Patents

Literature

116results about How to "Guaranteed dust removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

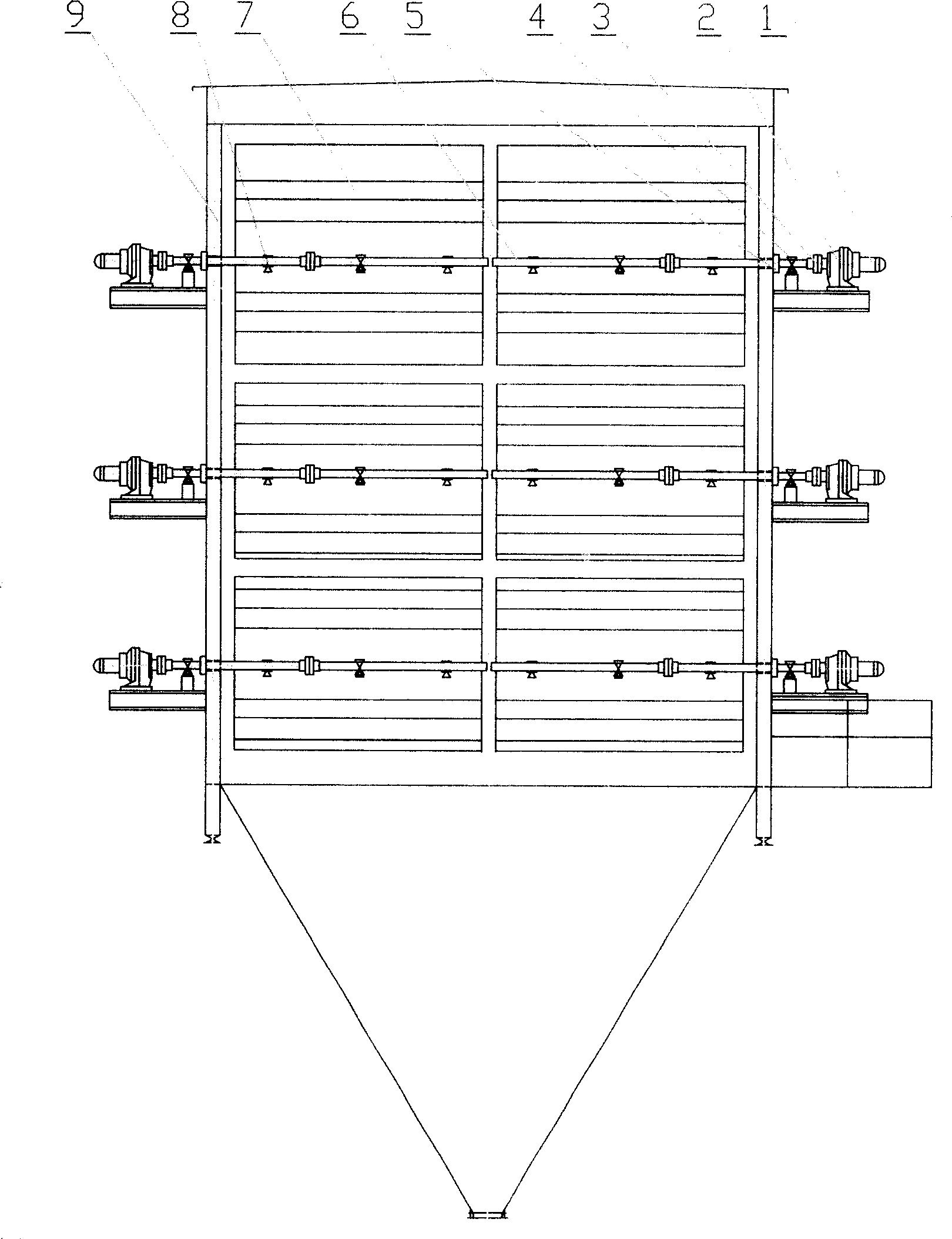

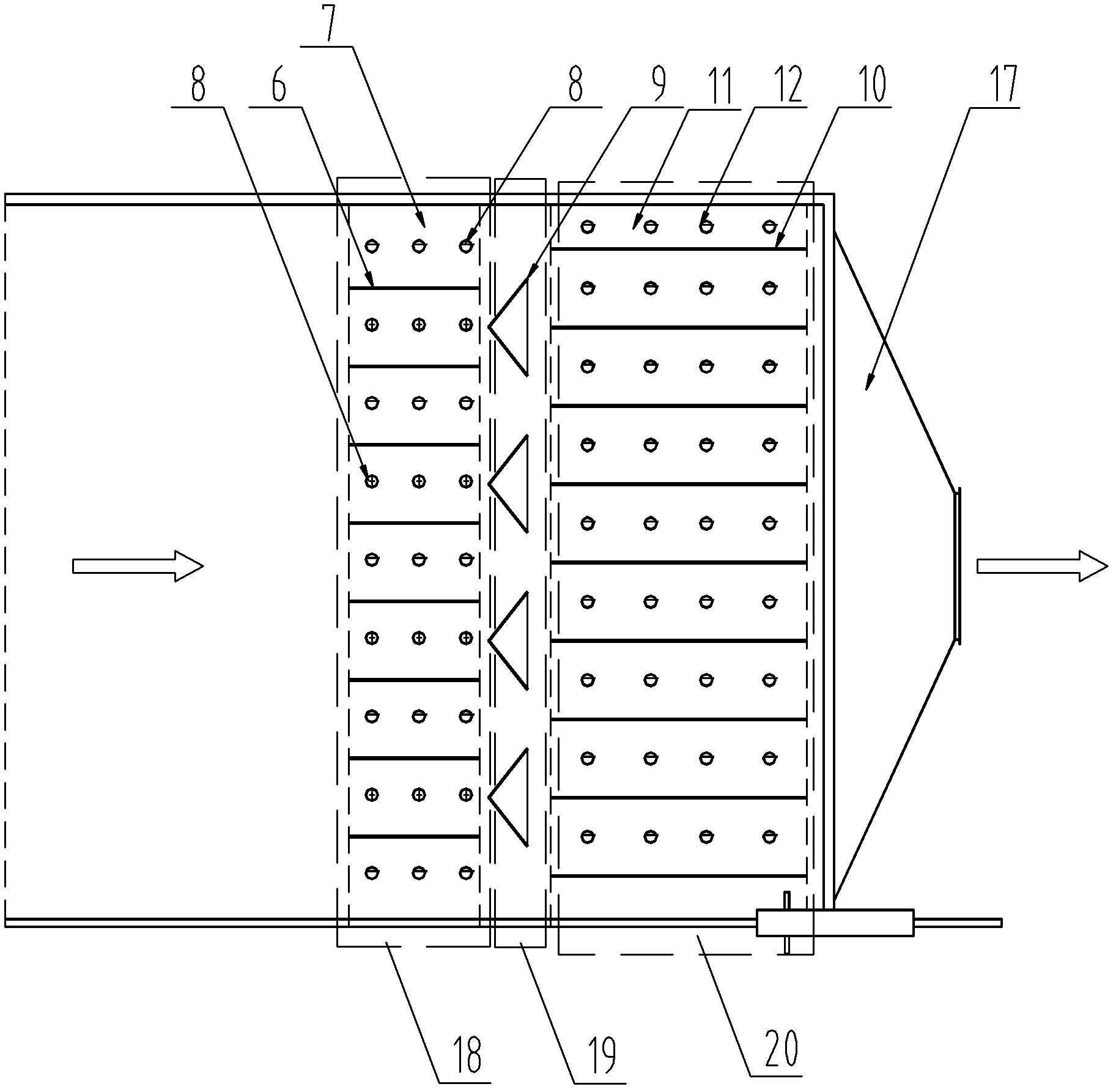

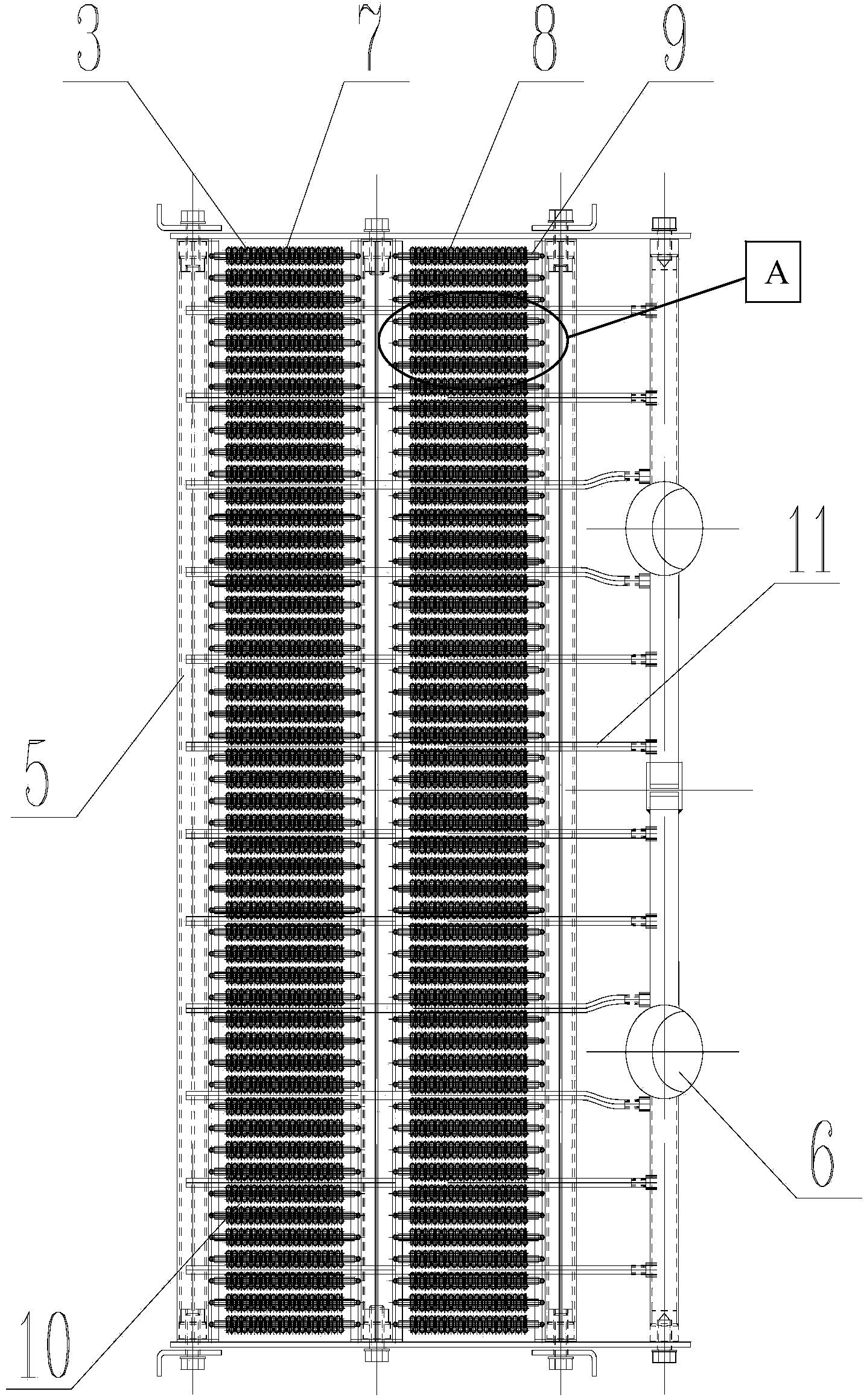

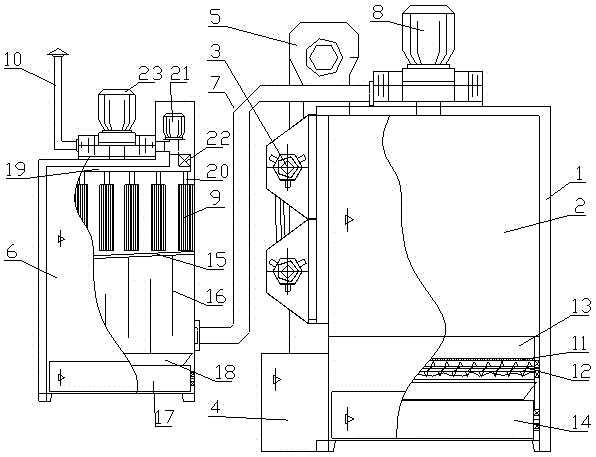

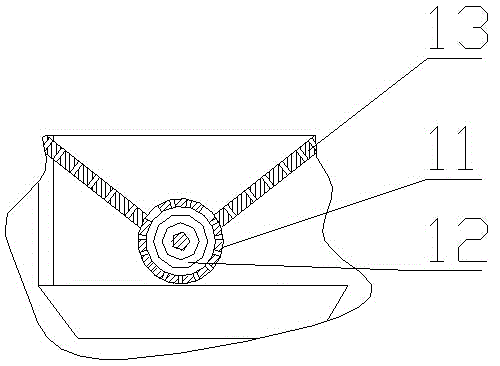

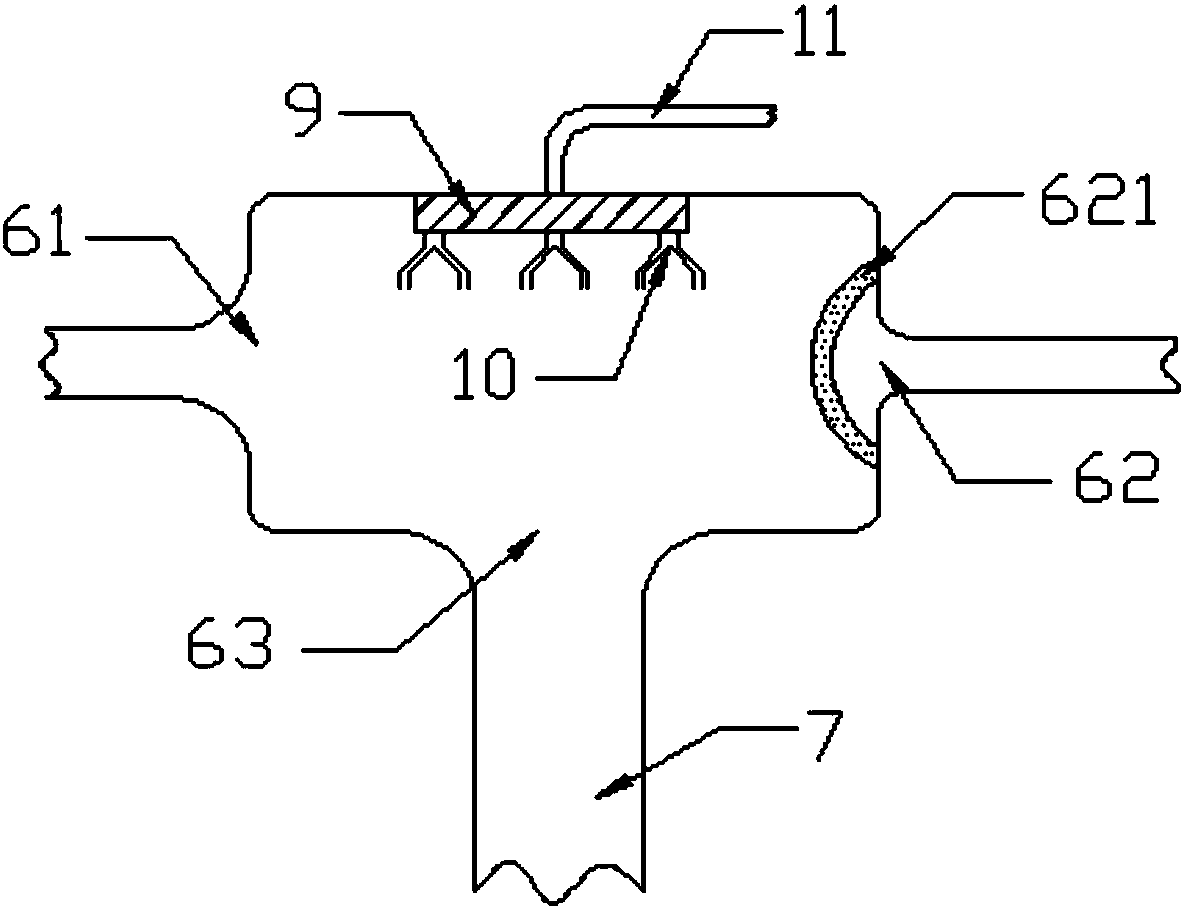

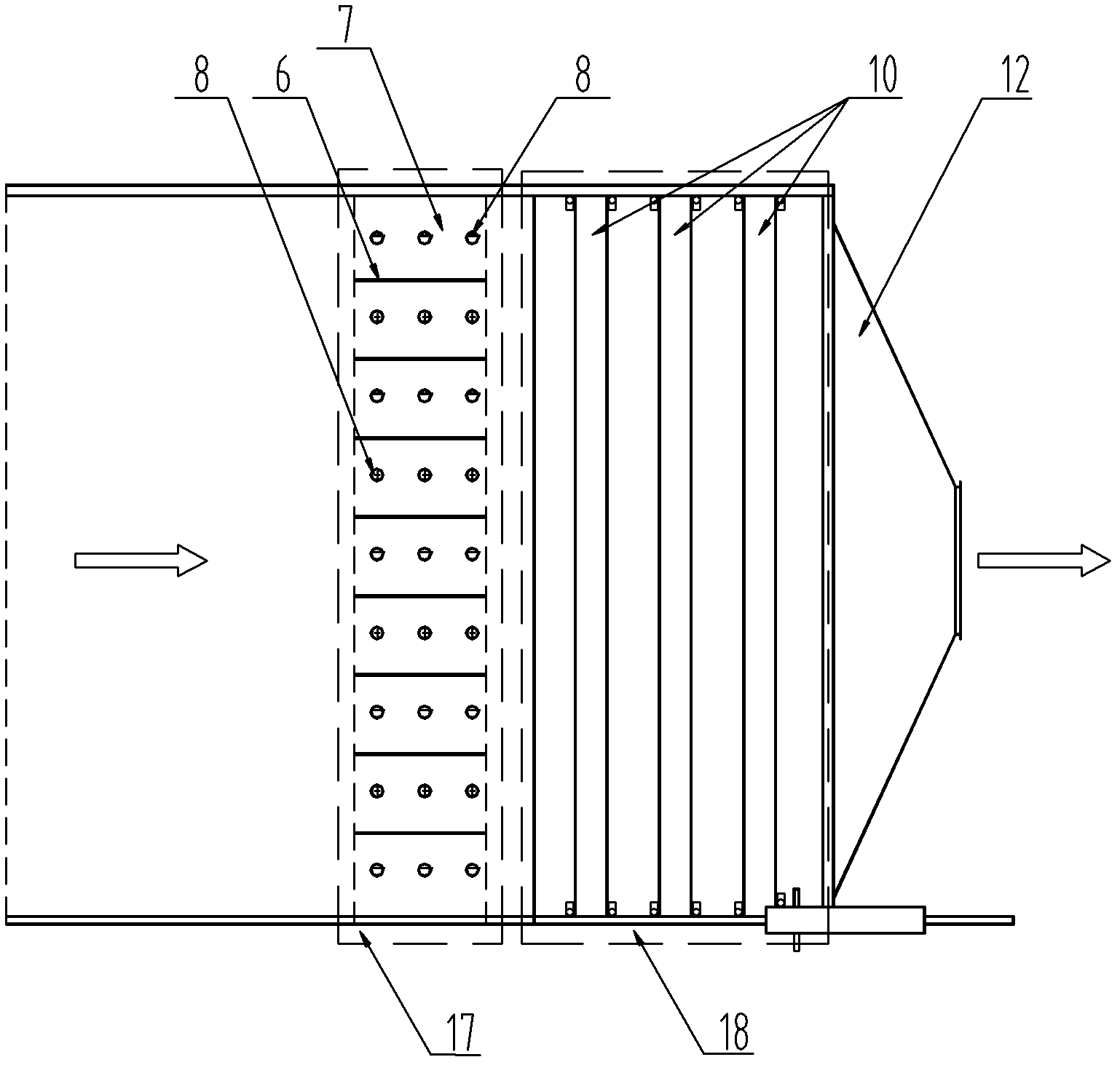

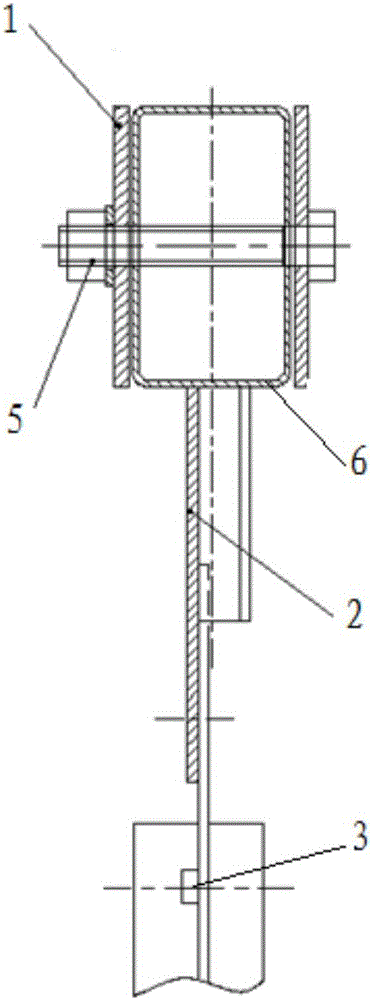

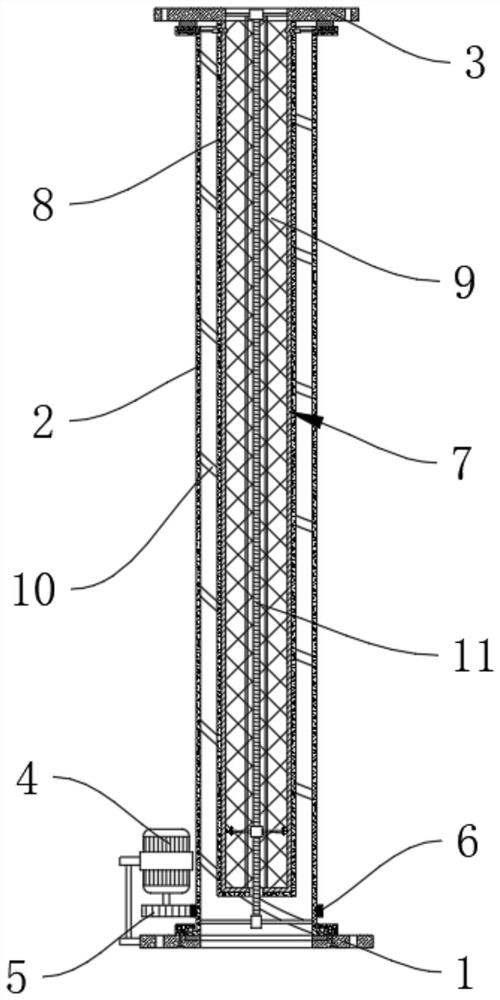

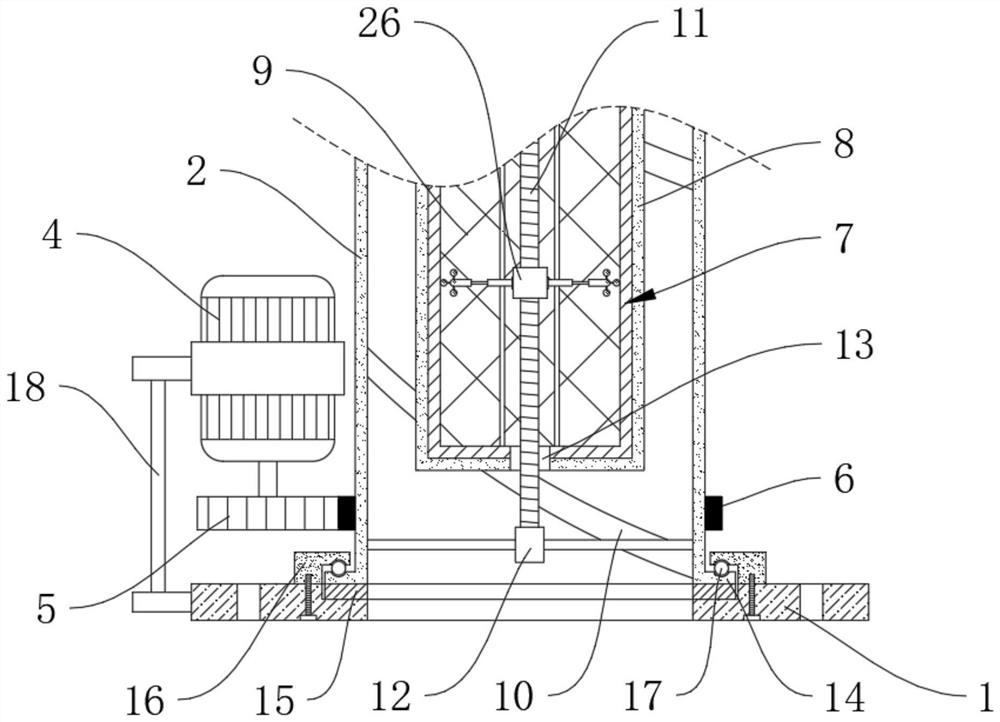

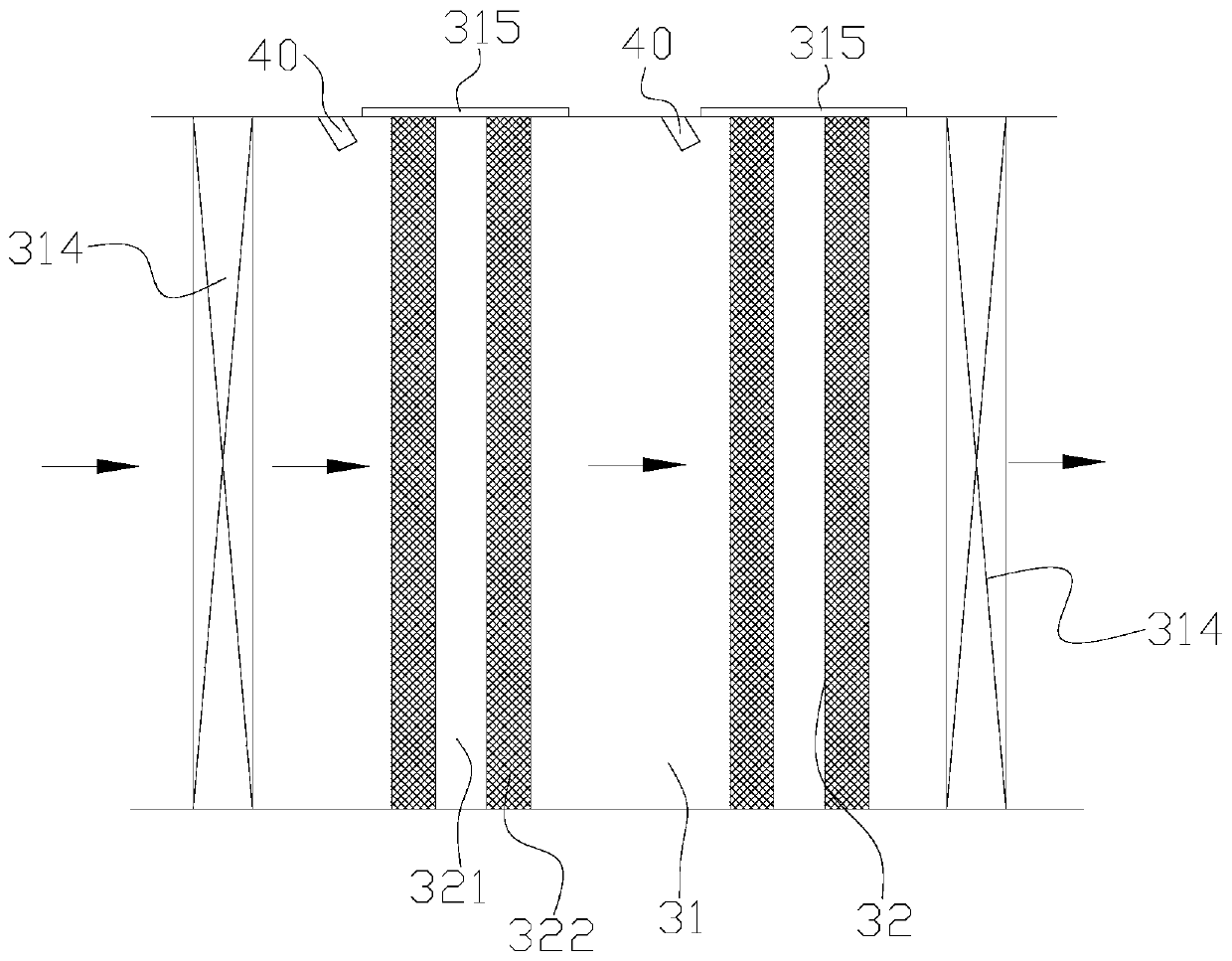

Method for adjusting airflow distribution of electricity and fabric combined dust catcher, and equipment

