A coal mine excavator system with an environmentally friendly filter

A technology for excavators and filters, which is applied to fuel air filters, charging systems, machines/engines, etc., can solve problems such as affecting work efficiency, and achieve the effects of reducing pollution, lowering production costs, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

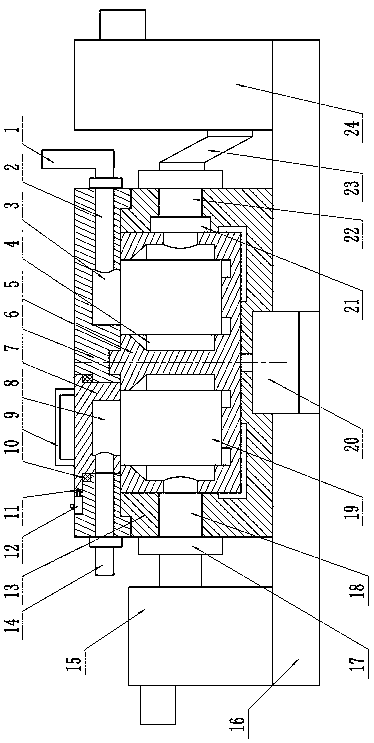

[0020] like figure 1 As shown, this specific embodiment adopts the following technical solutions: a coal mine excavator system with an environmental filter, including an excavator intake pipe 1, and also includes an air outlet 2, an air collection chamber 3, a tank body 4, and a movable seat 5. Upper cover 6, cover body 7, air intake slot 8, handle 9, sealing ring 10, card slot 11, latch 12 and fixing seat 13; the air outlet hole 2 is located inside the upper cover 6 right side, the outlet The outlet on the right side of the air hole 2 is connected to the inlet of the excavator intake pipe 1, and the left side inlet of the air outlet hole 2 is connected to the inside of the gas collection chamber 3; the gas collection chamber 3 is located inside the lower right side of the upper cover 6; The upper cover 6 is fixedly connected on the fixed seat 13; the movable seat 5 is movably connected inside the fixed seat 13, and several grooves 4 are arranged in a circular arrangement in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com