Painting method for antiseptic wear-resistant coating of PC joist steel jointing plate and PC joist steel jointing plate

A technology of anti-corrosion and wear-resisting, coating method, applied in the direction of coating, surface coating liquid device, pre-treatment surface, etc. Problems such as installation and construction quality, to achieve the effect of prolonging the normal service life, prolonging the normal service life, and reducing on-site maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

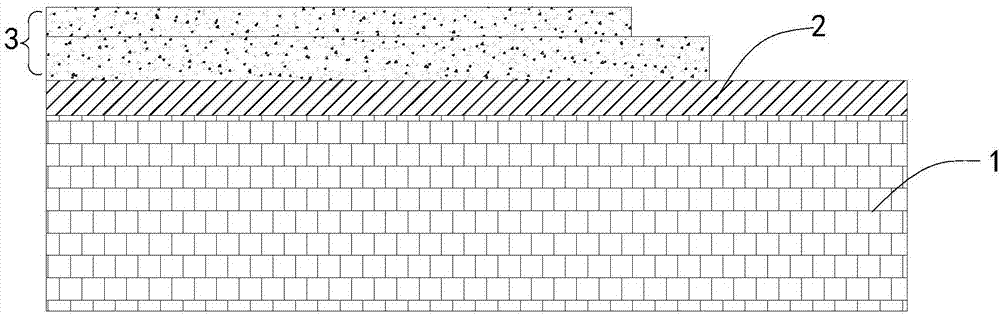

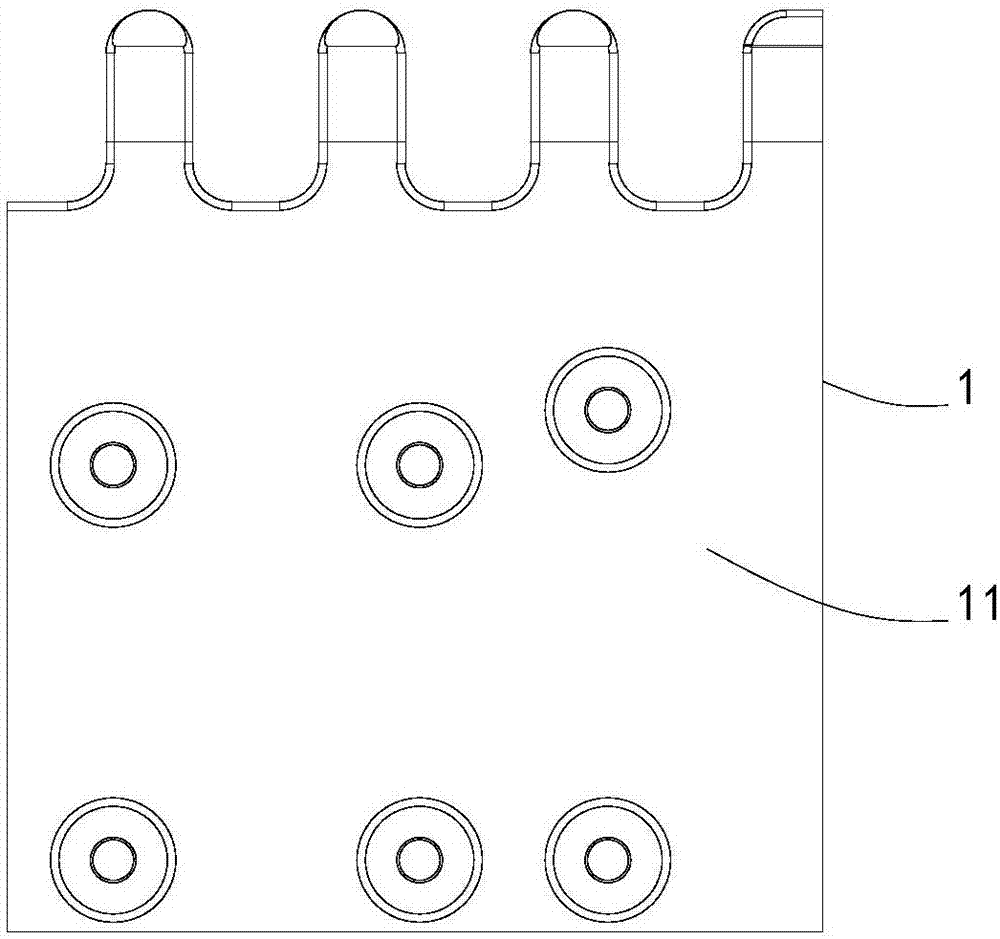

[0037] Such as figure 1 and figure 2 As shown, the PC beam steel seam plate anti-corrosion and wear-resistant coating method includes the following steps:

[0038] S1, performing pretreatment on the steel joint plate 1, so that the surface to be painted of the steel joint plate 1 is clean, dust-free, rust-free, and grease-free, and the roughness of the steel joint plate 1 reaches a preset level Require;

[0039] S2, performing co-infiltration anti-corrosion treatment on the pretreated surface of the steel joint plate 1 to be coated, so that a layer of metal alloy co-infiltration anti-corrosion layer 2 is formed on the surface to be coated of the steel joint plate 1;

[0040] S3, coating the anti-corrosion and wear-resistant paint film 3 on the metal alloy co-infiltrated anti-corrosion layer 2, and wait until the anti-corrosion and wear-resistant paint film 3 is dry.

[0041] The pretreatment process in S1 is specifically as follows: first, the surface of the steel seam pla...

Embodiment 2

[0068] Such as figure 1 and figure 2 As shown, in the PC beam steel seam plate of this embodiment, the steel seam plate is coated with an anti-corrosion and wear-resistant coating 3, and the anti-corrosion and wear-resistant coating 3 is coated on the The surface to be painted of the steel seam plate 1 . The PC beam steel joint plate of this embodiment has a long service life and good anti-corrosion and wear-resisting effects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com