Patents

Literature

32results about How to "Improve anti-corrosion and wear-resistant effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

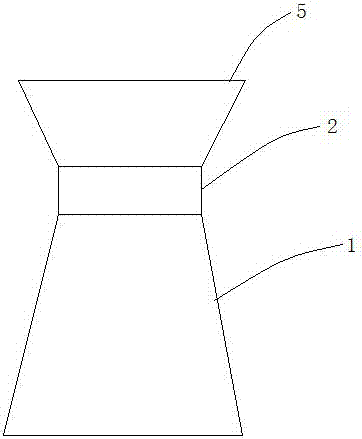

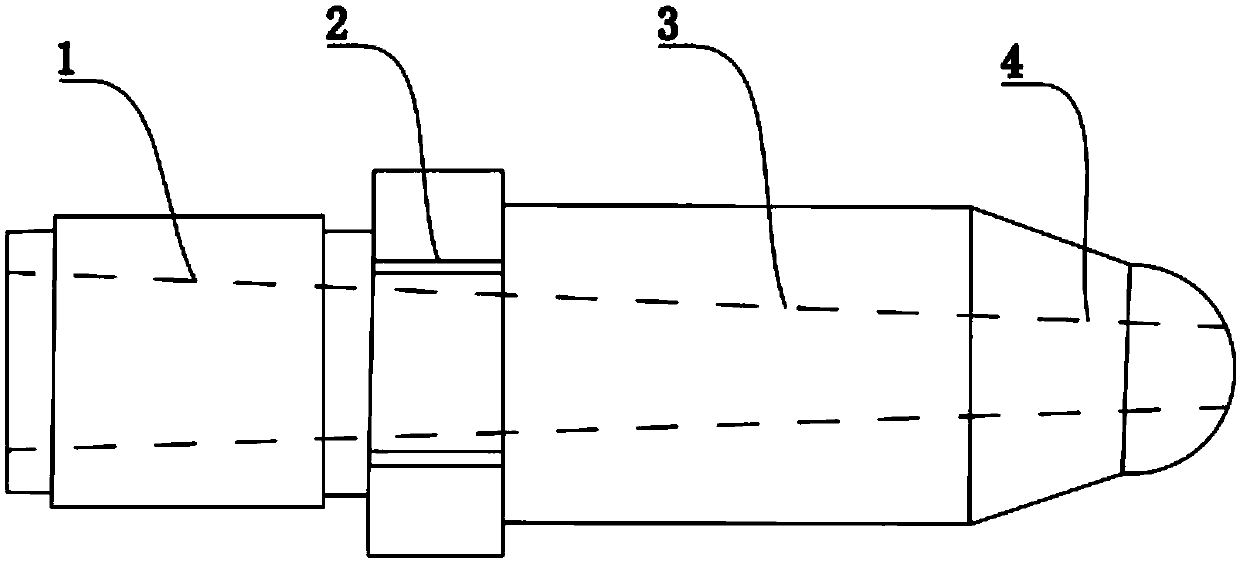

Hardening ceramic processing method for surface of piston rod

InactiveCN1403710AImprove anti-corrosion and wear-resistant effectShort cyclePositive displacement pump componentsLiquid fuel engine componentsWear resistanceMachining

The hardening ceramic processing method for surface of piston rod includes the steps of forging, normalizing, coarse machining, seasoning, semi-finishing, stress-eliminating tempering, coarse grinding, spraying ceramic and finishing. Compared with conventional production process, the present invention has reduced hot processing time, lowered rejected product rate, and greatly increased piston rod life.

Owner:SHENYANG YUANDA COMPRESSOR

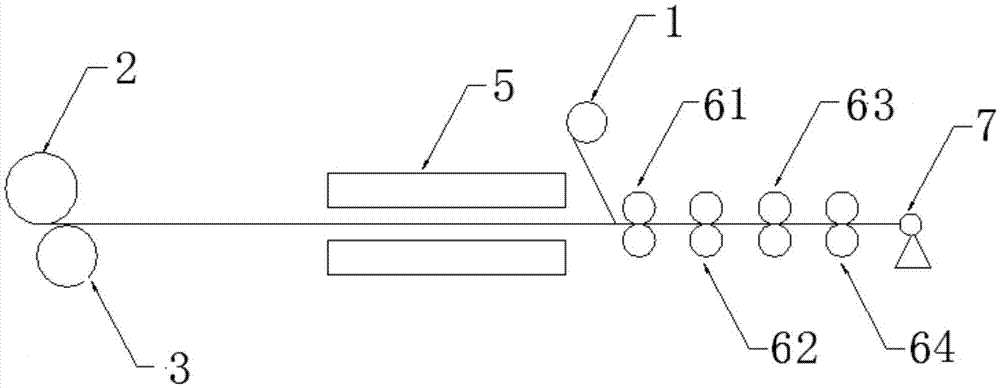

High speed fuel gas spraying process for treating piston rod surface

InactiveCN1986886AImprove anti-corrosion and wear-resistant effectShort cycleSuperimposed coating processPiston rodsHot workingWear resistance

The present invention is ceramic hardening treatment process for the surface of piston rod and aims at simplifying piston rod production, lowing the production cost and raising the product quality. The piston rod production process of the present invention includes the steps of: forging, normalizing, coarse machining, tempering, semi-finishing, stress eliminating tempering, coarse grinding, HVOF and finishing. The production process with ceramic treatment has greatly reduced hot working time and raised product quality, and the piston rod with antiwear and anticorrosive ceramic layer has greatly increased service life.

Owner:任希文

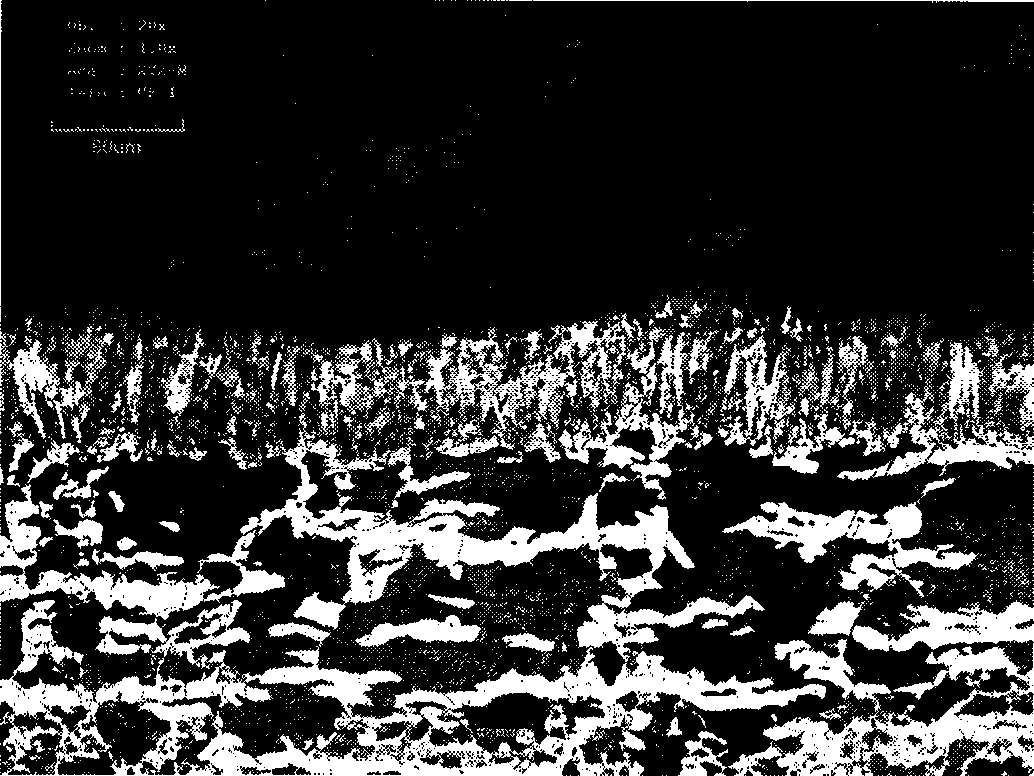

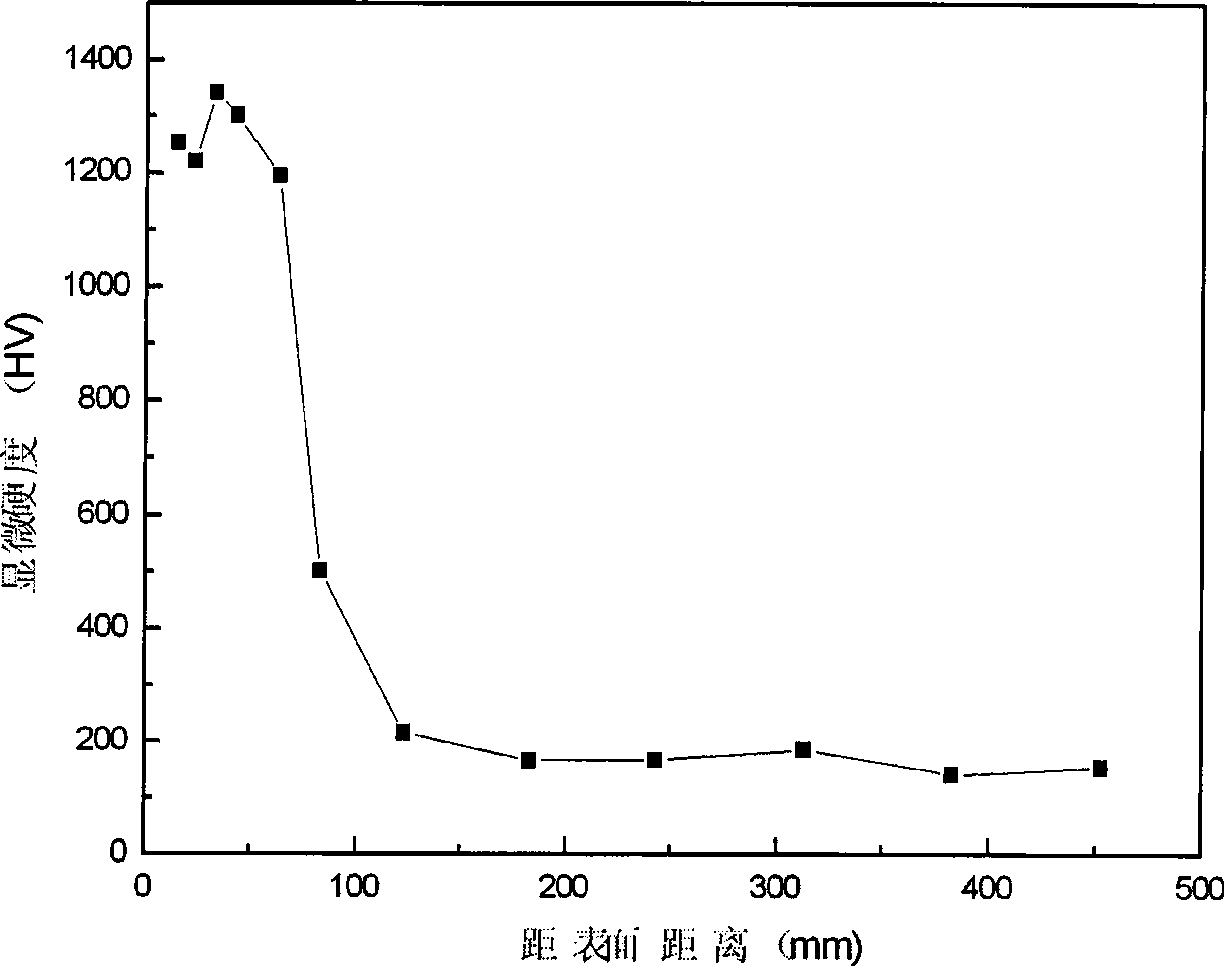

Oil well tubing coupling and sucker rod joint integrated boriding method

InactiveCN101487110AEasy to stretchGood anti-corrosion and wear-resistant effectSolid state diffusion coatingCouplingBoriding

The invention relates to a boronizing method of integration of a pumping tube coupling and a pumping rod collar, which is characterized in that the tube coupling is used as a container for containing a boronizing agent, the rod collar is used as a mandrel for reducing heat capacity and increasing cooling rate during the cooling process, the rod collar is placed in the middle of the boronizing agent inside the tube coupling and heated by high temperature. The ingenious conception of the method can ensure that the tube coupling can reach higher tensile properties, the effects of anticorrosion and wear-resistance are much better than the rod collar and tube coupling made by common heat treating method, and the same amount of boronizing rod collars can be produced when the boronizing tube couplings are being made, thus increasing the production efficiency significantly, reducing the amount of boronizing agent used and decreasing the cost greatly. The hardness of the inner surface of the tube coupling and the outer surface of the rod collar obtained through the methods is HV 1100 to 1600, the thickness of the boronizing layer is 50 Mum to 90 Mum, the yield strength of the tube coupling is more than 552 MPa, the tensile strength is more than 689 MPa, and the elongation is more than 16 percent.

