Patents

Literature

142results about How to "Small pressure drop loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

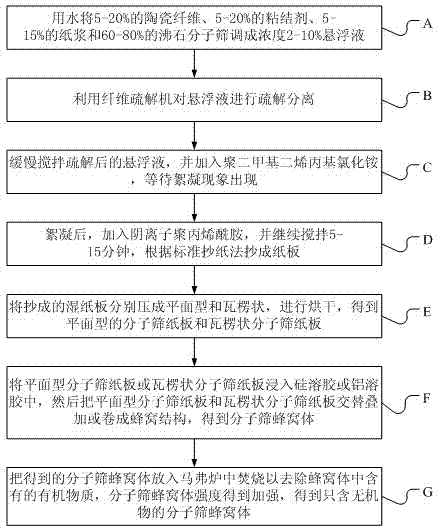

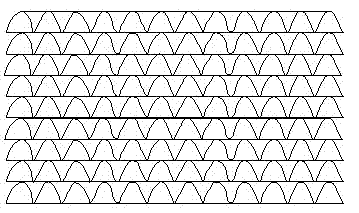

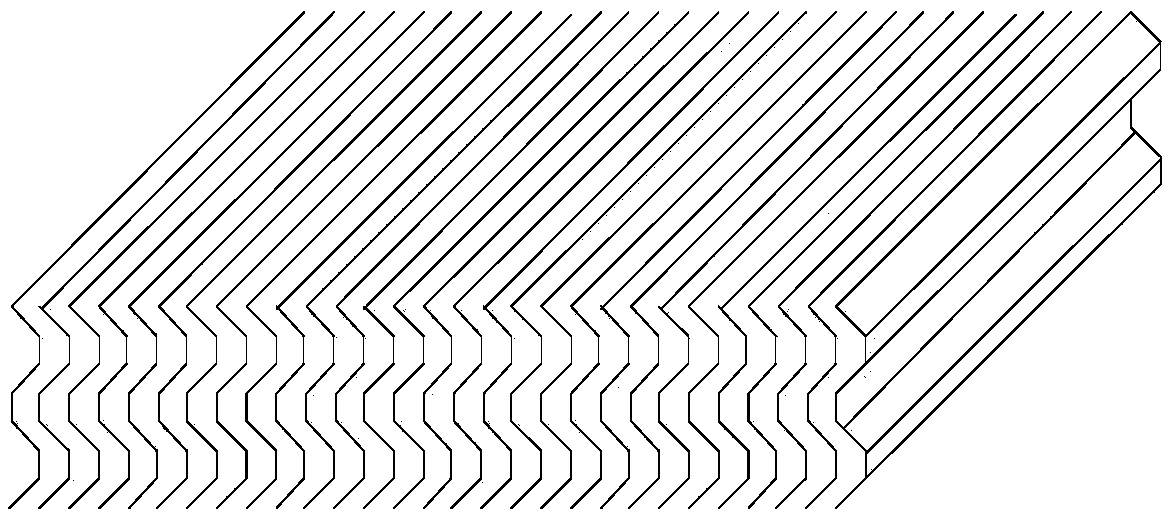

Manufacture method of molecular sieve honeycomb body for absorbing volatile organic compounds

InactiveCN102389773ASmall pressure drop lossLarge specific surface areaOther chemical processesDispersed particle separationFiberMolecular sieve

The invention discloses a manufacture method of a molecular sieve honeycomb body for absorbing volatile organic compounds, which comprises the steps of: regulating 5-20 percent of ceramic fiber, 5-20 percent of adhesion agent, 5-15 percent of paper pulp and 60-80 percent of zeolite molecular sieve with water into a suspension with concentration of 2-10 percent; defibering and separating the suspension; then slowly stirring and adding poly dimethyl diallyl ammonium chloride, after flocculation occurs, adding anionic polyacrylamide and continuously stirring for 5-15 min and then making a paper plate; and making the made wet paper plate into a planar molecular sieve paper plate and a corrugated molecular sieve paper plate, and alternatively overlapping or coiling the planar molecular sieve paper plate and the corrugated molecular sieve paper plate into a honeycomb structure to obtain the molecular sieve honeycomb body. A zeolite molecular sieve provided by the invention is not easy to peel off, and is easy to process into various shapes; and the molecular sieve honeycomb body can absorb organic matters under different temperatures and humidities.

Owner:FOSHAN ENVIRONMENTAL PROTECTION TECH & EQUIP RES DEV PROFESSIONAL CENT +3

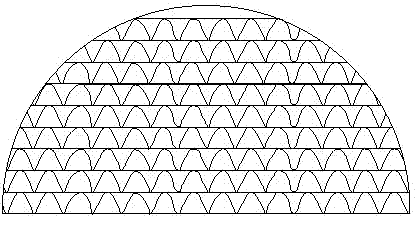

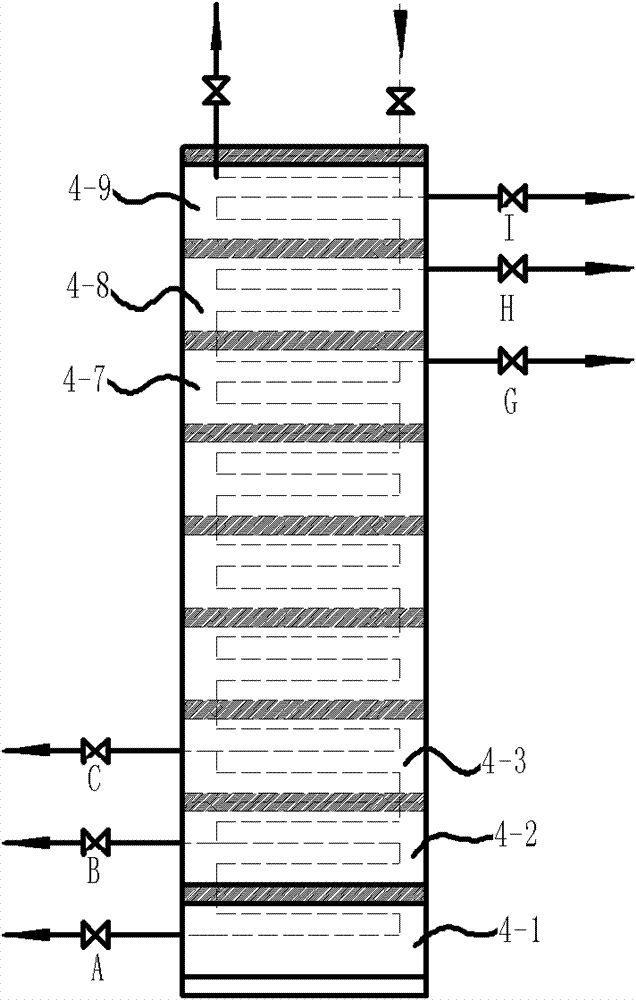

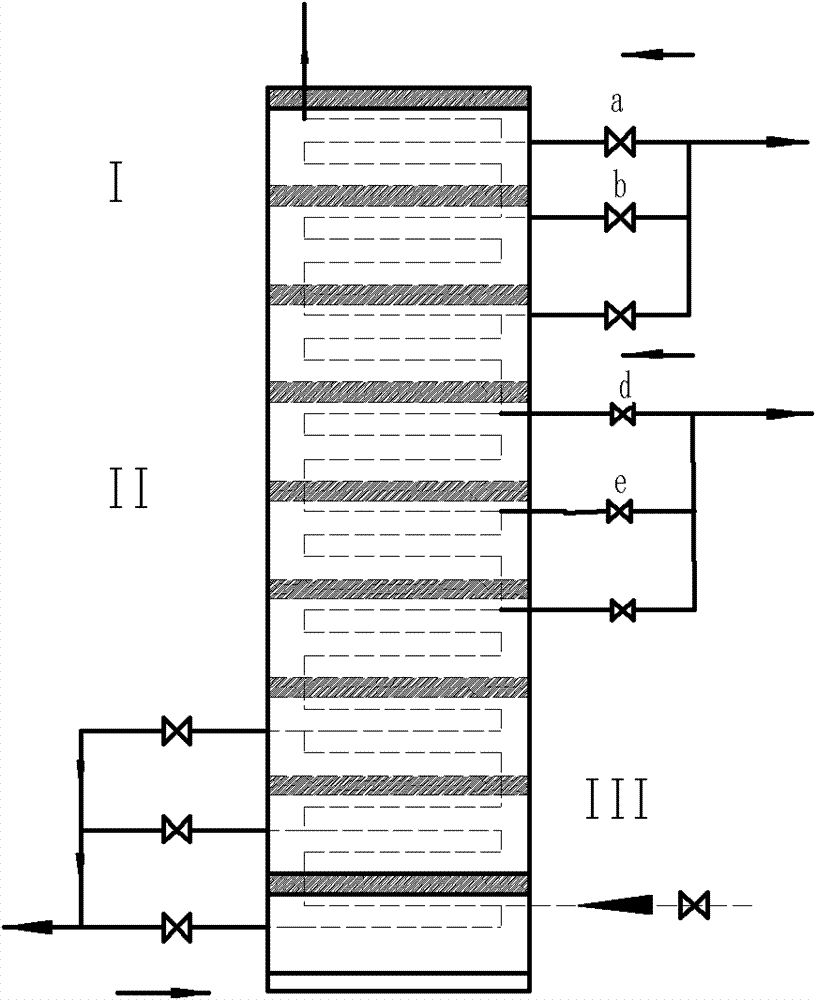

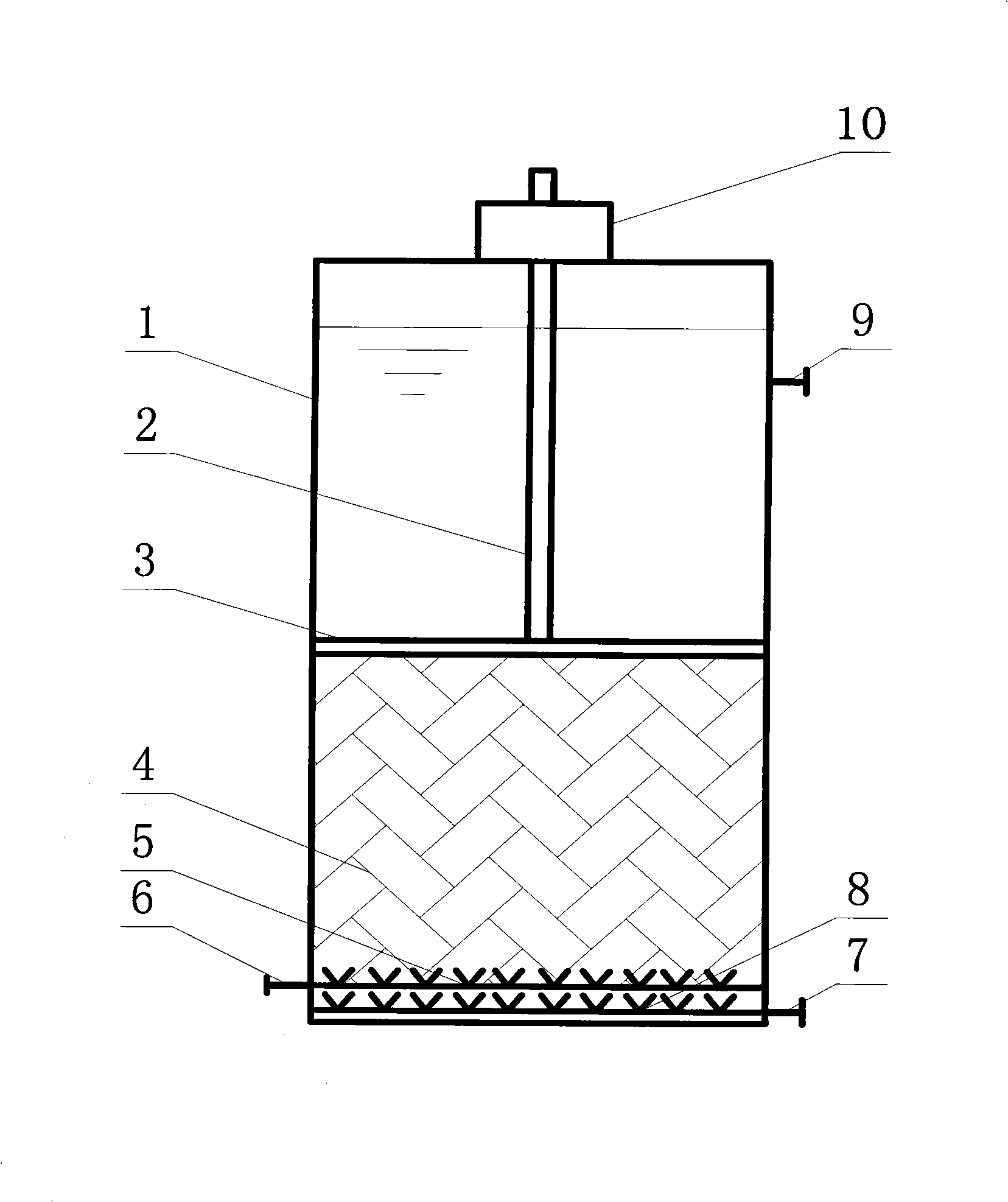

Solid heat storage device

InactiveCN102818468AGuaranteed uptimeImprove thermal conductivitySolar heating energyThermal insulationInsulation layerControl system

The invention provides a solid heat storage device which is formed by combining at least one heat storage unit in series and / or parallel. The heat storage unit comprises a casing, a solid heat storage medium arranged in the casing and a heat insulation layer arranged outside the casing. The outer surface of the solid heat storage medium is a heat exchange interface. Heat insulation layers are regularly arranged in the heat storage unit, an inclined temperature layer is arranged in the axial direction, and a layering control system is arranged in the heat storage unit to ensure high grade storage and output of heat. The heat storage unit of an array can be vertically arranged and can also be horizontally arranged with a certain inclined angle. The solid heat storage medium utilizes solid sensible heat to store heat, and is safe in running, simple to process and low in cost. The surface of the solid heat storage medium has good heat exchange efficiency and good heat storage performance and can be widely applied to various heat storage applications, especially a solar photo-thermal utilization system.

Owner:BEIJING TERASOLAR PHOTOTHERMAL TECH CO LTD

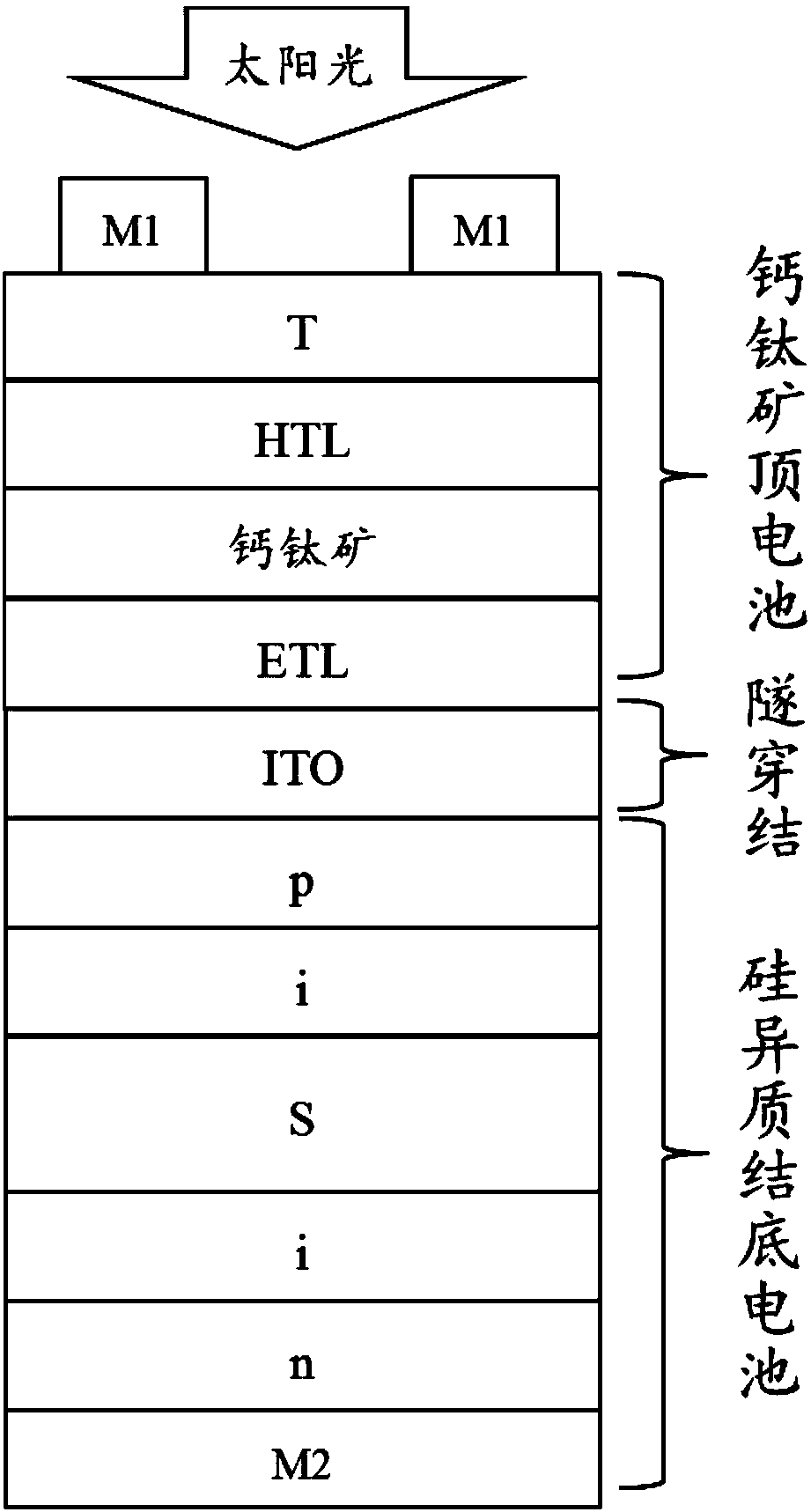

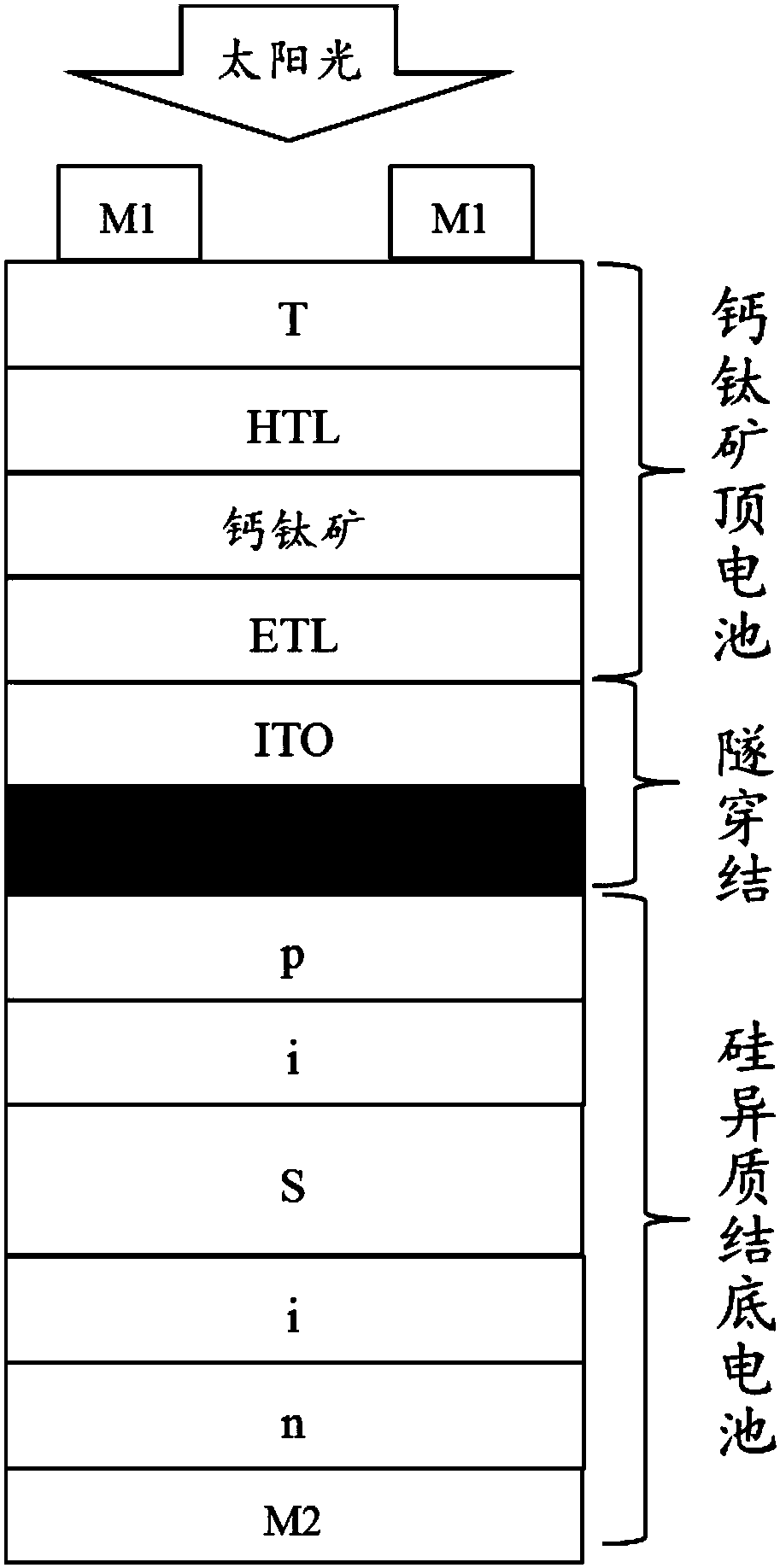

Structure design of tunnel junction in Perovskite/silicon heterojunction lamination solar battery

InactiveCN107564989AFacilitate hole extractionSmall pressure drop lossFinal product manufactureSolid-state devicesHeterojunctionValence band

The invention provides a structure design of tunnel junction in Perovskite / silicon heterojunction lamination solar battery, which relates to the field of solar batteries. A tunneling composite layer TRL with narrow band gap and high doping concentration is added at the junction of the top and bottom part of a lamination battery, and the quite small energy level difference between the conduction band and the valence band can effectively strengthen the carrier recombination at the tunneling junction. The gradient band order at the bottom battery p layer and the tunneling junction can effectivelyenhance the cavity draw-off of the bottom battery and the tunneling junction, and thereby a large amount of charge accumulation among the tunneling junction interfaces can be prevented. After the adding of the TRL having high doping concentration, the defect density of states at the tunneling junction is increased. The electronic cavity assists tunneling through defects, and the probability of recombination and tunneling can be increased. With the adoption of the heterojunction, the spectrum response of the bottom battery can be effectively enhanced, and the opening and pressing loss can be reduced. The preparation method is simple and easy to carry out.

