Device and method for pre-removing popcorn ash of SCR denitration system

A technology of popcorn ash and popcorn, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve problems such as wear and catalyst blockage, increase system energy consumption, reduce ash wear problems, and reduce local resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

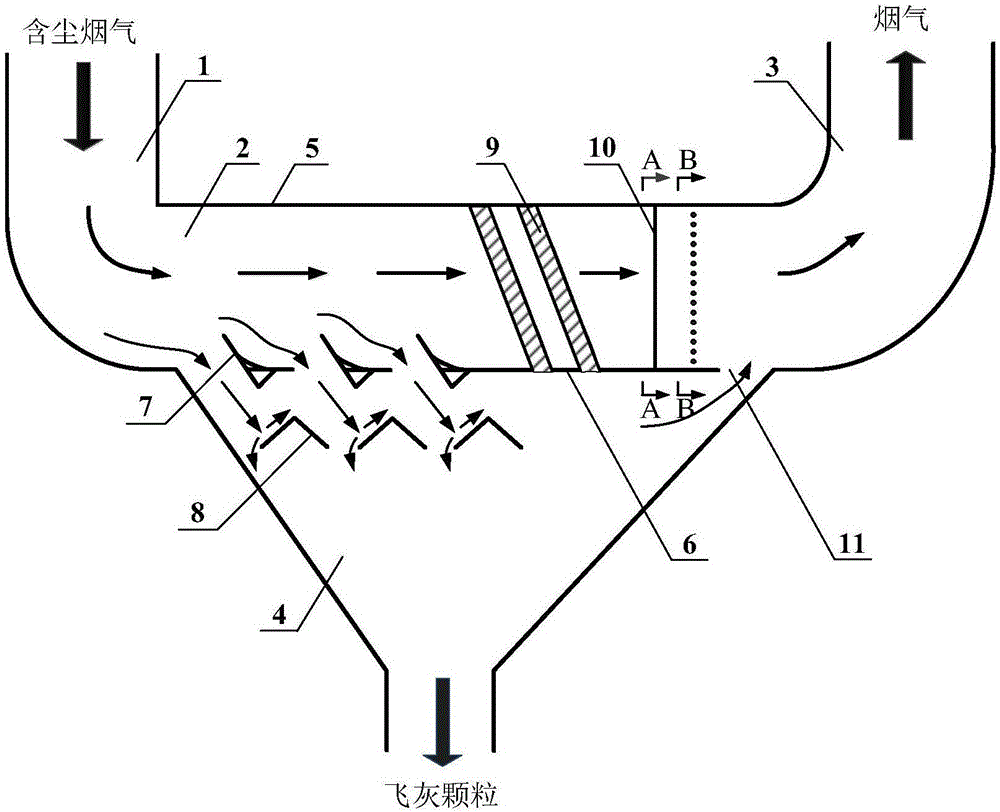

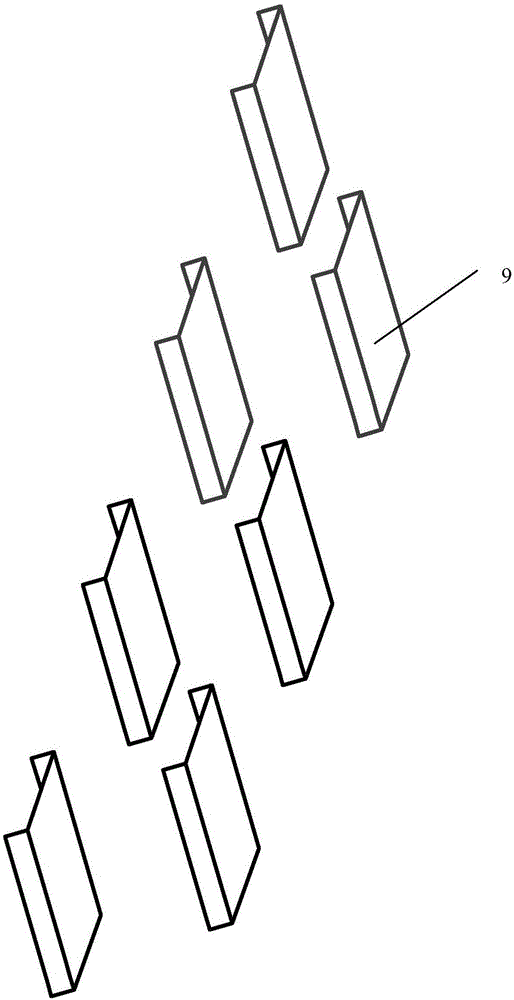

[0031] The present invention proposes a device for pre-removing popcorn ash in an SCR denitrification system, such as Figure 1~4 As shown, it includes vertical shaft flue 1, horizontal flue 2 and ascending flue 3 connected in sequence. The flue 3 is vertically connected with the horizontal flue 2, and the corner joint is