Patents

Literature

32 results about "Alcohol outlet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

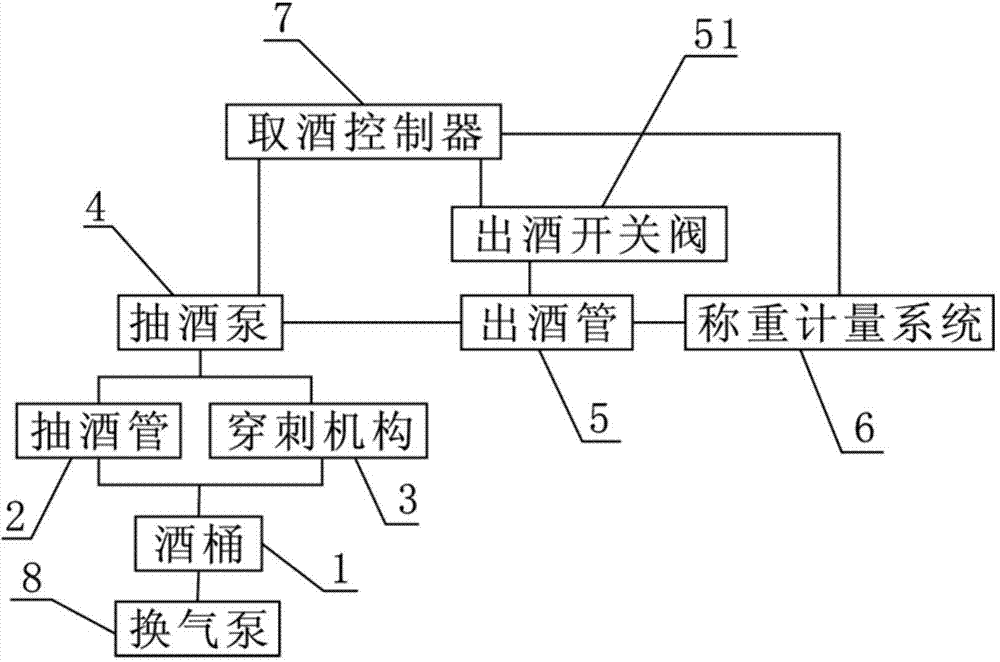

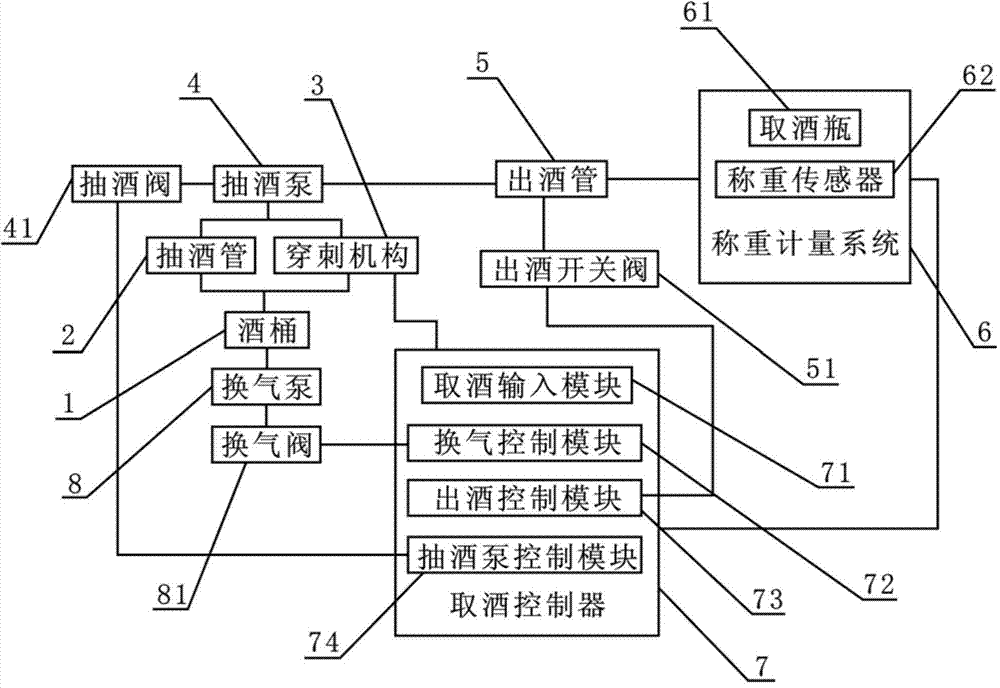

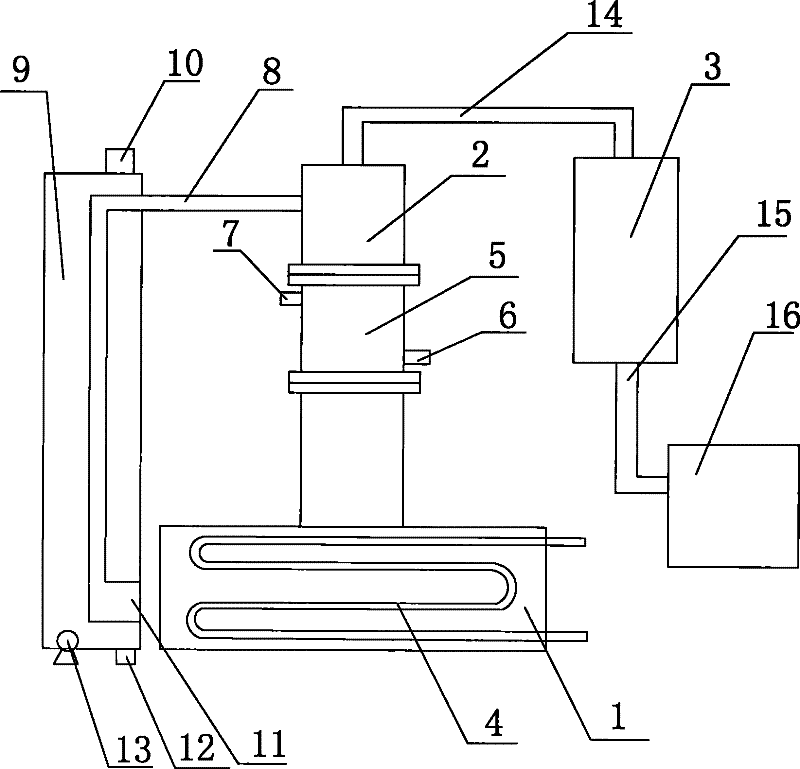

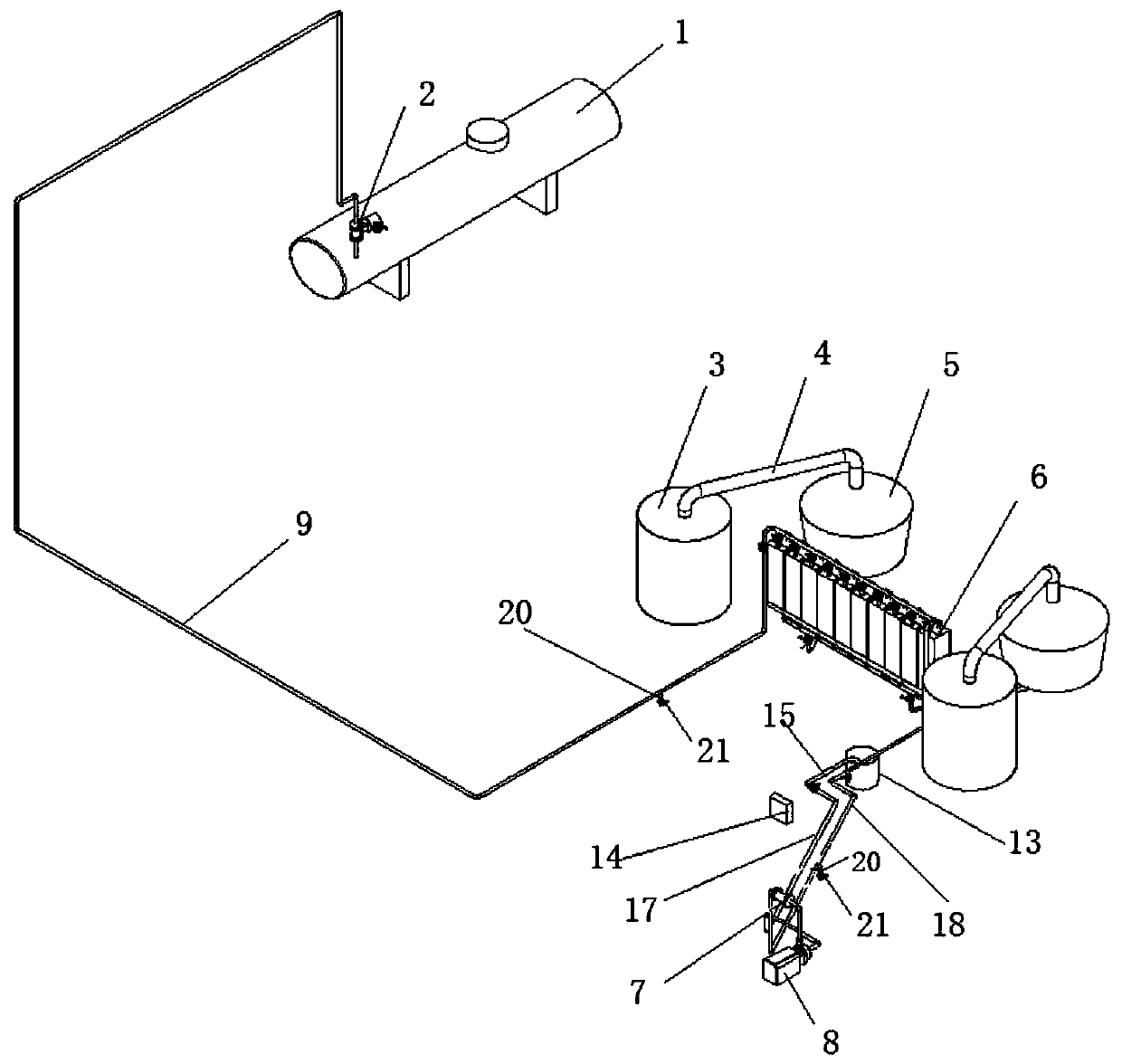

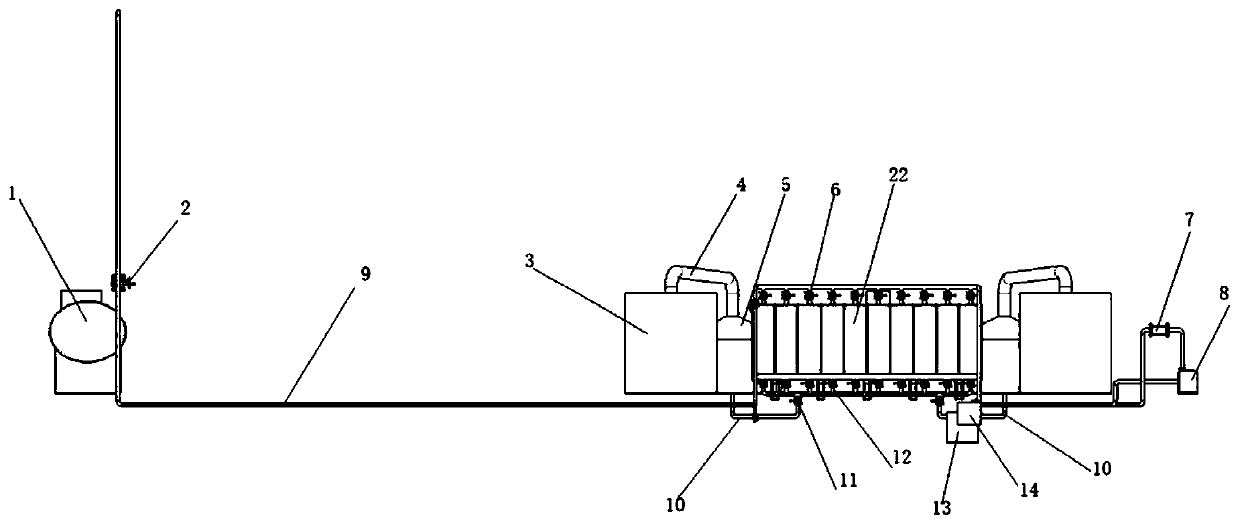

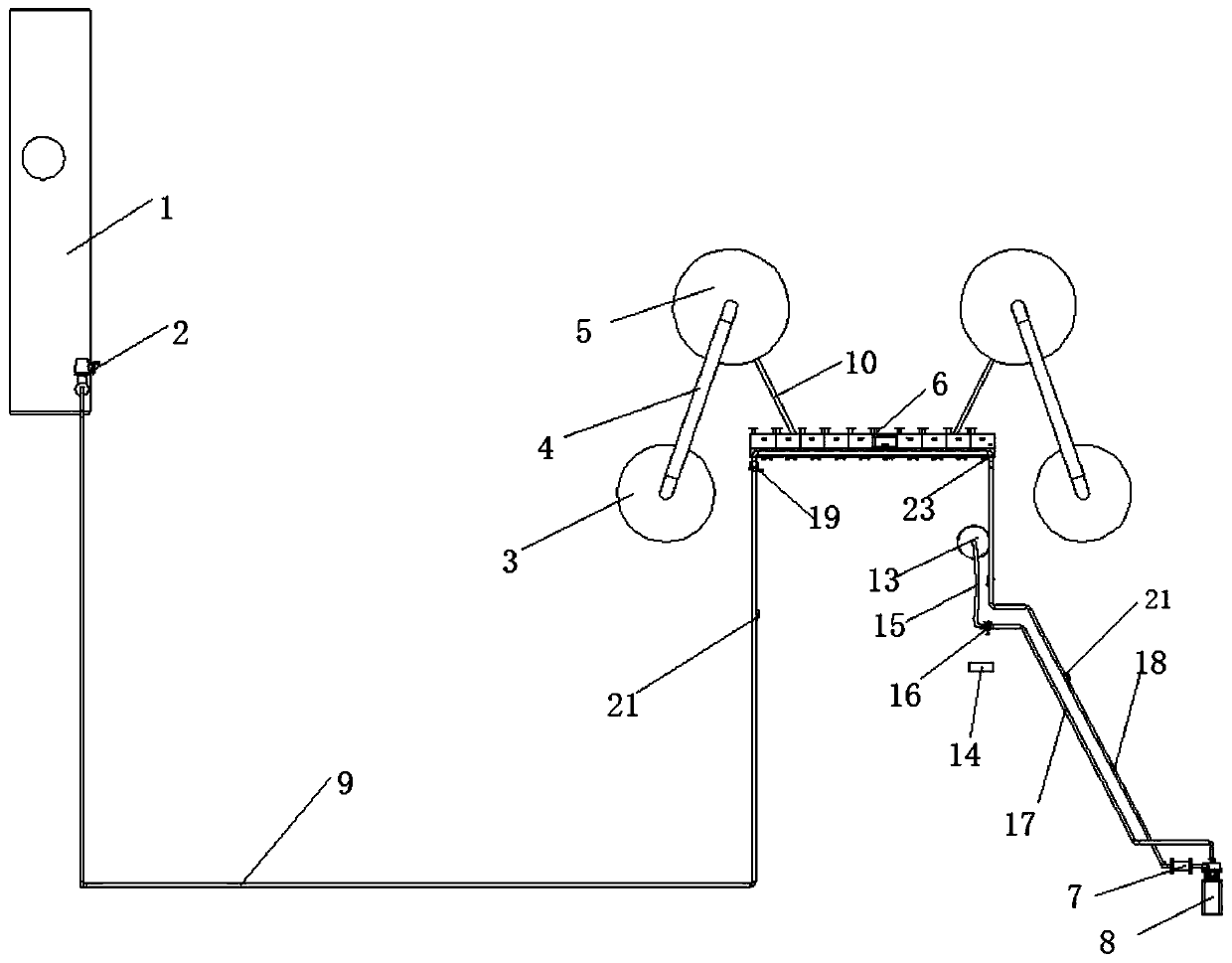

Automatic alcohol selling control system used on alcohol selling machine

The invention discloses an automatic alcohol selling control system used on an alcohol selling machine. The system comprises an alcohol barrel, an alcohol pumping pipe, an alcohol pump, an alcohol outlet pipe, a weighing and measuring system and an alcohol obtaining controller. The alcohol pump is connected with the alcohol barrel through the alcohol pumping pipe and a puncturing mechanism, and the alcohol outlet end of the alcohol pump is communicated with the alcohol outlet pipe. The alcohol barrel is communicated with a ventilation pump connected with a ventilation valve, the alcohol pump is connected with an alcohol pumping valve, the alcohol outlet pipe is connected with an alcohol outlet switch valve, and the puncturing mechanism, the ventilation valve, the alcohol pumping valve and the alcohol outlet switch valve are connected with the alcohol obtaining controller in a telecommunication mode. The weighing and measuring system comprises an alcohol obtaining bottle and a weighing sensor corresponding to the alcohol obtaining bottle, the alcohol obtaining bottle is correspondingly matched with the alcohol outlet pipe, the weighing sensor is used for measuring the weight of alcohol flowing into the alcohol obtaining bottle from the alcohol outlet pipe, and the weighing and measuring system is connected with the alcohol obtaining controller in a telecommunication mode. The system is applied to the alcohol selling machine and automatic interaction operation of alcohol selling and alcohol buying can be achieved.

Owner:SICHUAN DEMIN INVESTMENT CO LTD

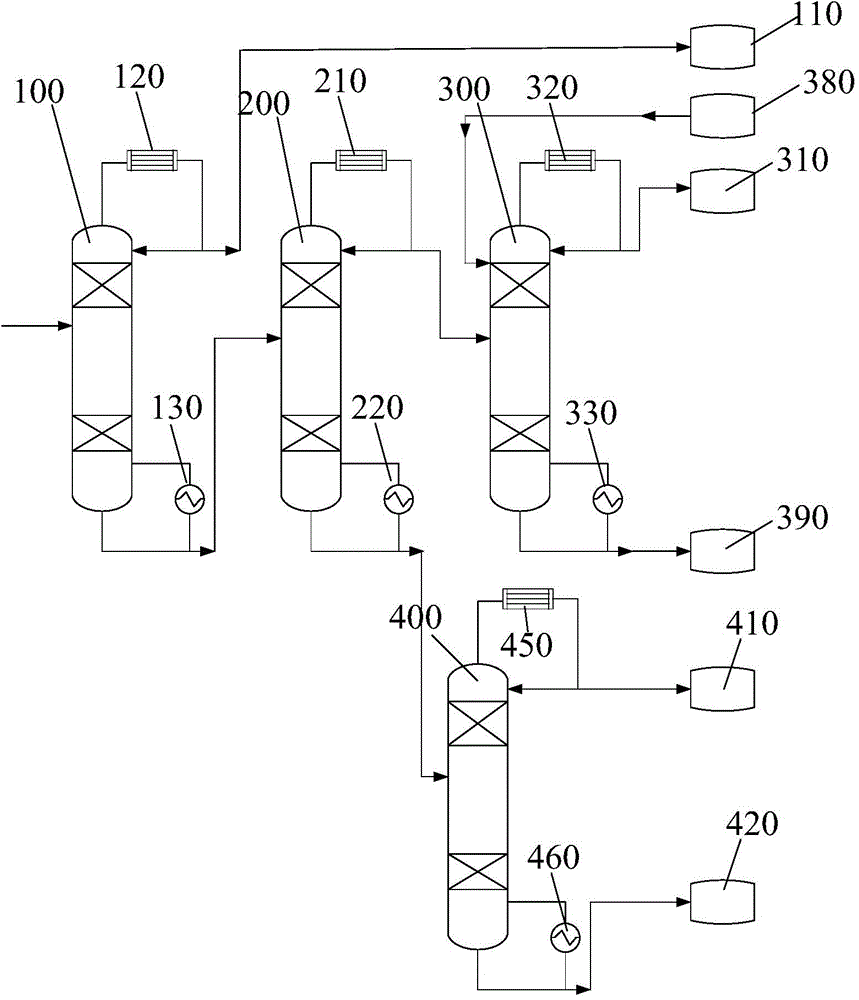

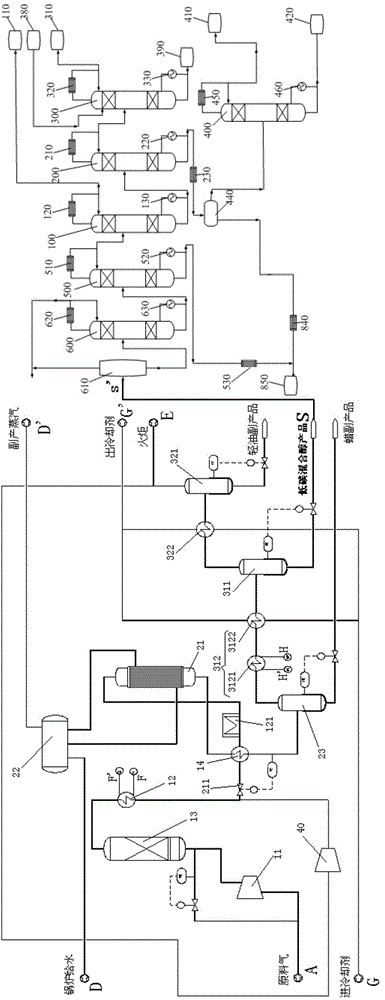

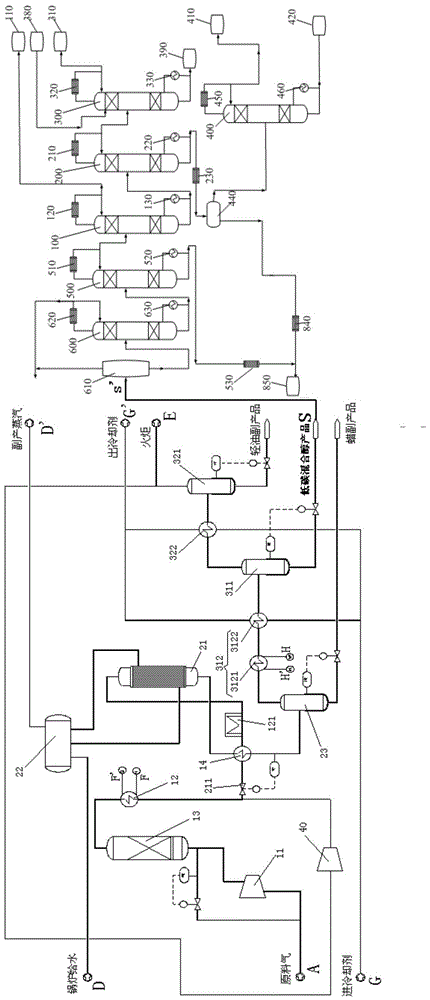

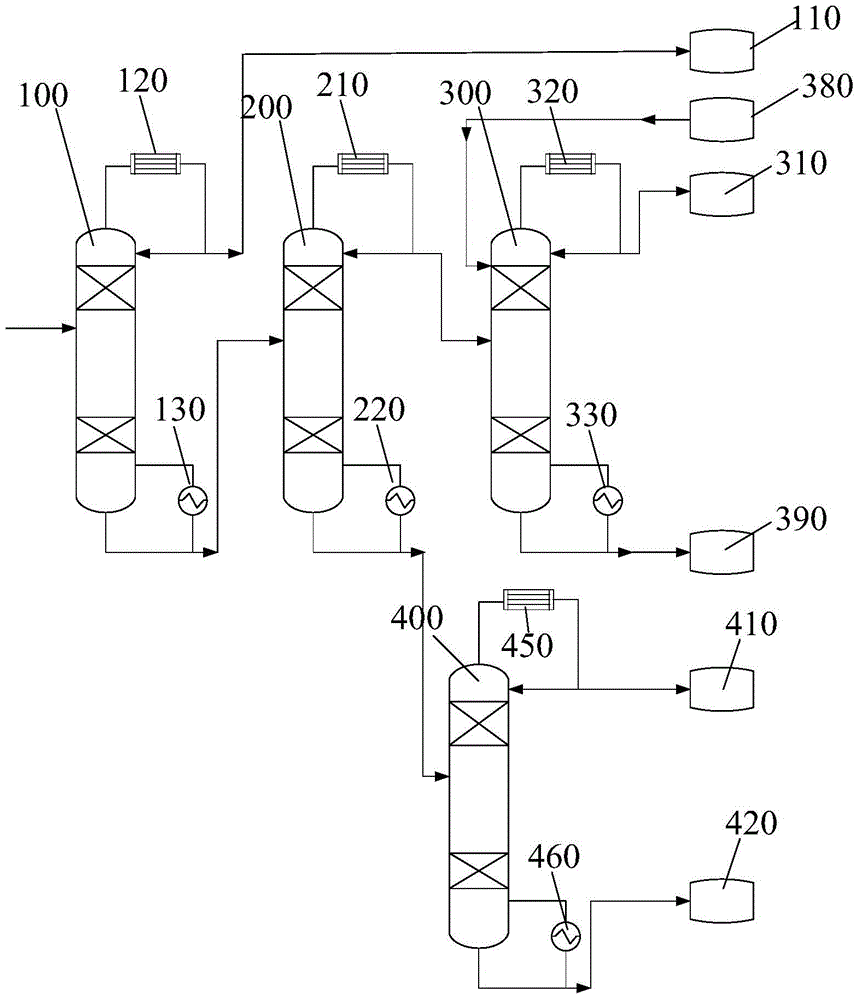

Separation system and separation method of low-carbon mixed alcohol

ActiveCN104529703AHigh purityOrganic compound preparationHydroxy compound separation/purificationAlcoholTower

