Wet type dust remover adopting spiral spraying

A technology of wet dust collector and spiral, which is applied in the field of dust collector and spiral spray wet dust collector, which can solve the problems of air gap, high wind pressure, uneven spraying, etc., and achieve the extension of airflow movement length, compact overall structure and low occupation small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

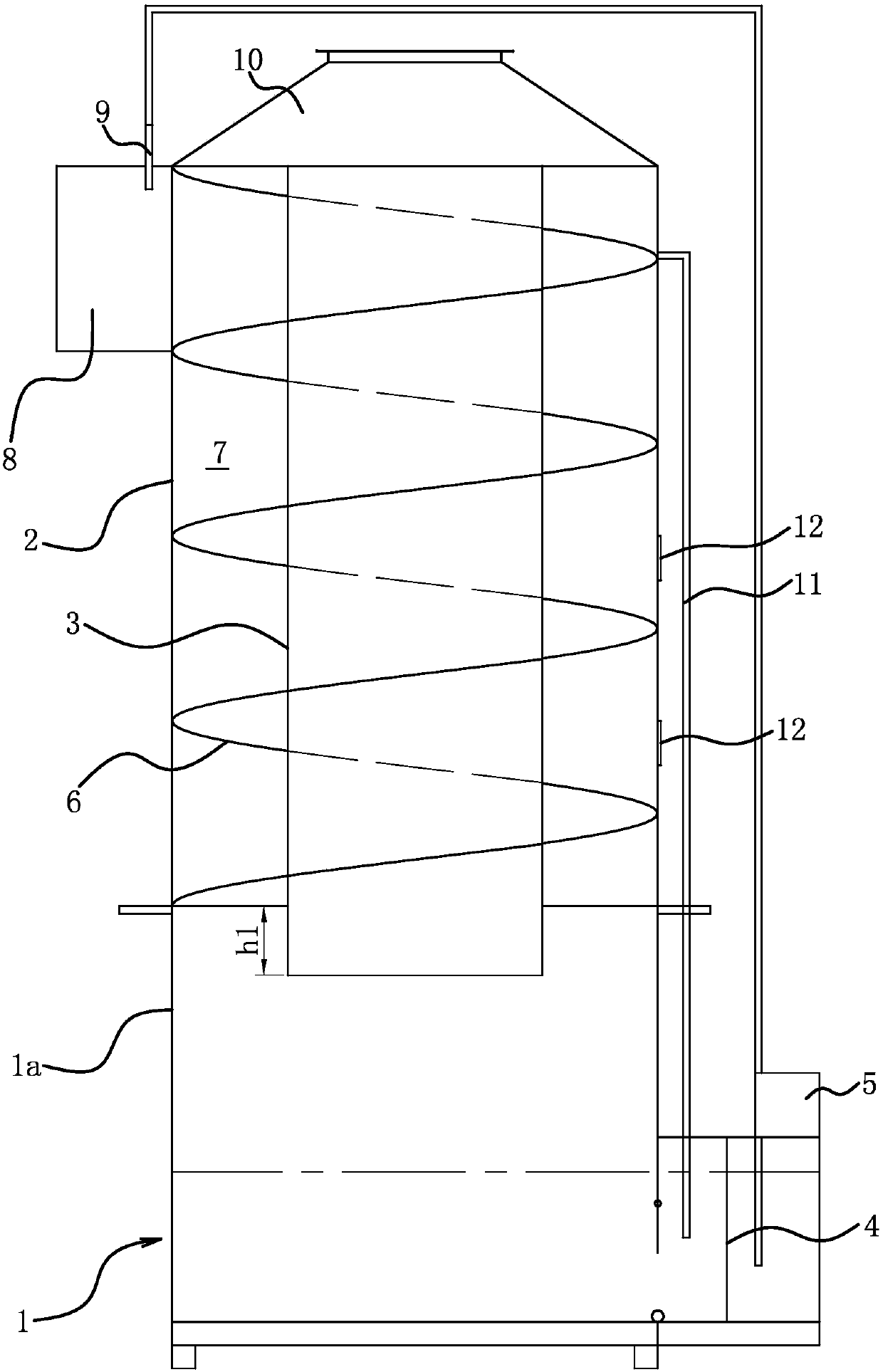

[0028] Such as figure 1 As shown, the spiral spray wet dust collector includes a water storage tank 1, a vertically arranged outer tube 2 and a vertically arranged inner tube 3.

[0029] The water storage tank 1 can be placed on the ground; the outer pipe 2 is arranged above the water storage tank 1. The water storage tank 1 has a tubular connecting seat 1a that matches the diameter of the outer tube 2. The outer tube 2 can be placed on the connecting seat 1a first, and then fixedly connected by bolts and nuts, thus the spiral spray wet dust removal The device can be disassembled for transportation and has the advantages of convenient assembly. A gasket is provided between the outer tube 2 and the connecting seat portion 1a to improve the sealing performance of the connection and thus the dust removal efficiency.