InactiveCN1915474AGuaranteed dust removal efficiencyExtend your lifeCombination devicesElectricityAuto regulation

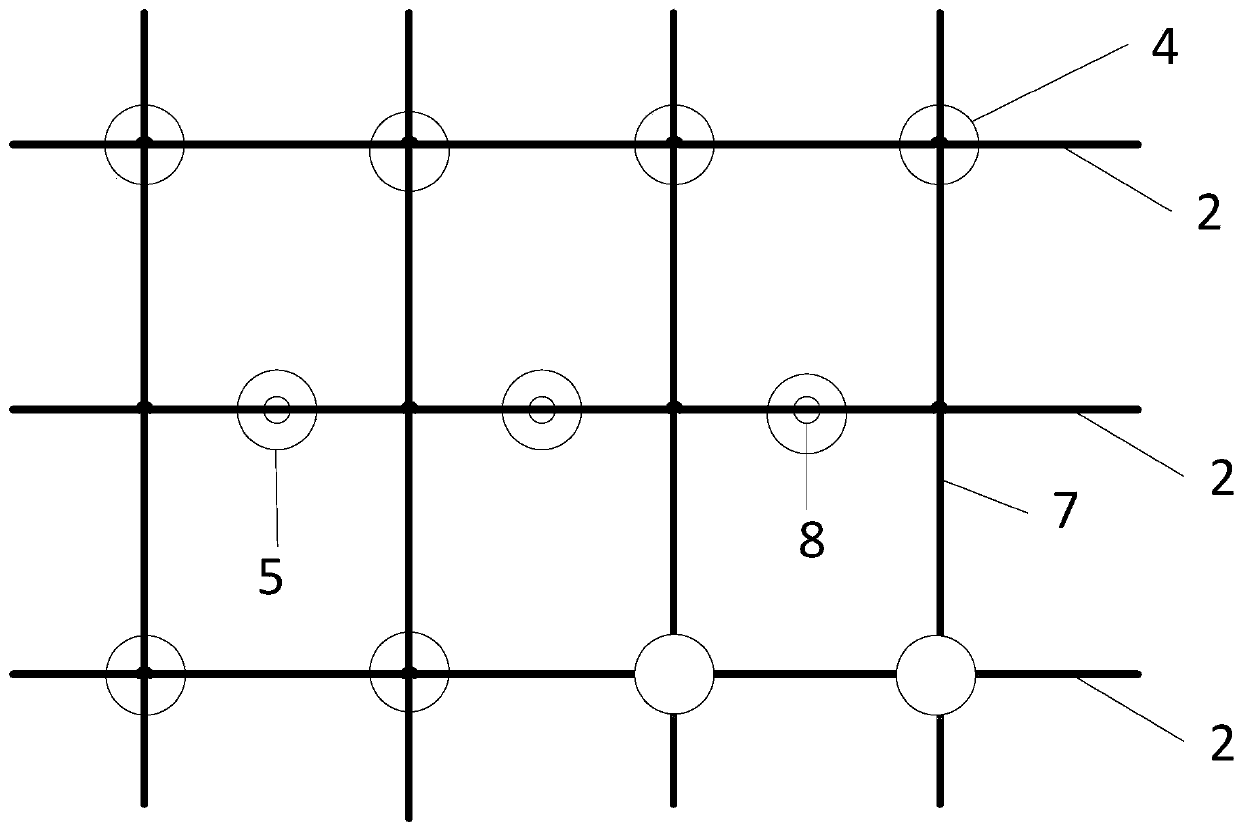

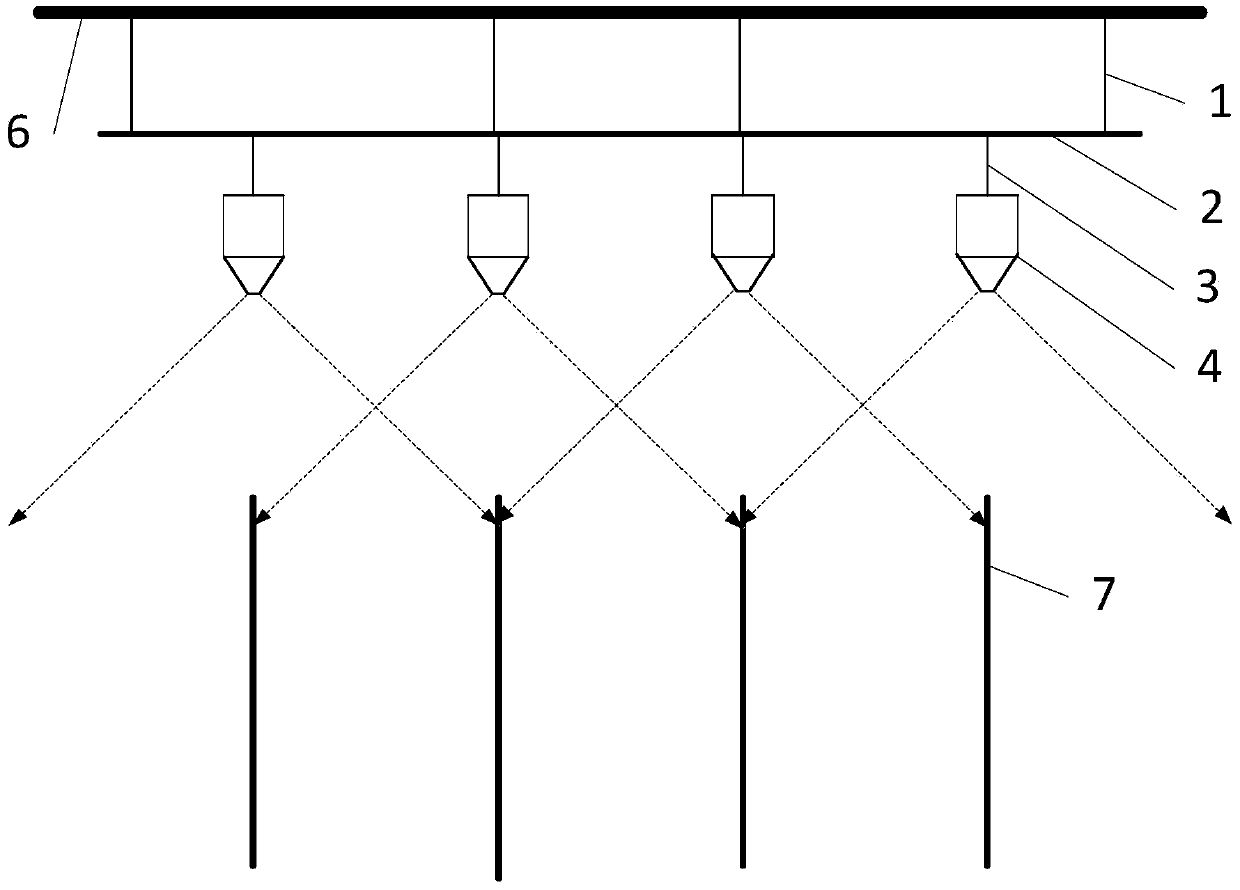

A method for regulating the airflow distribution in electricity-cloth combined duster includes such steps as measuring the data about the variation of flue speed by multiple high-sensitivity anemometers arranged on the cross-section of duster, sending the data to computer, comparing it with a predefined theoretic value, analyzing, and outputting the instruction according to calculated result to control the rotation of guide blades. Its apparatus is composed of horizontal duster's casing, regulating axle controlled by computer, guide blades on said regulating axle, axle coupling, speed reducer, electric executor and multi-hole plate.

Owner:JIANGSU YUDA POWER STATION AUX EQUIP & VALVE MFR

Electric mote remover

InactiveCN102631989AEfficient captureLow investment costExternal electric electrostatic seperatorElectricityElectrical polarity

The invention provides an electric mote remover, comprising a coagulation area, a diversion area and a film type static dust-removing area which are communicated in sequence. The coagulation area is conducted with a normal electric dust-removing system; a plurality of dust collecting boards are arranged at intervals, so as to form a plurality of mote channels the direction of which are consistent with the mote direction; discharging electrodes which are vertical to the mote direction and are the same in polarity are arranged in the same mote channel; the polarities of discharging electrodes in the adjacent mote channels are reverse, so that motes passing through the area carry different charges; the diversion area is communicated with the coagulation area; a plurality of diversion plates which are vertical with the mote direction are arranged; the side faces of the diversion plates face to the mote direction, so that the motes with the different charges are coagulated in the area; the film type static dust-removing area is communicated with the diversion area and is provided with a plurality of dust collecting films at intervals, so as to form a plurality of charge mote channels in a direction consistent to the mote direction; and a plurality of cathode discharging electrodes are arranged in each charge mote channel, so that the coagulated charge motes are captured by the dust collecting films. The electric mote remover provided by the invention has the advantages of optimal effect and low cost.

Owner:HUANENG CLEAN ENERGY RES INST

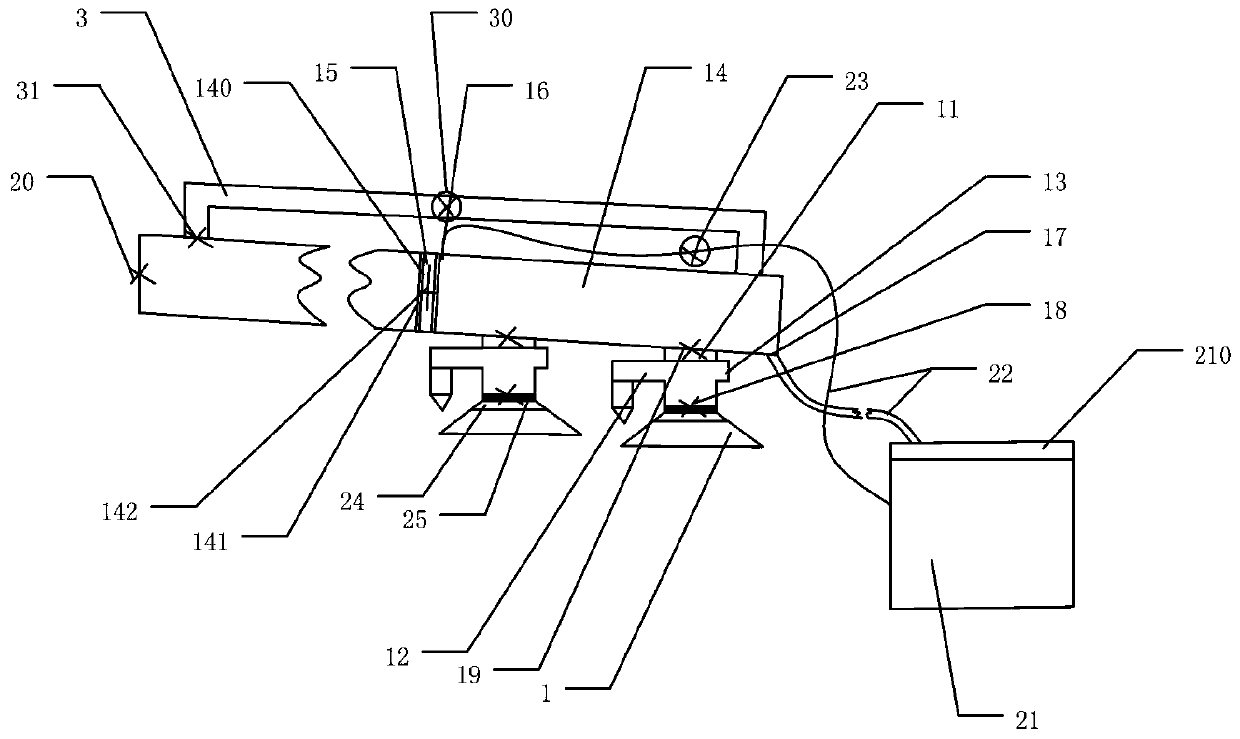

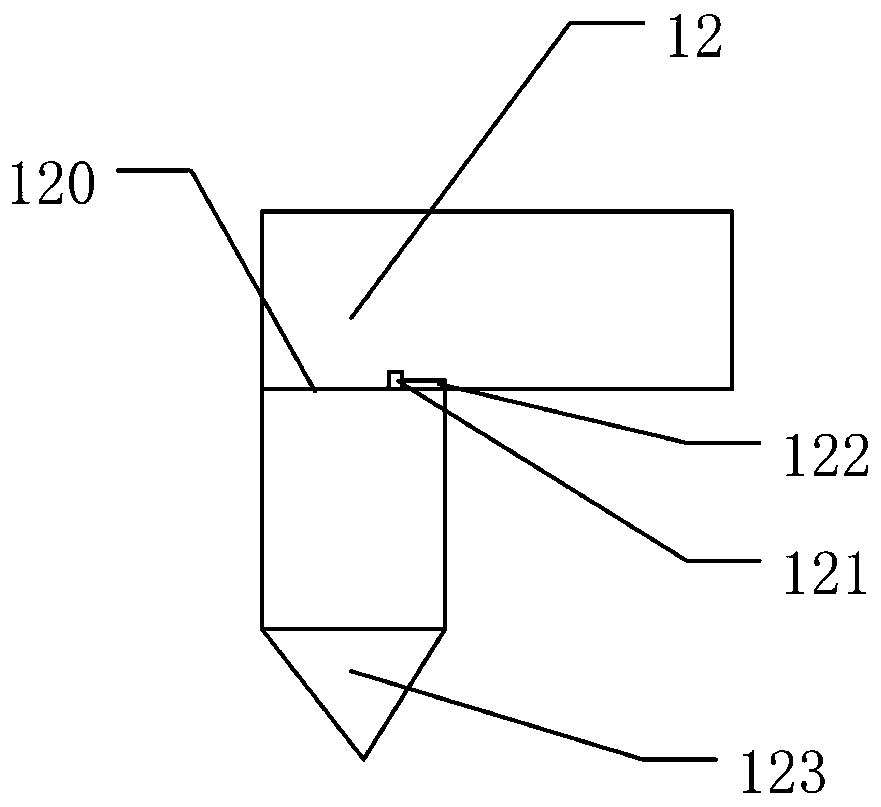

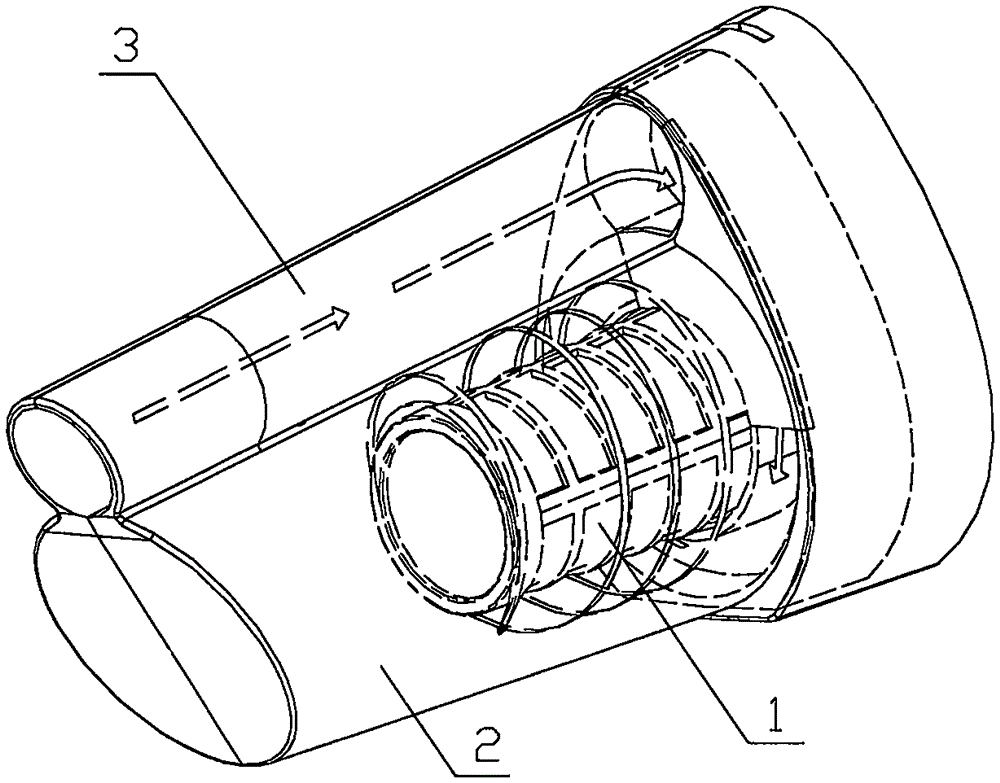

Water-spray-type tubular dust collector

InactiveCN103861402AAchieve clean emissionsGuaranteed dust removal efficiencyUsing liquid separation agentFlue gasLiquid water

The invention belongs to the technical field of waste gas purification, and particularly relates to a water-spray-type tubular dust collector. According to the water-spray-type tubular dust collector provided by the invention, the technical principles of an impingement dust collector and a water-film-type dust collector are combined together, the dust of the saturated wet flue gas can be removed, and the problems of dedusting and demisting the flue gas treated by a wet desulfurization device can be solved. The water-spray-type tubular dust collector is generally applied to the electric power environmental protection industry, and has the working position at the downstream part of the flue gas wet desulfurization device (FGD) of a thermal power plant; a water film is formed on the surface of a dust collection tube bundle in a water pouring way or a water spray way, so that impurities such as fine particle dust, gypsum, liquid water and the like in the flue gas can be caught; therefore, the clean emission of the flue gas of the thermal power plant can be realized, and the dust removing efficiency and the long-term work stability of equipment are guaranteed.