The invention discloses a separation system and a separation method of low-carbon mixed alcohol. The separation system comprises a low-carbon mixed alcohol feeding device, a methanol rectifying tower, an ethanol rectifying tower, an extraction rectifying tower and a normal propyl alcohol rectifying tower, wherein the low-carbon mixed alcohol feeding device is provided with a low-carbon mixed alcohol outlet; the methanol rectifying tower is provided with a methanol tower feeding hole, a methanol tower top discharging hole and a methanol tower bottom discharging hole, and the methanol tower feeding hole is connected with the low-carbon mixed alcohol outlet; the ethanol rectifying tower is provided with an ethanol tower feeding hole, an ethanol tower top discharging hole and an ethanol tower bottom discharging hole, and the ethanol tower feeding hole is connected with the methanol tower bottom discharging hole; the extraction rectifying tower is provided with an extraction tower feeding hole, an extraction agent feeding hole, an extraction tower top discharging hole and an extraction tower bottom discharging hole, and the extraction tower feeding hole is connected with the ethanol tower top discharging hole; the normal propyl alcohol rectifying tower is provided with a normal propyl alcohol tower feeding hole, a normal propyl alcohol tower top discharging hole and a normal propyl alcohol tower bottom discharging hole, and the normal propyl alcohol tower feeding hole is connected with the ethanol tower bottom discharging hole. In the separation system, a purification mode that a rectifying system is combined with an extraction system is utilized, so that obtained monoalcohol has relatively high purity.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

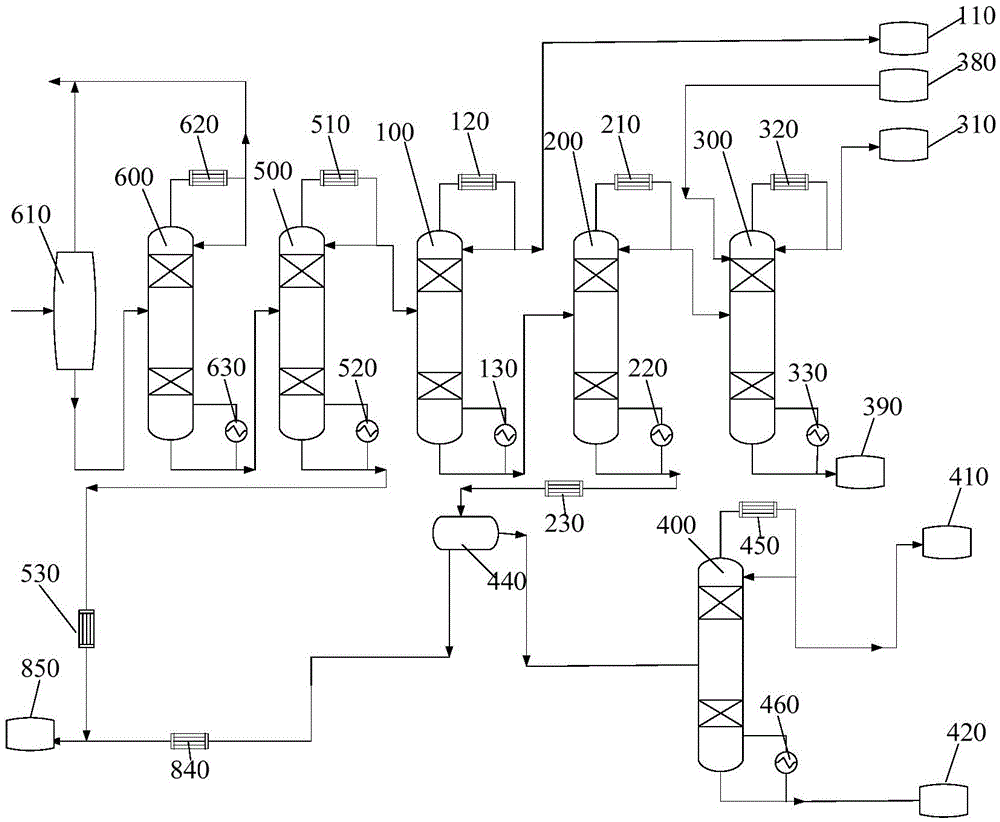

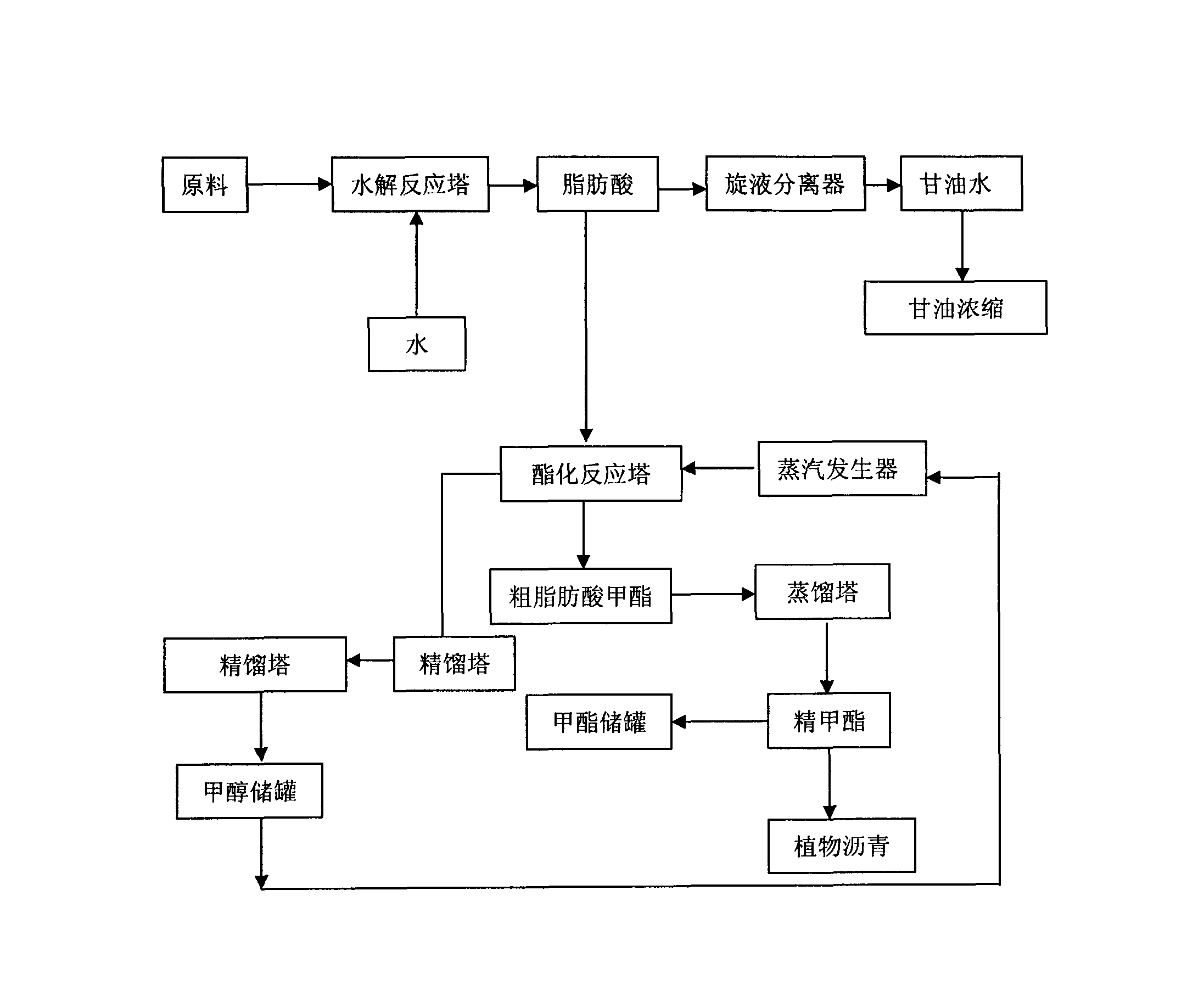

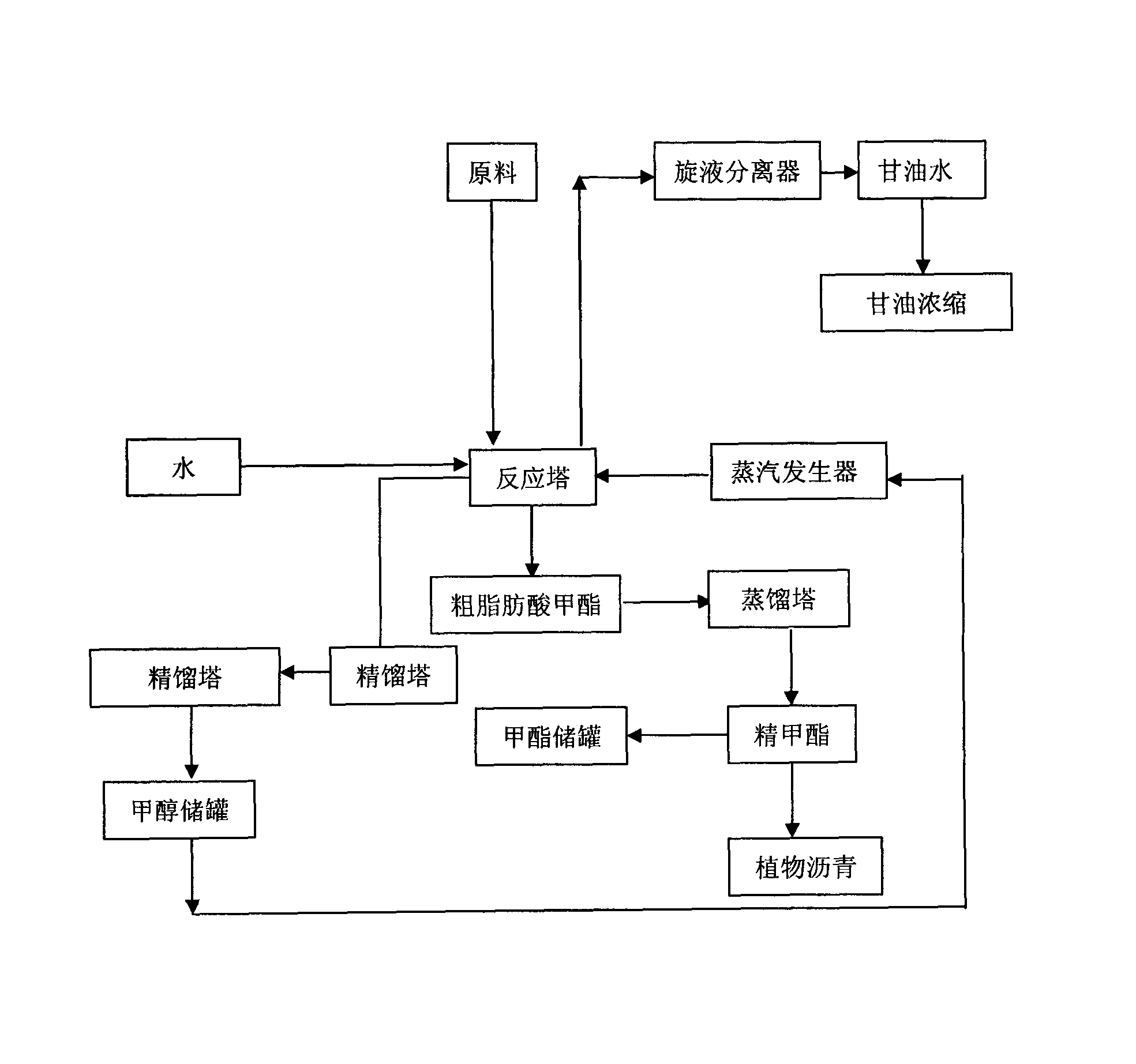

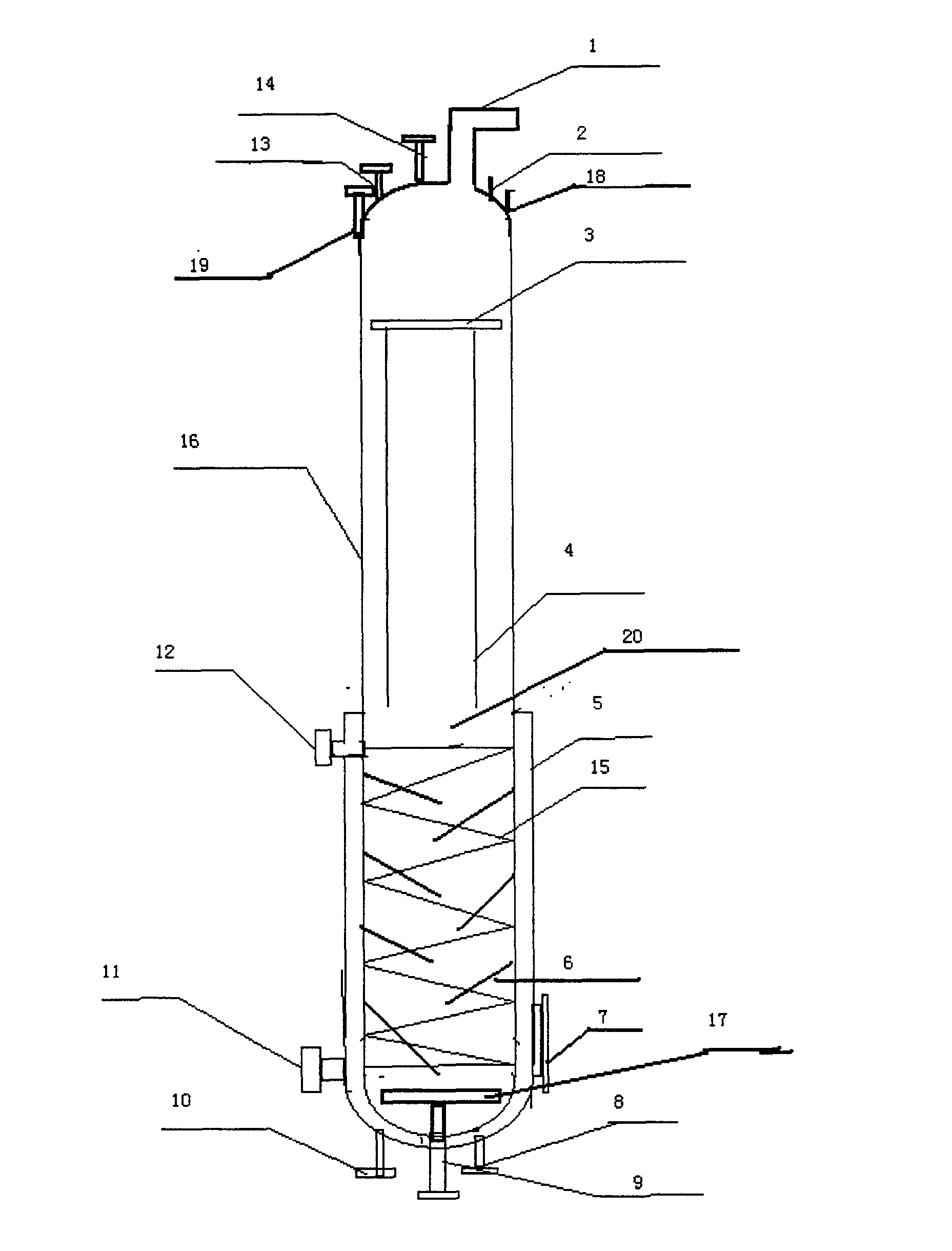

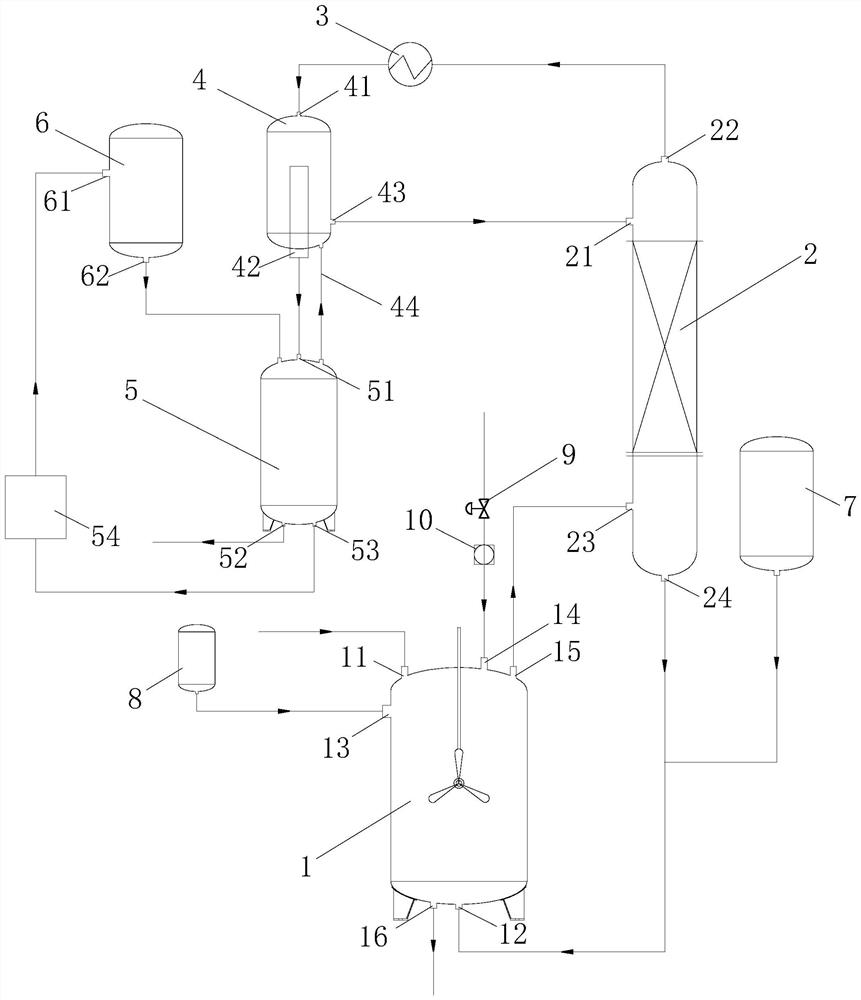

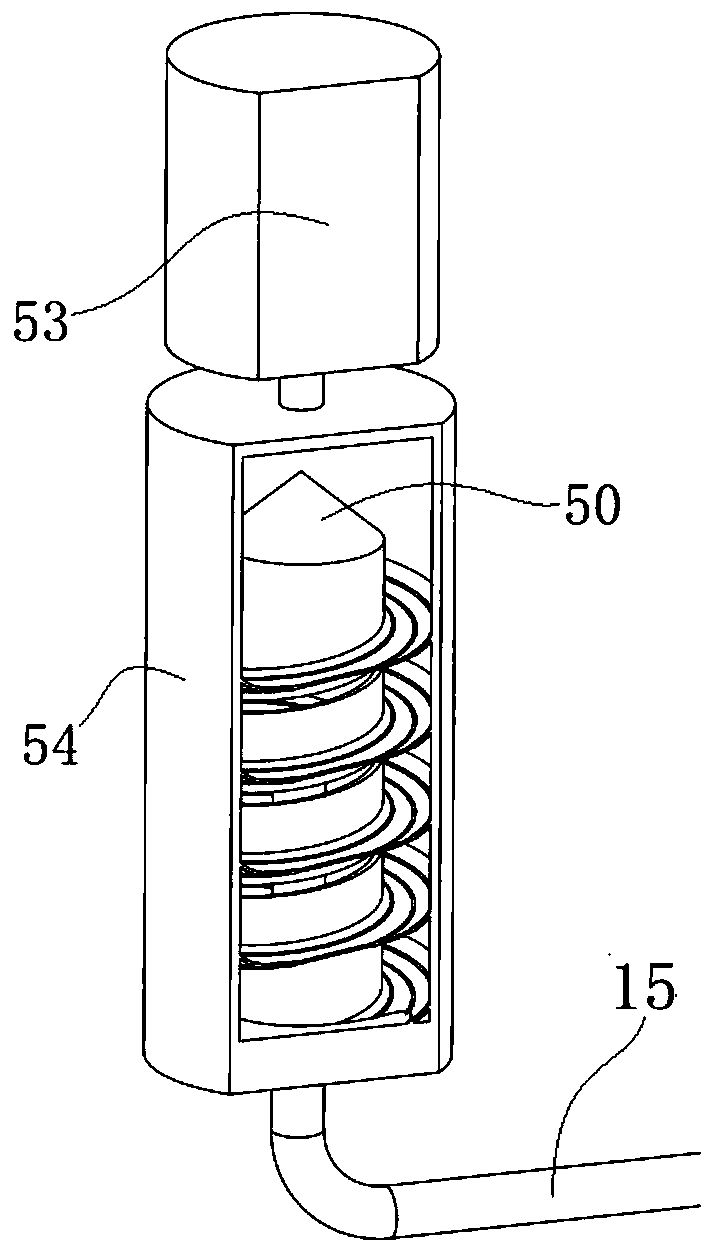

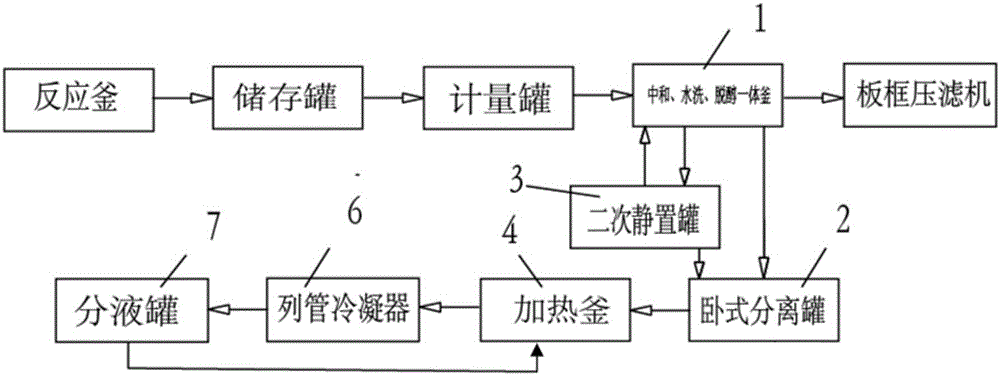

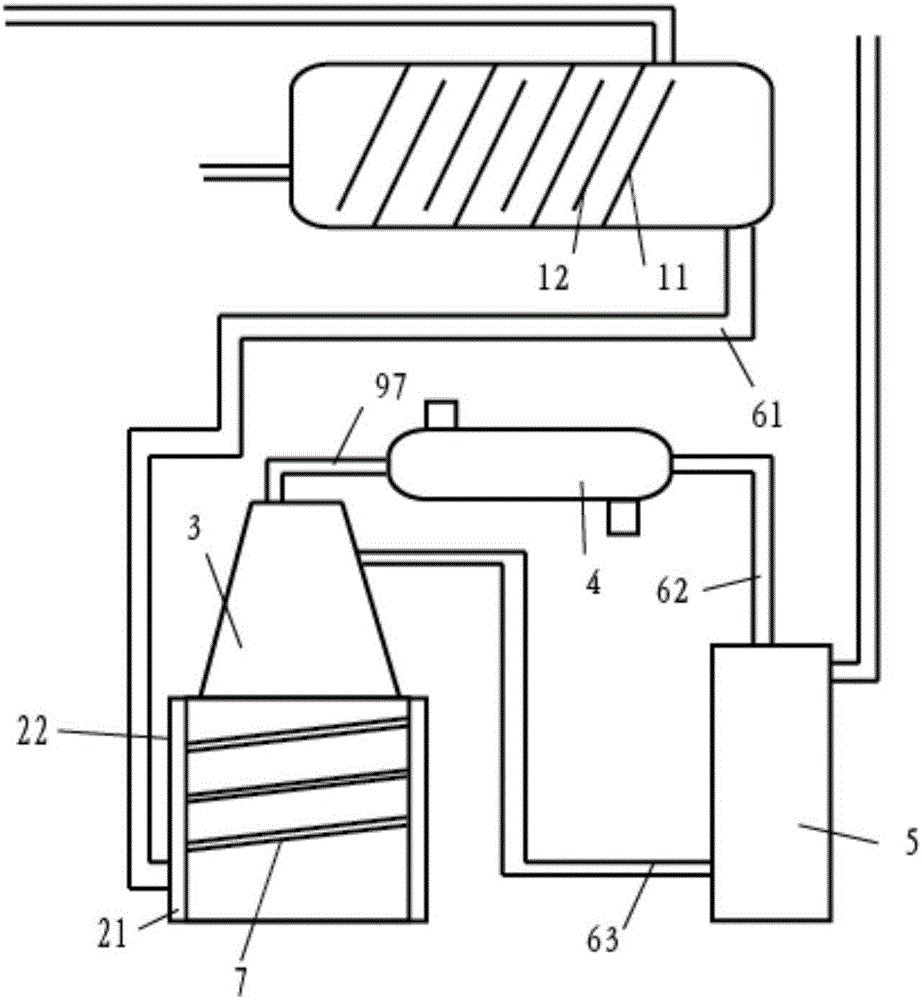

Technology process for producing biodiesel and key preparation device

InactiveCN103242966AConducive to the formation of swirlImprove the mixing effectFatty acid chemical modificationFatty acids production/refiningGas phaseSoftened water

The invention discloses a technology process for producing biodiesel and a key preparation device. The technology process mainly comprises the following steps of: carrying out hydrolysis reaction on raw material oil and softened water so as to generate fatty acid; carrying out esterification reaction on the fatty acid separated by a cyclone hydraulic separator and methyl alcohol under a certain condition, thereby preparing coarse fatty acid methyl ester, and separating; and distilling the coarse fatty acid methyl ester by a distilling tower, and separating, thereby obtaining fatty acid methyl ester-biodiesel. The key preparation device for achieving the technology process is a reaction tower which mainly comprises a tower body, a heavy separator, a baffle plate, an overhauling port, a distributor, a gas phase methyl alcohol inlet, a material outlet, a water outlet, a heat conduction oil inlet, a heat conduction oil outlet, a heat conduction oil jacket, a material inlet, a water inlet, a safety valve, a temperature meter, a pressure meter and a gas phase methyl alcohol outlet. The technology process for producing biodiesel and the key preparation device have the characteristics of no need of catalysts, no environmental pollution, low reaction pressure and reaction temperature, less energy consumption, low investment and running costs, wide raw material application range, high yield and the like.

