Low-cost metal filter bag for dust removal

A metal filter bag, low-cost technology, applied in filtration separation, dispersed particle filtration, transportation and packaging, etc., can solve the problem of high cost, achieve the effect of low production cost, good coating uniformity, and easy wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

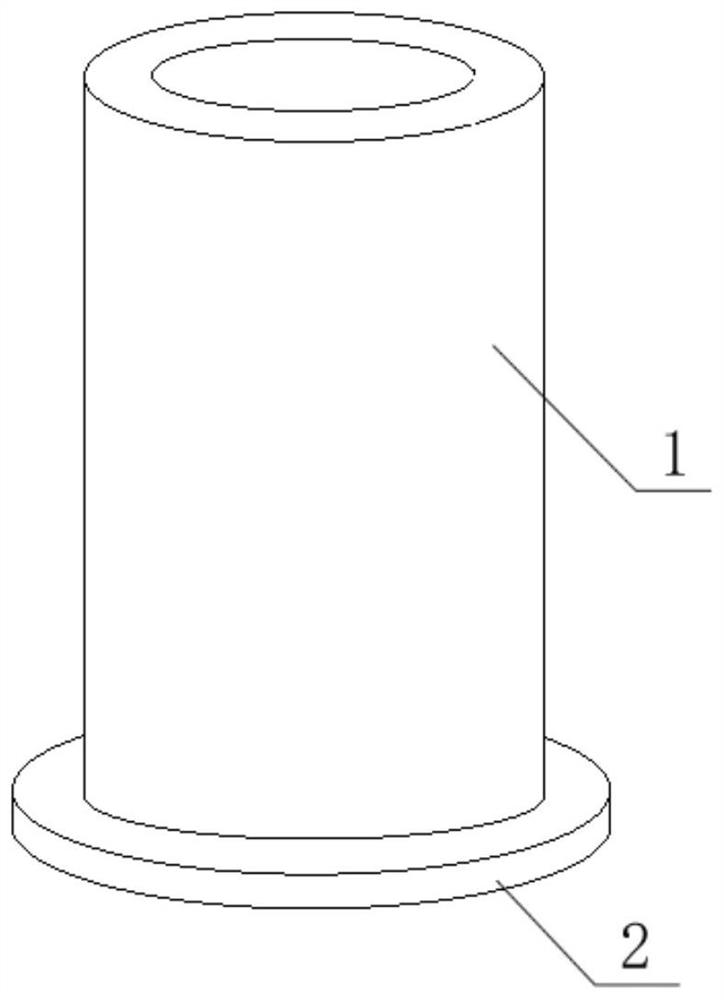

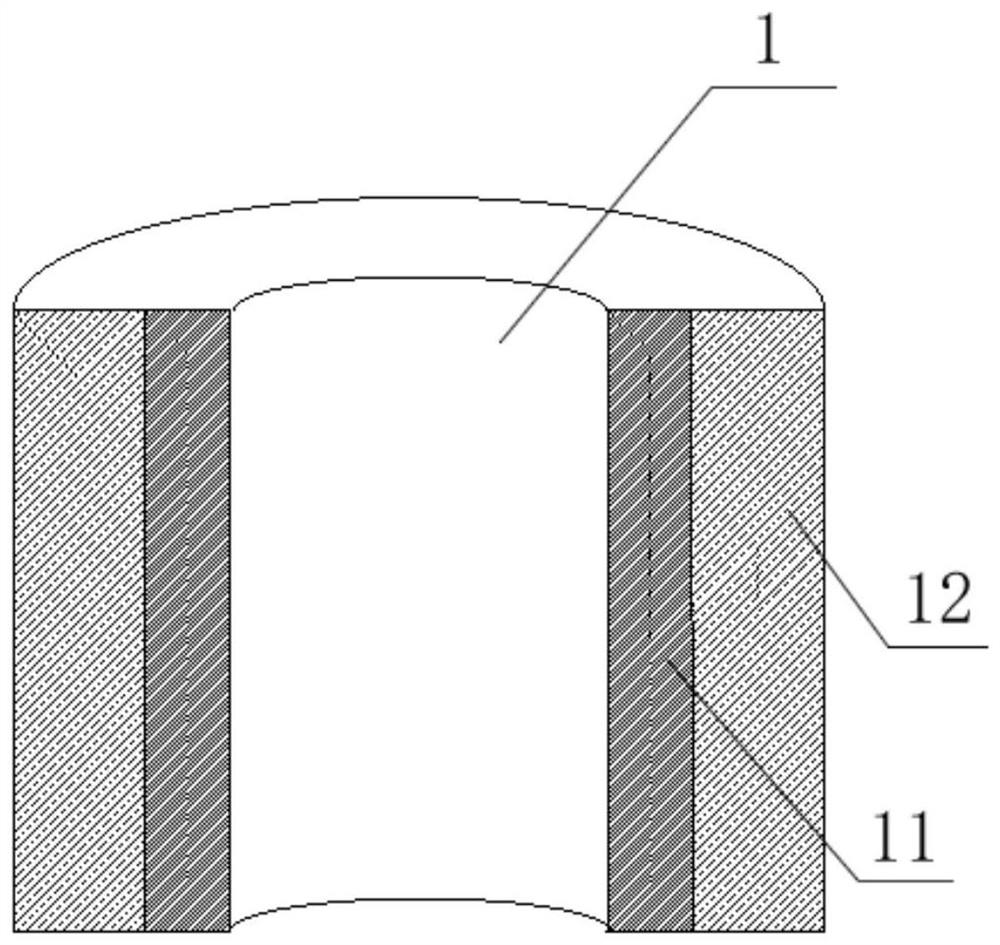

[0025] Such as figure 1 with figure 2 As shown, the present embodiment provides a low-cost metal filter bag 1 for dust removal, including a fine filter layer 11 and a coarse filter layer 12, the fine filter layer 11 is located inside the coarse filter layer 12, and the fine filter layer 11 is a filter structure. The coarse filter layer 12 is a supporting and air-permeable structure, the fine filter layer 11 includes 316L stainless steel metal fiber felt, and the coarse filter layer 12 includes 446 stainless steel or high temperature resistant carbon steel metal fiber felt. The metal filter bag for dust removal is a cascade filter material structure. The high temperature carbon steel metal fiber felt is Q235 metal fiber felt or Q195 metal fiber felt. The thickness of the coarse filter layer 12 is greater than the thickness of the fine filter layer 11 .

[0026] In terms of function, the fine filter layer is mainly used as a filter layer, and the coarse filter layer is used ...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, except that the coarse filter layer uses 446 stainless steel metal fiber felt with a relatively low price as the substrate, and the thickness ratio of the fine filter layer to the coarse filter layer is 1:2.

Embodiment 3

[0035] This embodiment is substantially the same as Embodiment 1, except that the coarse filter layer uses Q235 metal fiber felt which is relatively cheap as the substrate, and the thickness ratio of the fine filter layer to the coarse filter layer is 2:3.

[0036] Example 3

[0037] This embodiment is basically the same as Embodiment 1, except that the coarse filter layer uses Q195 metal fiber felt with a relatively low price as the substrate, and the thickness ratio of the fine filter layer to the coarse filter layer is 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com