Electric bag composite deduster

A compound type, dust collector technology, applied in combined devices, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of investment waste, increase in model size, and increase in engineering investment, and achieve improved dust removal efficiency and dust removal load balance. , the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

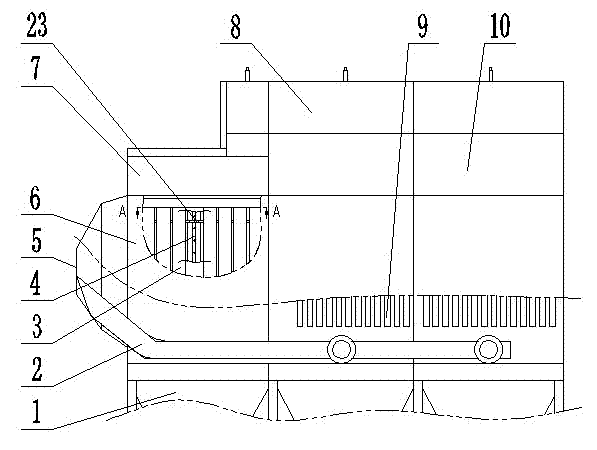

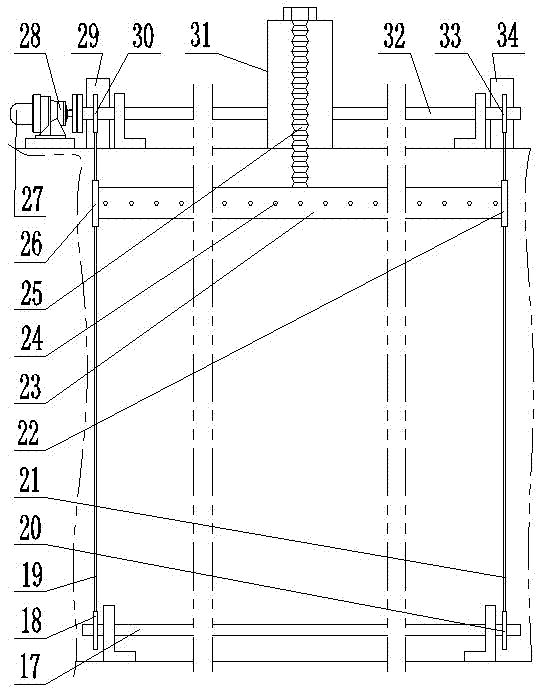

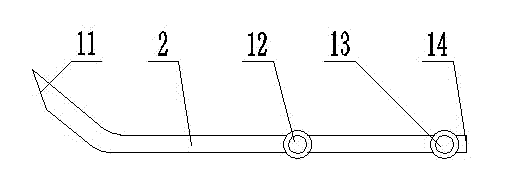

[0020] figure 1 Among them, an electric bag composite dust collector includes an electrostatic dust removal unit 7 and a bag dust removal unit 8, and the electrostatic dust removal unit 7 and the bag dust removal unit 8 are connected in series as a whole. The electrostatic precipitator unit 7 includes an electrostatic precipitator unit housing 6 , a flue gas inlet 5 , an anode system, a cathode system and an ash hopper 1 . The anode system contains an anode plate 3 and the cathode system contains a cathode wire 4 . The flue gas inlet 5 is located on the front end of the electrostatic precipitator unit housing 6 . A cloth bag 9 is arranged in the housing 10 of the bag dust removal unit. The electric bag compound dust collector also includes a vertical lifting jet cleaning device and a flue gas diversion device 2, as shown in the figure, figure 2 , image 3 with Figure 4 shown. The vertical lift jet cleaning device contains an upper drive shaft 32, a lower drive shaft 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com