Owner:阳谷县凯歌新能源生物科技有限公司

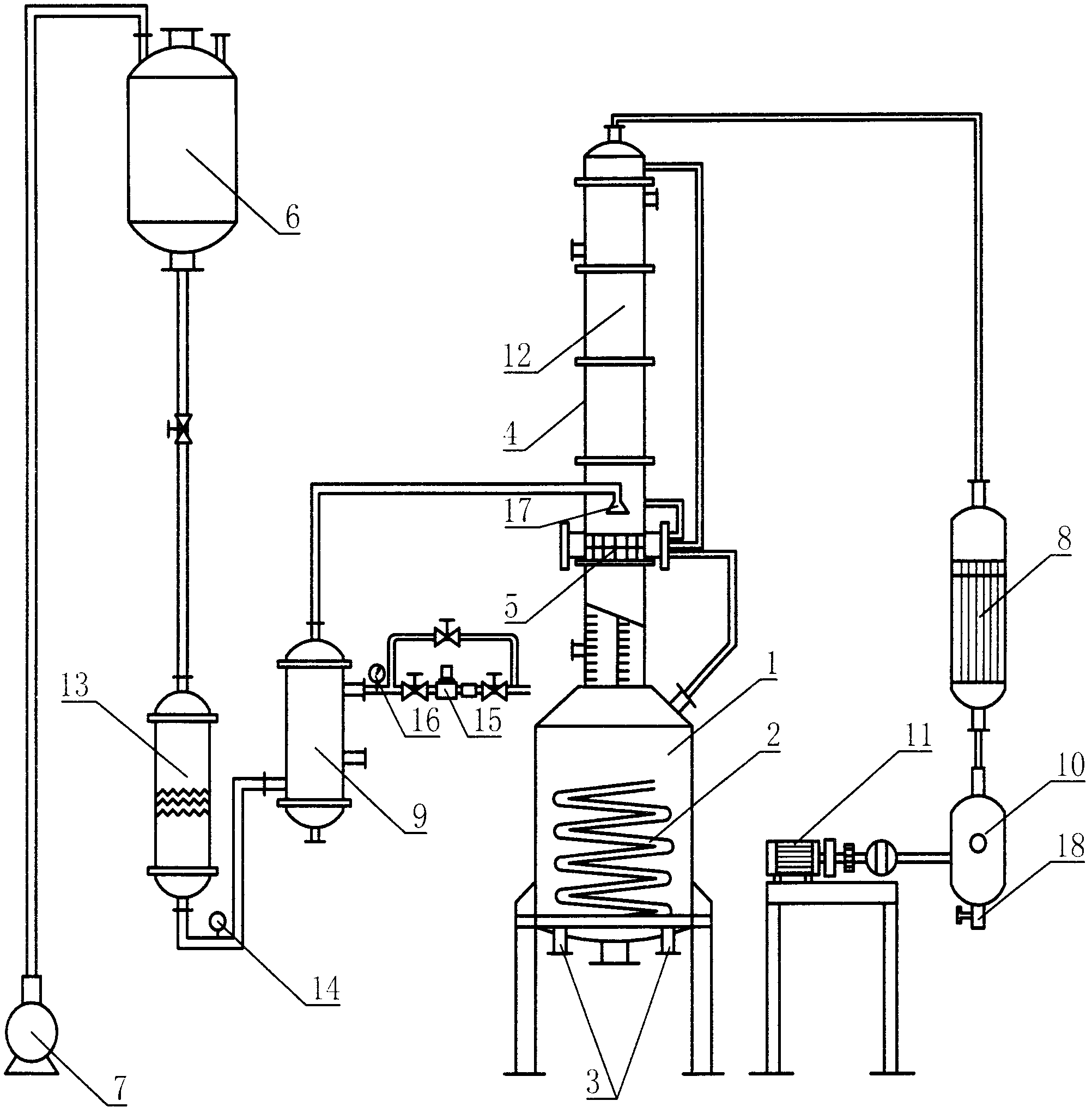

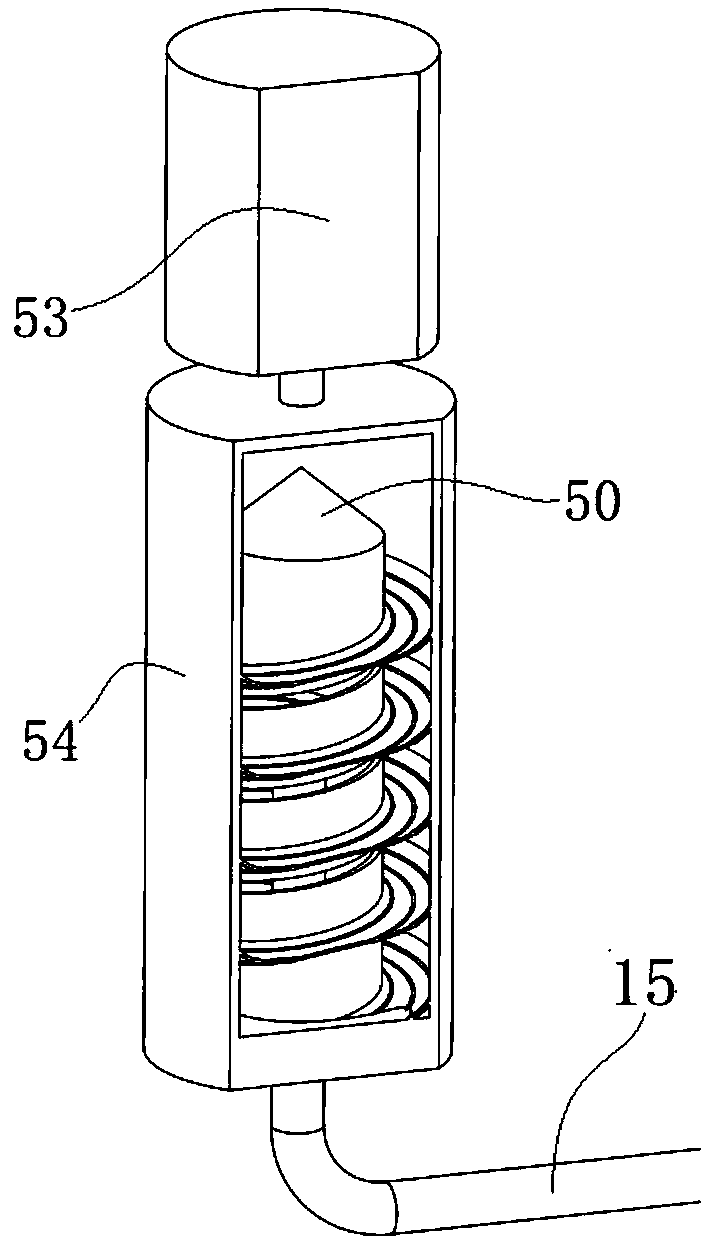

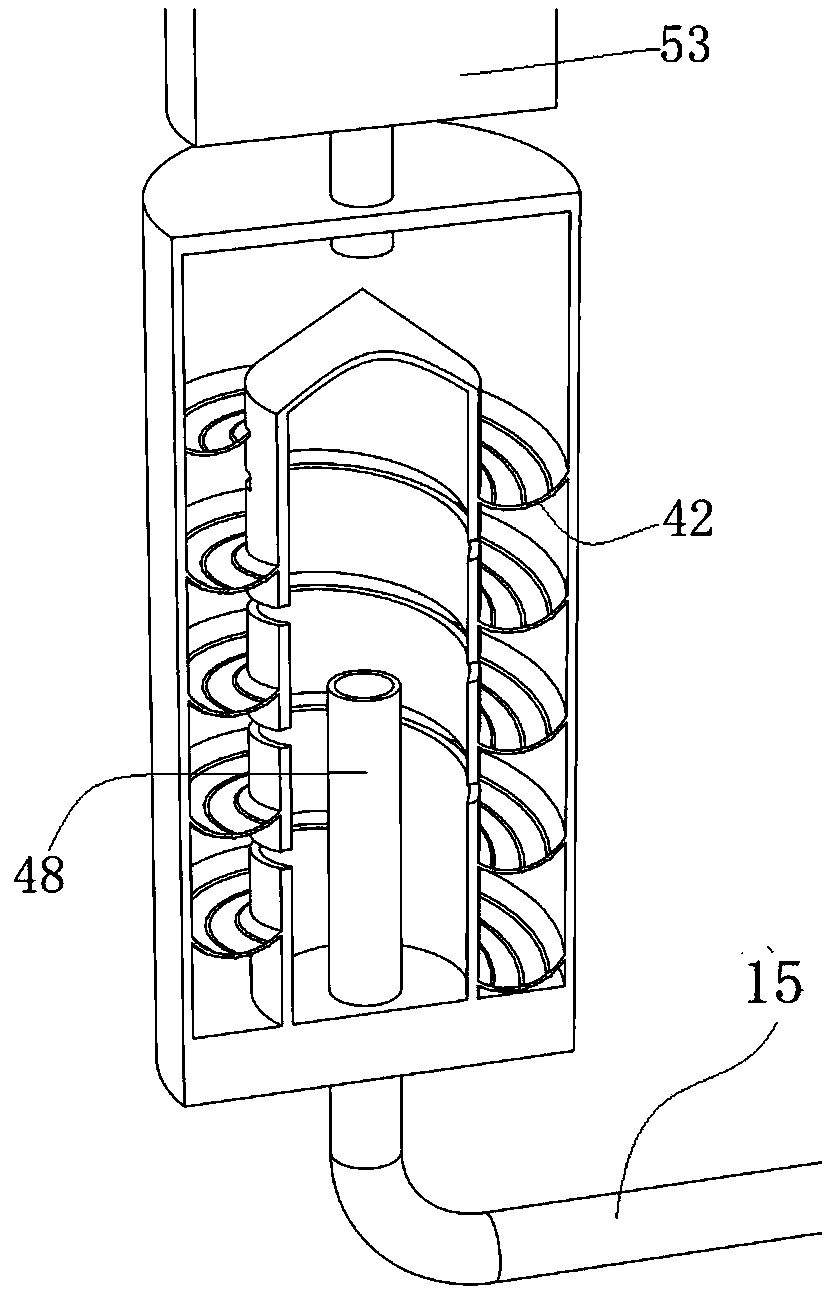

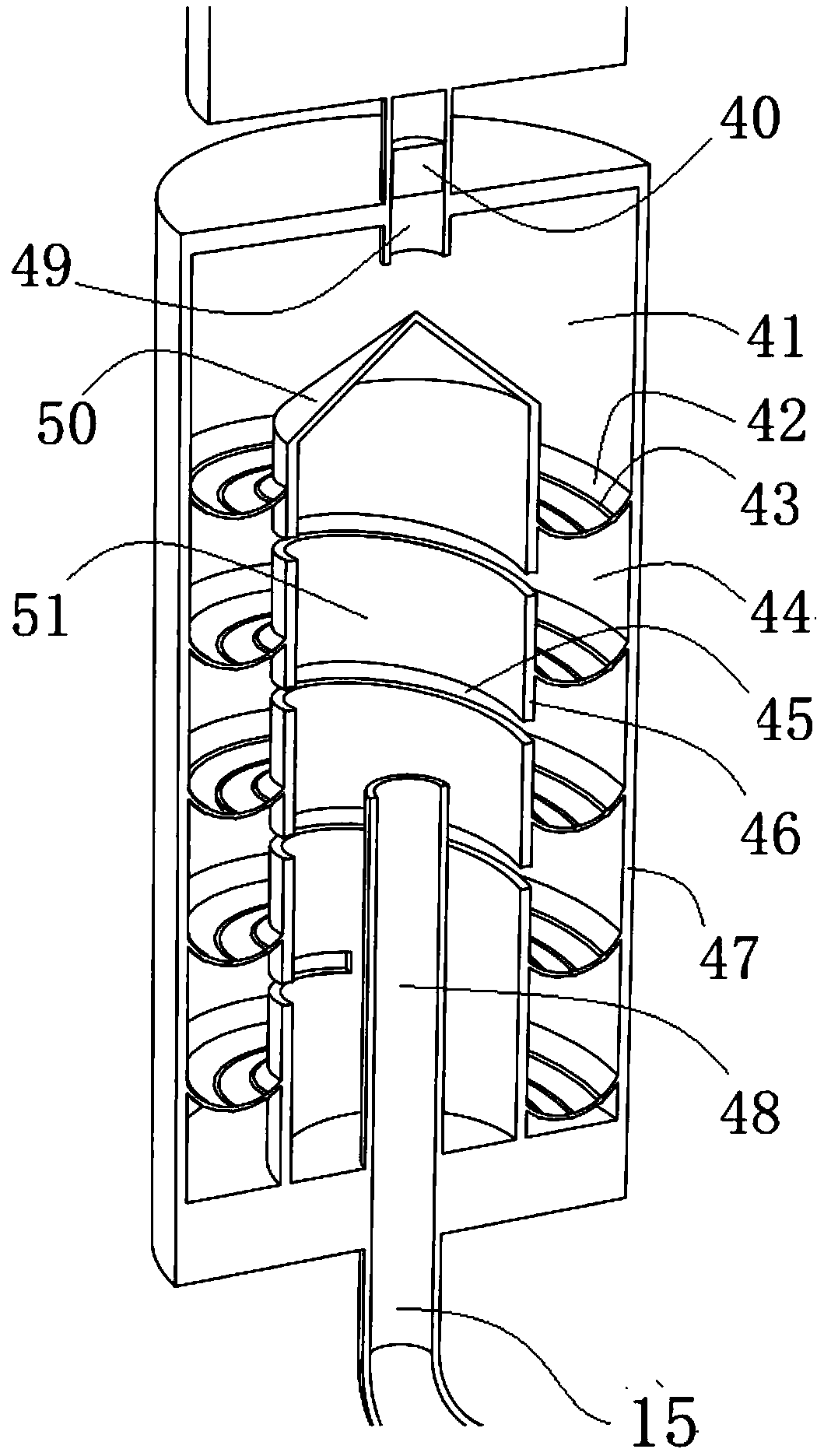

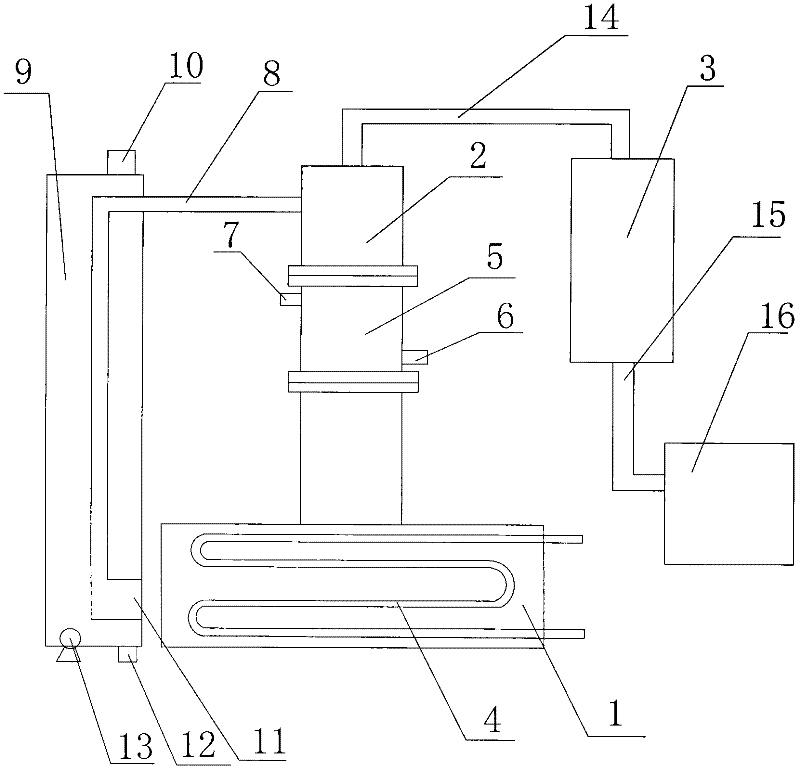

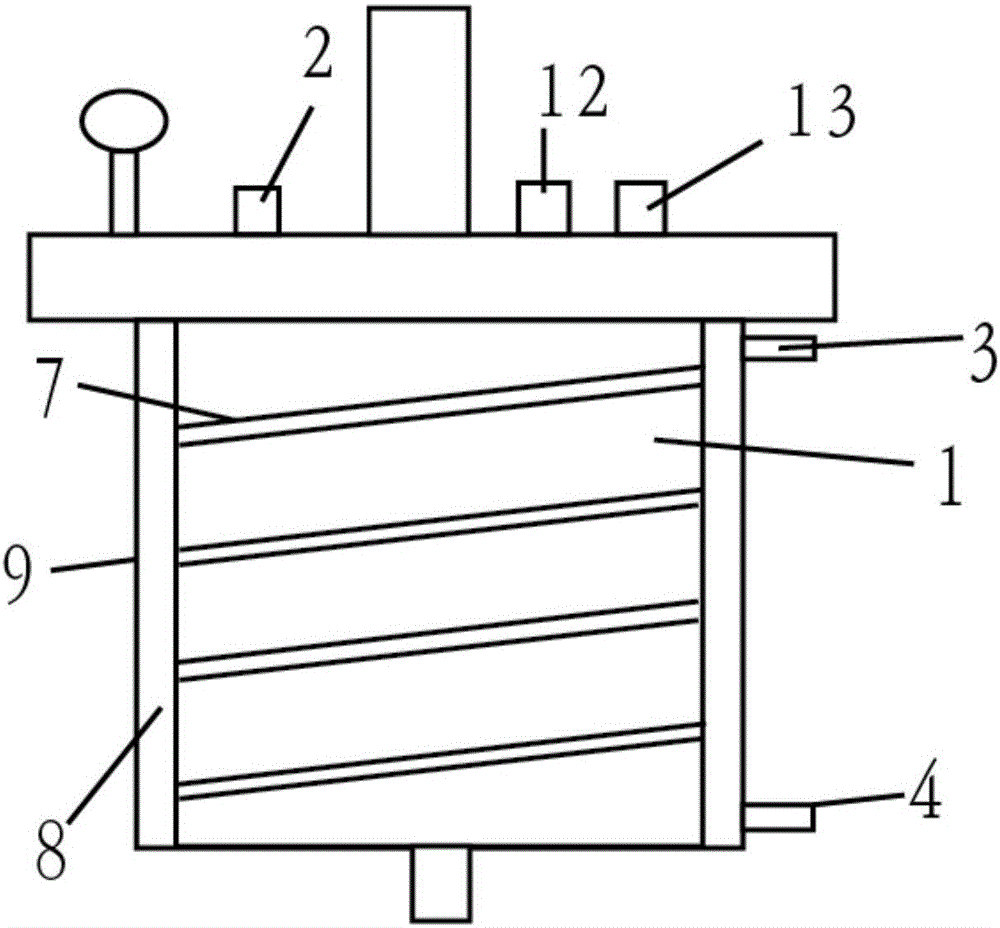

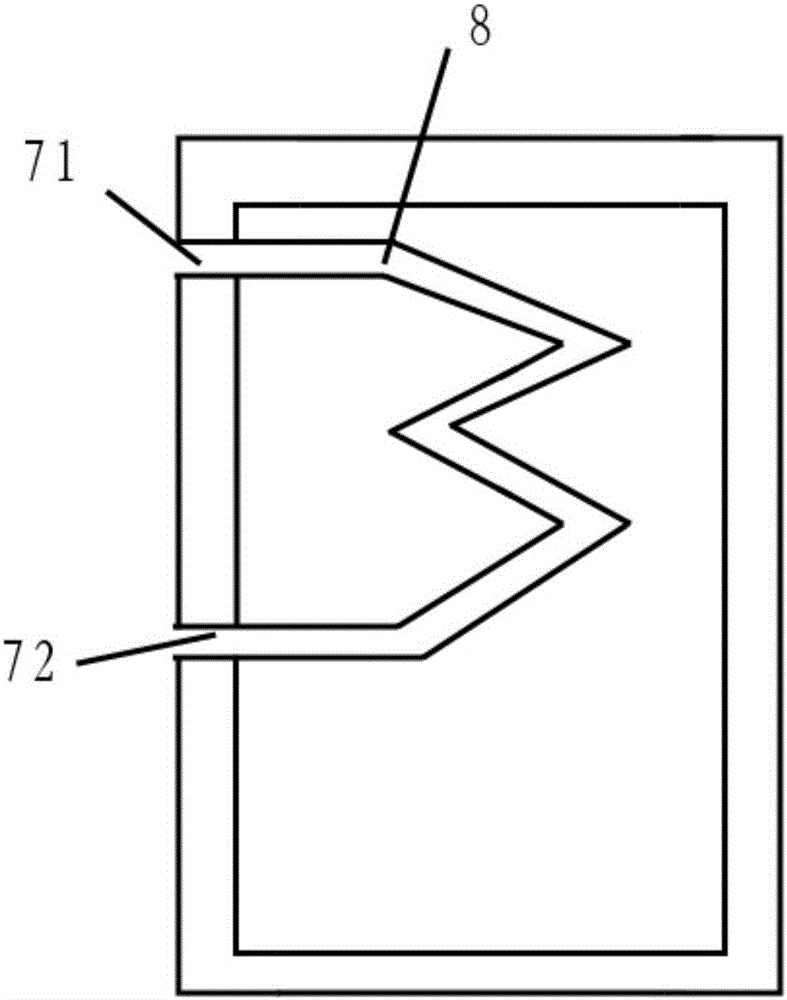

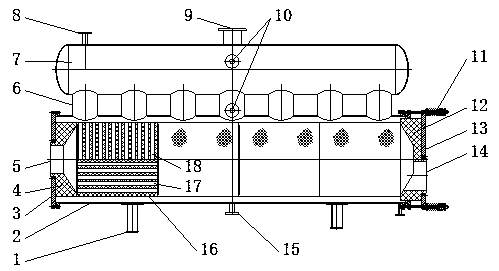

Alcohol recovery tower

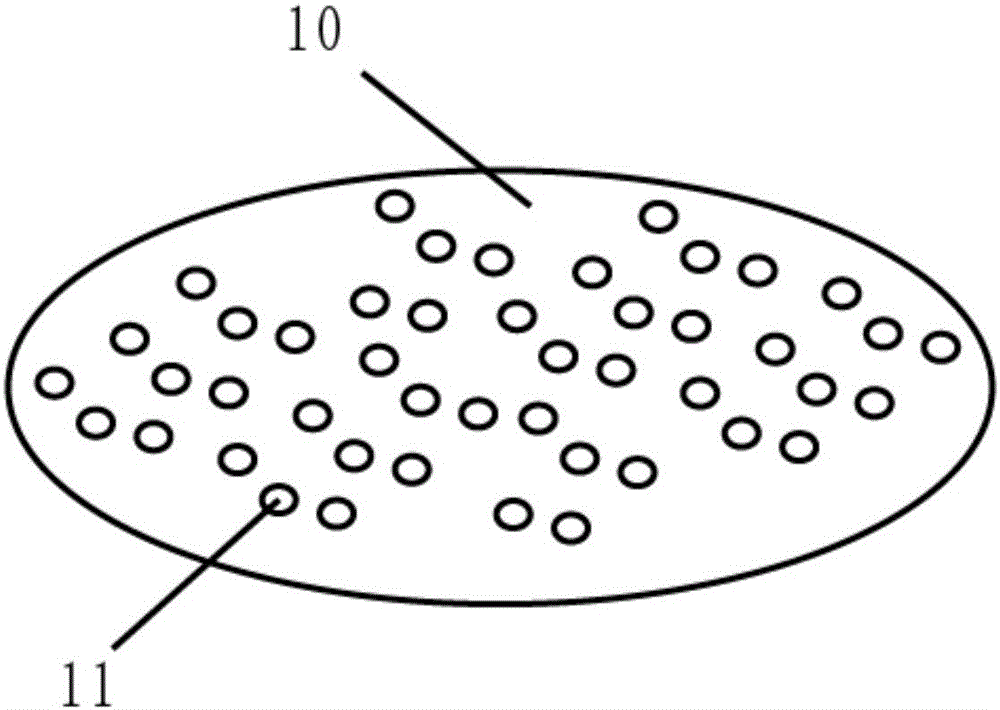

InactiveCN102584524AEffective primary filtrationHigh recovery purityOrganic compound preparationHydroxy compound preparationAqueous alcoholDistillation