set in a streamlined shape, with a deflector inside, an ash hopper 4 is set on the lower side of the bottom plate 6 of the horizontal flue, and a catcher 7 is set on the front of the upper side of the bottom plate 6 , The middle part between the top plate 5 and the bottom plate 6 is provided with a separator 9, the rear part is provided with a filter screen 10, and a flue gas communication port 11 is set on the tail bottom plate.

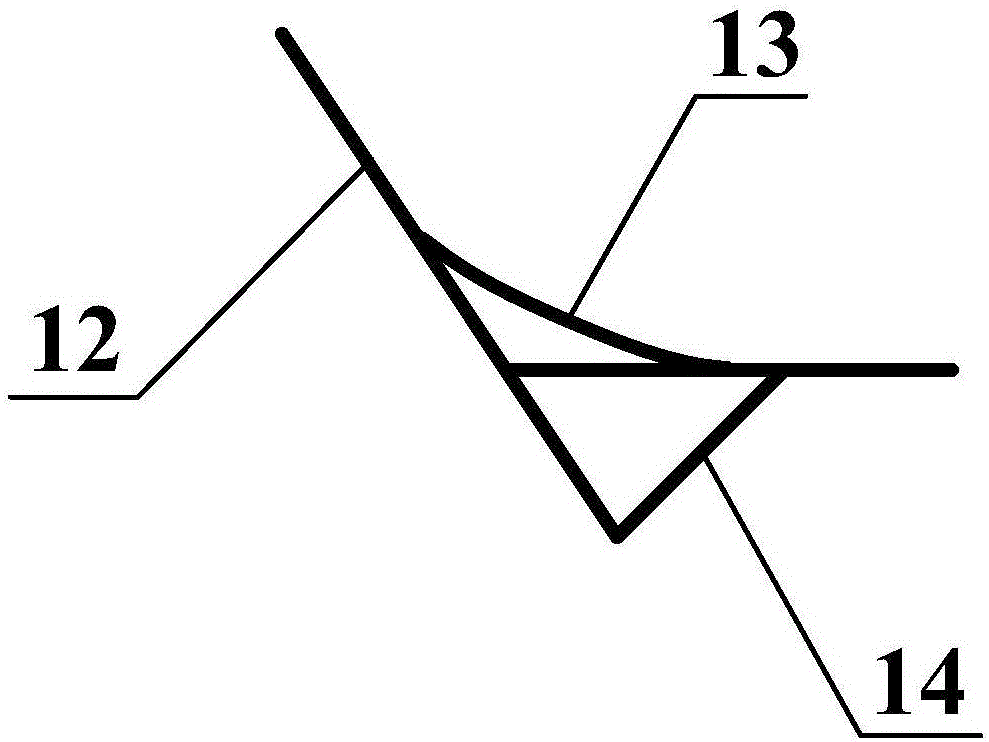

[0032] Among them, traps (such as figure 2 As shown) is composed of a collecting plate 12, a diversion plate 13 and a flow stabilizer 14, the angle between the collecting plate 12 and the bottom plate of the horizontal flue is θ=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com