Owner:NANKAI UNIV +1

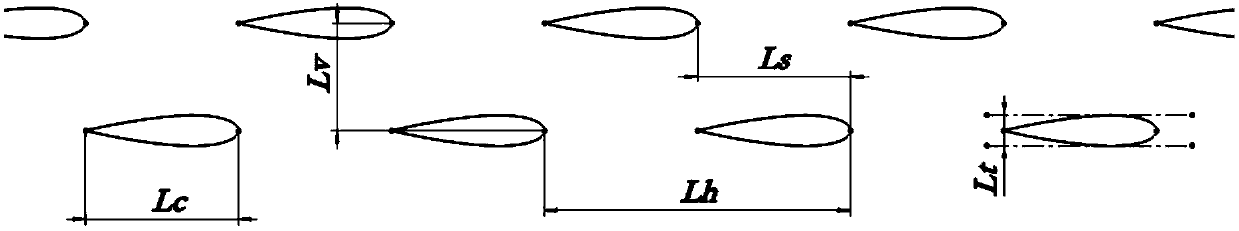

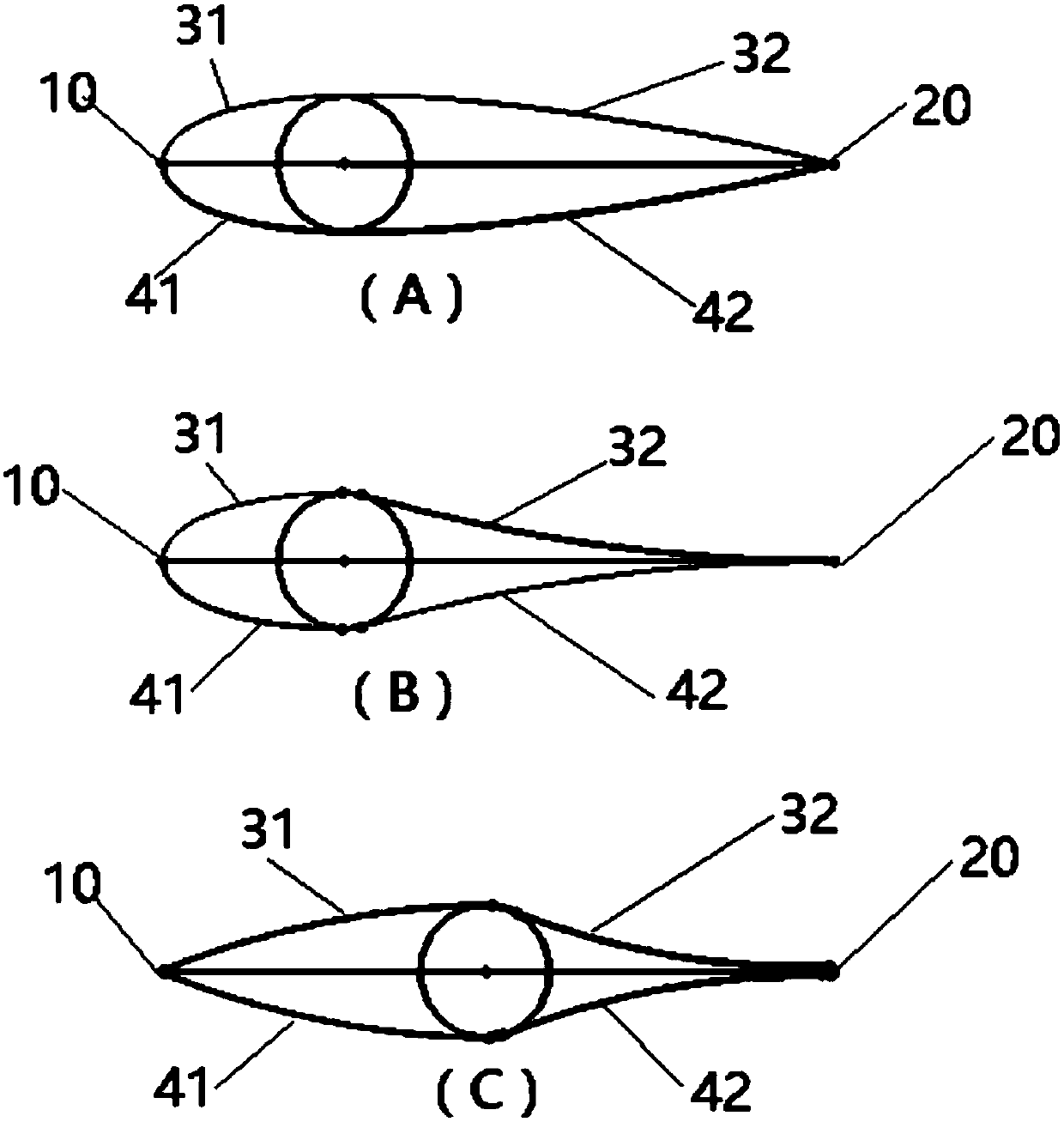

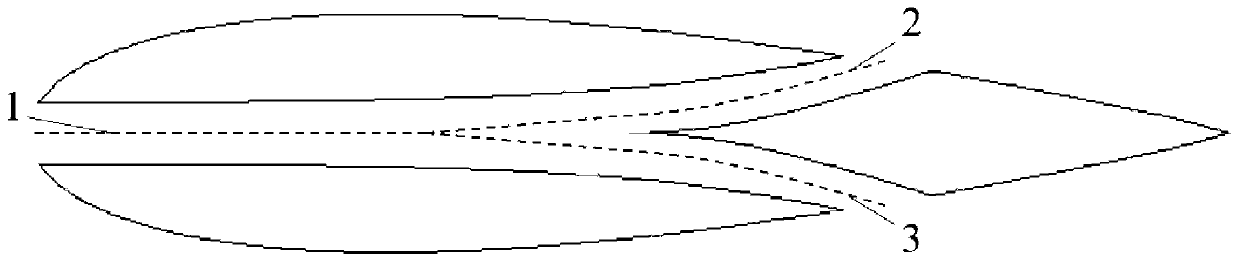

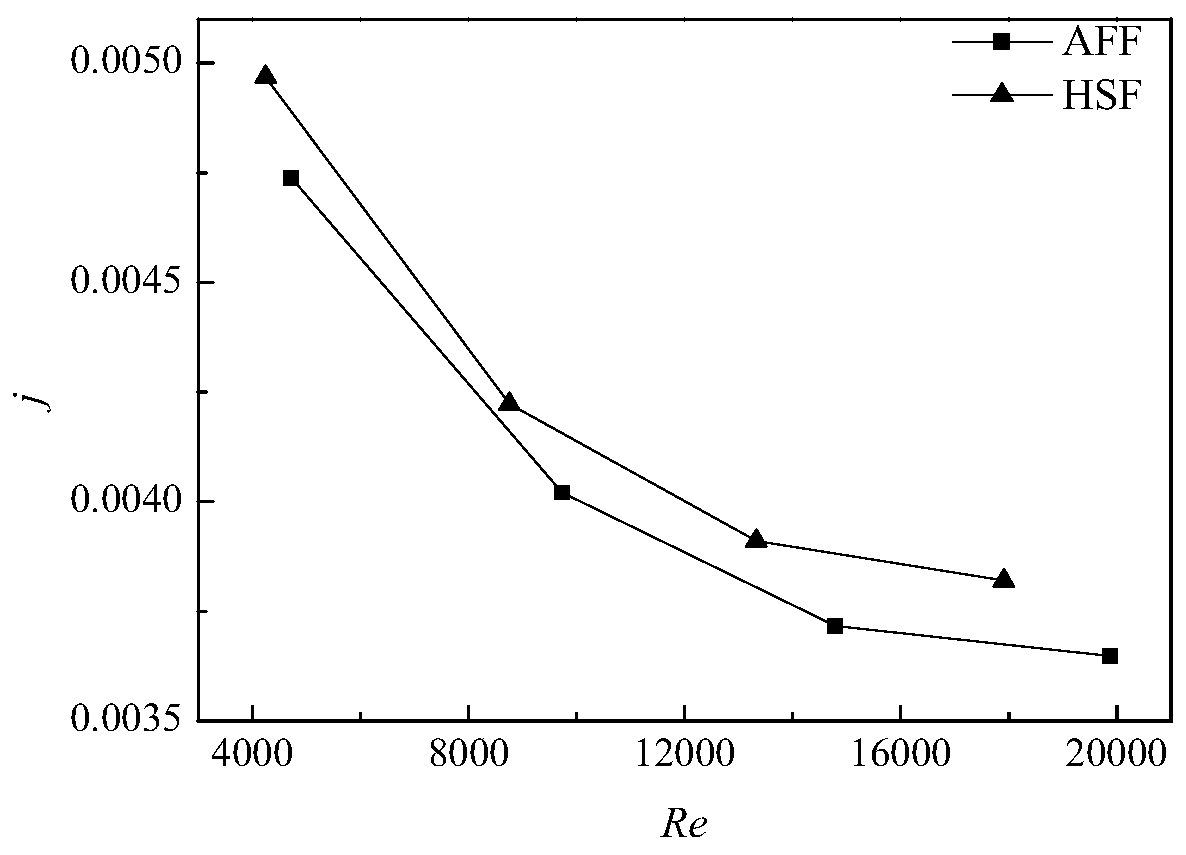

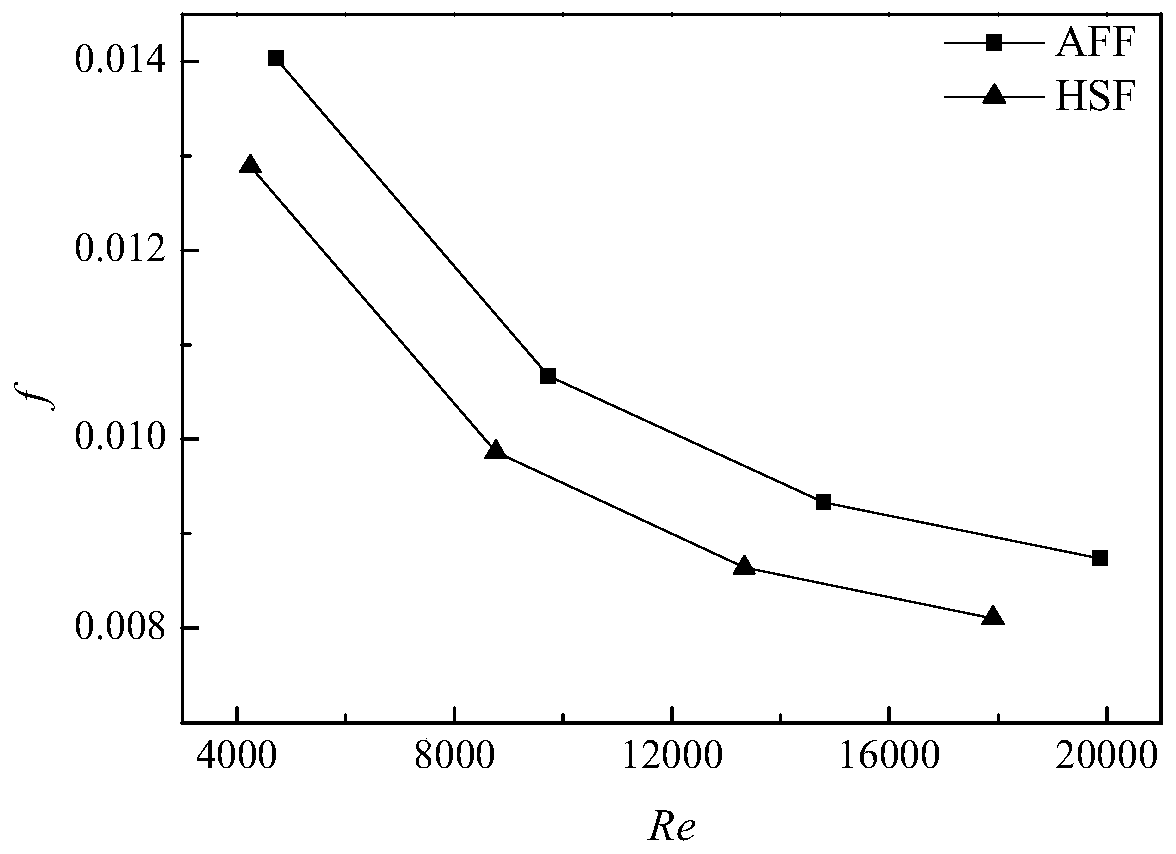

Heat exchange plate with streamline structure, and printed circuit board heat exchanger with same

ActiveCN107687780ATo achieve the purpose of heat exchangeDramatic changeLaminated elementsStationary plate conduit assembliesEngineeringFront end of line

The invention provides a heat exchange plate with a streamline structure, and a printed circuit board heat exchanger with same. The first segment of the upper arc and the first segment of the lower arc of a streamline rib extend to the position of a maximum incircle from the front edge of a wing form, each first segment is a convex smooth curve, the rear end of each convex smooth curve is in tangency with the maximum incircle, second segments extend to the rear edge of the wing form from the maximum incircle, each second segment is a concave smooth curve, the front end of each concave smooth curve is in tangency with the maximum incircle, and a smooth continuous curve is formed by each first segment and the corresponding second segment at the position of the maximum incircle. According tothe heat exchange plate with a streamline structure, and the printed circuit board heat exchanger with same, because the original structure of a wing-shaped rib is redesigned and optimized, when heatexchange fluid flows through wing-shaped ribs, changes between the front part and the rear part of the maximum width of a wing-shaped rib happen more violently, and the heat exchange performance of awing-shaped channel is improved; and because structural design is carried out on the front edge and the rear edge of a wing form, the heat exchange fluid can be guided to flow better, and therefore, the pressure drop loss of the wing-shaped channels is reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

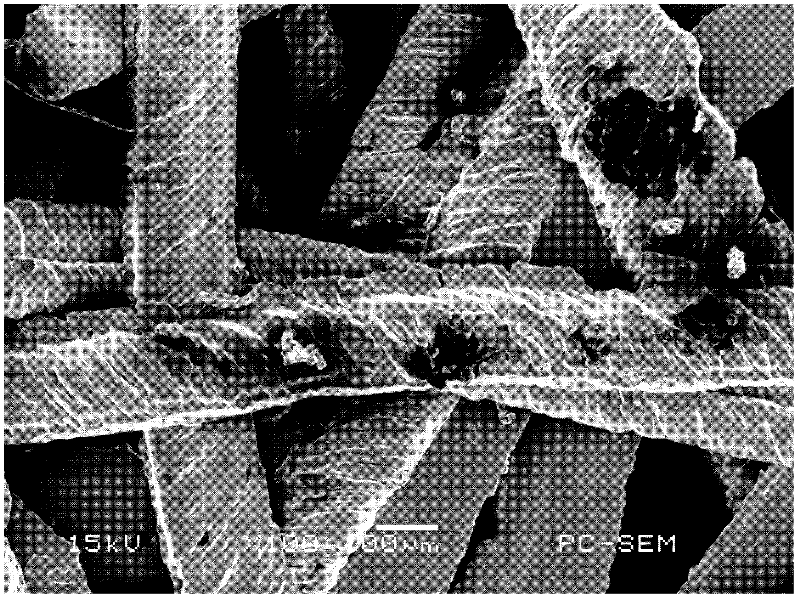

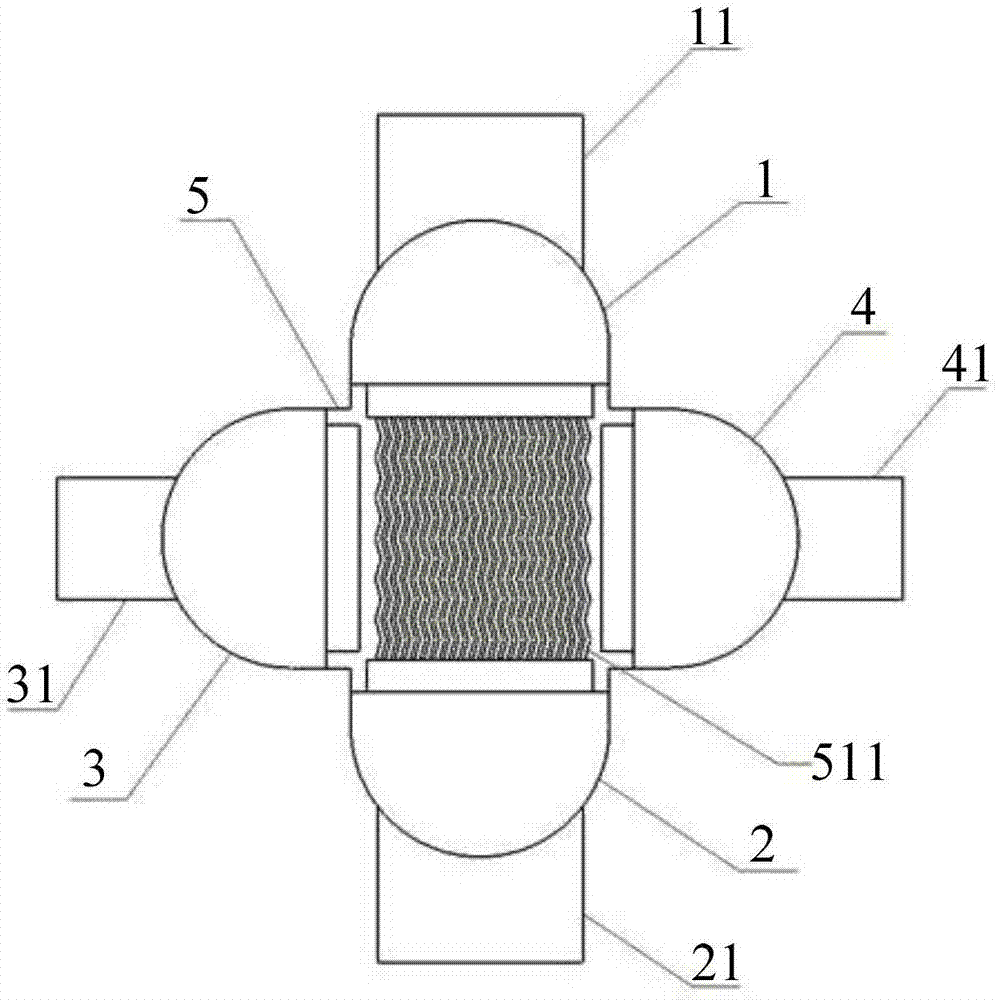

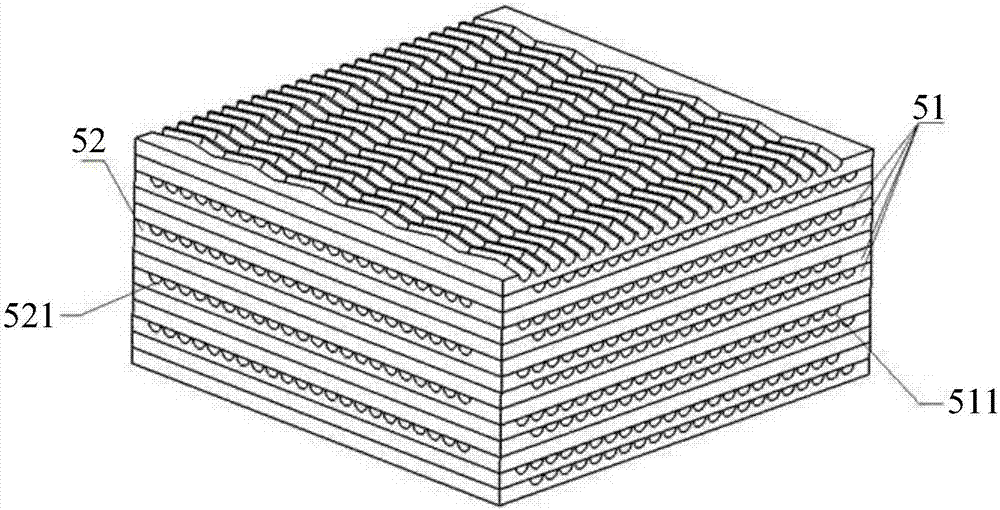

A kind of stainless steel fiber felt used for fuel cell bipolar plate and its manufacturing method

InactiveCN102290582AImprove structural uniformityGood heat and mass transfer performanceCell electrodesMetal fiberFuel cells

The invention discloses a stainless steel fiber felt used for fuel cell bipolar plates and a manufacturing method thereof, belonging to the technical field of fuel cell bipolar plate flow fields. The manufacturing method of stainless steel fiber mat can be divided into four steps: processing stainless steel fiber by cutting method, pretreatment of stainless steel fiber, molding of fiber mat, and high-temperature solid-state sintering. After the metal fibers are sintered, metallurgical bonding is achieved between the fibers, forming a large number of multi-scale pore structures. The manufactured stainless steel fiber felt has the advantages of high porosity, high specific surface area, good heat and mass transfer performance, surface hydrophobicity, simple manufacturing process and low cost. This method is applicable to manufacture various metal porous materials, and its pore size and porosity can be controlled.

Owner:SOUTH CHINA UNIV OF TECH

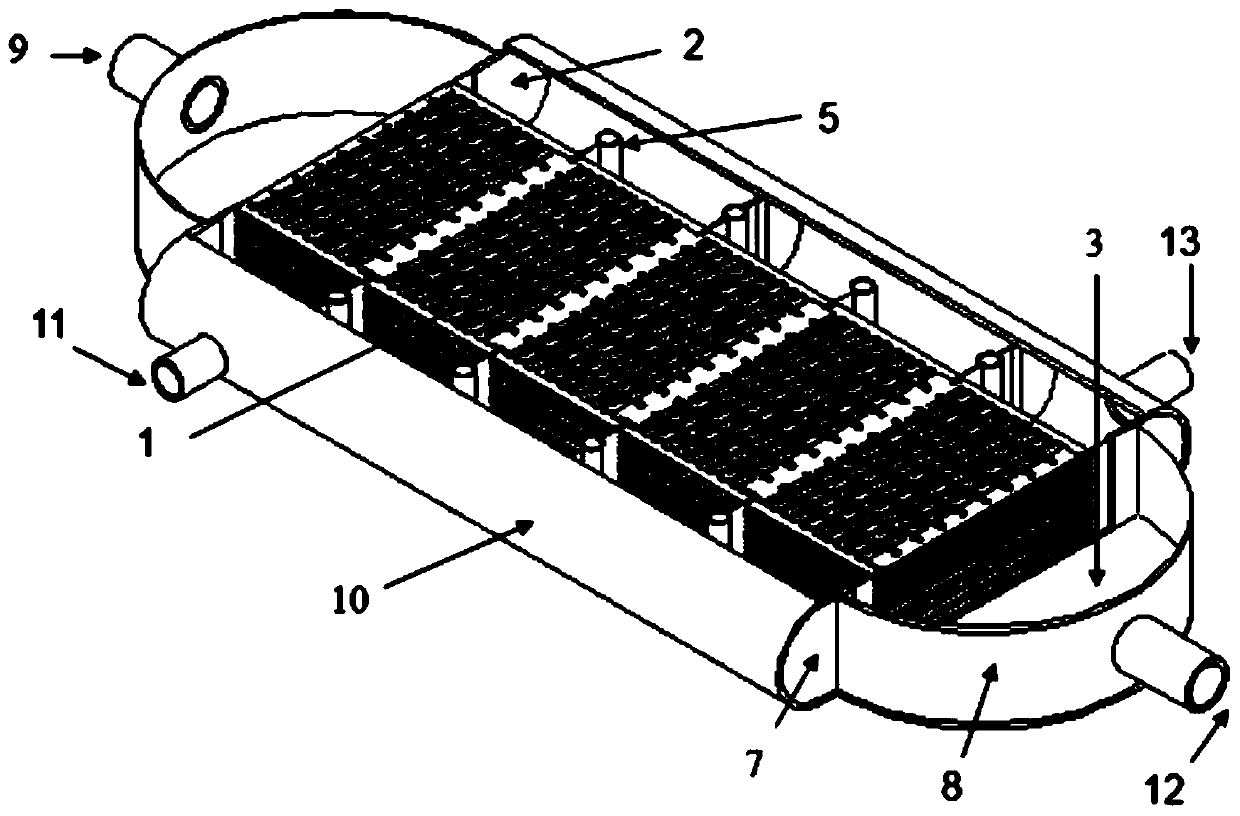

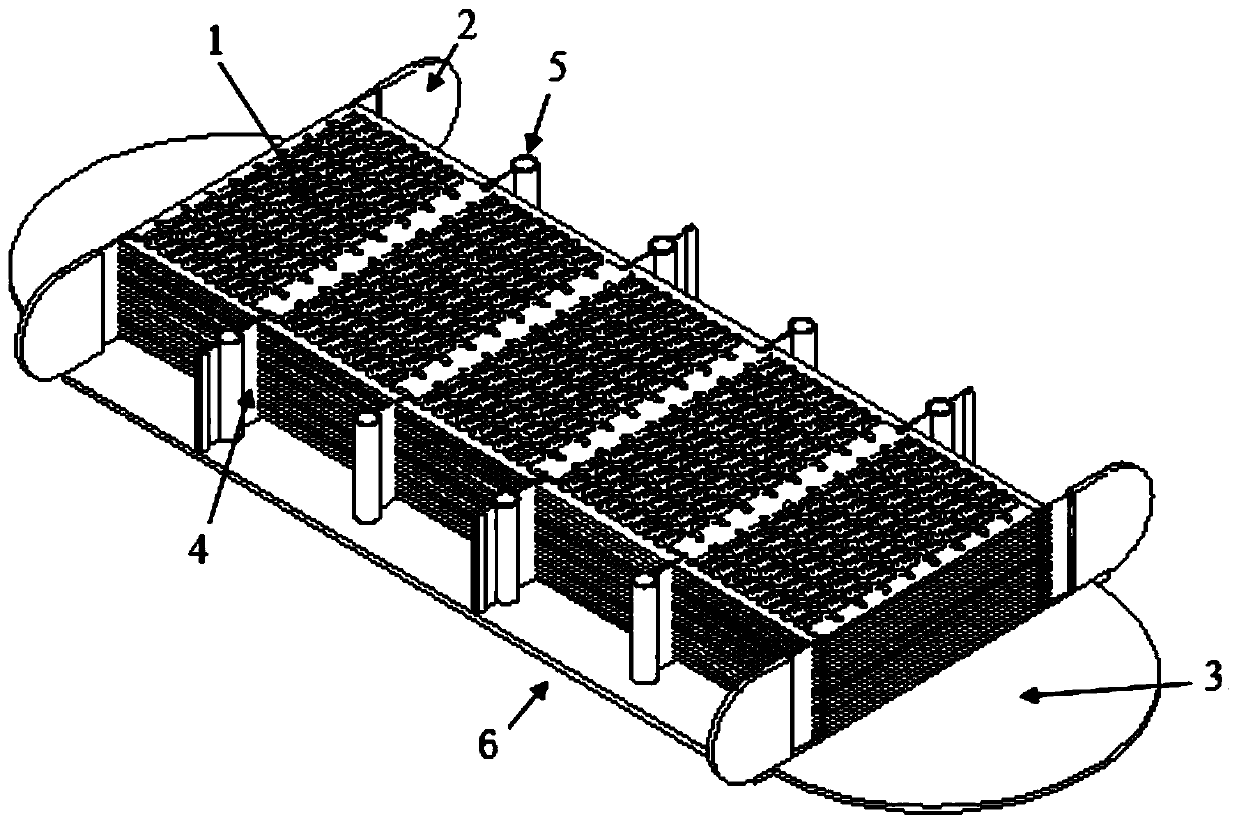

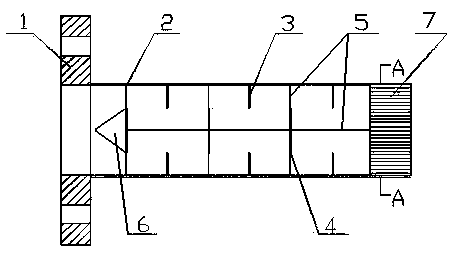

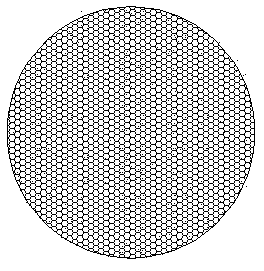

Multitubular fixed bed reactor and application thereof

InactiveCN103990420AIncrease profitIncrease elasticityHydrocarbon from oxygen organic compoundsEthylene productionChemical reactionFixed bed

The invention relates to a multitubular fixed bed reactor, which comprises at least one catalyst-loaded reaction tube longitudinally extending along a direction parallel to the axis of the reactor. The height of the reaction tube and the hydraulic diameter of the reaction tube's cross-section are in a ratio of 1-2000, preferably 10-1000, and more preferably 50-500. The reaction tube includes: one or more catalyst chambers, which are used for loading the catalyst to form a catalyst fixed bed; one or more inlet distribution chambers, which are used for leading a reactant flow into the reaction tube and distributing the reactant flow into the catalyst fixed bed; and one or more outlet collection chambers, which are used for collecting the reactant flow and leading the reactant flow out of the reaction tube. Specifically, through arrangement of the inlet distribution chamber(s) and the outlet collection chamber(s), the reactant flow passes through the catalyst fixed bed layer along a horizontal direction perpendicular to the axis of the reactor so as to contact the catalyst and react with the catalyst. The invention also relates to application of the multitubular fixed bed reactor in chemical reactions like endothermic or exothermic reaction.