Owner:北京新世翼节能环保科技股份有限公司

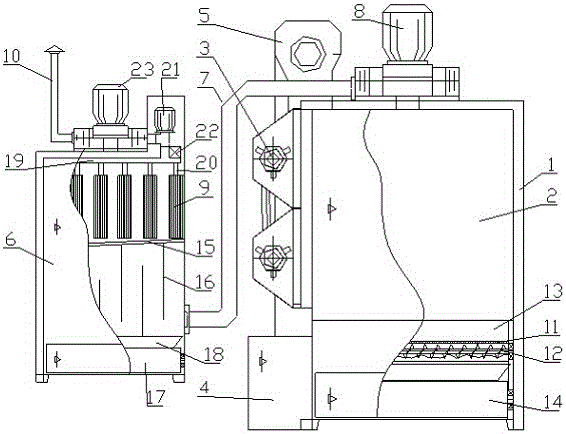

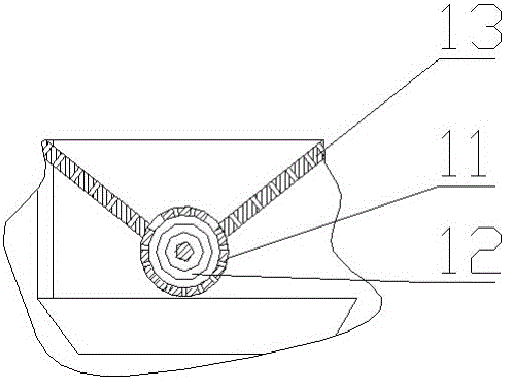

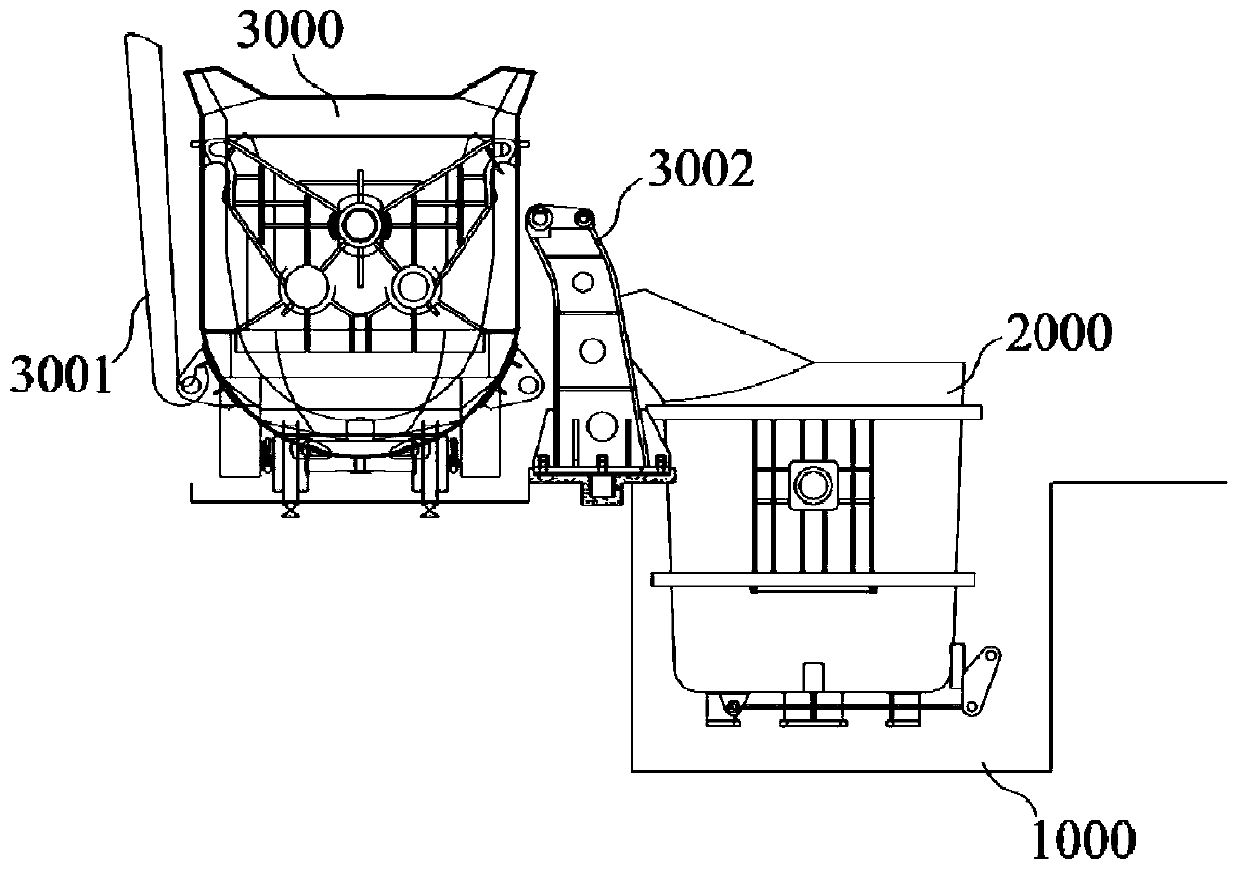

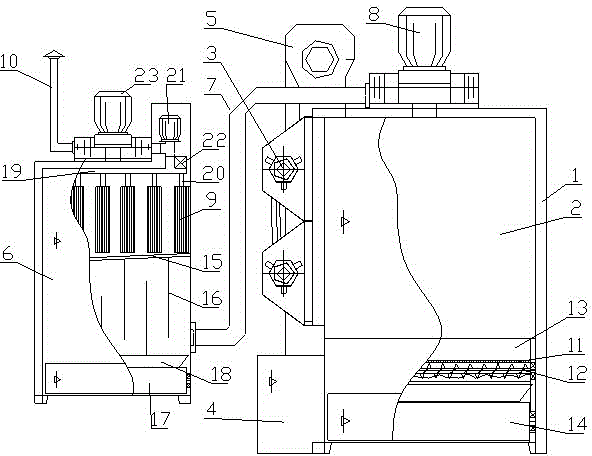

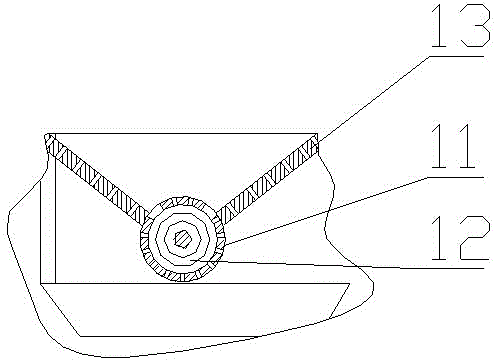

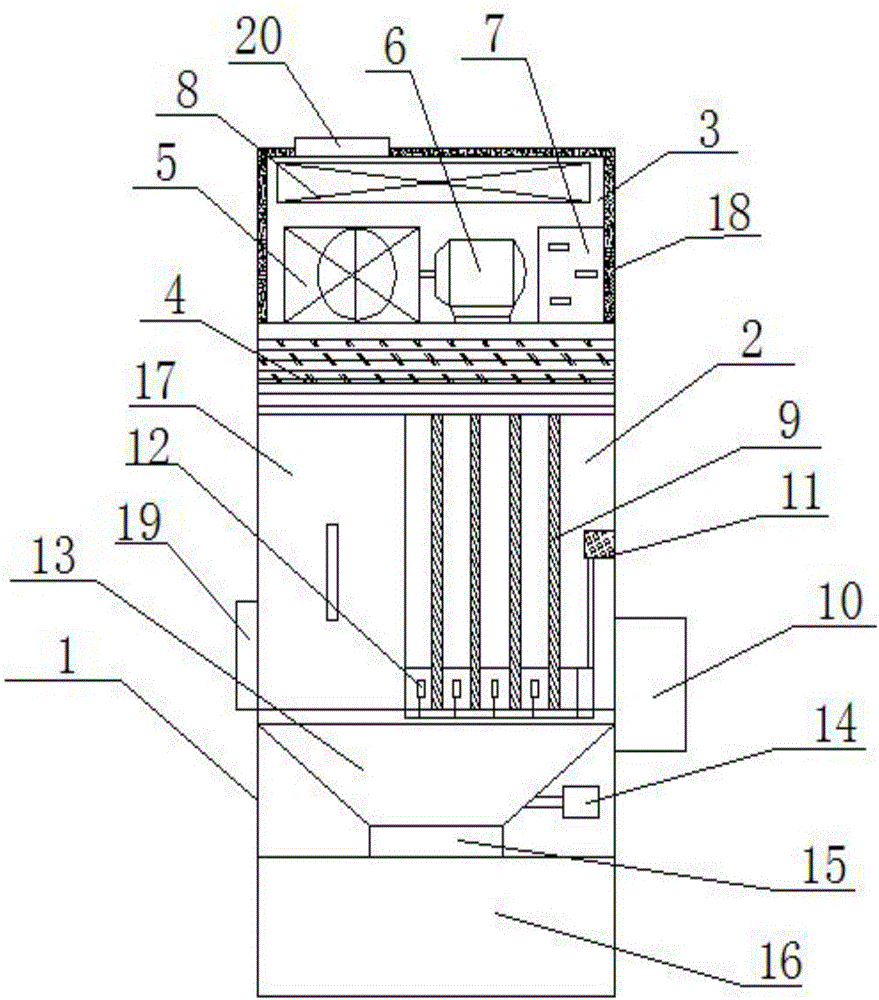

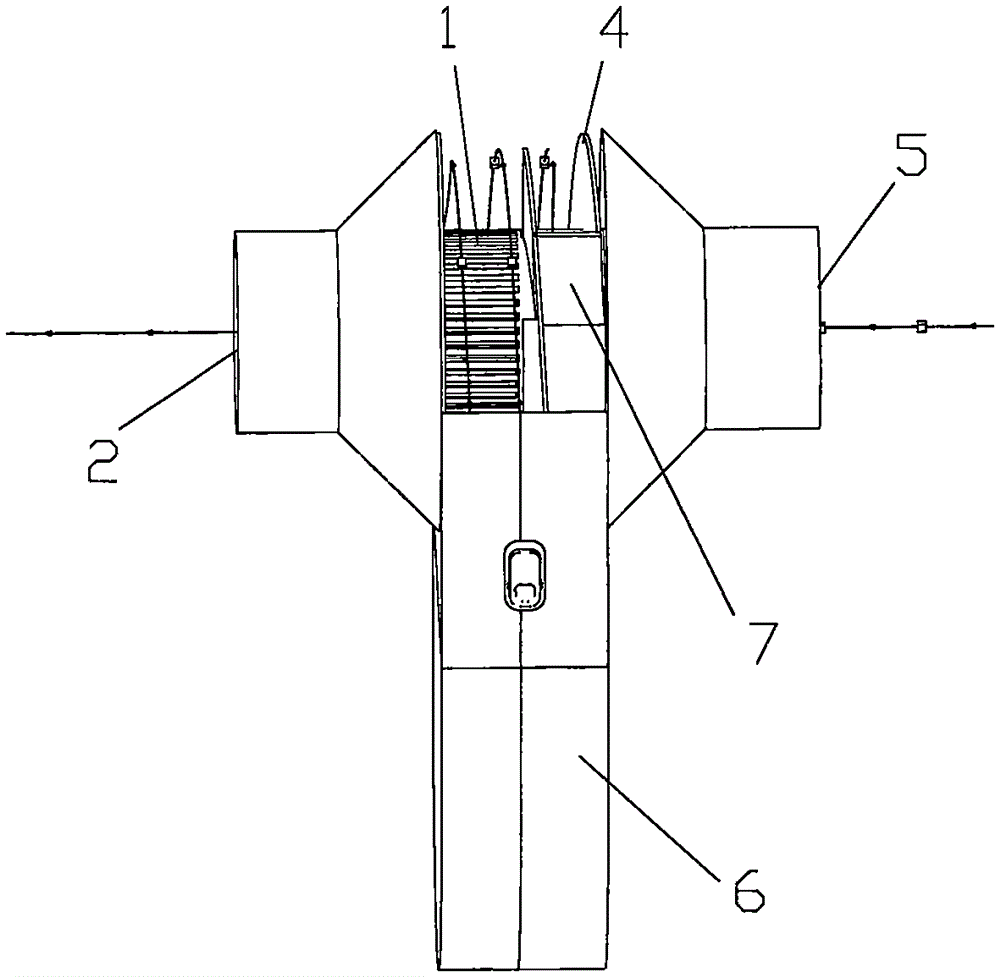

Shot blasting machine

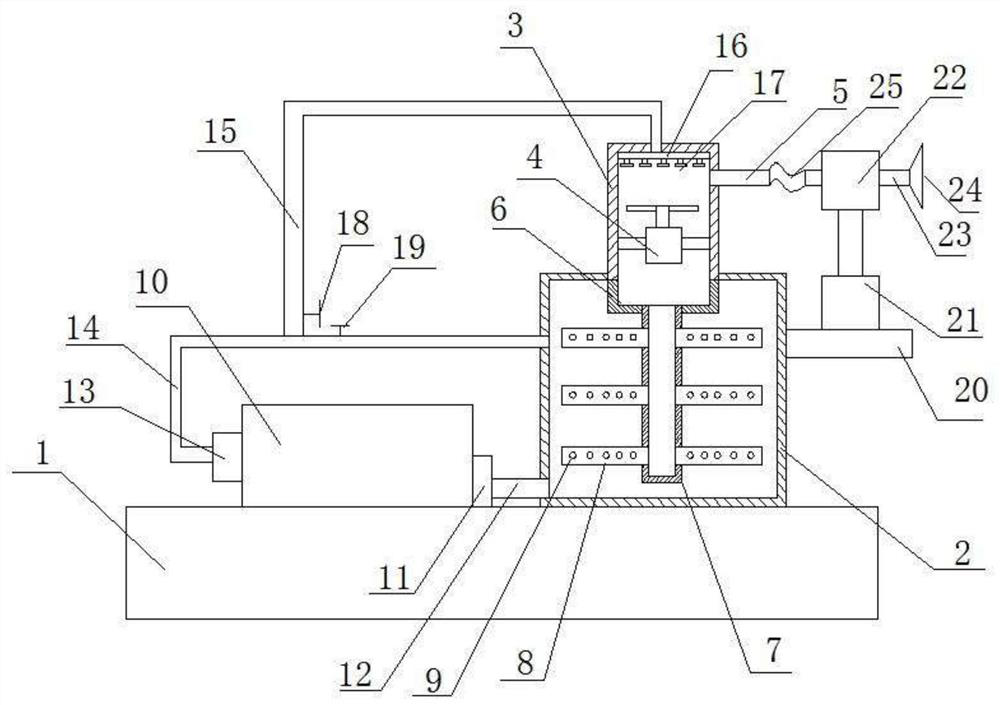

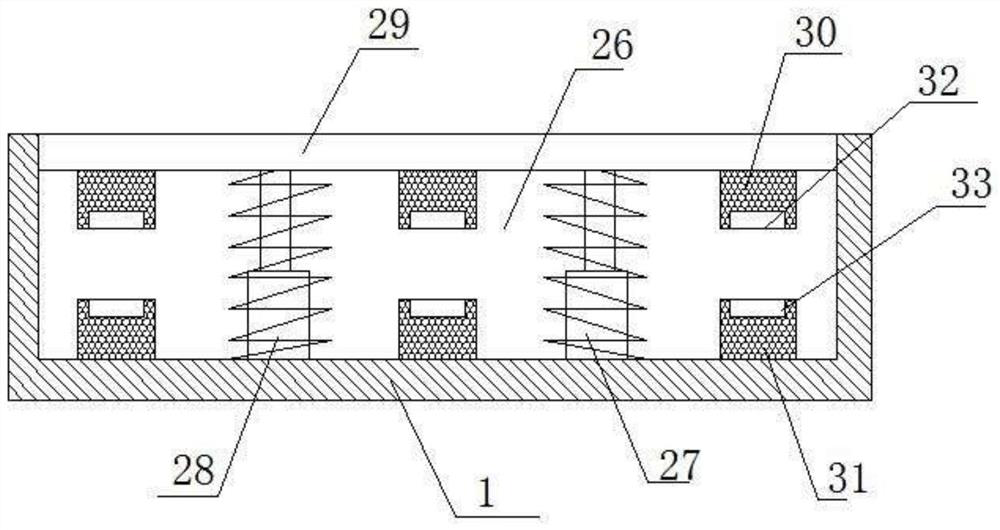

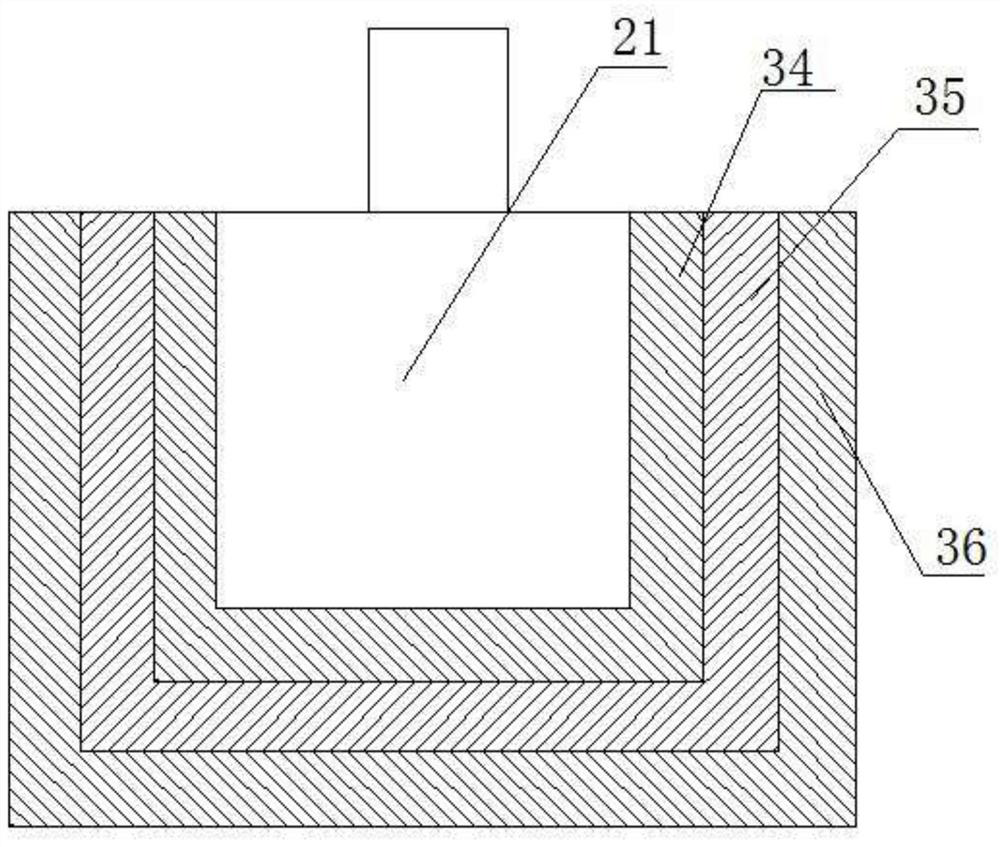

ActiveCN104608059AEfficient removalReliable removalCombination devicesDispersed particle filtrationTreatment effectHygiene

The invention discloses a shot blasting machine. The shot blasting machine comprises a rack, a shot blasting machine work room, a shot blasting device, a suspension mechanism, a shot collection device, a lower sand box, an upper sand box, a lifting device and a dust removal device, and is characterized in that a shot sorting structure is arranged in the shot collection device; the dust removal device comprises a dust removal box, the dust removal box is communicated with the top of the upper end of the shot blasting machine work room through a dust absorption pipeline, a dust absorption fan is arranged on the dust absorption pipeline, a plurality of dust removal cloth bags are arranged in the dust removal box, and an upward air outlet pipeline is arranged at the top of the dust removal box and an air flow needs to flow out from the air outlet pipeline through the dust removal cloth bags. The shot blasting machine disclosed by the invention is capable of efficiently and rapidly eliminating dust, realizing sorting during working, and synchronously removing small-diameter shots and impurities, has the advantages of being fast and efficient in dust removal, timely and reliable in impurity removal, capable of avoiding blockage and the like, shot blasting treatment effect and efficiency of the equipment are improved, the service life is prolonged, and the working hygiene of the equipment is improved.

Owner:宝武特冶航研科技有限公司

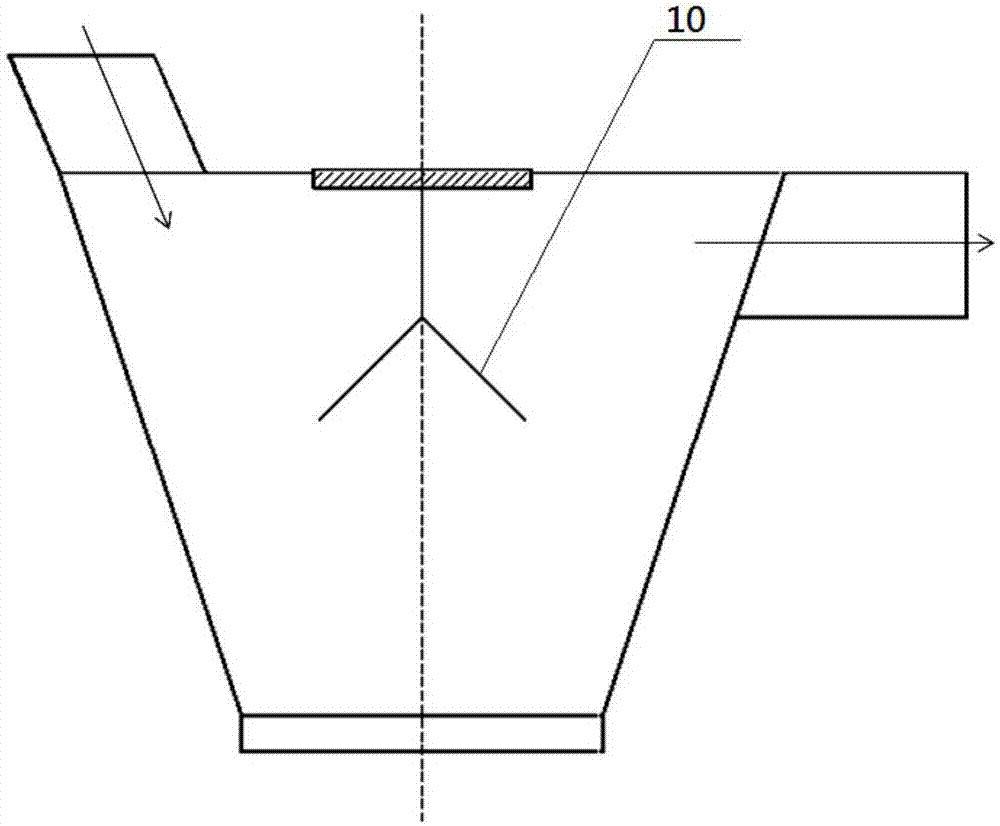

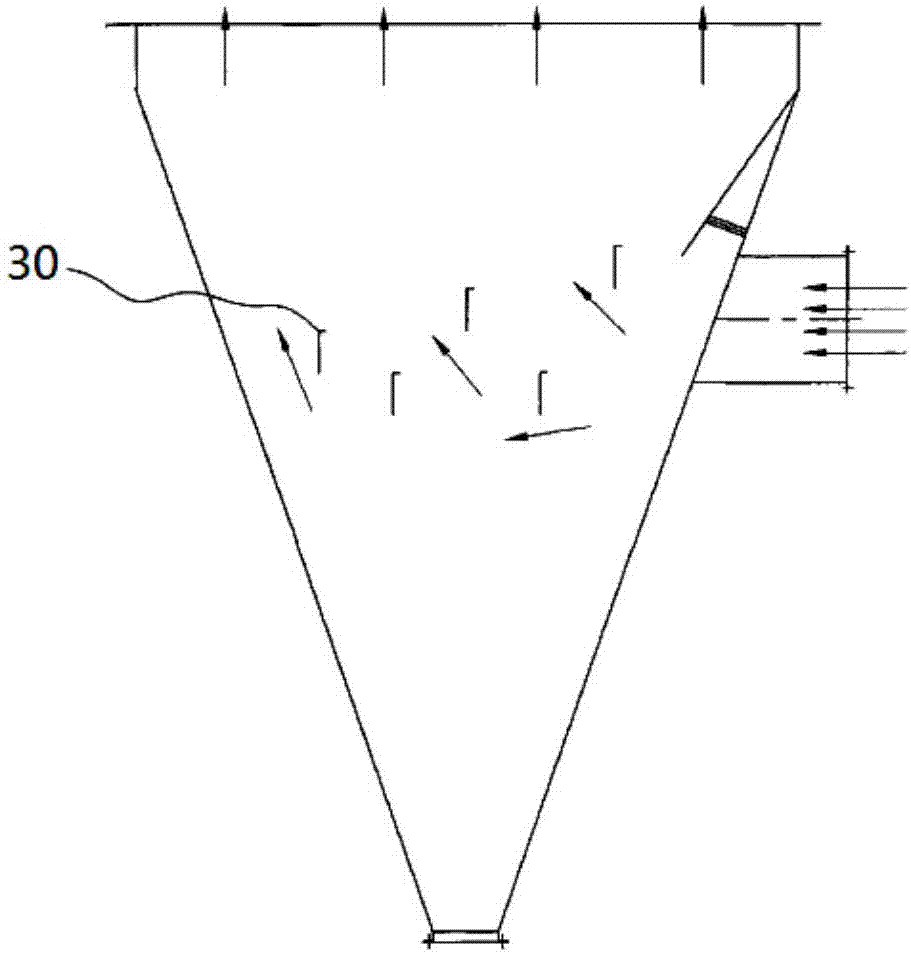

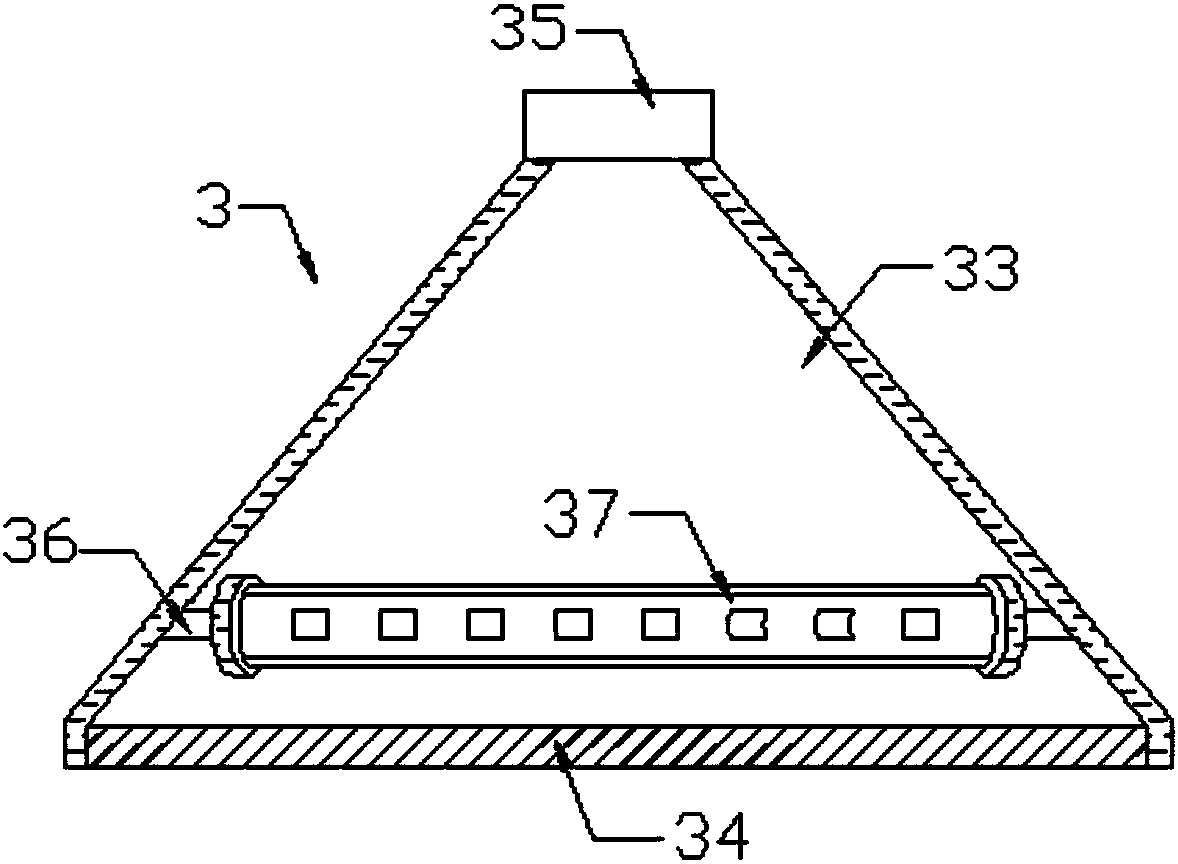

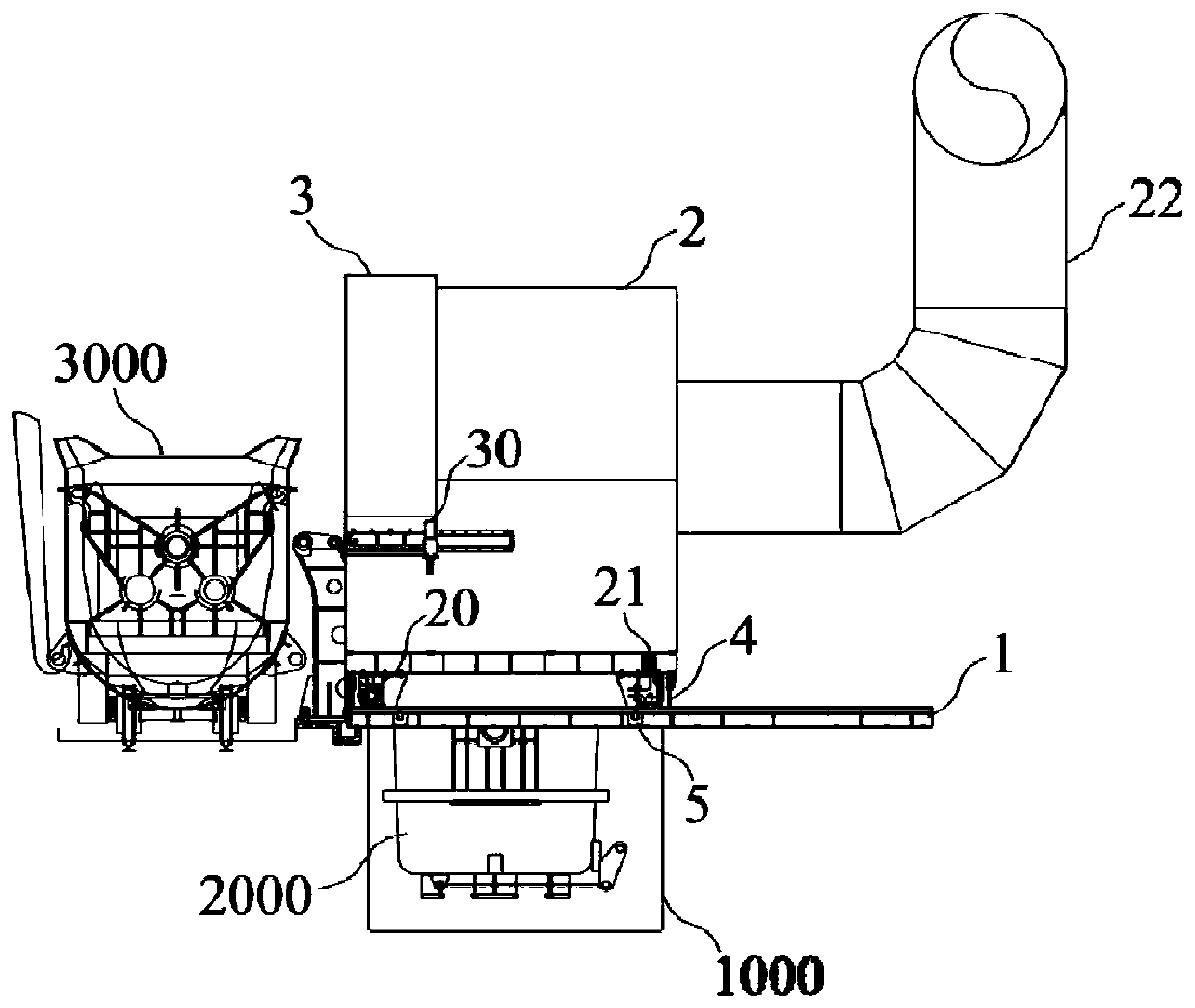

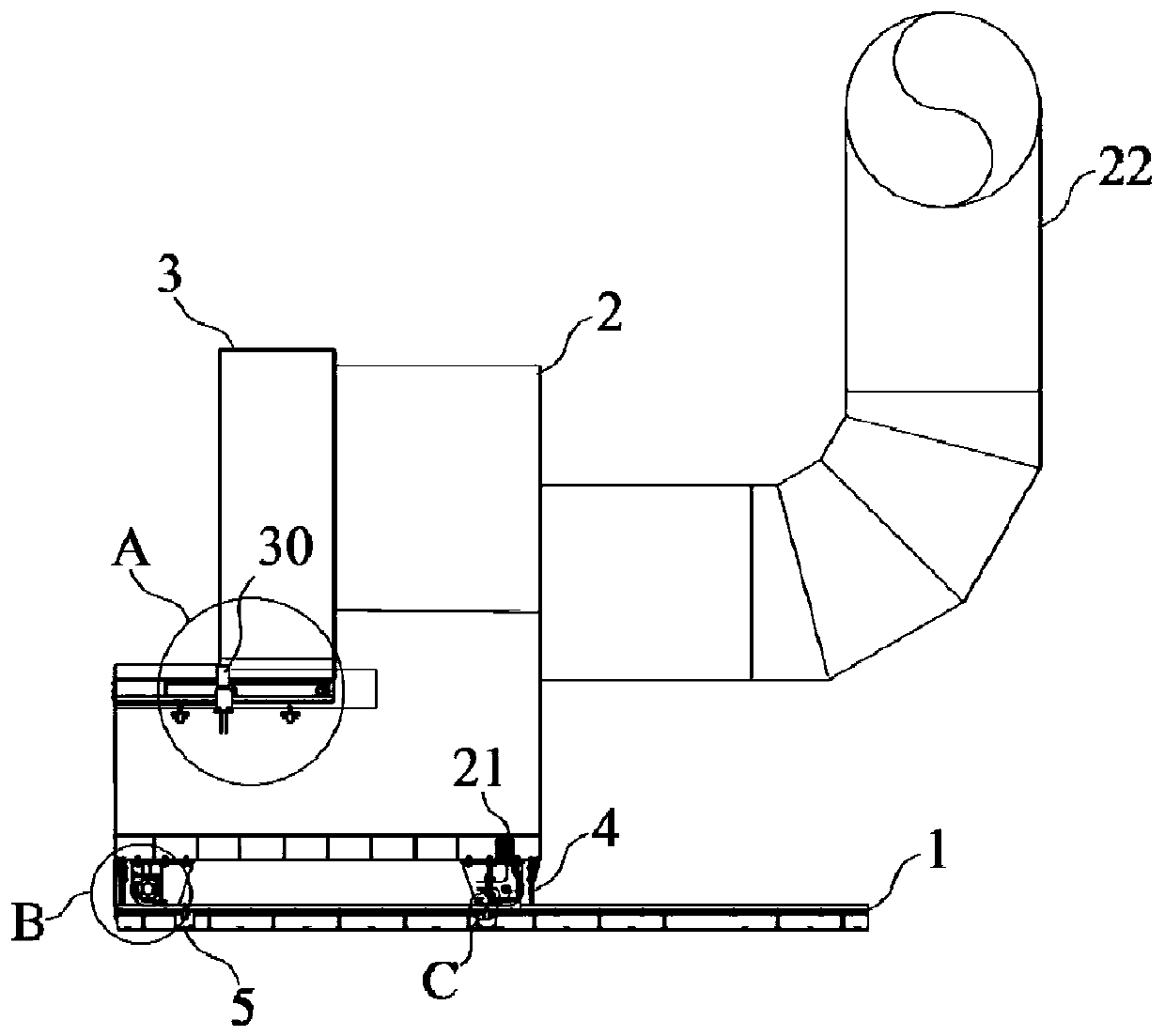

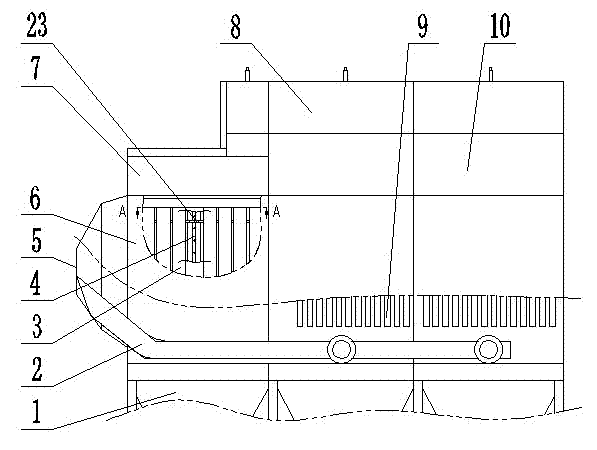

Gravity dust removal apparatus and asphalt stirring device

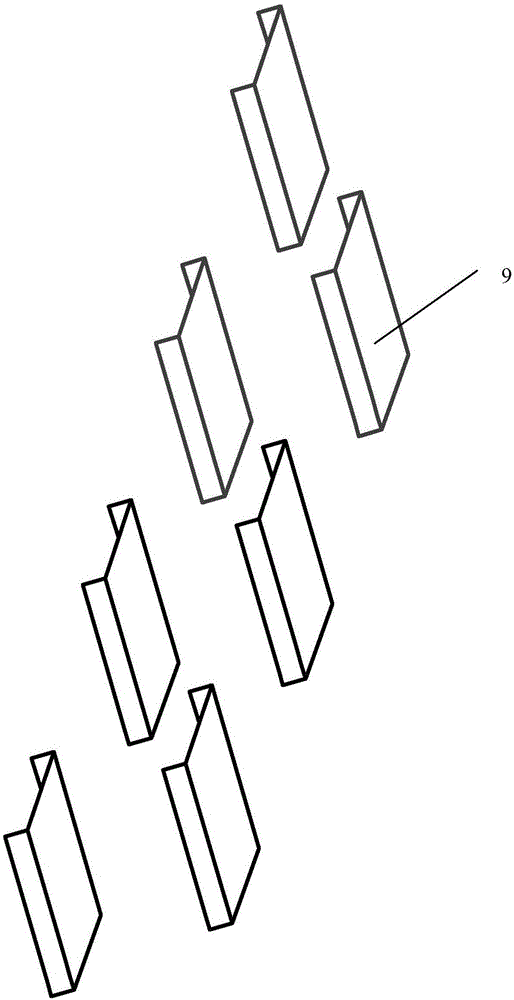

PendingCN107288012AAchieving AdaptivenessOvercome limitationsDispersed particle separationRoads maintainenceFlue gasAsphalt