Owner:吉林省大多天盛金属陶瓷技术有限公司

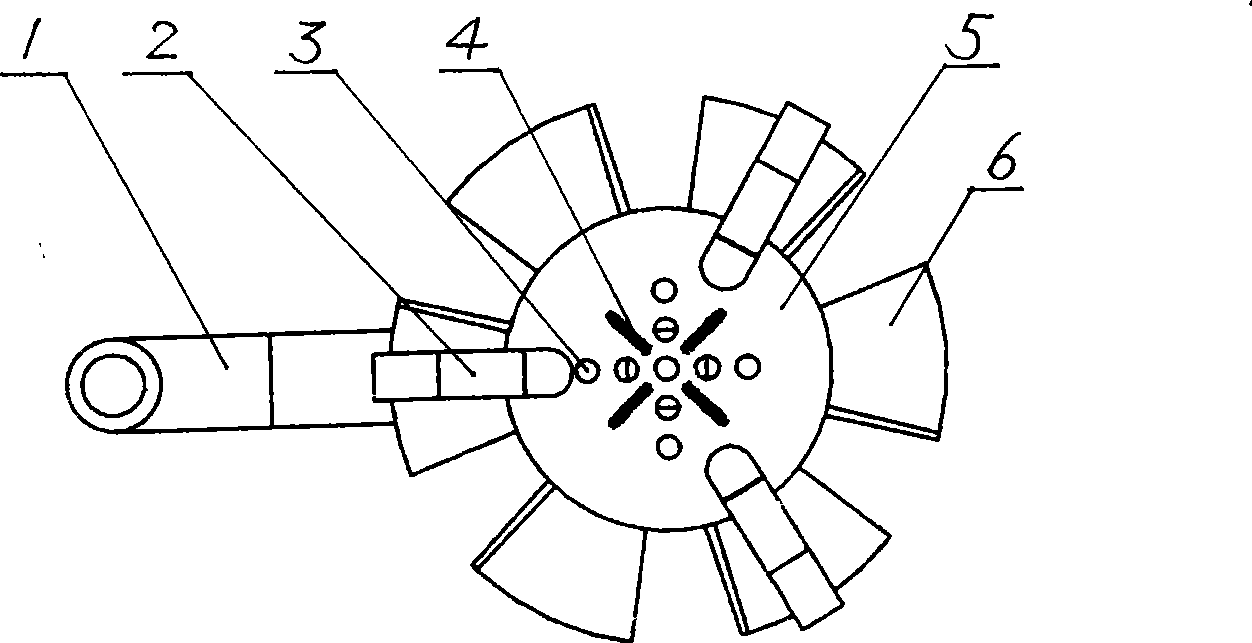

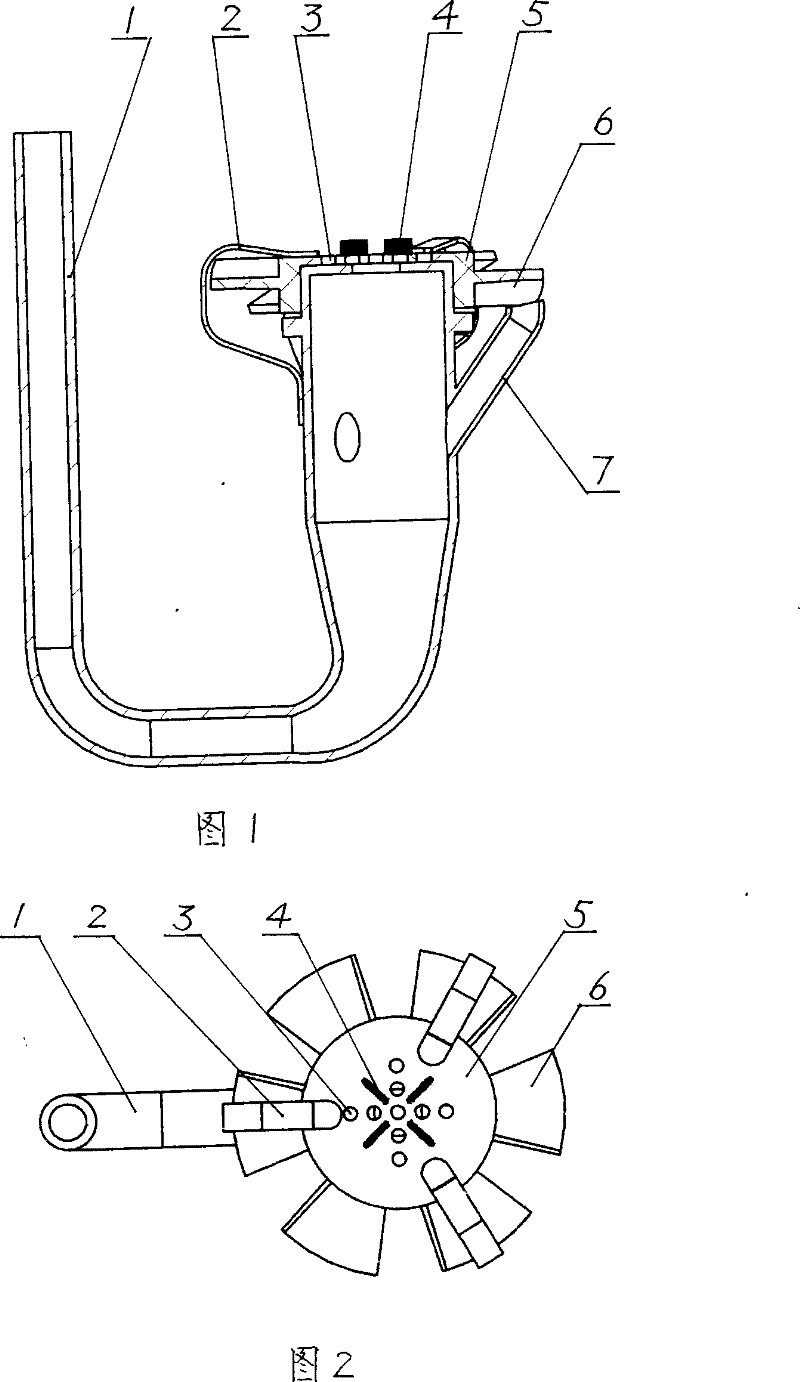

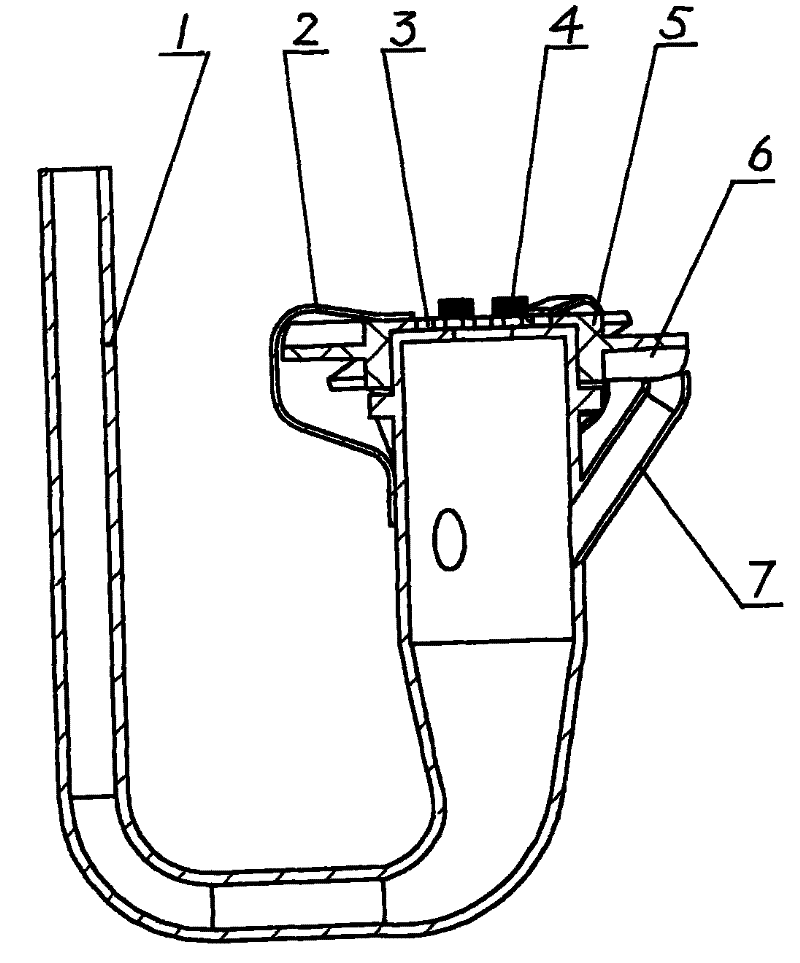

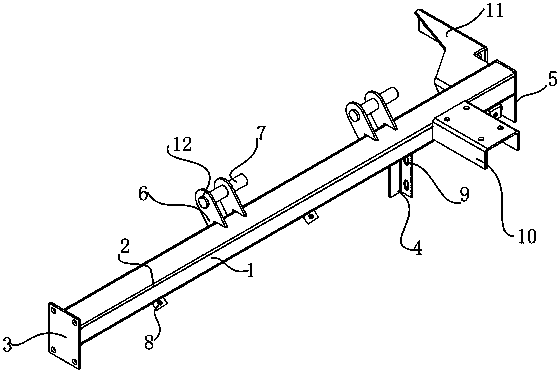

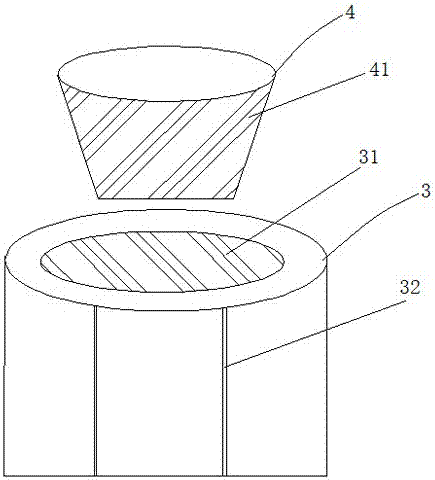

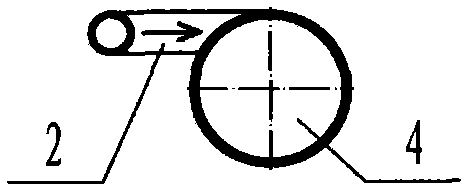

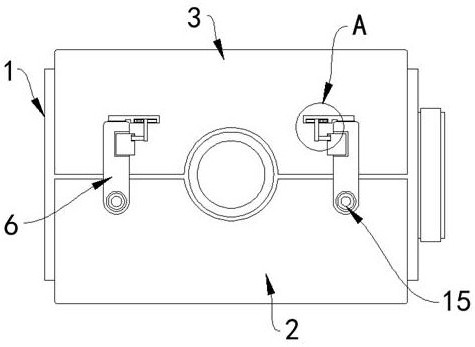

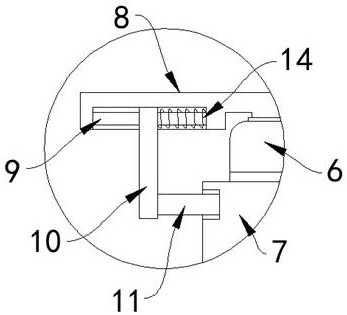

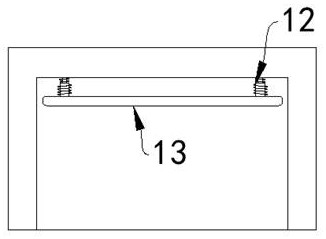

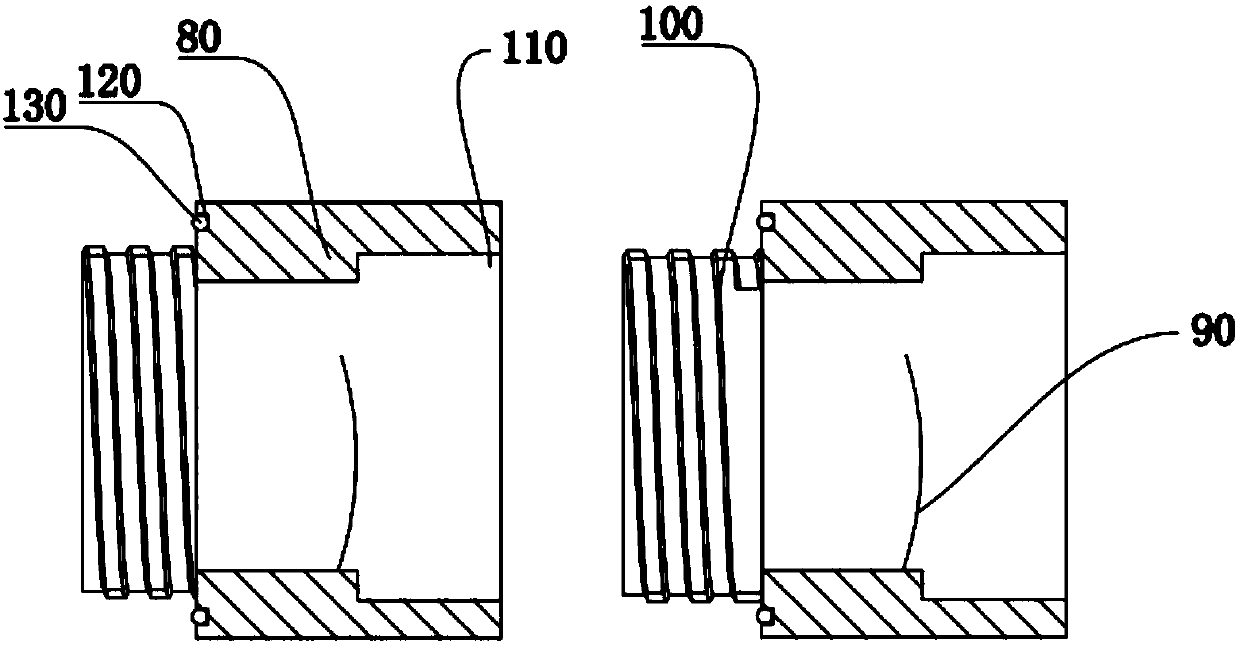

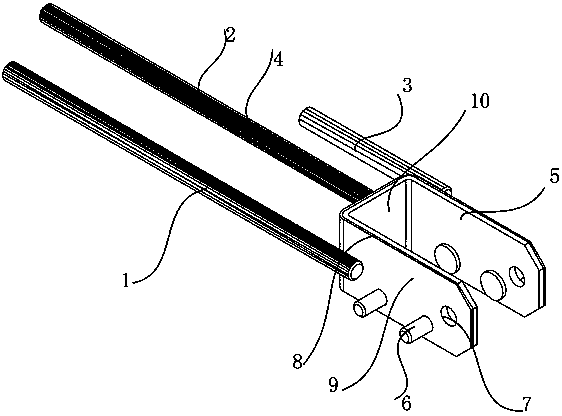

Sensor surface automatic cleaning device

InactiveCN101450347AReasonable forceEven by forceCleaning using toolsCleaning using liquidsImpellerHigh pressure water

The invention discloses an automatic cleaning device for the surface of a sensor, which is characterized in that a rotating impeller is arranged on a port on the head of a high-pressure water pipe, and the rotating impeller and the high-pressure water pipe form clearance fit; an axial elastic pressing piece is arranged between the rotating impeller and the high-pressure water pipe; blades are arranged on the circumference of the rotating impeller; the impeller is provided with an axial water outlet opening; the outer end face of the rotating impeller is provided with a chorionic strip; the head of the high-pressure water pipe is provided with a pipe orifice which is aligned to a spray pipe of the blades; and various members are made of corrosion and abrasion resistant materials. The device has a simple structure and good cleaning effect, adopts mechanical members, has good corrosion and abrasion resistance, can be arranged under water, is used for automatically cleaning the surface of an underwater sensor, is simple and convenient to operate, and can meet the demand of online instruments for on-scene monitoring.