Owner:SHANGHAI RONGYI INVESTMENT MANAGEMENT

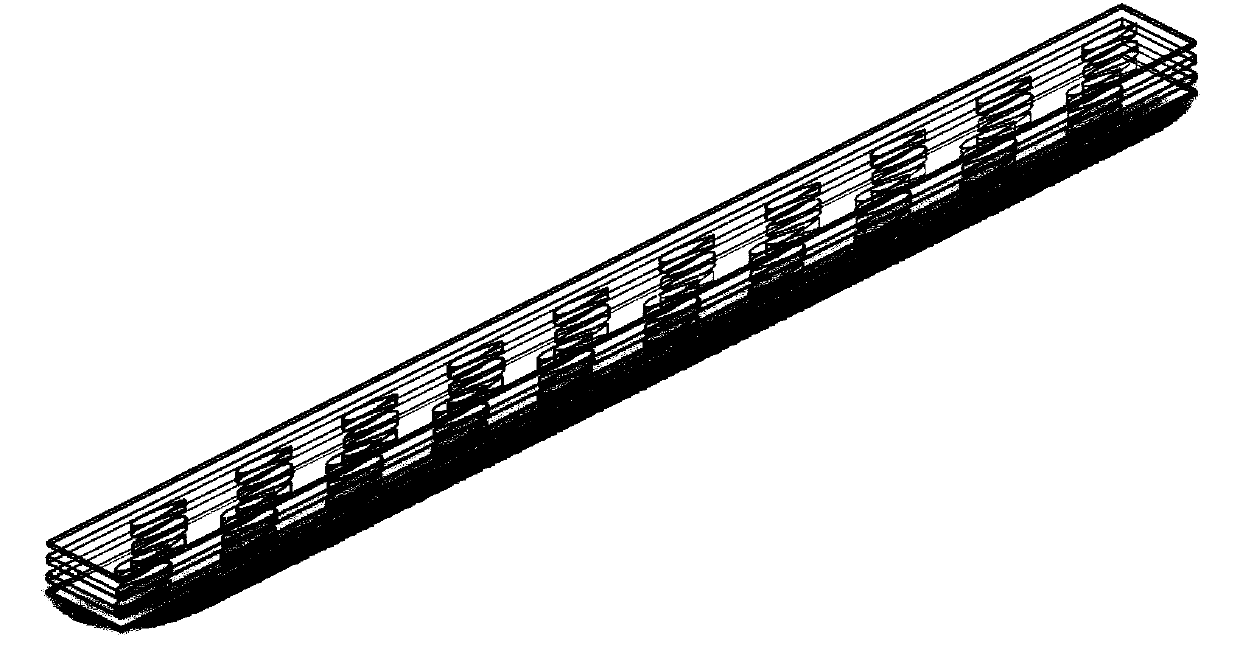

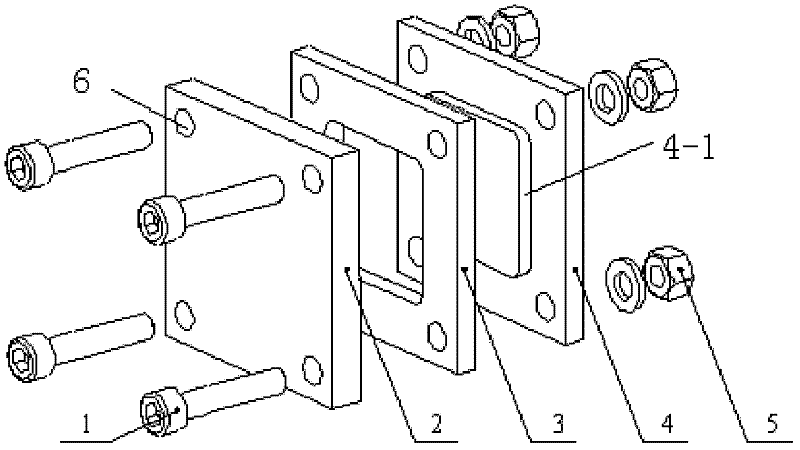

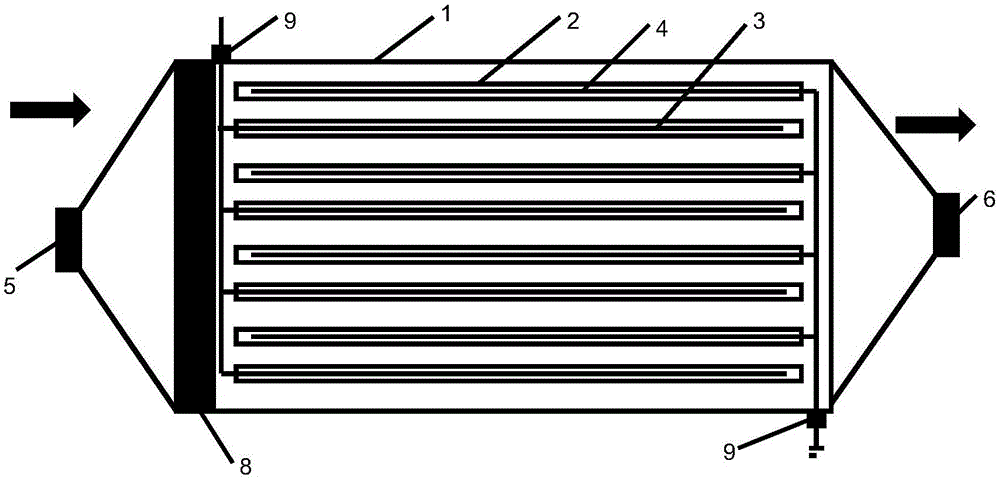

Double dielectric barrier discharge device with catalytic coating for waste gas treatment

PendingCN106807242AAvoid corrosionExtended service lifeGas treatmentDispersed particle separationNitrogen oxideProduct gas

The invention relates to a double dielectric barrier discharge device with a catalytic coating for waste gas treatment. The double dielectric barrier discharge device comprises a shell; a gas inlet and a gas outlet are formed in the two ends of the shell; a plurality of clamping grooves are formed in the side surface of the shell and are used for allowing plate electrodes and catalytic medium plates to be put in. The double dielectric barrier discharge device provided by the invention has the structure characteristic of plasma-catalytic module integration, is used for waste gas treatment and can not only realize plasma-catalytic efficient synergistic removal of volatile organic compounds, nitrogen oxides and other gaseous pollutants, but also realize the deep oxidation of the pollutants through catalyst formula adjustment aiming at different waste gas components; relative to a two-stage type plasma catalytic device, catalyst modules are reduced, the space is saved, and the pollutant removal efficiency is improved; relative to a traditional one-stage type plasma catalytic device, the caused airflow pressure drop is less, and the energy utilization efficiency is higher; when volatile organic waste gas is treated, the appearance of sediments on the inner wall of a discharge reactor can be effectively inhibited.

Owner:ZHEJIANG UNIV

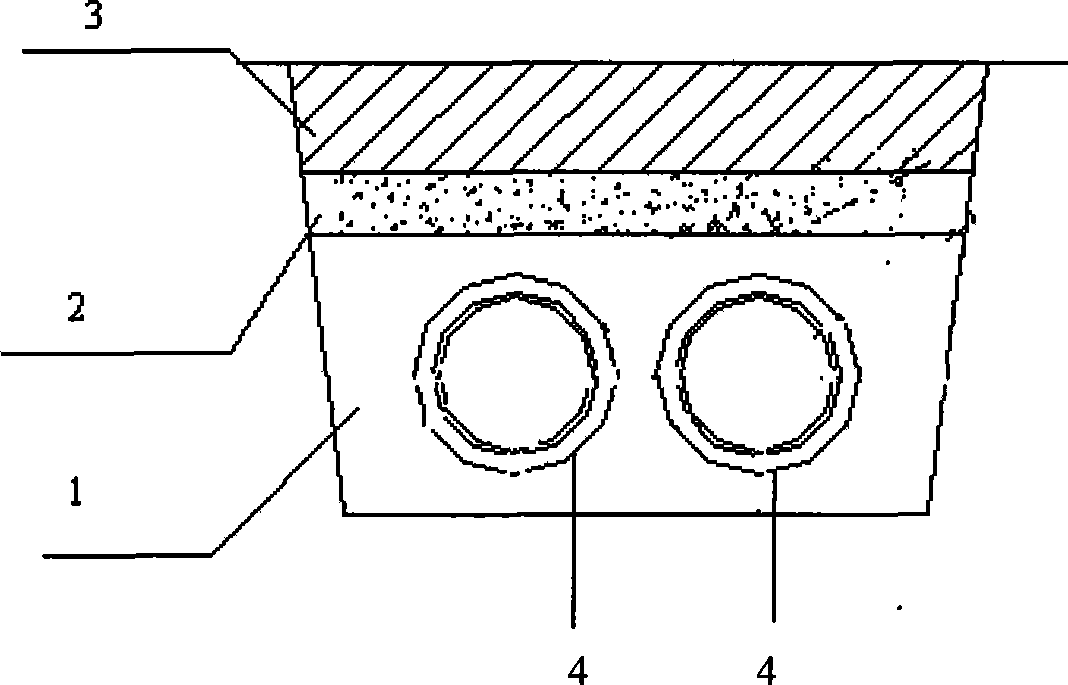

Non-compensation cold mounting method for large diameter heat supply pipeline

ActiveCN101482195AEasy to installLess anchoragePipe laying and repairThermal insulationEngineeringCaliber

The invention provides a large-caliber heat-supply pipeline uncompensated cold mounting method, comprising the following steps: digging a groove for arranging a heat-supply pipeline, and filling sand into the groove; mounting the heat-supply pipeline and a corresponding pipeline accessory into the groove; carrying out backfilling on the groove; wherein, the direct-buried net depth of the heat-supply pipeline is more than 1.7m; the pipeline accessory comprises an elbow with a large bending radius, bevel angles, a three-way pipe, a tapered pipe, and a valve; wherein, the bevel angles comprise a plurality of small bevel angles smaller than 1 degree or the elbow the radius of which is more than 5.0DN can be used for replacing; moreover, the mounting method provided by the invention is led to be suitable for paving the heat-supply pipelines the main tubular diameters of which are more than DN1000 by the processing technology on each node of the pipeline; moreover, the invention is simple to be mounted, has short construction period, reduces the maintaining cost, and is safe and reliable.

Owner:BERIS ENG & RES CORP

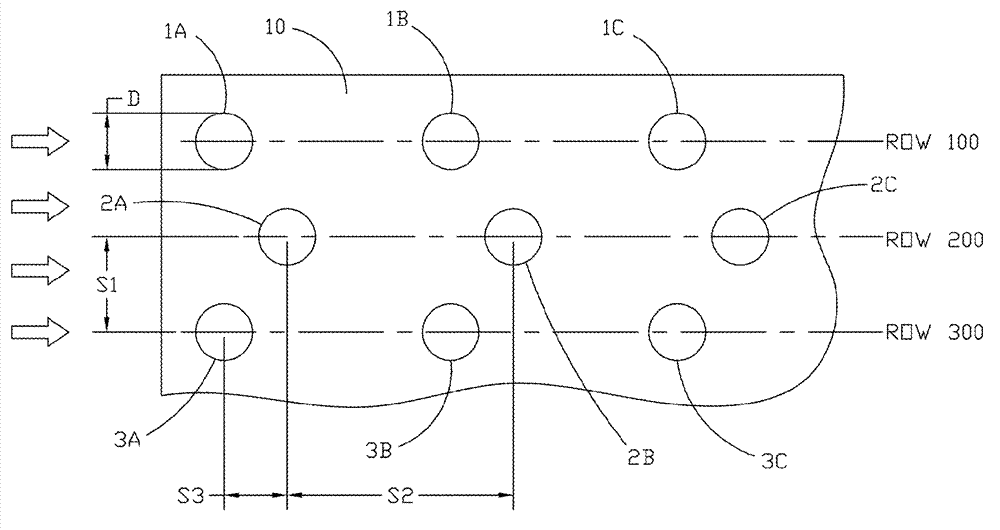

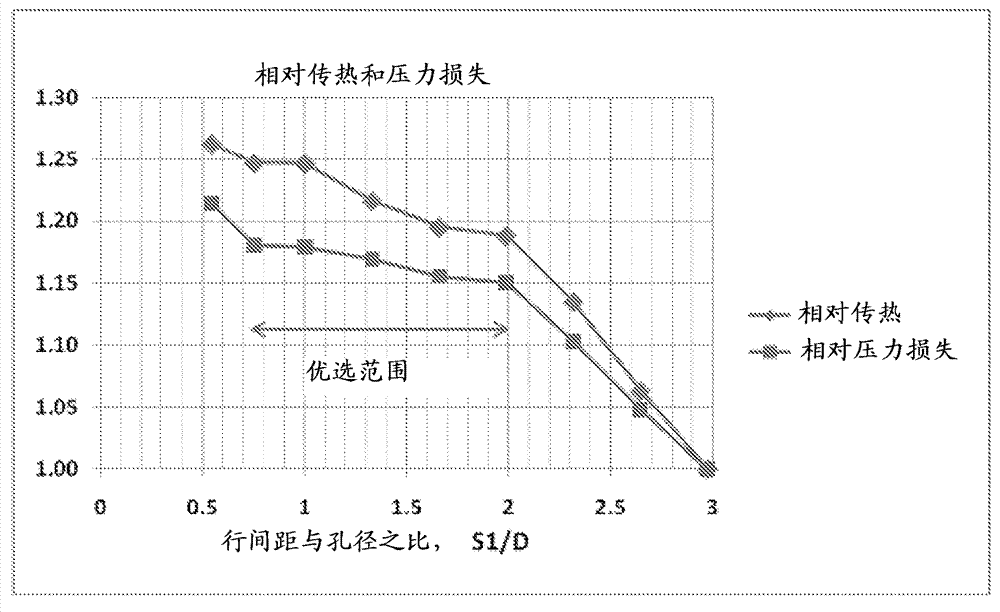

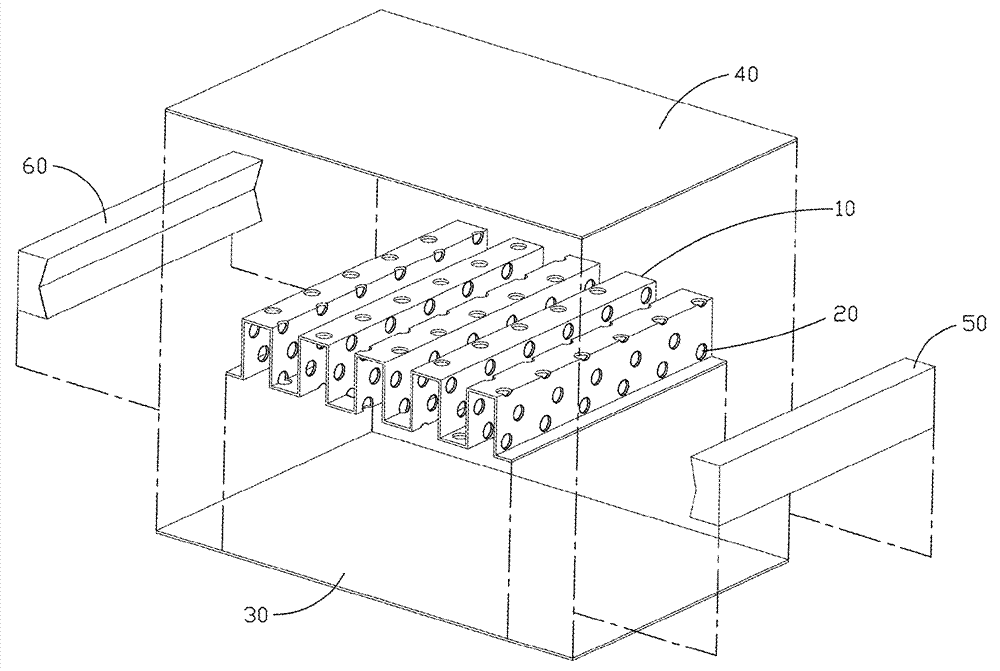

Heat exchanger perforated fins

InactiveCN103119388AHigh performance featuresEffective Air Separation ProcessLiquefactionHeat transfer modificationEngineeringMechanical engineering

A plate fin heat exchanger comprises a folded fin sheet comprising fins wherein the fin sheet comprises a plurality of perforations, such plurality of perforations are positioned on the fin sheet in parallel rows when such fin sheet is in an unfolded state, such parallel rows of perforations on the fin sheet comprise a first spacing between the parallel rows of perforations (S1), a second spacing between sequential perforations within the parallel row of perforations (S2), a third spacing (or offset) between the perforations in adjacent parallel rows of perforations (S3), and a perforation diameter (D), wherein the ratio of the first spacing between the parallel rows of perforations to the perforation diameter (S1 / D) is in the range of 0.75 to 2.0, and wherein the angle between the fins and the parallel rows of perforations is less than or equal to five degrees (= 5 DEG ).