The invention relates to a gravity dust removal apparatus and an asphalt stirring device. The gravity dust removal apparatus includes an air inlet bin (1), a gravity dust removal bin (2) and an air outlet bin (3). The air inlet bin is used for feeding dust-containing flue gas. The gravity dust removal bin is located at the downstream of the air inlet bin and is used for removing at least a part of dust in the dust-containing flue gas through gravity, wherein the purified flue gas is discharged through the air outlet bin. Flow-guide blades (51) are located in the gravity dust removal bin and are used for performing dust removal and guidance to the flue gas passing through the gravity dust removal bin, flow-guide angle of the flow-guide blades being adjustable. By arranging the flow-guide blades with adjustable flow-guide angle, limitation of a gravity dust removal apparatus in the prior art is overcome; in the gravity dust removal apparatus, the flow-guide angle of the flow-guide blades can be adjusted at any time according to actual operation status of the asphalt stirring device, so that self-adaption of the flow-guide angle is achieved. The gravity dust removal apparatus guarantees dust removal efficiency and satisfies dust removal demand.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

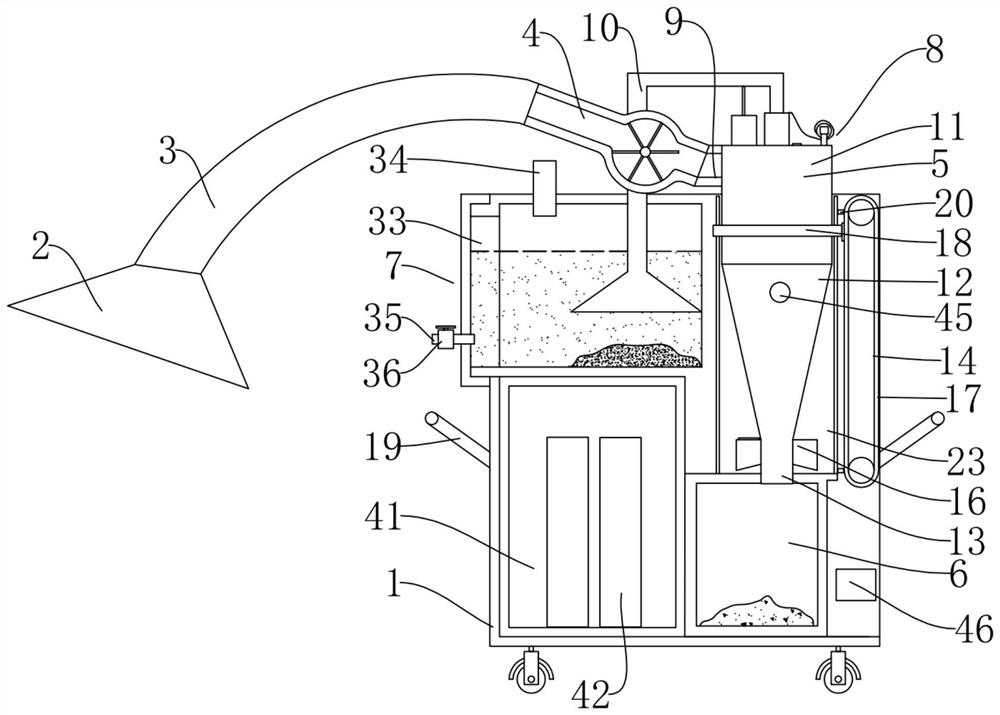

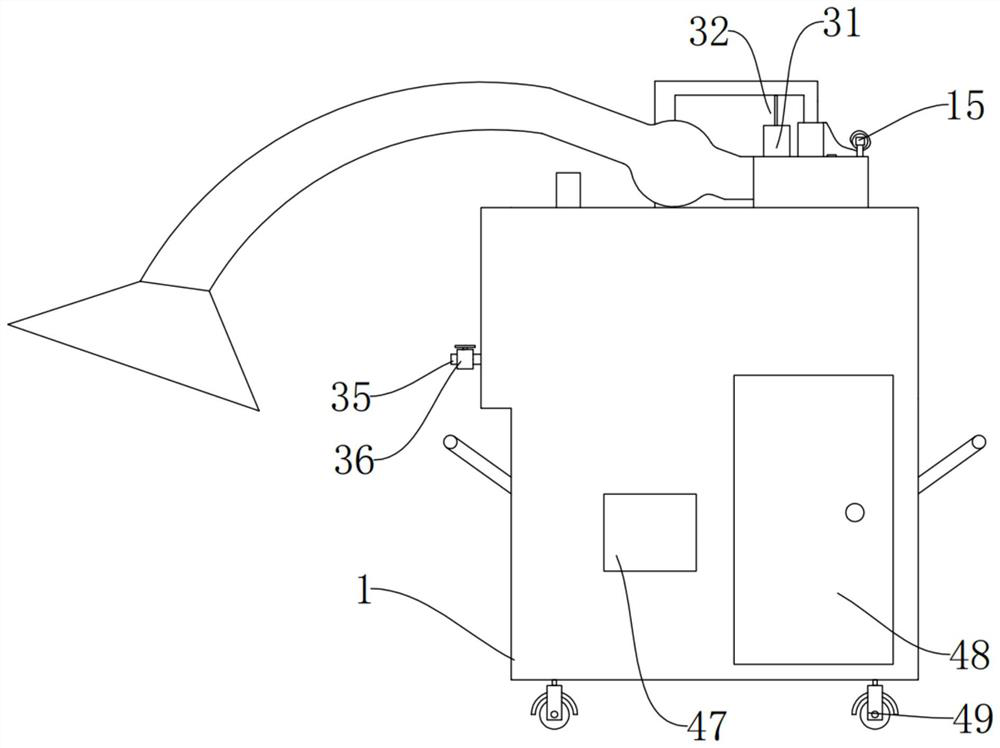

Metal dust collecting device for machining

ActiveCN111804113ASimple structureReasonable designCombination devicesDirt cleaningEngineeringMaterials science

The invention discloses a metal dust collecting device for machining. The device comprises a movable supporting box, a dust collecting cover, a telescopic dust collection pipe, a negative pressure dust collection apparatus, a cyclone dust collector, a dust collecting bin, a liquid filtering apparatus and a magnetic mud cleaning apparatus, the movable supporting box is arranged to be a hollow cavity, the cyclone dust collector penetrates through the upper wall of the movable supporting box and is arranged in the movable supporting box, an air inlet is formed in the side wall of the upper end ofthe cyclone dust collector, the negative pressure dust collection apparatus is arranged on the upper wall of the movable supporting box, the telescopic dust collection pipe is arranged at the input end of the negative pressure dust collection apparatus, the output end of the negative pressure dust collection apparatus is communicated with an air inlet of the cyclone dust collector, and the dust collecting cover is arranged at the end, away from the negative pressure dust collection apparatus, of the telescopic dust collection pipe. The invention belongs to the technical field of mining equipment, and particularly provides a metal dust collecting device which is high in practicability and safety, facilitates comprehensive collection of metal dust in the air, and facilitates machining in the cleaning apparatus.

Owner:徐州万佳机电设备制造有限公司

Dust removal device for textile production

InactiveCN107930306AImprove dust removal efficiencyQuick clearUsing liquid separation agentTextile fiberEngineering

The invention discloses a dust removal device for textile production. A textile chamber is arranged on one end of the top of the base; dust removal and air suction covers are arranged inside the textile chamber; the dust removal and air suction covers are connected with a dust removal fan through a dust conveying pipe; the dust removal fan is arranged on the base arranged at one end far away fromthe textile chamber; a dust reduction pipe is fixedly arranged on the dust conveying pipe arranged between the textile chamber and the dust removal fan. The dust removal device has the advantages thatthe structure is reasonable and simple; the dust removal efficiency is high; the use is convenient; the textile chamber is enabled to be clean; the textile quality influence due to dust adsorption onthe textile product in the spinning process is avoided; electrostatic elimination bars are arranged inside the first dust removal and air suction cover and the second dust removal and air suction cover, so that textile fiber dust passing though the first dust removal and air suction cover and the second dust removal and air suction cover can be subjected to electrostatic elimination; the dust conveying pipe blockage caused by dust adsorption on the dust conveying pipe due to the electrostatic adsorption force carried in the textile fiber dust is avoided; the dust removal efficiency of the dust removal device is further ensured.

Owner:瑞安市异想天开科技有限公司

Shot blasting machine

InactiveCN106112827AEfficient removalReliable removalCombination devicesAbrasive feedersTherapeutic effectEngineering

The invention discloses a shot blasting machine which comprises a rack, a shot blasting machine working chamber, shot blasting devices, a suspension mechanism, a shot collecting device, a drag box, a cope box, a lifting device and a dust removing device. The shot collecting device is provided with a shot sorting structure. The dust removing device comprises a dust removing box which communicates with the top of the upper end of the shot blasting machine working chamber through a dedusting tube. A dedusting fan is arranged on the dedusting tube. Six dust removing cloth bags are arranged inside the dust removing box. An upward air outlet pipeline is arranged at the top of the dust removing box, and air flow is made to flow out of the air outlet pipeline through the dust removing cloth bags. According to the shot blasting machine, dust can be efficiently and fast removed, sorting can be achieved in the working process, small-diameter shots and impurities are removed at the same time, and the shot blasting machine has the advantages of being fast and efficient in dust removing, timely and reliable in dust removing, free of blocking and the like; the shot blasting treatment effect and efficiency of the devices are improved; the service life is prolonged; and the working hygiene of the devices is improved.

Owner:陈铭鸿

Electrical automatic intelligent dust removal system

InactiveCN110538541AEasy to cleanAvoid wastingCombination devicesDirt cleaningHigh pressureWater spray

The invention discloses an electrical automatic intelligent dust removal system. The system comprises a dust removal device and an intelligent control device, wherein the dust removal device comprisesa plurality of dust removal covers, a plurality of first pipelines provided with first filtering devices, and a main pipeline; a dust collecting box and an air blowing device opposite to the dust collecting box are arranged in each first pipeline; a plurality of second filtering devices are arranged in the main pipeline; the top end of the main pipeline is provided with a high-pressure spray headtowards the second filtering devices; the main pipeline is butted with a drainage system; the intelligent control device comprises a controller and an intelligent detection module; and the intelligent detection module comprises a dust concentration monitoring module which transmits monitored information to the controller to control on / off and water spraying duration of a dust collection device and the high-pressure spray head, a data integration and analysis module, and a filtering early warning device which receives period information transmitted by the data integration and analysis module and sends the early warning information to maintenance personnel according to the period information. The filtering devices are convenient and labor-saving in cleaning; the dust removal efficiency is improved; and directional dust removal can be automatically started, so that unnecessary power consumption is avoided.

Owner:邓晓凝

Primary-secondary type movable dust removal cover vehicle for steelmaking environment and dust removal method

ActiveCN111331119AEasy to moveFlexible moving processMelt-holding vesselsDirt cleaningSteelmakingReciprocating motion

The invention discloses a primary-secondary type movable dust removal cover vehicle for a steelmaking environment and a dust removal method, and belongs to the technical field of steelmaking environment dust removal. The dust removal cover vehicle comprises a pit, guide rails, a primary dust removal cover vehicle, a secondary dust removal cover, a sweeping unit and a limiting unit, wherein a firstladle is arranged in the pit, and a second ladle is arranged on the ground beside the pit; the guide rails are laid on the ground on the two sides of the pit; the primary dust removal cover vehicle is movably connected with the guide rails through first bottom rollers, and the primary dust removal cover vehicle move on the guide rails under the driving of a first driving part in a reciprocating mode; the secondary dust removal cover is movably connected with the upper part of the vehicle side of the primary dust removal cover vehicle, and the secondary dust removal cover move along the direction of the second ladle under the driving of a second driving unit in a reciprocating mode; the sweeping unit is fixedly connected with the bottom of the primary dust removal cover vehicle and sweepsthe surface of the guide rails along with the movement of the primary dust removal cover vehicle; and the limiting unit is used for limiting the driving distance between the first driving unit and thesecond driving unit. According to the primary-secondary type movable dust removal cover vehicle for the steelmaking environment and the dust removal method, the dust removal cover vehicle is designedaccording to the working conditions of the steelmaking environment, the operation is stable, moving is flexible, potential safety hazards are reduced, and high dust removal efficiency can be guaranteed.

Owner:马钢集团设计研究院有限责任公司

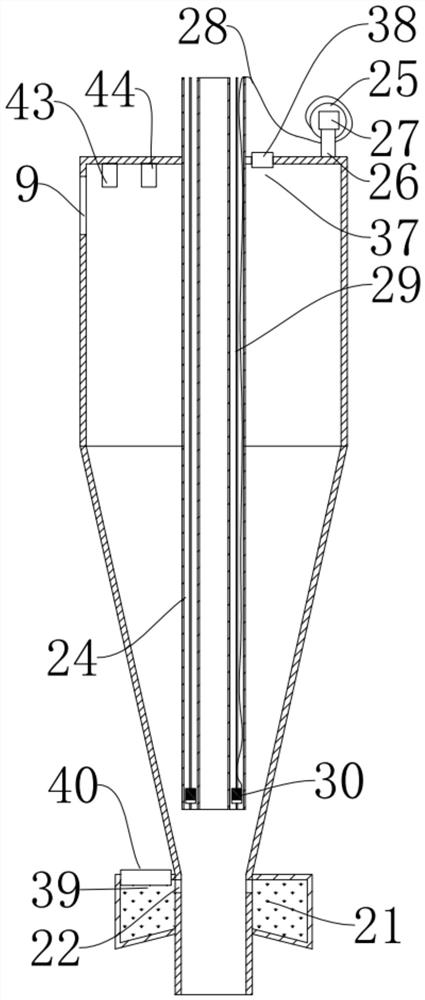

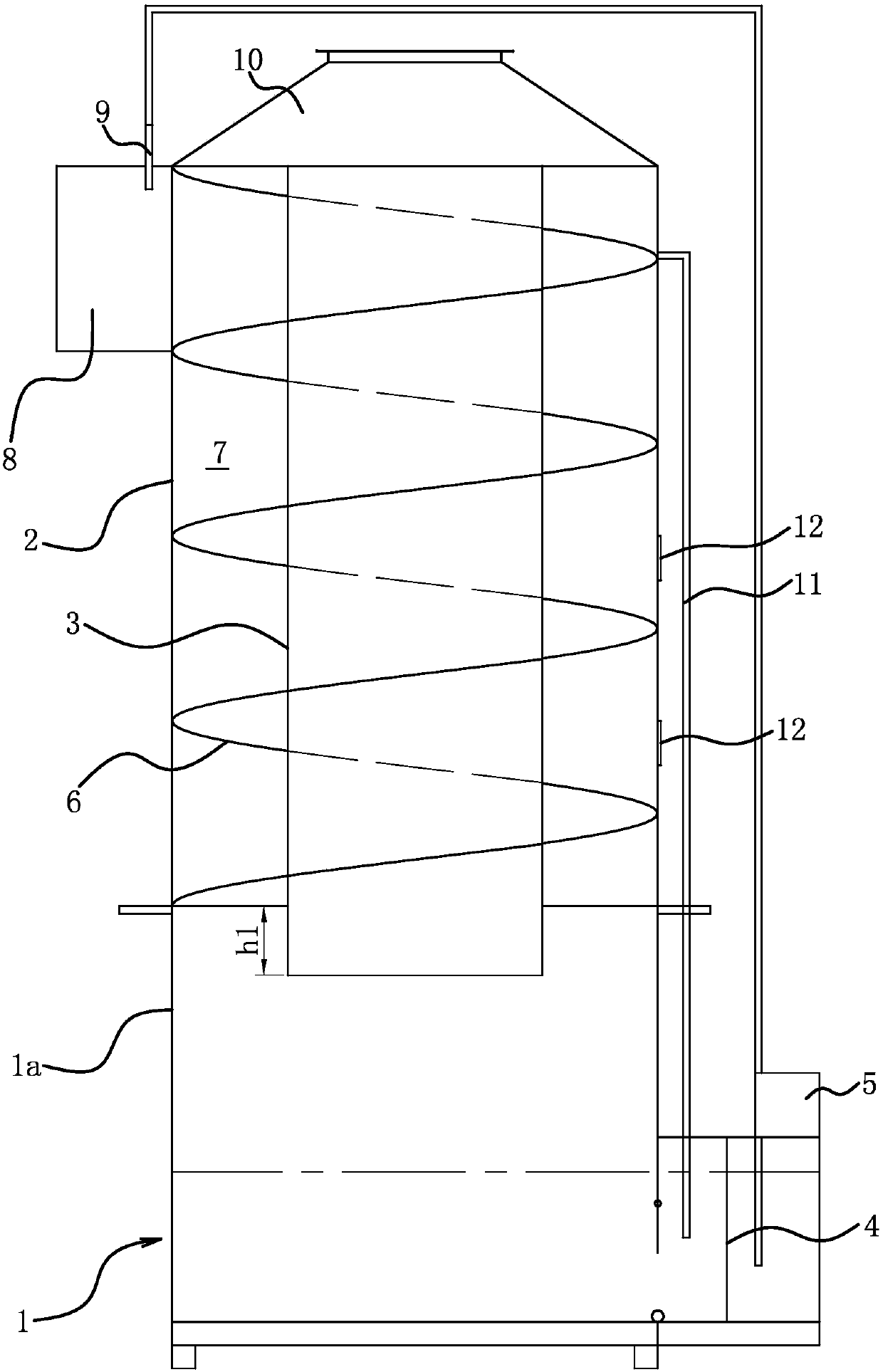

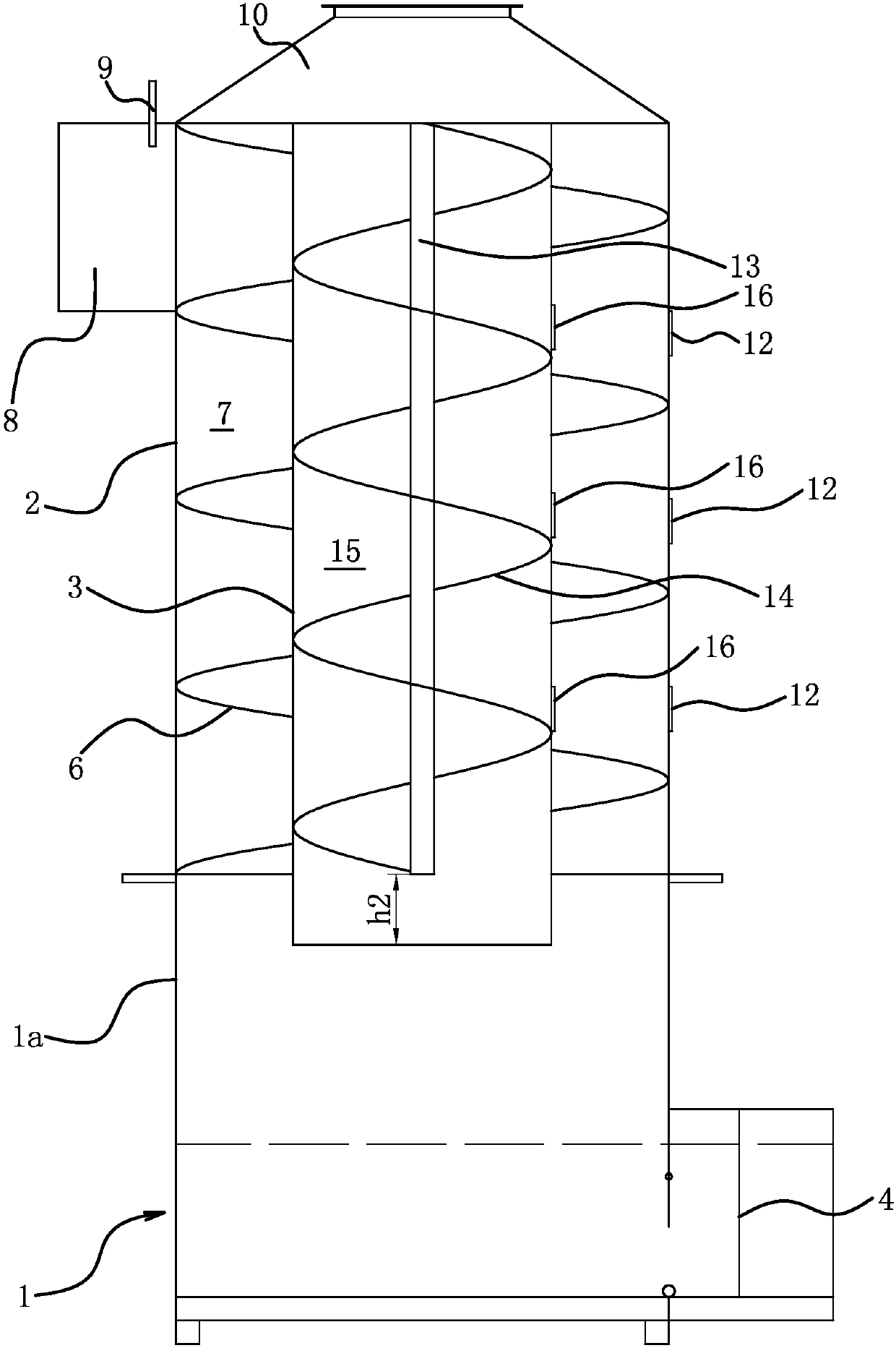

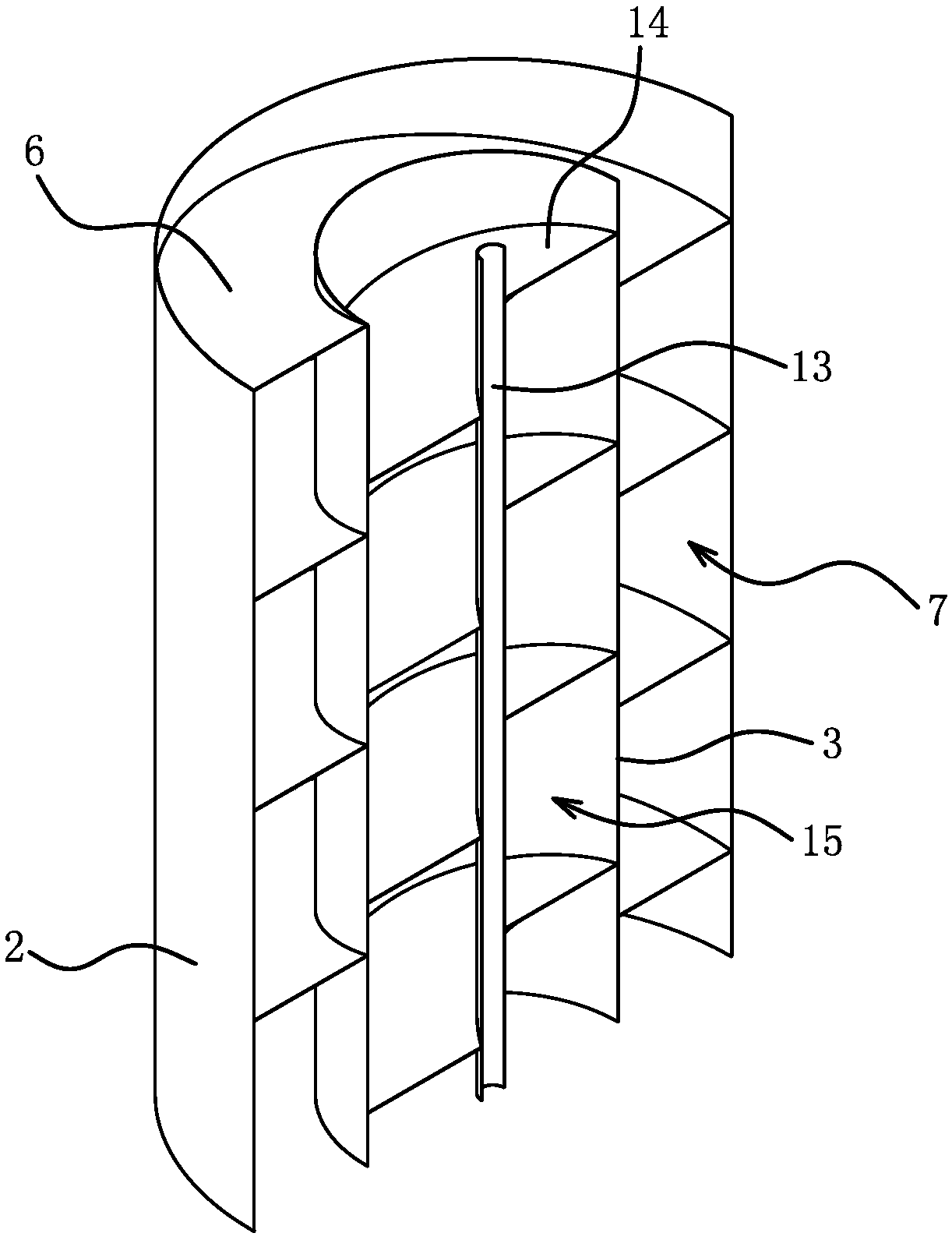

Wet type dust remover adopting spiral spraying

PendingCN107670441AGood value for moneyGuaranteed dust removal efficiencyUsing liquid separation agentSeparation devicesWater storage tankEngineering

The invention provides a wet type dust remover adopting spiral spraying, belongs to the field of operation technologies, and solves the problem that an existing wet type dust remover is inconvenient to use and maintain. The wet type dust remover comprises a water storage tank, a vertically-arranged outer pipe and an inner pipe at the axis of the outer pipe and is characterized in that a first partition is spirally arranged relative to the axial line of the outer pipe is arranged between the outer pipe and the inner pipe, the first partition is hermitically and fixed connected with the inner side of the outer pipe and the outer side of the inner pipe, and a first channel is spirally arranged relative to the axial line of the outer pipe is formed between the outer pipe and the inner pipe; anair inlet pipe communicated with the upper port of the first channel is fixedly connected to the top of the lateral wall of the outer pipe, a water inlet pipe is fixedly connected to the air inlet pipe, and the water outlet of the water inlet pipe is located in the air inlet pipe; the lower port of the outer pipe can be sealed by liquid stored in the storage tank. The wet type dust remover has the advantages that a spraying head is not needed, water is directly supplied into the air inlet pipe through the air inlet pipe, and the phenomenon of spraying head blocking is avoided.

Owner:玉环太平洋机械有限公司

PM2.5 (Particulate Matter 2.5) electrostatic precipitator with box-type dedusting area

InactiveCN102614986AEfficient captureLow investment costExternal electric electrostatic seperatorElectricityParticulates

The invention discloses a PM2.5 (Particulate Matter 2.5) electrostatic precipitator with a box-type dedusting area. After being arranged in a common electrical dedusting system, the PM2.5 electrostatic precipitator with the box-type dedusting area comprises a coagulation area and the box-type dedusting area which are successively communicated, wherein the coagulation area is conducted with the common electrical dedusting system and is provided with a plurality of dust collection plates at equal intervals to form a plurality of particulate channels which have the consistent direction with particulates; the same particulate channel is provided with discharging electrodes which are vertical to the particulate direction and have the same polarity; the polarities of the discharging electrodes in adjacent particulate channels are opposite, the particulates passing through the area can be provided with different electric charges, and the particulates are coagulated to form big-particle particulate; the box-type dedusting area is communicated with the coagulation area and is provided with a box-type dust collecting films at equal intervals; the bottom of each box-type dust collecting film is hung to form a big-particle particulate channel through which the big-particle particulate can pass; the box-type dust collecting film is provided with a negative electric charge by a connected power supply; the film body structure of each surface of the box-type dust collecting film is consistent and is formed by respectively arranging a polypropylene film on the upper surface and lower surface of a conducting film; and static dust removal is finished in the area. The PM2.5 electrostatic precipitator has the advantages of excellent effect and low cost.