The invention relates to an alcohol recovery device, in particular to an alcohol recovery tower, which has a high recovery speed and high recovery purity and is economical and durable. The alcohol recovery tower comprises a distillation tower kettle (1), a distillation tower body (4), a high-level storage tank (6), a centrifugal pump (7), a condensation cooler (8), a filter (13), a preheater (9) and a vacuum storage tank (10), wherein the distillation tower body (4) is arranged above the distillation tower kettle (1); a heating pipe (2) is arranged inside the distillation tower kettle (1); two steam inlets (3) are symmetrically formed at the bottom of the distillation tower kettle (1); a filler (5) is arranged in the distillation tower body (4); one side of the distillation tower body (4) is connected with the high-level storage tank (6) provided with the centrifugal pump (7) through a pipeline; the other side of the distillation tower body (4) is connected with the condensation cooler (8) through a pipeline; the preheater (9) is arranged between the high-level storage tank (6) and the distillation tower body (4), and a steam heating way is adopted for the preheater (9); the vacuum storage tank (10) is arranged below the condensation cooler (8); one side of the vacuum storage tank (10) is provided with a vacuum pump (11); and the bottom of the vacuum storage tank (10) is provided with an alcohol outlet (18).

Owner:付顺林

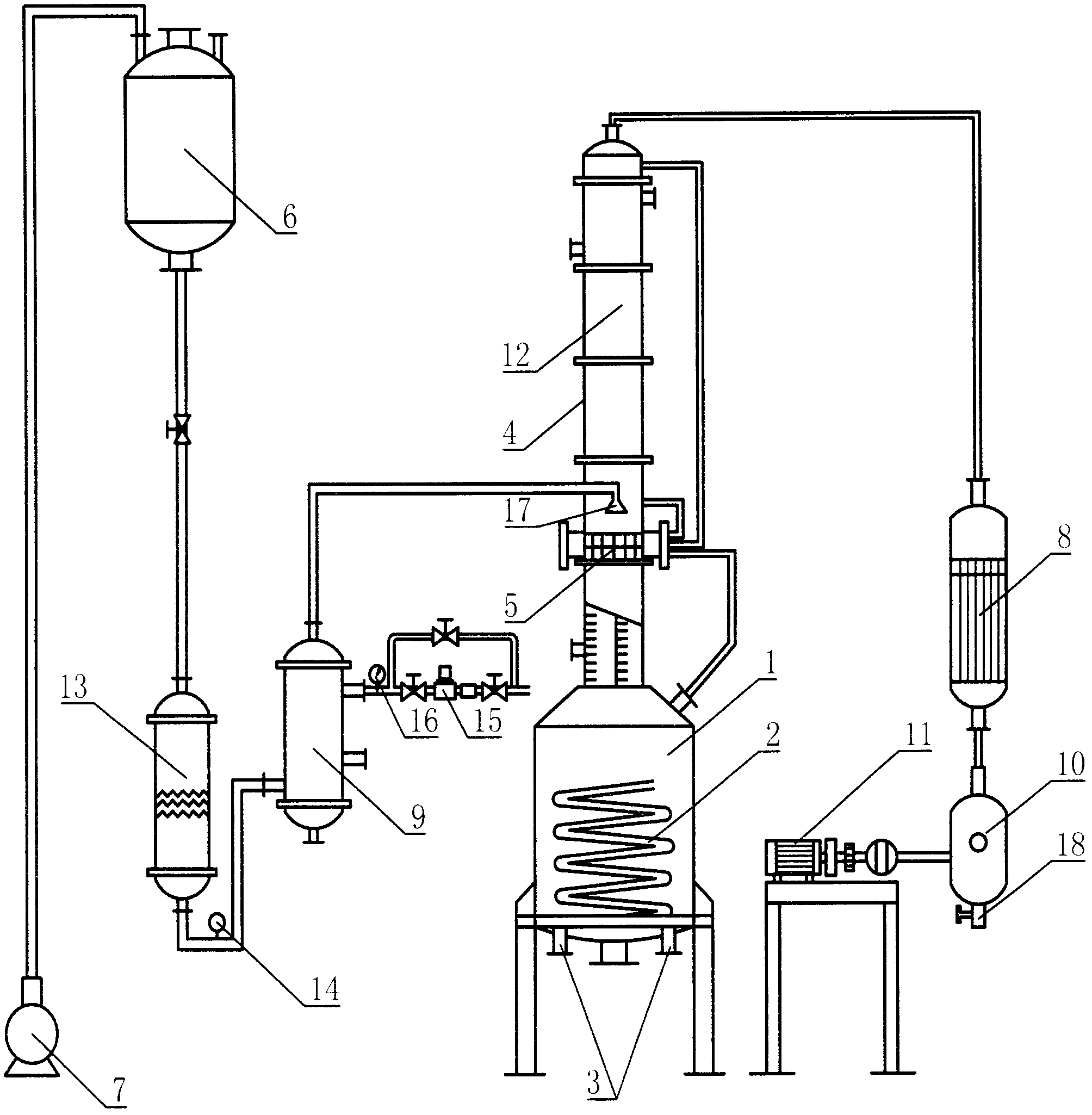

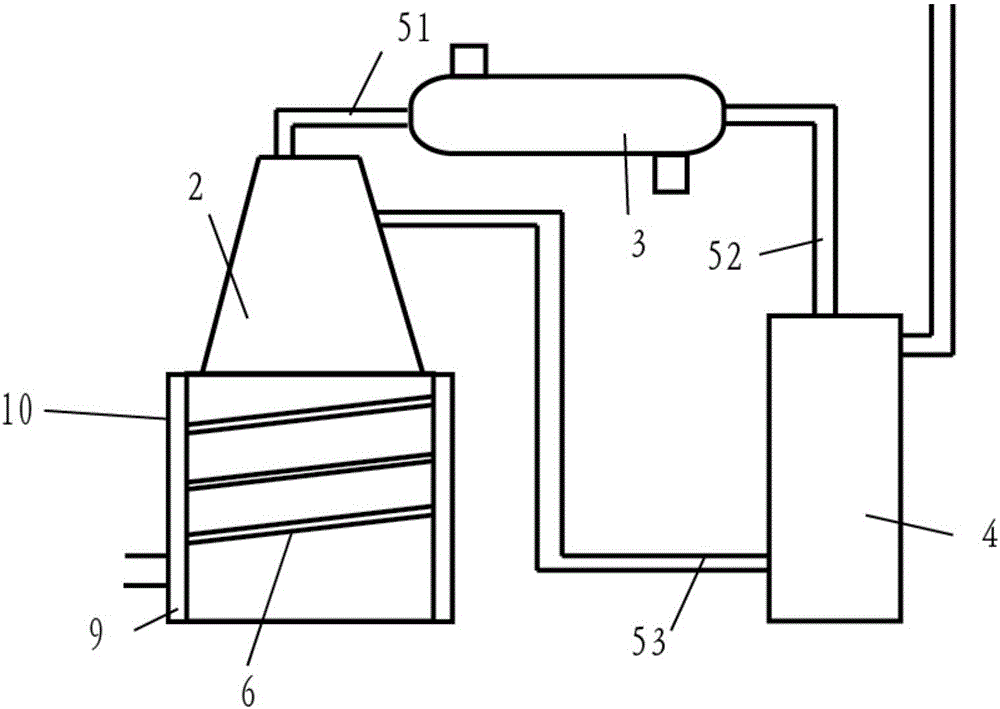

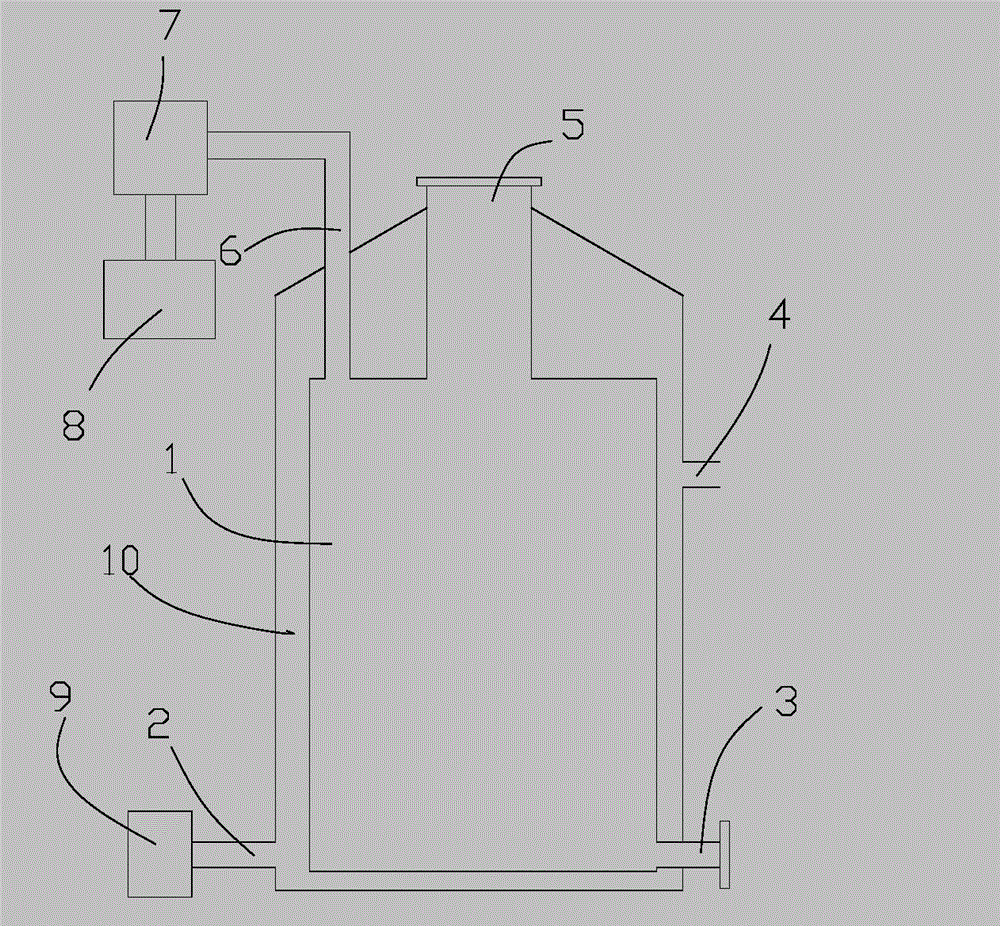

Automatic alcohol recycling system

The invention discloses an automatic alcohol recycling system which belongs to the field of pharmacy and solves the problems of high labor intensity, large workload, long working period and the like of the existing alcohol recycling system as the whole alcohol recycling process is operated manually. In the invention, multiple waste ethanol storage tanks are arranged in parallel; an exit of each waste ethanol storage tank is connected with a pre-heater; a connection pipeline is provided with a first feed pump and a feed regulation valve; an exit of the pre-heater is connected with a waste ethanol inlet of an alcohol recycling tower; a dilute alcohol outlet is arranged at the bottom of the alcohol recycling tower; a reboiler is connected in series between the dilute alcohol outlet and an entrance; a wastewater outlet is formed on the pre-heater; the top of the alcohol recycling tower is provided with an alcohol steam outlet; a cooling water loop is connected in series with a first overhead condenser; and one part of the alcohol discharged by the condenser returns to the alcohol recycling tower through a return tank and a first return pump, and the other part enters a finished product ethanol storage tank through a finished product alcohol regulation valve and a finished product condenser. The automatic alcohol recycling system disclosed by the invention is used for recycling waste alcohol.

Owner:中国船舶重工集团公司第七〇三研究所

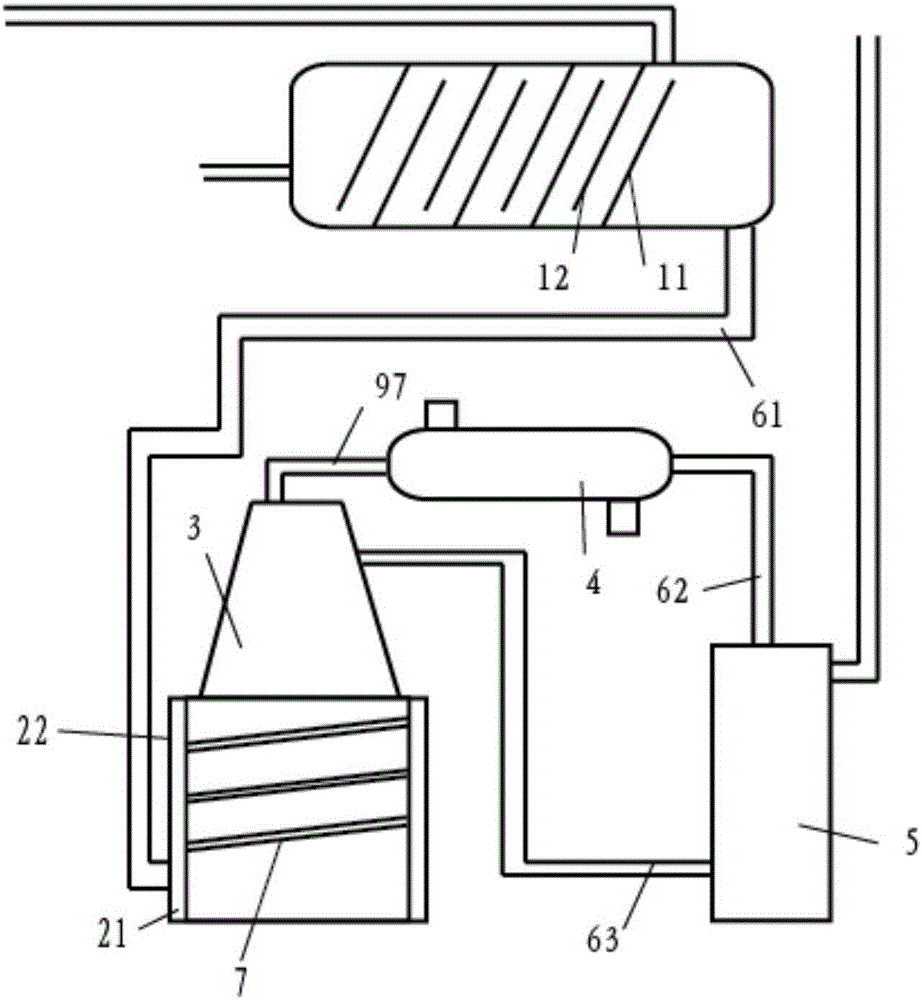

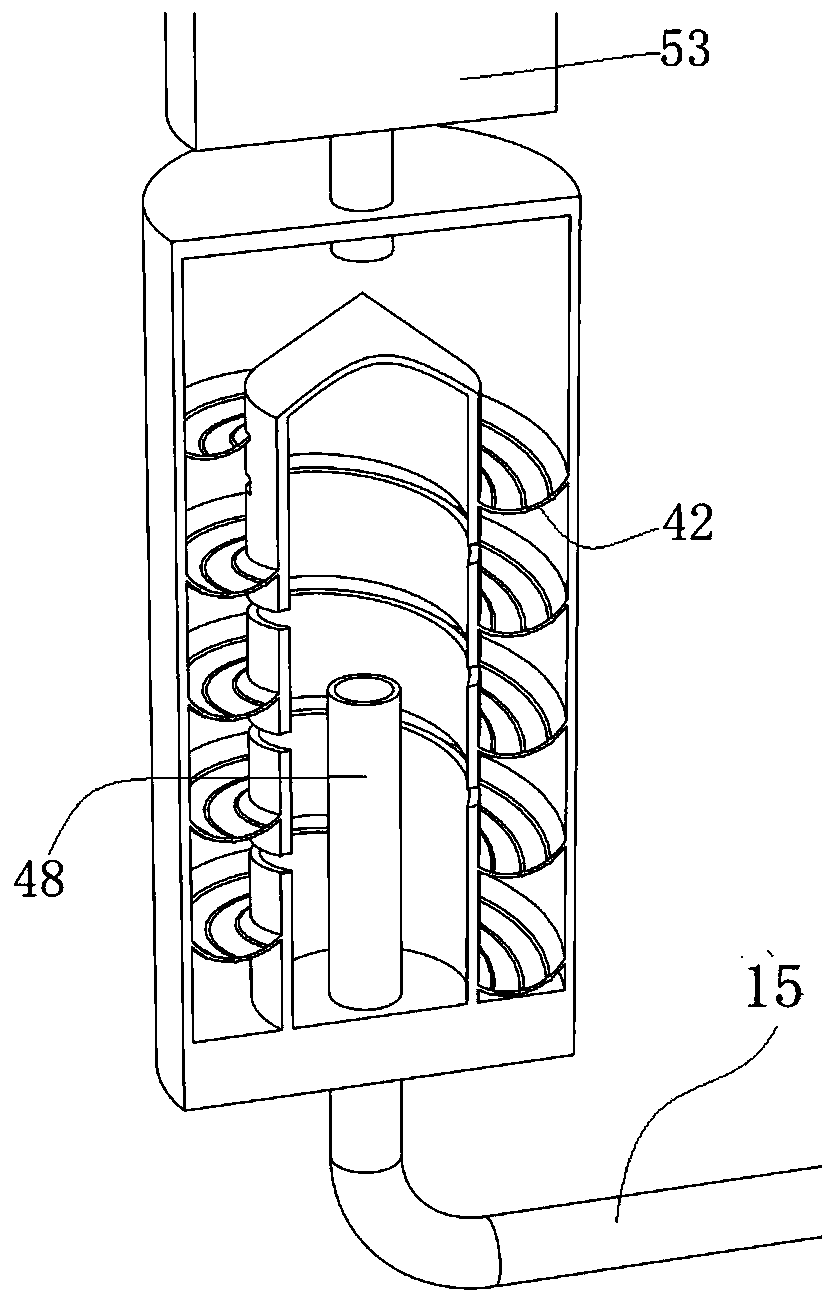

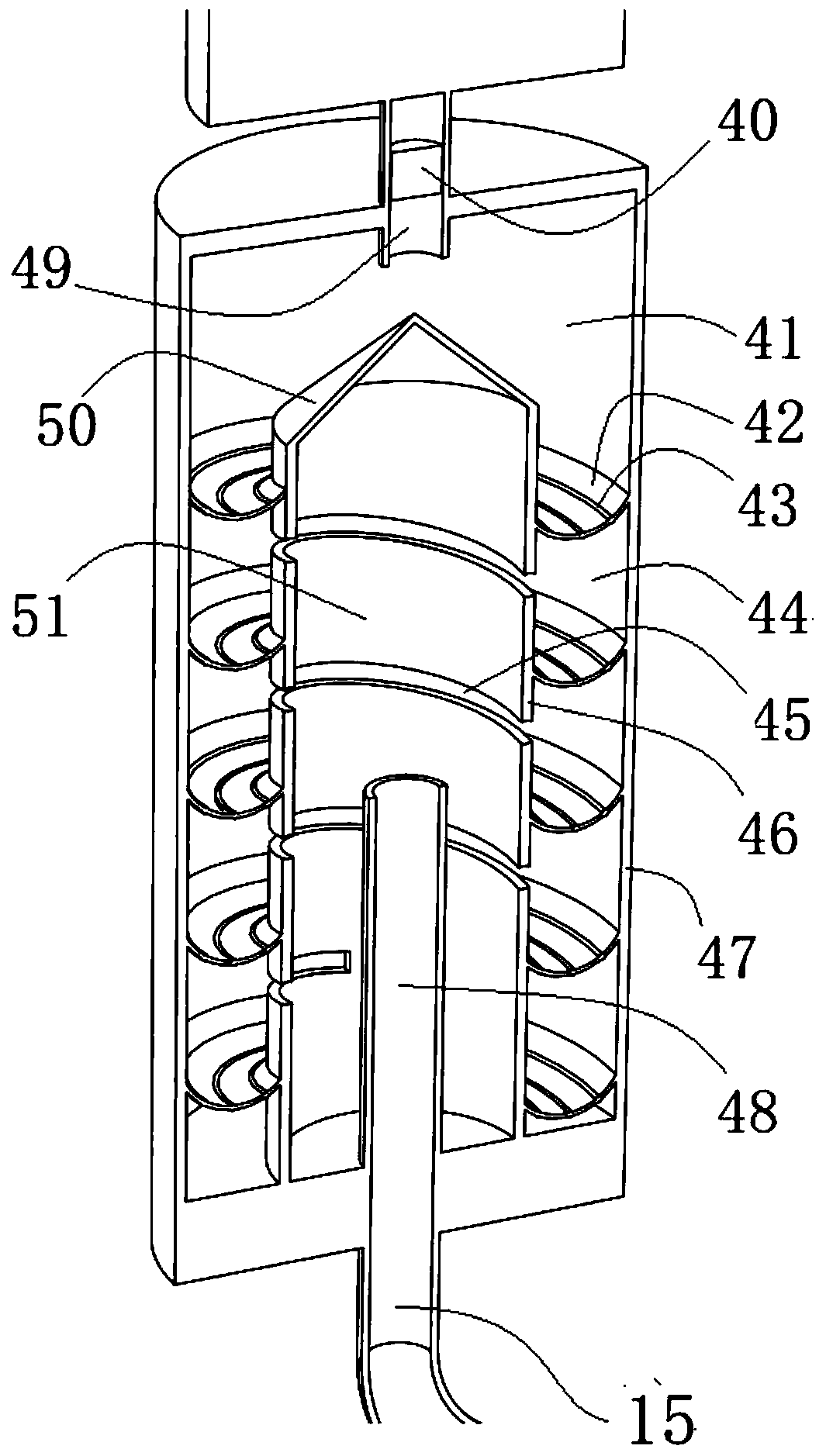

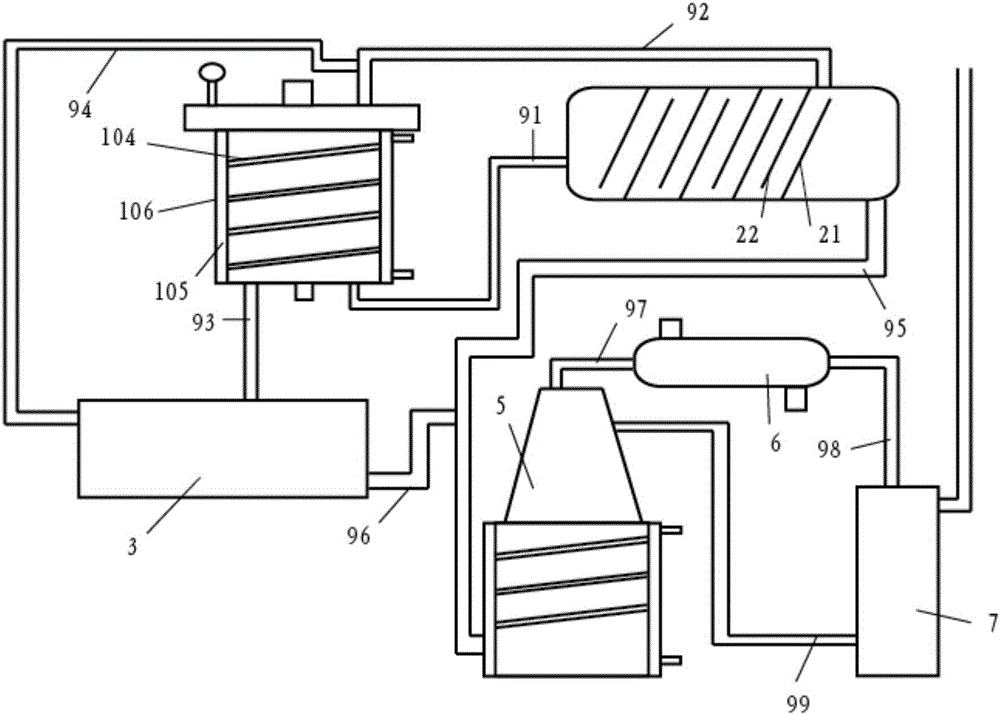

Thermal desorption based soil repair heat source system and method thereof

ActiveCN109268804AReal-time adjustment of heating powerTake advantage ofSteam generation heating methodsContaminated soil reclamationCombustionAlcohol

The invention discloses a thermal desorption based soil repair heat source system. The system comprises an ethyl alcohol liquid supply device, an ethyl alcohol steam generator and a combustion heatingfurnace body; the ethyl alcohol outlet end of the ethyl alcohol liquid supply device is connected with the ethyl alcohol inlet end of the ethyl alcohol steam generator through an ethyl alcohol supplypipe; the ethyl alcohol steam outlet end of the ethyl alcohol steam generator is communicated with an ethyl alcohol steam guiding out pipe; by controlling the flow of liquid flowing from the ethyl alcohol supply pipe in real time and adjusting the heating power of an electric heating wire in real time, ethyl alcohol liquid is just gasified completely when flowing to the lower end of a spiral slope surface along an ethyl alcohol gasification spiral slope, and heat emitted by the slope surface of the whole ethyl alcohol gasification spiral slope is sufficiently utilized.