Owner:AIR PROD & CHEM INC

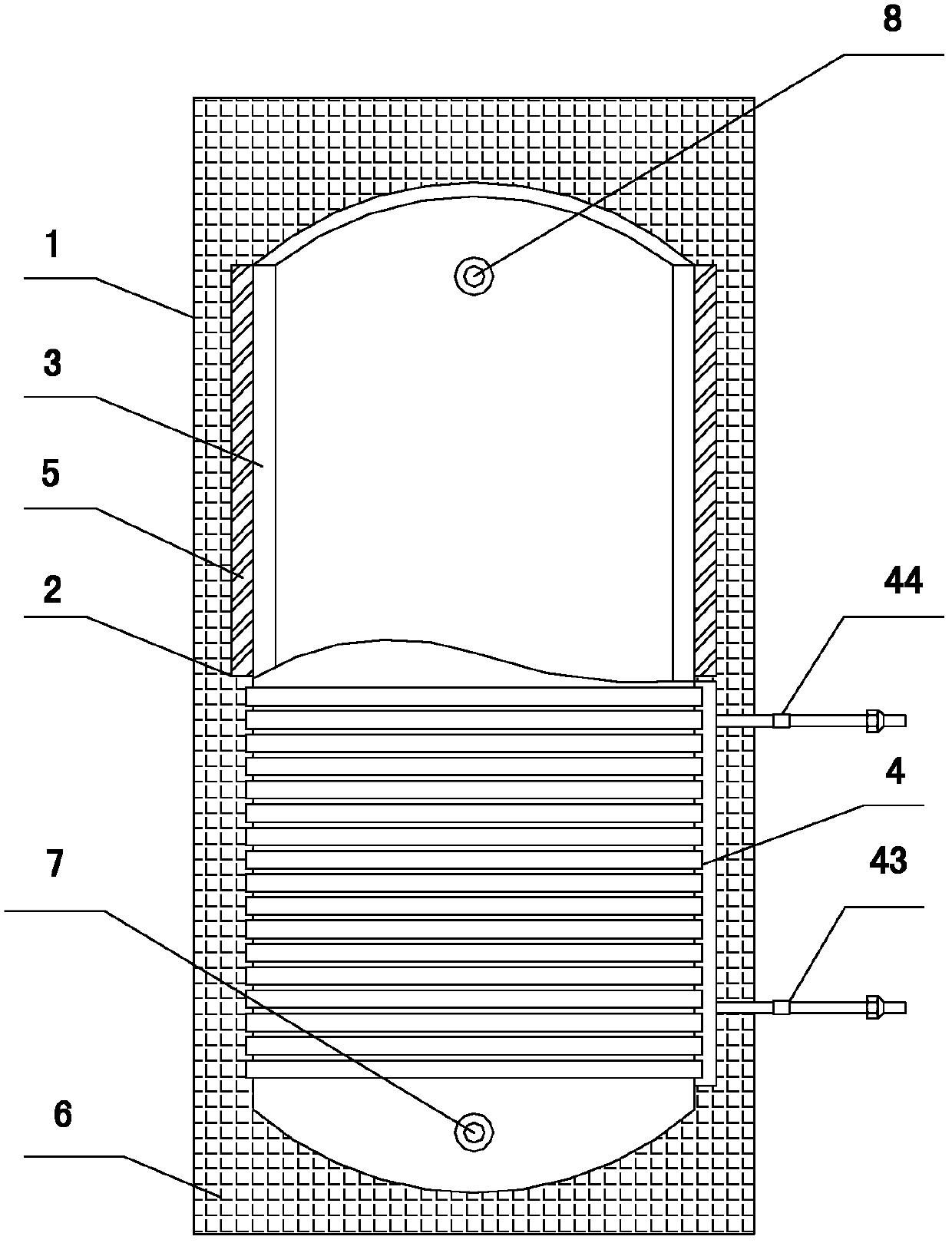

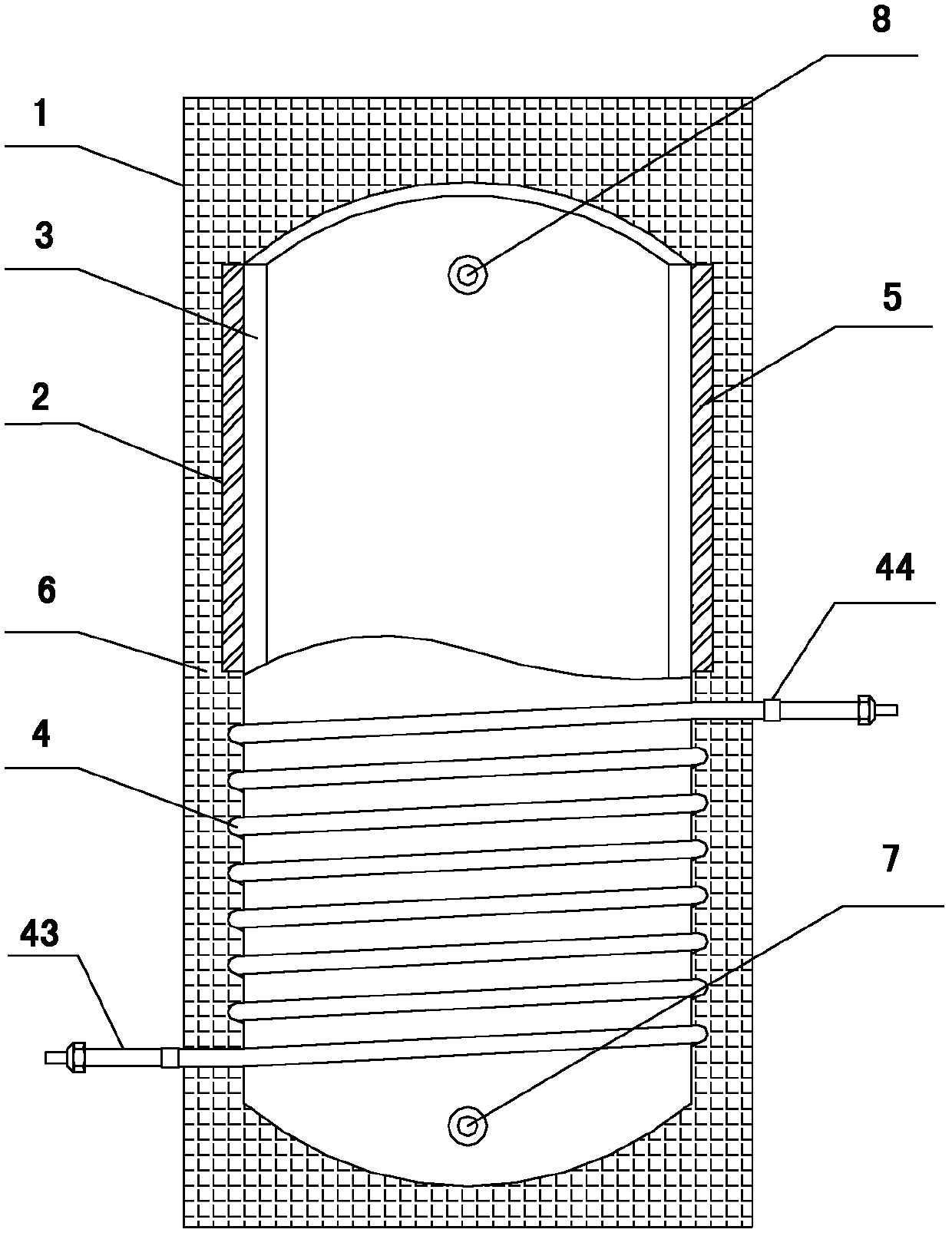

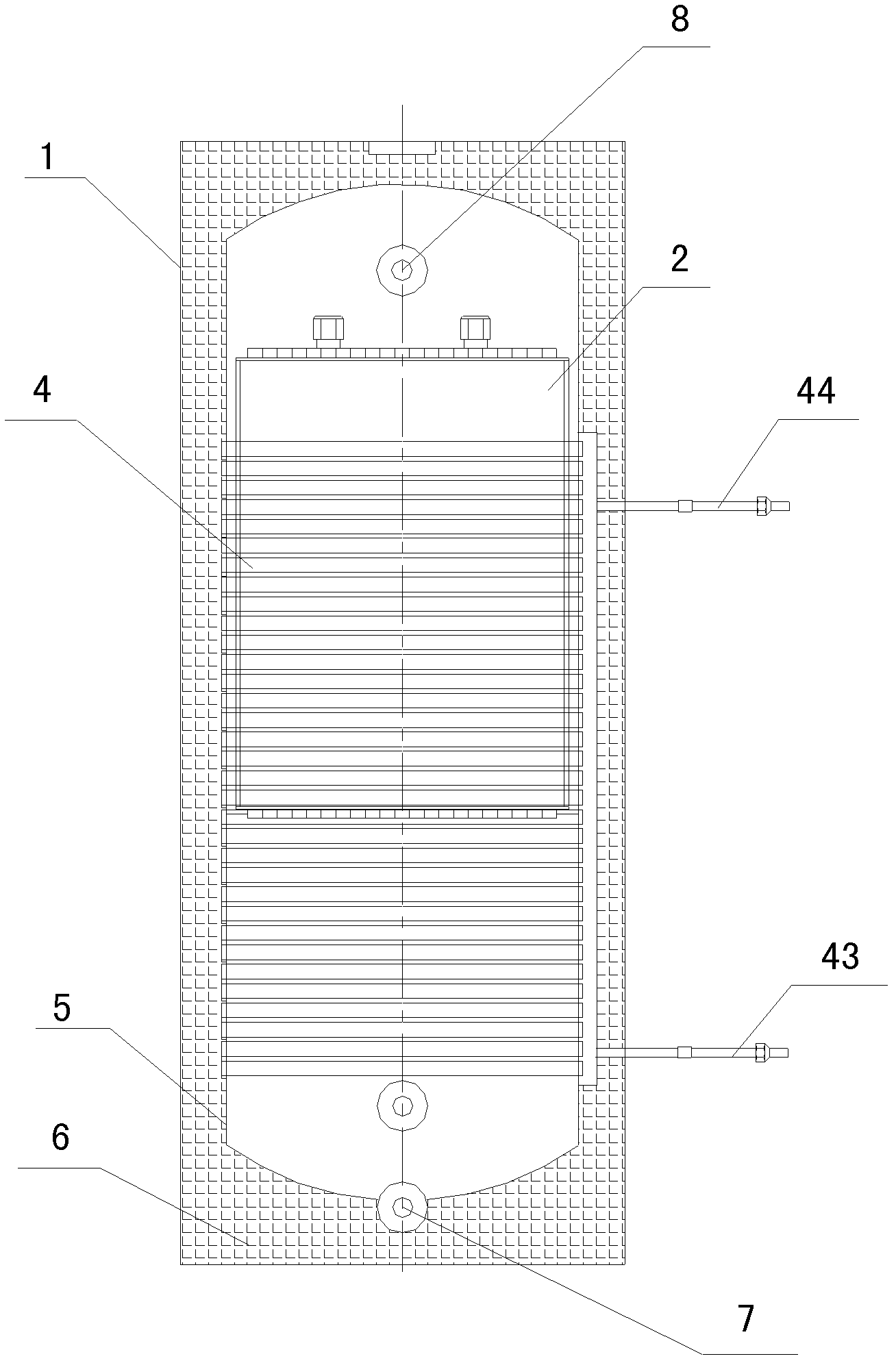

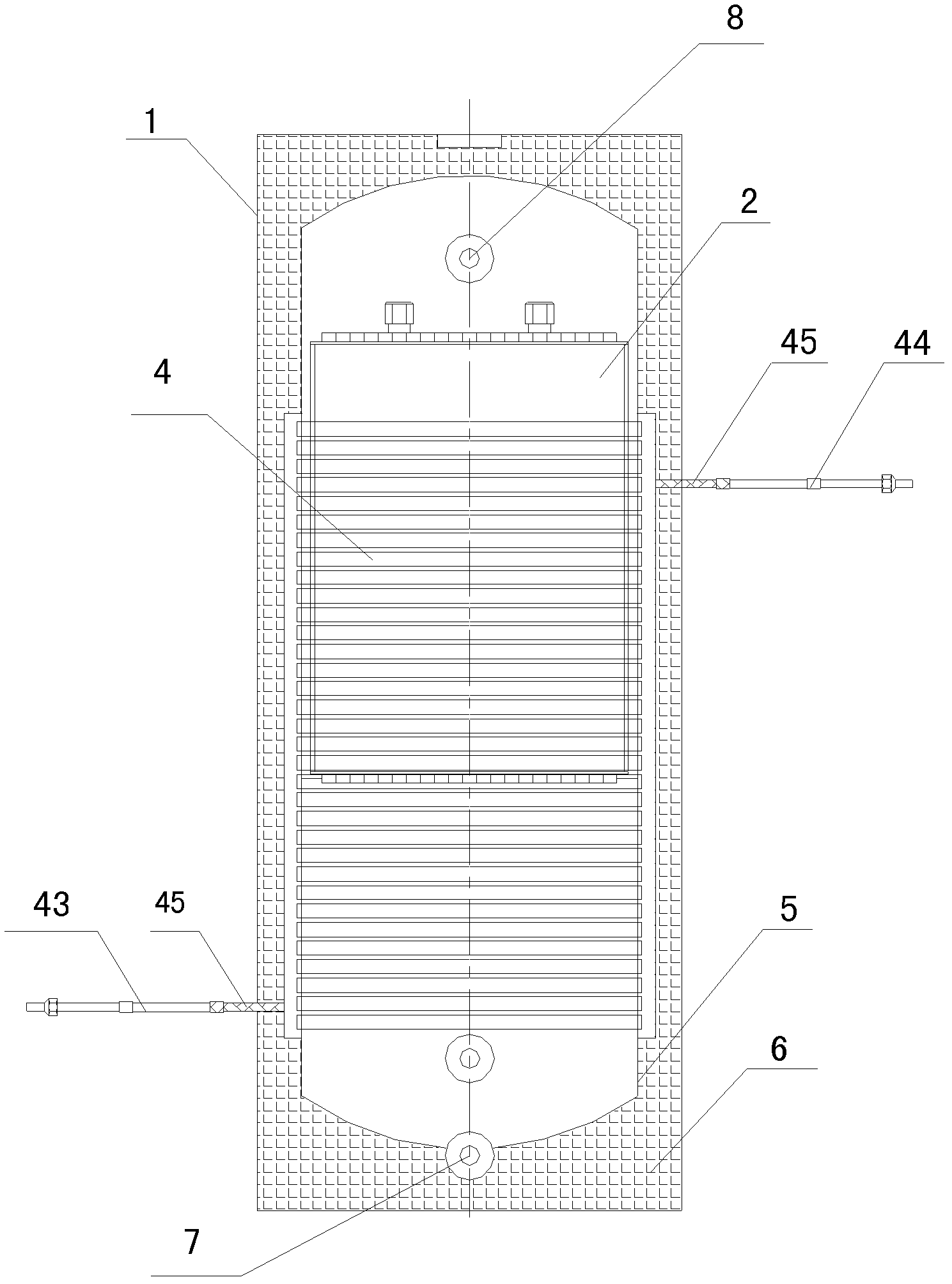

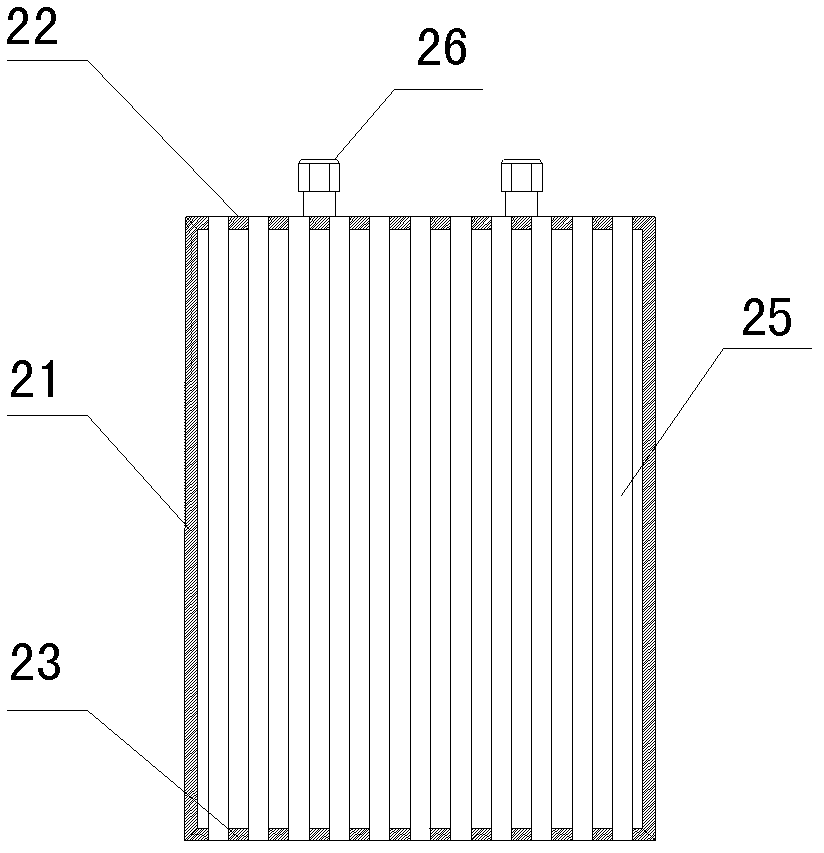

Combination type heat storage water tank of external disk heat storage casting box and condensation heat exchanger

InactiveCN102635948ALarge water storage capacityNo longer takes up volumeFluid heatersWater storageWater quality

The invention discloses a combination type heat storage water tank of an external disk heat storage casting box and a condensation heat exchanger. The combination type heat storage water tank comprises a shell, the heat storage casting box, a heat storage material, a water tank liner, the condensation heat exchanger and an insulating material; the heat storage material is filled in the heat storage casting box; the insulating material foams between the shell and the water tank liner; the water tank liner is provided with a water inlet and a water outlet; the outer wall of the water tank liner is externally wrapped by the heat storage casting box; and the outer wall of the water tank liner is externally wrapped by the condensation heat exchanger. According to the invention, the heat storage casting box and the condensation heat exchanger are not directly immersed in water, so as to ensure safety of water quality; and at the same time, the heat storage casting box and the condensation heat exchanger are not corroded, so as to prolong the service lives; and the heat storage casting box and the condensation heat exchanger do not occupy volume of the water tank liner, so as to increase the water storage capacity of the water tank.

Owner:SOUTH CHINA UNIV OF TECH

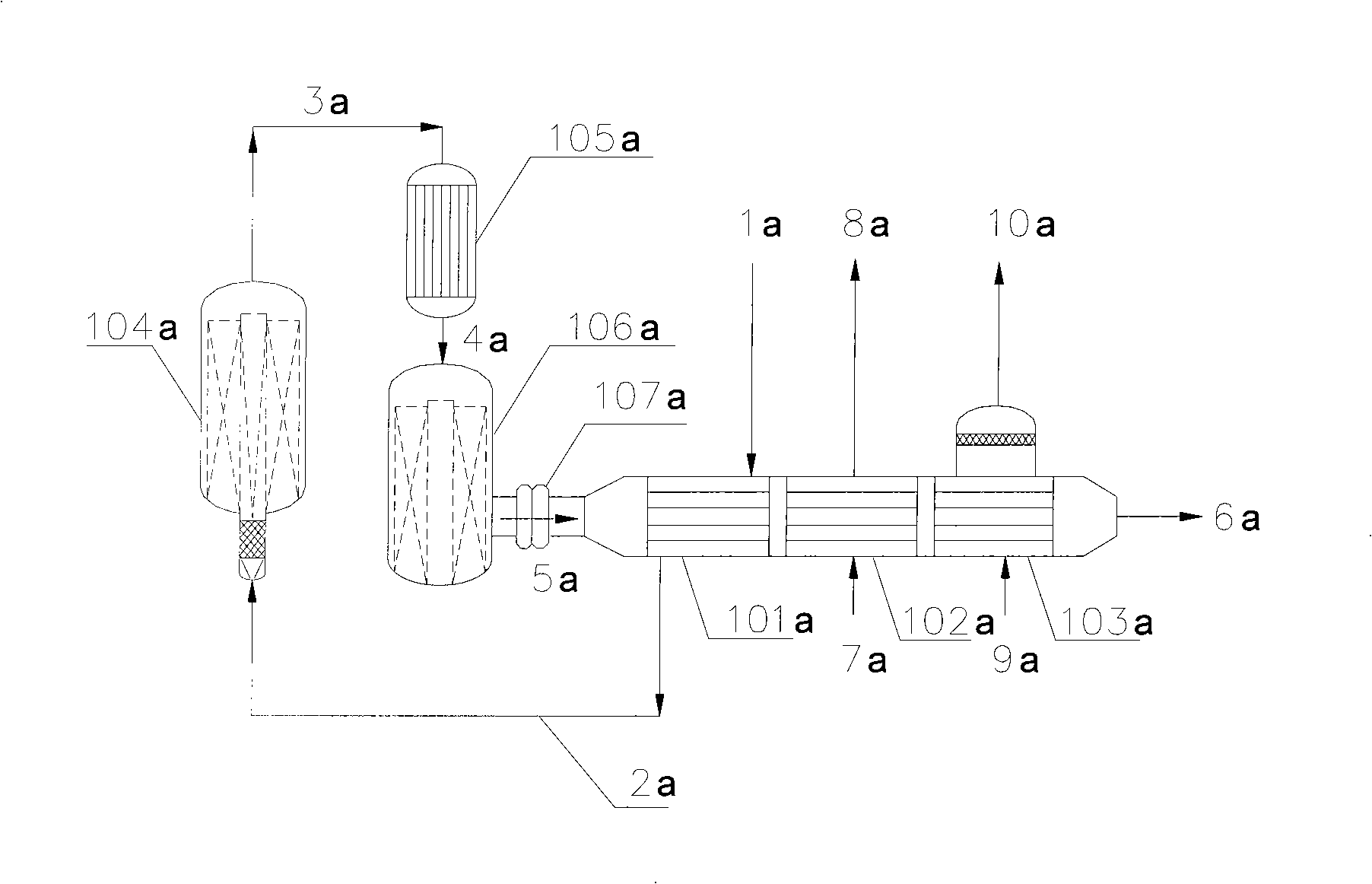

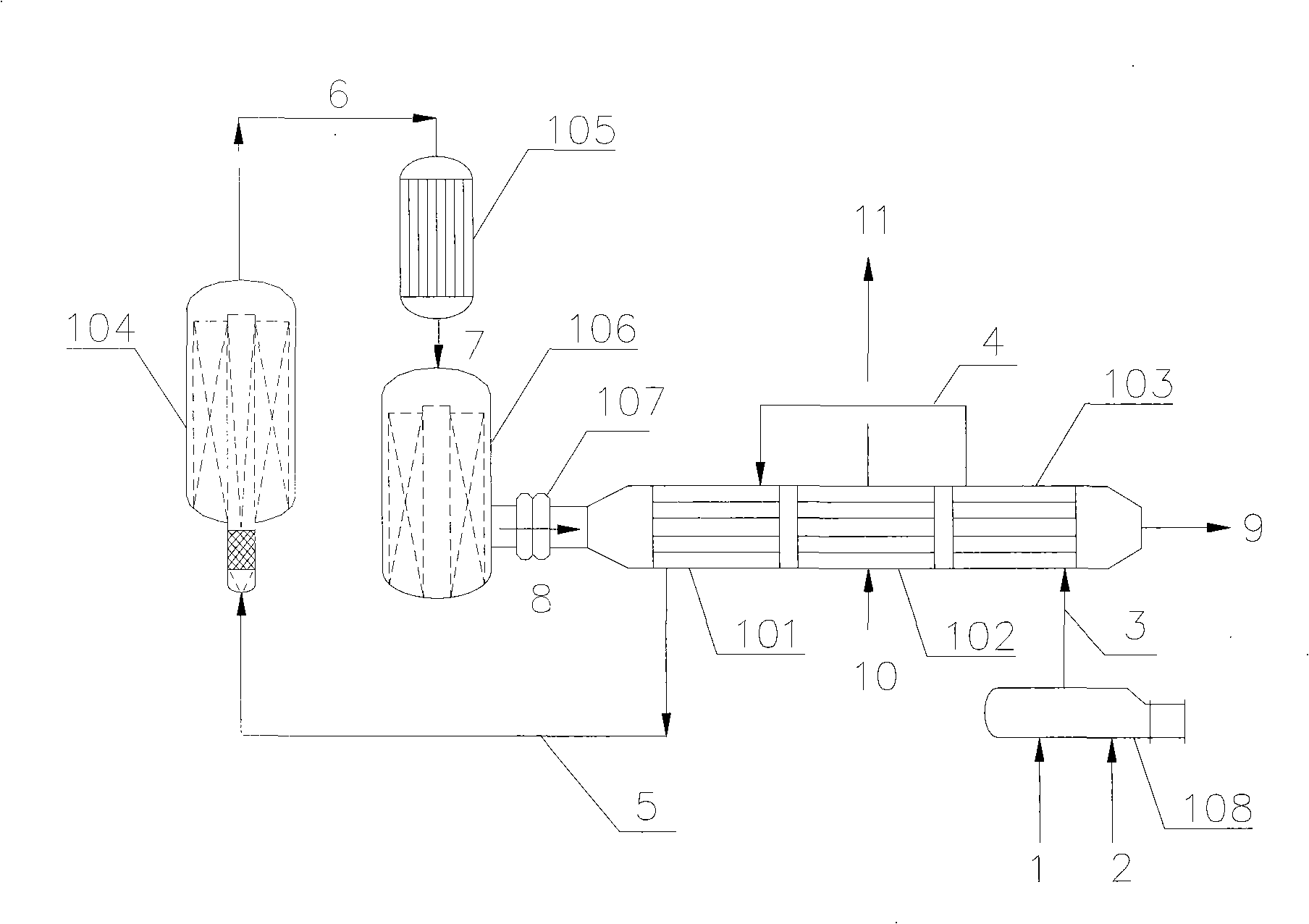

Method for heating ethylbenzene by ethylbenzene dehydrogenation reaction

InactiveCN101279883AReduce tensile stressReduce axial thermal expansion differenceChemical industryHydrocarbonsThree levelGas phase

The invention relates to a heating method of ethyl benzene of an ethyl benzene dehydrogenation reaction material, which mainly solves the problems of frequent accidents of the combined heat exchanger, difficult long-period and stable running, large pressure drop in the pipeline of a reactive system and inadequate heat recovery of a reactor charging / discharging three-level combined heat exchanger in the traditional styrene device due to the unreasonable flow for heating the ethyl benzene by utilizing the discharging of the high temperature reactor. The invention adopts the technical proposals that a liquid phase ethyl benzene material and ingredient water vapor are firstly vaporized to a gas phase with a temperature of between 90 and 110 DEG C through an independently arranged evaporator, and then enter the third level shell pass of the reactor charging / discharging combined heat exchanger to be preheated to a temperature of between 200 and 250 DEG C and then enter the first level shell pass of the reactor charging / discharging combined heat exchanger for being super-heated to a temperature of between 450 and 550 DEG C by the discharging of the high temperature reactor, and the second level shell pass of the reactor charging / discharging combined heat exchanger is used for generating saturated water vapor with a pressure of between 400KPaA and 1000KPaA; and the reactor charging / discharging three-level combined heat exchanger adopts the horizontal or vertical straight-line type arrangement mode, a linear type pipeline expansion joint is disposed between an exit of a dehydrogenation reactor and a material inlet of the first level in the reactor charging super-heater, namely the three-level combined heat exchanger to maintain the shortest distance for allowing installation between the dehydrogenation reactor and the charging super-heater, thereby reducing the tube shell pass thermal expansion difference of the first level heat exchanger.

