PM2.5 (Particulate Matter 2.5) electrostatic precipitator with box-type dedusting area

An electrostatic precipitator, electrostatic precipitator technology, applied in the direction of external electrostatic separator, etc., can solve the problems of low maintenance cost, threat to the environment, long cycle, etc., and achieve the effect of low maintenance cost and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

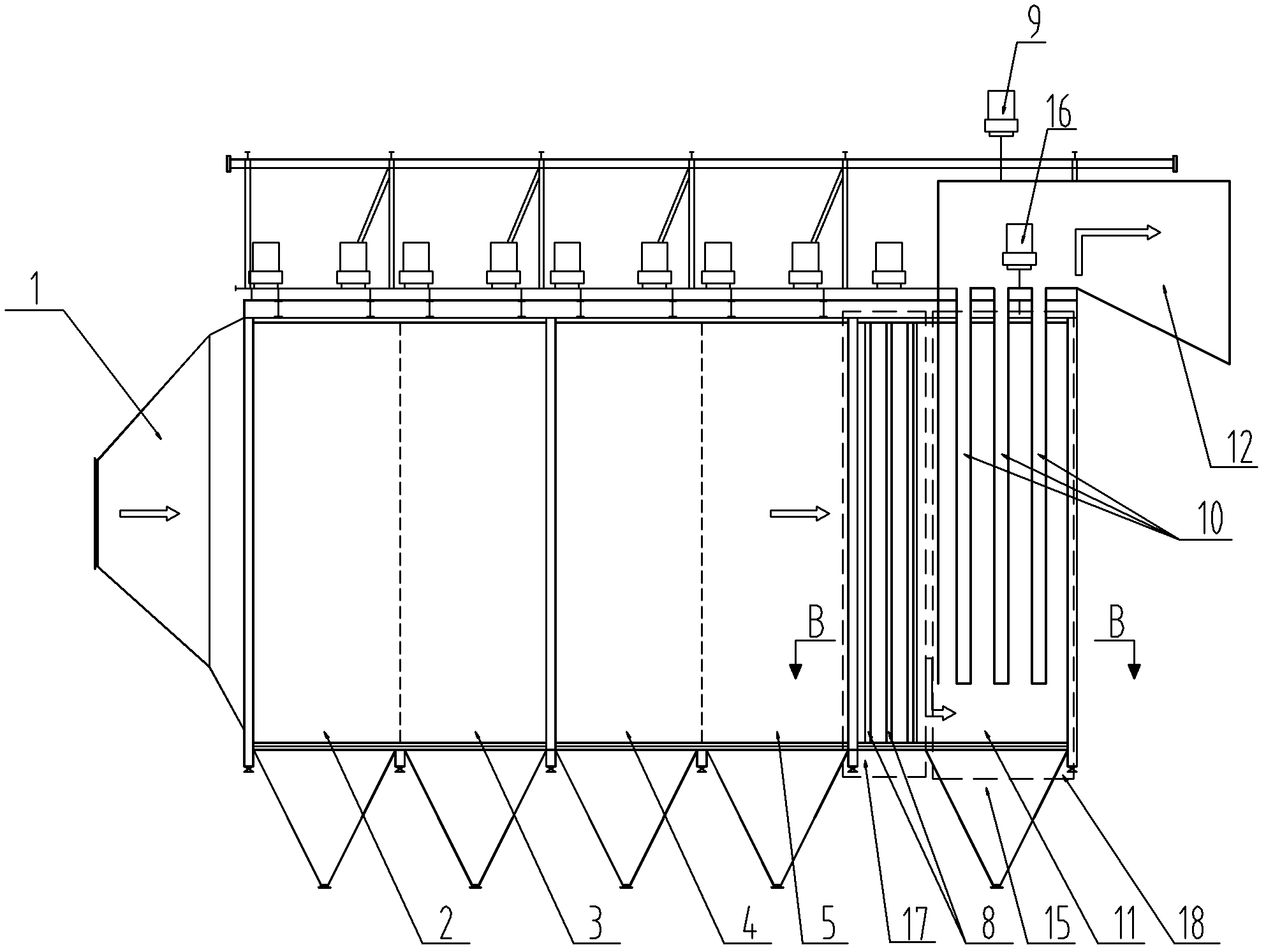

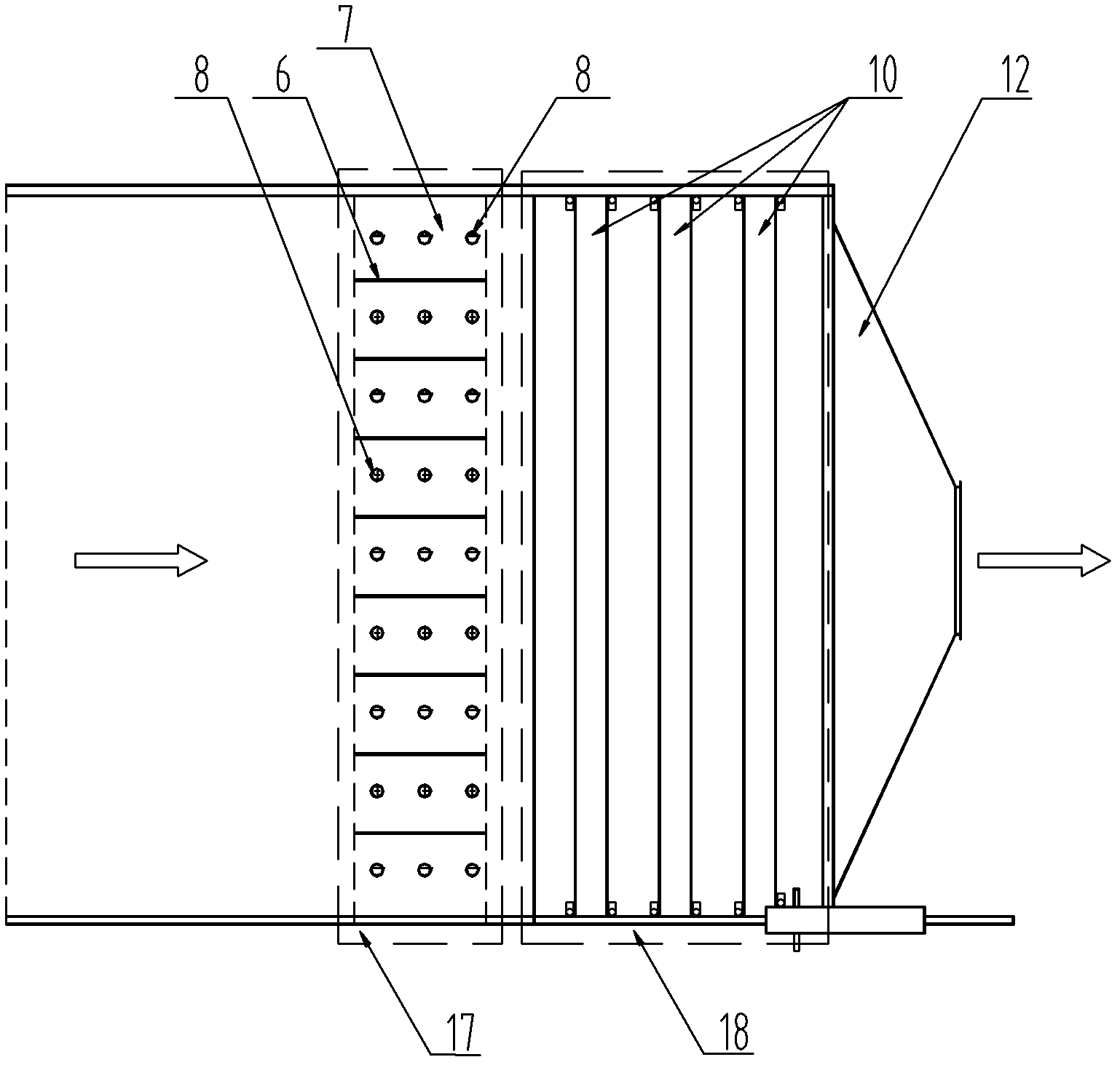

[0047] like figure 1 and figure 2 As shown, it is a schematic diagram of the structure of the present invention. The arrows in the figure are the flow direction of the dust. The dust enters the conventional electrostatic precipitator system from the inlet smoke box 1. The conventional electrostatic precipitator system includes the original first electric field 2, the original second electric field 3, the original The three electric fields 4 and the original four electric fields 5 are four original electric fields. After the dust passes through the conventional electrostatic precipitator system, most of the large particles of dust are removed, and then enters the condensation zone 17 .

[0048] The coagulation area 17 is connected to the conventional electrostatic precipitator system, and a plurality of dust collecting plates 6 at equal interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com