Shot blasting machine

A technology of shot blasting machine and projectile, which is applied in the direction of used abrasive processing device, combination device, abrasive feeding device, etc., which can solve the problems of easily affecting the surface treatment effect of the workpiece, low dust removal efficiency, and lack of timeliness. , to achieve the effect of timely and reliable removal of impurities, improvement of effect and efficiency, and efficient and rapid removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in combination with specific embodiments.

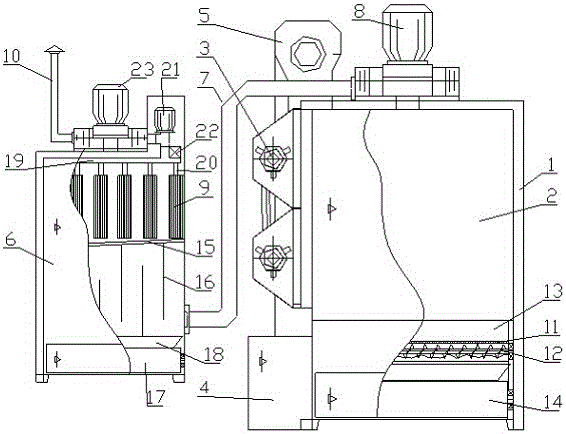

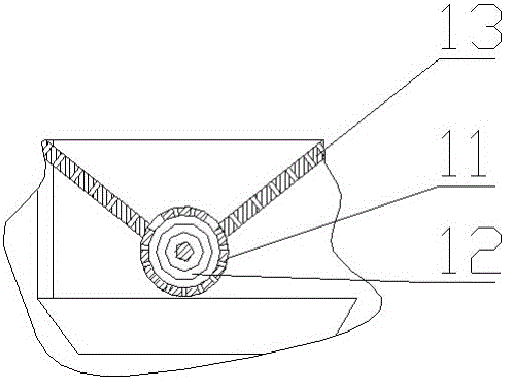

[0033] During specific implementation: as shown in Figure 1-2, a shot blasting machine includes a frame 1 and a shot blasting machine studio 2 with a box structure arranged on the frame 1, and one side of the shot blasting machine studio 2 There is a shot blasting device 3 facing the room, a suspension mechanism for hanging workpieces is set above the inner cavity of the shot blasting machine working room 2, and a projectile collecting device and a lower sand box 4 are arranged below, and the projectile collecting device can collect the shot blasting machine working room. 2 and sent to the lower sand box 4, the upper sand box 5 is arranged above the shot blasting machine working room 2, and a lifting device is arranged between the lower sand box 4 and the upper sand box 5 and can lift the lower sand box The projectiles of 4 are lifted into the upper sand box 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com