Owner:JIANGSU JIANGFEN ELECTROANALYTICAL INSTR

Anti-corrosion and anti-wear modification method of anti-freezing cooling liquid

InactiveCN110724502AReduce the degree of reunionSmall granularityHeat-exchange elementsAnilineBasalt fiber

The invention discloses an anti-corrosion and anti-wear modification method of an anti-freezing cooling liquid. The modification method comprises the following steps: calcining expandable graphite ina muffle furnace, taking the calcined expandable graphite out for cooling, adding a hydrochloric acid solution, carrying out ultrasonic treatment, adding aniline, carrying out cooling in an ice bath,adding zinc phosphate, dropwise adding an ammonium persulfate solution under stirring, carrying out a reaction, performing standing, carrying out washing with water until a neutral state is reached, then performing washing with acetone, and carrying out vacuum drying to obtain zinc phosphate-polyaniline-graphene composite particles; diluting water-soluble polyurethane with deionized water to obtain a sizing agent, adding carboxylated carbon nanotubes, carrying out ultrasonic treatment, immersing desized basalt fibers in the sizing agent, and carrying out drying to obtain carbon nanotube-modified basalt fibers; and adding water into ethylene glycol, then adding floridosides, disodium hydrogen phosphate, sodium benzoate, sebacic acid, benzotriazole, borax, the zinc phosphate-polyaniline-graphene composite particles and the carbon nanotube modified basalt fibers, and carrying out ultrasonic dispersion and uniform mixing so as to prepare the anti-corrosion anti-wear modified anti-freezingcooling liquid.

Owner:界首市金一龙粮食机械购销有限公司

Painting method for antiseptic wear-resistant coating of PC joist steel jointing plate and PC joist steel jointing plate

InactiveCN107398412AImprove wear resistanceImprove skid resistancePretreated surfacesCoatingsWear resistantMetal alloy

The invention relates to a painting method for an antiseptic wear-resistant coating of a PC joist steel jointing plate and the PC joist steel jointing plate. The painting method comprises the following steps: S1, carrying out pretreatment to a steel jointing plate so as to enable the surface to be painted of the steel jointing plate to be clean and free of dust, rust and grease, and enabling the roughness of the steel jointing plate to meet the preset requirement; S2, carrying out co-penetrated antiseptic treatment to the surface to be painted of the steel jointing plate subjected to the pretreatment so as to enable the surface to be painted of the steel jointing plate to form a co-penetrated antiseptic layer for metal alloy; and S3, coating antiseptic wear-resistant paint film on the co-penetrated antiseptic layer for the metal alloy to obtain the antiseptic wear-resistant coating after the antiseptic wear-resistant paint film dries and solidifies. The painting method provided by the invention increases the wear resistance and skid resistance of the steel jointing plate, prolongs the normal tenure of use of the antiseptic wear-resistant coating of the steel jointing plate, reduces on-site maintenance in later period, enables a train to normally travel and is safe and reliable.

Owner:重庆樽明机械工业有限公司

Fender bracket fixing seat structure for logistics vehicle

InactiveCN107776681AHigh strengthIncrease connection areaSuperstructure subunitsEngineeringWear resistance

The invention discloses a fender bracket fixing seat structure for a logistics vehicle, which includes a bracket fixing seat body, and each part can be connected firmly by welding to increase the overall fixability of the structure. The limit fixing unit can fix the fender bracket Fixed on the car, the first cavity and the second cavity are provided with reinforcing ribs, the reinforcing ribs can effectively increase the strength of the first cavity and the second cavity, and the reinforcing ribs are protruding, which can further Fasten the fixity of the fender installed in the first cavity and the second cavity; the connection between the second support plate, the second connecting plate and the lateral support assembly is equipped with an arc-shaped bending section, and the arc-shaped bending section The section can increase the connection area of the second support plate, the second connection plate and the lateral support assembly, making the connection stronger; the body of the bracket fixing seat is cast from stainless steel or aluminum alloy as an integrated structure, and the stainless steel or aluminum alloy has excellent anti-corrosion and wear resistance , high strength, ensuring the overall strength of the fender bracket.

Owner:江苏金卡汽车部件有限公司

Low-cost metal filter bag for dust removal

PendingCN111643980AReduce manufacturing costGuaranteed dust removal efficiencyDispersed particle filtrationTransportation and packagingMetal fiberDust control

The invention relates to a low-cost metal filter bag for dust removal. The metal filter bag comprises a fine filtering layer and a coarse filtering layer, wherein the fine filtering layer is located on the inner side of the coarse filtering layer, the fine filtering layer is of a filtering structure, the coarse filtering layer is of a supporting and ventilating structure, the fine filtering layercomprises 316L stainless steel metal fiber felt, and the coarse filtering layer comprises 446 stainless steel or high-temperature-resistant carbon steel metal fiber felt. Compared with the prior art,the dust removal efficiency is guaranteed, the production cost of the metal filter bag is greatly reduced, and wide application is facilitated.

Owner:ZHONGDIAN HUACHUANG ELECTRIC POWER TECH RES +1

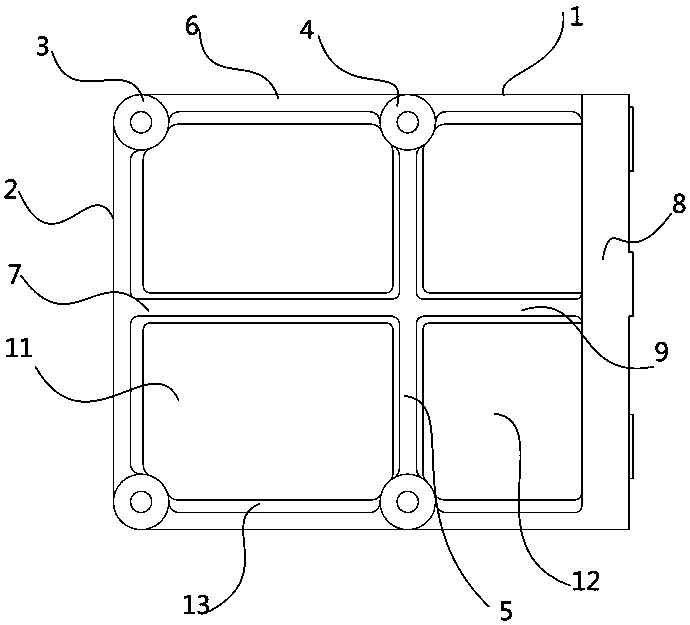

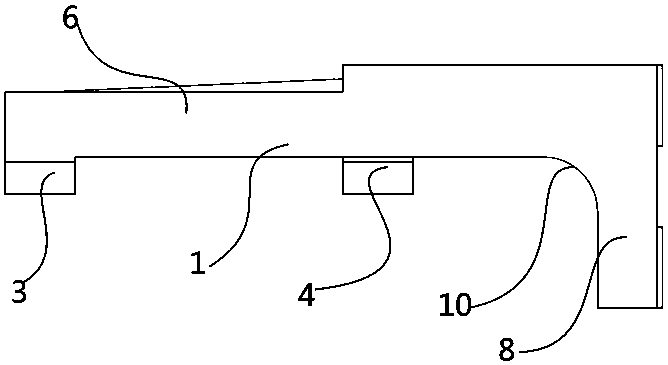

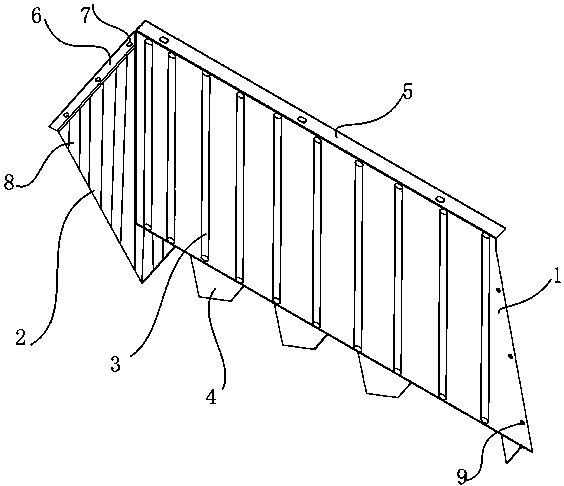

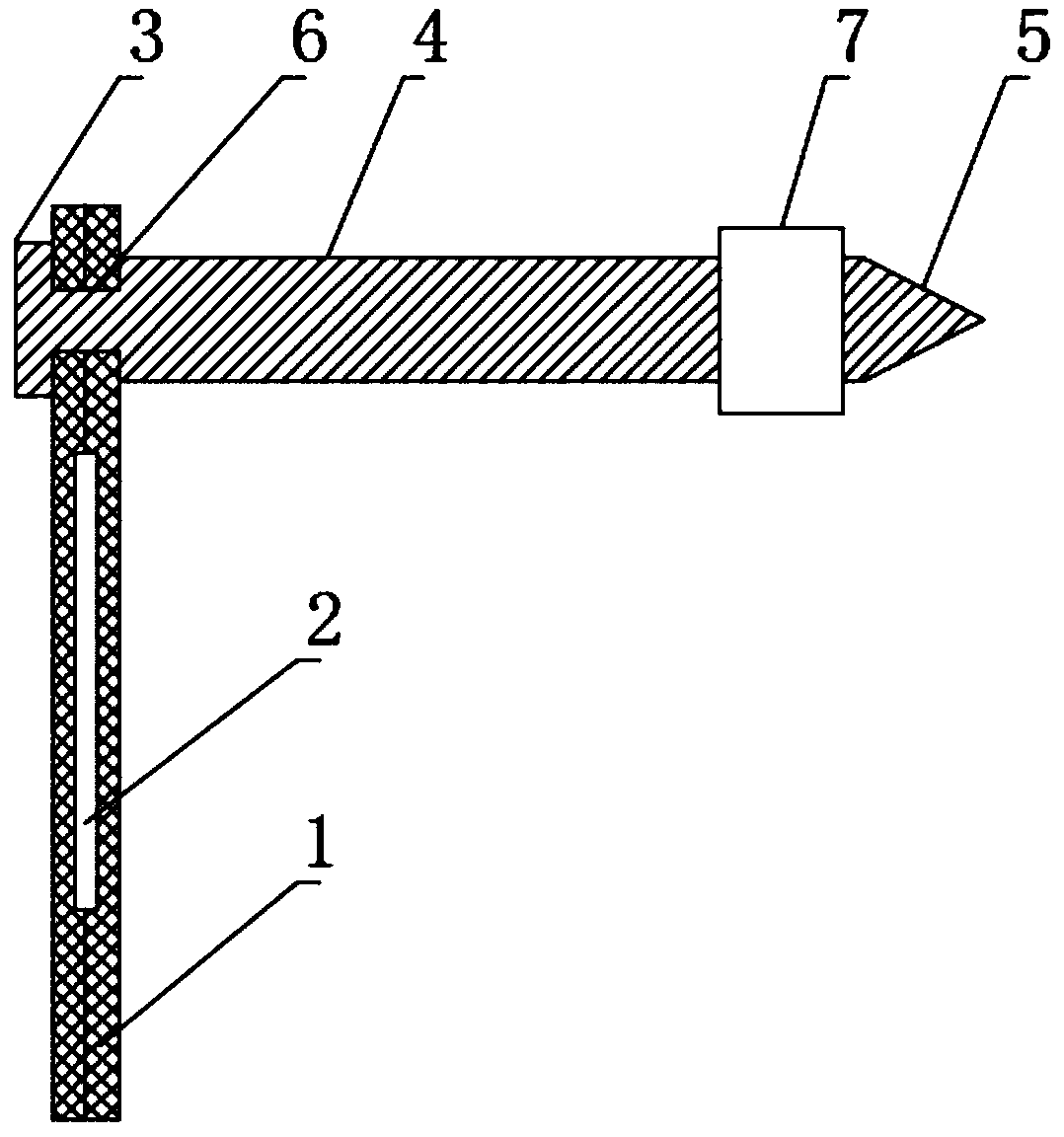

Straw-discharging cover for harvester

InactiveCN107683681AFirmly connectedSimple structural designMowersAgricultural engineeringUltimate tensile strength

The invention discloses a grass discharge cover for a harvester, which comprises an upper cover plate (1), a support plate (2), a reinforcing rib (3), a grass discharge board (4), a first reinforced edge removal (5), a second Reinforced edge removal (6) and wear-resistant and anti-corrosion layer (8); the upper cover plate (1) is provided with reinforcing ribs (3), and one side of the upper cover plate (1) is provided with a first reinforced edge removal (5) , the upper cover plate (1) is connected with the first reinforced edge (5) through welding, the upper cover plate (1) is symmetrically provided with a support plate (2), and the upper cover plate (1) is welded and supported The plates (2) are connected, and the support plate (2) is provided with a second reinforced edge (6), and the support plate (2) is connected with the second reinforced edge (6) by welding, and the support plate (2) A wear-resistant and anti-corrosion layer (8) is provided on the top, and the wear-resistant and anti-corrosion layer (8) is attached to the support plate (2), and the upper cover plate (1) is provided with a grass discharge board (4) and a grass discharge board (4) It is connected with the upper cover plate (1) by welding. The structure design of the invention is simple and reasonable, the structure connection is very stable, the strength is high, and the support plate has excellent wear resistance and anticorrosion performance.

Owner:朱怀东

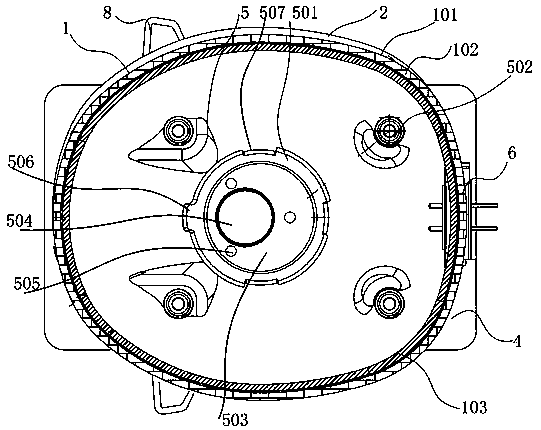

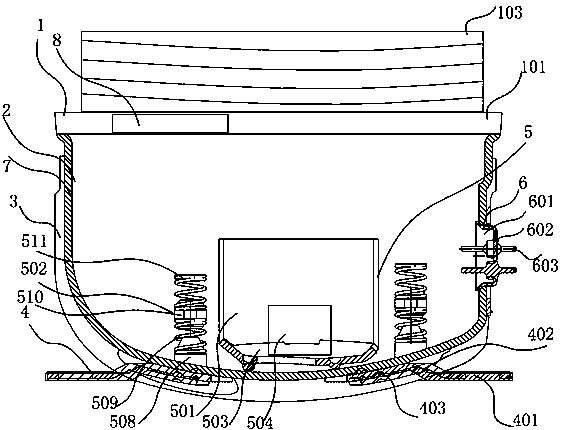

Lower shell assembly for refrigerator compressor

InactiveCN111102170AExtended service lifeHigh strengthPositive displacement pump componentsSound producing devicesIceboxEngineering

The invention discloses a lower shell assembly for a refrigerator compressor. The lower shell assembly comprises a positioning top annular seat component, a shell body component, a reinforced protective support, a positioning support plate component, an elastic positioning component and a radiating unit component, wherein the reinforced protective support is welded to the outer wall of the shell body component and is an integrated forming structure formed through casting stainless steel or alloy, and the stainless steel or alloy is high in strength and excellent in corrosion preventing and wear-resisting performance, so that the shell body component is effectively protected, and the service life of the entire shell body is prolonged; the positioning support plate component penetrates through a through hole in the reinforced protective support, extends inwards to the bottom end of the shell body component and plays the role of fixing the bottom end of the shell body component, so that fixation of the bottom end of the shell body component is ensured; a ventilating pipeline plays a radiating role in the interior of the compressor, so that the situation that poor radiation of the compressor causes damage to internal components is effectively prevented; a filter net is arranged in the ventilating pipeline, and the pore diameter of the filter net is 0.15-0.25 mm, so that the situation that impurities enter the compressor from the ventilating pipeline to affect overall operation is effectively prevented.