Owner:鸿灌环境技术有限公司

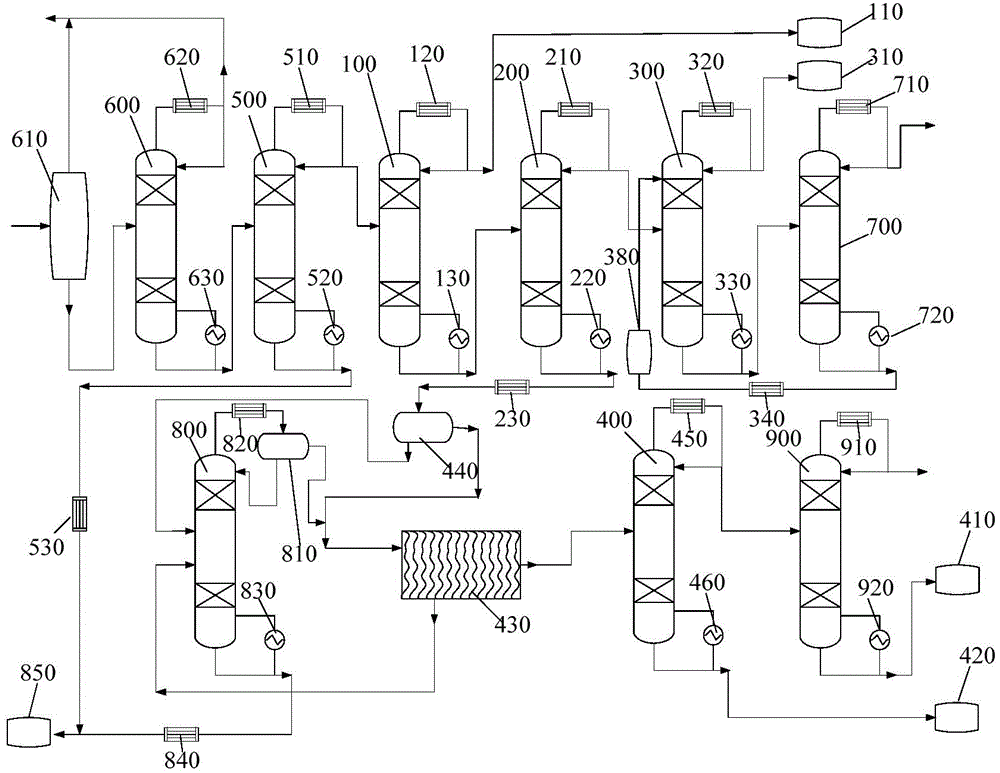

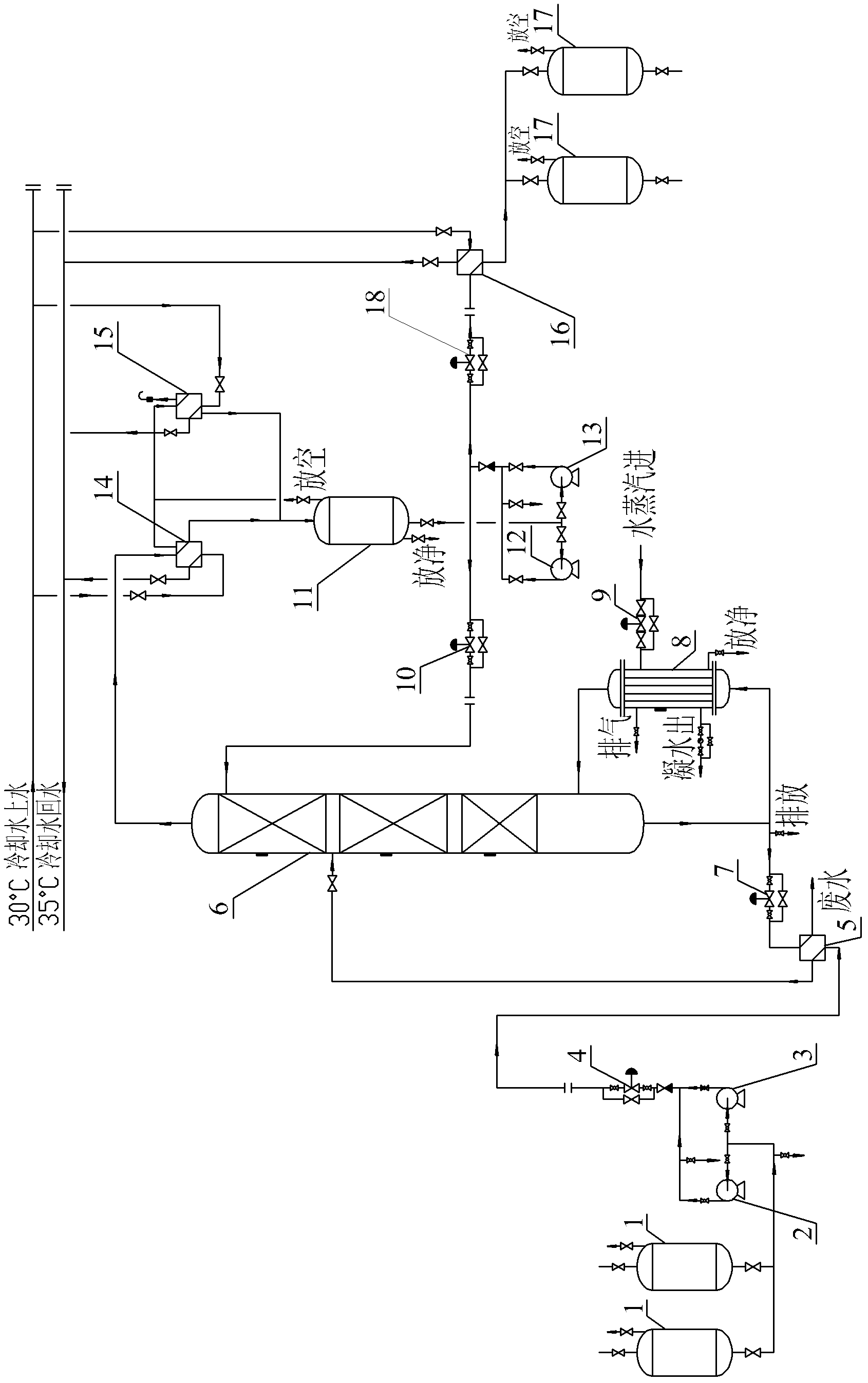

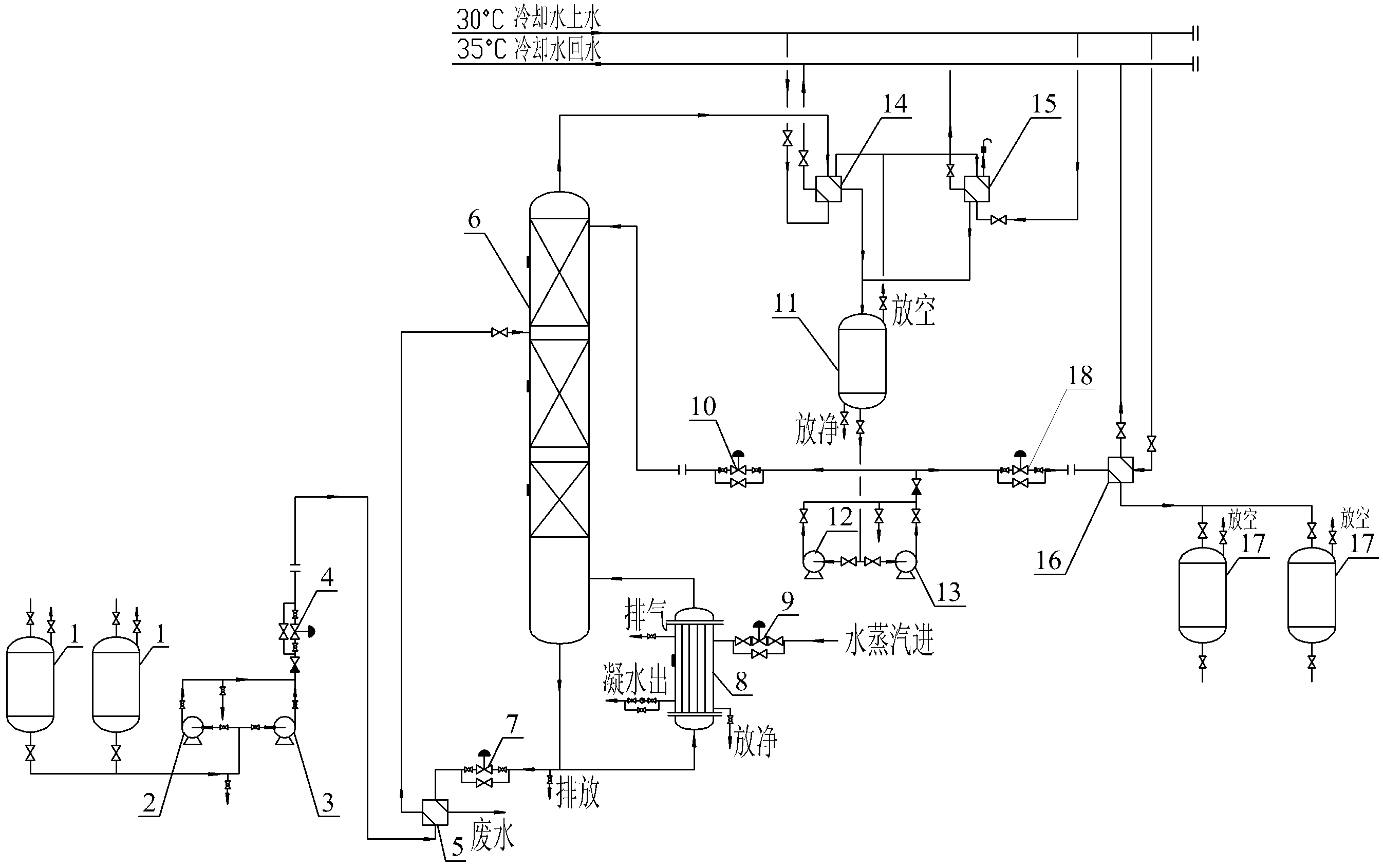

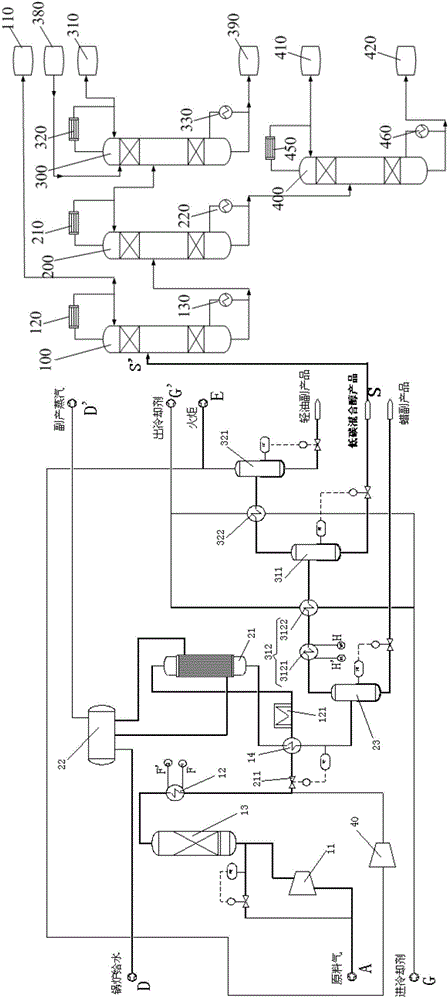

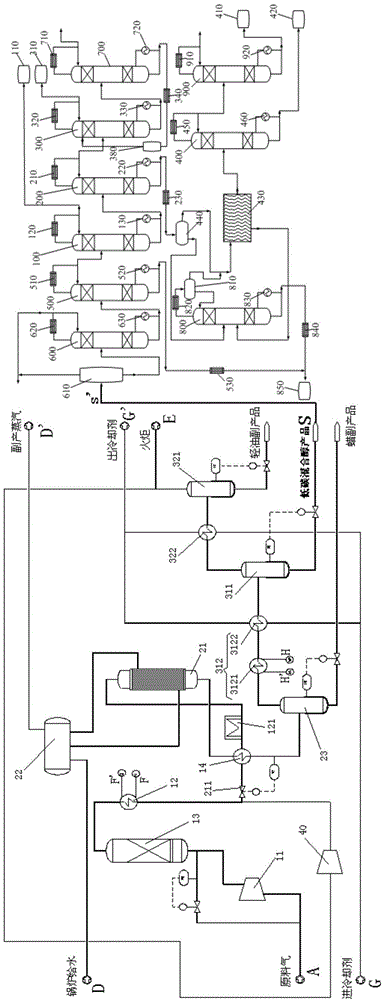

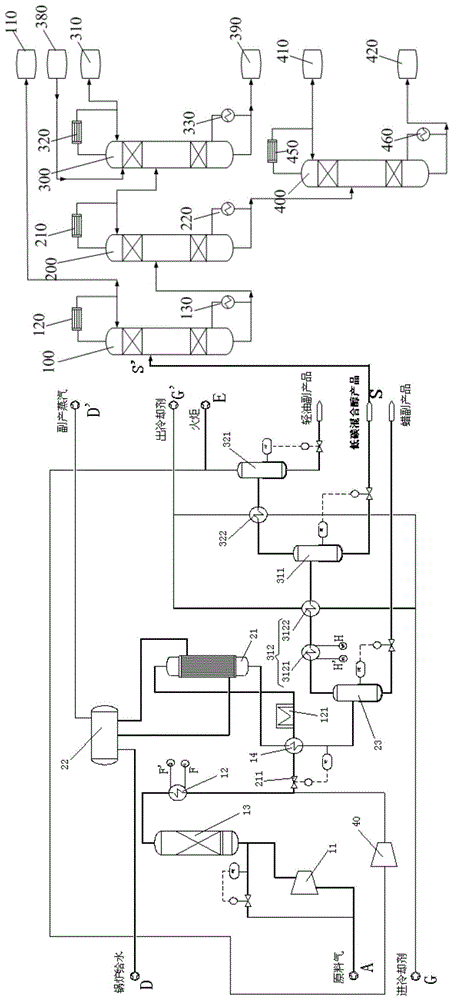

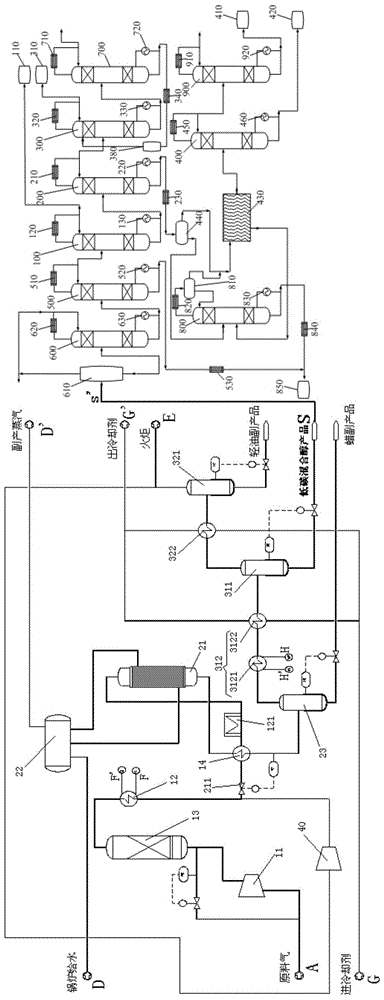

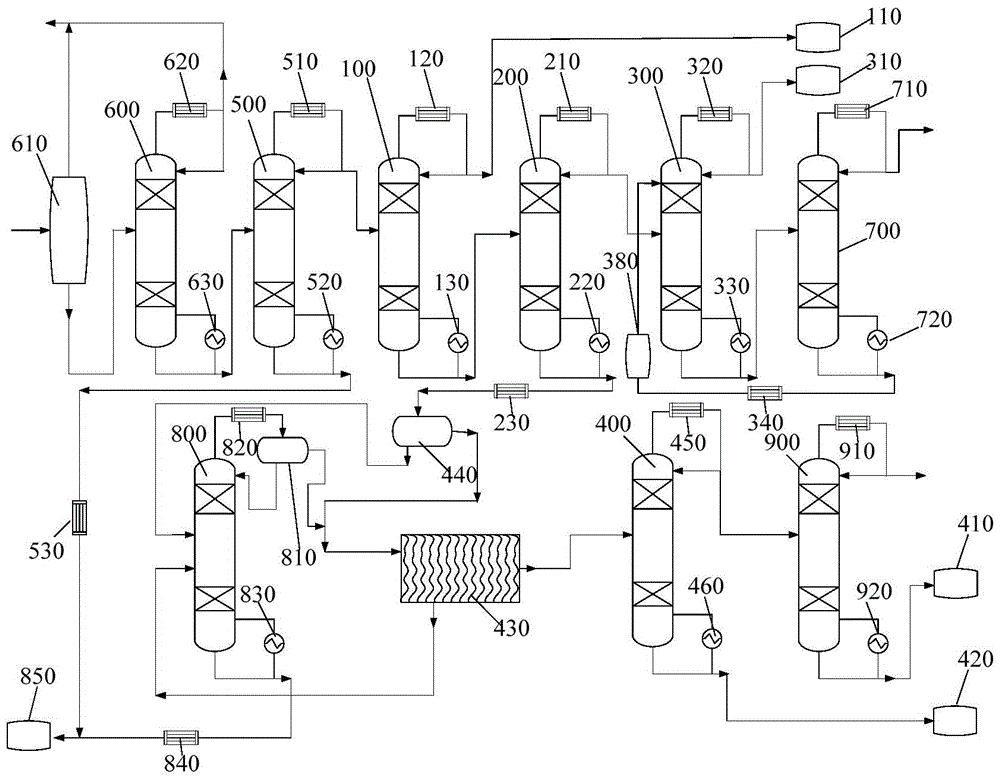

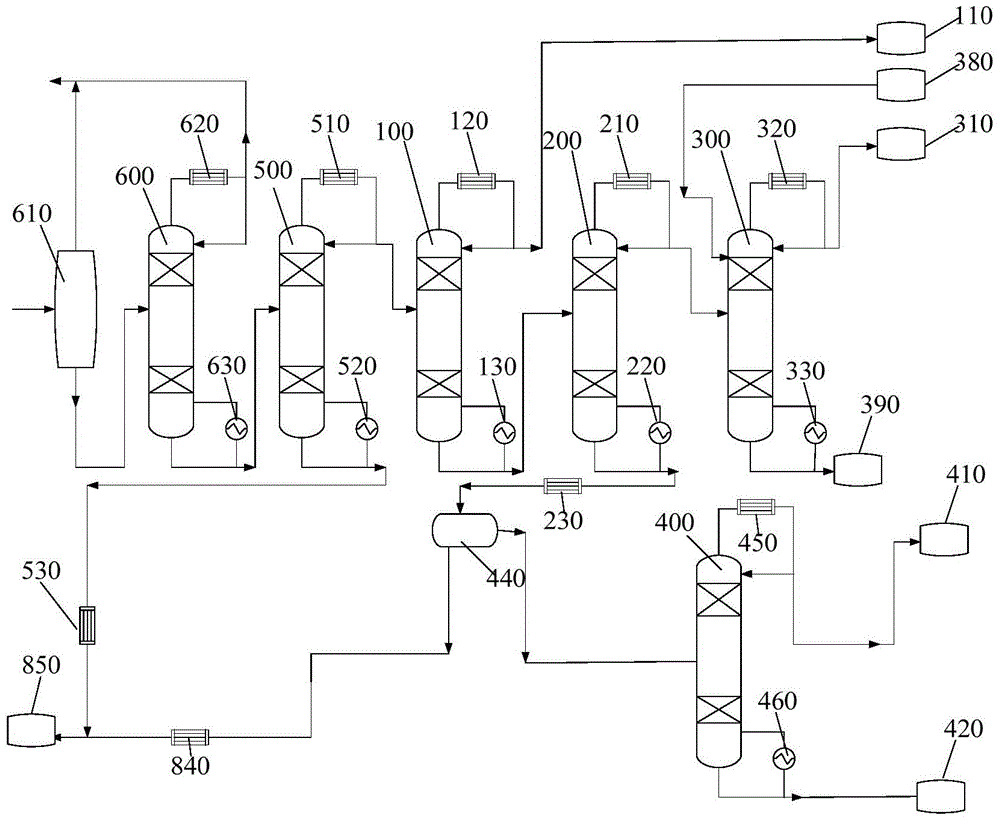

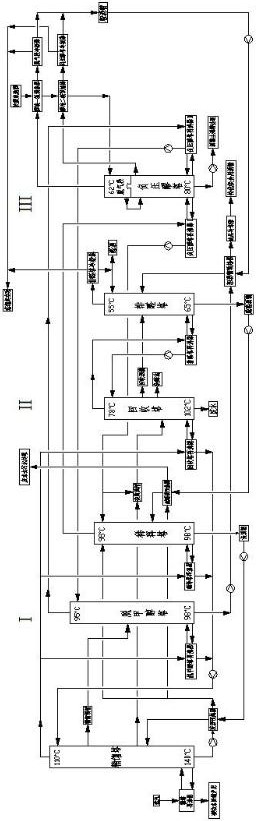

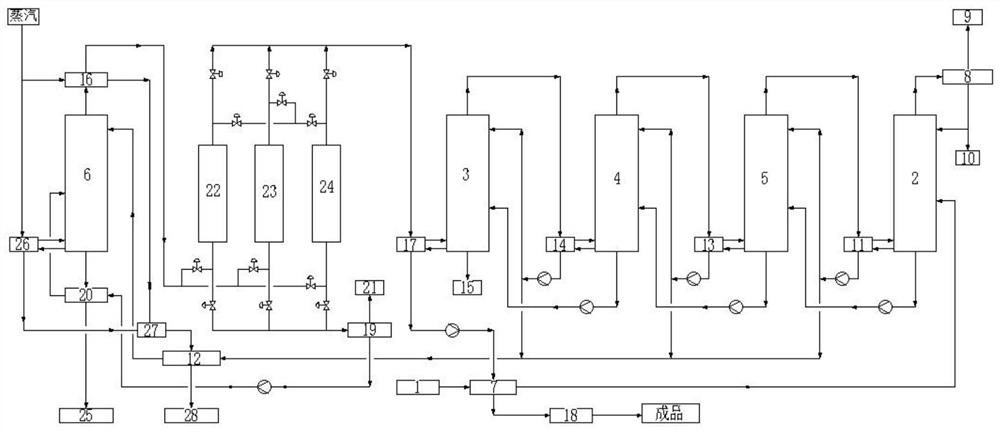

Joint production system and joint production process for synthesizing and separating low-carbon mixed alcohol