Owner:CHINA PETROLEUM & CHEM CORP +1

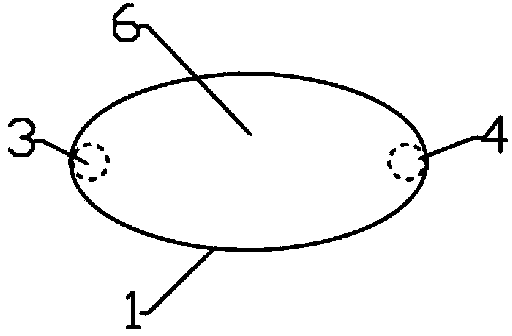

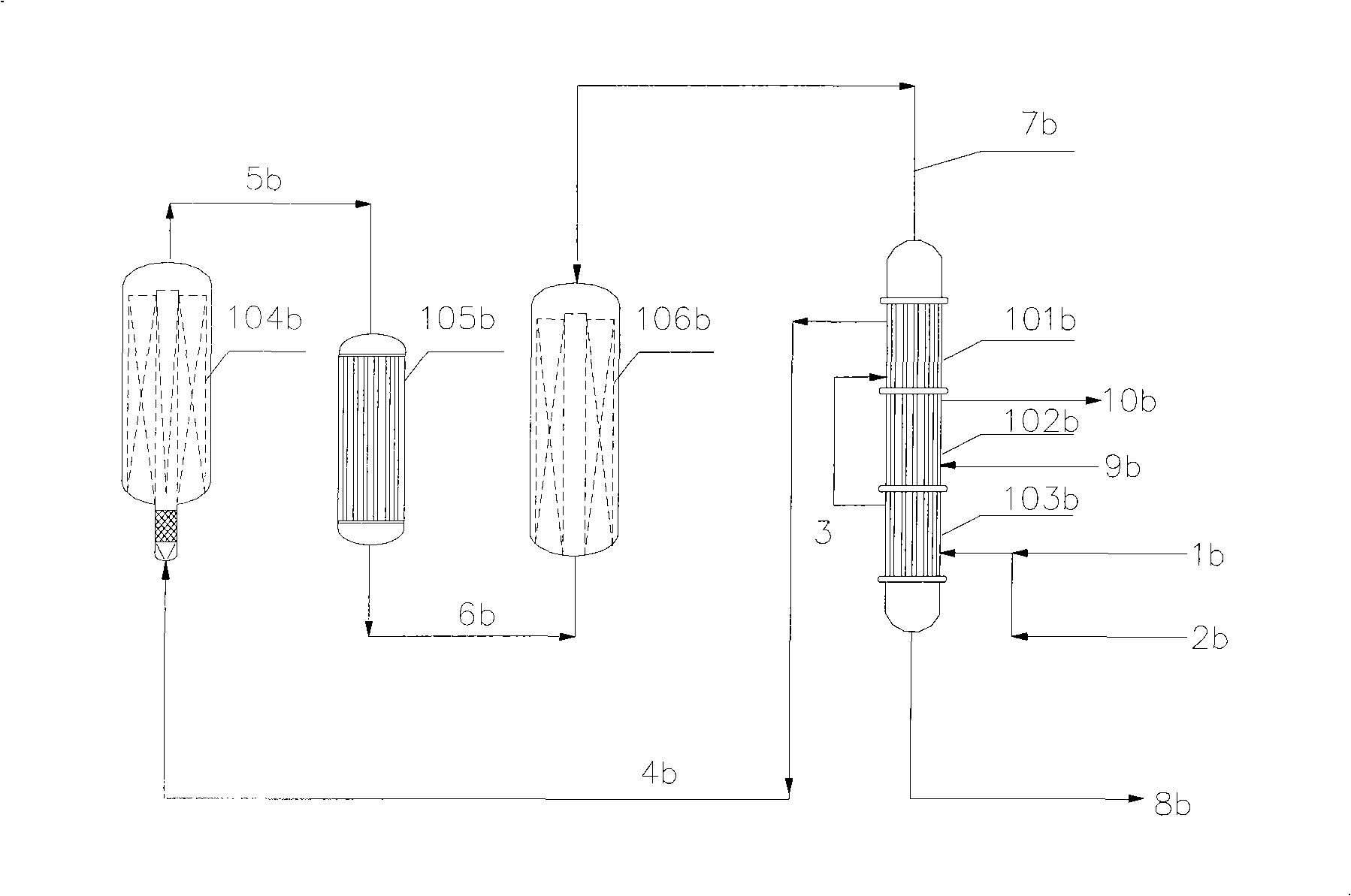

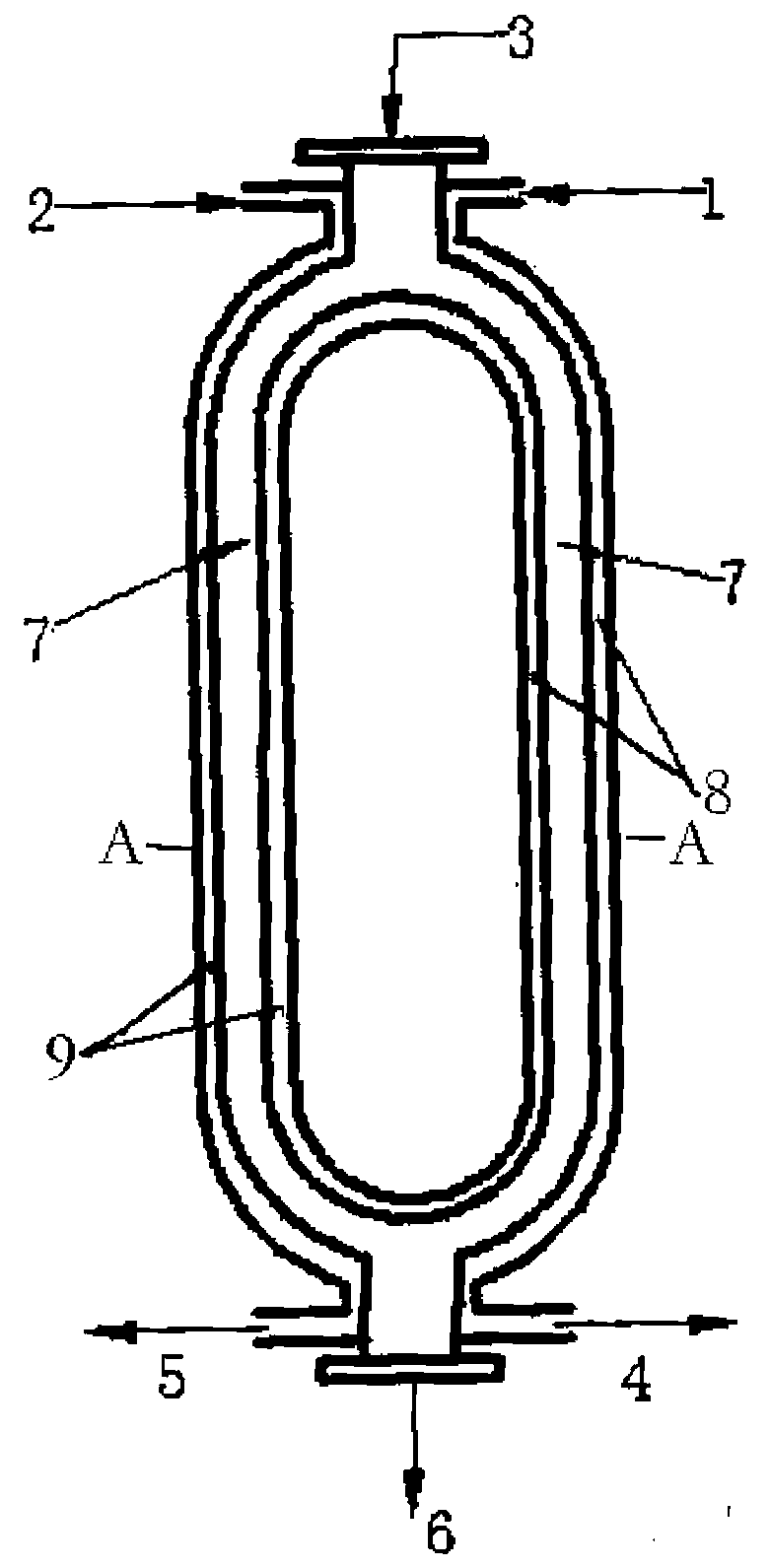

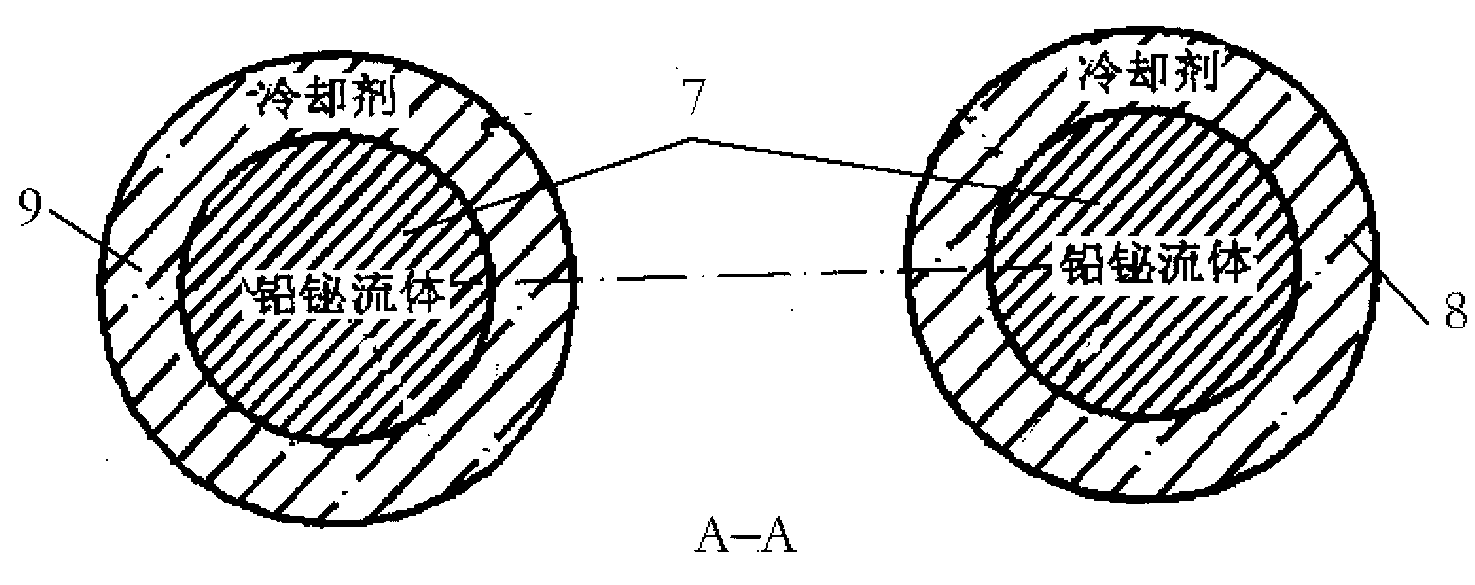

0-shaped lead-bismuth heat exchange device

InactiveCN102831941ASmall pressure drop lossType unlimitedNuclear energy generationCooling arrangementCoolant flowSecondary loop

The invention belongs to the technical field of heat exchange of nuclear energy equipment, and particularly relates to a 0-shaped lead-bismuth heat exchange device which is a device for realizing flowing heat transfer at the two sides. Coolant flowing heat exchange channels are welded on outer peripheries of left and right annular casing pipes of a 0-shaped lead-bismuth alloy flowing channel, wherein the lead-bismuth alloy fluid flows in an inner tube, and the coolant flows in an external annular space channel; the lead-bismuth alloy exchanges heat with the coolant in the annular space channel while flowing through the device; and device transfers the heat to the coolant at a secondary loop through the liquid lead-bismuth alloy, thereby carrying away the heat of the lead-bismuth fluid. The device has two heat transfer flowing modes, namely forced circulation and natural circulation; the device has the characteristics of being simple in structure, low in manufacturing cost, good in heat exchange performance, small in pressure drop loss of the lead-bismuth fluid and having no limit on types of coolant and the like, so that the device is applicable to a lead-bismuth heat exchange system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Variable-volume sewage interception and acceptance solid-liquid separator and method thereof

InactiveCN101337138AFast fermentation rateHigh interception capacityLoose filtering material filtersGravity filtersAutomatic controlFilter media

The present invention discloses a volume-variable solid-liquid separating device with functions of sewage capturing and dirt accepting, and a separating method thereof. The solid-liquid mixture to be separated flows(down-to-up or up-to-down) through the filtering medium which is compressed to have a height equal to 60% to 90% of the natural filling height. With the increase of captured solid phases, a shaft lifting driver drives a lifting shaft to lift a compress screen, and the height of the filtering medium increases gradually. When the height of the filtering medium reaches 90% of the natural filling height, the compress screen is lifted to the highest position, the filtering medium is loosened completely, at the same time, reverse flushing gas is charged from the intake pipe for a period of 10 to 15 minutes, after the reverse flushing, the compress screen is lowered to compress the filtering medium for refiltration. As a result, the invention has a fast filtering speed reaching a level of 45m / h, sewage capturing speed is increased while the pressure drop loss is decreased; the reverse flushing is complete while the water consuming is less; the operation is simple, and complete auto-control can be realized.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

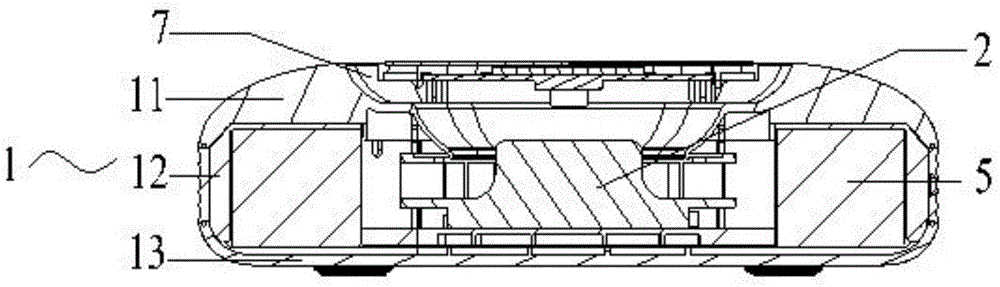

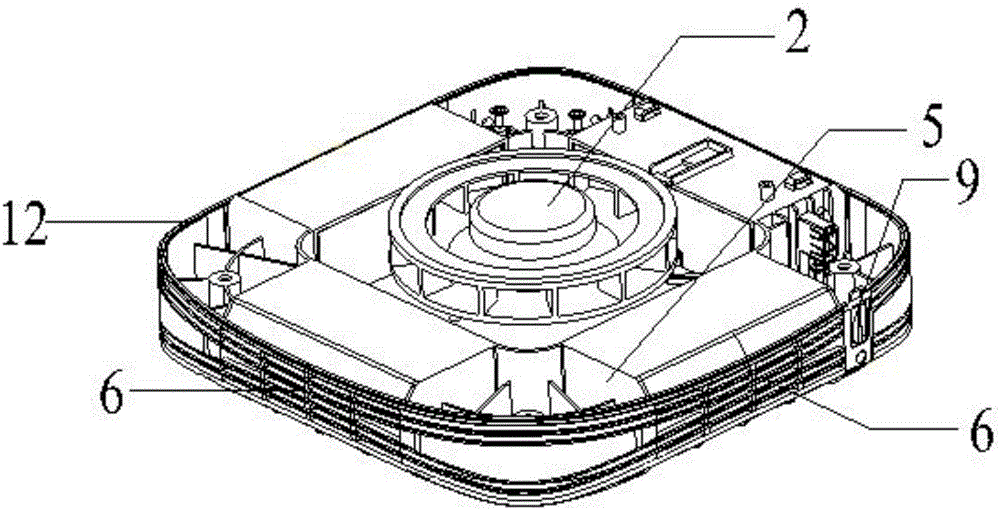

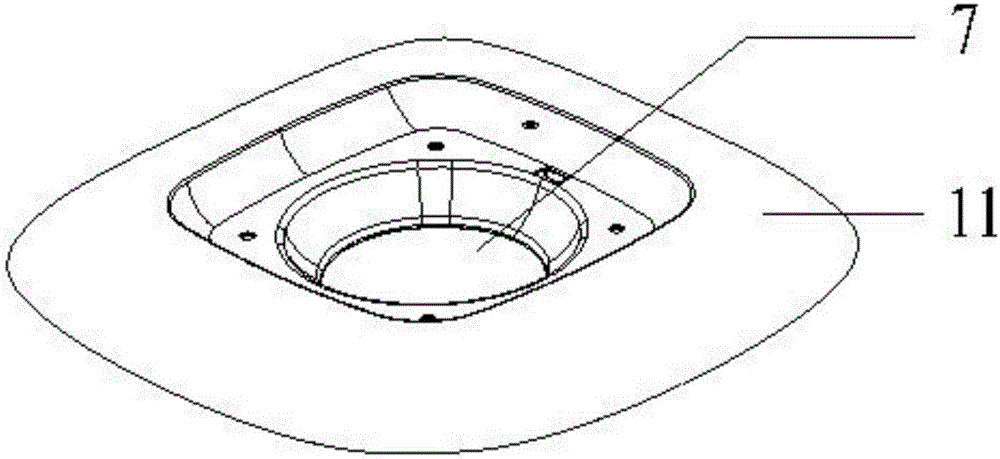

Vehicle air purifier

The invention discloses a vehicle air purifier which comprises a shell, a centrifugal fan, a controller, a display and several filters. The shell comprises from the top to the bottom a upper shell, a middle shell and a base plate. The centrifugal fan is provided at the center of the middle shell. A plurality of filters are provided in the middle shell and at the periphery of the centrifugal fan. The ventilation holes are provided at the corresponding positions to the filters in the middle shell. The middle position of the upper shell is provided with an air inlet. A display is mounted at the upper shell. The display is connected to the controller, which is also connected to the centrifugal fan by the signal cable. The invention of the vehicle air purifier applies the centrifugal fan, which is mounted in the shell center. The air inlet is located at the top of the centrifugal fan. The air inlet is perpendicular to the centrifugal fan and the air outlet is provided along the circumference of the shell. The direction of air is identical to the air flow direction of centrifugal fan. The placement of bending corners and elbows are minimized which reduces the wind loss and pressure loss. The air purifier applies a plurality of filters. The air outlet section area is big. All these guarantee an ideal purification effects.

Owner:长春三友智造科技发展有限公司

Printed circuit board type fused salt heat exchanger adopting double-layer board arrangement

ActiveCN106895725AHeat absorption smoothlySmall sizeHeat exchanger casingsStationary plate conduit assembliesCause blockagePlate heat exchanger

The invention provides a printed circuit board type fused salt heat exchanger adopting double-layer board arrangement. The printed circuit board type fused salt heat exchanger adopting double-layer board arrangement comprises a shell and a heat change board core arranged in the shell. The heat exchange board core comprises at least one periodical structure. Each periodic structure is composed of a first cold salt heat exchange board, a second cold salt heat exchange board and a hot salt heat exchange board, wherein the first cold salt heat exchange board, the second cold salt heat exchange board and the hot salt heat exchange board are sequentially stacked. Each first cold salt heat exchange board and each second cold salt heat exchange board are provided with multiple cold salt flow channels, wherein the flowing directions of the multiple cold salt flow channels are parallel. Each cold salt flow channel extends from the longitudinal first end of the corresponding cold salt heat exchange board to the longitudinal second end of the corresponding cold salt heat exchange board. Each hot salt heat exchange board is provided with multiple hot salt flow channels. Each hot salt flow channel extends from the transverse first end to the transverse second end of the corresponding hot salt heat exchange board. By the adoption of the printed circuit board type fused salt heat exchanger adopting double-layer board arrangement, it is avoided that fused salt causes blockage of the flow channels in a low-temperature environment, it is also avoided that in a high-temperature environment, the fused salt causes a thermal expansion effect on the flow channels of the heat exchanger, and the service life of heat exchange equipment is prolonged.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Wide-channel plate type heat exchanger and heat exchanger particle swarm optimization structure design method

InactiveCN110160380AImprove robustnessImprove heat transfer effectHeat exchanger casingsLaminated elementsOrthogonal methodEngineering

The invention discloses a wide-channel plate type heat exchanger and a heat exchanger particle swarm optimization structure design method, and belongs to the technical field of heat exchanger design.Six variables of a trapezoid boss on the surface of a single-layer heat exchange plate are extracted for forming structure parameters, and the design range is determined; an orthogonal method is adopted, and 25 sets of typical heat exchanger plates with different structures and operation conditions are generated; through Soliworks, the single-layer heat exchange plate is generated, and on the basis of Fluent numerical simulation software, a heat exchange nusselt number and the pressure drop of the corresponding heat exchanger plate structure are obtained; according to the obtained sample set,a heat exchange nusselt number and pressure drop comprehensive criterion relation model of a heat exchanger plate is fitted; the maximum heat exchange nusselt number and the minimum pressure drop serve as optimization targets, particle swarm optimization is adopted, and optimizing is carried out to obtain the structural parameters of the optimal heat exchanger plate; and the heat exchanger has theadvantages that the heat exchanger is suitable for finding shape parameters obviously affecting flowing and heat exchange characteristics of the plate type heat exchanger, under the condition that core parameters are continuously distributed, the shape parameter distribution range with the best heat exchange effect and meanwhile the minimum pressure drop losses can be searched.

