Method and device for harmless treatment of industrial waste salt by utilizing alkaline melt

A technology for harmless treatment and industrial waste salt, which is applied in the field of hazardous waste treatment and recycling, can solve the problems of toxic tail gas and low organic matter removal efficiency, and achieve the effects of improving thermal efficiency, lowering temperature, and avoiding land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

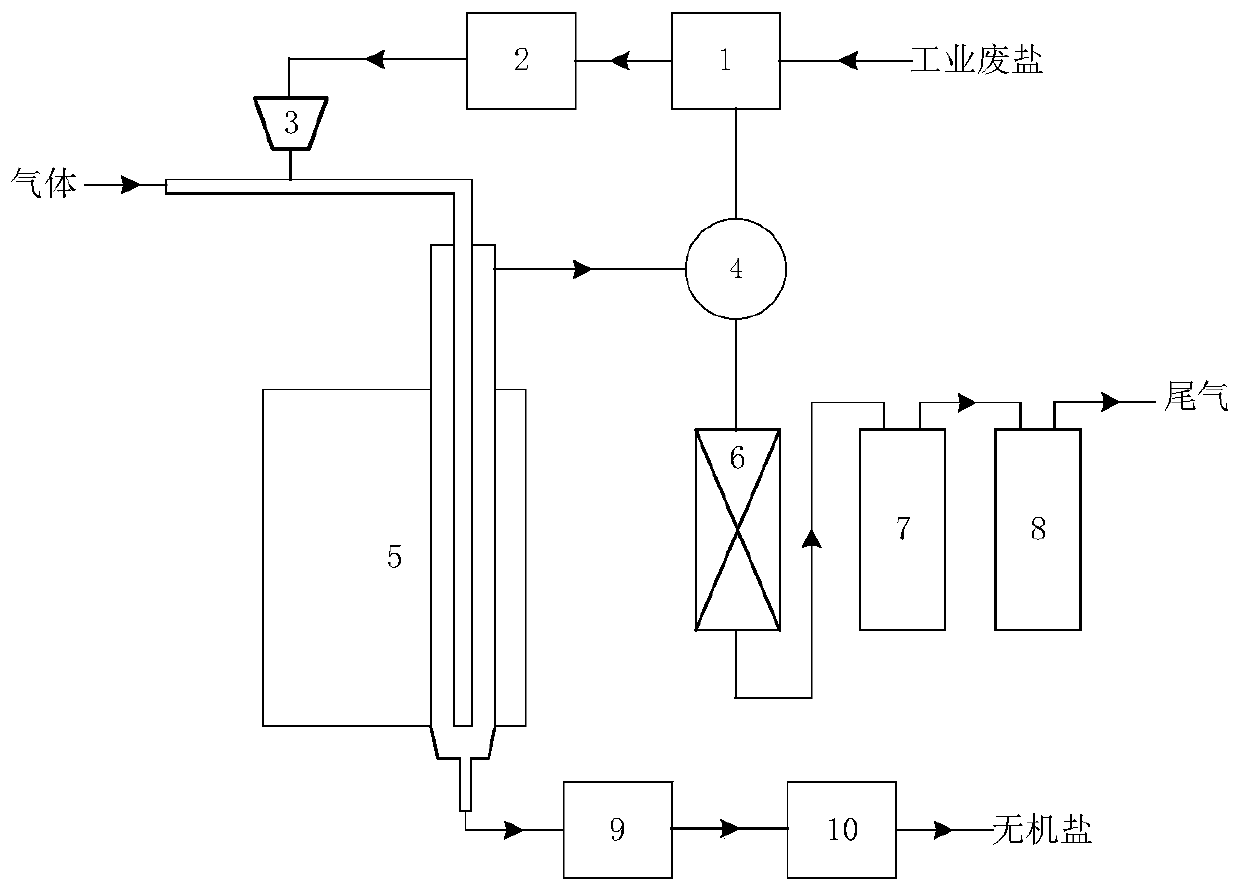

[0047] A device for the harmless treatment of industrial waste salt using alkaline melt, the schematic diagram of which is shown in figure 1 shown, including:

[0048]Melting reaction furnace 5, the melting reaction furnace 5 is connected with a gas supply pipeline; the gas totaling pipeline is connected with a feeding mechanism, and the feeding mechanism in this embodiment includes a drier 1, a crusher 2 and a feeder 3 connected in sequence , the feeding mechanism cooperates with the gas supply pipeline to realize the carrier gas transportation of industrial waste salt and the introduction of a separate oxidizing gas; the tail gas discharge port passes through the heat exchanger 4, the dust collector 6, and the gas scrubber 7 of the alkaline absorption liquid It is connected with the gas scrubber 8 of the organic solvent absorption liquid to realize the treatment and discharge of tail gas; the outlet of the reaction furnace at the bottom is connected with a salt washing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com