Anticorrosion tape and preparation method thereof

An anti-corrosion tape, anti-corrosion and wear-resistant technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems affecting the application range of anti-corrosion tape, poor interlayer adhesion, and reduced service life. Achieve the effects of simple manufacturing process, good anti-corrosion and wear-resistant effect, and corrosion-resistant service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

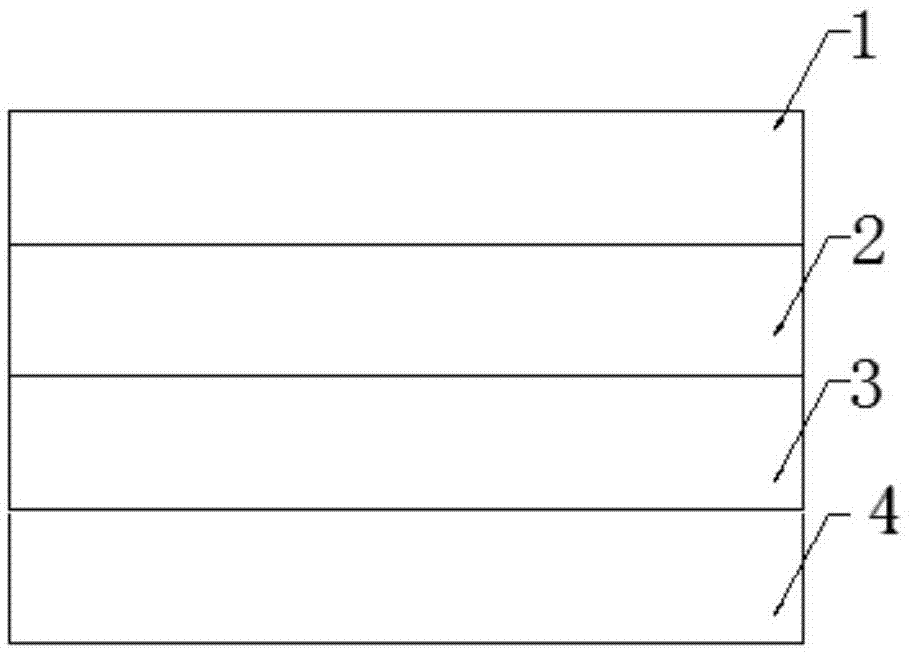

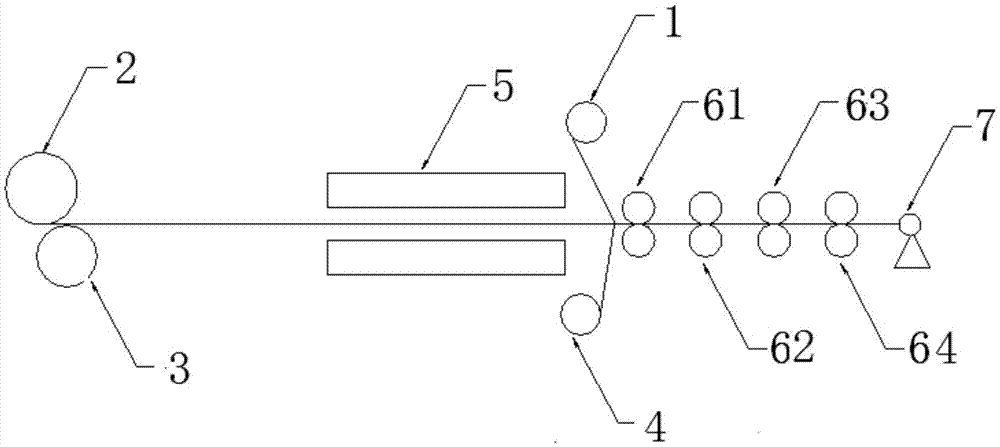

[0033] Such as figure 1 as shown, figure 1 It is a schematic structural view of the anti-corrosion tape shown in Example 1. figure 2 It is a schematic diagram of the molding process of the anti-corrosion tape shown in Example 1.