Owner:何俊

Hardening ceramic processing method for surface of piston rod

InactiveCN1164870CImprove anti-corrosion and wear-resistant effectShort cyclePositive displacement pump componentsLiquid fuel engine componentsWear resistanceMachining

The hardening ceramic processing method for surface of piston rod includes the steps of forging, normalizing, coarse machining, seasoning, semi-finishing, stress-eliminating tempering, coarse grinding, spraying ceramic and finishing. Compared with conventional production process, the present invention has reduced hot processing time, lowered rejected product rate, and greatly increased piston rod life.

Owner:SHENYANG YUANDA COMPRESSOR

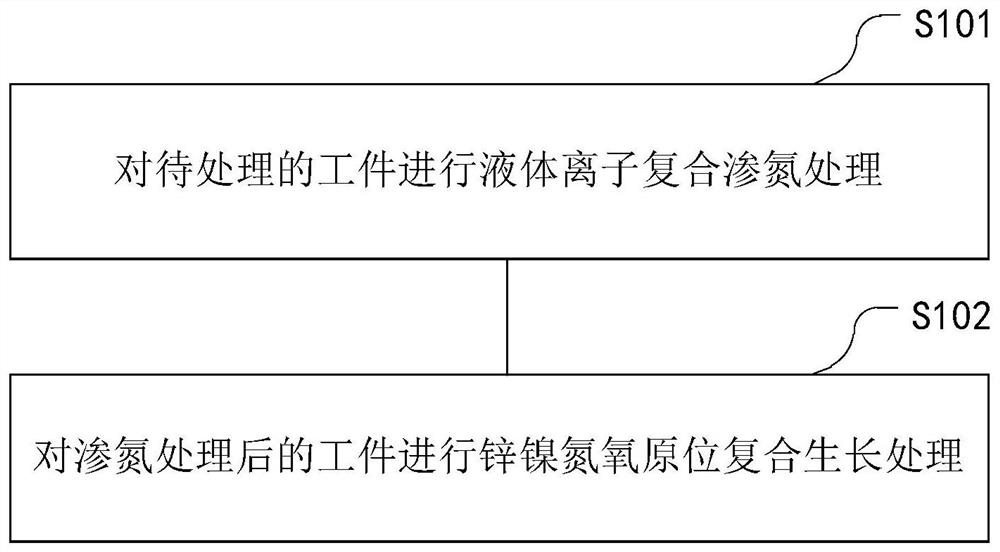

In-situ growth surface heat treatment process based on composite nitrided metal surface substrate

ActiveCN109609896BImprove corrosion and wear resistanceImprove anti-corrosion and wear-resistant effectSolid state diffusion coatingSuperimposed coating processCarbideWear resistance

The invention relates to an in-situ growth surface heat treatment process based on a composite nitriding metal surface base. The in-situ growth surface heat treatment process comprises the steps thatliquid ion composite nitriding treatment is carried out on a to-be-treated workpiece so as to form an anti-corrosion and wear-resisting compound layer structure on the surface of the workpiece; the compound layer structure comprises a nitride structure, a carbide structure and an oxide structure; and the workpiece subjected to nitriding treatment is subjected to zinc-nickel-nitrogen-oxygen in-situcomposite growth treatment so as to form an anti-corrosion and wear-resisting layer on the surface of the workpiece. The binding force of a diffusion layer on the surface of the workpiece treated through the process and a matrix is high, falling off is not prone to happening, the anti-corrosion performance and wear resistance of the workpiece are good, surface hardness is high, and high impact resistance and washing resistance are achieved.

Owner:SHAANXI TIEMA FORGING

Sensor surface automatic cleaning device

InactiveCN101450347BReasonable forceEven by forceCleaning using toolsCleaning using liquidsImpellerHigh pressure water

The invention discloses an automatic cleaning device for the surface of a sensor, which is characterized in that a rotating impeller is arranged on a port on the head of a high-pressure water pipe, and the rotating impeller and the high-pressure water pipe form clearance fit; an axial elastic pressing piece is arranged between the rotating impeller and the high-pressure water pipe; blades are arranged on the circumference of the rotating impeller; the impeller is provided with an axial water outlet opening; the outer end face of the rotating impeller is provided with a chorionic strip; the head of the high-pressure water pipe is provided with a pipe orifice which is aligned to a spray pipe of the blades; and various members are made of corrosion and abrasion resistant materials. The device has a simple structure and good cleaning effect, adopts mechanical members, has good corrosion and abrasion resistance, can be arranged under water, is used for automatically cleaning the surface ofan underwater sensor, is simple and convenient to operate, and can meet the demand of online instruments for on-scene monitoring.

Owner:JIANGSU JIANGFEN ELECTROANALYTICAL INSTR

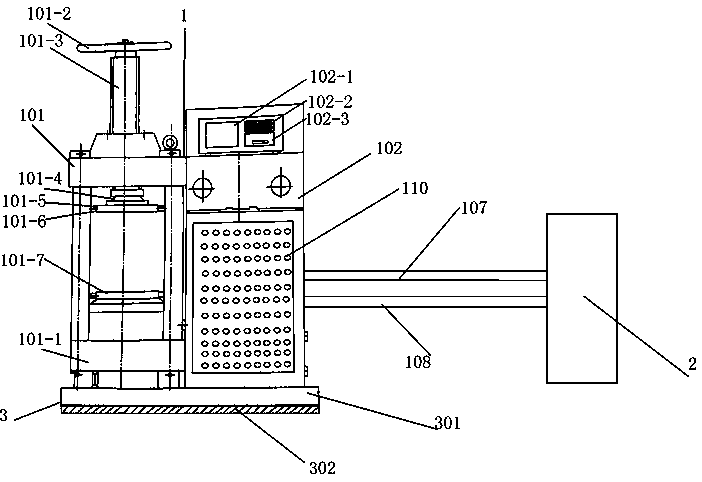

Circulating water-cooled pressure test device

InactiveCN110836813AExtended service lifePrevent overflowCooling/ventilation/heating modificationsStrength propertiesLiquid storage tankCooling fluid

The invention discloses a circulating water-cooled pressure test device. The device comprises a pressure test machine body, a cooling circulating device and an anti-skid damping component, wherein thecooling circulating device is arranged at one end of the pressure test machine body and is connected with the pressure test machine body through a conveying pipeline; the cooling liquid flows into aliquid storage tank through liquid supply equipment, a liquid feeding pump accelerates to enable the cooling liquid to flow into a cooling liquid pipeline cavity groove through the conveying pipelineto cool a host, a liquid suction pump accelerates to enable the cooling liquid to flow into a cooler from an output pipeline for cooling, the cooling liquid flows into the liquid storage tank after cooling to form a cycle, the using amount of the cooling liquid is greatly reduced, the cost is saved, and the cyclic and continuous utilization of resources is realized; and an anti-skid shock-absorbing layer is arranged at the bottom end of a fixed base, the anti-skid shock-absorbing layer is of an integrally formed structure formed by injecting polyurethane rubber, the polyurethane rubber is excellent in anti-skid performance, the elastic shock-absorbing effect is good, the polyurethane rubber can effectively prevent the pressure test machine from generating offset due to the vibration of themachine body driven by a working cylinder body when the pressure test machine carries out the test, and the stability of the whole structure is ensured.

Owner:泰州市恒信建设工程质量检测有限公司

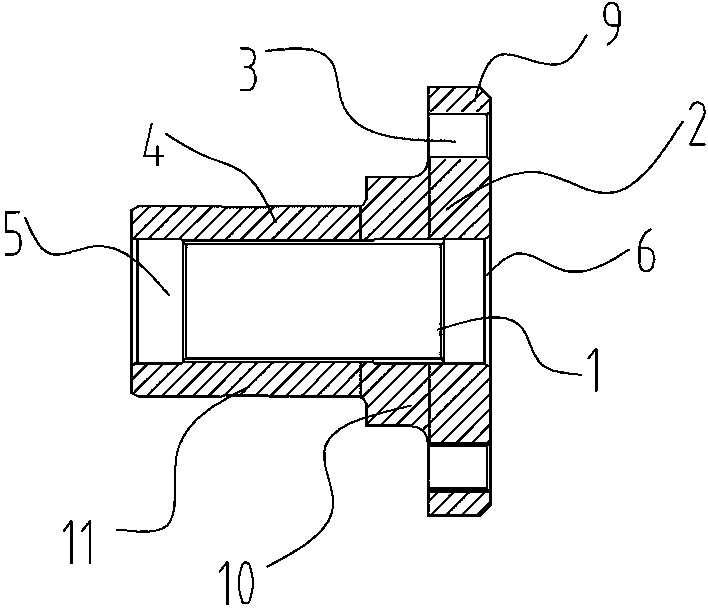

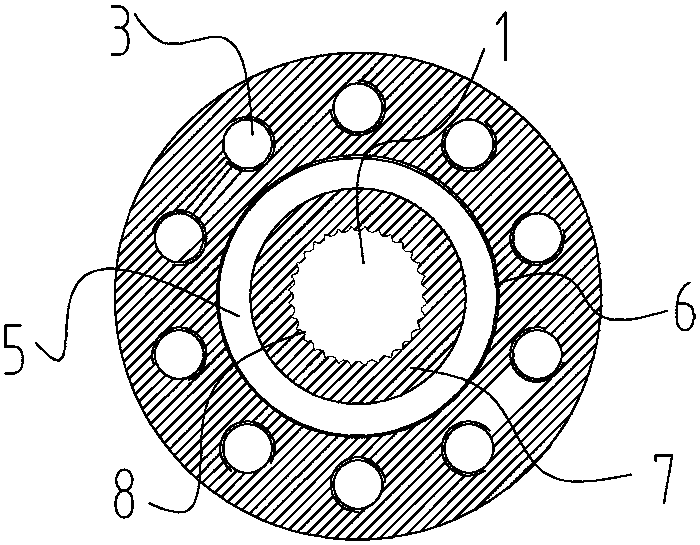

Anchoring bolt device of concrete cover

ActiveCN109629399AImprove anti-corrosion and wear-resistant effectImprove toughnessBridge structural detailsBridge materialsWear resistantEngineering

The invention discloses an anchoring bolt device of a concrete cover for a PC beam support, which comprises an anchoring bolt; a first spherical nut is in threaded connection with the first end of theanchoring bolt; a spherical nut seat is arranged at the first end of the anchoring bolt, and the concave spherical surface of the spherical nut seat is closely matched with the convex spherical surface of the first spherical nut; a second spherical nut is in threaded connection with the second end of the anchoring bolt; a spherical washer is arranged at the second end of the anchoring bolt, and the convex spherical surface of the spherical washer is closely matched with the concave spherical surface of the second spherical nut; a locking nut is in threaded connection with the second end of the anchoring bolt and is positioned at one side of the second spherical nut facing the second end direction; the surfaces of the first spherical nut, the spherical nut seat, the spherical washer, a plane washer, the second spherical nut and the locking nut are treated by a nitriding process and an in-situ growth composite material process to form an anti-corrosion wear-resistant material infiltration layer. According to the anchoring bolt device, the corrosion resistance and wear resistance of the anchoring bolt of the concrete cover can be improved, and the service life can be prolonged.

Owner:SHAANXI TIEMA FORGING

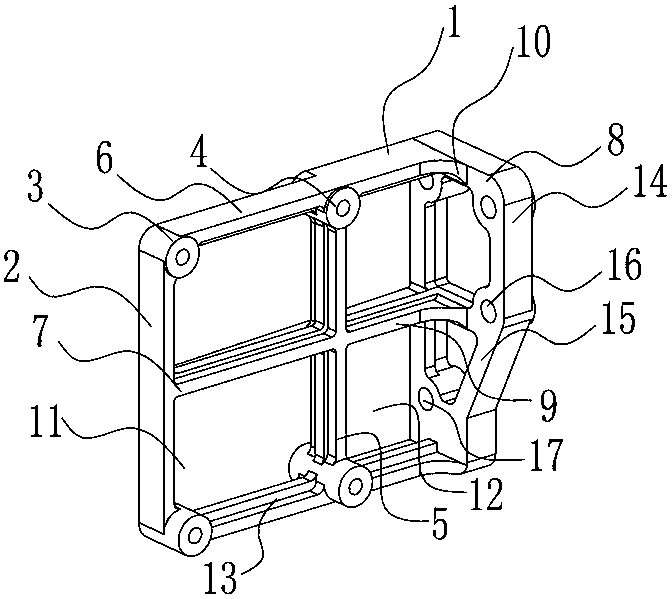

Harvester assembly bracket seaming structure

InactiveCN107683703ASimple and reasonable structural designFirmly connectedAgricultural undercarriagesCorrosion resistantWear resistant

The invention discloses a harvester assembly bracket welding structure, comprising a fixed column (1), a wear-resistant anti-corrosion layer (2), a first support plate (3), a second support plate (4), and a third support plate ( 5), positioning pin mounting seat (6), positioning pin (7), fixed plate (10) and oblique extension plate (11); the fixed column is provided with a wear-resistant and anti-corrosion layer, and the wear-resistant and anti-corrosion layer is attached to the fixed column Above, the bottom of the fixed column is provided with a second support plate, the second support plate is connected with the support plate by welding, the two sides of the fixed column are respectively provided with the first support plate and the third support plate, the first support plate and the third support plate The support plate is connected with the support plate by welding, the front end of the fixed column is provided with an oblique extension plate, the oblique extension plate of the positioning pin is connected with the fixed column by welding, the rear end of the fixed column is provided with a fixed plate, and the fixed plate is welded Connected to the fixed column. The structure design of the invention is simple and reasonable, the structure connection is very stable, and the fixed column has excellent wear resistance and anticorrosion performance.

