A high-efficiency extraction device for oil development

A high-efficiency and petroleum technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve problems such as easy blockage and extraction efficiency, and achieve the effects of easy maintenance, improved extraction efficiency, and high extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

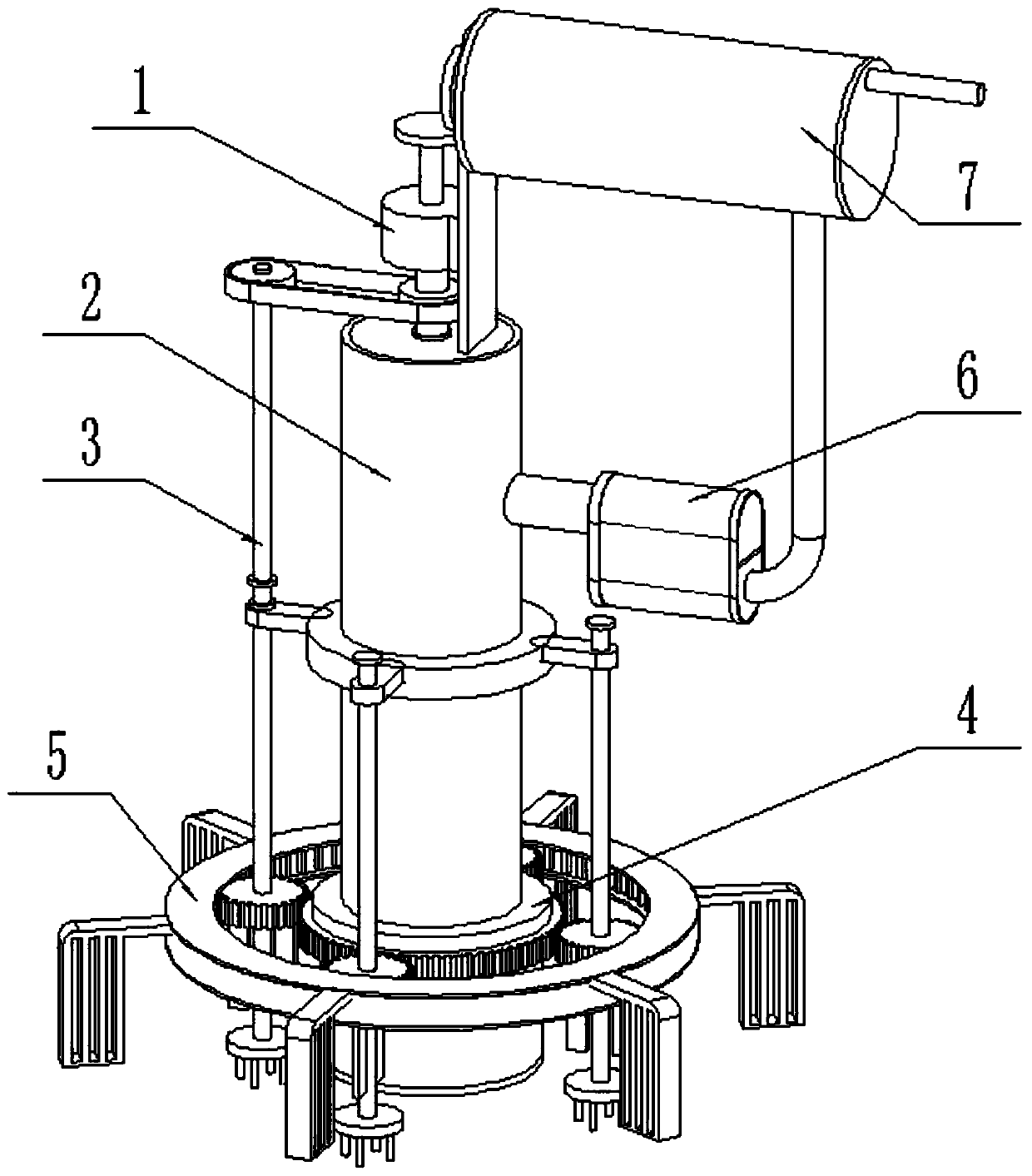

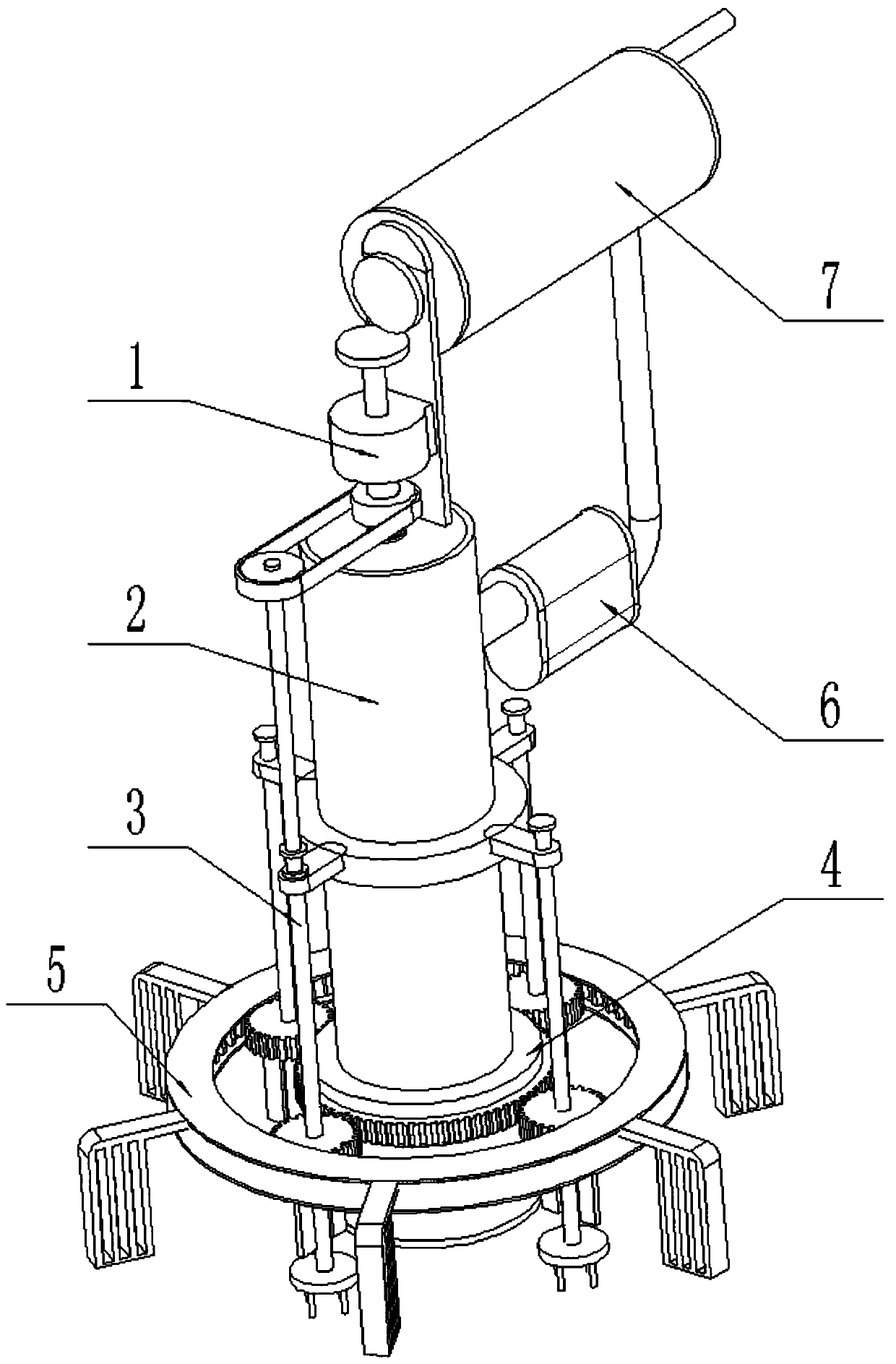

[0042] Such as Figure 1-14 As shown, a high-efficiency extraction device used for oil extraction includes a driving device 1, an oil extraction cylinder assembly 2, a transmission fixing seat assembly 3, an oil inlet preliminary filter assembly 4, a swirling flow assembly 5, an anti-backflow oil delivery device 6 and a stirring The filter cartridge assembly 7, the driving device 1 is fixedly connected to the top end of the oil extraction cylinder assembly 2; the transmission fixing seat assembly 3 is fixedly connected to the middle end of the oil extraction cylinder assembly 2, and the transmission fixing seat assembly 3 The upper end is connected to the driving device 1; the oil inlet preliminary filter assembly 4 is rotatably connected to the lower end of the oil extraction cylinder assembly 2, and the outside of the oil inlet preliminary filter assembly 4 is connected to the inner side of the transmission fixing seat assembly 3; the swirl assembly 5 Connected to the outside...