Owner:HUANENG CLEAN ENERGY RES INST

Method for cleaning projectiles of shot blasting machine

ActiveCN104608060AEfficient removalEfficient and quick removalGas treatmentDispersed particle filtrationTreatment effectPulp and paper industry

The invention discloses a method for cleaning projectiles of a shot blasting machine. The method is characterized in that in the working process of the shot blasting machine, the projectiles are sorted on line by adopting a filtering mode, and the projectiles with the size reduced after abrasion and a part of solid impurities mingled in the projectiles are sorted out; and meanwhile, after air is drafted from a working chamber of the shot blasting machine, dust removal treatment in a filtering mode is carried out by virtue of a dust removal bag. The method is capable of effectively and rapidly removing dust, realizing sorting while working, synchronously removing the projectiles with small diameter and the impurities, improving the shot blasting treatment effect and efficiency of the shot blasting machine, prolonging the service life and improving the working hygiene of the shot blasting machine and has the advantages of performing dust removal rapidly and efficiently, timely and reliably removing the impurities, avoiding blockage and the like.

Owner:宝武特冶航研科技有限公司

One-machine bag type dust collector

InactiveCN105709519AExtended service lifeImprove cleanlinessDispersed particle filtrationTransportation and packagingBaghousePollution

The invention provides a one-machine bag type dust collector. The one-machine bag type dust collector comprises a rack, a filtering box, an ash removing mechanism, a dust collection drawer, an ash hopper, an air inlet and an air outlet, wherein the filtering box is fixedly installed at the upper end of the rack, the ash hopper is connected to the lower end of the filtering box, and the dust collection drawer is arranged on the lower portion of the ash hopper; a glass cotton layer is arranged in the middle of the filtering box and divides the filtering box into a purified air chamber and a filtering chamber, the air inlet is formed in one side of the filtering chamber, and a plurality of filtering bags are evenly arranged in the filtering chamber and matched with the ash removing mechanism on one side. According to the dust collector, due to the effect of the ash removing mechanism, the ash removing effect is effectively improved, dust suction stability, connecting performance and dust removing efficiency are guaranteed, the service life of the filtering bags is prolonged, meanwhile, due to cooperation of the glass cotton layer and a sound absorbing layer, noise in the work process is lowered, secondary pollution is avoided, the dust removing effect is further guaranteed due to cooperation of a sub-high-efficiency filter, and the service life is prolonged.

Owner:苏州保酚环境科技有限公司

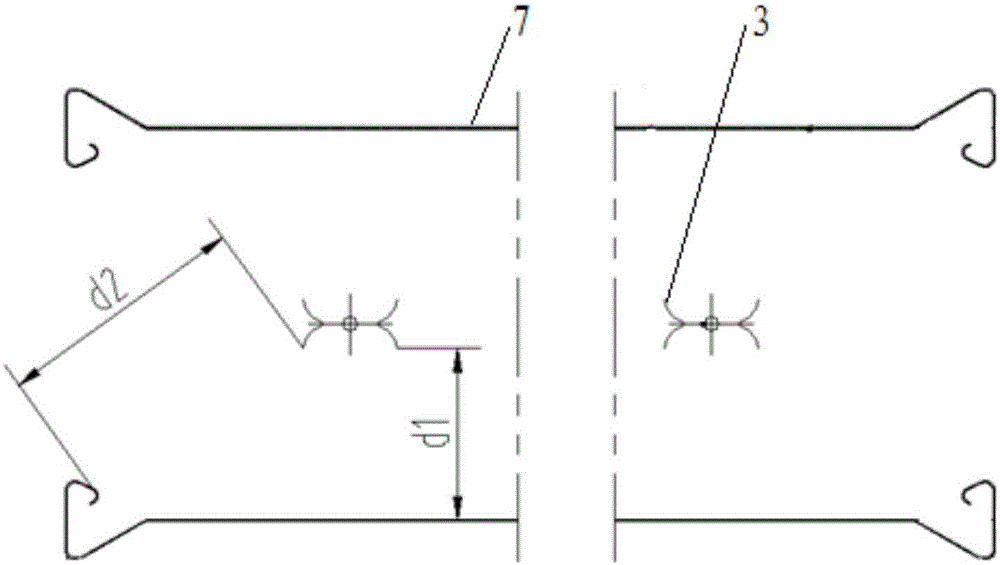

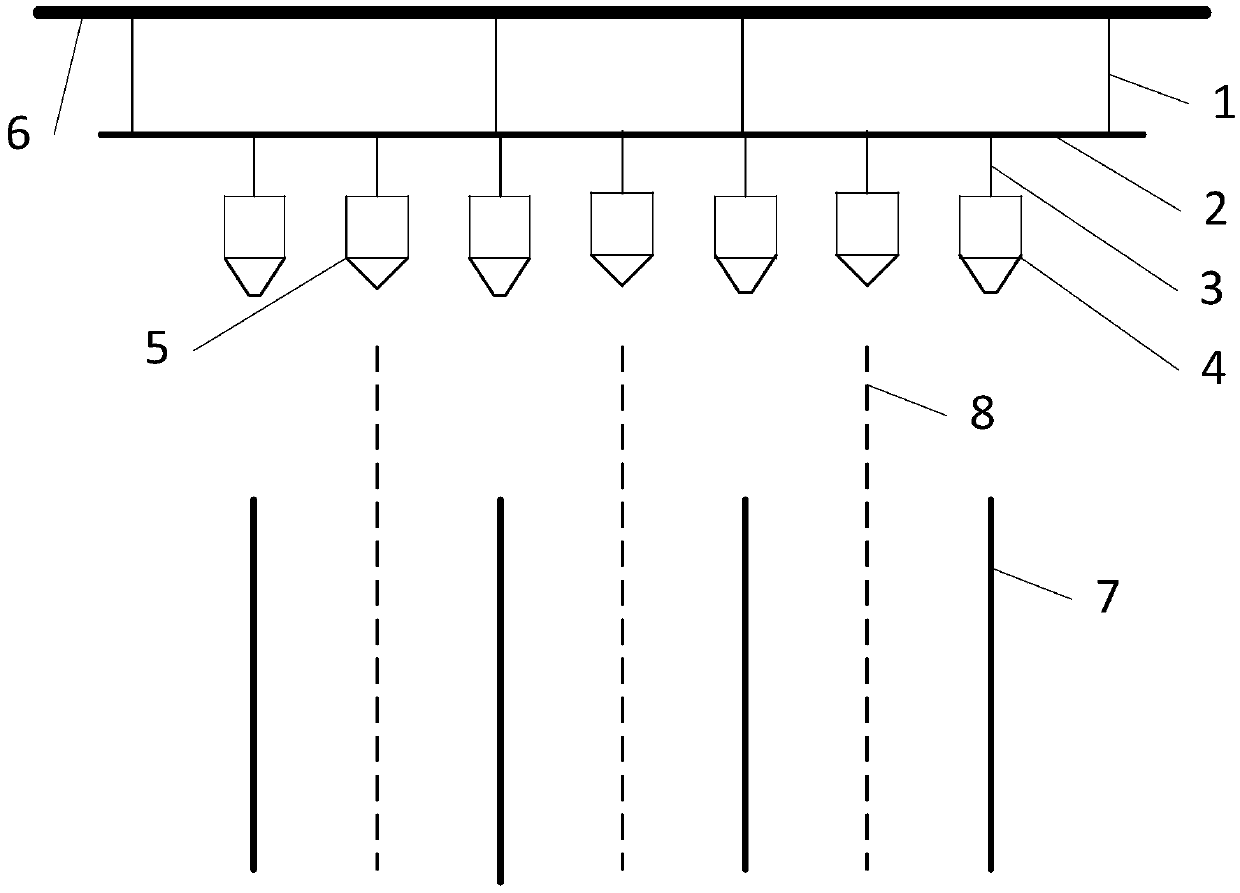

Electrostatic dust remover and cathode system thereof

InactiveCN106179752AGuaranteed dust removal efficiencyKeep a safe distanceExternal electric electrostatic seperatorElectrode constructionsEngineeringCathode

The invention discloses a cathode system of an electrostatic dust remover. The cathode system comprises a cathode frame, a cathode line connecting piece and a cathode line used for discharge. A through groove is formed in the cathode frame. One end of the cathode line connecting piece is fixedly connected with the cathode line, the other end of the cathode line connecting piece is connected with the through groove, and the cathode line connecting piece can move in the length direction of the through groove. The through groove is formed in the cathode frame, and therefore the cathode line connecting piece can move in the length direction of the through groove, that is, the position of the cathode line can be adjusted; the position of the cathode line can be adjusted, and therefore after the electrostatic dust remover is mounted, the position of the cathode line can be adjusted in real time according to needs so as to guarantee the safety distance between the cathode line and an anode plate; and therefore mounting difficulty can be reduced, the production and mounting error-tolerant rate can be increased, and the dust removal efficiency of the electrostatic dust remover can be guaranteed. The invention further discloses the electrostatic dust remover including the cathode system.

Owner:HANGZHOU TEAMS ENVIRONMENTAL PROTECTION ENG

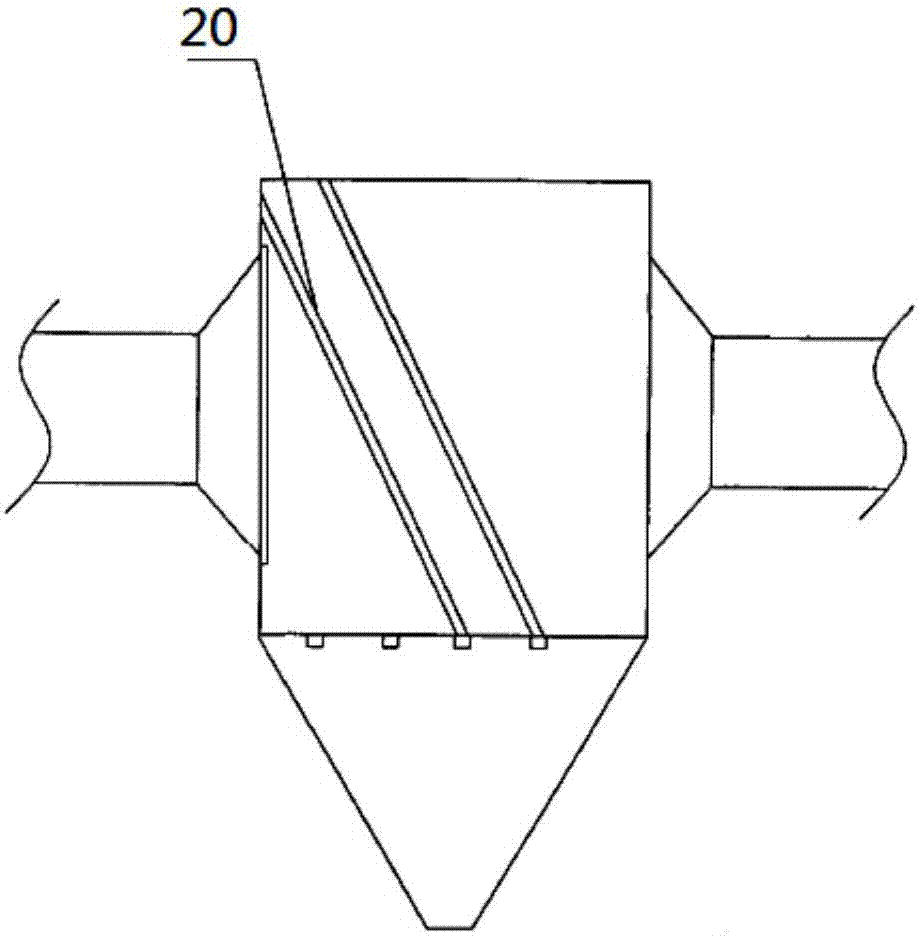

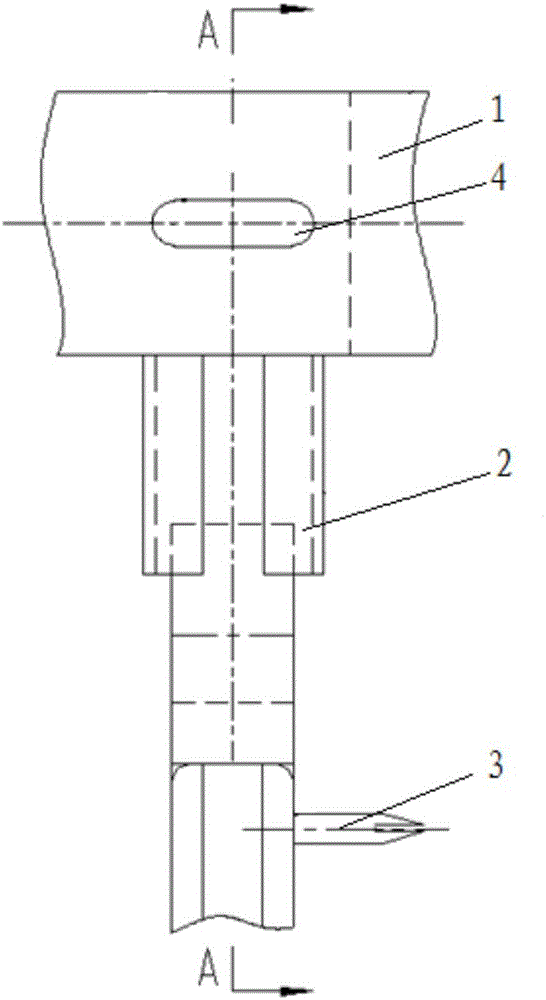

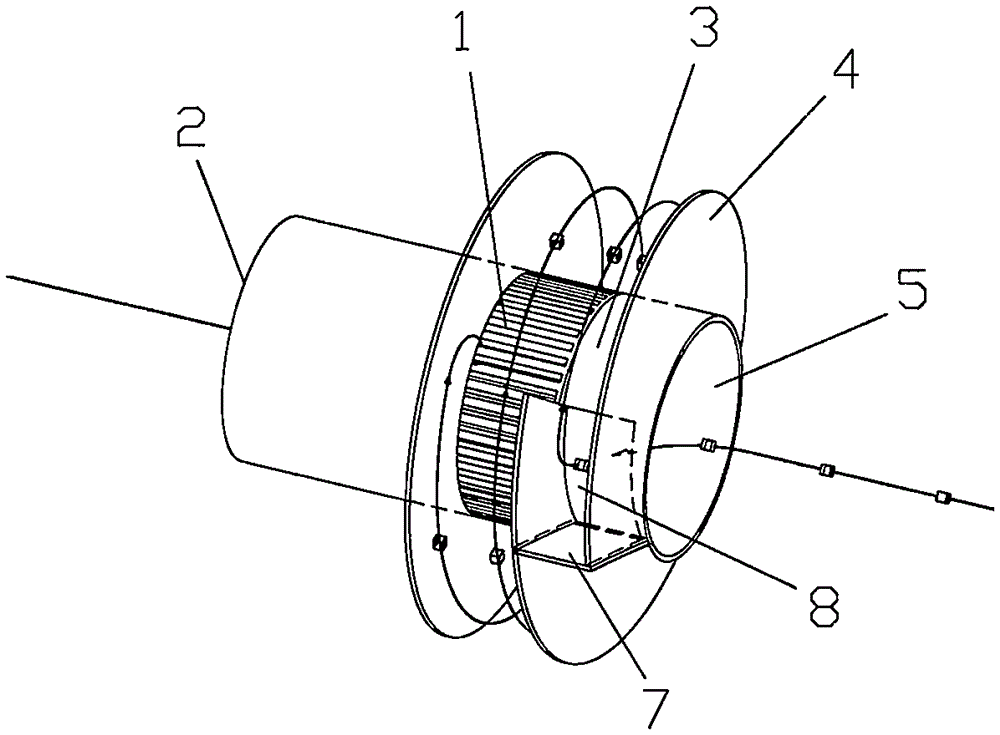

Filter device and dust removal equipment

ActiveCN105311915AExtended service lifeGuaranteed dust removal efficiencyCombination devicesInlet channelCentrifugal force

The invention discloses a filter device. The filter device comprises a working chamber and a filter arranged inside the working chamber, wherein one end of the filter is connected with an air outlet channel and a connecting shaft is coaxially installed at the other end of the filter; a spiral plate surrounds at least 90% of one circle of the connecting shaft so as to form a spiral air duct; an air inlet channel communicated with the spiral air duct is arranged in the connecting shaft; and the side of the working chamber is communicated with a dust chamber. Compared with the prior art, the filter device has the advantages that the side of the working chamber of the filter device is communicated with the dust chamber; gas enters the working chamber along the spiral air duct and then spirally moves; and the dust approaches the side wall of the working chamber under the action of the centrifugal force and moves along the side wall, and in the process, the dust can enter the dust chamber from the side of the working chamber to keep away from the filter, thus prolonging the service life of the filter and ensuring the dust removal efficiency. The invention also discloses dust removal equipment.