Owner:朱怀东

Axle shaft tube structure

InactiveCN107757257ASimple and reasonable structural designReduce bushing bendingAxle unitsSolderingEngineering

The invention discloses an axle tube structure of a vehicle axle, which comprises a shaft tube body, a shaft sleeve, a reinforcing rib, a limit ferrule, a sealing groove ring, a threaded groove and a threaded protrusion. The fixed base section has a reinforced raised section in the middle and a fixed support section at one end, which can effectively disperse the load of each part and reduce the risk of bending or even breaking the bushing; the bushing is equipped with a limit ferrule and connected by welding, which can The connection between the shaft sleeve and the limit ferrule is more firm, the shaft tube body is sleeved in the limit ferrule, and the limit ferrule can fix the shaft tube, which can prevent the shaft tube from moving in the shaft sleeve; the inner circumference of the shaft sleeve Both ends are equipped with sealing groove rings, which can prevent dust from entering the shaft sleeve and ensure the cleanliness of the shaft sleeve; there are reinforcing ribs on the outer surface of the shaft tube body, which can enhance the strength of the shaft tube , so that it will not break, the shaft tube body, shaft sleeve and limit ferrule are all cast from alloy steel as an integrated structure. The alloy steel has excellent anti-corrosion and wear resistance and high strength.

Owner:江苏金卡汽车部件有限公司

Antiseptic and durable grinder for black garlic

InactiveCN107348826AReasonable structural designAchieve grindingStrainersEconomic benefitsEngineering

The invention provides an antiseptic and durable grinder for black garlic. The antiseptic and durable grinder for black garlic comprises a bottle body with an inner wall coated with an antiseptic layer, a base arranged on the bottle body in a sleeved mode, an outer grinding core, an inner grinding core, a cover body and a cover plate, wherein a discharging through hole is formed in the middle of a closed end face, a connecting pipe is inserted into the discharging through hole, the closed end face is coated with an anti-static layer and an abrasion-resistant layer, the outer grinding core is inserted into the inner wall of the connecting pipe, a grinding groove is formed in the inner wall in the peripheral direction, the outer wall and the inner wall are coated with abrasion-resistant layers, the inner grinding core is embedded into the outer grinding core, an outer wall protrudes out of a convex grinding edge and is coated with an abrasion-resistant layer, a connecting piece is arranged in the middle of the inner side of the upper open end, a plurality of connecting rods are arranged on the outer wall of the connecting piece in a protruding mode, the connecting piece is connected with the inner wall of the upper open end through the connecting rods, and the cover plate covers the upper open end of the cover body. The antiseptic and durable grinder is reasonable in structural design, can effectively achieve antiseptic and durable grinder grinding and achieve instant use while grinding, is convenient to carry, long in service life, low in production and manufacturing costs and good in economic benefit and has a good antiseptic and abrasion-resistant effect.

Owner:太仓市林港农场专业合作社

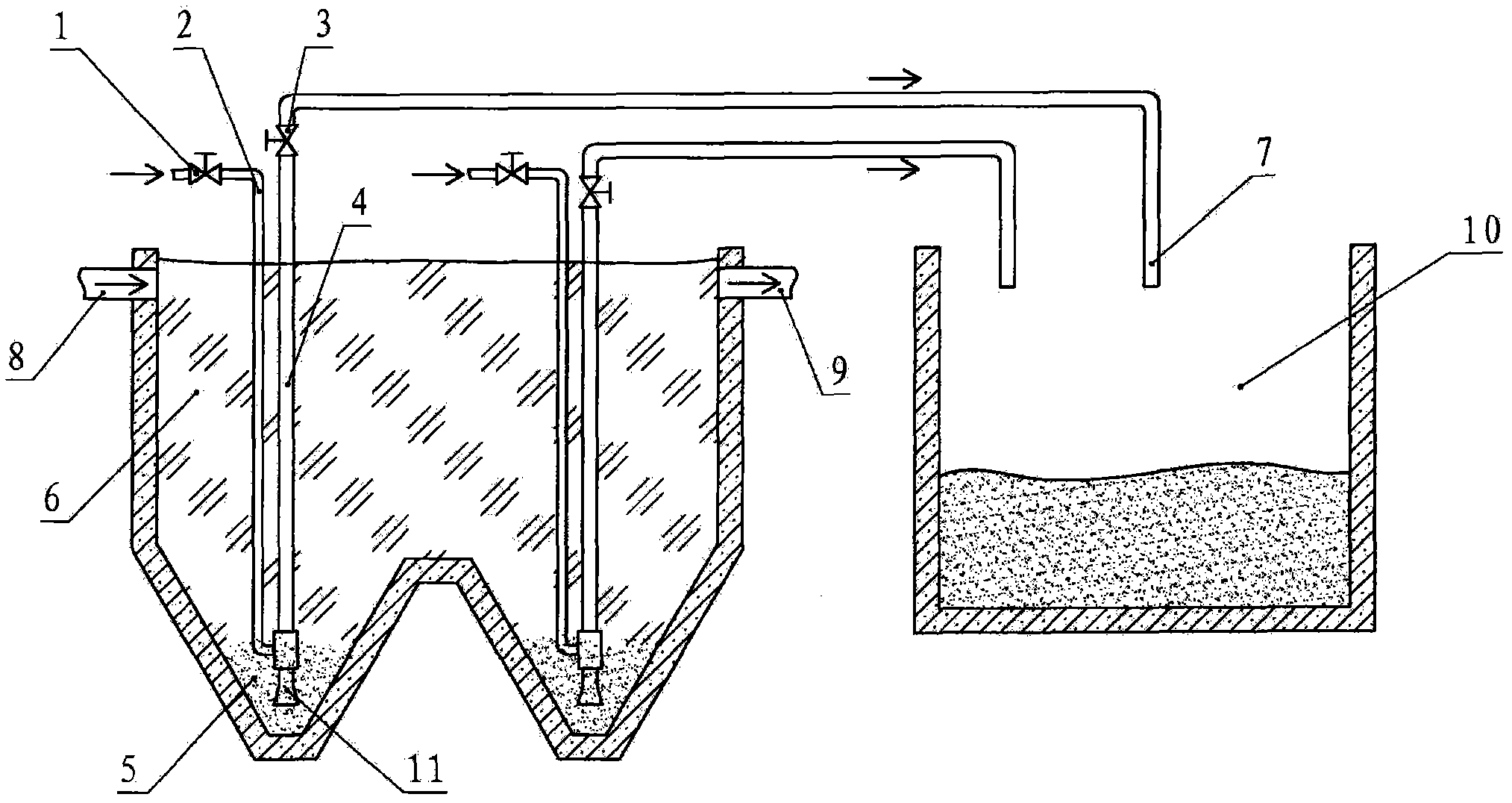

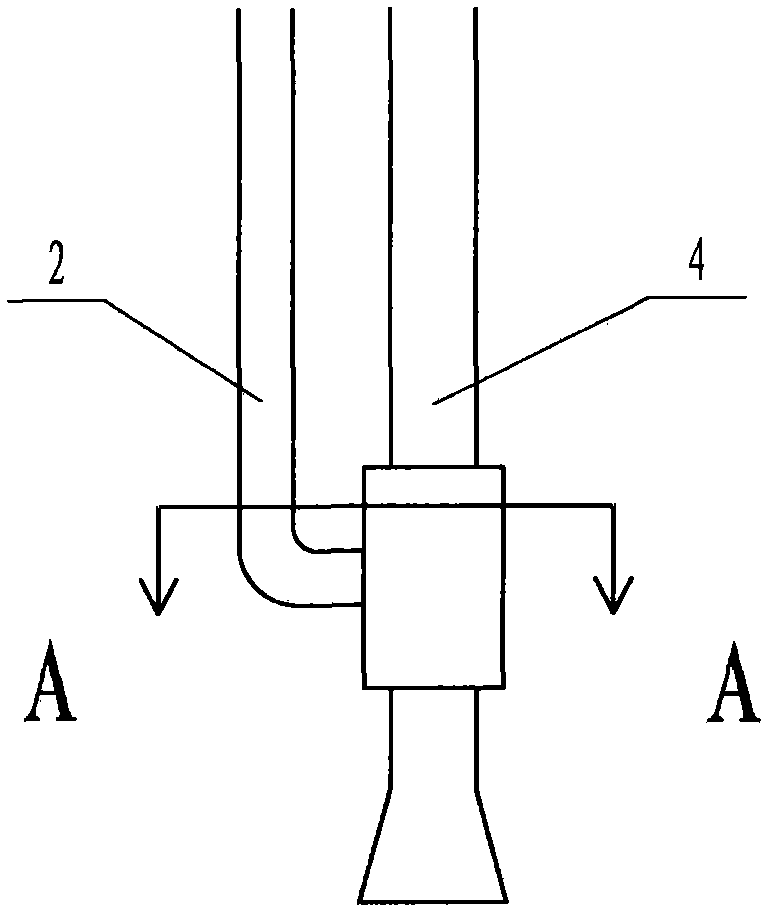

Slag discharge device in dust removal and desulfurization system

InactiveCN102120110ACompact and reasonable structureEasy constructionDispersed particle separationSettling tanks feed/dischargeSlagSlurry

The invention belongs to a slag discharge device in a dust removal and desulfurization system. The slag discharge device is characterized in that a slag-liquid storage area is arranged in a sedimentation basin; the upper part of the sedimentation basin is provided with a liquid storage area for separating the slag and liquid in a dust removal and desulfurization slurry, a container composed of the sedimentation basin, and a delivery channel of the dust removal and desulfurization slurry; the delivery channel is positioned at the upper part of the sedimentation basin and is formed by a slurry inlet and a purified liquid outlet corresponding to the slurry inlet; the bottom of the sedimentation basin is a slag storage area; a stripper is arranged in the sedimentation basin; the output port of the inlet pipe of the stripper is communicated with the lower part of a slag discharge pipe; an adsorption area formed at the lower end of the slag discharge pipe is arranged in the slag storage area; and a discharge delivery channel for the waste slag in the dust removal and desulfurization slurry is formed by the inlet pipe of the stripper and the slag discharge pipe. According to the technical scheme provided by the invention, a pneumatic lifting method is adopted, the slag and slurry produced by the dust removal and desulfurization system can be automatically cleared and discharged, and the oxidation process of the desulfurized slag and slurry is further completed. Meanwhile, the slag discharge device has the advantages of simple overall structure, small investment, good corrosion and wear resistance and low maintenance cost, is flexible and convenient to use and can meet the requirements of different users.

Owner:BAODING RUNLI ENERGY SAVING & ENVIRONMENTAL PROTECTION

Corrosion-resistant and durable pig ear tag and preparation method thereof

InactiveCN109006549AMake sure to eatComprehensive Records ManagementAnimal husbandryPig breedingComputer science

The invention provides a corrosion-resistant and durable pig ear tag and a preparation method thereof. The pig ear tag of the invention includes a main tag and an auxiliary tag. The main tag includesan ear tag face, an ear tag neck, and an ear tag head. The ear tag face comprises a protective layer. The protective layer is embedded with a chip. The protective layer has a connecting portion thereon connected to the ear tag neck. The ear tag neck includes a nail head and a top rod integrally connected with the nail head. The top rod is connected integrally with the ear tag head. An annular groove is formed on the top rod at a position close to the nail head. The connecting portion of the ear tag face is mounted in the annular groove. The ear tag neck has an anti-corrosion coating thereon. The ear tag head includes a clamping portion. The invention effectively prevents the pig ear tag from corroding or falling off during the use, facilitates management and epidemic situation and diseasetracking in the pig breeding and pork production process, and ensures that the public eats healthy pork.

Owner:扬中市红光金属制品有限公司

Anti-corrosion and wear-resistant treatment method for Lurgi gasifier

ActiveCN107573972BSolve the phenomenon of corrosionImprove anti-corrosion and wear-resistant effectAnti-corrosive paintsCombustible gas productionActivated Aluminum OxideAluminium oxides

The invention discloses an anticorrosive and antiwear treatment method for a Lurgi gasifier, belongs to the technical field of coal gasification equipment, and provides the anticorrosive and antiweartreatment method for the Lurgi gasifier to solve a technical problem. The technical scheme adopted to solve the technical problem is that the anticorrosive and antiwear treatment method for the Lurgigasifier comprises the following steps: (1) performing sanding on the corroded surface of the interior of a neutral cylinder and / or the inner wall of an upper conical segment of the Lurgi gasifier byusing abrasive paper to remove a corrosive layer, and welding a hexsteel; and (2) performing preheating treatment on the hexsteel, and then performing thermal spraying with an anticorrosive and antiwear material; and the anticorrosive and antiwear material is composed of the following components in parts by weight: 35-50 parts of tungsten carbide powder, 27-46 parts of nano zirconium oxide, 10-15parts of nano titanium dioxide, 5-10 parts of zinc, and 10-15 parts of activated aluminium oxide. The anticorrosive and antiwear method provided by the invention has good anticorrosive and antiwear effects, can effectively reduce maintenance charges, and can be widely applied to the field of synthesis gas preparation.