Owner:CHINA UNIV OF MINING & TECH

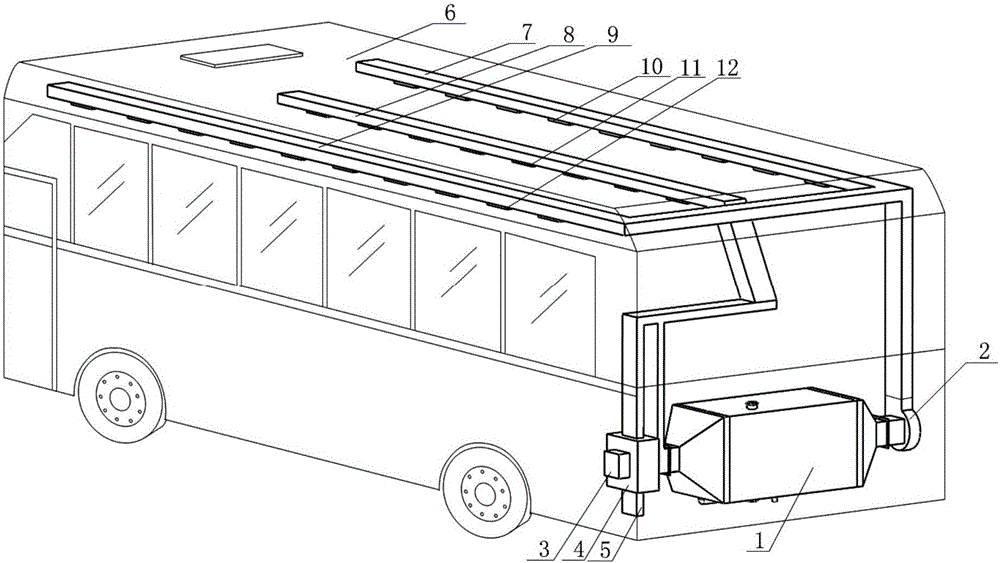

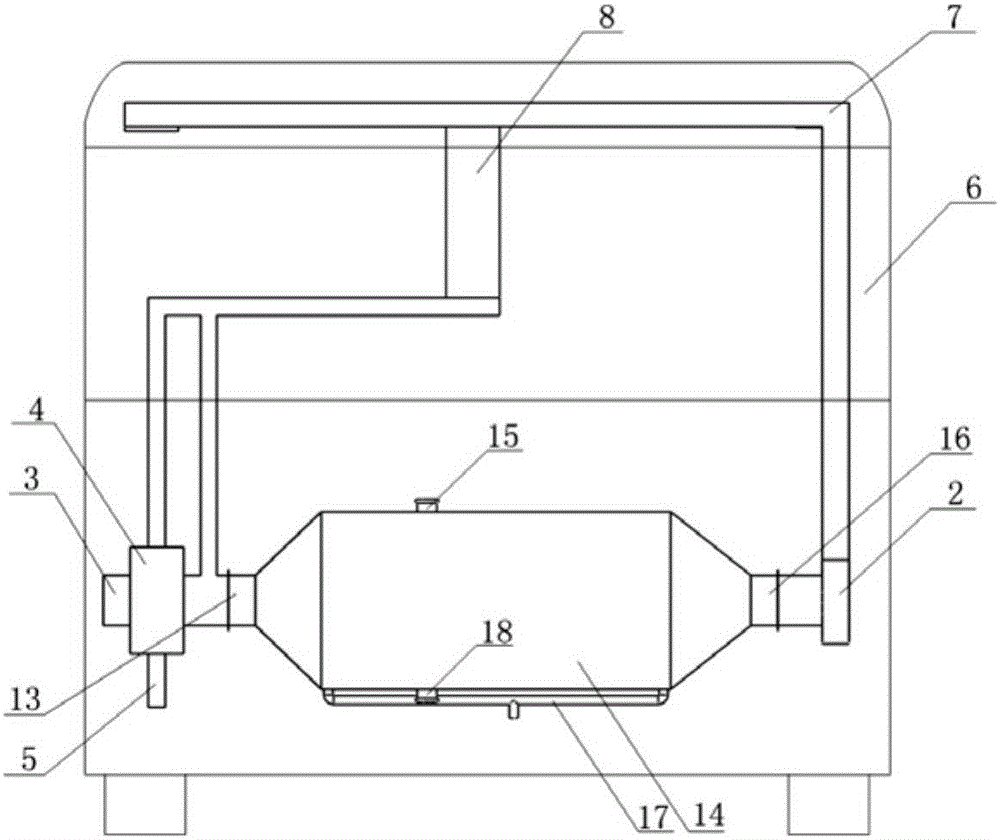

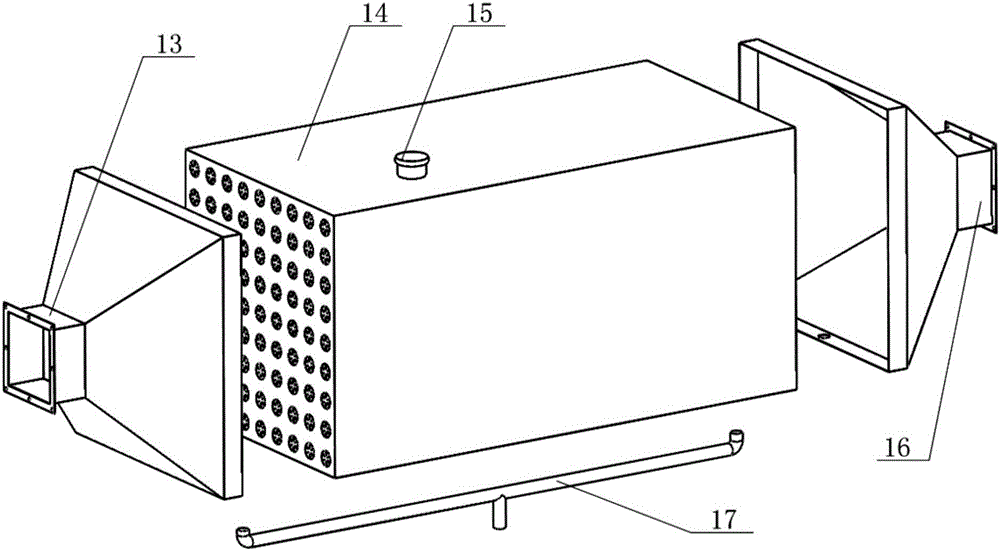

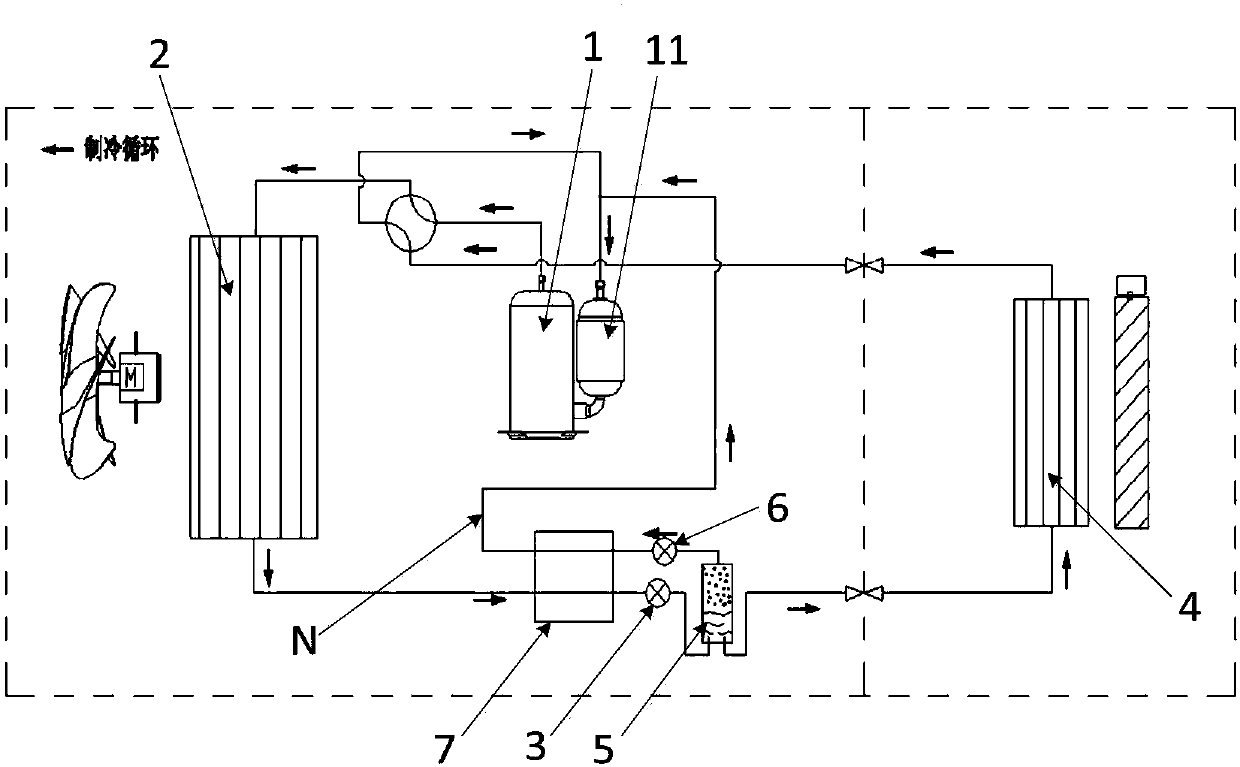

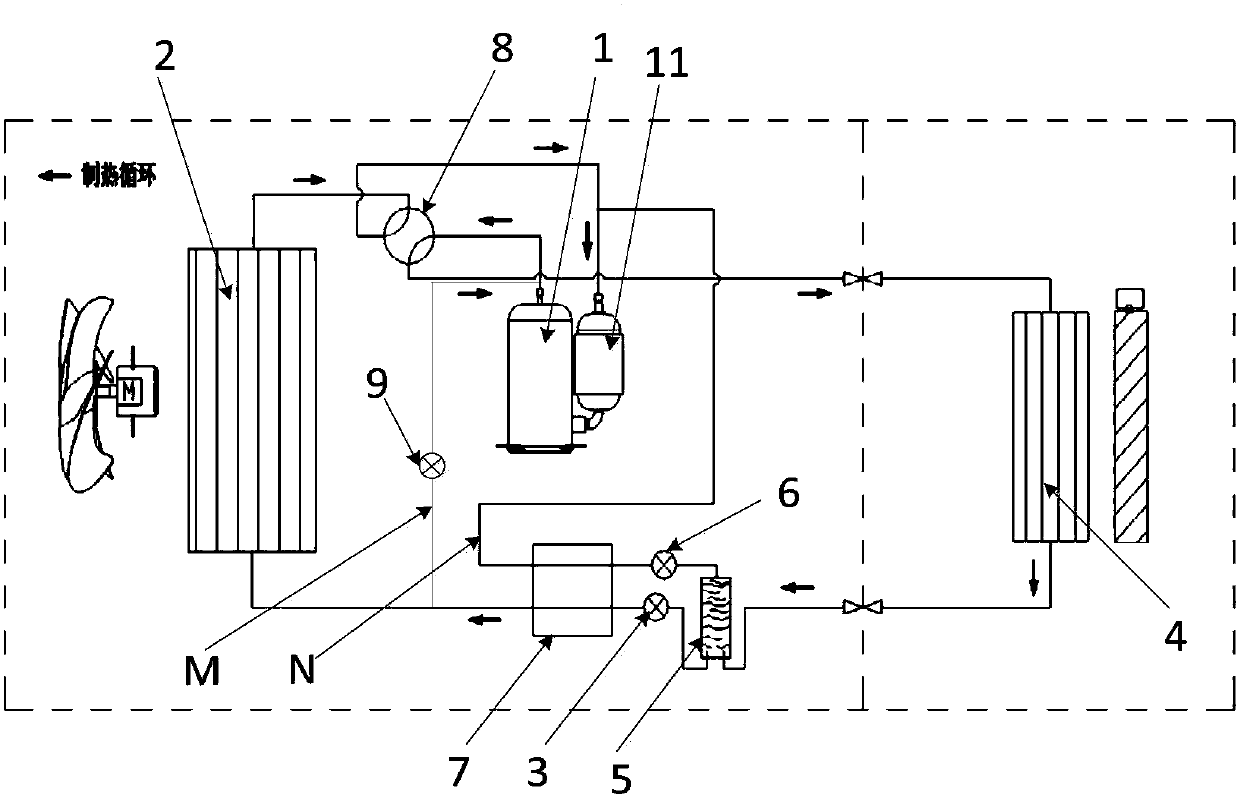

Dynamic ice slurry cold accumulation bus air conditioner cold supply system

ActiveCN105644301ARealize the comprehensive utilization of "moving peaks and filling valleys"Reduce energy consumptionAir-treating devicesVehicle heating/cooling devicesInjection portFresh air

The invention provides a dynamic ice slurry cold accumulation bus air conditioner cold supply system which comprises an air system and a cold accumulation device. The air system comprises a left air supply pipe, a right air supply pipe, an air return pipe, a draught fan, a fresh air port, a total heat exchanger and an exhausting port. Air supply ports are formed in the bottom of each air supply pipe. Air return ports are formed in the bottom of the air return pipe. The cold accumulation device comprises a box body with the two ends opened, a cold accumulation tank heat exchanger arranged in the middle portion of the box body, an air inlet, an air outlet, a slurry injection port and a liquid drainage port, wherein the air inlet and the air outlet are formed in the two opening ends of the box body, and the slurry injection port and the liquid drainage port are formed in the circumferential direction of the box body. The air outlet communicates with the right air supply pipe through the draught fan. The left air supply pipe and the right air supply pipe communicate with the air return pipe. The fresh air port, the exhausting port and the air inlet communicate with the total heat exchanger. The air return pipe communicates with the total heat exchanger and the air inlet. By the adoption of the system, the dynamic ice slurry cold accumulation technology and the feature of short circuits of a bus are combined so that energy supply for public transport can be reduced, and the dynamic feature of the bus in the travel process is improved.

Owner:XI AN JIAOTONG UNIV

Air-conditioning refrigeration circulating system and air conditioner

InactiveCN107763774AImprove drynessIncrease subcoolingMechanical apparatusCorrosion preventionVapor–liquid separatorCondensation temperature

The invention belongs to the technical field of air conditioners and particularly relates to an air-conditioning refrigeration circulating system and an air conditioner. In order to improve the air-conditioning refrigeration circulating effect and reduce the energy consumption, the system comprises a compressor in series connection with a main loop, an outdoor heat exchanger, a first throttling device and indoor heat exchanger; a first gas-liquid separator is further in series connection with the main loop; a bypass loop is arranged between the first gas-liquid separator and the compressor; after a cold medium flowing out of the outdoor heat exchanger flows into the first gas-liquid separator through the first throttling device, a gaseous cold medium flows to the compressor along the bypass loop, and a liquid cold medium flows to the indoor heat exchanger along the main loop. By the aid of the system and the air conditioner, the pressure drop loss of the gaseous cold medium in the system is low, the energy consumption of the system is reduced, meanwhile, the return gas pressure of the system can be increased, and the exhaust pressure and the condensing temperature of the system areincreased, so that the heat convection temperature difference of the cold medium in the outdoor heat exchanger is increased, and the purpose of increasing the refrigerating capacity of the system isachieved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Slotted streamline rib type structure heat exchange plate

ActiveCN109990640AAvoid vertical impactAvoid it happening againAdditive manufacturing apparatusSemiconductor/solid-state device detailsEngineeringHeat exchanger

The invention discloses a slotted streamline rib type structure heat exchange plate used for a printing circuit board heat exchanger. Inverted-V-shaped streamline grooves are formed in rib sheets so that a part of heat exchange fluid can flow into channels and flow out of the tails of the rib sheets, vertical collisions to the rib sheets from incoming flow are avoided, generation of a flowing stagnation area is prevented, the phenomenon that local resistance in the area is high is improved, and accordingly channel pressure drop losses are reduced. Meanwhile, in the slotting area, the heat exchange area can be obviously increased, and the heat exchange performance is improved as well.

Owner:ANHUI RUNAN SIBIAN ENERGY TECH CO LTD

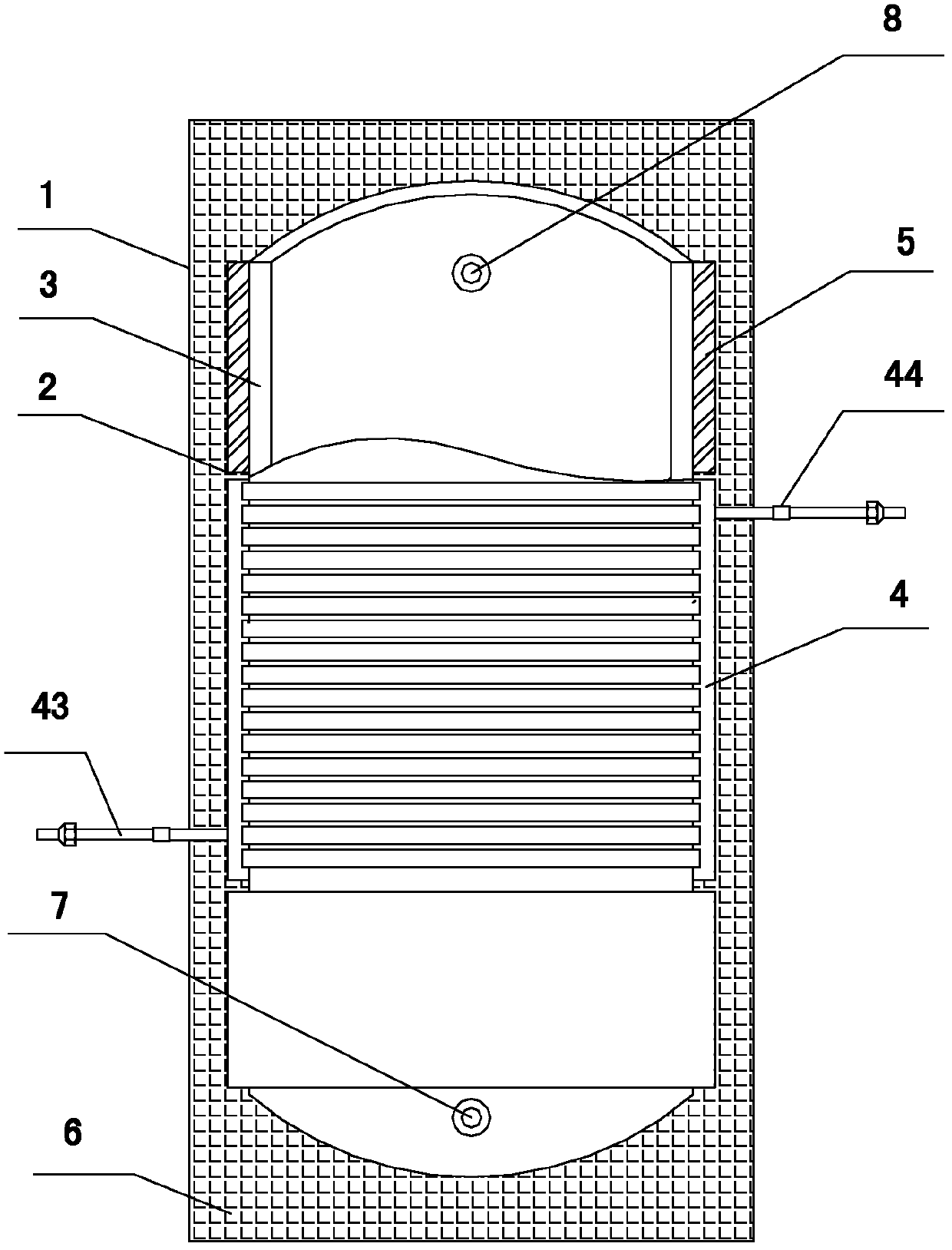

Outer-disk micro channel type thermal storage water tank for heat pump water heater

InactiveCN102645024AImprove heat transfer effectLarge water storage capacityFluid heatersWater flowEngineering

The invention discloses an outer-disk micro channel type thermal storage water tank for a heat pump water heater, which comprises a casing, a thermal storage molding flask, a thermal storage material, a water tank inner container, a condensation heat exchanger and an insulation material. The thermal storage material is filled in the thermal storage molding flask, the thermal storage molding flask is arranged in the water tank inner container, the insulation material is foamed between the casing and the water tank inner container, and a water inlet / outlet is positioned on the water tank inner container. The thermal storage molding flask comprises a barrel body lateral wall, an upper end cover and a lower end cover, wherein vertically opposite holes are arranged on the upper end cover and the lower end cover, and a communication pipe is positioned between the two vertically opposite holes to form a vertically communicated water flow channel. The thermal storage material is filled outside the communication pipe and in sealed cavities formed by the upper end cover, the lower end cover and the barrel body lateral body. The condensation heat exchanger wraps the outer wall of the water tank inner container. The thermal storage molding flask enables heat exchanger performance between water and the thermal storage material to be remarkably increased. The condensation heat exchanger increases heat exchanger areas and improves systematic heat exchanger efficiency.

Owner:SOUTH CHINA UNIV OF TECH

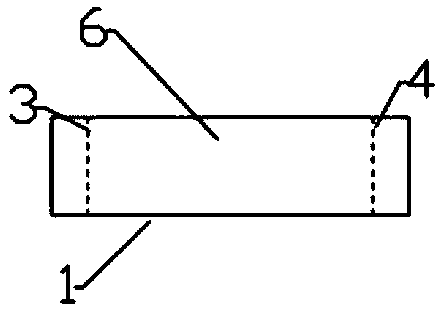

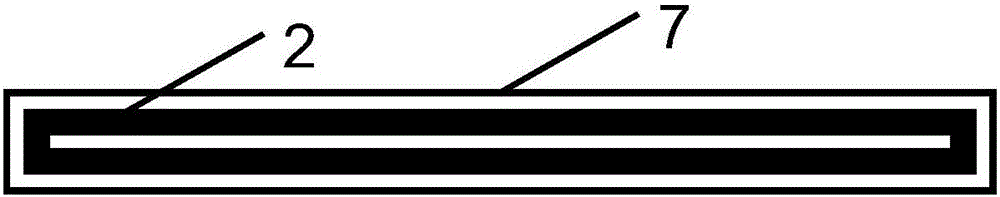

Composite muffler used in pipeline

InactiveCN103899875ASmall pressure drop lossSimple structurePipe elementsUltrasound attenuationEngineering

The invention relates to a composite muffler used in a pipeline. The composite muffler used in the pipeline comprises a sound attenuation outer tube. A plurality of labyrinth outer plates and a plurality of labyrinth inner plates are arranged in the sound attenuation outer tube. A plurality of through holes are formed in the sidewall of the sound attenuation outer tube. The two ends of the sound attenuation outer tube are provided with a connecting flange and a flow guide cover respectively. The composite muffler used in the pipeline has the advantages of being simple in structure and convenient to install and use, reducing pressure drop loss of fluid, combining the diffraction sound attenuation principle and the phase-position sound attenuation principle, eliminating turbulent flow and vortexes in the fluid according to the flow rectifying principle and having good sound attenuation effect.

Owner:曹鹏飞

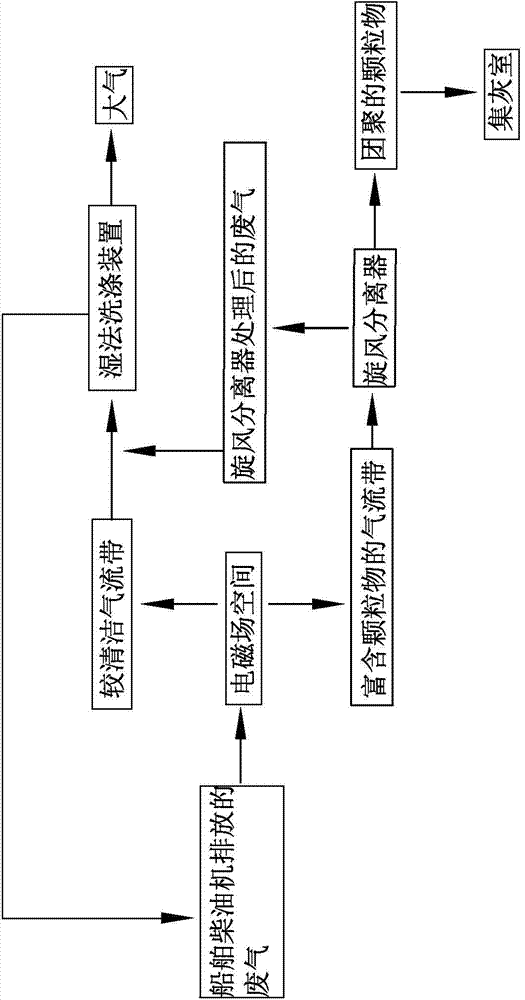

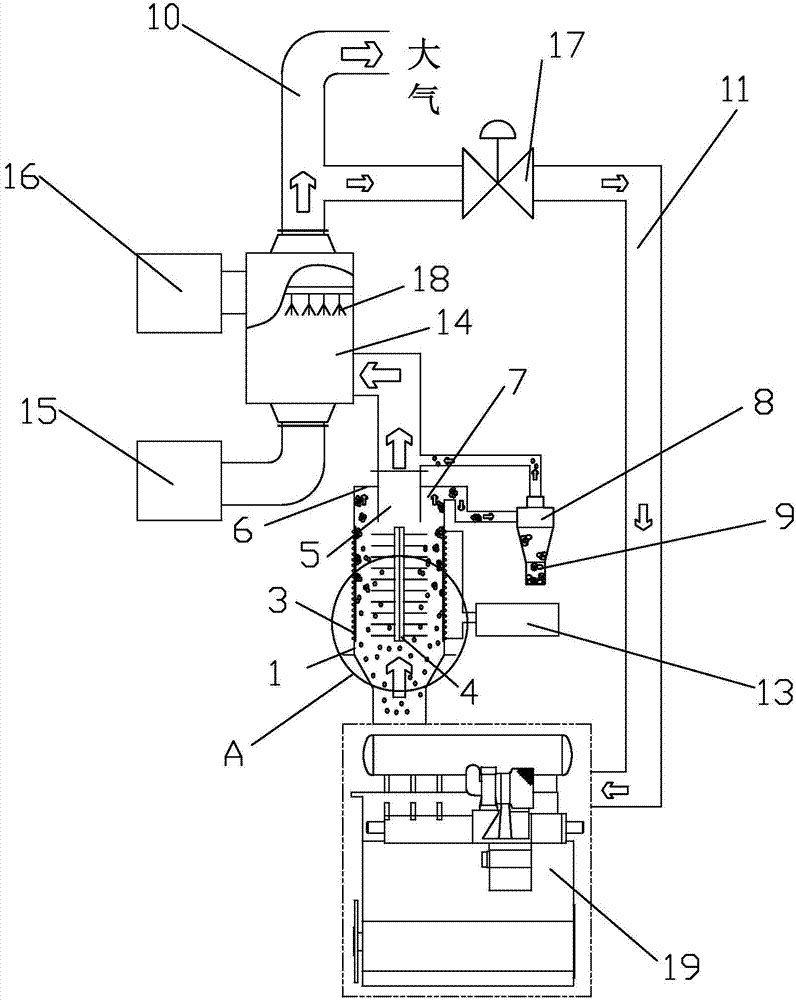

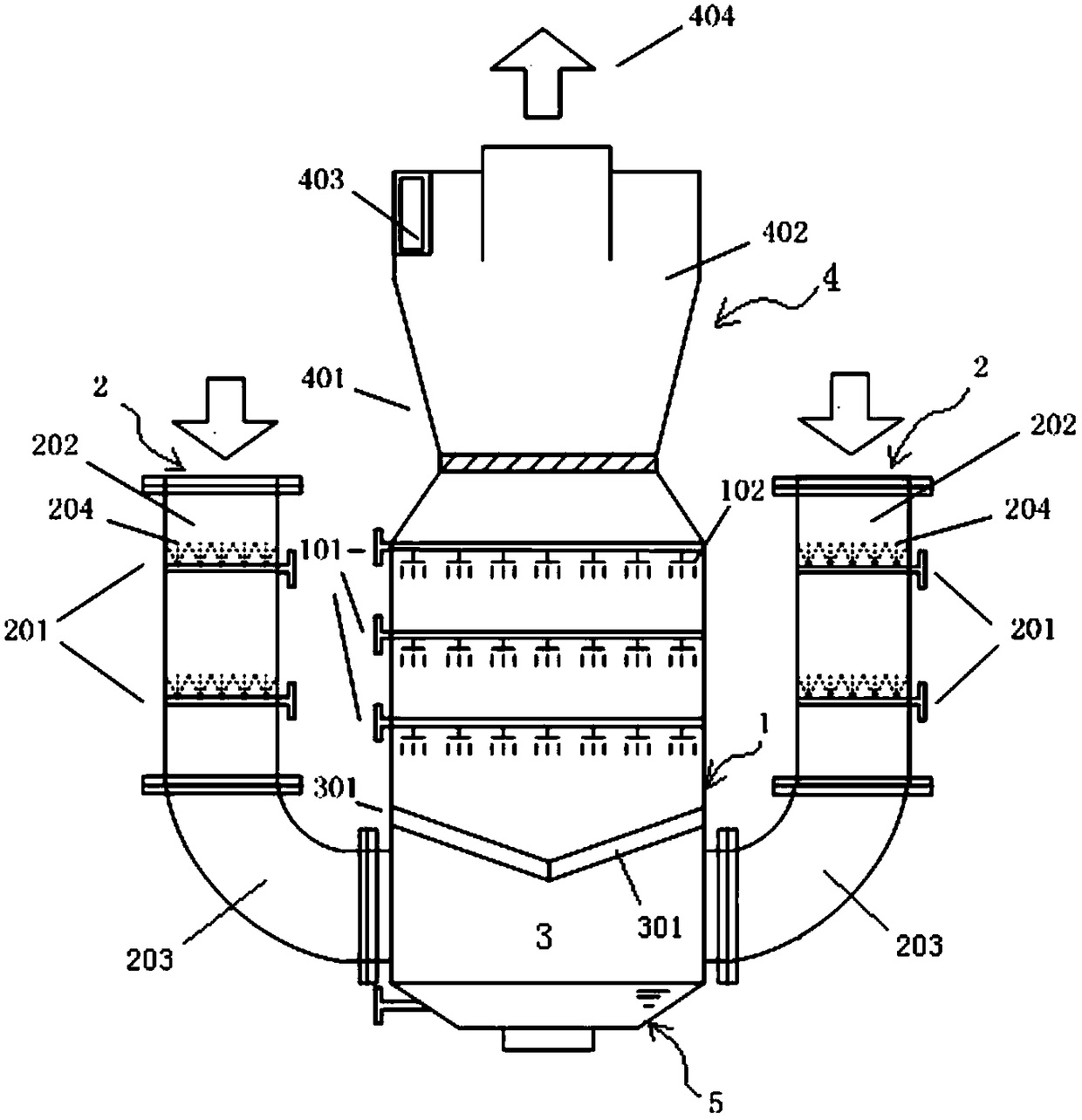

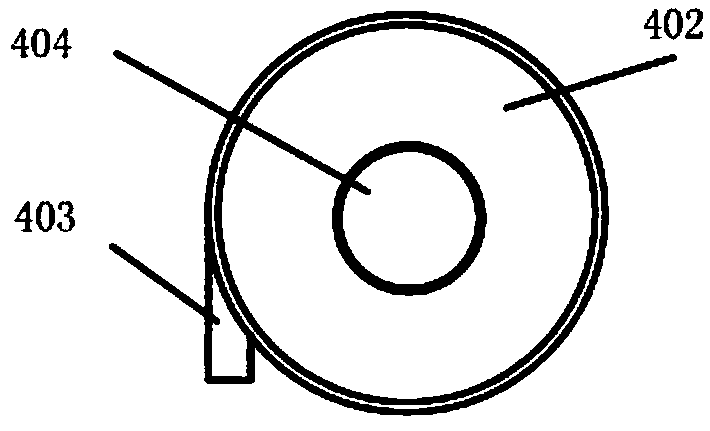

Novel ship exhaust gas multi-pollutant combined removing method and apparatus thereof

InactiveCN104492211AReduce volumeSmall pressure drop lossCombination devicesLiquid wasteParticulates

The invention discloses a novel ship exhaust gas multi-pollutant combined removing method. The novel ship exhaust gas multi-pollutant combined removing method comprises following steps: exhaust gas discharged by a ship diesel engine is delivered through an electromagnetic field, and is separated into relatively clean gas flow and particle-enriched gas flow; the particle-enriched gas flow is delivered into a cyclone separator, is processed, and then is mixed with the relatively clean gas flow; obtained gas flow is delivered into a wet washing device, and is processed using the wet washing device; a part of obtained waste gas is discharged into the air directly, and the other part of the obtained waste gas is delivered into the ship diesel engine via a recirculation bypass pipe. The invention also discloses a novel ship exhaust gas multi-pollutant combined removing apparatus comprising a cylindrical flue gas channel; and the wet washing device is communicated with the cyclone separator. The novel ship exhaust gas multi-pollutant combined removing method is capable of reducing secondary pollution of impurity components of waste liquid such as oil-containing particles on ocean environment, and separating recovery difficulty of solid particles, increasing clean degree of recirculated exhaust gas, and minimizing corrosion wearing of diesel engines.