Owner:胡国海

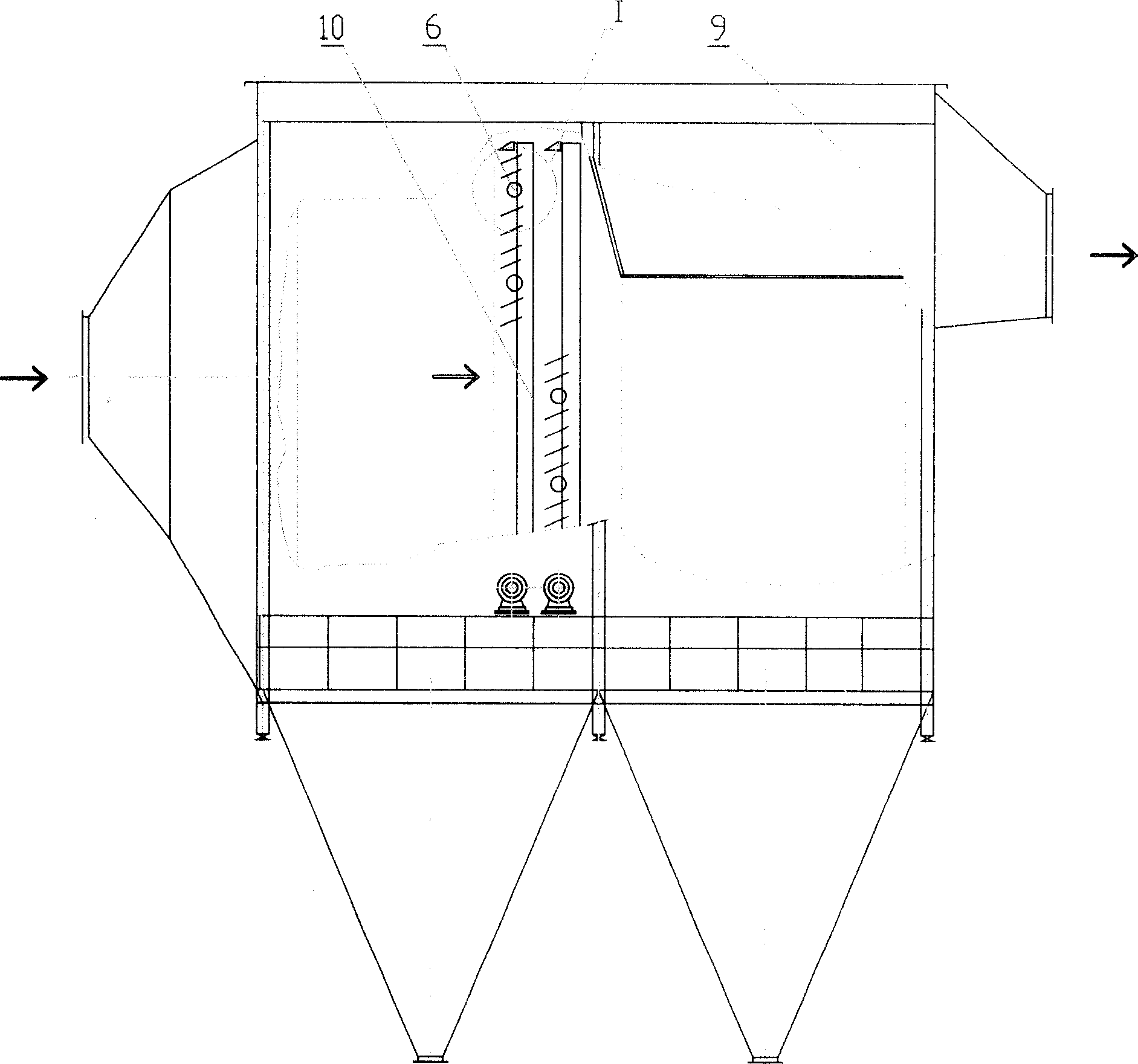

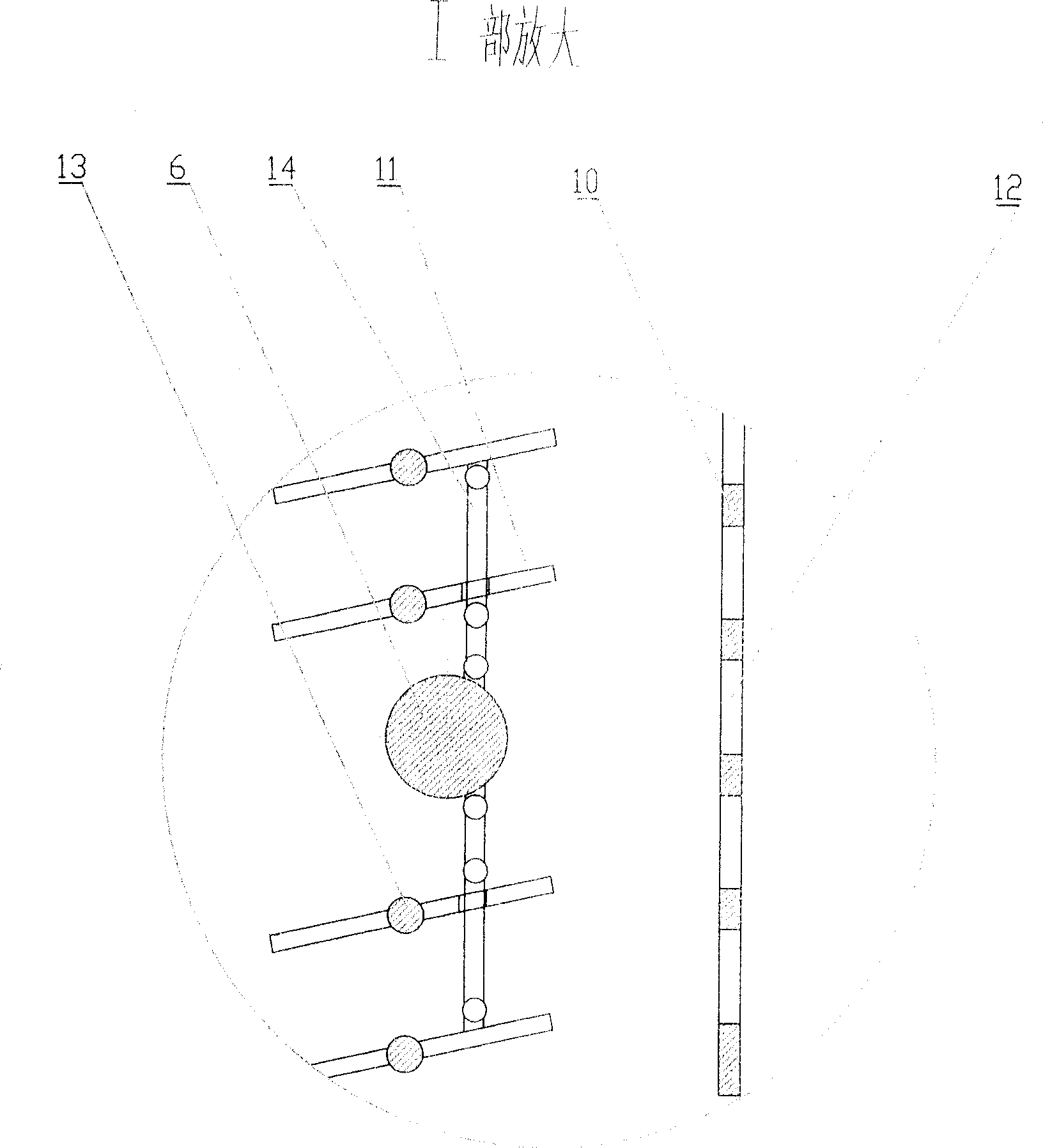

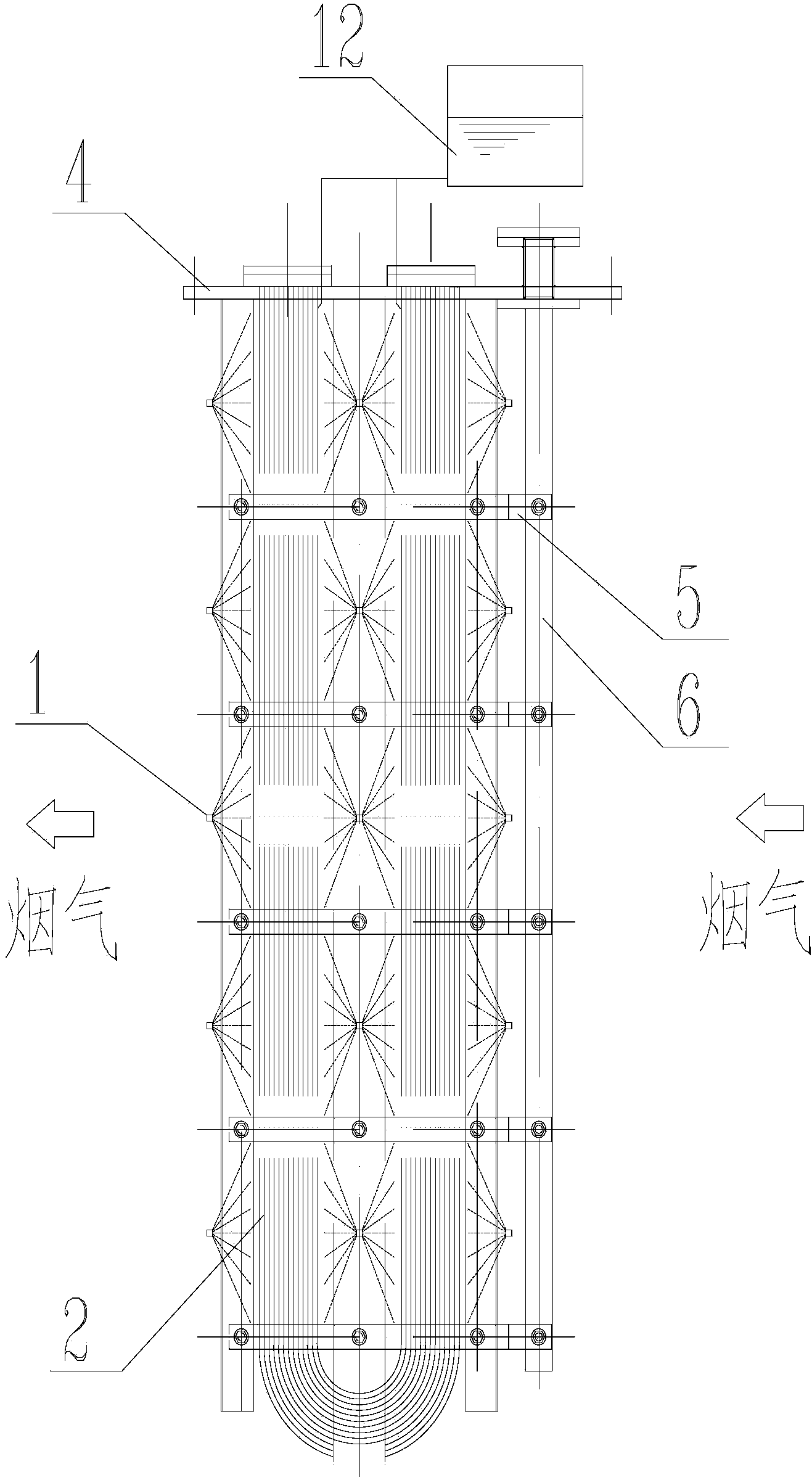

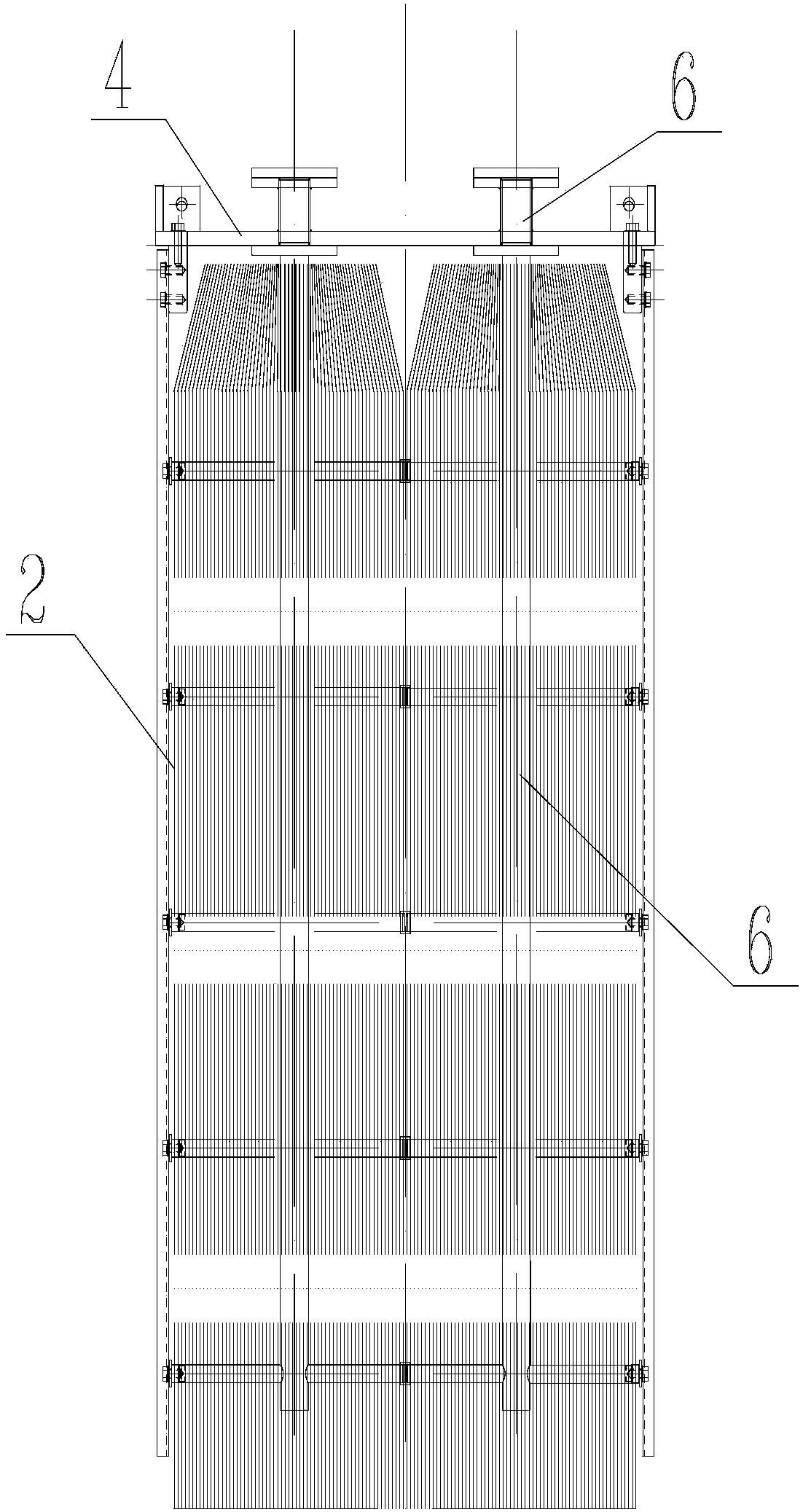

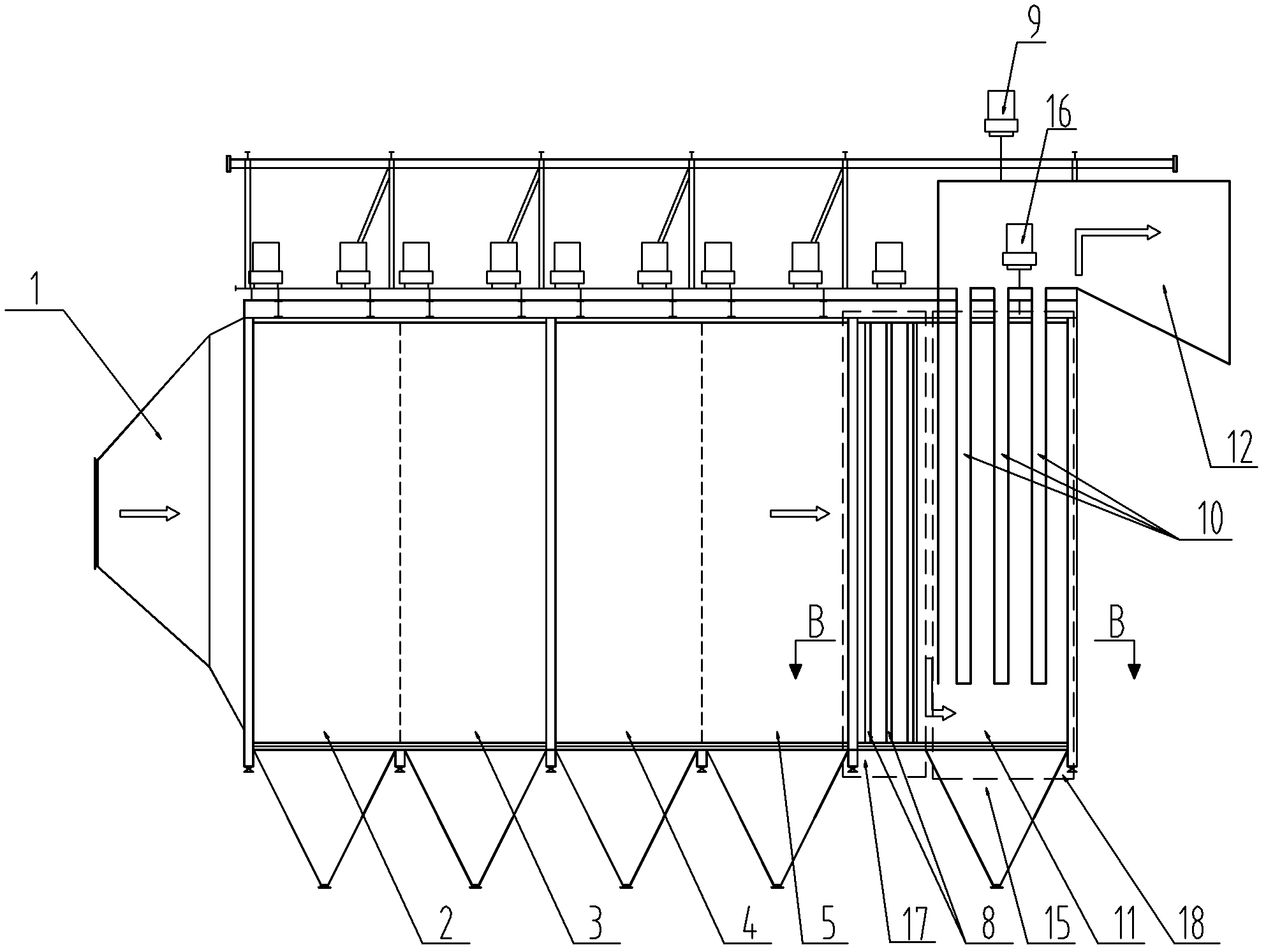

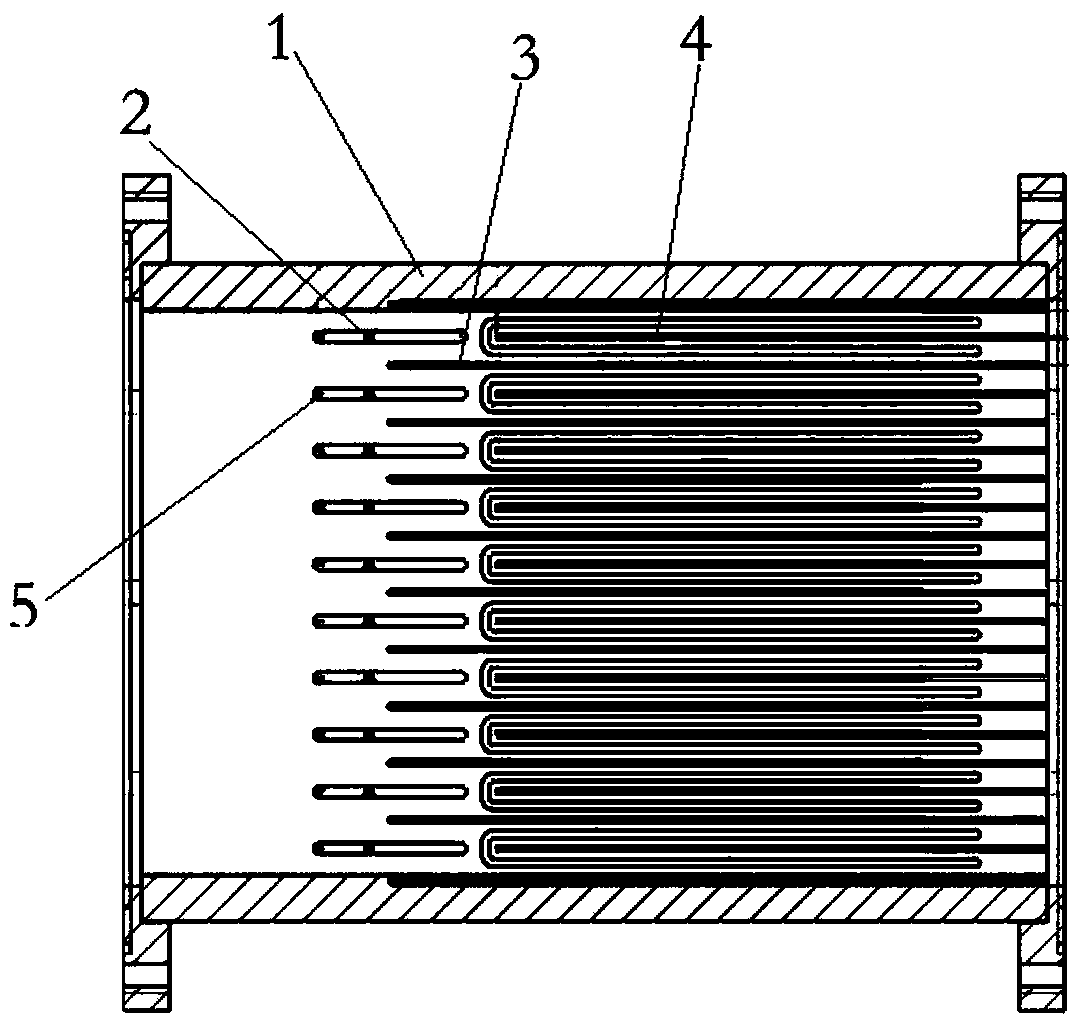

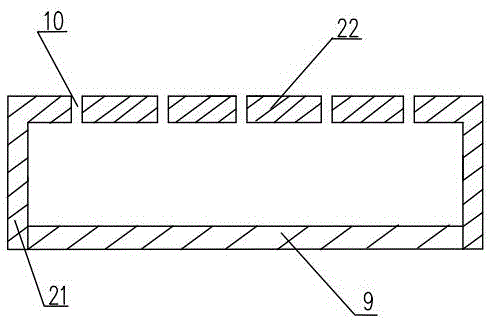

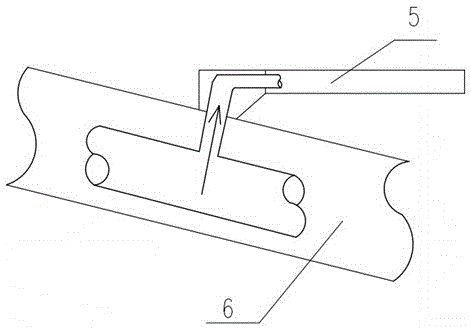

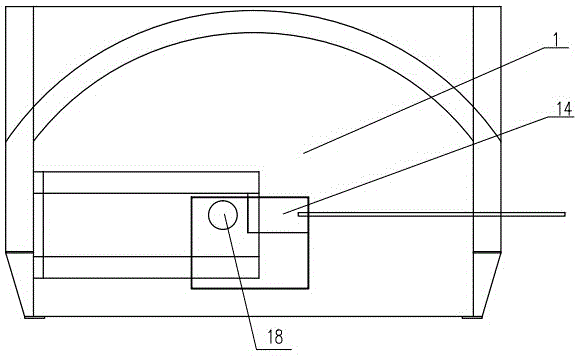

Electric bag composite deduster

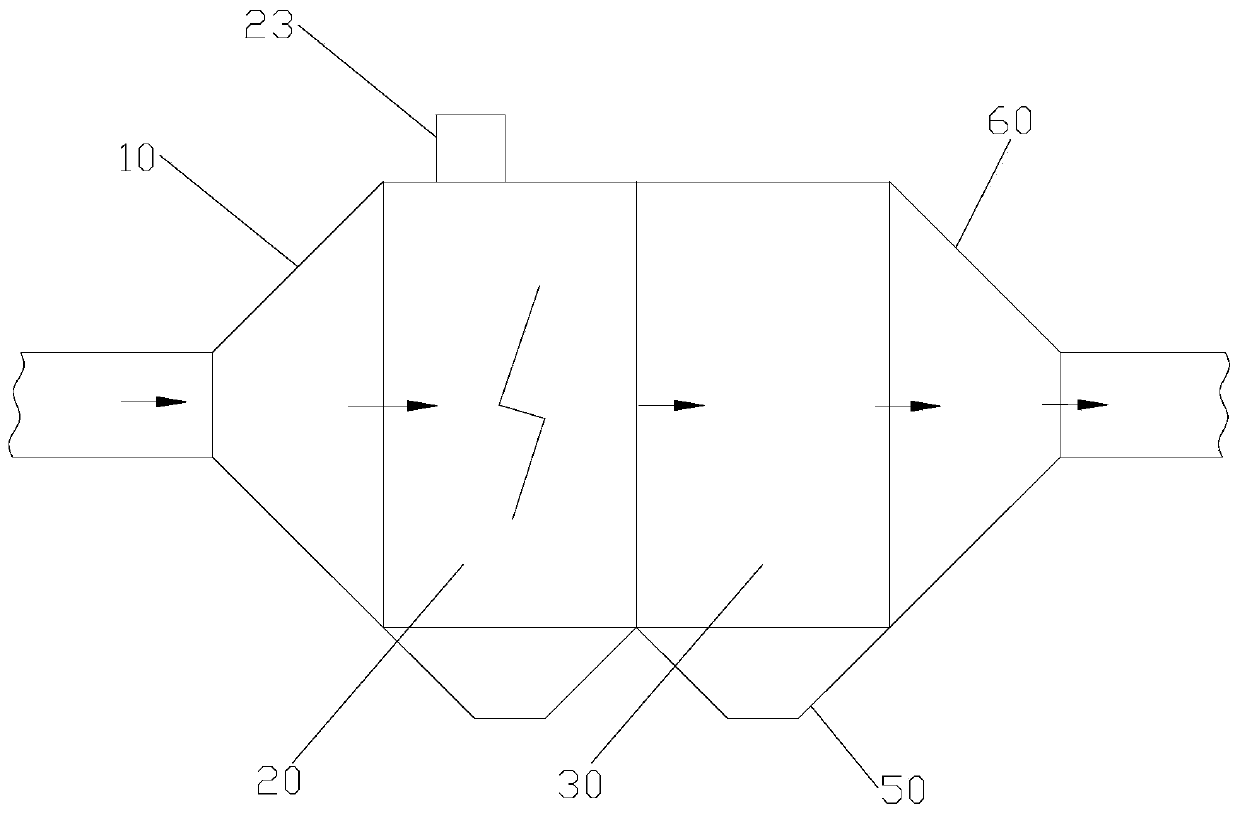

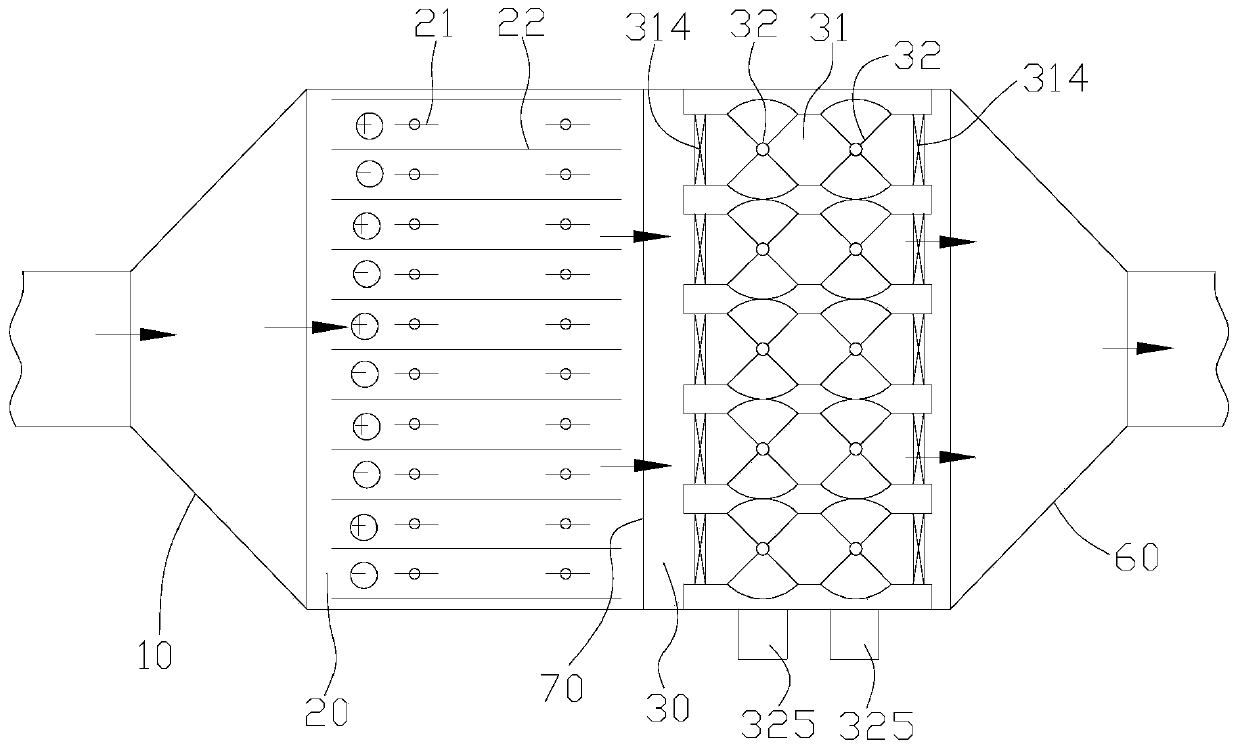

ActiveCN102755808ADust removal load balanceImprove dust removal efficiencyCombination devicesSprocketDust control

The invention discloses an electric bag composite deduster which comprises an electrostatic dedusting unit, a cloth bag dedusting unit, a vertically lifting spray-blow ash cleaning device and a smoke diversion device, wherein an upper transmission shaft of the vertically lifting spray-blow ash cleaning device and a lower transmission shaft of the vertically lifting spray-blow ash cleaning device are respectively arranged at the top and the bottom of a casing of the electrostatic dedusting unit, an upper left chain wheel and an upper right chain wheel are respectively arranged at the left end and the right end of the upper transmission shaft, and a lower left chain wheel and a lower right wheel are respectively arranged at the left end and the right end of the lower transmission shaft. The upper left chain wheel is connected with the lower left chain wheel through a left chain, the upper right chain wheel is connected with the lower right chain wheel through a right chain, a left end cover a spray-blow pipe and a right end cover of the spray-blow pipe are respectively arranged on the left chain and the right chain, and the spray-blow pipe is located between an anode plate and a cathode line. A diameter-expansion air outlet pipe of the smoke diversion device is arranged on an air inlet pipe, an adjusting valve is arranged on the diameter-expansion air outlet pipe, an air inlet of the air inlet pipe is located in a smoke inlet of the electrostatic dedusting unit, and the diameter-expansion air outlet pipe on the air inlet pipe is located below a cloth bag arranged in a casing of the cloth bag dedusting unit.

Owner:YANCHENG LANFENG ENVIRONMENTAL ENG TECH

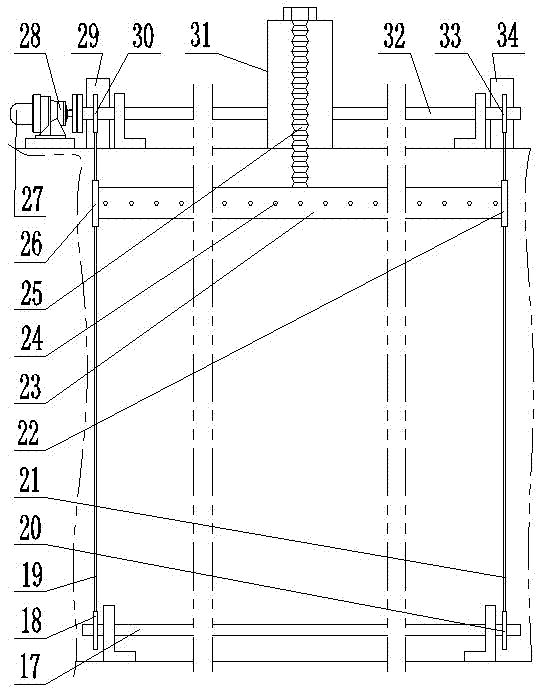

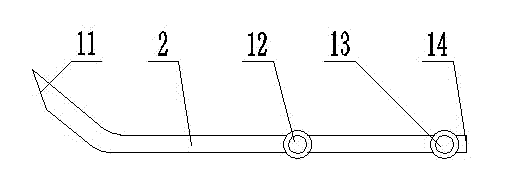

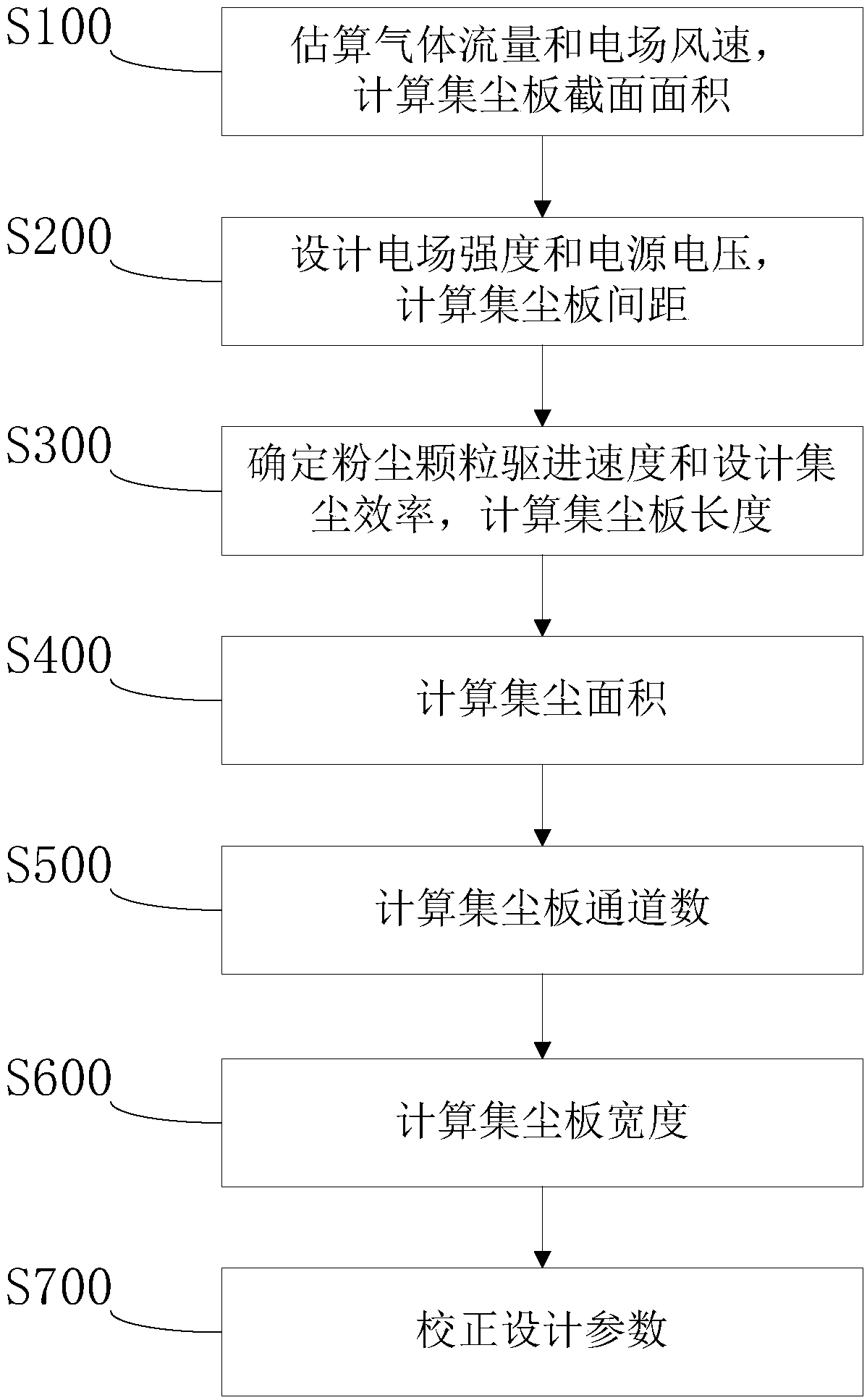

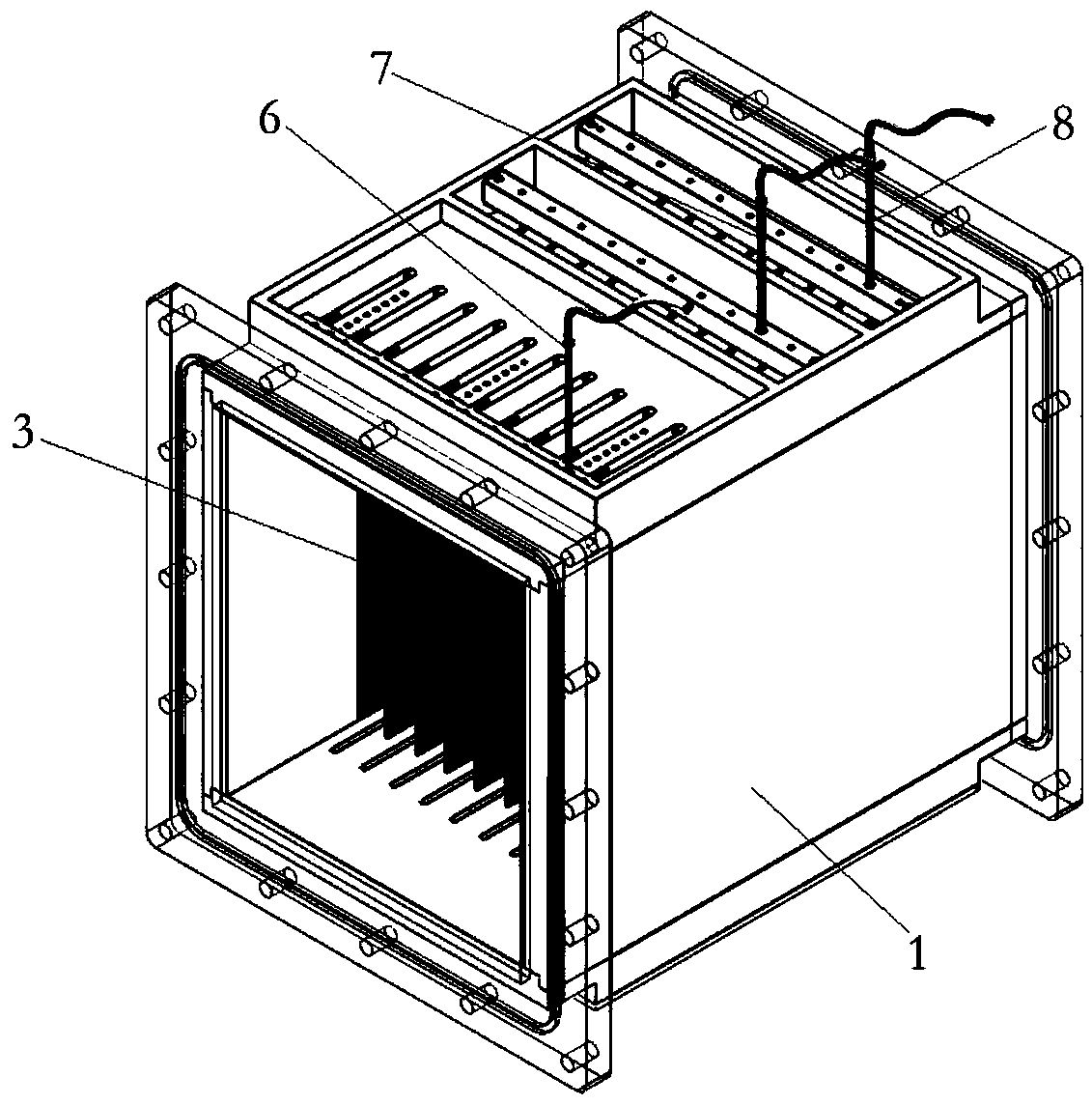

Design method of electrostatic dust removal reactor and indoor dust removal equipment

ActiveCN109604062AImprove removal efficiencyRemove the electric field structureGeometric CADExternal electric electrostatic seperatorParticulatesElectrical field strength

The invention discloses a design method of an electrostatic dust removal reactor. The design method comprises the following steps that S100, indoor gas flow Q and electric field wind speed v are estimated, and the cross section area F of a dust collecting plate is calculated; S200, the electric field intensity E and the power supply voltage U are designed, and the distance b of polar plates is calculated; S300, the dust particle driving speed omega is determined, and the dust collecting efficiency eta' is designed, and next, the length L of the dust collecting plate is calculated; S400, the dust collecting area S is calculated; S500, the number n of channels of the dust collecting plate is calculated; S600, the width W of the dust collecting plate is calculated; and S700, the design parameters are corrected. The invention further discloses indoor dust removal equipment designed by the method. According to indoor conditions needing to be purified, the parameters of the electrostatic dust removal reactor are designed, then the charge mechanism and the migration rule of the particles with different particle sizes and different morphologies in the system are inspected, and the size, the distance and the electric field intensity of the dust collecting plate are adjusted based on the efficiency formula, next, the electric field structure capable of effectively removing the particleswith multiple particle sizes can be designed, and the removal efficiency of the submicron particles can be improved.