Owner:SHANXI LUAN COAL BASED SYNTHETIC OIL +1

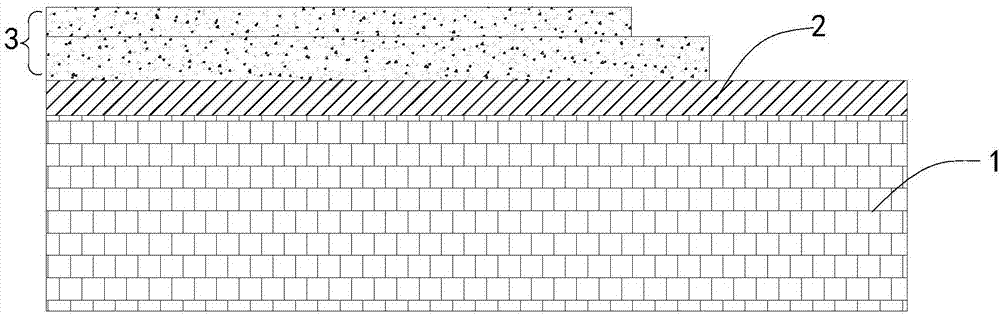

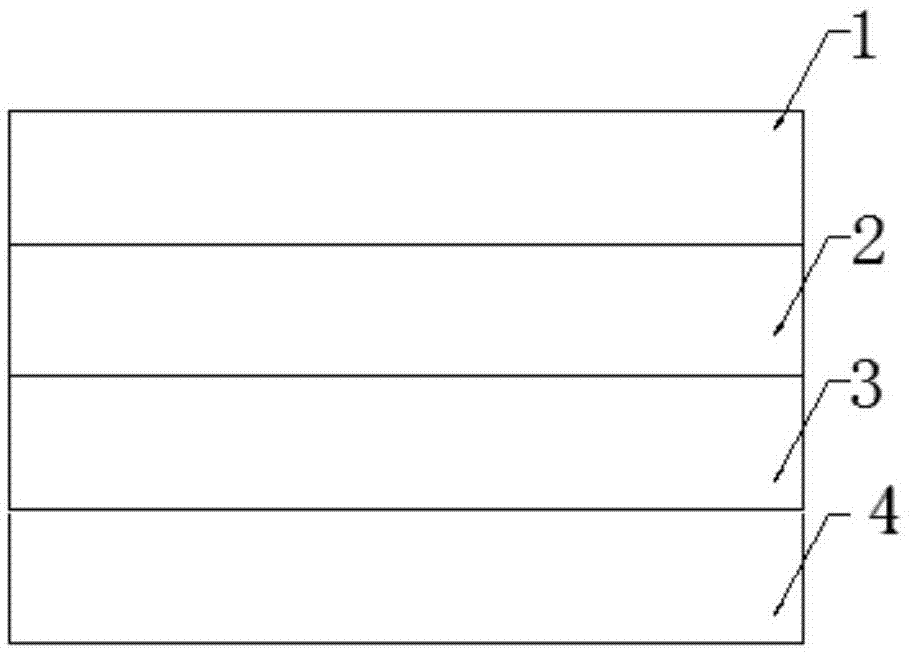

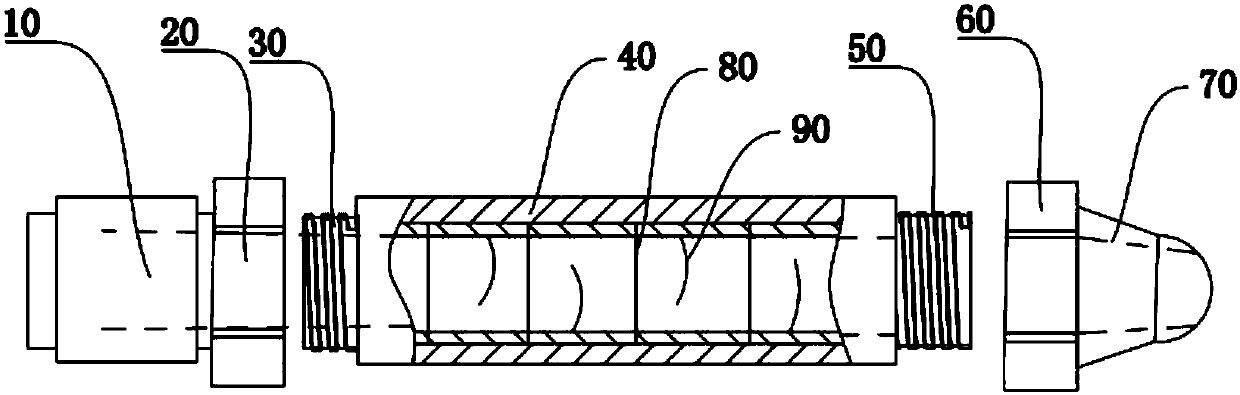

Anticorrosion tape and preparation method thereof

InactiveCN106863975AGreenHigh strengthLamination ancillary operationsSynthetic resin layered productsSurface layerUltimate tensile strength

The invention discloses an anticorrosion tape. The anticorrosion tape comprises, from top to bottom, a thin-film layer (1), an anticorrosion wearing layer (2), a connection layer (3) and a binder layer (4). The invention also discloses a preparation method for the anticorrosion tape. The preparation method comprises the following steps: heating the anticorrosion wearing layer (2) and the connection layer (3), and subjecting the anticorrosion wearing layer (2), the connection layer (3), the thin-film layer (1) and the binder layer (4) to rolling together so as to form the anticorrosion tape; or heating the anticorrosion wearing layer (2) and the connection layer (3), then subjecting the anticorrosion wearing layer (2), the connection layer (3) and the thin-film layer (1) to rolling so as to form an outer surface layer anticorrosion tape, and compounding the outer surface layer anticorrosion tape with the binder layer (4) so as to form the anticorrosion tape. The anticorrosion tape for a pipeline in the invention has the advantages of environment friendliness, high strength, good toughness, resistance to friction, water, moisture, high and low temperature and corrosion, long service life, etc.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

