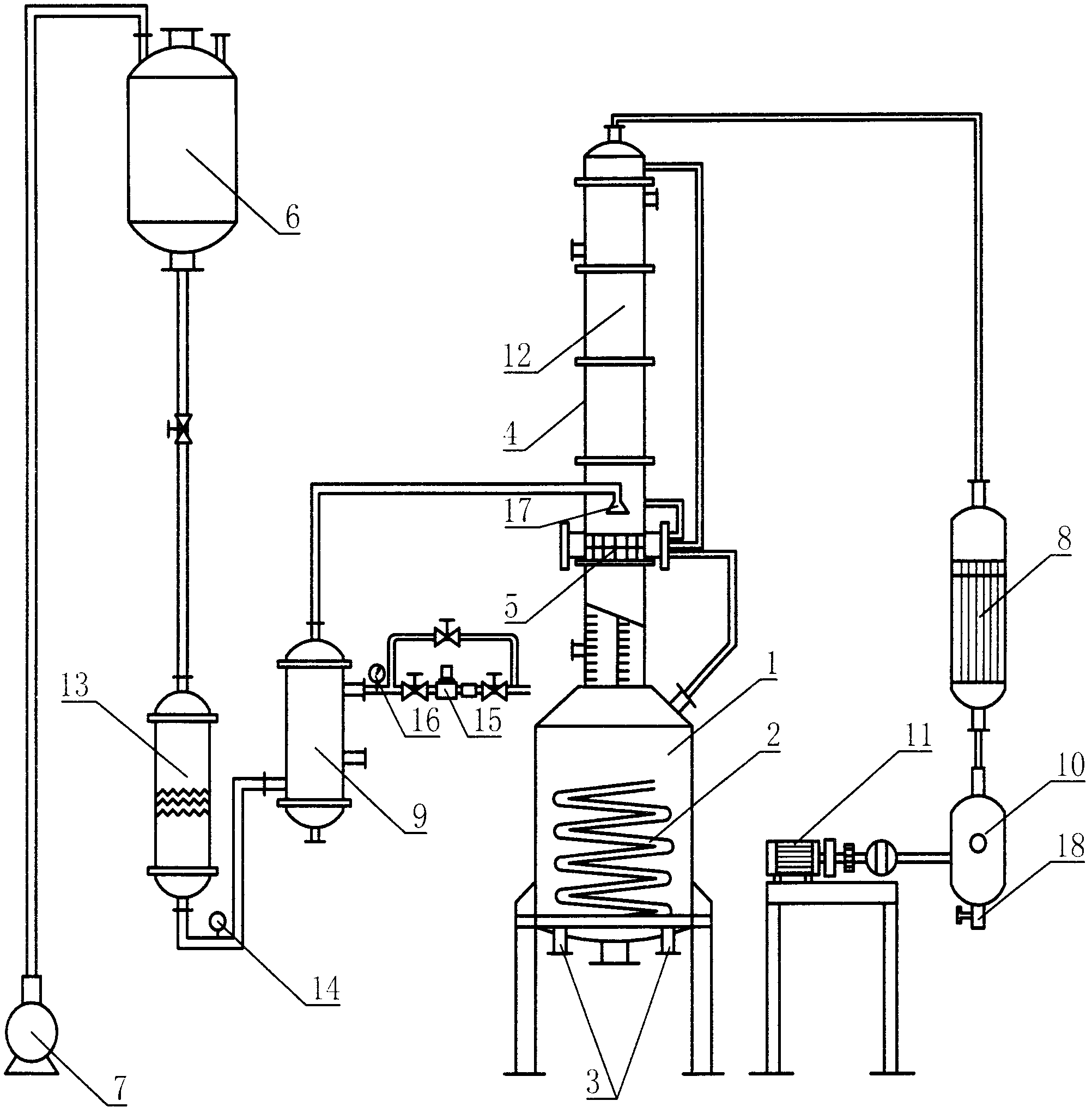

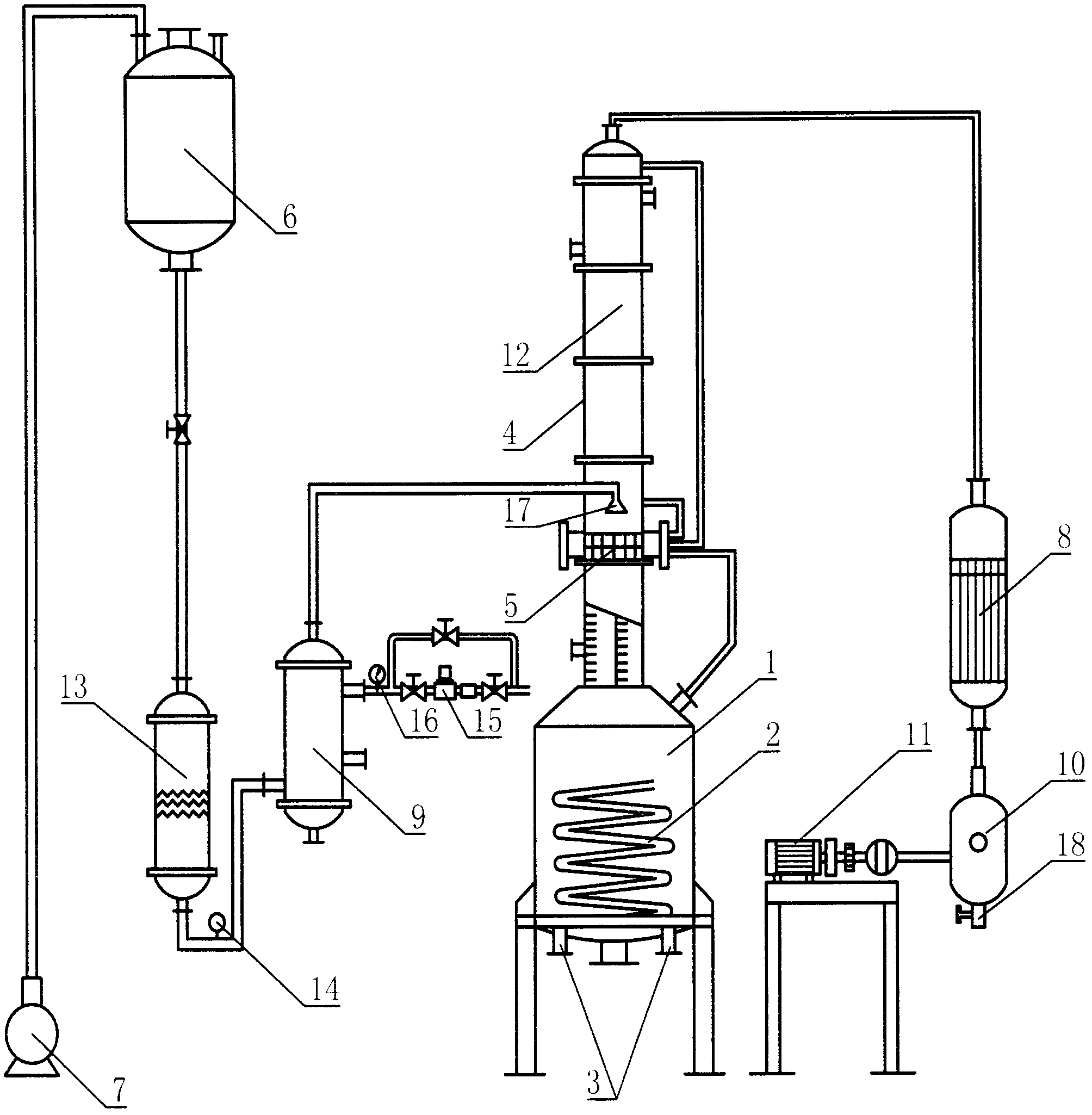

[0018] An alcohol recovery tower of the present invention comprises a distillation tower kettle 1, a heating pipe 2 is arranged inside the distillation tower kettle 1, and two steam inlets 3 are arranged symmetrically at the bottom; a distillation tower body 4 is arranged above the distillation tower kettle 1 , the inside of which is provided with packing 5; the high-level storage tank 6 is arranged on one side of the distillation tower body 4 through pipeline connection, and a centrifugal pump 7 is installed on it; the preheater 9 adopts a steam heating method, and it is installed on the high-level storage tank 6 and Between the distillation tower body 4; the condensing cooler 8 is arranged on the other side of the distillation tower body 4, and a vacuum storage tank 10 equipped with a vacuum pump 11 is connected below it; the bottom of the vacuum storage tank 10 is provided with an alcohol outlet 18.

[0019] When the present invention is used for alcohol recovery, the dilute...

example 2

[0021] An alcohol recovery tower of the present invention, as shown in the figure, wherein the distillation tower body 4 is provided with several temperature control tower sections 12, which can effectively adjust the temperature in the distillation tower body 4 and accelerate the volatilization speed of the dilute alcohol stock solution A filter 13 is installed between the high-level storage tank 6 and the preheater 9, a flowmeter 14 is installed on the pipeline on one side, and a filter 13 is installed in the process, so that the dilute that needs to be recovered can be The alcohol stock solution carries out initial impurity removal and filtration treatment, so that the recovery speed is faster and the recovery effect is better. At the same time, the following process equipment can be protected, and the flow meter 14 can grasp the processing capacity in time; the described One side of the preheater 9 is provided with a pipeline for steam input, on which a solenoid valve 15 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com