Owner:倪圣洁

Automatic decoking combustion chamber for combusting biomass fuel

The invention discloses an automatic decoking combustion chamber for combusting biomass fuel, and belongs to the technical field of combustion equipment. The automatic decoking combustion chamber for combusting the biomass fuel comprises movable grate plates arranged in a furnace and fixed grate plates fixed in the furnace, the movable grate plates move front and back and are in friction fit with the fixed grate plates, the fixed grate plates and the movable grate plates are alternately arranged in a stair-step mode and sequentially descend from a furnace mouth of the furnace to the back portion of the furnace, and all the movable grate plates act synchronously; each furnace grate plate comprises a groove-shaped metal cover plate, plate legs of the metal cover plate are in friction fit with the plate surface of the furnace grate plate below the metal cover plate, the plate surface of the furnace grate plate is provided with multiple air holes, and the lower surface of the furnace grate plate is provided with an air supply system which supplies air to the furnace through the air holes; the automatic decoking combustion chamber for combusting the biomass fuel is further provided with a hopper, a material pushing plate and an igniter. According to the automatic decoking combustion chamber for combusting the biomass fuel, the market vacancy is filled, the problem that sticky jelly-like matter generated in the combustion process of the biomass fuel blocks the air holes of the furnace grate plates is effectively solved, decoking is automatically performed, materials are distributed evenly, and full combustion is guaranteed; the automatic decoking combustion chamber is simple in structure and convenient and fast to operate.

Owner:张露纯

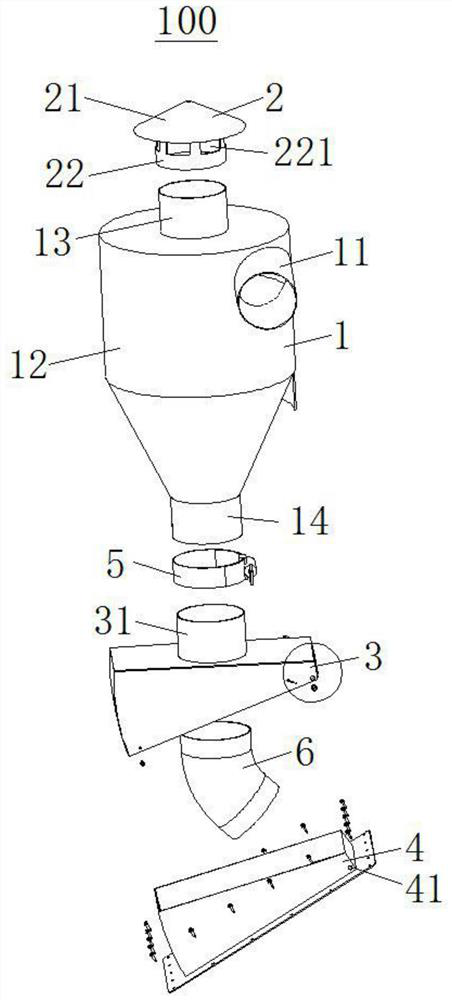

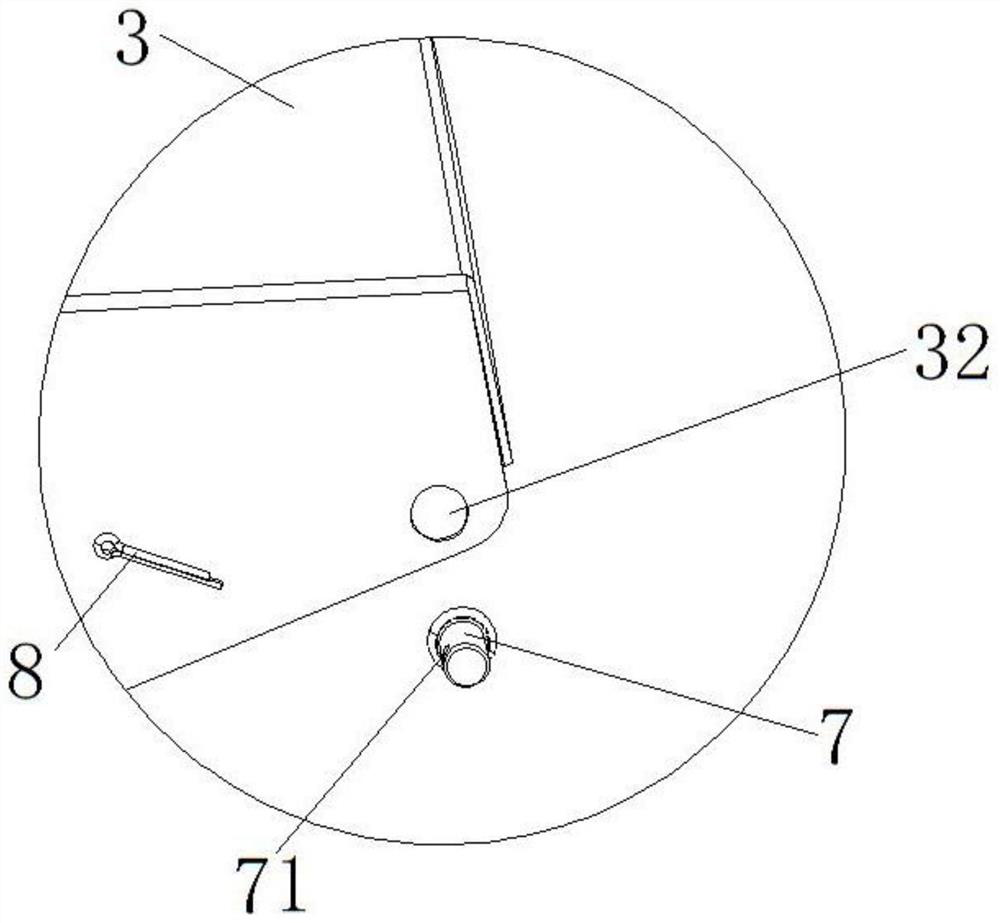

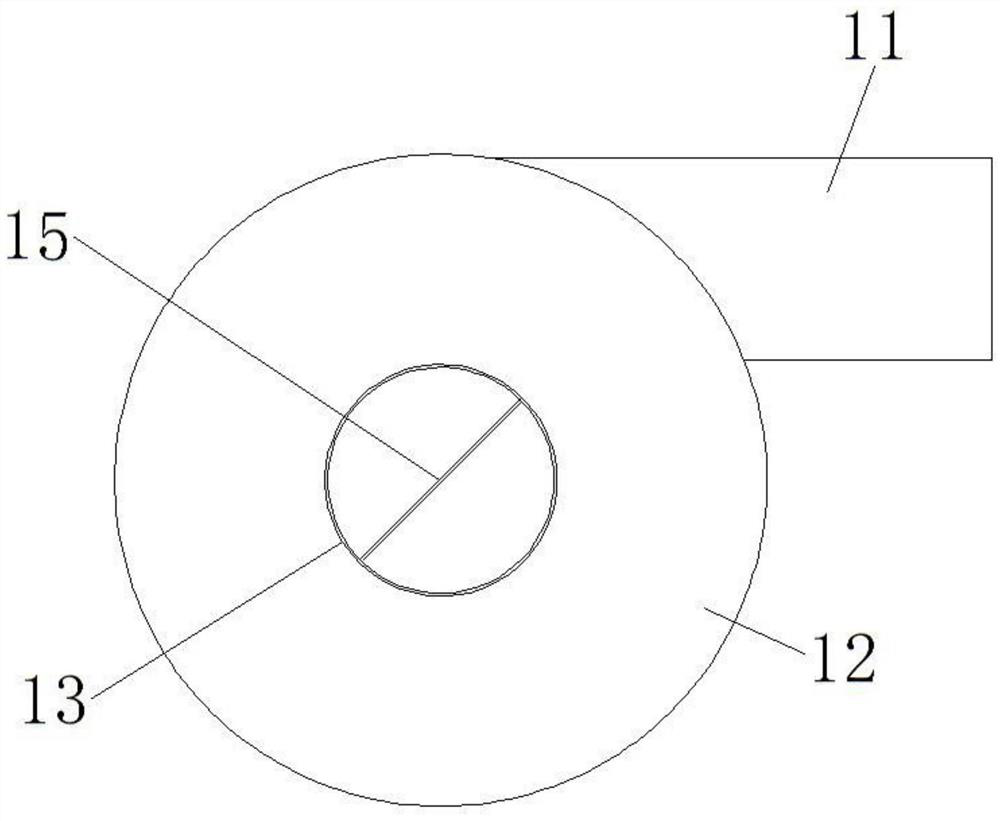

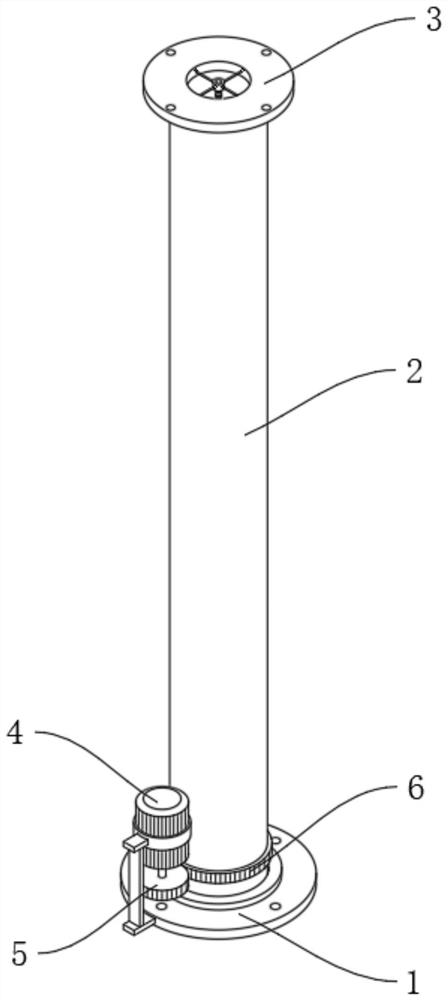

Gas-material separator

PendingCN112403694AGuaranteed installation stabilityInstallation Stability ImpactReversed direction vortexBulk conveyorsPhysicsEngineering

The invention provides a gas-material separator which is installed on a material tower. The gas-material separator comprises a cyclone dust collector, a rainproof cap, an adjusting connecting piece and a base, wherein the cyclone dust collector comprises a gas inlet and a barrel, the gas inlet is tangent to the side wall of the barrel, the gas inlet communicates with a cavity of the barrel, a gasoutlet is formed in the upper end of the barrel, the gas outlet is basically located over the central axis of the barrel, and a discharging opening is formed in the lower end of the barrel and basically located under the central axis of the barrel; and the rainproof cap is connected to the gas outlet, the adjusting connecting piece is connected to the discharging opening, and the adjusting connecting piece is arranged on the base through a pin shaft in an angle-adjustable mode. The gas inlet of the gas-material separator is connected with a positive-pressure pneumatic conveying pipeline for farm materials, the positive-pressure pneumatic conveying pipeline conveys the materials into the cyclone dust collector, gas is exhausted from the gas outlet, the materials fall into the material towerfrom the discharging opening, and dust in the materials separated by the cyclone dust collector can be effectively removed.

Owner:WUXI CULTIVATION MACHINERY

Bag-type dust collector with efficient ash removal function

InactiveCN114470985AEfficient cleaning functionGuaranteed dust removal performanceDispersed particle filtrationDrive shaftGear wheel

The invention discloses a bag-type dust collector with an efficient dust removal function, which comprises a support net rack, the outer side of the support net rack is sleeved with a filter bag, and a top mounting plate is fixed at the top end of the support net rack; the outer side of the filter bag is movably sleeved with an outer cylinder, a bottom mounting plate is rotationally arranged at the bottom end of the outer cylinder, a brush is arranged on the inner wall of the outer cylinder, the brush is spiral and makes contact with the filter bag, a stepping motor is fixedly mounted on the bottom mounting plate, a driving gear is fixed to a driving shaft of the stepping motor, and the driving gear is driven by the stepping motor to rotate. The bottom of the outer wall of the outer barrel is fixedly sleeved with a gear ring, the gear ring is meshed with the driving gear, a driving block is fixed to the position, close to the bottom mounting plate, in the outer barrel in a suspended mode, the driving block is located below the filter bag, and a screw rod is fixed to the driving block and penetrates through the supporting net rack. According to the bag-type dust collector with the efficient ash removal function, the integrity of the primary layer of the filter bag is ensured while the ash of the filter bag is removed.

Owner:江苏普向环保科技有限公司

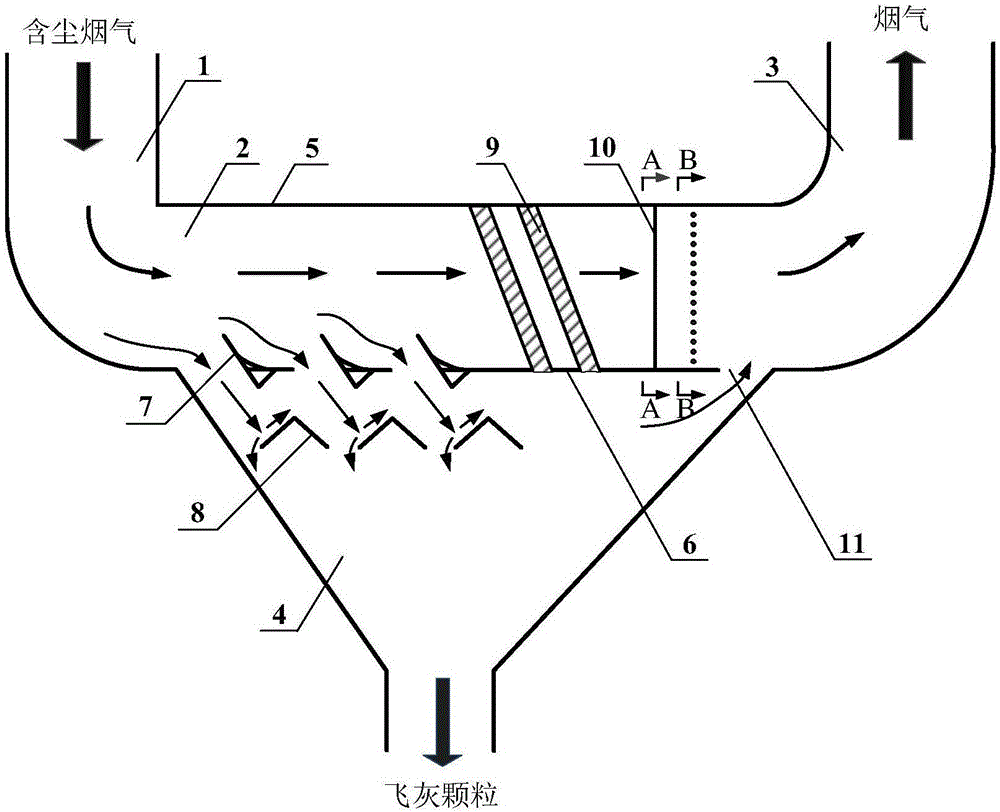

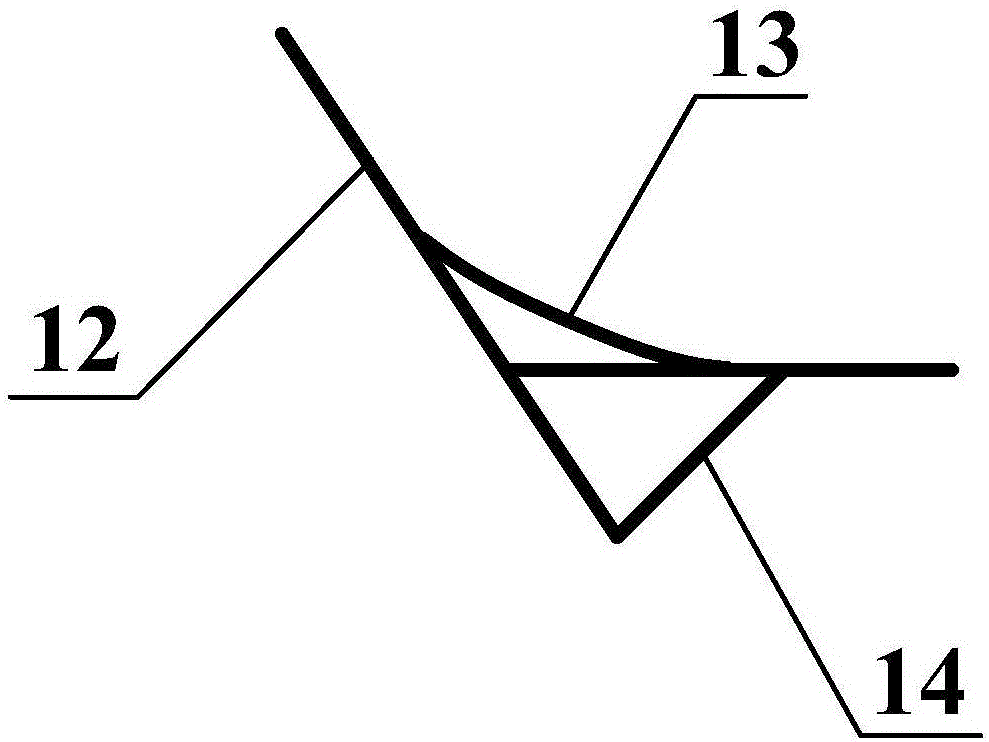

Device and method for pre-removing popcorn ash of SCR denitration system

The invention discloses a device for pre-removing popcorn ash of an SCR denitration system. The device comprises a vertical shaft flue, a horizontal flue and an uptake shaft which are connected in sequence, wherein the turning connection positions between the horizontal flue and the vertical shaft flue and the uptake shaft respectively have streamline appearances, an ash hopper is arranged on the lower side of a base plate of the horizontal flue, and a catcher, a separator and a filter screen are sequentially arranged on the side in the smoke flowing direction. A smoke circulating port is formed in a base plate of the tail portion of the horizontal flue and is communicated with the ash hopper. The invention further provides a method for pre-removing popcorn ash of the SCR denitration system. The flinging wall characteristics at the connection positions of the streamline vertical shaft flue and the horizontal flue which are installed without guiding plates are utilized to form a high-ash-concentration flue airflow, and popcorn ash and smoke are efficiently separated by sequentially adopting the catcher, the separator and the filter screen based on streaming impact type separation, gravity settling separation and intercepting separation principles. Rapid and effective separation of high-temperature and high-concentration popcorn ash is achieved by adopting the method, and the device has the advantages of being simple in structure and safe and stable in operation.

Owner:SOUTHEAST UNIV

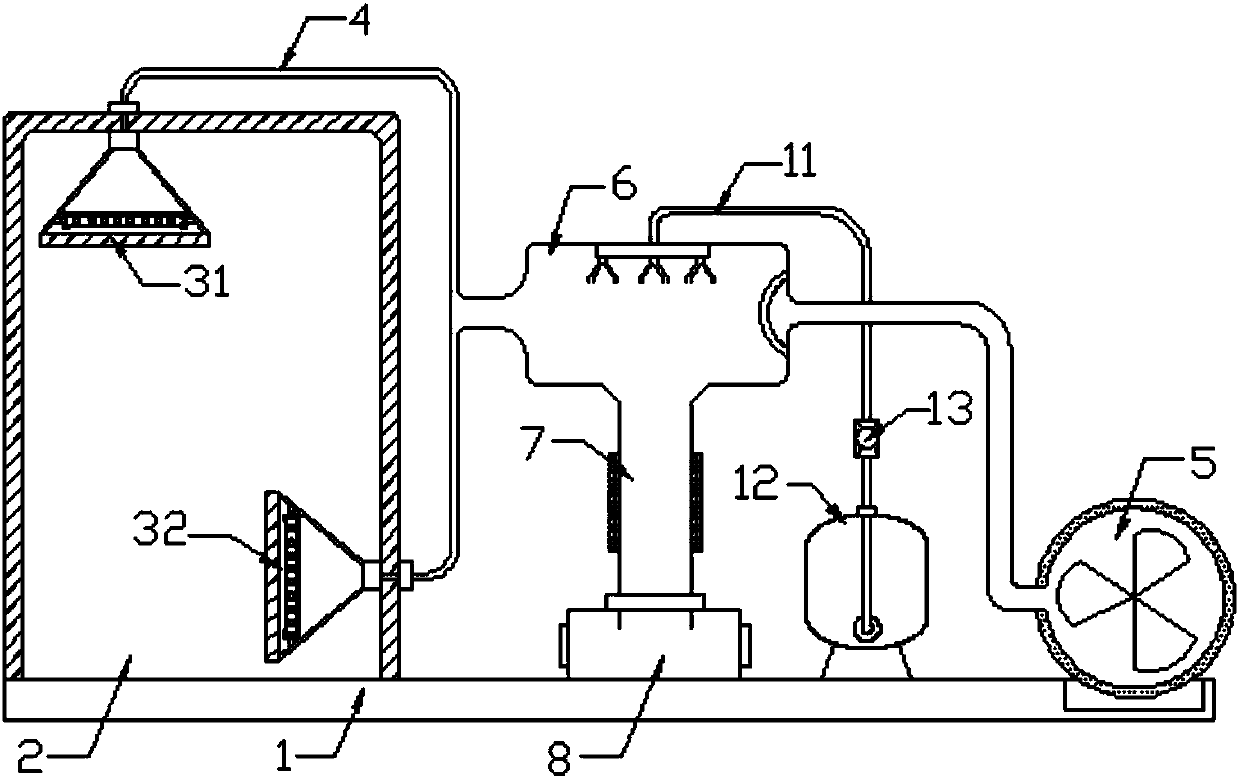

Intelligent mining equipment dust removal and collection equipment

InactiveCN111878152AGuaranteed dust removal efficiencyPracticalPump componentsDust removalDust controlFan blade

The invention relates to the field of mining equipment, in particular to intelligent mining equipment dust removal and collection equipment. The dust removal and collection equipment comprises a base,a filter box is arranged on the upper side of the base, a first water pump is arranged at the right end of the filter box, the first water pump is connected with a water tank through a water pumpingpipe, a second water pump is arranged at the left end of the filter box, a first water supply pipe is arranged on the second water pump, the other end of the first water supply pipe communicates withthe upper portion of the water tank, a second water supply pipe is arranged in the middle of the first water supply pipe, the other end of the second water supply pipe is connected with a spray disc arranged at the upper end of the interior of a connection box, a plurality of spray heads are arranged on the lower side of the spray disc, a first control valve is arranged on the lower portion of thesecond water supply pipe, and a second control valve is arranged at the position, located on the right of the second water supply pipe, of the first water supply pipe. According to the dust removal and collection equipment, through the structural arrangement, fan blades are sprayed and cleaned through the spray heads of the spray disc, so that the fan blades are kept clean, the dust removal efficiency is guaranteed, and the practicability is high.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

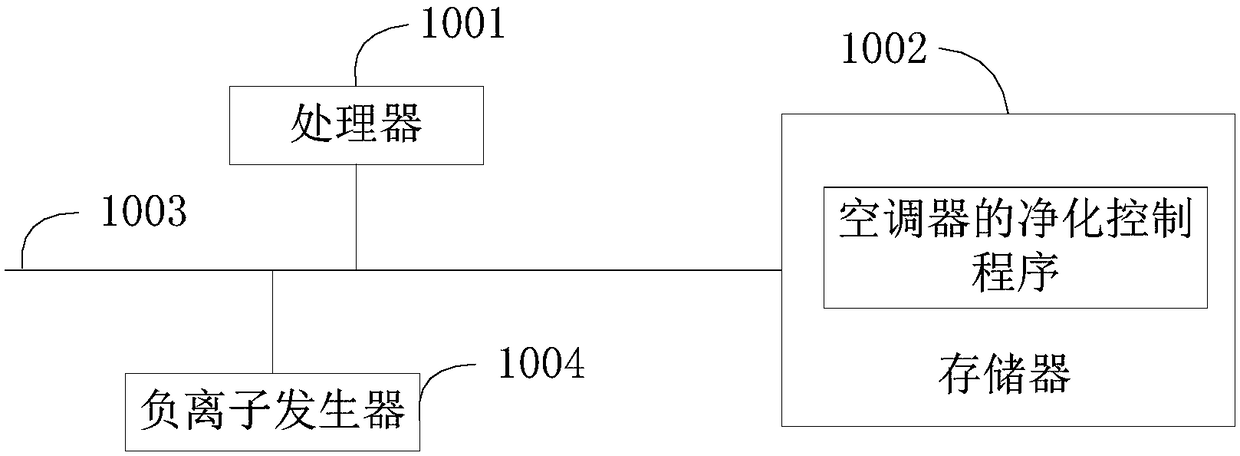

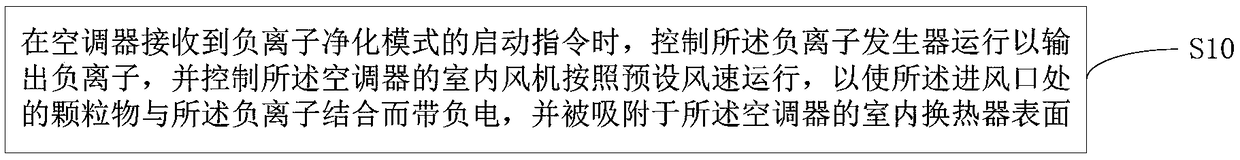

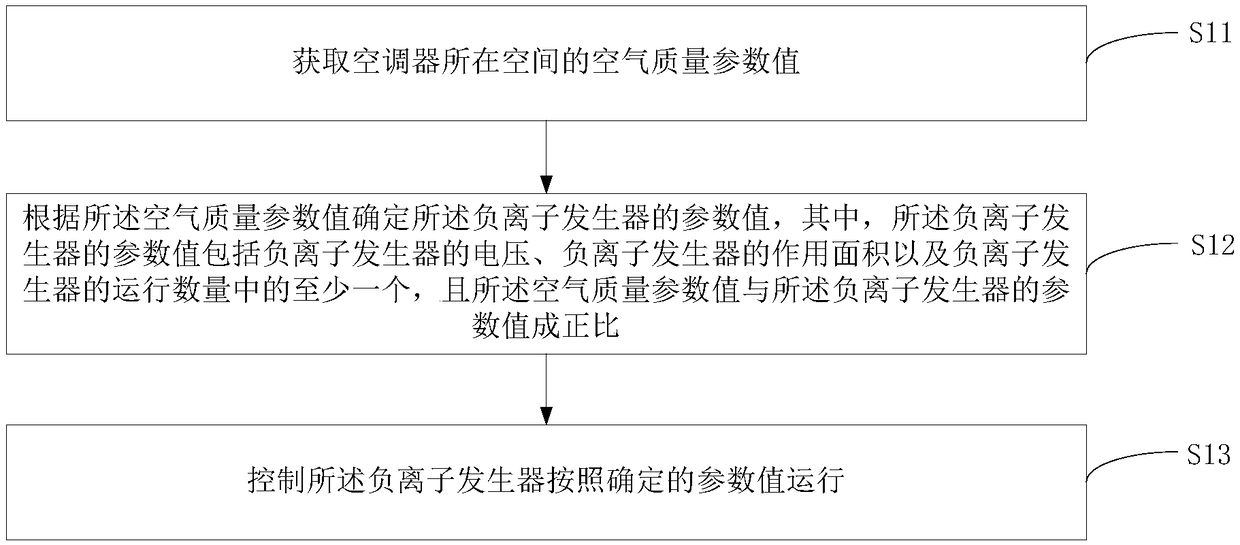

Air conditioner, purification control method thereof and computer readable memory medium

ActiveCN109114731AGuaranteed dust removal efficiencyImprove purification efficiencyMechanical apparatusSpace heating and ventilation safety systemsElectricityControl theory

The invention discloses a purification control method of an air conditioner. An air inlet of the air conditioner is provided with one or more anion generators. The purification control method of the air conditioner comprises the following steps that when the air conditioner receives an anion purification mode start command, the anion generators are controlled to operate so that anions can be output; and an indoor fan of the air conditioner is controlled to operate at the preset air speed so that particulate matter at the air inlet can be combined with the anions to be loaded with negative electricity and adsorbed to the surface of an indoor heat exchanger of the air conditioner. The invention further provides the air conditioner and a computer readable memory medium. The air conditioner islow in energy consumption when the anion purification mode operates.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

Spraying system of wet-type electric dust remover

InactiveCN105498976AAvoid short circuit dischargeImprove removal efficiencyElectrodes cleaningElectrical and Electronics engineeringWater supply

The invention discloses a spraying system of a wet-type electric dust remover. The spraying system comprises a water supply pipe, connecting pipes, positive plate nozzles and negative wire nozzles. The water supply pipe is installed at the supporting position of a wet-type electric dust remover body through supporting and lifting frames to form supporting of the spraying system. The connecting pipes are arranged on the water supply pipe, the positive plate nozzles and the negative wire nozzles are installed on the connecting pipe and spray water to positive plates and negative wires respectively, and dust removing work of the positive plates and the negative wires is achieved.

