Alcohol Recovery Condenser for Heparin

A technology of alcohol recovery and condenser, which is applied in the direction of heat exchanger type, indirect heat exchanger, fixed tubular conduit assembly, etc. It can solve the problems of reduced condensation area, reduced condensation efficiency of condenser, and uneven cooling liquid. Achieve the effect of increasing heat exchange time, reasonable and compact structure, simple and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

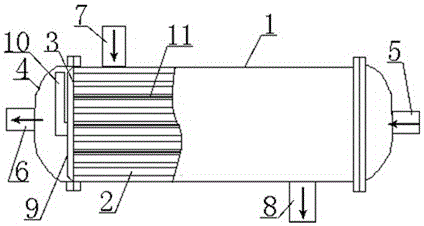

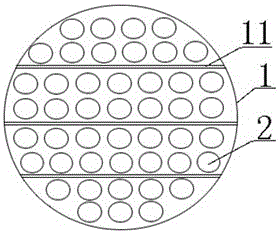

[0012] In order to further illustrate the present invention, introduce below in conjunction with accompanying drawing of description:

[0013] With reference to accompanying drawing, heparin uses the alcohol recovery condenser, and it comprises housing 1, cooling water pipe 2, partition 3, end cover 4, housing 1 two ends are equipped with partition 3, and partition 3 is equipped with some round holes, some Cooling water pipes 2 are installed between the round holes, end caps 4 are installed at both ends of the housing 1, cooling water inlet 5 is installed on the right end cover, cooling water outlet 6 is installed on the left end cover, and the upper end of the housing 1 is equipped with Alcohol steam inlet 7, alcohol outlet 8 is installed at the lower end of the housing, a sealing cover 9 is connected to the outer side of the partition 3 on the left side of the housing 1, and a diversion tube 10 is installed in the middle of the sealing cover 9, and the outlet of the diversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com