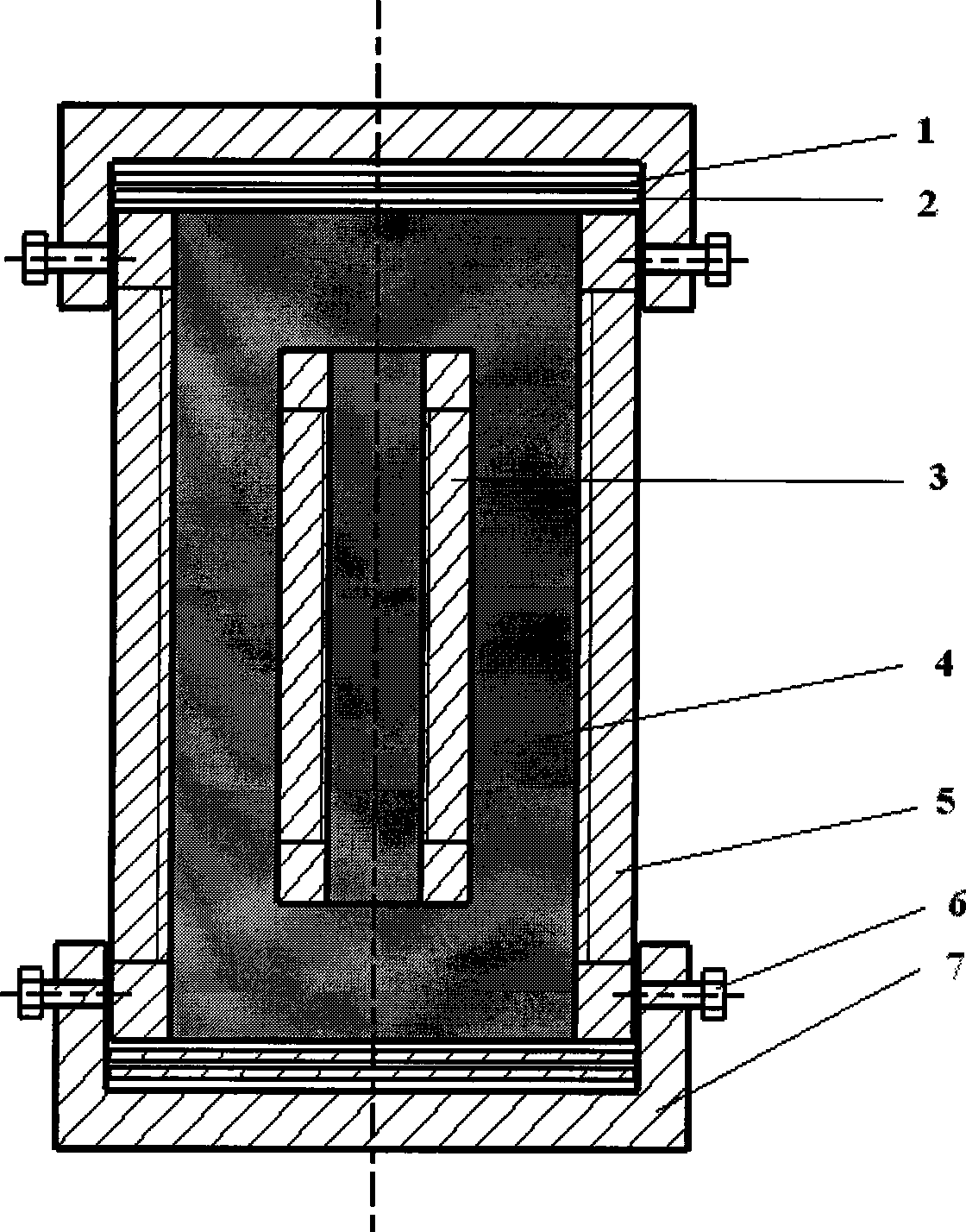

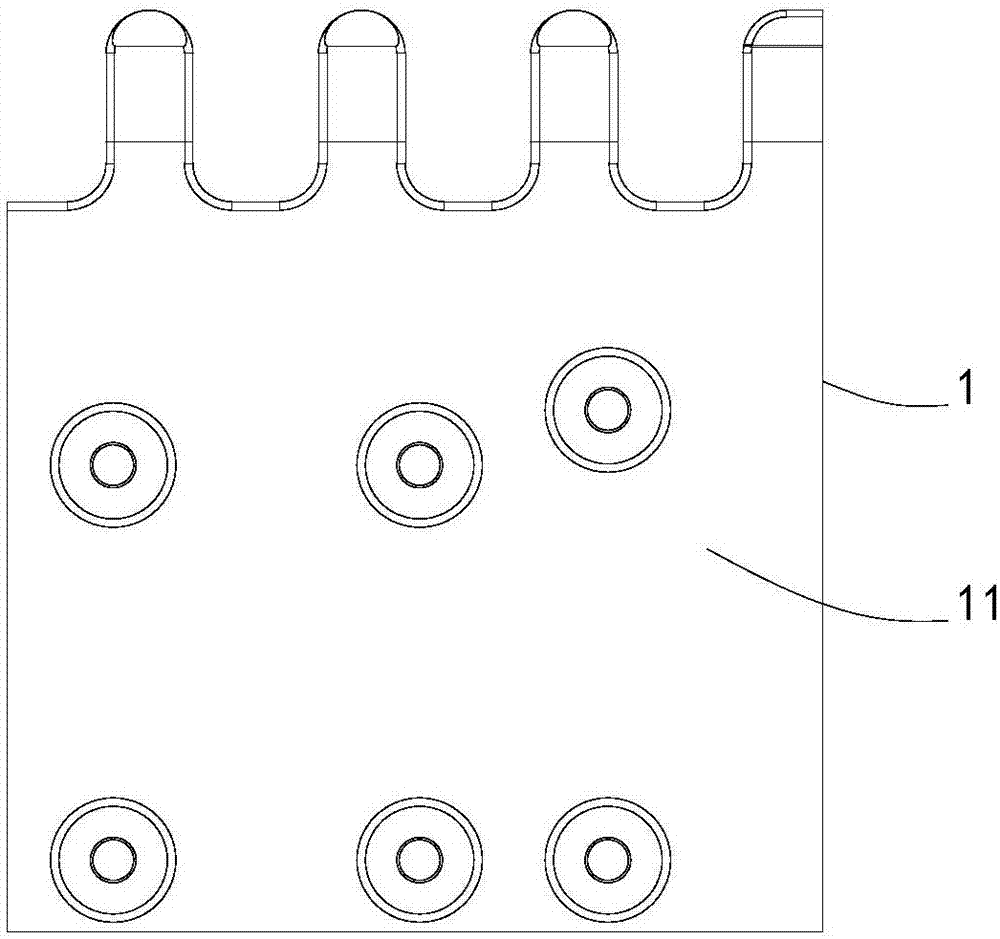

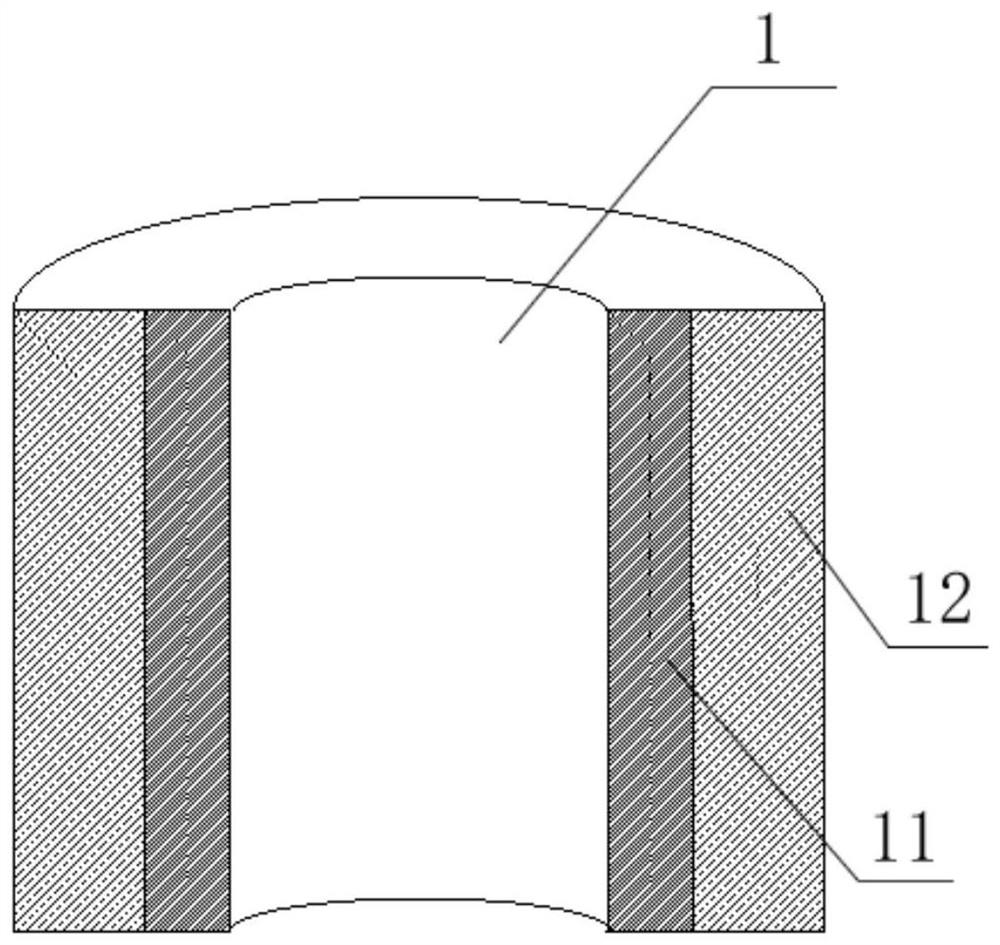

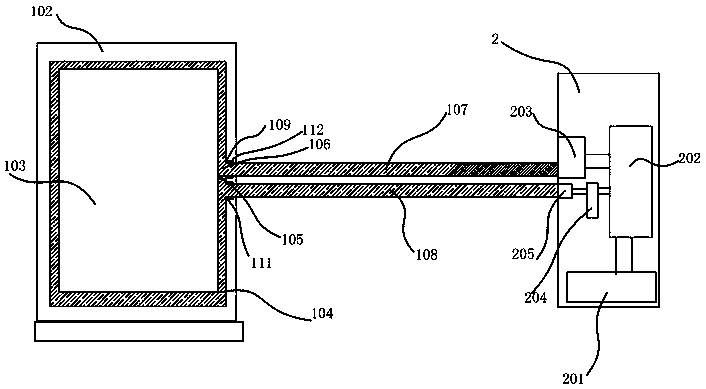

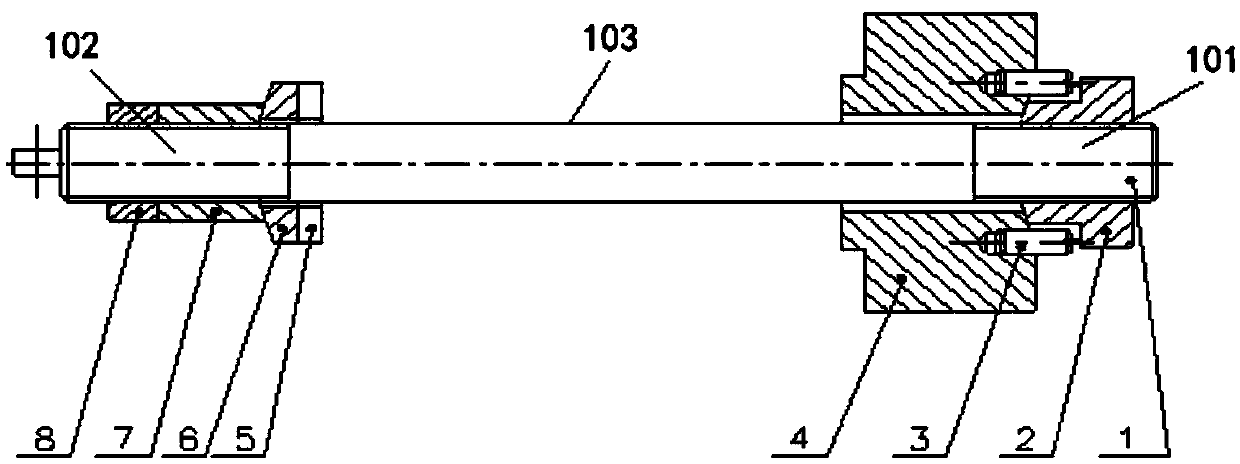

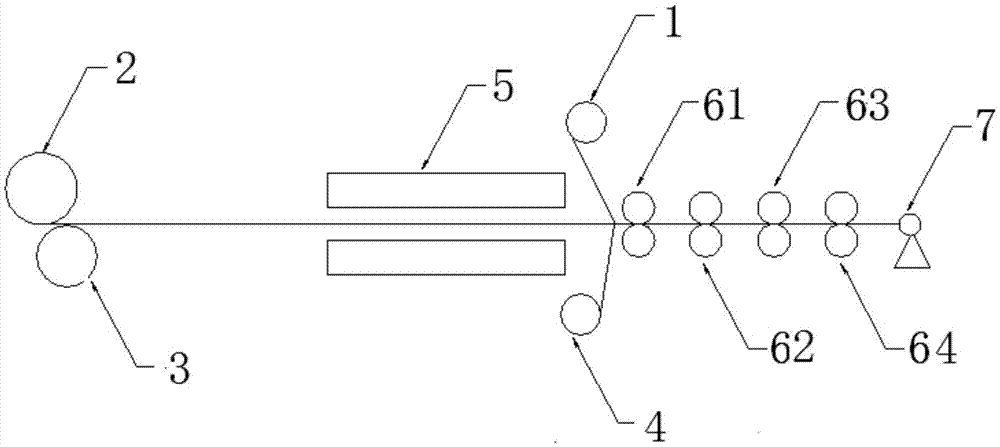

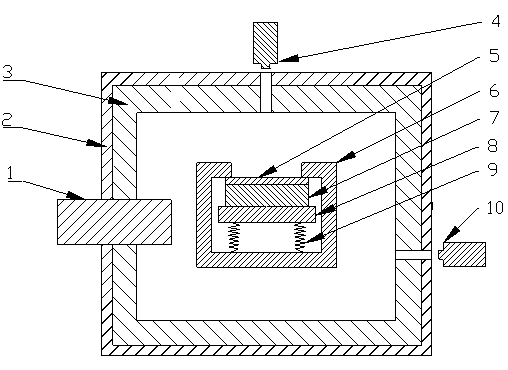

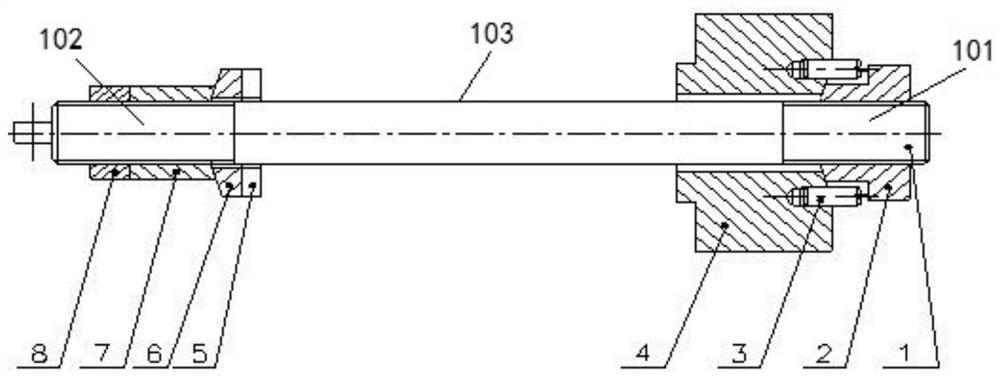

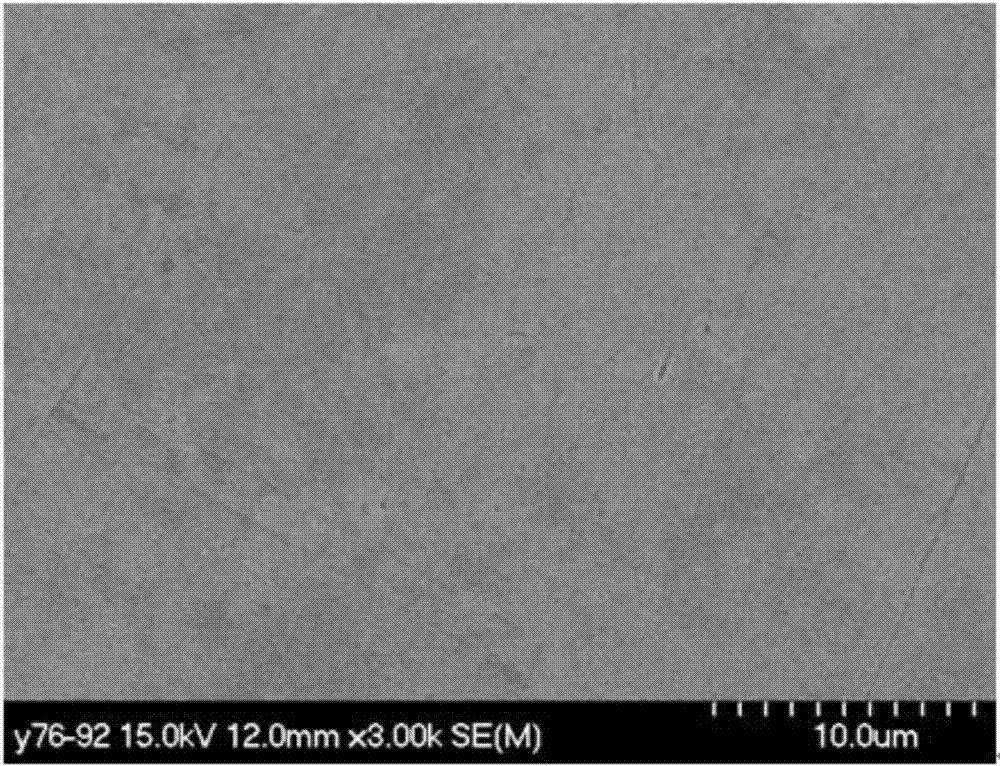

Method and device for preparing composite ceramic layer surface strengthened aluminum alloy material

InactiveCN102601373BImprove mechanical propertiesImprove wear resistanceChemical reactionSurface layer

Disclosed are a method and a device for preparing a composite ceramic layer surface strengthened aluminum alloy material. A composite ceramic layer is of a polyphase structure comprising SiC, SiO2, Al2O3, MgAl2O4 and the like, and grain size distribution of the polyphase structure ranges from submicron to nanometer. The basic production process method includes: coating mixed powder with a proper grain size and proper components on a cleaned matrix aluminum alloy surface; placing the matrix aluminum alloy surface coated with the mixed powder into a microwave sintering device and heating the matrix aluminum alloy surface to reach a proper temperature; leading a surface layer coated with the mixed powder to have corresponding physical and chemical reaction to generate the polyphase structure; and leading the surface layer and matrix aluminum alloys to be in metallurgical bonding to form the composite ceramic layer surface strengthened aluminum alloy material. The microwave sintering device used in the method comprises a microwave generator, a far infrared thermometer, a heat insulation plate, a microwave absorbing layer, a workpiece platform, a compression spring and the like, and an aluminum alloy matrix and the surface layer coated with the mixed powder can be simultaneously heated in the same microwave field.

Owner:CHINA UNIV OF MINING & TECH

Corrosion-resistant and abrasion-resistant VVT engine electromagnetic valve with outer protection structure

PendingCN114427487AEffective protectionAvoid collision damageMachines/enginesLift valveStructural engineeringMechanical engineering

The anti-corrosion and wear-resistant VVT engine electromagnetic valve with the outer protection structure comprises an electromagnetic valve body and a protection mechanism, the protection mechanism comprises a first clamping plate and a second clamping plate, anti-corrosion layers are arranged on the outer surface of the first clamping plate and the outer surface of the second clamping plate, wear-resistant layers are arranged on the outer sides of the anti-corrosion layers, and the anti-corrosion layers are arranged on the outer sides of the wear-resistant layers. The VVT engine electromagnetic valve comprises a first clamping plate and a second clamping plate, the two ends of the first clamping plate are each rotationally connected with two positioning plates, the two ends of the second clamping plate are each fixedly connected with two positioning blocks, clamping grooves corresponding to the positioning blocks are formed in the side walls of one ends of the positioning plates, and transverse plates are fixedly connected to the positioning plates. The electromagnetic valve can be effectively protected through the arrangement of the external protection assembly, collision damage is avoided, the good anti-corrosion and wear-resisting effects are achieved, the service life is prolonged, and the electromagnetic valve is suitable for application and popularization.

Owner:句容嘉晟汽车配件有限公司

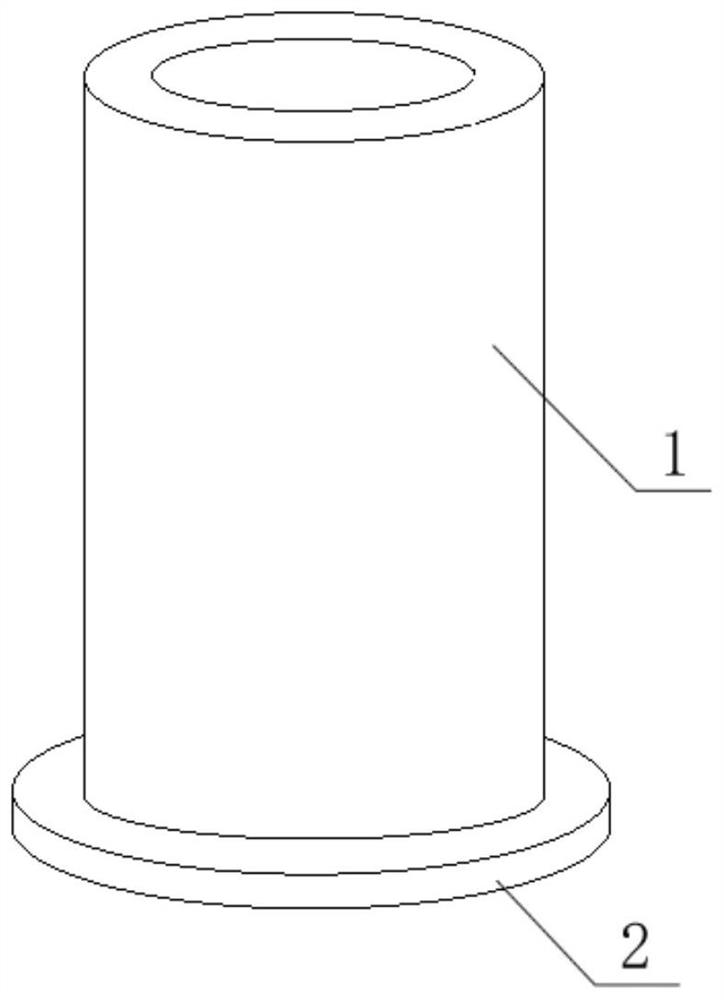

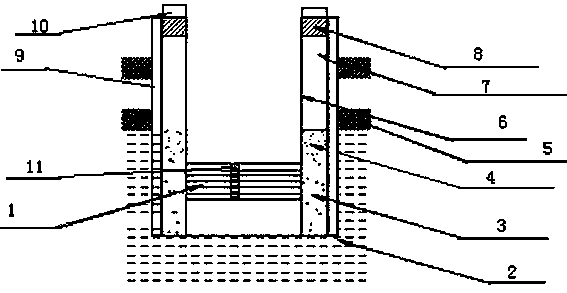

Novel well pipe structure

InactiveCN110939175ASimple and reasonable structural designGuaranteed cleanlinessWater conservationDrinking water installationCorrosion preventionWater pipe

The invention discloses a novel well pipe structure which comprises a water filtering pipe, a water-bearing layer, an artificial sand layer, a well pipe body, a building sand layer, a clay closing layer, a locating strengthening layer, a protecting layer and a filtering assembly. The filtering assembly is arranged in the water filtering pipe. The protecting layer is arranged at the side end of thewell pipe body. The clay closing layer is arranged at the upper end of the well pipe body. The locating strengthening layer is arranged at the upper end of the clay closing layer. The novel well pipestructure is simple and reasonable in design. The filtering assembly is arranged in the water filtering pipe, the filtering assembly can effectively filter and remove impurities in the water filtering pipe, and therefore the cleanness degree of water in the water filtering pipe is ensured. The protecting layer is arranged at the side end of the well pipe body, the clay closing layer is arranged at the upper end of the well pipe body, the locating strengthening layer is arranged at the upper end of the clay closing layer, the locating strengthening layer and the protecting layer are cast intoan integrally formed structure through stainless steel, the stainless steel is high in strength and good in corrosion and abrasion resisting property, the locating strengthening layer and the protecting layer can have the function of protecting the well pipe body, the service life of the well pipe body is prolonged, and the overall stability of the structure is ensured.