Owner:SHANGHAI CHAOQING ENVIRONMENTAL PROTECTION TECH CO LTD

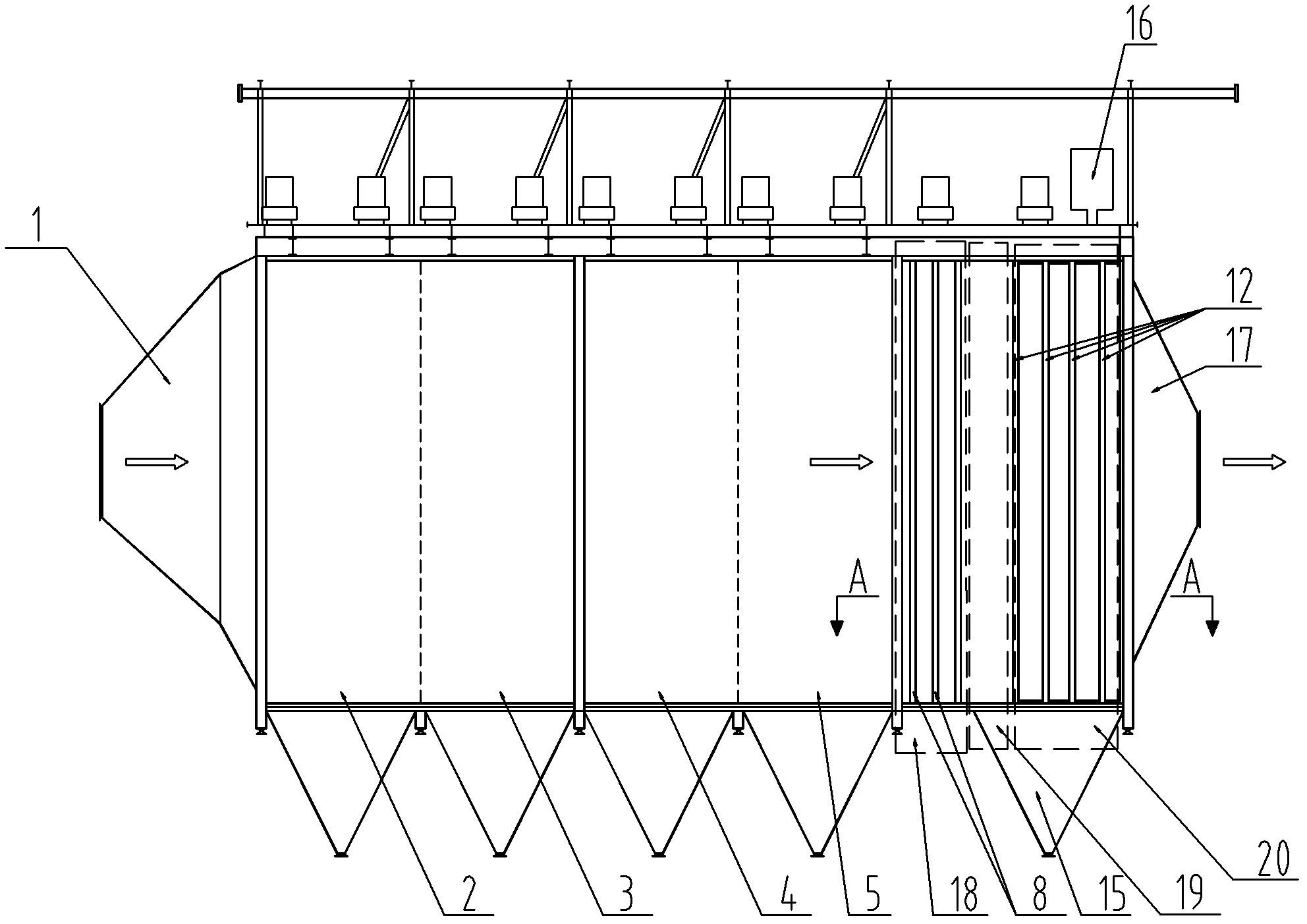

Ultra-clean electrostatic-fabric integrated precipitator

ActiveCN110314477AImprove dust removal efficiencyUnlimited lengthCombination devicesFlue gasEngineering

The invention discloses an ultra-clean electrostatic-fabric integrated precipitator. The precipitator comprises an electric field area and a bag dust removal area arranged in the back of the electricfield area; the bag dust removal area comprises a plurality of mutually parallel flue gas channels, the walls of the flue gas channels are parallel to the height direction of the bag dust removal area; in the flue gas flow direction, at least one first metal filtering component is arranged in each flue gas channel, and each first metal filtering component includes a shaft perpendicular to the fluegas flow direction and multiple metal meshes which are distributed in the circumferential direction of the shaft; the shafts can rotate and are arranged to be that flue gas flowing into the flue gaschannels passes through the metal meshes and then flows out of the flue gas channels, at least part of the flue gas flows through two or more metal meshes. According to the ultra-clean electrostatic-fabric integrated precipitator, the structure of a metal filter screen is improved, the flue gas can be filtered through at least two metal filter screen layers, and the dust removal efficiency is improved.

Owner:FUJIAN LONGKING

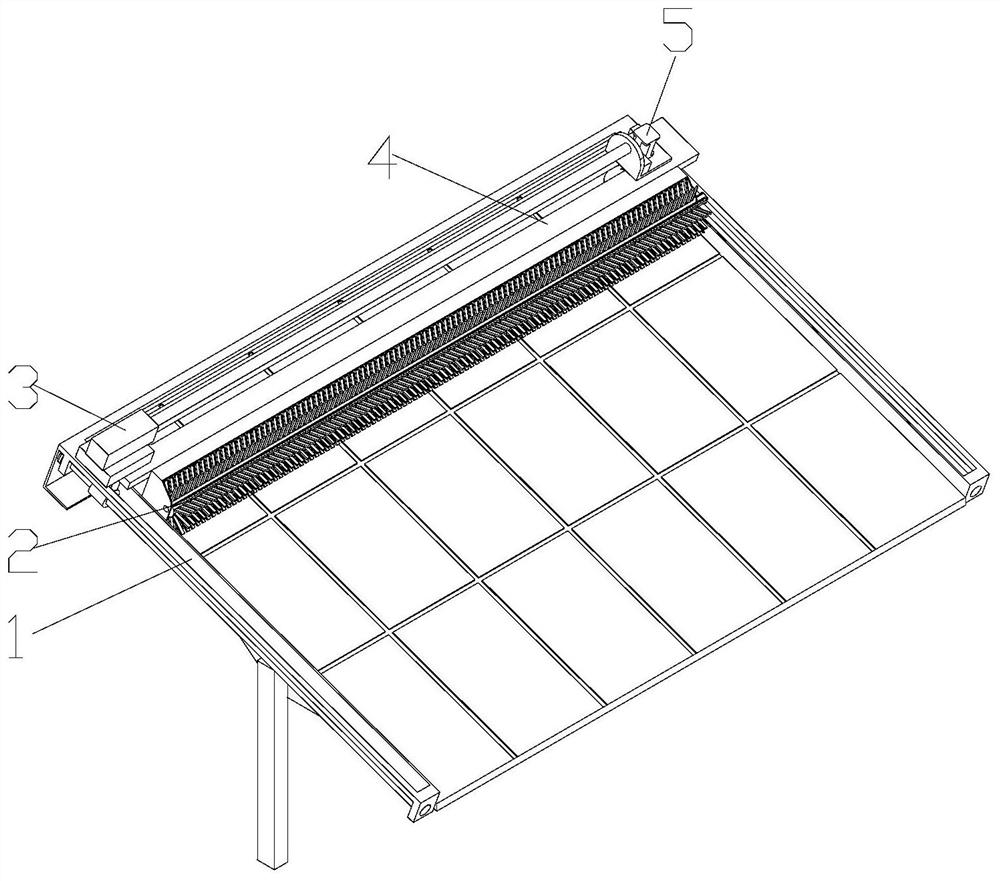

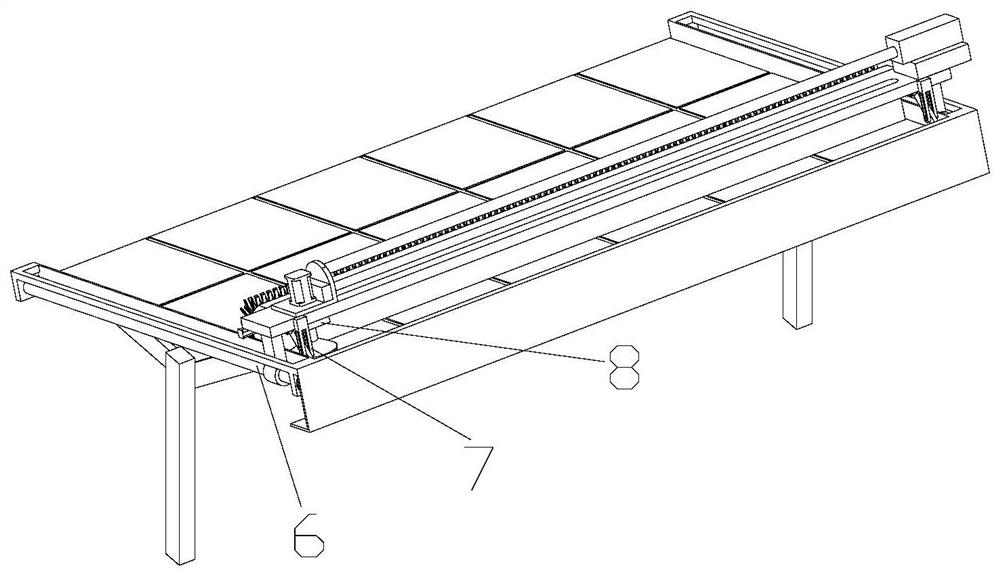

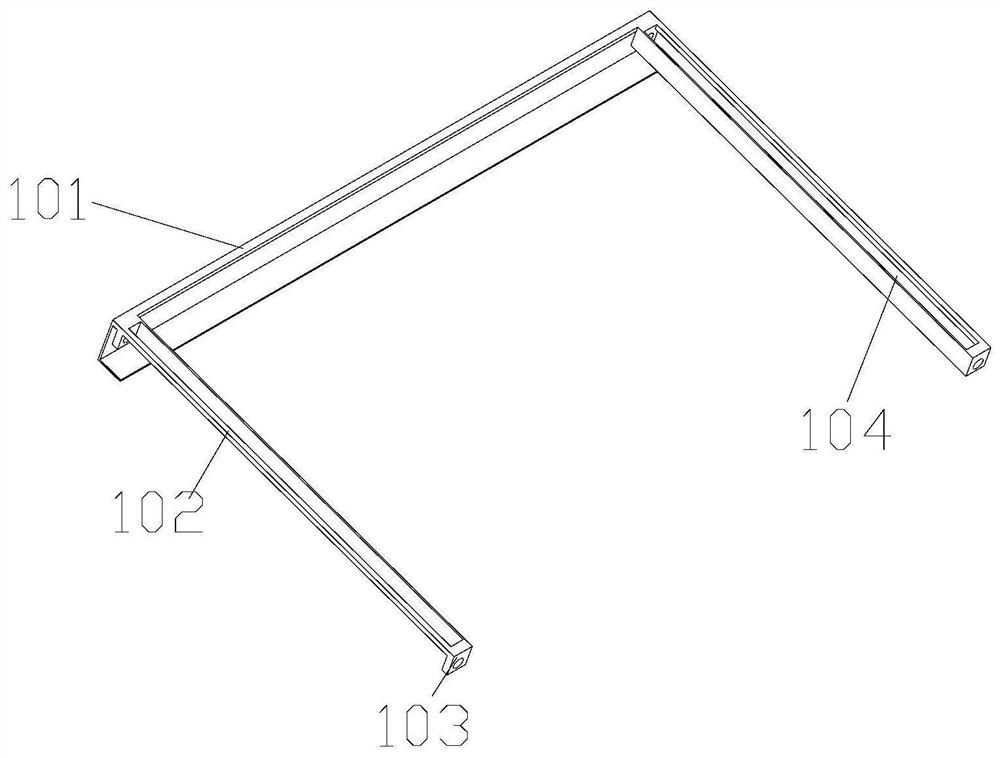

Solar photovoltaic panel efficient cleaning device

ActiveCN113967624AImprove cleanlinessWon't scratchCleaning using toolsCleaning using liquidsDust controlEngineering

The invention discloses a solar photovoltaic panel efficient cleaning device. The solar photovoltaic panel efficient cleaning device comprises a frame, a transmission mechanism is installed on the frame, a support is installed on the transmission mechanism, an air cylinder, a sweeping assembly, a water spraying assembly, a dust removal assembly and a wiping assembly are installed on the support, the air cylinder is installed at one end of the top of the support, one end of a piston rod of the air cylinder is installed on the sweeping assembly, the sweeping assembly is installed at the top of the support, and the water spraying assembly is installed on the sweeping assembly. The transmission mechanism can drive the support to move front and back, so that the purpose of driving the sweeping assembly, the water spraying assembly, the dust removal assembly and the wiping assembly to move front and back is achieved, the dust removal assembly can remove dust on a solar photovoltaic panel, the sweeping assembly cooperates with the water spraying assembly to clean away bird droppings and plant juice left on the solar photovoltaic panel, the wiping assembly can wipe away cleaning water sprayed out by the water spraying assembly, and soil and dust are prevented from adhering to the solar photovoltaic panel again.

Owner:PINGYIN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Blast furnace gas cloth bag dust extraction technology

InactiveCN108251586AAvoid corrosionGuaranteed dust removal efficiencyBlast furnace detailsDust arrestersGlass fiberBaghouse

The invention provides a blast furnace gas cloth bag dust extraction technology. The blast furnace gas cloth bag dust extraction technology comprises the following steps that (1) crude blast furnace gas coming from a blast furnace passes through a gravity dust separator to become semi-clean gas; (2) the semi-clean gas is fed into a moisture absorption device to be subject to moisture absorption treatment; (3) the gas obtained after moisture absorption passes through a temperature controller; (4) the semi-clean gas in the step (3) is fed into a cloth bag dust extraction device to be subject tofurther dust extraction, then the gas becomes low-pressure low-temperature chloridion-carrying clean gas through power generation of TRT equipment or a pressure reducing valve set, and the gas entersa dechlorinating device; and (5) the clean gas is subject to dechlorinating through the dechlorinating device to become clean gas, and the gas enters a gas pipe network to be used by a user. Accordingto the technology, the moisture absorption device is additionally arranged, and the dust extraction efficiency can be guaranteed; the cloth bag dust extraction device adopts a glass fiber punched felt dust extraction filter bag, and the technology can adapt to dry dedusting treatment in high temperature conditions; and in addition, the dechlorinating device in the technology can wash away chloridions, and corrosion of corrosive matter on gas main pipes is effectively avoided.

Owner:天津浩创节能环保设备有限公司

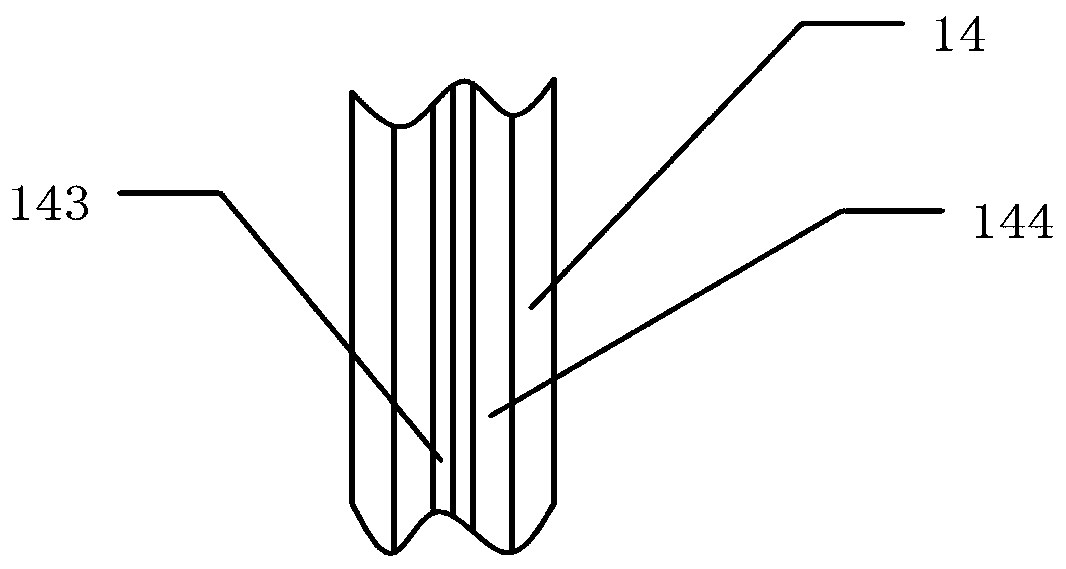

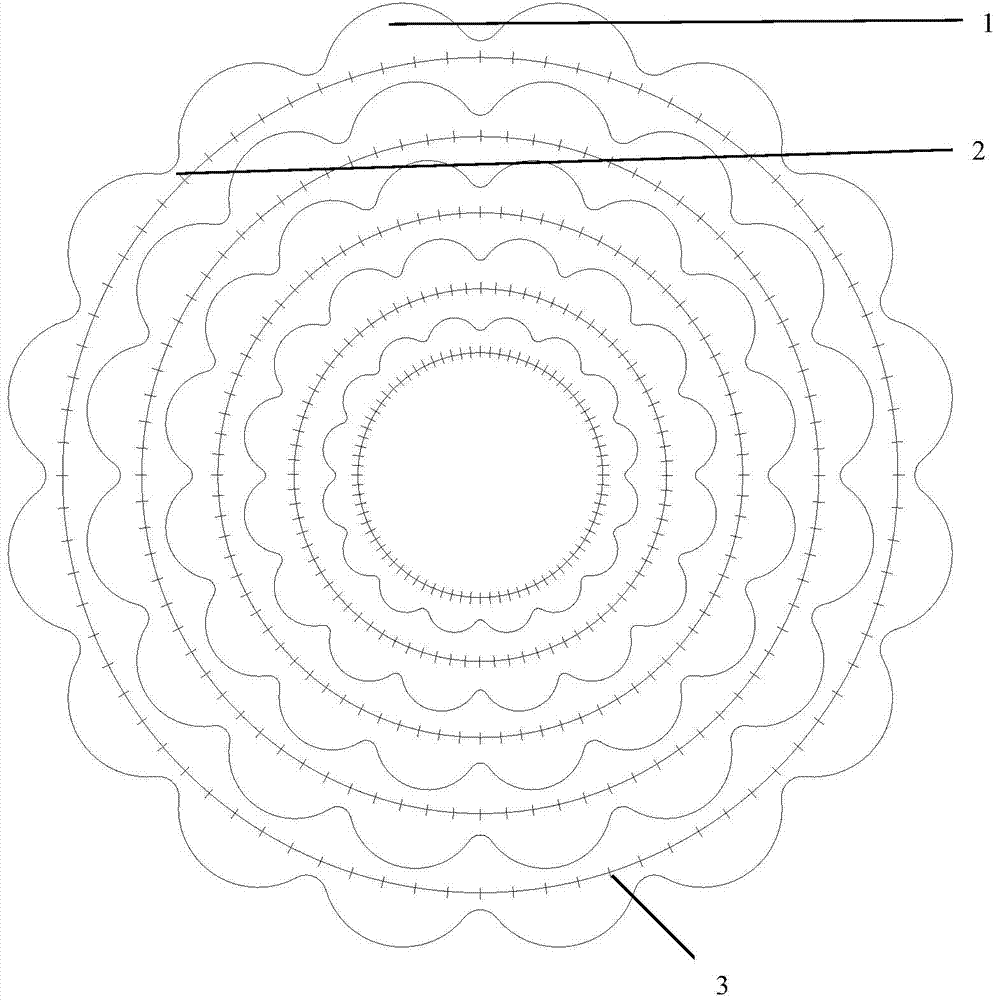

Corrugated wet-type electric dust remover anode

InactiveCN104722406AReduce voltageIncrease spacingElectrode constructionsTitanium alloyTitanium plate

The invention belongs to the field of environmental engineering and relates to a corrugated wet-type electric dust remover anode. The electric dust remover anode is a titanium plate or a titanium alloy plate. The thickness of the titanium plate or the titanium alloy plate is 2-4 mm; the titanium plate or the titanium alloy plate is pressed into a corrugated shape which is formed by up-down connection of a 30-degree arc and a semicircle with the diameter being 10-500mm. The corrugated wet-type electric dust remover anode has the advantages that due to adoption of a large-channel corrugated design, the dust depositing effect is effectively improved, the dust-depositing blind areas are solved, and the anode spacing is increased under the condition of not increasing the voltage, so that the occurrence of the short-circuit phenomenon is reduced, the quantity of anode plates is reduced and the expenditure is saved; and due to the corrugated design, the discharging and the dust deposition are divided into two areas, so that the problem that the power needs to be cut off when the existing wet-type electric dust remover is washed is effectively solved. Since the titanium plate or the titanium alloy plate is used as the dust remover anode, the problems that the existing anode is too heavy, the base frame cannot bear the weight and the anode is extremely easy to corrode are solved.

Owner:UNIV OF SCI & TECH BEIJING

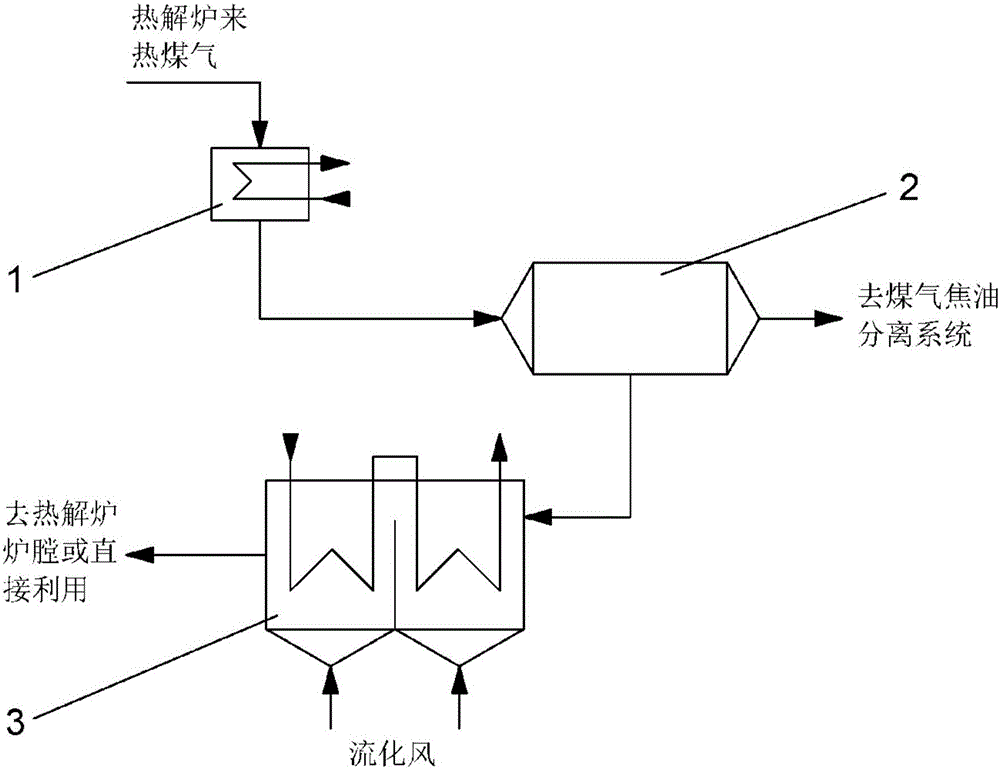

Coal pyrolysis poly-generation device coal gas and high-temperature fly ash waste heat utilizing system

InactiveCN105733621AOvercome Inlet Temperature VariationsGuaranteed dust removal efficiencyEnergy inputSpecial form destructive distillationWorking temperatureReaction temperature

A coal pyrolysis polygeneration device gas and high-temperature fly ash waste heat utilization system, a pyrolysis furnace economizer, a high-temperature electric dust collector and a coal gas tar cooling separation system are arranged between the coal pyrolysis polygeneration device pyrolysis furnace The high-temperature ash heat exchanger realizes the full utilization of the waste heat of coal pyrolysis high-temperature gas and the physical sensible heat of high-temperature fly ash, and improves the system efficiency; the economizer of the pyrolysis furnace and the economizer of the combustion furnace are arranged in parallel, and by adjusting the The proportion of feed water flow can overcome the fluctuation of pyrolysis furnace reaction temperature to the temperature of combustion furnace feed water and the working temperature of gas electrostatic precipitator, so as to ensure the efficiency of gas dust removal device, prevent tar condensation from clogging pipes, improve the quality of tar products, and improve the stability of system operation; By arranging pyrolysis furnace economizers, high-temperature electric dust collectors, and high-temperature ash heat exchangers, spray washing and dust removal devices are omitted, and system water consumption and sewage treatment costs are reduced.

Owner:HUANENG POWER INTERNATIONAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com