specific Embodiment approach 2

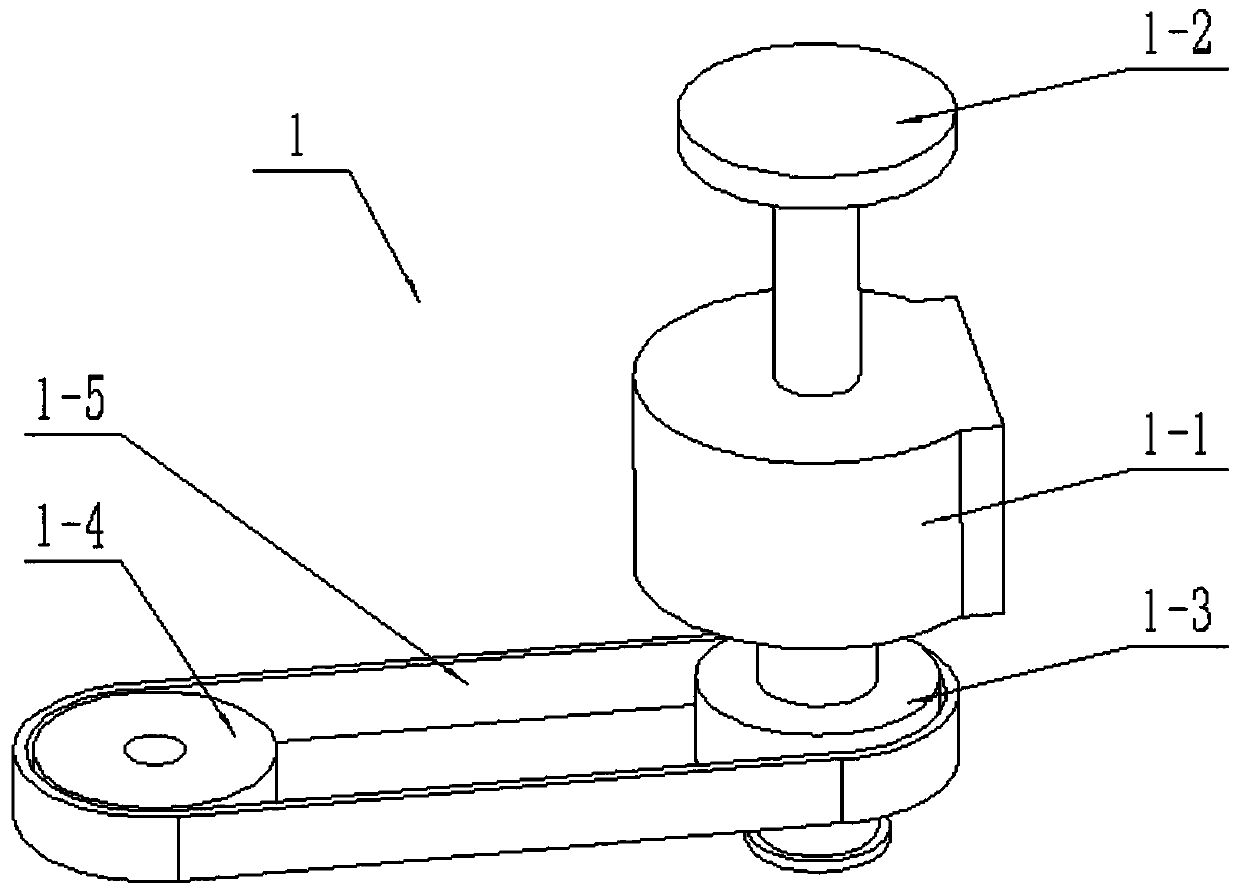

[0044] Such as Figure 1-14 As shown, the driving device 1 includes a dual-axis motor 1-1, a transmission bevel gear 1-2, a transmission sprocket 1-3, a passive sprocket 1-4, and a chain 1-5; the dual-axis motor 1-1 The output shaft at the upper end is fixedly connected to the transmission bevel gear 1-2; the output shaft at the lower end of the dual-shaft motor 1-1 is fixedly connected to the transmission sprocket 1-3; the transmission sprocket 1-3 passes through the chain 1- 5 Connect the passive sprocket 1-4. When the driving device 1 is in use, after the biaxial motor 1-1 is connected to the power source and turned on by the control switch, the upper end of the biaxial motor 1-1 drives the transmission bevel gear 1-2 to rotate, and the transmission bevel gear 1-2 Drive the mixing filter cartridge assembly 7 to work, the lower end of the dual-axis motor 1-1 drives the oil extraction cartridge assembly 2 to work; at the same time, the dual-axis motor 1-1 also drives the tran...

specific Embodiment approach 3

[0046] Such as Figure 1-14 As shown, the oil extraction cylinder assembly 2 includes an extraction cylinder body 2-1 with a hollow bottom surface, a rotating shaft 2-2 and an oil pumping screw 2-3; the upper end of the rotating shaft 2-2 passes through a bearing with a bearing The base is connected to the middle of the top surface of the extraction cylinder body 2-1, the top end of the rotating shaft 2-2 is connected to the output shaft of the lower end of the biaxial motor 1-1 through a coupling; the lower end of the rotating shaft 2-2 is fixed Connecting the sucking spiral body 2-3; the outer arc surface of the sucking spiral body 2-3 is inscribed on the inner wall of the extraction cylinder body 2-1; the lower end of the sucking spiral body 2-3 penetrates the extraction cylinder body 2- 1; The upper end of the outer side of the extraction cylinder body 2-1 is provided with an oil delivery hole. When the oil extraction cylinder assembly 2 is in use, the rotating shaft 2-2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com