Owner:DALIAN MARITIME UNIVERSITY

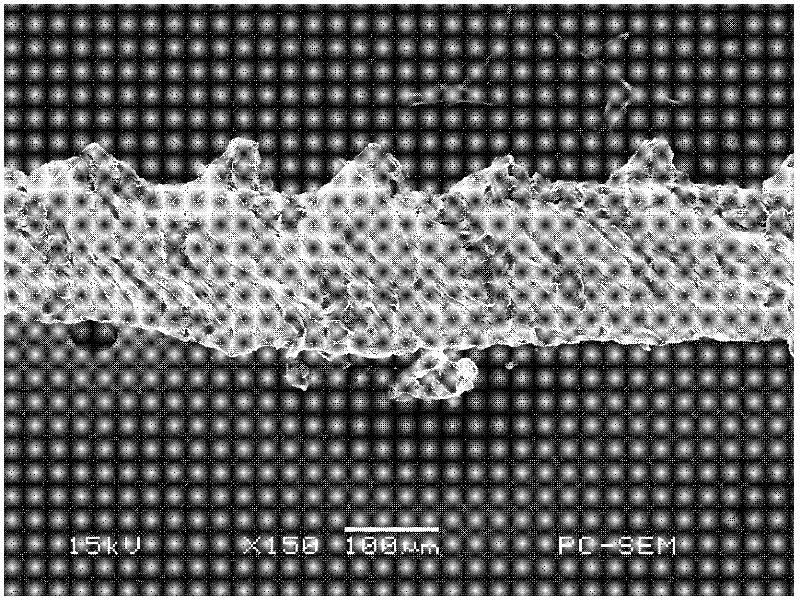

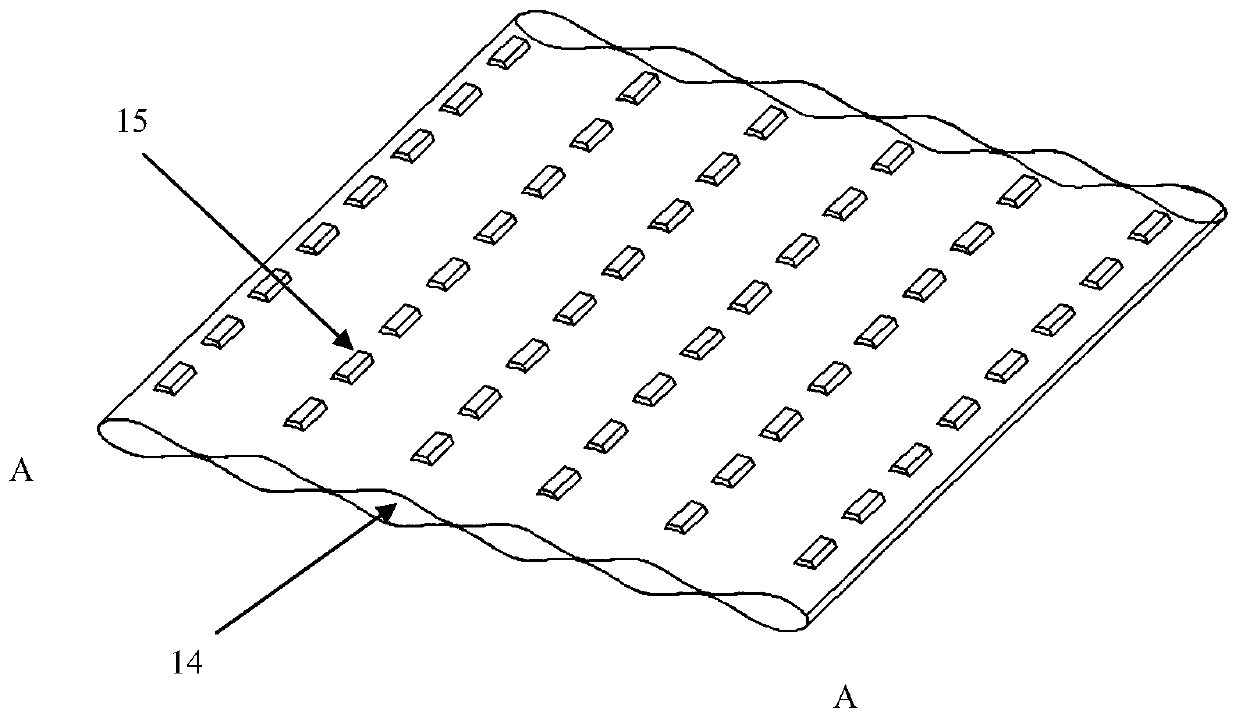

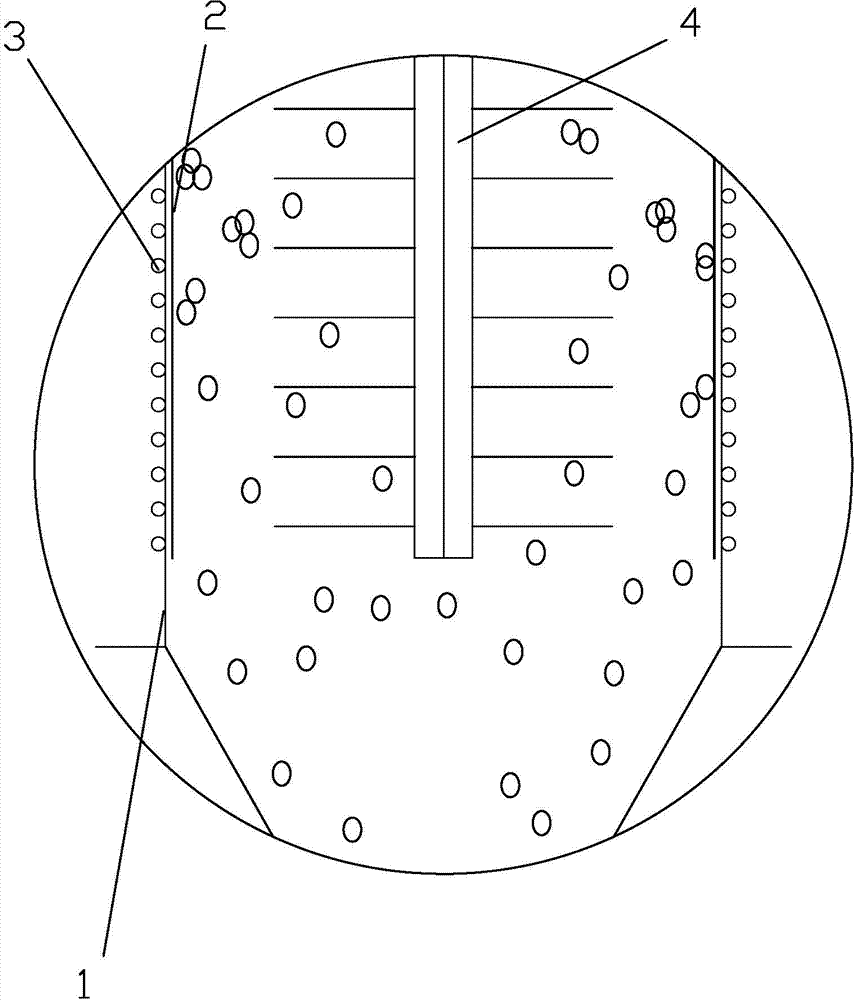

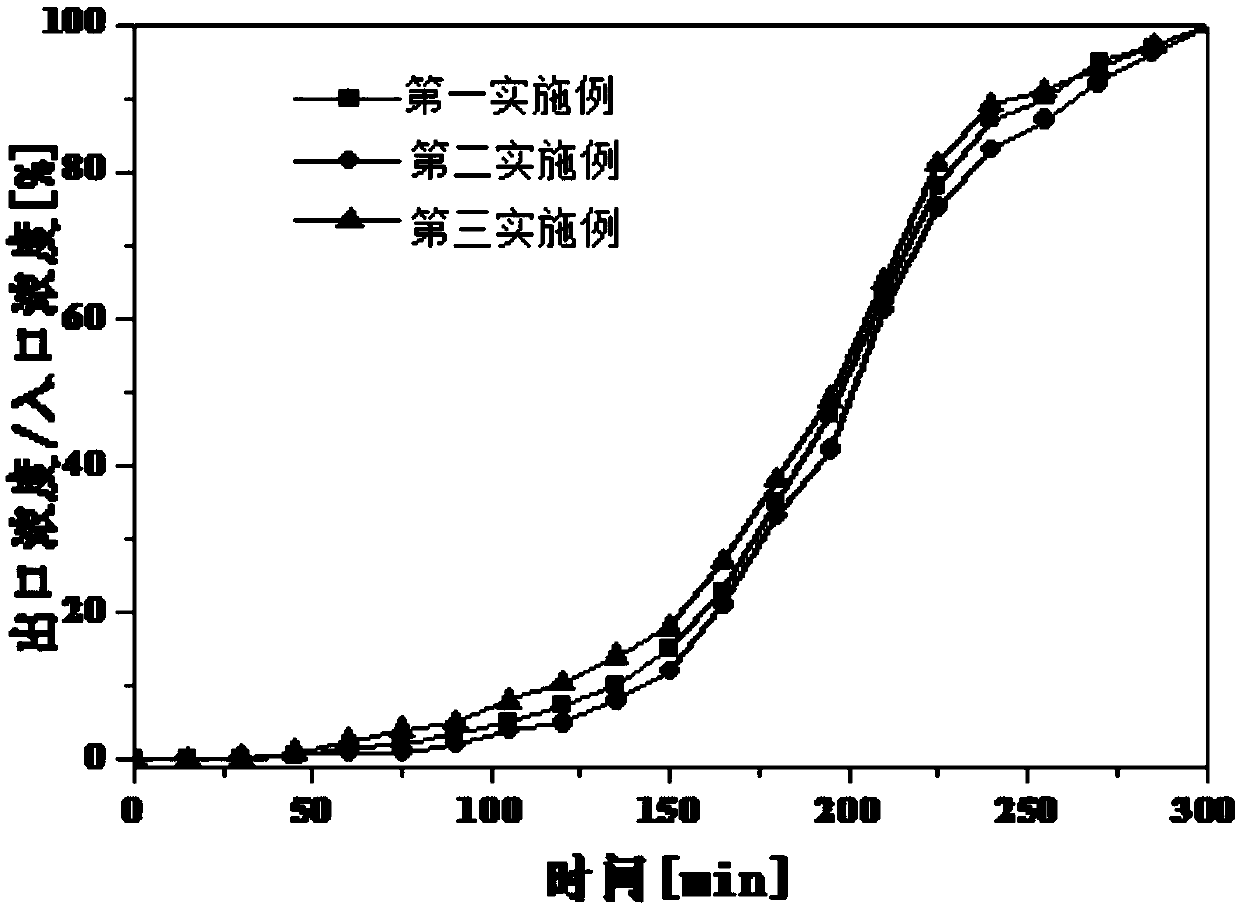

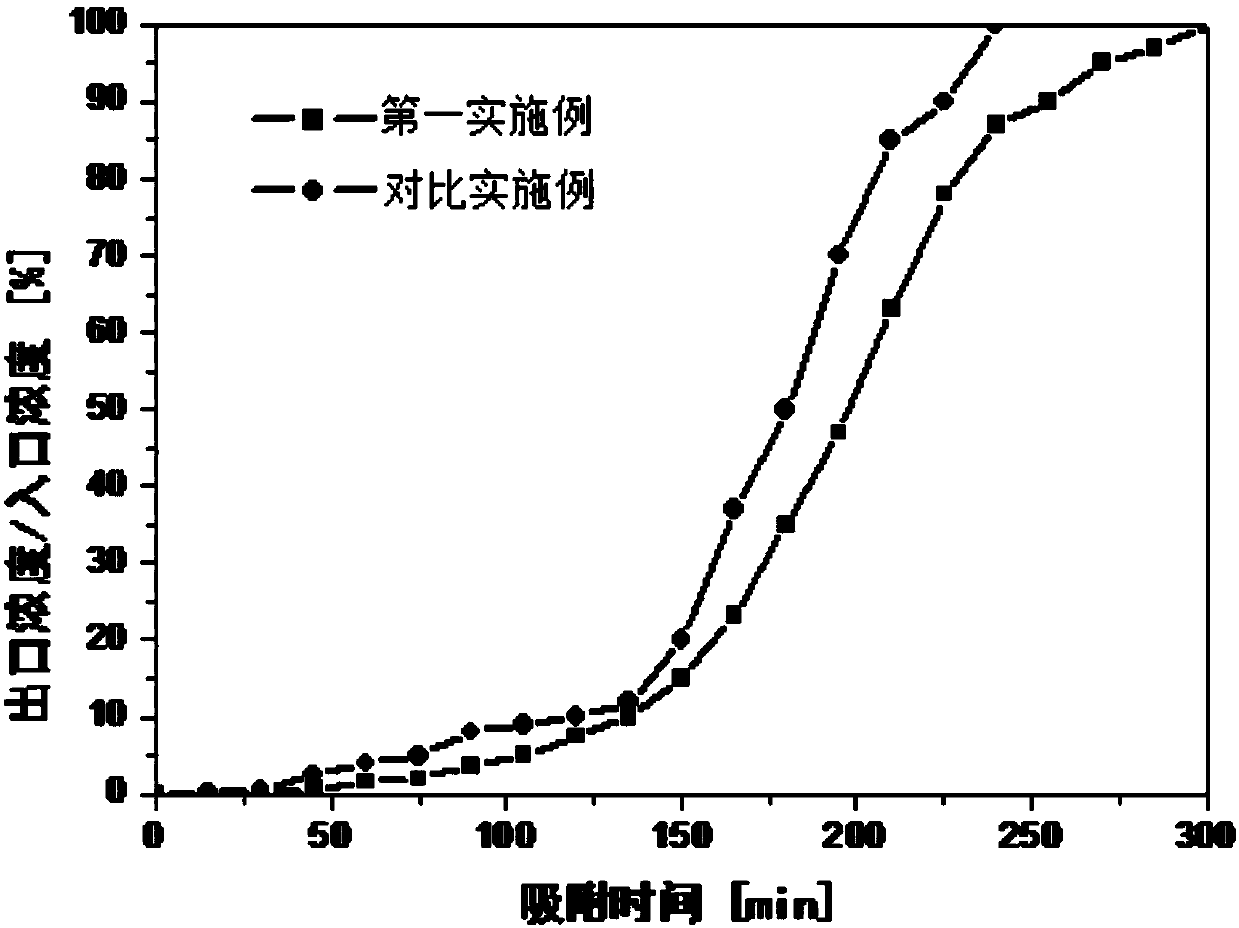

Glass fiber framework molecular sieve paper with porous structure and preparation method of paper

InactiveCN109647328ASimple manufacturing methodEasy to operateGas treatmentOther chemical processesGlass fiberMolecular sieve

The invention discloses glass fiber framework molecular sieve paper with a porous structure. The paper is prepared from, by mass, 70-80% of molecular sieves, 5-15% of glass fibers and 5-15% of silicondioxide. The invention also discloses a preparation method of the glass fiber framework molecular sieve paper with the porous structure. In the prepared glass fiber framework molecular sieve paper with the porous structured, the content of the molecular sieves reaches 75% or above, the content of adsorption materials is high, and the adsorption capacity in unit volume is large. The porous structure in the paper can obviously increase the specific surface area of the glass fiber framework molecular sieve paper, increase the contact area between the paper and organic waste gas and the adsorption capacity, prolong the service life, reduce the pressure drop loss and adapt to different temperature and humidity environments.

Owner:BEIJING LONGTAO ENVIRONMENTAL TECH CO LTD

Electric split axial-flow type regulating valve

ActiveCN104847917AImproved shut-off sealing performanceOutstanding FeaturesOperating means/releasing devices for valvesSlide valveCrankEngineering

The invention discloses an electric split axial-flow type regulating valve. The electric split axial-flow type regulating valve is characterized in that a crank connecting rod mechanism composed of a regulating valve rod, a turning crank arm, a pull rod, a regulating disc and a valve core and a regulating locking mechanism composed of a regulating bolt, a locking bolt and a regulating disc are assembled in the split valve body. The electric split axial-flow type regulating valve is convenient to pull and regulate the sealing position when the valve core is closed so as to compensate the mounting size error generated by producing, assembling and overlapping components, the valve core is firmly locked after regulating, the sealing surface of the valve core is capable of closely fitting with the valve seat sealing surface to form a tight and effective sealing pair, and the cut-off sealing performance of the axial-flow type regulating valve is greatly improved under the closed state. The trial proves that the electric split axial-flow type regulating valve has prominent advantages of simple structure, low manufacturing cost, convenience in production, assembly and regulation, fast regulation reaction speed, stable running, small vibration noise, large flow rate, small pressure drop and high cut-off sealing performance under closed state, and the electric split axial-flow type regulating valve is especially suitable for conveying pipelines of the petrochemical industry.

Owner:四川长仪油气集输设备股份有限公司

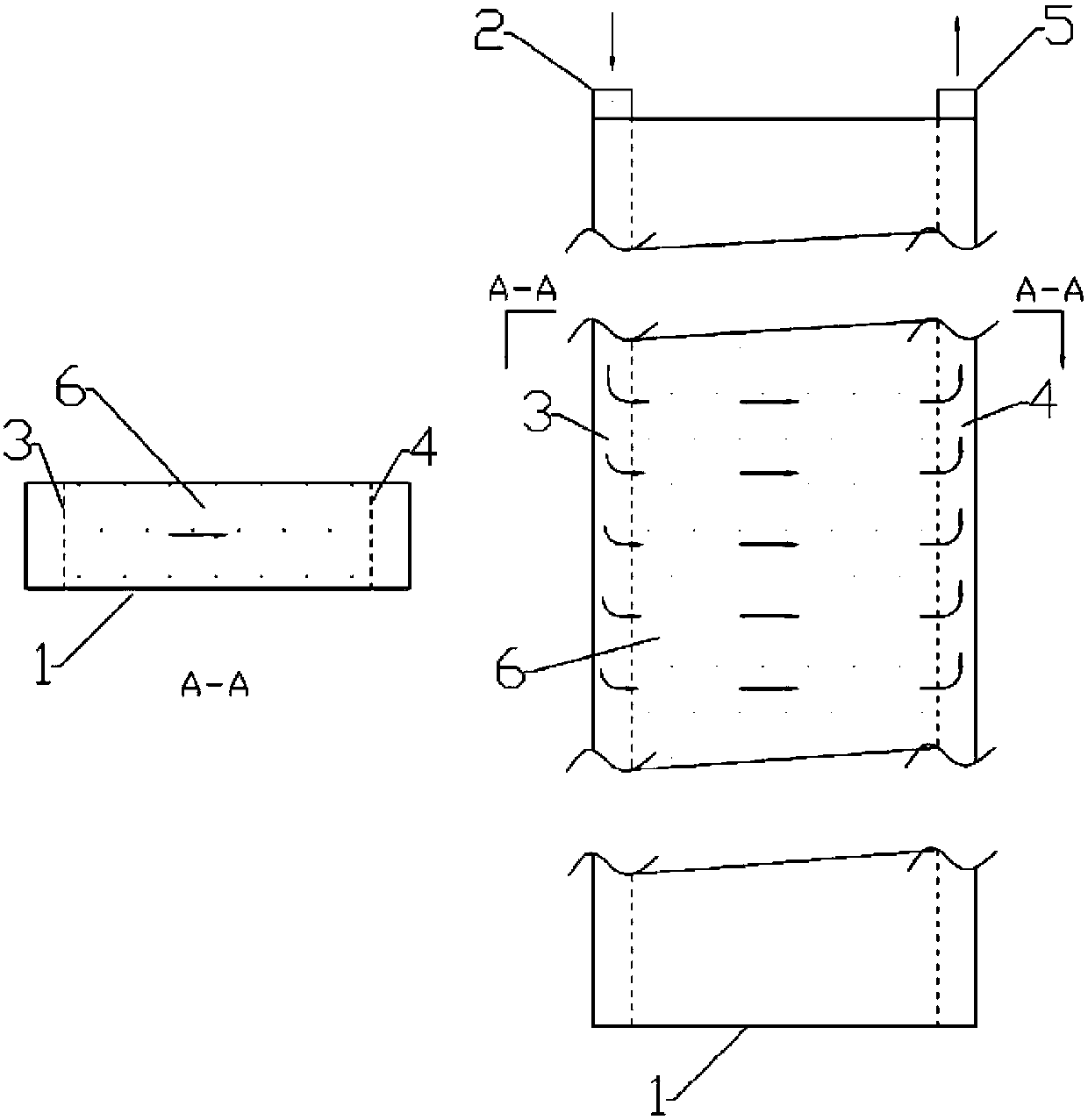

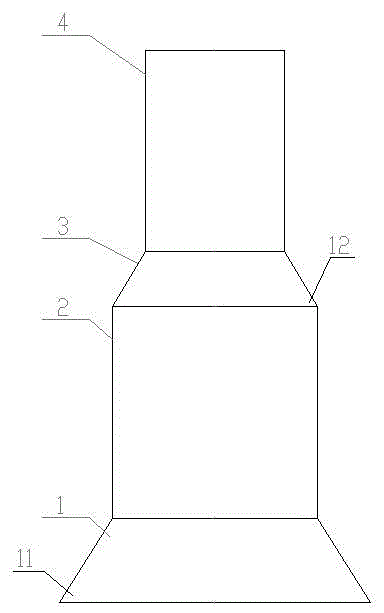

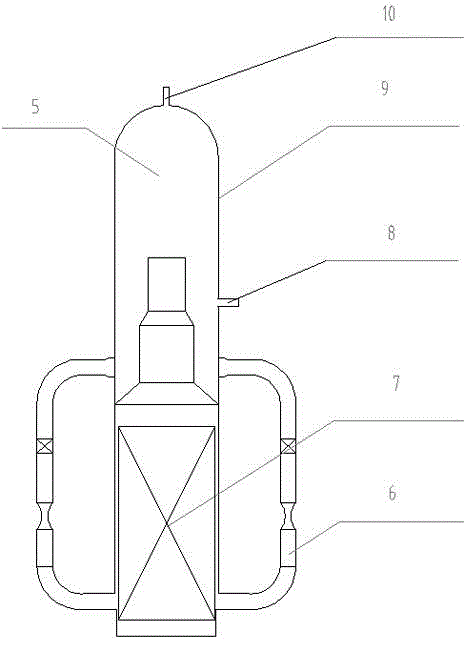

Steam-water separator and steam generator simulation body

ActiveCN103557512ASimple structureLow costSteam separation arrangementsThermodynamicsMechanical engineering

The invention discloses a steam-water separator. The steam-water separator is formed by the lower cone section (1), the ascending cylinder lower section (2), the upper cone section (3) and the ascending cylinder upper section (4); the lower cone section (1) and the upper cone section (3) are of structures with wide lower portions and narrow upper portions; the upper end of the lower cone section (1) is connected with the lower end of the ascending cylinder lower section (2); the upper end of the ascending cylinder lower section (2) is connected with the lower end of the upper cone section (3); the upper end of the upper cone section (3) is connected with the lower end of the ascending cylinder upper section (4). The invention also discloses a steam generator simulation body. According to the steam-water separator and the steam generator simulation body, rotating blades and a dryer are omitted under the condition that the test requirements are met and accordingly the structure is simple and the cost is low.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

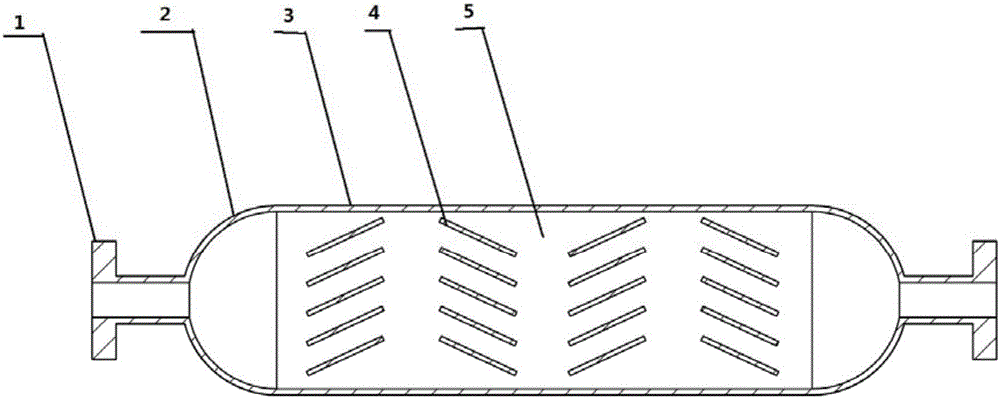

Pipeline airflow pulsation attenuation device of grid reciprocating compressor

InactiveCN105840460AResonant frequency adjustmentImprove the attenuation effectPositive displacement pump componentsPositive-displacement liquid enginesState of artUltrasound attenuation

The invention relates to a grid plate type reciprocating compressor pipeline air flow pulsation attenuation device, the attenuation device includes a cylinder body, a pulsation attenuation chamber is formed inside the cylinder body, a head is provided at the front end of the cylinder body, and an inlet method is provided at the front end of the head Lan, the pulsation attenuation cavity is provided with a deflector grid, and the deflector grid is set as an inclined structure; the rear end and front end of the cylinder are set as a mutually symmetrical structure. It can solve the problems of airflow pulsation and impact vibration that exist in the prior art when large-scale reciprocating compressor units are sucked and exhausted, making it wide-band, small in size, convenient in processing, and high in efficiency; it is aimed at traditional airflow pulsation attenuators In particular, the ordinary buffer tank can significantly reduce the volume. Under the condition of producing the same pulsation suppression effect, the volume of the device is significantly reduced. Compared with the buffer tank with a perforated plate, the device can reduce the air flow pressure drop loss.