Owner:丁克芳

Nozzle of injection molding machine

The invention discloses a nozzle of an injection molding machine. A dirt isolation module is additionally arranged in an injecting cavity, and comprises multiple dirt isolation parts; each dirt isolation part comprises a cylindrical shell, and a dirt isolation baffle plate arranged in the shell; the dirt isolation baffle plates are magnetic components, and can absorb hard blocks or impurities on the surfaces to prevent blockage of the injecting cavity and the nozzle due to feeding into the injecting cavity and the nozzle along with injection molding raw material fluids; the dirt isolation baffle plates are staggered on the inner wall of the injecting cavity to increase the contacted areas between the fluids and the dirt isolation baffle plates, so that the hard blocks or the impurities inthe fluids are easier to contact with the dirt isolation baffle plates to be absorbed by the baffle plates; the injecting cavity, the nozzle and a connecting part are in threaded connection, so that the injecting cavity can be disassembled for replacement or cleaning as needed to achieve convenience, practicability and reasonable design; and the shells of the dirt isolation parts are made of corrosion-resistance and wear-resistance polytetrafluoroethylene materials, so that the scouring corrosion of the injection molding raw material fluids to the shells is effectively prevented, the service life of the shells is prolonged, and the service life of the nozzle is prolonged.

Owner:NINGBO XINKETUO MACHINERY MFG CO LTD

Concrete cover anchor bolt device

ActiveCN109629399BImprove anti-corrosion and wear-resistant effectImprove toughnessBridge structural detailsBridge materialsArchitectural engineeringEngineering

Owner:SHAANXI TIEMA FORGING

Tensioning bracket structure for harvester

InactiveCN107683680AFirmly connectedSolve the problem of unstable structural connectionsMowersEngineeringUltimate tensile strength

The invention discloses a harvester tensioning support structure, comprising a first support (1), a second support (2), a third support (3), a reinforcing rib assembly (4), a fixed support (5) and a Wear-resistant anti-corrosion layer (8); the surface of the fixed support (5) is coated with a wear-resistant anti-corrosion layer (8), and the wear-resistant anti-corrosion layer (8) is attached to the fixed support (5), and the fixed support ( 5) A first bracket (1) is provided on one side, and the first bracket (1) is connected to a fixed support (5) by welding, and a second bracket (2) is provided on the other side of the fixed support (5) ) and the third bracket (3), the second bracket (2) and the third bracket (3) are connected to the fixed support (5) by welding, the second bracket (2) is parallel to the third bracket (3), The first bracket (1), the second bracket (2) and the third bracket (3) are provided with reinforcing rib components (4). The structure connection of the invention is very stable, the support strength is high, the fixed support has excellent wear resistance and anticorrosion performance, and is extremely suitable for large-scale agricultural production.

Owner:朱怀东

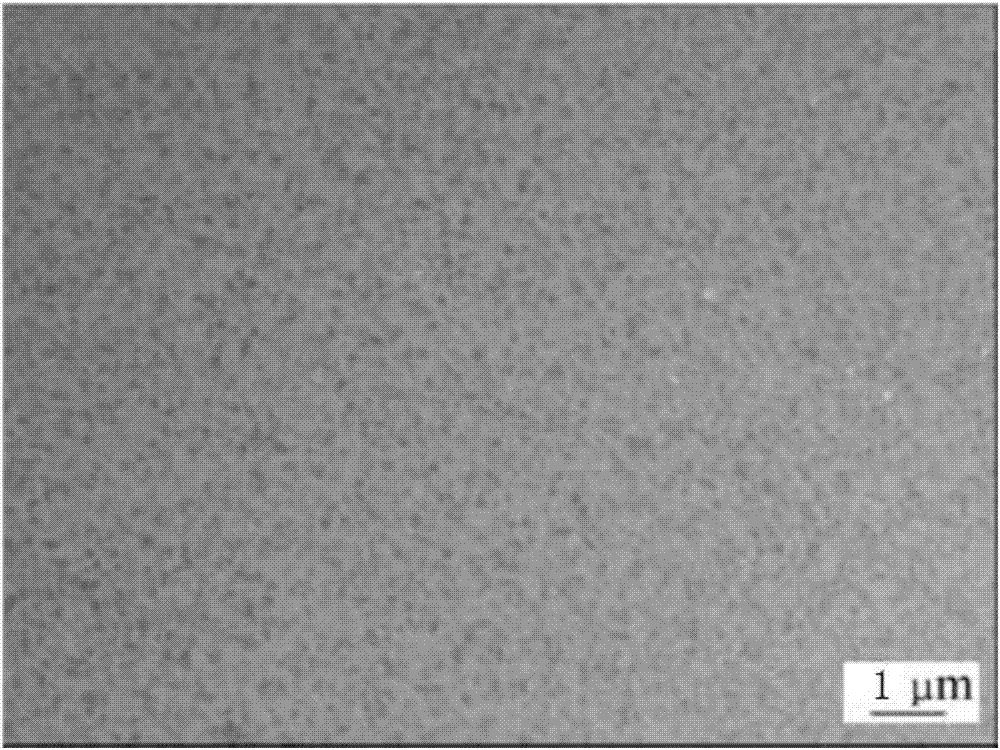

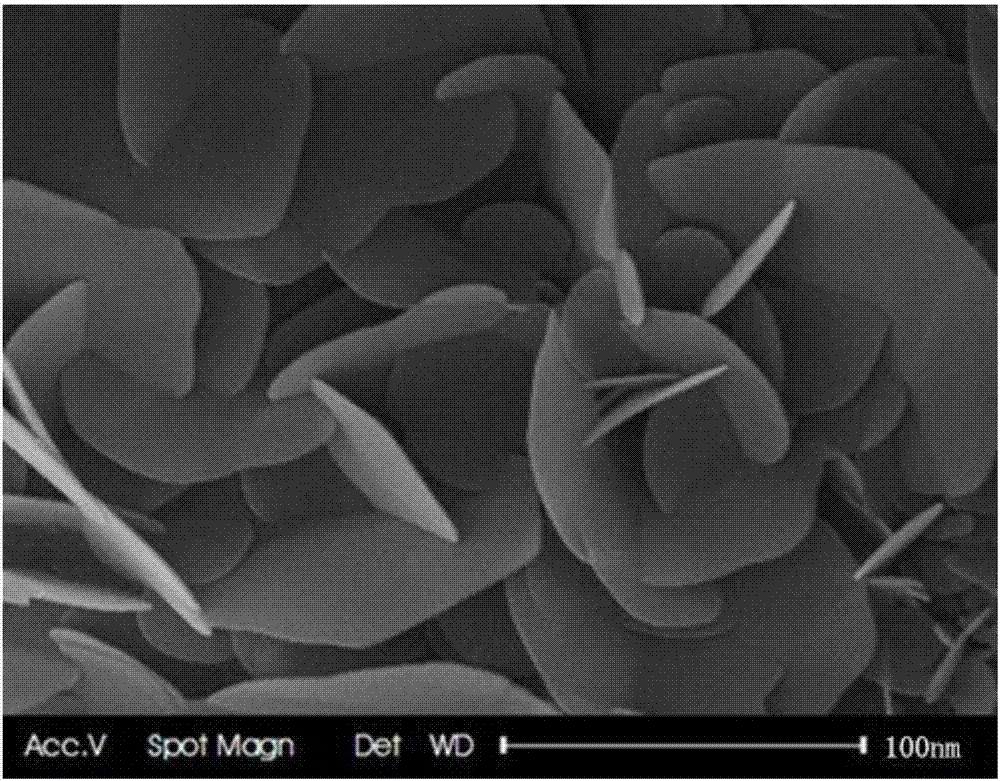

A rare earth-nickel-cobalt-tungsten disulfide multi-element alloy anti-corrosion and wear-resistant composite coating, electroplating solution and preparation method thereof

The invention discloses a rare earth-nickel-cobalt-tungsten disulfide multi-element alloy anti-corrosion and wear-resisting composite plating layer and electroplating solution and a preparation method of the electroplating solution. The plating layer is of a particle structure with an intermetallic compound and nanometer tungsten disulfide dispersed on a nanocrystalline matrix. The plating-state microhardness of the plating layer ranges from HV 700 to HV 1,200. The plating layer is prepared from, by weight, 1%-55% of cobalt, 0.5%-12% of rare earth, 0.1%-5% of tungsten disulfide and the balance nickel. The electroplating solution is prepared from 260 g / L-400 g / L of nickel sulfate, 10 g / L-75 g / L of cobalt sulfate, 30 g / L-50 g / L of nickel chloride, 35 g / L-55 g / L of boric acid, 0.1 g / L-28 g / L of rare earth, 1 g / L-35 g / L of sodium borohydride, 2 g / L-20 g / L of triethylene tetramine, 5 g / L-40 g / L of citric acid, 5 g / L-20 g / L of malonic acid and 0.01 g / L-4.9 g / L of tungsten disulfide. The appearance of the plating layer is bright, smooth, free of cracks and compact, and meanwhile the plating layer is high in plating-state hardness, small in internal stress, high in thickness plating capacity and good in anti-corrosion and wear-resisting performance and has good comprehensive mechanical performance; meanwhile, the electroplating solution and the plating layer are simple in preparation method, and operation is easy; and adopted materials are friendly to environment, production efficiency is high, and energy saving and environment protection are achieved.

Owner:上海荟金纳米材料有限公司

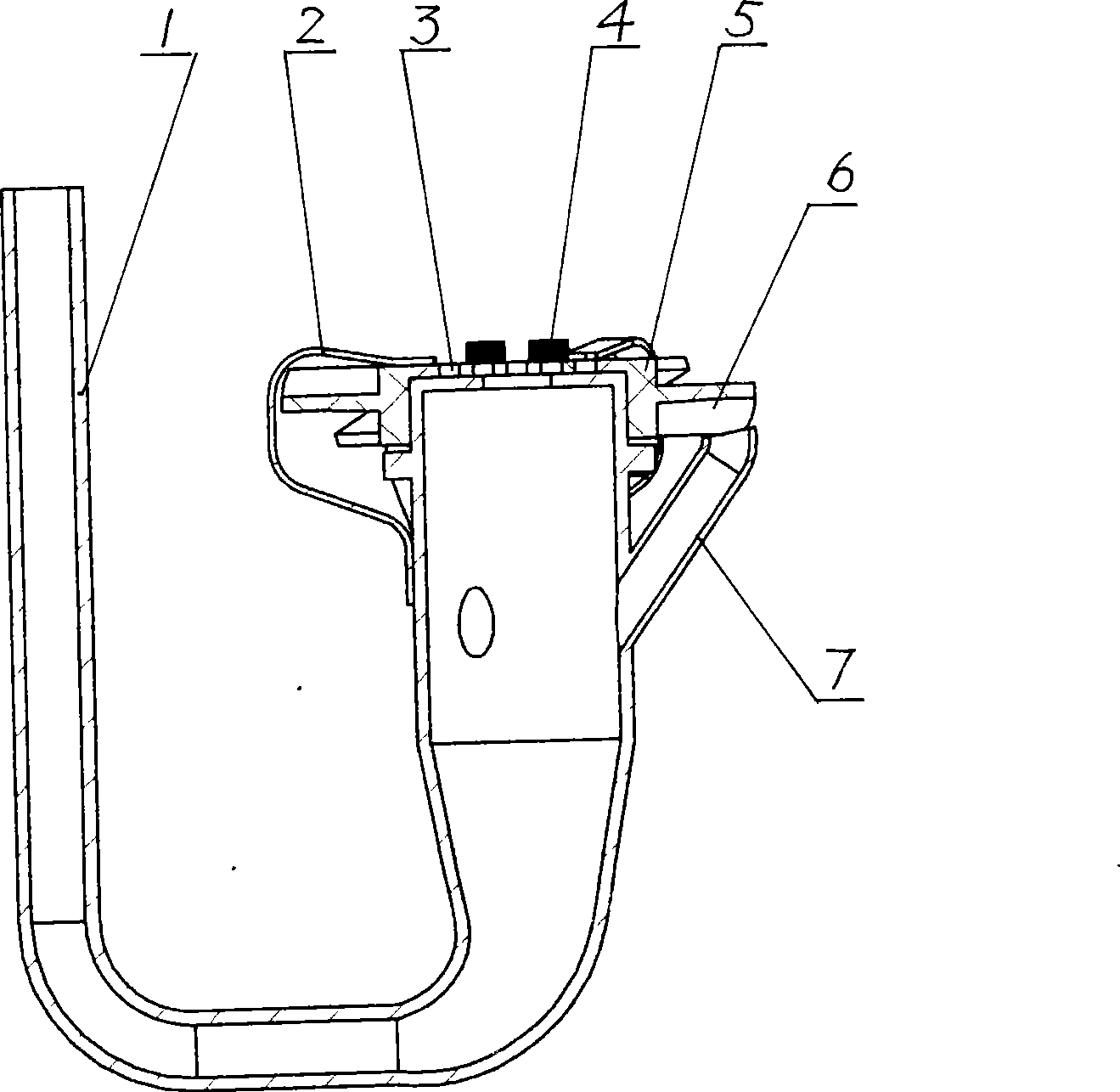

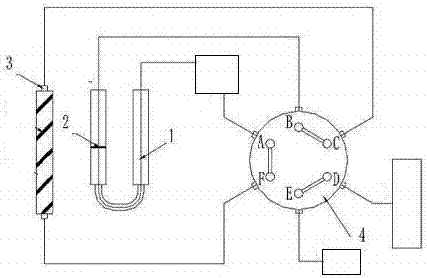

Degassing device for on-line monitoring of transformer oil chromatography

The invention relates to a degassing device for transformer oil-chromatography online monitoring. The degassing device for transformer oil-chromatography online monitoring comprises a U-shaped blow-sweep pipe, a porous quartz sieve plate, a trapping pipe and a six-way valve, wherein the external surface of the six-way valve is coated with an anticorrosion and antiwear layer, and the anticorrosion and antiwear layer is prepared from, by weight, 20-30 parts of quartz powder, 10-15 parts of mica powder, 5-7.5 parts of silicon carbide, 2-6 parts of isocyanate, 11-15 parts of acrylic resin, 22-30 parts of chlorinated polyether resin, 5-10 parts of zinc stearate, 1-4 parts of zinc borate, 10-15 parts of xylene, 2-6 parts of poly 2,3-dimethylaniline, 4-7 parts of double benzylamine ether, 10-13 parts of polymeric ferric silicate sulfate, 10-23 parts of white oil, 5-10 parts of ferro-silicon nitride powder and 15-20 parts of water. The degassing device is provided with the anticorrosion and antiwear multiple-way valve, and the safety performance of the degassing device can be fully guaranteed.

Owner:JIANGSU UONONE ELECTRIC AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com