Magnesium alloy raw material or magnesium alloy product and its conductive anti-corrosion coating method

A conductive anti-corrosion and magnesium alloy technology, which is applied in the direction of metal material coating process, coating, metal layered products, etc., can solve the problems of poor corrosion resistance, poor bonding force, poor electrical conductivity, etc., and reduce production costs , improve production efficiency, and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

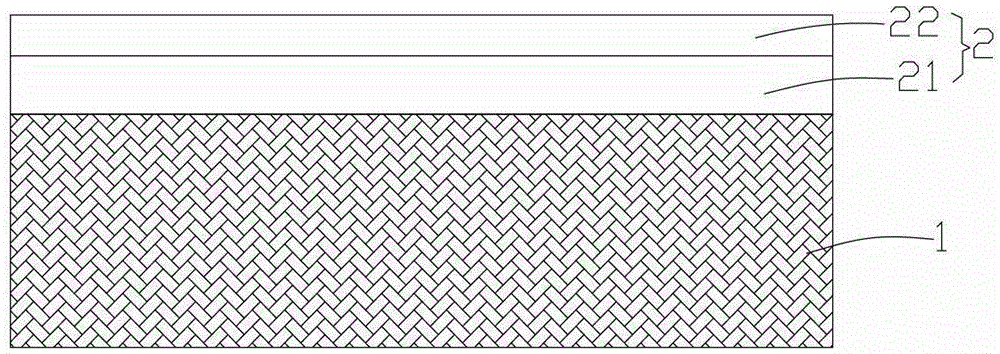

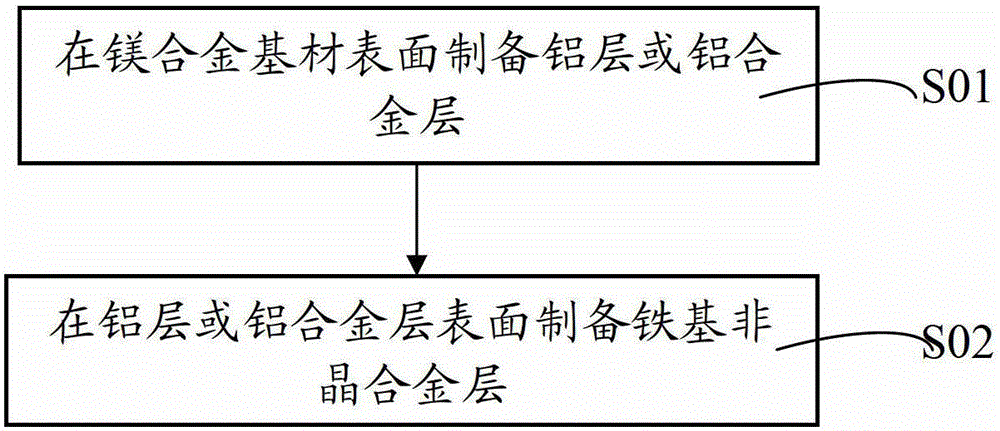

[0100] The invention discloses a magnesium alloy AZ91D raw material and a method for preparing a conductive anti-corrosion coating on its surface.

[0101] The preparation method of the conductive anti-corrosion coating on the surface of the magnesium alloy AZ91D raw material is as follows:

[0102] (1) Dirt stripping and cleaning treatment: Magnesium alloy AZ91D is used as the base material, and ultrasonic acetone is used for degreasing treatment first;

[0103] (2) Surface roughness treatment of the magnesium alloy AZ91D base material: the magnesium alloy AZ91D base material treated in step (1) is sandblasted with 120# white corundum sand grains to treat its surface, and the surface of the treated base material has a certain roughness A uniform rough surface with a roughness of 90±10 microns;

[0104] (3) Prepare an aluminum layer on the surface of the magnesium alloy AZ91D substrate: use supersonic flame spraying technology, the supersonic flame spraying process can be set...

Embodiment 2

[0116] A magnesium alloy AZ31 raw material and a method for preparing a conductive anti-corrosion coating on its surface.

[0117] The preparation method of the conductive anticorrosion coating on the surface of the magnesium alloy AZ31 raw material is as follows:

[0118] (1) Dirt stripping and cleaning treatment: using magnesium alloy AZ31 as the base material, first use ultrasonic acetone for degreasing treatment;

[0119] (2) Surface roughness treatment of the magnesium alloy AZ31 substrate: the magnesium alloy AZ31 substrate treated in step (1) is sandblasted with 120# white corundum sand grains to treat its surface, and the surface of the treated substrate has a certain roughness A uniform rough surface with a roughness of 80±10 microns;

[0120] (3) Prepare an aluminum layer on the surface of the magnesium alloy AZ31 substrate: Atmospheric plasma spraying technology is used. The atmospheric plasma spraying process can be set and debugged according to the operating inst...

Embodiment 3

[0132] The invention discloses a magnesium alloy AZ91D raw material and a method for preparing a conductive anti-corrosion coating on its surface.

[0133] The preparation method of the conductive anti-corrosion coating on the surface of the magnesium alloy AZ91D raw material is as follows:

[0134] (1) Dirt stripping and cleaning treatment: three samples of magnesium alloy AZ91D raw materials were obtained, defined as sample 1, sample 2 and sample 3, and each sample was treated according to step (1) of Example 1;

[0135] (2) Surface roughening treatment of magnesium alloy AZ91D substrate: Surface roughening treatment was carried out on sample 1, sample 2 and sample 3 respectively. The surface roughness of sample 3 is 90±10 microns;

[0136] (3) Prepare an aluminum layer on the surface of the magnesium alloy AZ91D substrate: use supersonic flame spraying technology, the supersonic flame spraying process can be set and debugged according to the operating instructions, using i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com