[0030] After the water storage tank 1 stores water, it has the characteristic of high weight, thus effectively improving the installation stability of the spiral spray ...

Embodiment 2

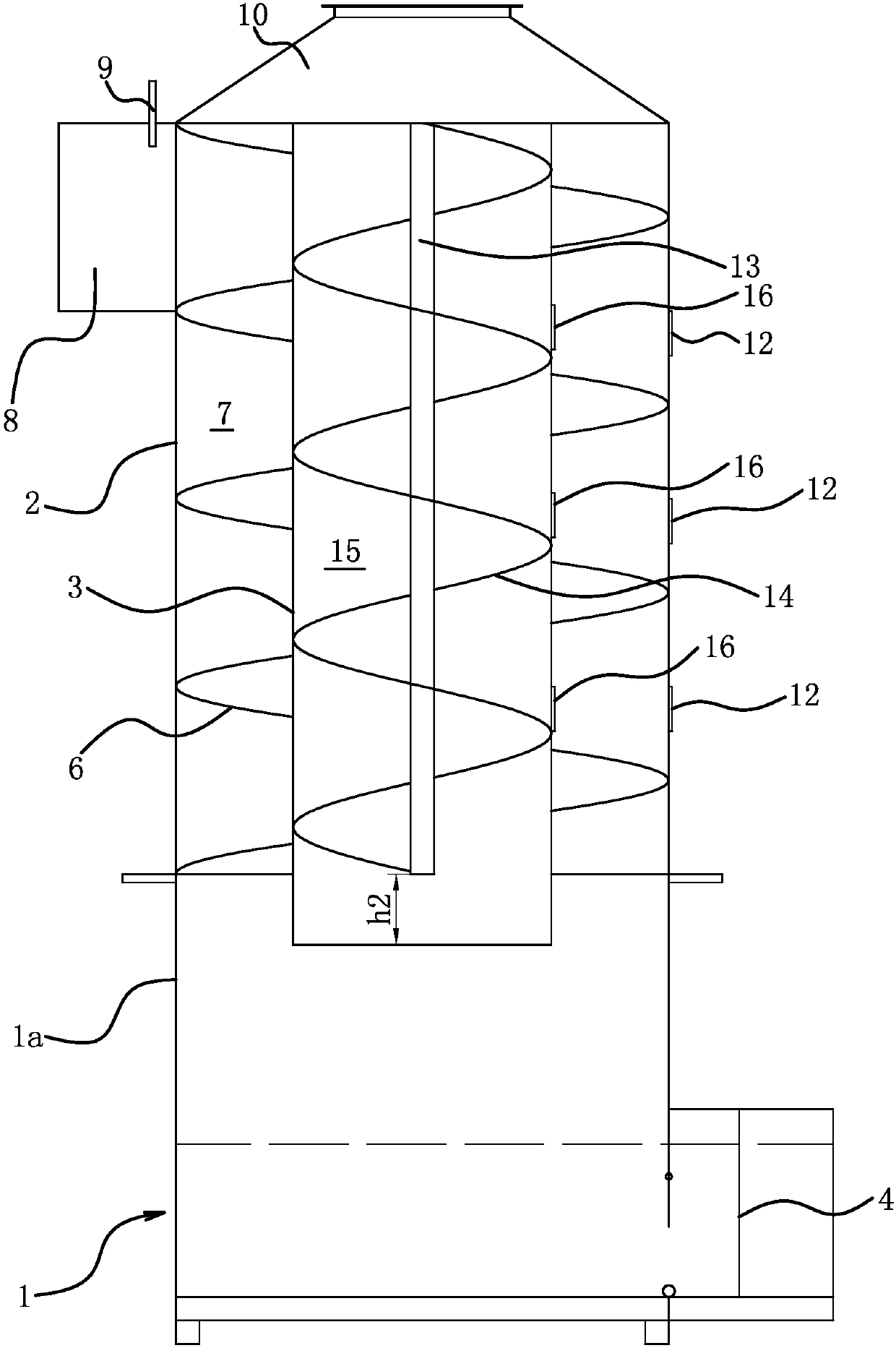

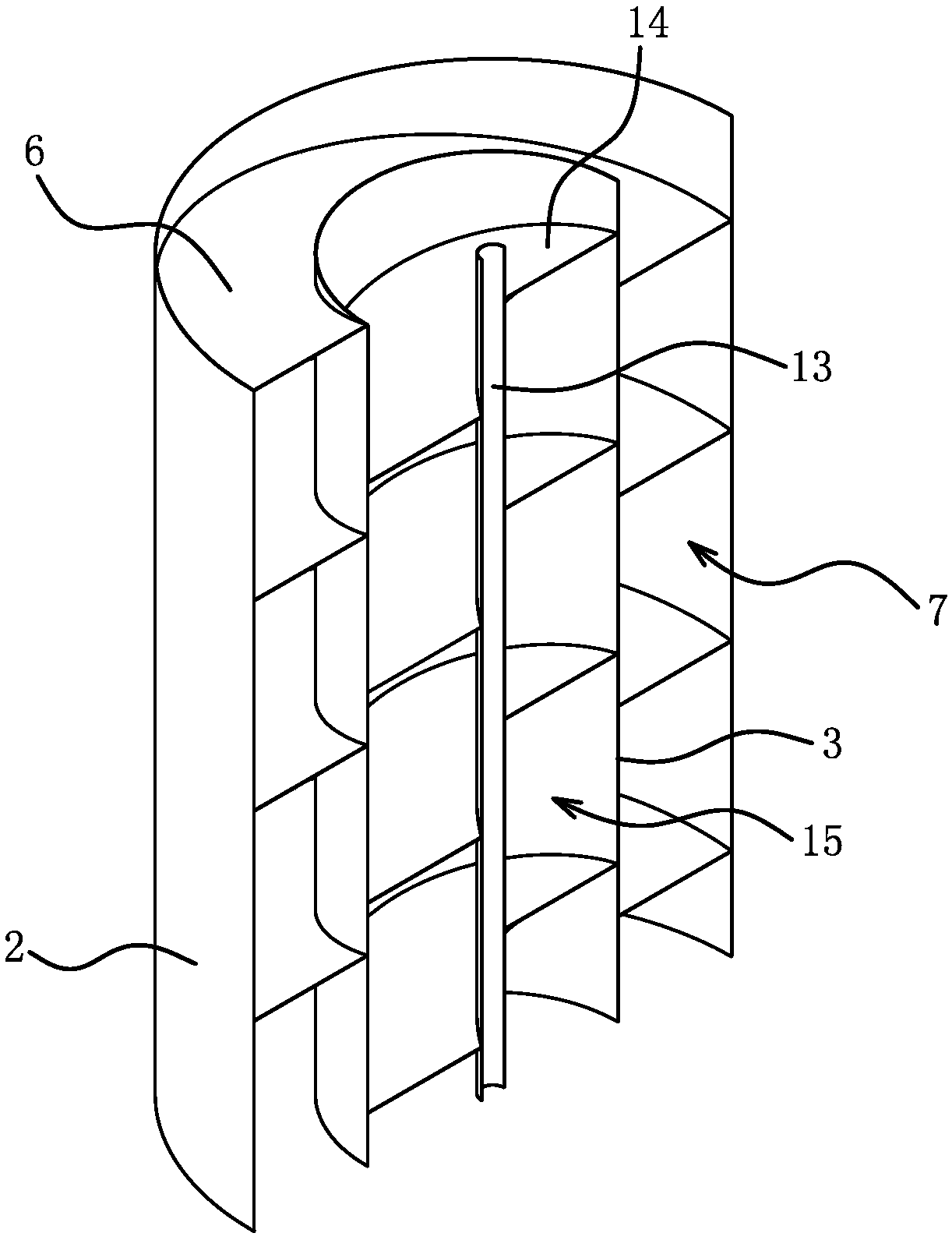

[0038] The structure and principle of this embodiment are basically the same as those of the first embodiment. The basic similarities will not be described redundantly, and only the differences will be described. The differences are as follows: figure 2 with image 3 As shown, the inner tube 3 is provided with a water separation mechanism. The water separation mechanism includes a central rod 13 arranged at the axis of the inner tube 3, and an axis relative to the inner tube 3 is provided between the central rod 13 and the inner tube 3 The second partition plate 14 is arranged spirally. The second partition plate 14 is sealed and fixedly connected with the inner side of the inner tube 3 and the outer side of the center rod 13; the center rod 13 and the inner tube 3 form a strip opposite to the inner tube 3 The axis of the second channel 15 is spirally arranged. The spiral direction of the second partition 14 is opposite to the spiral direction of the first partition 6, that is,...

Embodiment 3

[0042] The structure and principle of this embodiment are basically the same as those of the second embodiment. The basic similarities will not be described redundantly. Only the differences are described. The differences are as follows: Figure 4 As shown, the connecting seat portion 1a is provided with an inverted cone-shaped windproof pipe 17, and the outer edge of the windproof pipe 17 is sealed and fixedly connected with the inner wall of the connecting seat portion 1a. The windproof pipe 17 can significantly reduce the amplitude of liquid level fluctuations caused by the airflow and the influence of liquid level fluctuations on the stability of the airflow. In short, the windproof pipe 17 can significantly improve the stability of the airflow, thereby increasing the efficiency of dust removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com