Dust removal device for textile production

A technology of dust removal device and textile room, which is applied in the direction of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of human health injury, adsorption and blockage of dust removal device, affecting dust removal efficiency, etc., to improve efficiency and Comprehensiveness, increase the falling collection speed, and ensure the effect of dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

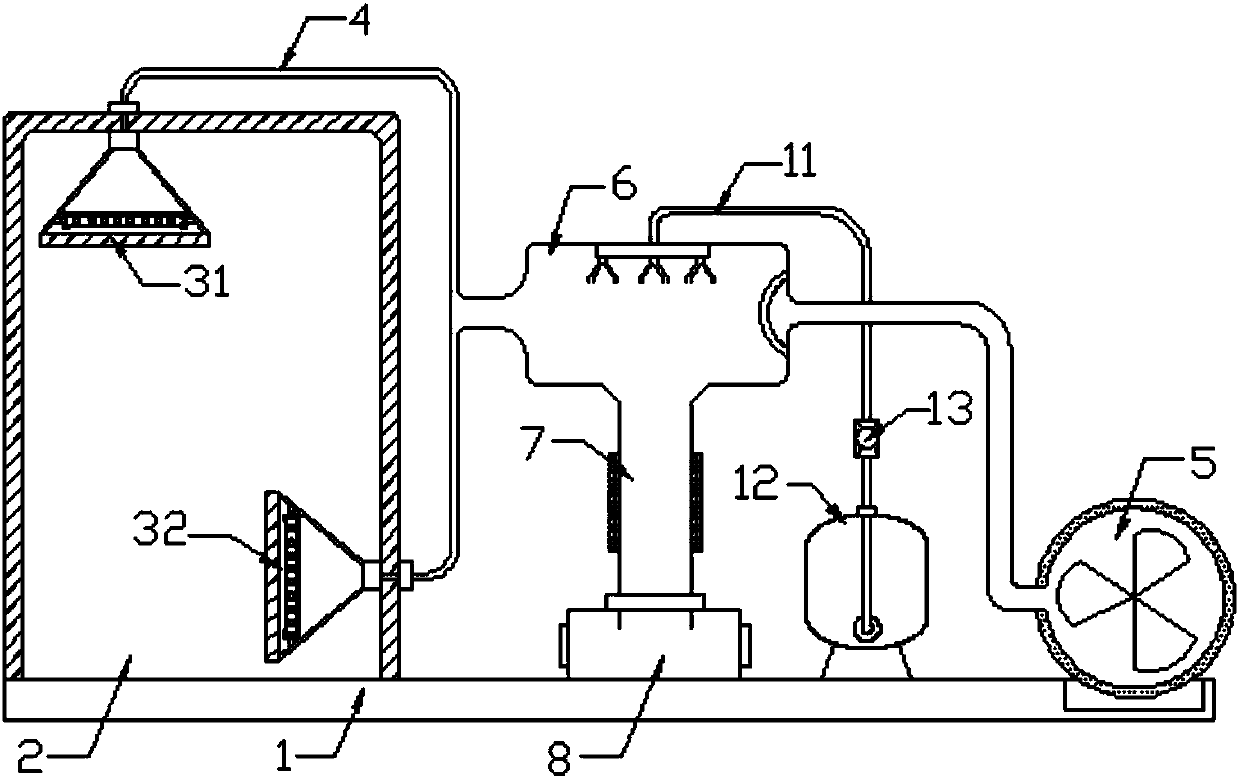

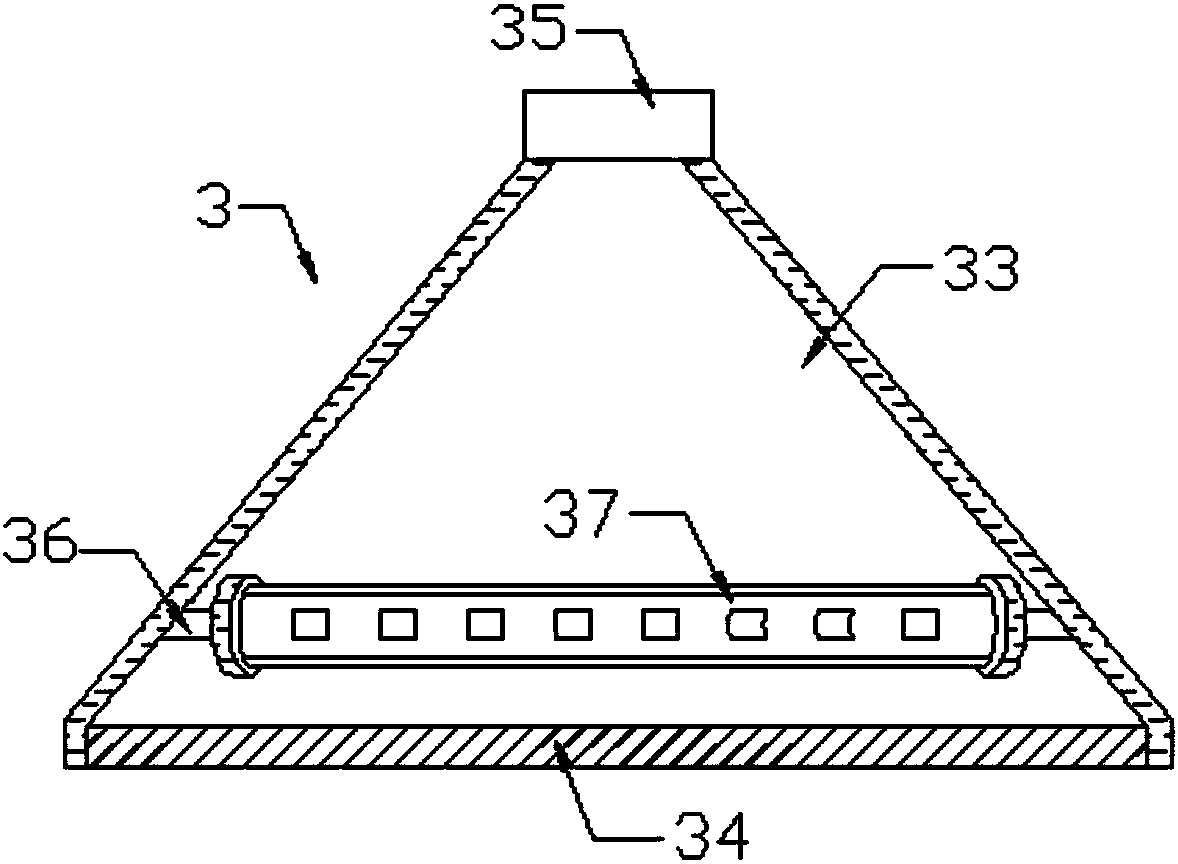

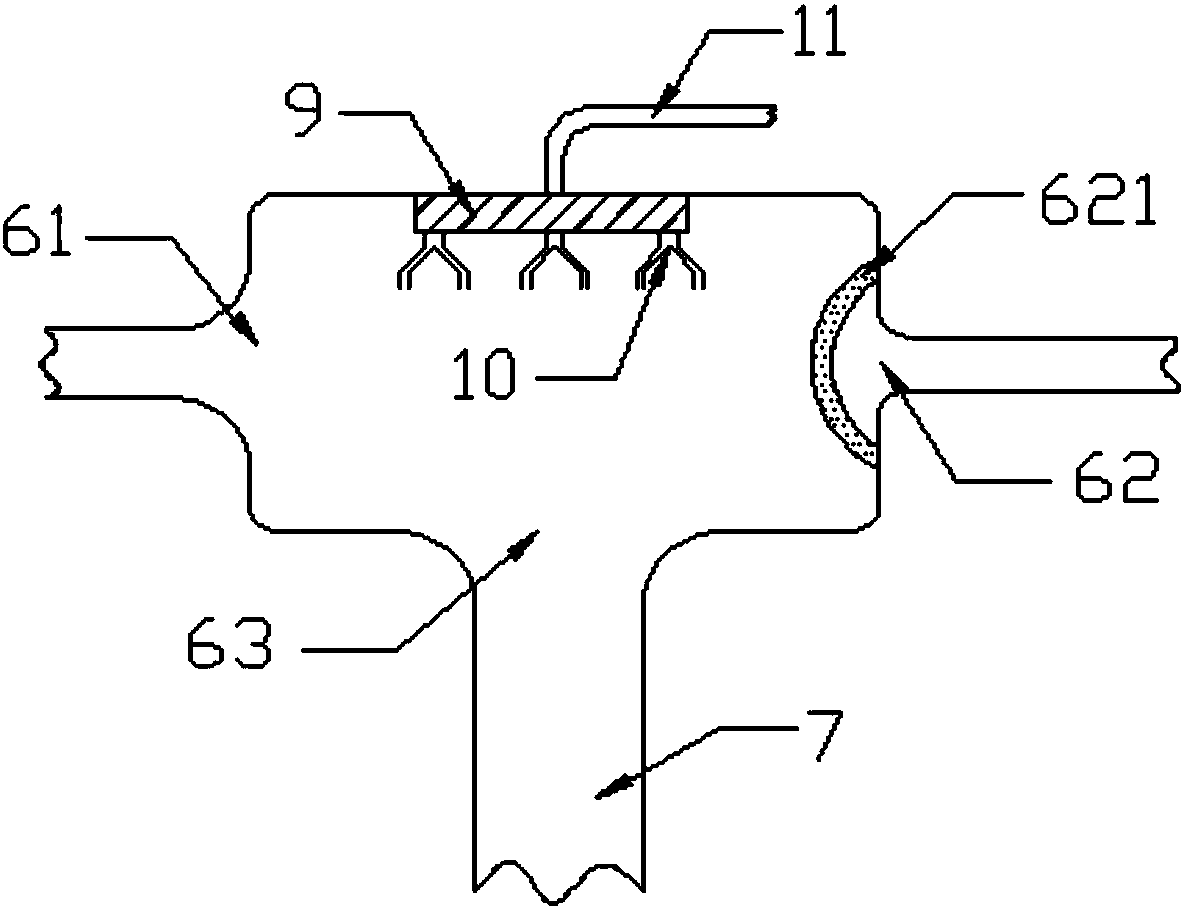

[0021] Such as Figure 1-Figure 4 As shown, this specific embodiment adopts the following technical solutions: a dust removal device for textile production, including a base 1, a textile chamber 2 is arranged on one end of the top of the base 1, and a dust removal device is installed inside the textile chamber 2. Suction hood 3, the dust removal hood 3 is connected to the dust removal fan 5 through the dust delivery pipe 4, the dust removal fan 5 is installed on the base 1 far away from the end of the weaving room 2, between the weaving room 2 and the dust removal fan 5 A dust-falling pipe 6 is fixedly installed on the dust-feeding pipe 4 between them, and the dust-falling pipe 6 includes an air inlet 61, an air outlet 62 and a dust-falling port 63, and the air inlet 61 and the air outlet 62 are respectively arranged on two opposite sides of the dust-falling pipe 6. On the end, the dust falling port 63 is arranged at the bottom of the dust falling pipe 6, the dust falling pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com