[0034] An anti-corrosion belt comprises a film layer 1, an anti-corrosion and wear-resistant layer 2, a connecting layer 3 and an adhesive layer 4 sequentially from top to bottom.

[0035] The thickness of the film layer is 0.1mm; the thickness of the anti-corrosion and wear-resistant layer is 0.5mm; the thickness of the connecting layer is 0.2mm; the thickness of the adhesive layer is 0.5mm.

[0036] The film layer is polyethylene terephthalate (PET).

[0037] The anti-corrosion and wear-resistant layer is a continuous fiber reinforced thermoplastic composite material, the thermoplastic substrate is polyethylene terephthalate, and the continuous fiber is continuous glass fiber.

[0038] The connecting layer is polyester fiber cloth.

[0039] T...

Embodiment 2

[0047] An anti-corrosion belt comprises a film layer 1, an anti-corrosion and wear-resistant layer 2, a connecting layer 3 and an adhesive layer 4 sequentially from top to bottom.

[0048] The thickness of the film layer is 0.5mm; the thickness of the anti-corrosion and wear-resistant layer is 1mm; the thickness of the connecting layer is 0.4mm; the thickness of the adhesive layer is 1.5mm.

[0049] The film layer is PET-aluminum foil composite film.

[0050] The anti-corrosion and wear-resistant layer is a continuous fiber reinforced thermoplastic composite material, the thermoplastic substrate is selected from polypropylene, and the continuous fiber is continuous aramid fiber.

[0051] The connecting layer is polyester fiber cloth.

[0052] The adhesive layer is polyamide hot melt adhesive.

[0053] A preparation method of the above-mentioned anti-corrosion tape, comprising the following steps:

[0054] (1) Prepare continuous fiber-reinforced thermoplastic composite mater...

Embodiment 3

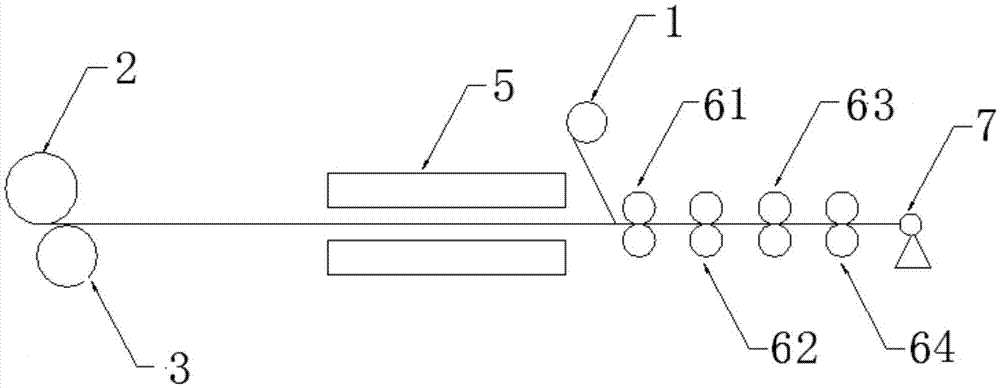

[0060] Such as image 3 as shown, image 3 It is a schematic flow chart of the molding process of the anti-corrosion tape shown in Example 3. intention.

[0061] An anti-corrosion belt comprises a film layer 1, an anti-corrosion and wear-resistant layer 2, a connecting layer 3 and an adhesive layer 4 sequentially from top to bottom.

[0062] The thickness of the film layer is 0.2mm; the thickness of the anti-corrosion and wear-resistant layer is 0.15mm; the thickness of the connecting layer is 0.25mm; the thickness of the adhesive layer is 1mm.

[0063] The film layer is PET-aluminum foil composite film.

[0064] The anti-corrosion and wear-resistant layer is a continuous fiber reinforced thermoplastic composite material, the thermoplastic substrate is selected from polyethylene, and the continuous fiber is continuous glass fiber.

[0065] The connecting layer is nylon fiber cloth.

[0066] The adhesive layer is epoxy resin coal tar pitch mixture.

[0067] A preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com