ActiveCN104529704ARealize clean utilizationReduce dependencyOrganic compound preparationHydroxy compound separation/purificationN-Propyl alcoholAlcohol synthesis

The invention provides a joint production system and a joint production process for synthesizing and separating low-carbon mixed alcohol. The joint production system for synthesizing and separating the low-carbon mixed alcohol comprises a low-carbon mixed alcohol synthesis subsystem and a low-carbon mixed alcohol separation subsystem, wherein the low-carbon mixed alcohol synthesis subsystem comprises a raw gas treatment module, a low-carbon alcohol synthesis module and a product treatment module which are communicated with one another in order, and the product treatment module comprises a low-carbon alcohol separation part which comprises a low-carbon alcohol separator and is provided with a low-carbon mixed alcohol outlet for draining a low-carbon mixed alcohol product; and the low-carbon mixed alcohol separation subsystem comprises a methanol rectifying tower, an ethanol rectifying tower, an extraction rectifying tower and an n-propyl alcohol rectifying tower. By adopting the system and the process provided by the invention, the problem of production technical difficulty during synthesis of the low-carbon mixed alcohol by using a raw material synthetic gas in the prior art is solved, and meanwhile, the problem of poor separation effect of the low-carbon mixed alcohol is solved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

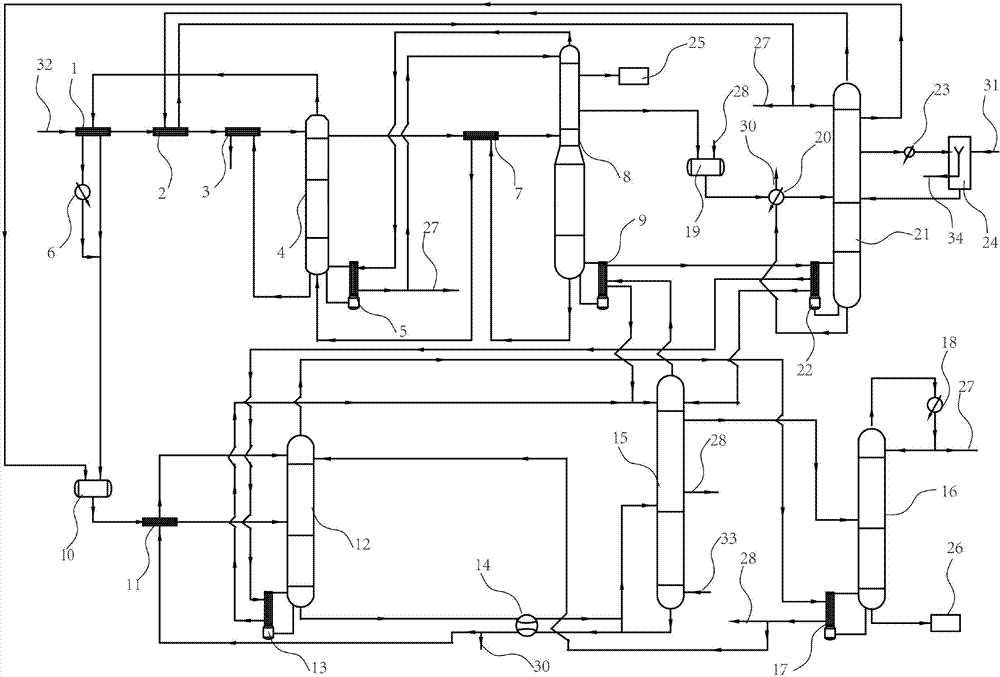

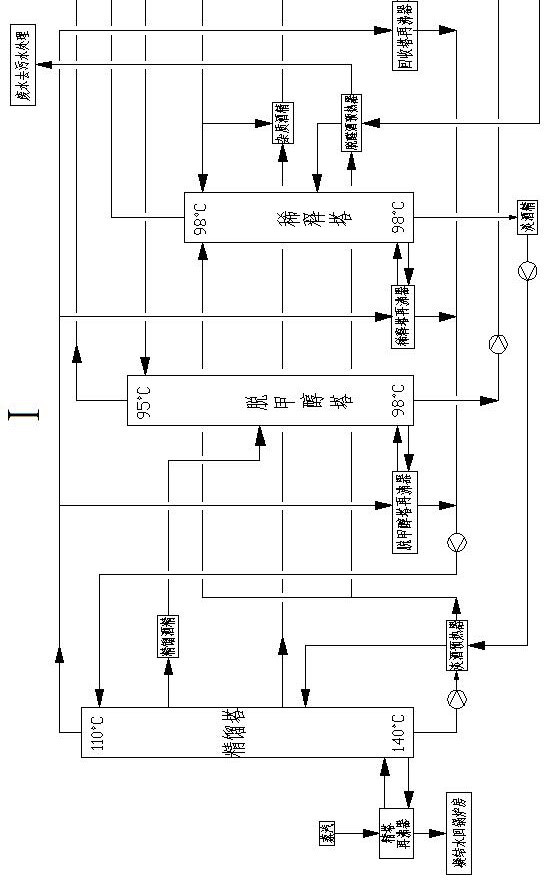

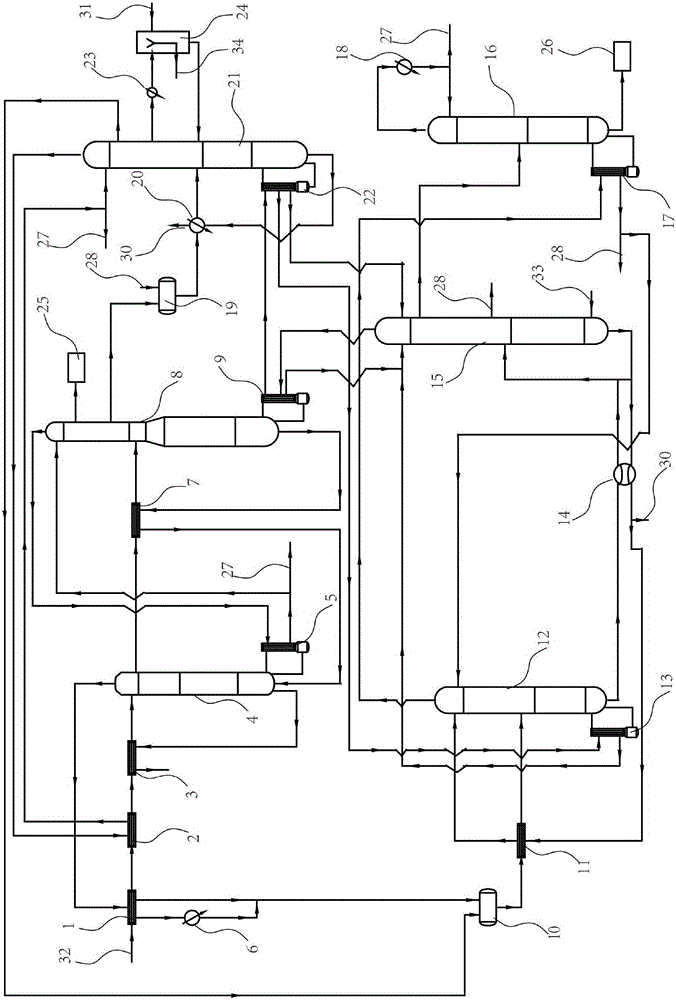

Common and superior edible alcohol co-production distillation energy-saving device and energy-saving process thereof

ActiveCN104232455AReduce consumptionReduce energy consumptionAlcoholic beverage preparationAlcoholDistillation

The invention discloses a common and superior edible alcohol co-production distillation energy-saving device and an energy-saving process thereof. The common and superior edible alcohol co-production distillation energy-saving device comprises a coarse distillation tower, a combined tower, a water scrubbing tower, a rectification tower, a methanol tower and a mash preheating device, wherein the mash preheating device, the coarse distillation tower and the combined tower are sequentially communicated with one another; the rectification tower, the water scrubbing tower and the methanol tower are sequentially communicated with one another; the mash preheating device is further communicated with the water scrubbing tower; the mash preheating device is communicated with a mature fermented mash feeding pipeline; the combined tower is provided with a common alcohol outlet, and the methanol tower is provided with a superior alcohol outlet. The common and superior edible alcohol co-production distillation energy-saving device provided by the invention can ensure flexible adjustment between common edible alcohol and superior edible alcohol, can rapidly meet market demands, and lowers steam consumption and water consumption of a whole set of distillation system.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

Alcohol recovery tower

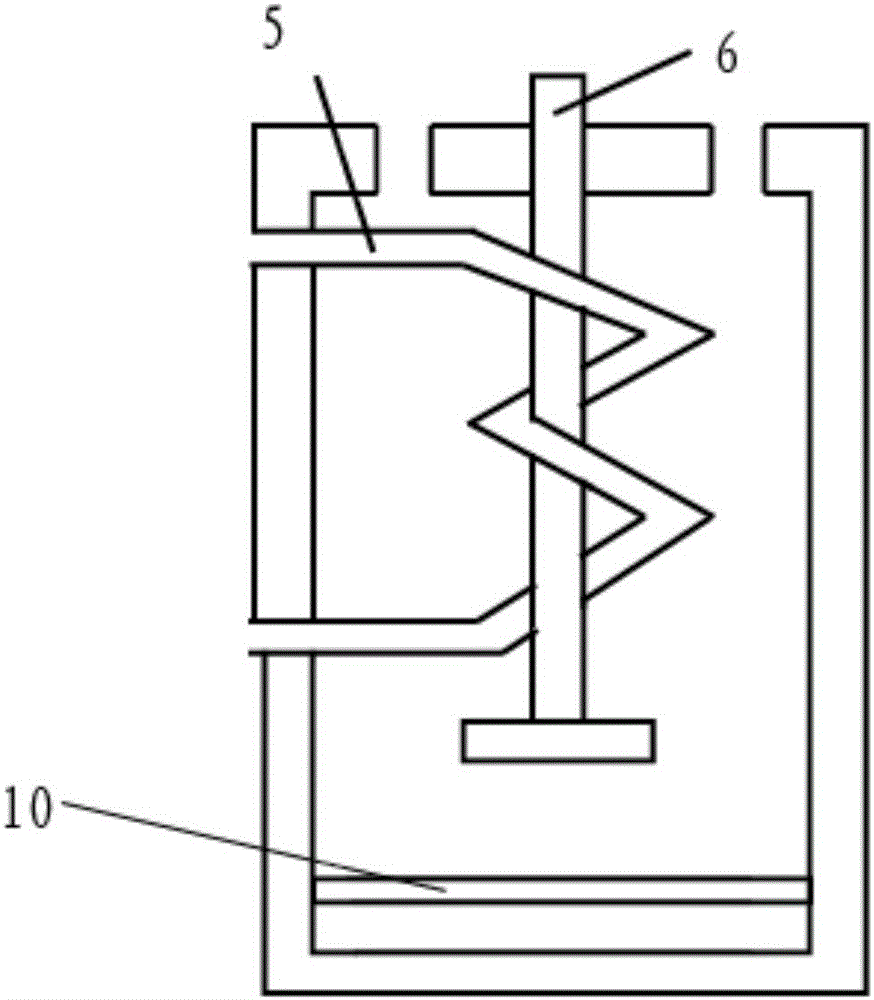

InactiveCN102671401AAdjustable temperatureNo backflowDistillation separationHydroxy compound separation/purificationTemperature controlAlcohol

The invention relates to an alcohol recovery tower which comprises a tower kettle, a tower body and a condenser, wherein the tower kettle and the tower body are a whole; a heating pipe is arranged in the tower kettle; a temperature control tower section is arranged on the tower body; a cooling water inlet is arranged at one side of the lower part of the temperature control tower section; a cooling water outlet is arranged at the other side of the upper part of the temperature control tower section; the upper part of the tower body is connected with an alcohol pre-heating chamber through a cooling water pipe; a cooling water inlet is arranged on the top part of the alcohol pre-heating chamber; an alcohol inlet is arranged on one side of the bottom part of the alcohol pre-heating chamber; a circulating water outlet is arranged on the bottom part of the alcohol pre-heating chamber; the top part of the tower body is connected with the condenser through a connecting catheter; and an alcohol outlet is arranged on the bottom part of the condenser, and the alcohol outlet is connected with a product tank. The alcohol recovery tower disclosed by the invention has the advantages that: the temperature in the tower body can be adjusted by the arrangement of the temperature control tower section, the tower body is connected with the condenser without backflow phenomenon and the alcohol recovery tower is safe and reliable.

Owner:倪建英

Combined production system for synthesis and separation of low-carbon mixed alcohols and its combined production process

ActiveCN104529704BRealize clean utilizationReduce dependencyOrganic compound preparationHydroxy compound separation/purificationN-Propyl alcoholAlcohol synthesis

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Tail alcohol processing system

PendingCN110255481AReduce volatilityIncrease profitLiquid transferring devicesChemistryAlcohol outlet

The invention provides a tail alcohol processing system. The system comprises a tail alcohol containing device, wherein the tail alcohol containing device is connected with one end of an alcohol pump through a first alcohol pipe, the other end of the alcohol pump is connected with the first end of a tee joint through a second alcohol pipe, the second end of the tee joint is connected with an inlet of a tail alcohol tank, and the third end of the tee joint is connected with an inlet of a tail alcohol large tank through a fourth alcohol pipe. A tail alcohol inlet tank valve is arranged at the joint of the second end of the tee joint and the inlet of the tail alcohol tank, an outlet of the tail alcohol tank is connected with a ground kettle through a third alcohol pipe, a tail alcohol outlet tank valve is arranged at the joint of the outlet of the tail alcohol tank and the third alcohol pipe, and an inlet ground kettle valve is arranged at the joint of the third alcohol pipe and the ground kettle. A tail alcohol inlet large tank valve is arranged at the joint of the third end of the tee joint and the fourth alcohol pipe, and a tail alcohol large tank valve is arranged at the joint of the fourth alcohol pipe and the inlet of the tail alcohol large tank. The system has the beneficial effects that the structure is simple, the operation is convenient, multiple storage channels exist, the functions are complete, the utilization rate of tail alcohol is improved, the application range is wide, and the system is suitable for popularization and application.

Owner:普瑞特机械制造股份有限公司

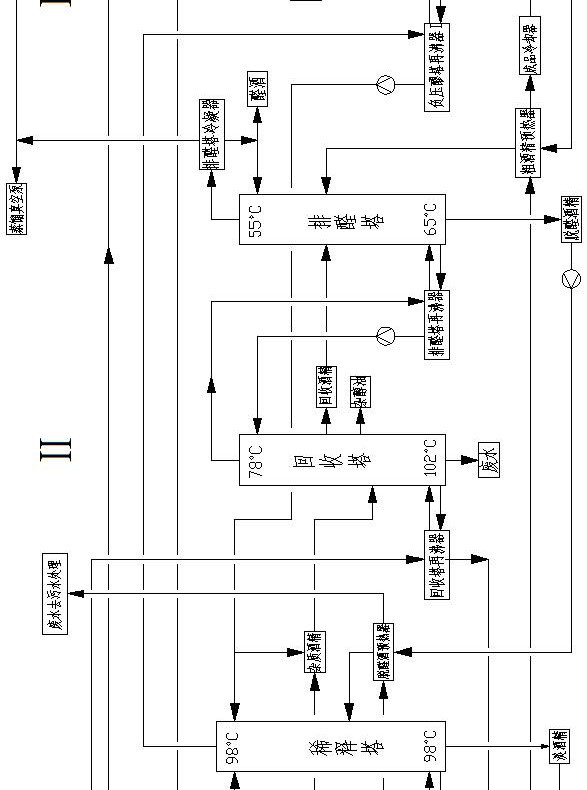

Wastewater separation device of dibutyl phthalate production system

InactiveCN105800853AReduce processing costsEfficient recyclingFatty/oily/floating substances removal devicesOrganic compound preparationAlcoholWastewater

The invention discloses a wastewater separation device of a dibutyl phthalate production system. The wastewater separation device comprises a horizontal separation tank, a heating tank, a wastewater tower, a condenser and a liquid separation tank, wherein a feeding port is formed in the front end of the horizontal separation tank, an ester returning port is formed in the top of the back end of the horizontal separation tank, a wastewater drain outlet is formed in the bottom of the back end of the horizontal separation tank and communicated with the heating tank, the wastewater tower is arranged at the top of the heating tank, the top of the wastewater tower is communicated with a gas inlet of the condenser, a liquid outlet of the condenser is communicated with the upper end of the liquid separation tank, and the liquid separation tank is provided with an alcohol outlet and a water outlet positioned below the alcohol outlet. The wastewater separation device of the dibutyl phthalate production system has the advantages that products and raw materials are recycled effectively, environmental pollution is reduced and later-period water treatment cost is lowered.

Owner:安徽力天环保科技股份有限公司

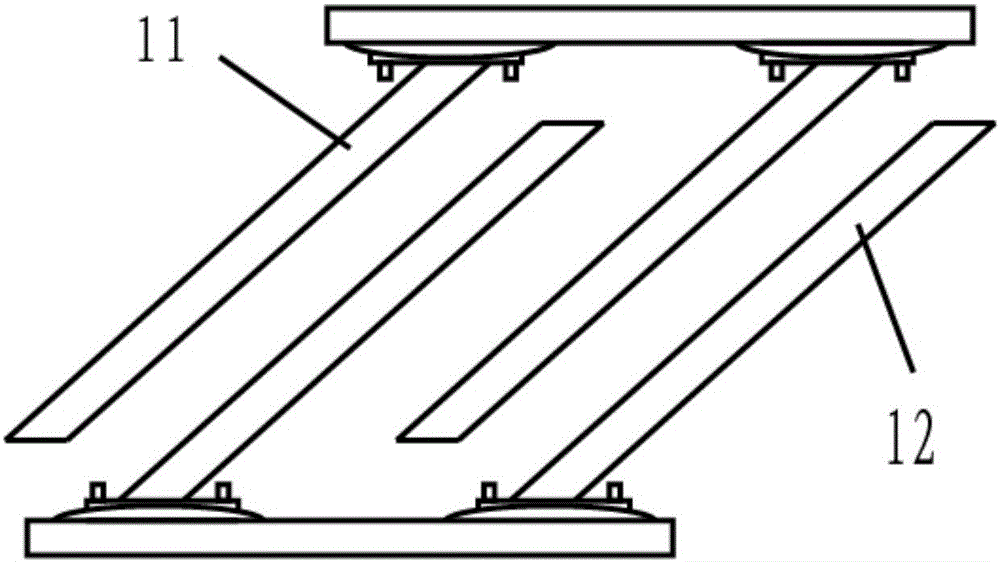

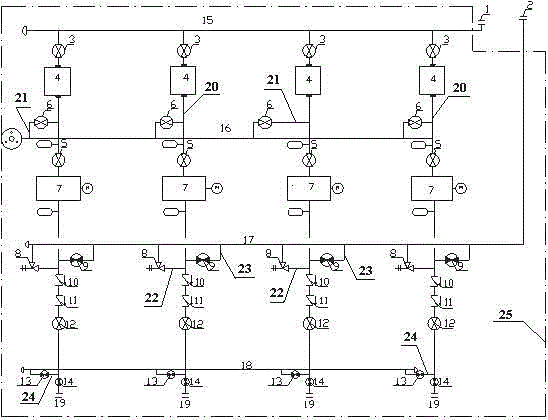

Skid-mounted device based on large cluster well group alcohol injection system

The invention provides a skid-mounted device based on a large cluster well group alcohol injection system. The skid-mounted device comprises a first header and a plurality of methanol alcohol conveying pipes connected in parallel, wherein the first header is communicated with a methanol alcohol tank through a first connector; the inlet end of each methanol alcohol conveying pipe is communicated with the first header; the other end of each methanol alcohol conveying pipe is connected with a methanol alcohol outlet; the first header and the methanol alcohol conveying pipes are arranged on a prying base. The skid-mounted device based on the large cluster well group alcohol injection system facilitates management of a large cluster well group, avoids wellhead stopping and influence on downstream production operation caused by trouble shooting of a wellhead alcohol injection pump, reduces the cost, reduces the land occupation and accelerates the construction progress.

