Water-spray-type tubular dust collector

A dust collector and water-spraying technology, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agents, etc., can solve the problems of considerable power consumption of auxiliary machines, difficult to arrange, and difficult to arrange, so as to ensure dust removal efficiency and Long-term working stability, avoiding the problem of ash plugging and scaling, and the effect of avoiding secondary dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

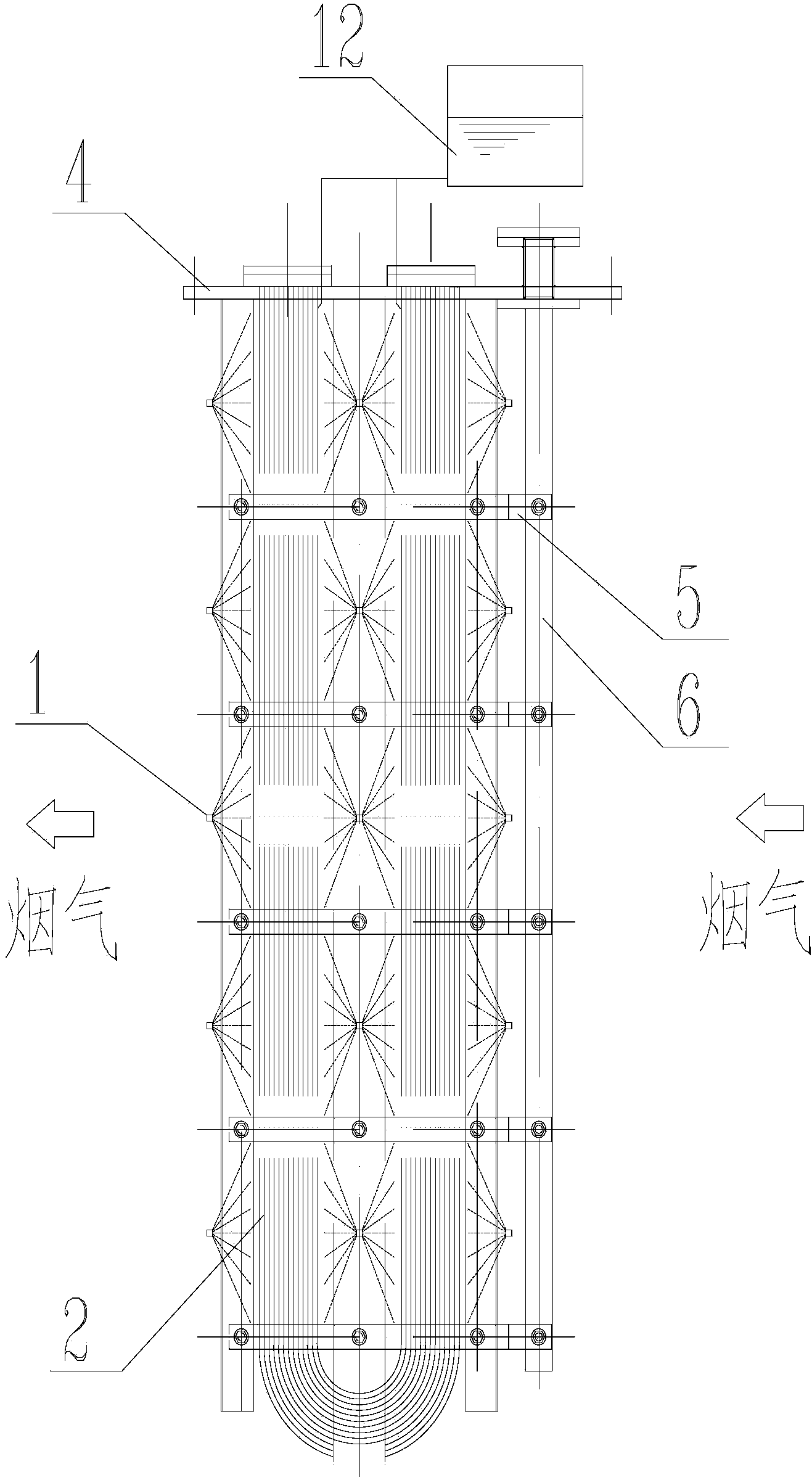