Owner:XIAN CHANGQING TECH ENG

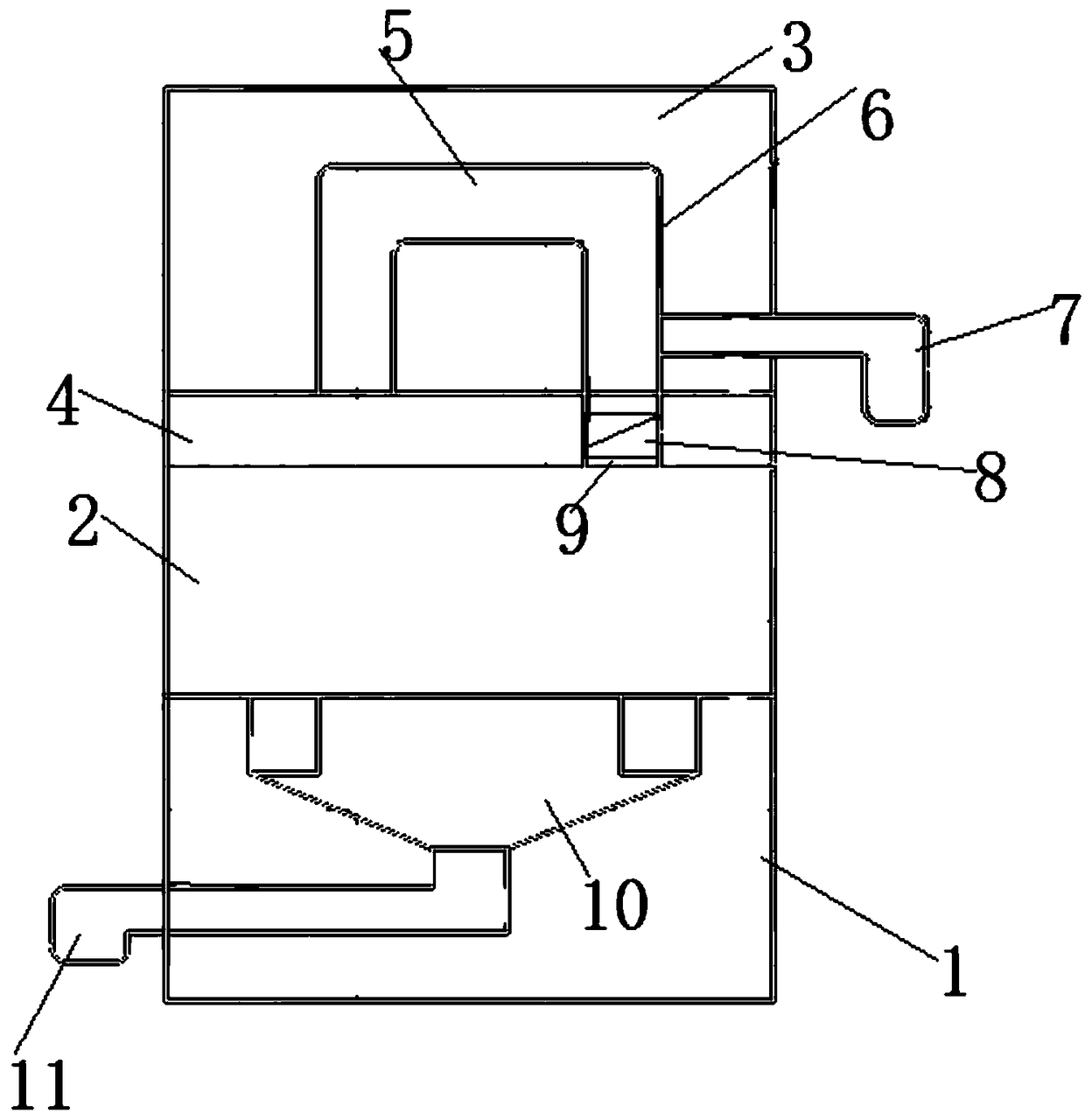

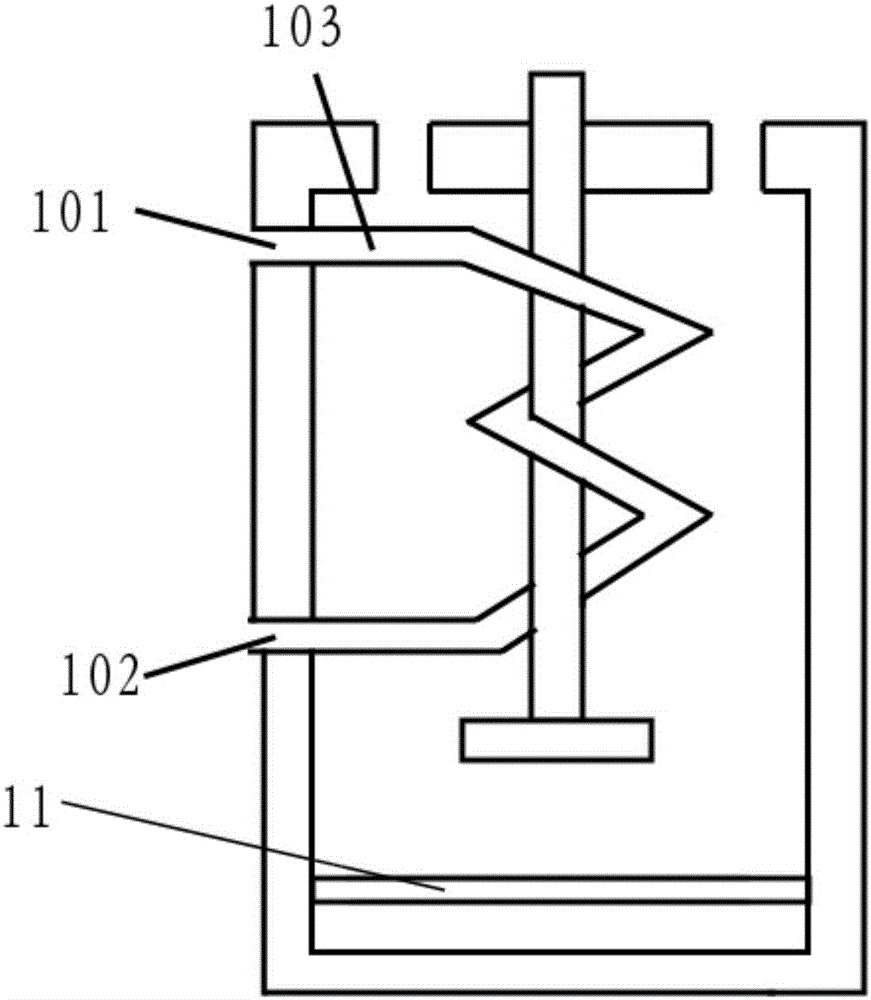

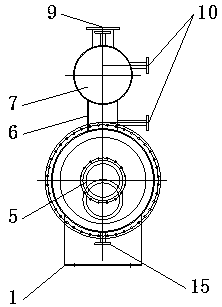

Diisobutyl phthalate neutralizing, washing and dealcoholizing integrated reaction kettle

InactiveCN105797670AIncrease temperatureImprove alcohol vaporization rateChemical/physical/physico-chemical stationary reactorsCarboxylic acid esters separation/purificationControl engineeringSmall footprint

The invention discloses a diisobutyl phthalate neutralizing, washing and dealcoholizing integrated reaction kettle comprising a kettle body. An alcohol outlet is formed in the top of the kettle body, the kettle body is provided with a steam inlet and a steam outlet, one of the steam inlet and the steam outlet is positioned on the upper portion of the kettle body while the other is positioned on the lower portion of the kettle body, a steam pipe is arranged in an inner cavity of the kettle body, and two ends of the steam pipe are communicated with the steam inlet and the steam outlet correspondingly. The diisobutyl phthalate neutralizing, washing and dealcoholizing integrated reaction kettle has the advantages of lower equipment cost, small occupied area, convenience in operation and high dealcoholizing efficiency.

Owner:ANQING SHENGFENG CHEM CO LTD

Alcohol-flavone synchronous distillation tower and distillation method thereof

PendingCN109337788AImprove use valueEasy to adjustFermented solutions distillation/rectificationAlcoholic beverage preparationAlcoholDistillation method

The invention belongs to the technical field of alcohol-flavone preparation and discloses an alcohol-flavone synchronous distillation tower and a distillation method thereof. A fermented to-be-distilled buckwheat sample is put in the distillation tower and heated for distilling alcohol, when alcohol flows into a condensing tower, a probe in the condensing tower detects the concentration of alcohol, and the concentration of alcohol is measured by an alcohol detector; when ending liquor is detected, an alcohol distillation outlet is closed, and alcohol starts to be stored; after alcohol reaches12-15 L, a rotary distillation valve is opened, alcohol flows into the distillation tower, and rotary distillation is started; after 2-2.5 h, distilled flavone is taken out by a lower filtering device, and distillation of alcohol and flavone is realized. With the adoption of the alcohol-flavone synchronous distillation tower, flavone in waste buckwheat can be distilled out, and 30%-40% of the flavone component is saved; flavone is distilled out sufficiently and effectively.

Owner:HUBEI UNIV OF TECH

Activated carbon-removed low-color diisobutyl phthalate production device and production method thereof

PendingCN114832758AGuaranteed overdoseProcess stabilityOrganic compound preparationCarboxylic acid esters separation/purificationActivated carbonTemperature control

The invention relates to the field of chemical engineering, and discloses a deactivated carbon low-color diisobutyl phthalate production device and a production method thereof.The device comprises an esterification kettle with a temperature control device, an esterification tower, a phase splitter, an alcohol-water separator and an alcohol recovery tank which are sequentially connected through pipelines in the material flowing direction; the esterification kettle is provided with a nitrogen inlet, and a reflux pipeline is further arranged between the phase splitter and the alcohol-water separator; the alcohol-water separator comprises an alcohol outlet, the alcohol recovery tank comprises a seventh feed port and a seventh discharge port, the seventh feed port of the alcohol recovery tank is connected with the alcohol outlet of the alcohol-water separator through a pipeline, and the seventh discharge port of the alcohol recovery tank is connected with the alcohol-water separator through a pipeline. In the production process, the nitrogen protection of an esterification kettle is kept, and recovered isobutanol is added at 135-138 DEG C, so that the generation of side reactions and the generation of coloring substances are reduced, the addition of a decolorizing agent is avoided, and the produced diisobutyl phthalate has the characteristic of low color. The process is simple, the device is reliable, and positive quality benefits and environmental protection benefits are achieved.

Owner:ZHEJIANG JIANYE CHEM

A heat source system and method for soil remediation based on thermal desorption

ActiveCN109268804BReal-time adjustment of heating powerTake advantage ofSteam generation heating methodsContaminated soil reclamationAlcoholCombustion

The invention discloses a thermal desorption based soil repair heat source system. The system comprises an ethyl alcohol liquid supply device, an ethyl alcohol steam generator and a combustion heatingfurnace body; the ethyl alcohol outlet end of the ethyl alcohol liquid supply device is connected with the ethyl alcohol inlet end of the ethyl alcohol steam generator through an ethyl alcohol supplypipe; the ethyl alcohol steam outlet end of the ethyl alcohol steam generator is communicated with an ethyl alcohol steam guiding out pipe; by controlling the flow of liquid flowing from the ethyl alcohol supply pipe in real time and adjusting the heating power of an electric heating wire in real time, ethyl alcohol liquid is just gasified completely when flowing to the lower end of a spiral slope surface along an ethyl alcohol gasification spiral slope, and heat emitted by the slope surface of the whole ethyl alcohol gasification spiral slope is sufficiently utilized.

Owner:鸿灌环境技术有限公司

Alcohol extracting device for dioctyl phthalate production system

InactiveCN105833558AReduce processing costsEfficient recyclingOrganic compound preparationDistillation in boilers/stillsAlcoholTower

The invention discloses an alcohol extracting device for a dioctyl phthalate production system. The device comprises a heating tank, a waste water tower, a condenser and a liquid separation tank, wherein the waste water tower is arranged at the top of the heating tank; the top of the waste water tower is connected with a material inlet of the condenser; a liquid outlet of the condenser is connected with the upper end of the liquid separation tank; a water outlet and an alcohol outlet are formed in the liquid separation tank; the water outlet is positioned below the alcohol outlet. The alcohol extracting device has the advantages that raw materials are effectively recovered, environment pollution is reduced, and the cost for the post water treatment is reduced.

Owner:安徽力天环保科技股份有限公司

Low-carbon mixed alcohol separation system and separation method

ActiveCN104529703BHigh purityOrganic compound preparationHydroxy compound separation/purificationAlcoholTower

The invention discloses a separation system and a separation method of low-carbon mixed alcohol. The separation system comprises a low-carbon mixed alcohol feeding device, a methanol rectifying tower, an ethanol rectifying tower, an extraction rectifying tower and a normal propyl alcohol rectifying tower, wherein the low-carbon mixed alcohol feeding device is provided with a low-carbon mixed alcohol outlet; the methanol rectifying tower is provided with a methanol tower feeding hole, a methanol tower top discharging hole and a methanol tower bottom discharging hole, and the methanol tower feeding hole is connected with the low-carbon mixed alcohol outlet; the ethanol rectifying tower is provided with an ethanol tower feeding hole, an ethanol tower top discharging hole and an ethanol tower bottom discharging hole, and the ethanol tower feeding hole is connected with the methanol tower bottom discharging hole; the extraction rectifying tower is provided with an extraction tower feeding hole, an extraction agent feeding hole, an extraction tower top discharging hole and an extraction tower bottom discharging hole, and the extraction tower feeding hole is connected with the ethanol tower top discharging hole; the normal propyl alcohol rectifying tower is provided with a normal propyl alcohol tower feeding hole, a normal propyl alcohol tower top discharging hole and a normal propyl alcohol tower bottom discharging hole, and the normal propyl alcohol tower feeding hole is connected with the ethanol tower bottom discharging hole. In the separation system, a purification mode that a rectifying system is combined with an extraction system is utilized, so that obtained monoalcohol has relatively high purity.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Distillation system and distillation method for producing super-superior alcohol by six-tower triple-effect differential pressure distillation

PendingCN114642894ARealize multi-effect thermal couplingReduce energy consumptionOrganic compound preparationHydroxy compound preparationWater savingAlcohol

The invention relates to a distillation system and a distillation method for producing super-superior alcohol by six-tower triple-effect differential pressure distillation. The distillation system comprises a negative pressure mash tower, an aldehyde discharge tower, a recovery tower, a dilution tower, a methanol removal tower and a rectifying tower, a crude alcohol outlet of the negative-pressure mash tower and a crude alcohol outlet of the degassing section are both communicated with a working cavity of the aldehyde discharging tower, a dealdehyded alcohol outlet of the aldehyde discharging tower is communicated with a working cavity of the diluting tower, a light alcohol outlet of the diluting tower is communicated with a working cavity of the rectifying tower, and a rectified alcohol outlet of the rectifying tower is communicated with a working cavity of the methanol removing tower; the impurity alcohol outlet of the rectifying tower is communicated with the working cavity of the recovery tower. Through the arrangement of the system structure, multi-effect thermal coupling, one-tower steam admission and six-tower work are realized, the energy consumption in the distillation process is reduced to the greatest extent, and the water-saving and steam-saving effects are remarkable; compared with five-tower triple-effect superior alcohol distillation equipment, by adding the aldehyde discharge tower, the product quality far exceeds the superior grade, part of indexes exceed the special grade, and the product quality is obviously improved.

Owner:肥城金塔机械科技有限公司

Ester recovery device for dibutyl phthalate production

InactiveCN105837446AImprove layering timeRealize dynamic separationCarboxylic acid esters separation/purificationAlcoholWastewater

The invention discloses an ester recovery device for dibutyl phthalate production. The device comprises an alcohol removing kettle, a horizontal separation tank and a secondary standing tank, wherein a water outlet and a liquid outlet are formed in the bottom of the alcohol removing kettle, and an alcohol outlet is formed in the upper part of the alcohol removing kettle; a feed opening is formed in the front end of the horizontal separation tank, a first ester return port is formed in the top of the rear end of the horizontal separation tank, and a wastewater outlet is formed in the bottom of the rear end of the horizontal separation tank; the water outlet is communicated with the feed opening, and the first ester return port is communicated with the alcohol removing kettle; the liquid outlet is communicated with the top of the secondary standing tank; a second ester return port is formed in the sidewall of the secondary standing tank, and is communicated with the alcohol removing kettle. The device has the advantages of simple structure and capability of effectively recovering a product and reducing environmental pollution.

Owner:安徽力天环保科技股份有限公司

Co-production distillation energy-saving device and its energy-saving technology for general-grade and premium-grade edible alcohol

ActiveCN104232455BReduce consumptionReduce energy consumptionAlcoholic beverage preparationAlcoholDistillation

The invention discloses a common and superior edible alcohol co-production distillation energy-saving device and an energy-saving process thereof. The common and superior edible alcohol co-production distillation energy-saving device comprises a coarse distillation tower, a combined tower, a water scrubbing tower, a rectification tower, a methanol tower and a mash preheating device, wherein the mash preheating device, the coarse distillation tower and the combined tower are sequentially communicated with one another; the rectification tower, the water scrubbing tower and the methanol tower are sequentially communicated with one another; the mash preheating device is further communicated with the water scrubbing tower; the mash preheating device is communicated with a mature fermented mash feeding pipeline; the combined tower is provided with a common alcohol outlet, and the methanol tower is provided with a superior alcohol outlet. The common and superior edible alcohol co-production distillation energy-saving device provided by the invention can ensure flexible adjustment between common edible alcohol and superior edible alcohol, can rapidly meet market demands, and lowers steam consumption and water consumption of a whole set of distillation system.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

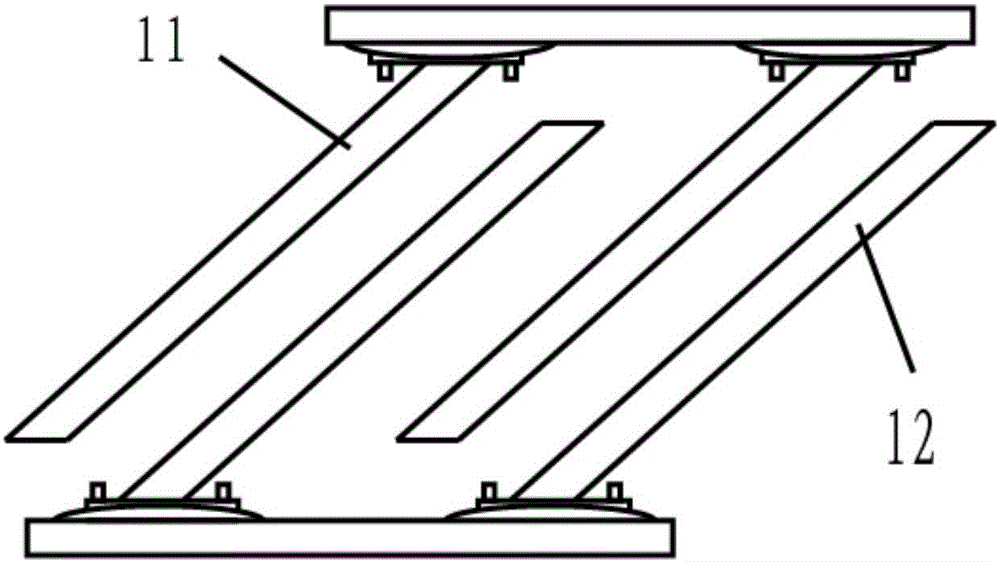

Energy-saving graphite heat exchanger utilizing methane chloride for achieving synthesis of heat energy and production method

InactiveCN107490315AReduce usageReduce heatingRecuperative heat exchangersChemical industryLiquid level measurementAlcohol

The invention discloses an energy-saving graphite heat exchanger utilizing methane chloride for achieving synthesis of heat energy. The graphite heat exchanger comprises a base, a barrel on the base, a plurality of communication tubes on the barrel and a vaporization barrel connected to the upper portions of the communication tubes, wherein a feeding end cover plate is arranged at one end of the barrel, a feeding end socket is arranged in the position, on the inner side of the feeding end cover plate, of the barrel, and the feeding end cover plate and the feeding end socket are provided with feeding inlets; a discharging end cover plate is arranged at the other end of the barrel, a discharging end socket is arranged in the position, on the inner side of the discharging end cover plate, of the barrel, and the discharging end cover plate and the discharging end socket are provided with discharging outlets; the discharging end cover plate is connected with the barrel through a compression spring bolt; a graphite heat exchange block is arranged in the position, between the feeding end socket and the discharging end socket, of the barrel; the graphite heat exchange block is provided with a plurality of sets of transverse holes and a plurality of sets of longitudinal holes; a methyl alcohol inlet is formed in the bottom of the barrel; a vaporize methyl alcohol outlet is formed in the upper portion of the vaporization barrel; and the communication tubes and the vaporization barrel are provided with liquid level measurement openings. The graphite heat exchanger is simple in structure, heating can be conducted through reaction heat energy of the graphite heat exchanger, reactant can be cooled through the temperature of raw materials, and energy-saving production is achieved.

Owner:NANTONG HUANAITE GRAPHITE EQUIP

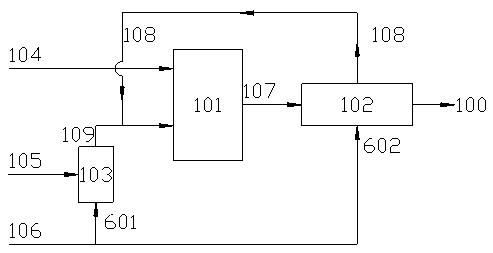

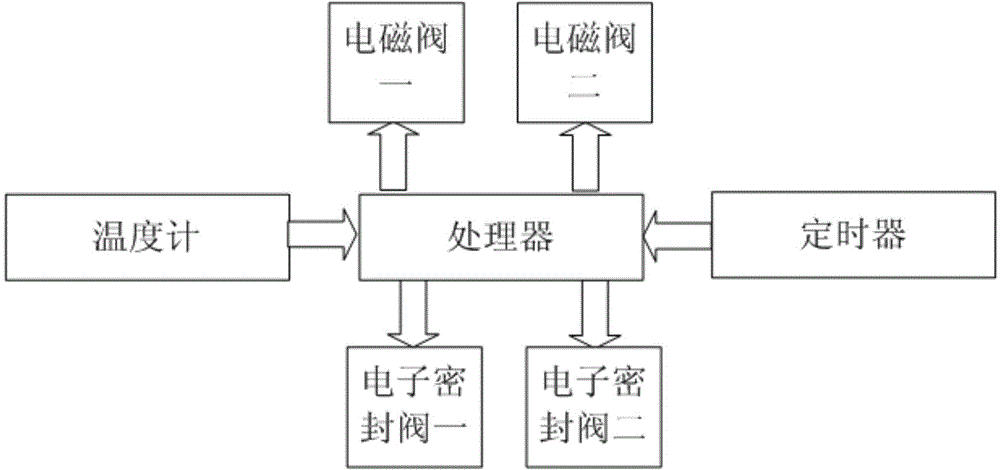

Control system of recyclable alcohol extraction device

InactiveCN104667567AEliminate inefficienciesPrecise managementSolvent extractionEvaporator accessoriesAlcoholAutomatic control