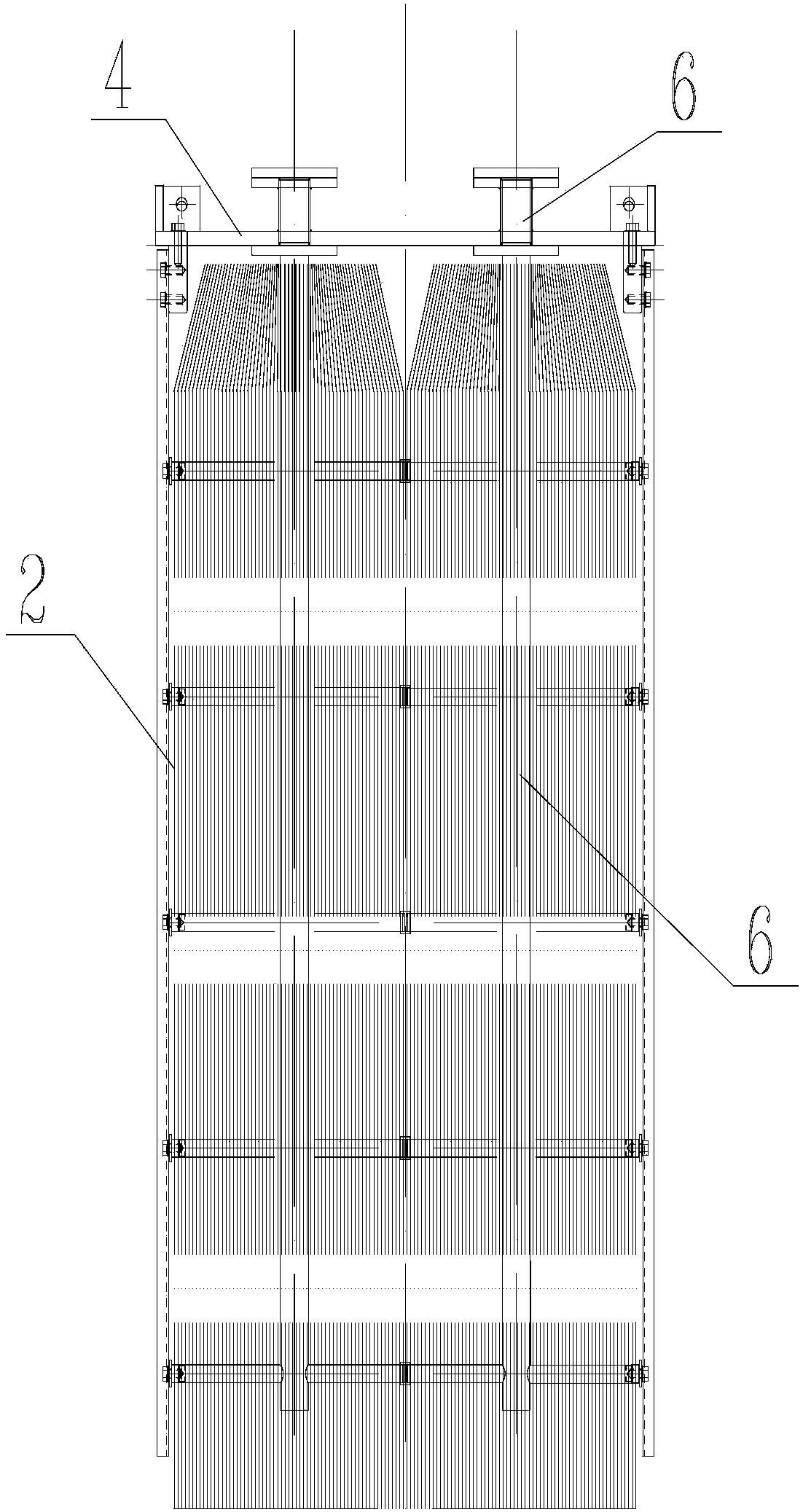

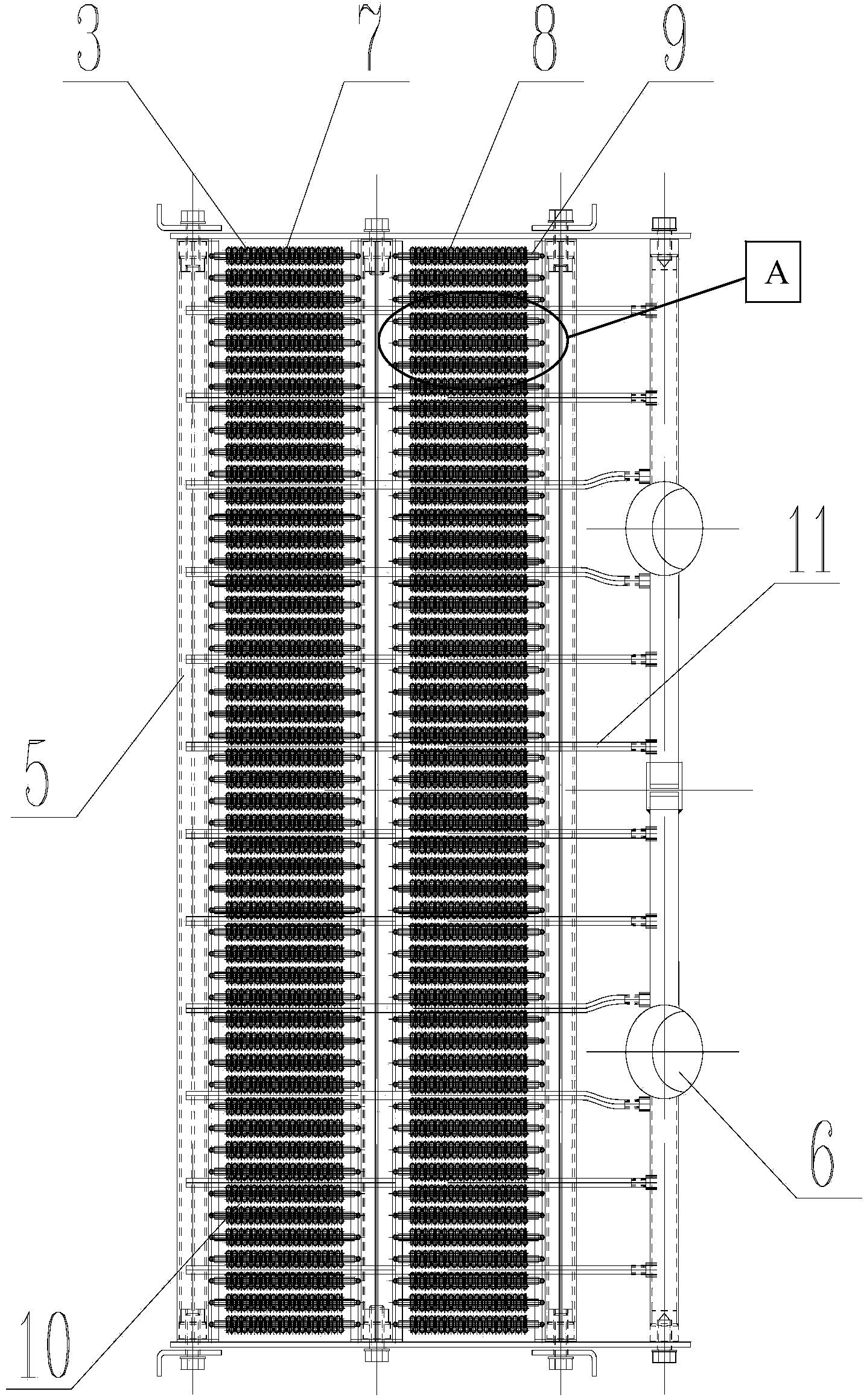

[0039] In the following, the water-sprinkling tubular dust collector of the present invention will be further explained in detail in conjunction with the accompanying drawings and embodiments.

[0040] Such as Figure 1-4 As shown, the sprinkler tubular dust collector in this embodiment includes an atomizing nozzle 1 , a dust removal pipe grid 2 , a dust removal pipe 3 , a top cover 4 , a pipe grid support member 5 , and a flushing water pipe 6 .

[0041] Among them, the dust removal pipe 3 is a U-shaped pipe, which is arranged perpendicular to the direction of the flue, and a plurality of atomizing nozzles 1 are arranged in the front and back, so that a uniform water film is formed on the surface of the dust removal pipe 3; or a high-level stabilized water tank 12 is arranged outside the flue A uniform water film is formed on the surface of the dust removal pipe 3 through the stable water supply of the water pipe; the tube bundles of a plurality of dust removal pipes 3 are ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com