Owner:XIAN GUOLONG BAMBOO TECH

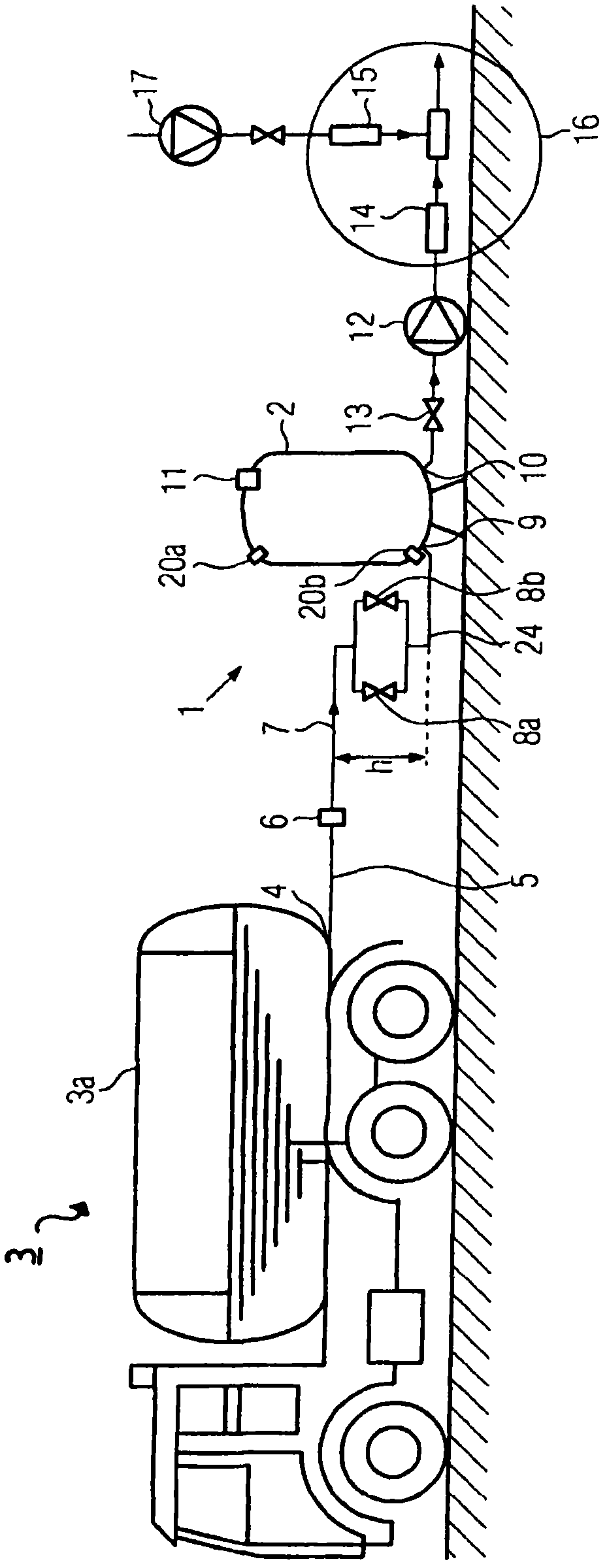

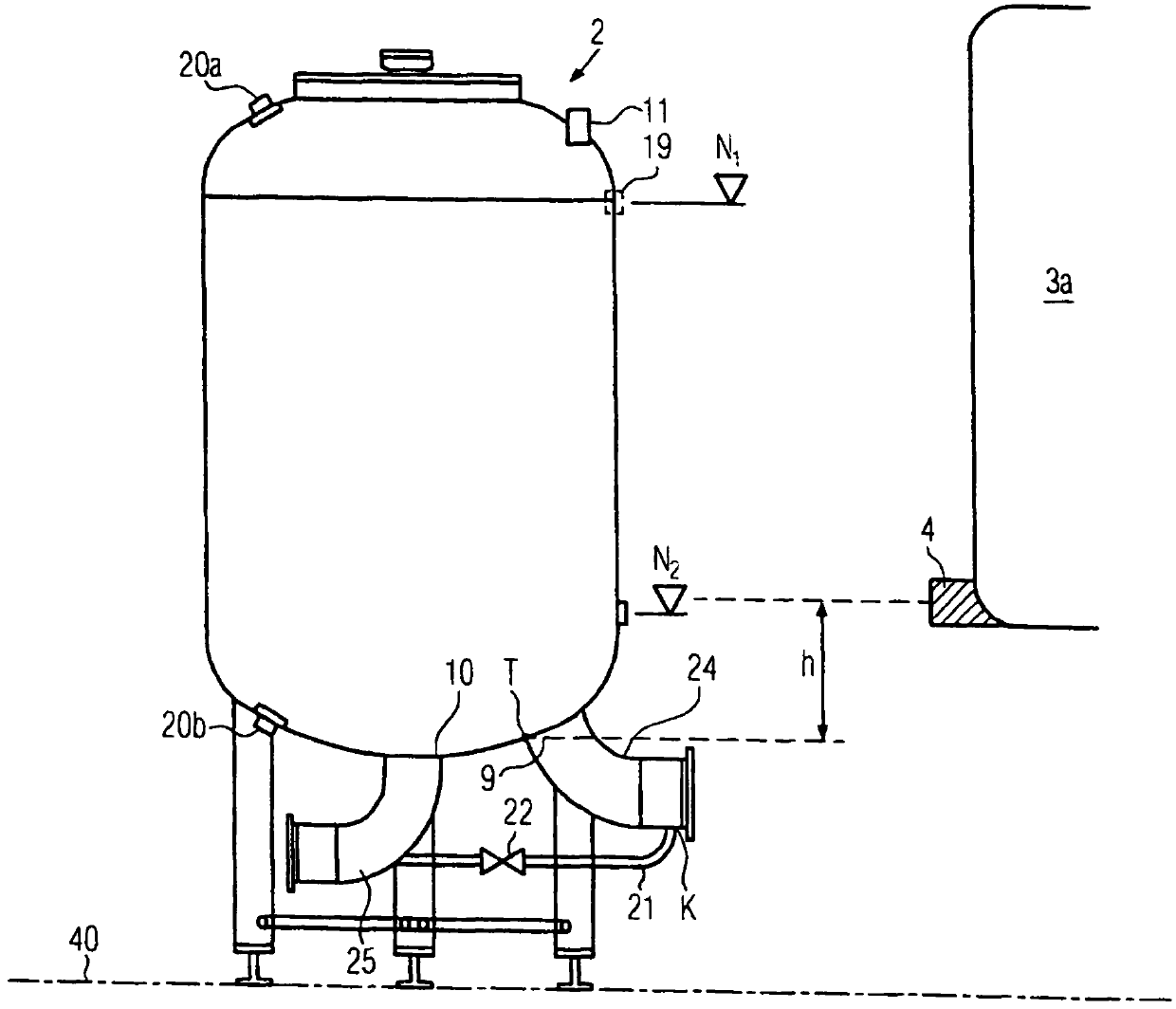

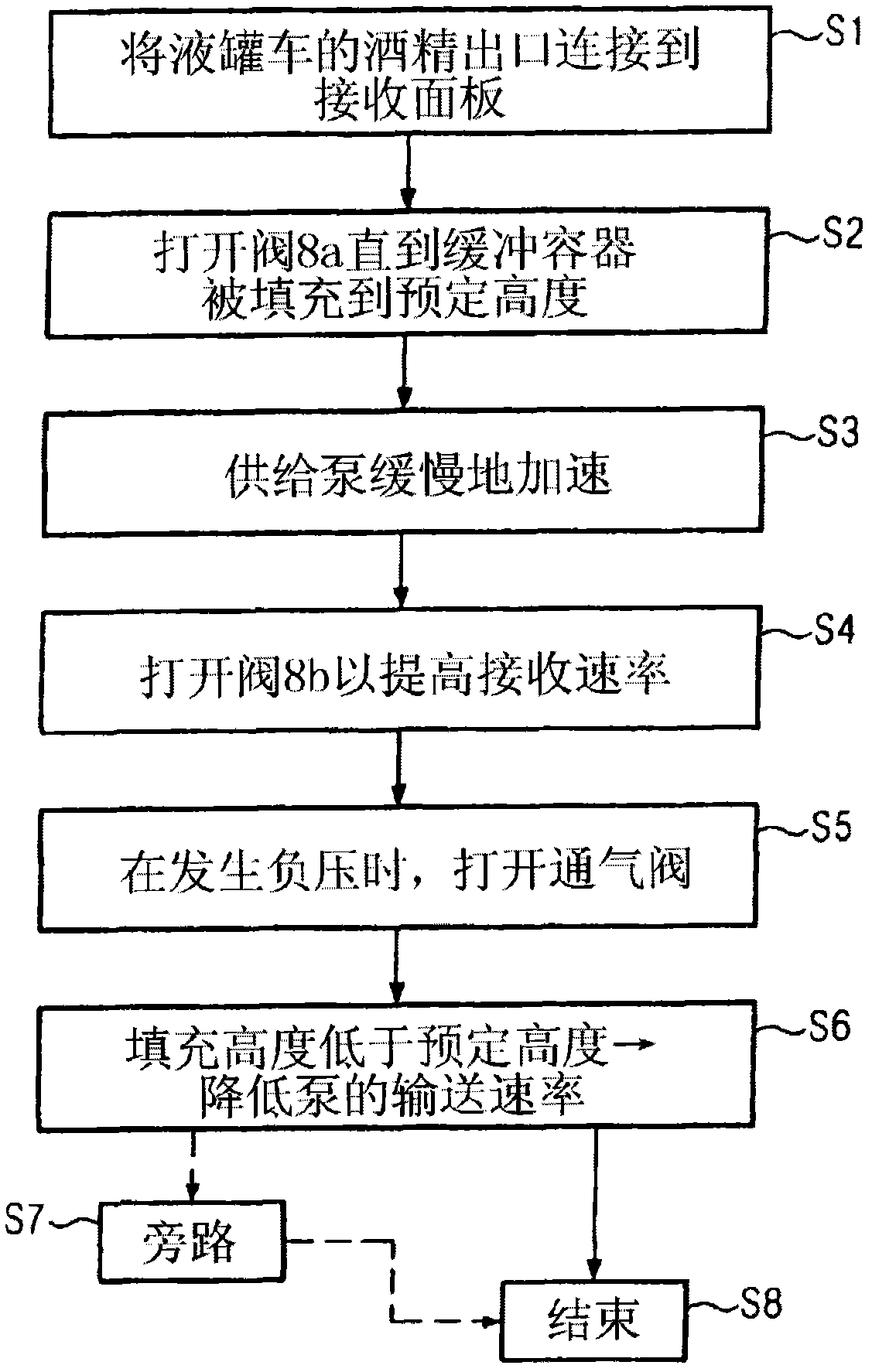

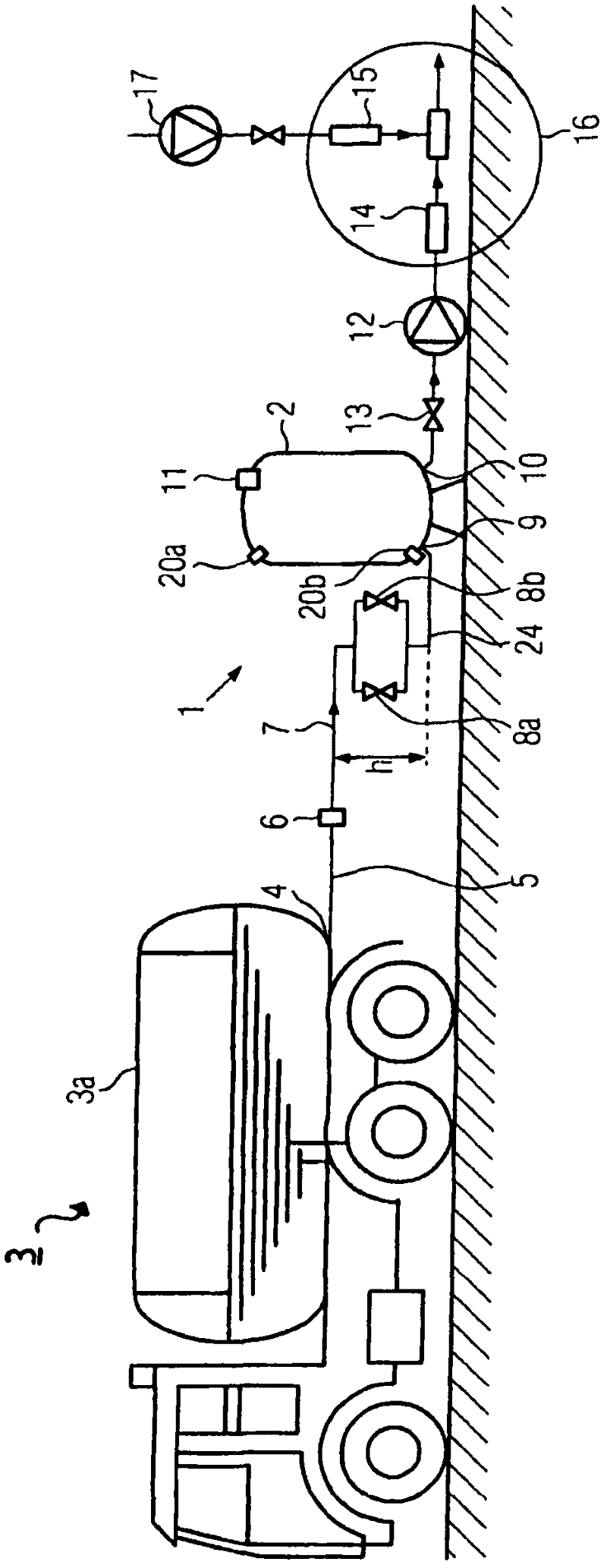

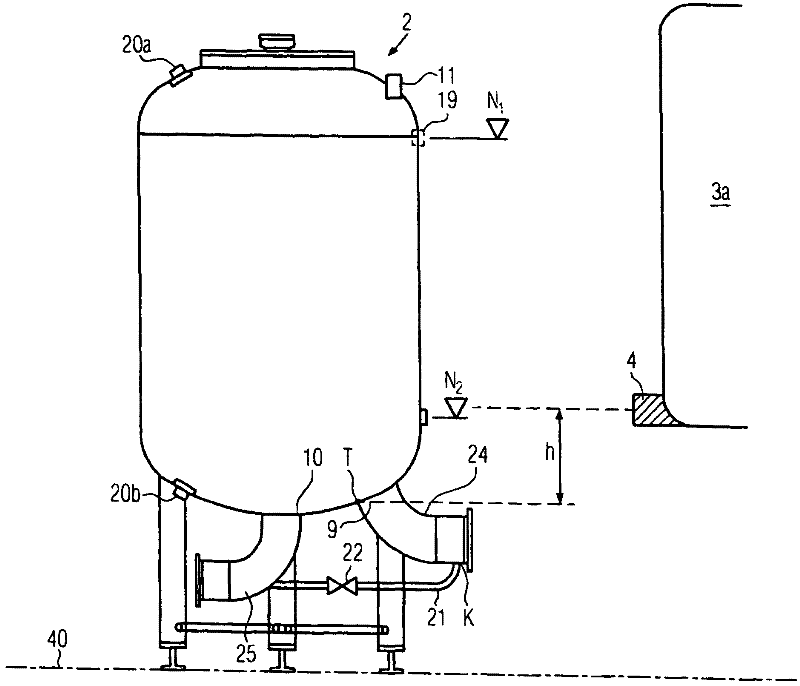

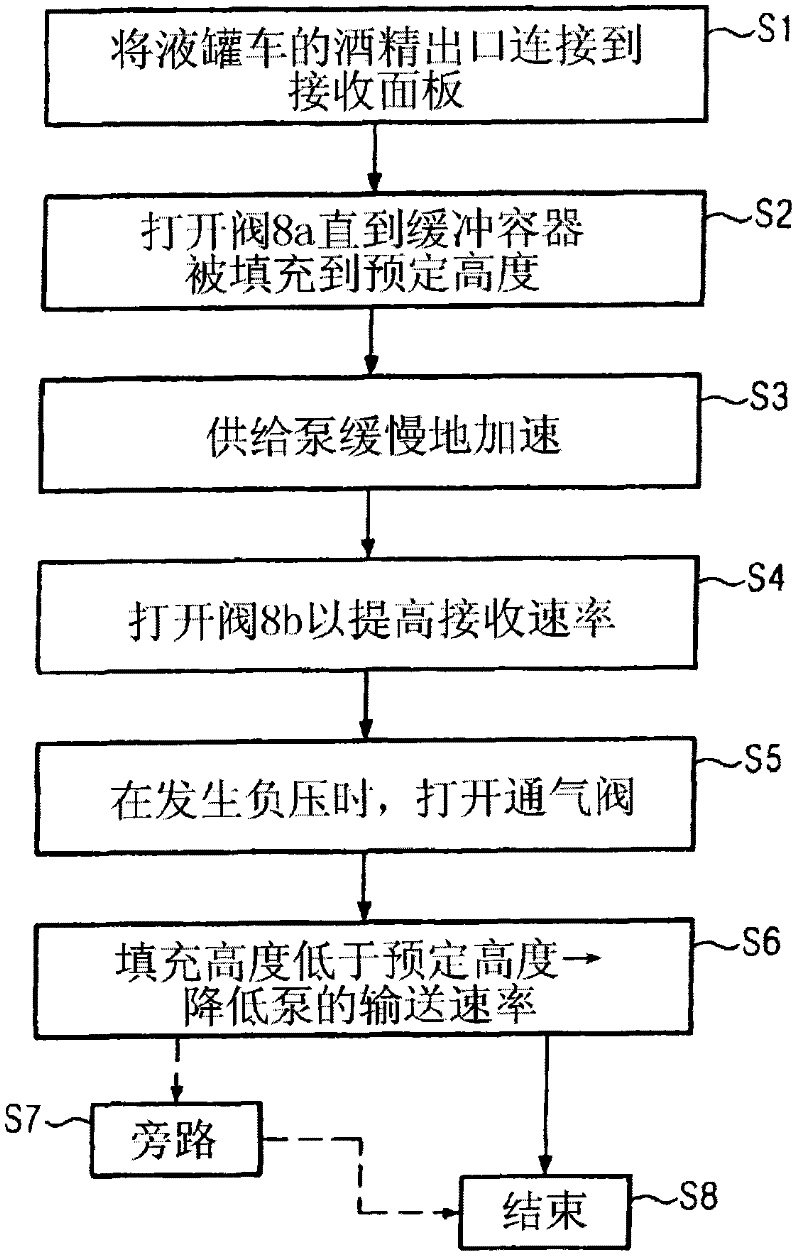

Alcohol receiving station

InactiveCN102245497BAccurately determineRegulating volume flowLiquid degasification regulation/controlLiquid transferring devicesAbove groundEngineering

The invention relates to a device and to a method for receiving highly volatile liquids, in particular for receiving alcohol from a tank truck having a degassing container, into which alcohol is conducted from the tank truck, wherein the degassing container has an alcohol inlet and an alcohol outlet. The alcohol inlet and the alcohol outlet are arranged in the lower area of the degassing container, and the device for receiving alcohol may thus be located above ground.

Owner:KRONES AG

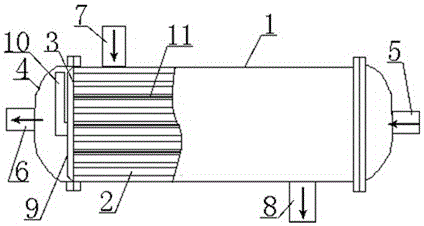

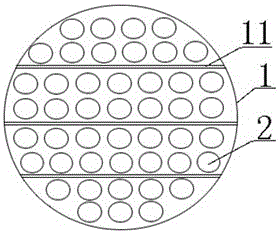

Alcohol Recovery Condenser for Heparin

ActiveCN105066746BSolve the phenomenon of corrosionImprove commutative lawStationary tubular conduit assembliesAlcoholEngineering

The invention relates to a recycling condenser for ethyl alcohol for heparin. The recycling condenser comprises a shell, cooling water pipes, separating plates and end covers. The separating plates are installed at the two ends of the shell and provided with a plurality of round holes. The cooling water pipes are installed between the round holes. The end covers are installed at the two ends of the shell. A cooling water inlet is formed in the end cover on the right side. A cooling water outlet is formed in the end cover on the left side. An ethyl alcohol steam inlet is formed in the upper end of the shell. An ethyl alcohol outlet is formed in the lower end of the shell. The outer side of the separating plate on the left side of the shell is connected with a sealing covering plate, a flow guide pipe is installed in the middle of the sealing covering plate, and an outlet of the flow guide pipe is upward and located in the uppermost end of the corresponding end cover. Three dripping plates are transversely installed in the middle of the shell, evenly installed in the upper, middle and lower positions inside the shell respectively, and located among the multiple cooling water pipes. The recycling condenser for ethyl alcohol for heparin has the advantages of being simple and ingenious in design, avoiding the phenomenon of corrosion of condensate water above to a row of tubes at the interface of the condenser, being small in loss of ethyl alcohol, and paying the condensation effect to the maximum extent.

Owner:南通天龙畜产品有限公司

High-purity anhydrous alcohol production system, and method for producing high-purity anhydrous alcohol

PendingCN113069783AAchieve reuseGood energy saving effectOrganic compound preparationEnergy recuperation in distillationReboilerAlcohol production

The invention discloses a high-purity anhydrous alcohol production system. The system comprises a raw material tank, a fourth-effect light component removal tower, a first-effect rectifying tower, a second-effect rectifying tower, a third-effect rectifying tower, adsorption equipment and an evaporation recovery tower; the raw material tank is connected with the middle inlet end of the fourth-effect light component removal tower; the alcohol steam outlet end at the top of a fourth-effect light component removal tower is connected with the inlet end of a condenser of the light component removal tower; an alcohol outlet end at the bottom of the fourth-effect light component removal tower is connected with an inlet end at the middle lower part of the third-effect rectifying tower; an outlet end at the bottom of the third-effect rectifying tower is connected with an inlet end at the middle lower part of the second-effect rectifying tower; an alcohol outlet end at the bottom of the second-effect rectifying tower is connected with an inlet end at the middle lower part of the first-effect rectifying tower; an alcohol steam outlet end at the top of the first-effect rectifying tower is connected with an inlet end of a reboiler of the second-effect rectifying tower; an alcohol steam outlet end at the top of the second-effect rectifying tower is connected with an inlet end of a reboiler of the third-effect rectifying tower; and an alcohol steam outlet end at the top of the third-effect rectifying tower is connected with an inlet end of a reboiler of the fourth-effect light component removal tower. The production cost is low, and the steam consumption for producing one ton of anhydrous alcohol is not more than 0.5 ton.

Owner:肥城金塔机械科技有限公司

Wastewater lifting device for producing dioctyl phthalate

InactiveCN105800854AReduce processing costsEfficient recyclingFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWastewaterPhthalate

The invention discloses a wastewater lifting device for producing dioctyl phthalate. The wastewater lifting device comprises a horizontal separating tank, a heating tank, a wastewater tower, a condenser and a liquid separating tank, the front end of the horizontal separating tank is provided with a feeding port, the top of the rear end of the horizontal separating tank is provided with an ester returning port, a wastewater discharging port is arranged at the bottom of the rear end of the horizontal separating tank and communicated with the heating tank, the wastewater tower is arranged at the top of the heating tank the top of the wastewater tower is communicated with an air inlet of the condenser, a liquid outlet of the condenser is communicated with the upper end of the liquid separating tank, a water outlet and an alcohol outlet are arranged on the liquid separating tank, and the water outlet is positioned below the alcohol outlet. The wastewater lifting device has the advantages that products and raw materials are effectively recycled, environment pollution is reduced, and subsequent water treatment cost is lowered.

Owner:安徽力天环保科技股份有限公司

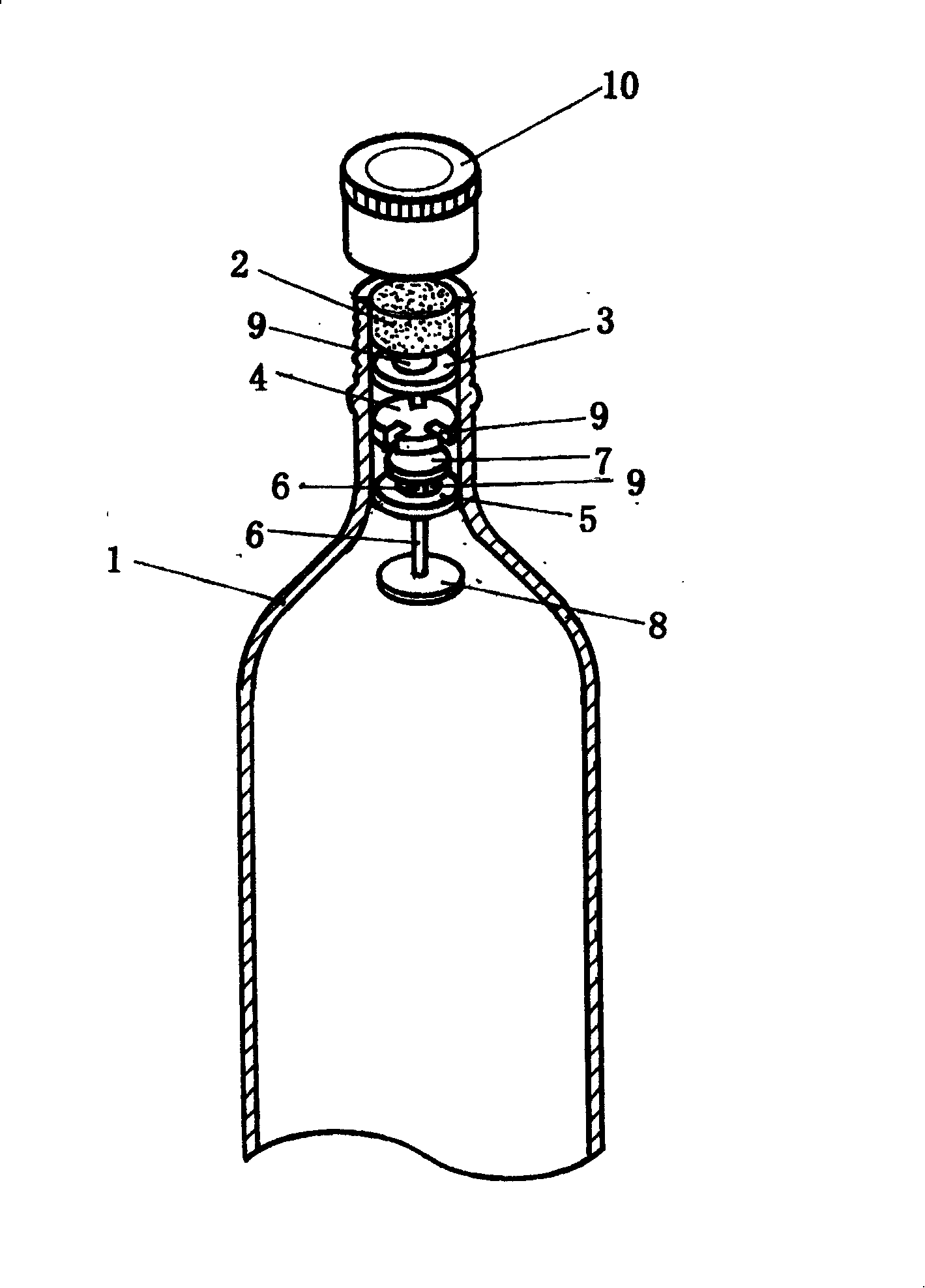

Wine bottle

InactiveCN101190729APut an end to the phenomenon of filling fake wineClosures to prevent refillingWine bottleEngineering

The invention provides a winebottle and comprises an upper outlet ring, an opening plunger, a lower outlet ring which are successively arranged under the opening plunger in the bottle mouth in the upper part of the winebottle from top to bottom; wherein, the centers of the upper outlet ring and the lower outlet ring are provided with alcohol outlets and the surrounding of the opening plunger is provided with a plurality of alcohol outlets; the upper end of an axle in the alcohol outlet in the center of the lower outlet ring is connected with an alcohol outlet cover and the lower end is connected with an alcohol outlet valve; the bottle opening in the upper part of the winebottle is provided with a bottle lip. When the invention is empty, alcohol can not be infused into the bottle from the bottle opening, thereby effectively stamping out the phenomenon of filling adulterated wine by using empty bottles.

Owner:张念现

Alcohol receiving station

InactiveCN102245497AAccurately determineRegulating volume flowLiquid degasification regulation/controlLiquid transferring devicesAbove groundWaste management

The invention relates to a device and to a method for receiving highly volatile liquids, in particular for receiving alcohol from a tank truck having a degassing container, into which alcohol is conducted from the tank truck, wherein the degassing container has an alcohol inlet and an alcohol outlet. The alcohol inlet and the alcohol outlet are arranged in the lower area of the degassing container, and the device for receiving alcohol may thus be located above ground.

Owner:KRONES AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com