Owner:BEIJING UNIV OF CHEM TECH

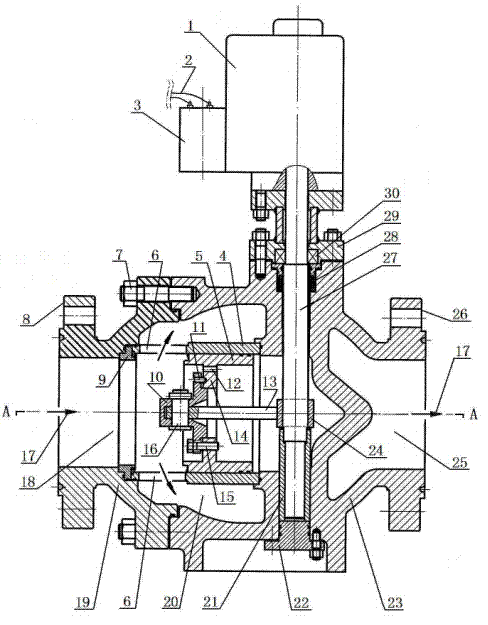

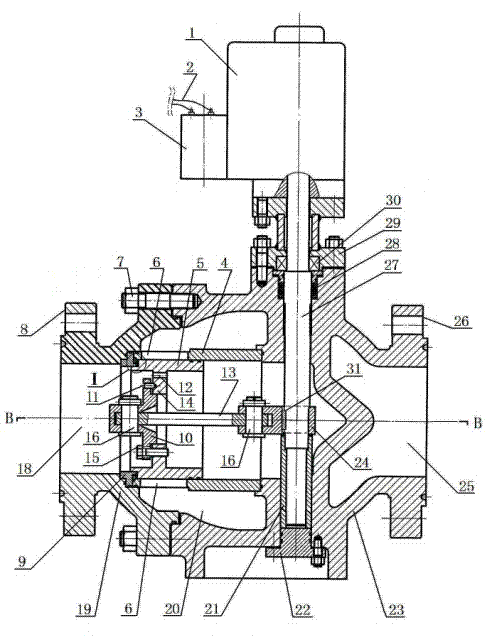

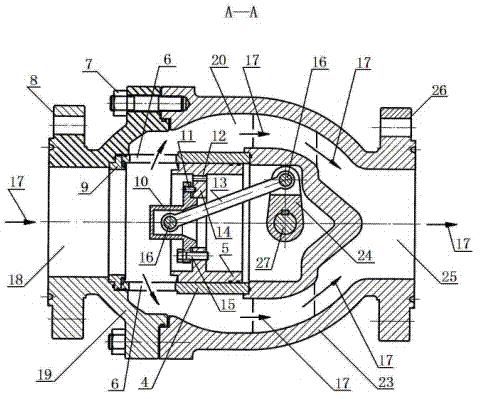

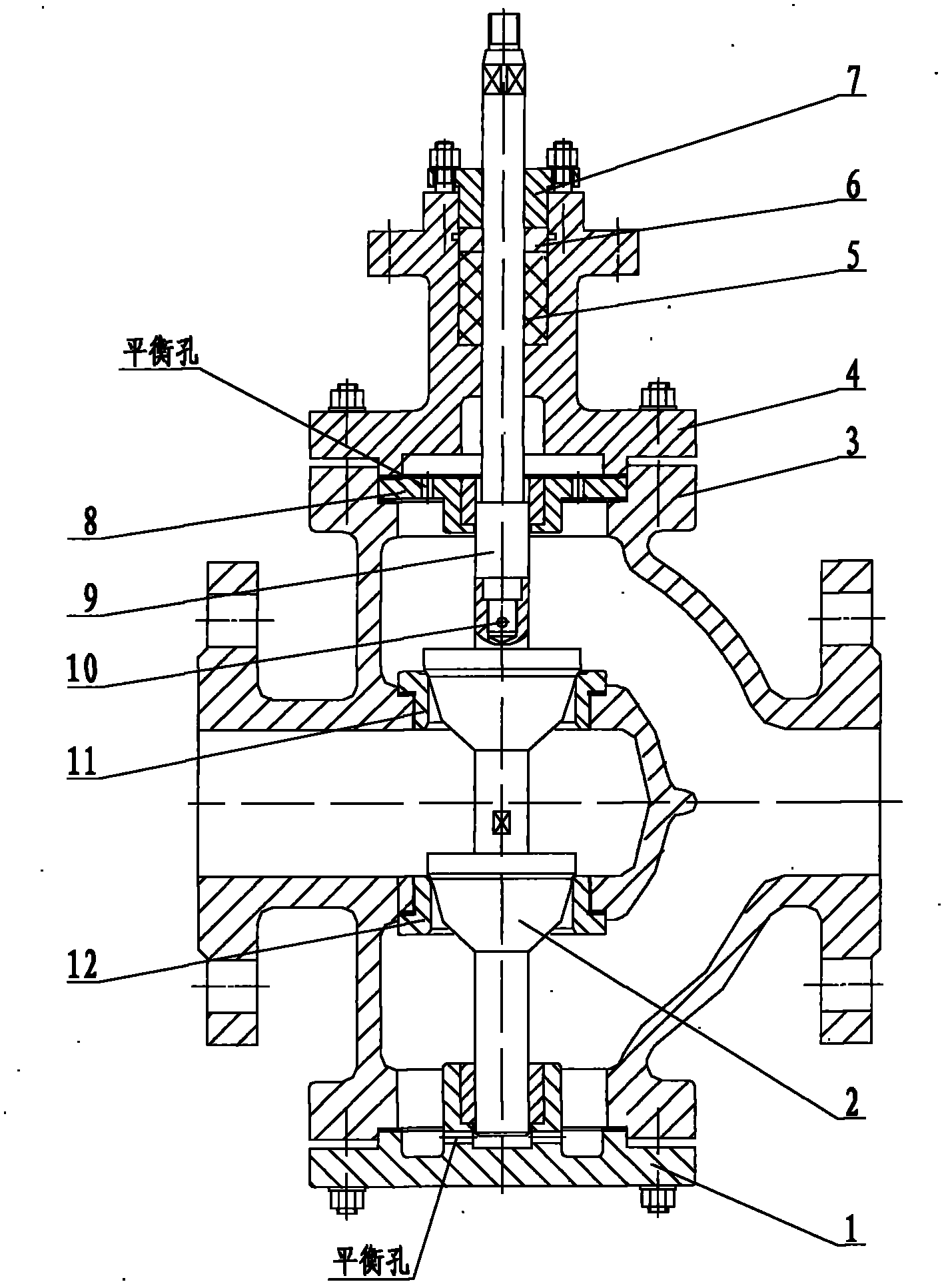

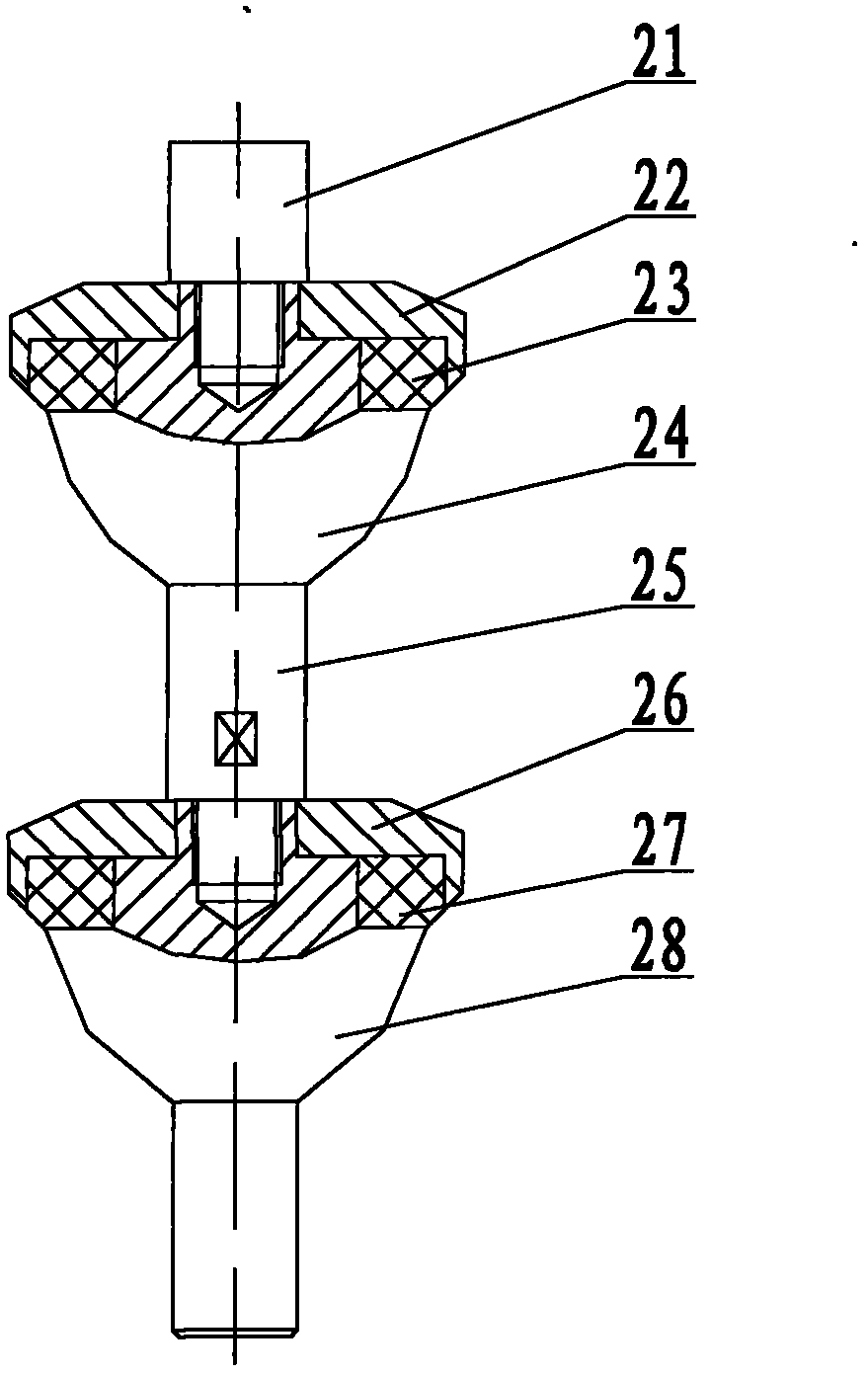

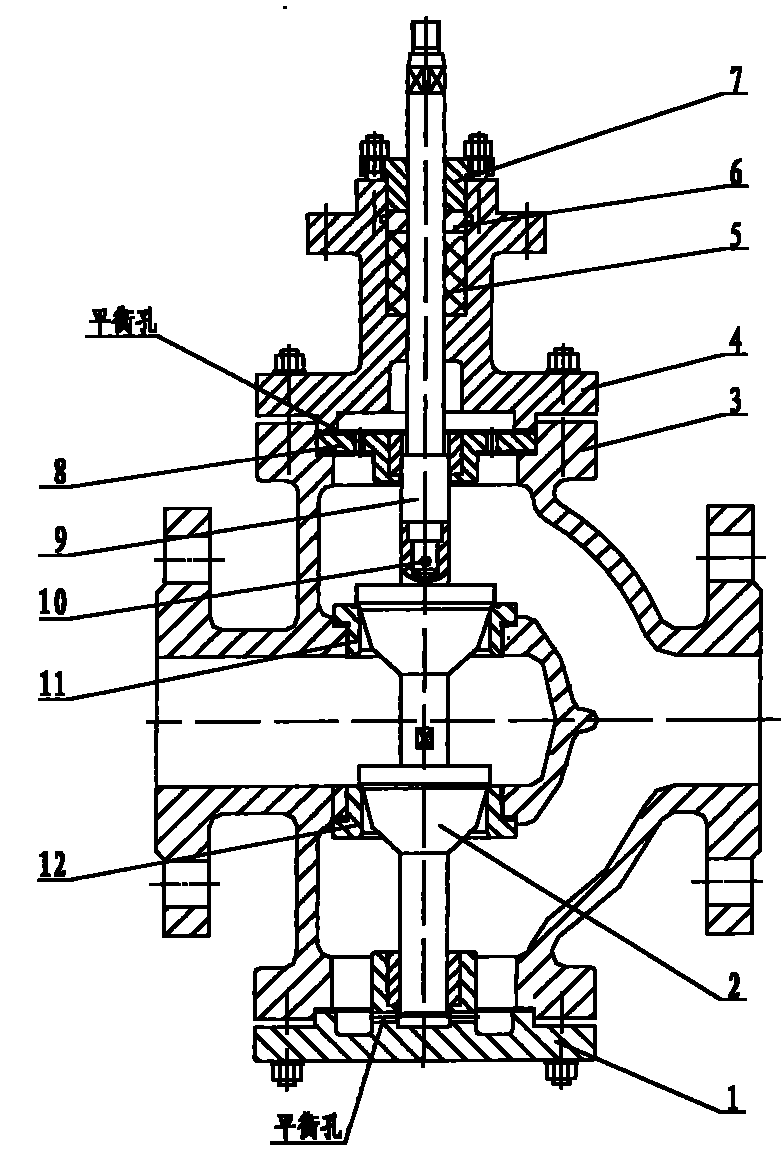

Regulating valve with double valve seats

InactiveCN102221103ASmall pressure drop lossHigh trafficEqualizing valvesSafety valvesEngineeringCaliber

The invention relates to a regulating valve with double valve seats. The regulating valve comprises a bottom cover, a valve core, a valve body, a sealing packing material, a packing material washer, a packing gland, an upper guide sleeve, a valve rod, a positioning pin, an upper valve seat, a lower valve seat and a connecting piece, wherein the valve body is a large valve cavity structure valve body with an upper valve seat insulating wall and a lower valve seat insulating wall; a double valve core structure of integrated same flow characteristic curve is adopted for the valve core; a double guide structure of two orientations at the upper guide sleeve and a valve body bottom part blank cap is adopted; balance holes are manufactured on the blank cap and the upper guide sleeve; and copper sleeves manufactured by adopting tin bronze is adopted for the embedding of the guide holes on the upper guide sleeve and the blank cap. The invention has the beneficial effects of less loss of pressure drop, large flow, wide adjustable extent, good action stability, and the regulating valve is especially suitable for the use of a pipeline system that the caliber is greater than DN 200, the front and rear pressure difference of the valve is great, the required rated flow is great, the leakage level requirement is low, and mediums have fine impurity working conditions.

Owner:ZHEJIANG KEHAI INSTR

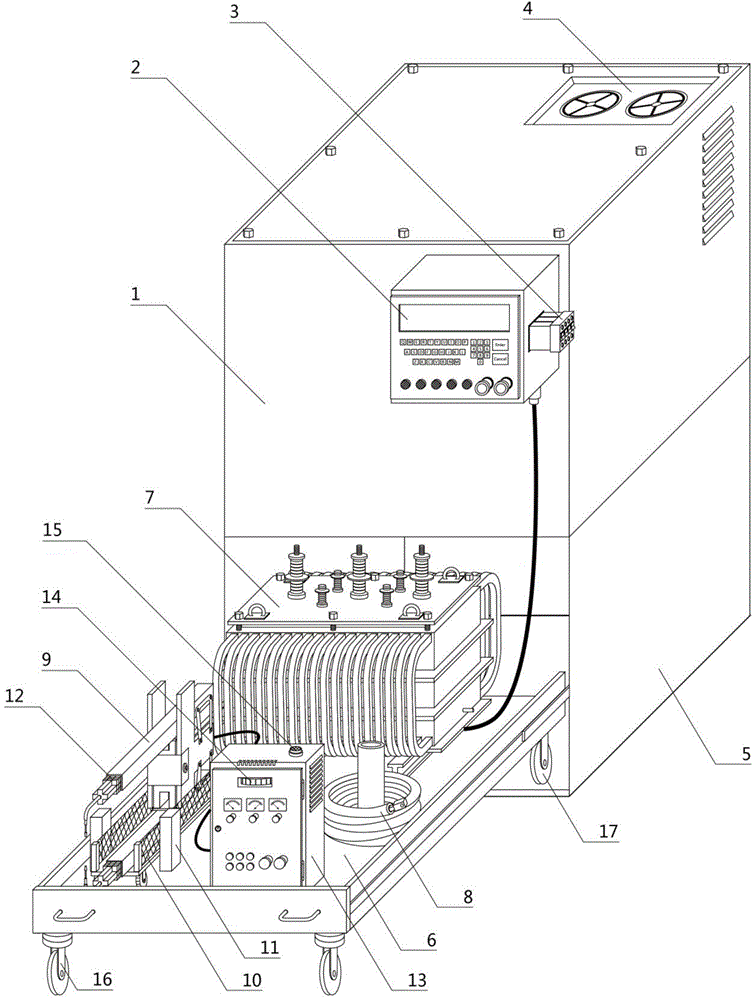

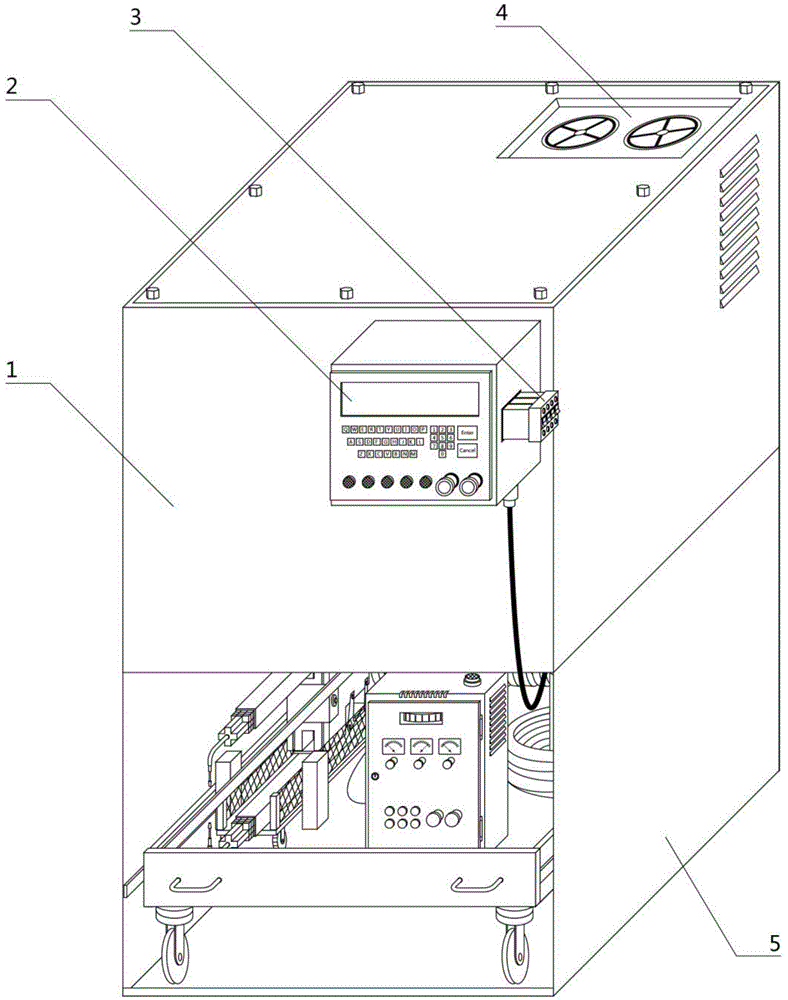

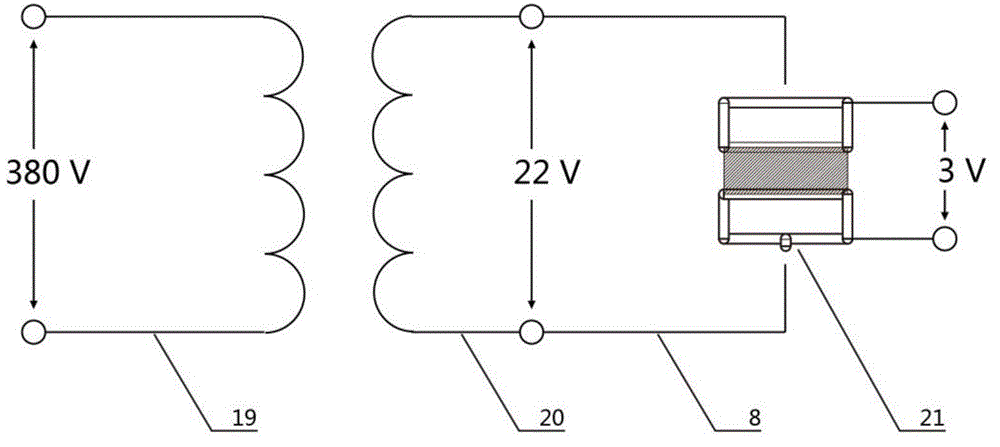

Split type sealing weld mechanism

ActiveCN104889626ADoes not affect normal welding workStable currentWelding/cutting auxillary devicesAuxillary welding devicesTransformerEngineering

The invention aims at providing a split type sealing weld mechanism. The technical scheme includes that the split type sealing weld mechanism is broken into parts in size, a transformer, a water passing cable, welding pliers and a control box are fixed on the upper portion of a bottom disk so as to form a triune composite structure, and the bottom disk is designed in a drawer type structure, and thereby is convenient to use and maintain. Four pulleys are arranged on the lower portion of the bottom disk, and thereby achieve movement in underground welding operation, and effectively solve problems in underground welding of generator stator windings. A contact thermometer of an alarm bell uses an end face copper thermal resistor, and a moving coil type indicating regulator and the alarm bell are arranged in the control box. When the split type sealing weld mechanism performs the welding, the control box, the welding pliers and an operator are abutted, and therefore the operator can accurately hear an alarm signal. A layer of cable clamp is added on the outer side of the water passing cable, and therefore a winding phenomenon in use is avoided, and loss of a lead wire is reduced. The split type sealing weld mechanism adds functions on a weld machine, improves applicability of the weld machine, improves economic benefit for a company, and recoups investment cost in a short term.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

Ship exhaust gas desulfurization device

ActiveCN108939755AShare desulfurization loadReduce occupancyGas treatmentUsing liquid separation agentContact timeProcess engineering

The invention discloses a ship exhaust gas desulfurization device. The device comprises a desulfurization spray unit and pretreatment flues on both sides of the desulfurization spray unit. A pre-spraying layer is arranged in the pretreatment flue. A spraying layer is arranged in the desulfurization spray unit. A flow guiding unit for receiving exhaust gas from the pretreatment flue, uniformly distributing gas flows and feeding the gas flows into the spraying layer. The desulfurization spray unit is connected to a defogging unit for absorbing moisture of particles in the tail gas purified by the spraying layer and growing and separating the particles. The device has long gas-liquid contact time and high desulfurization efficiency and improves the space utilization rate of the ship.

Owner:SOUTHEAST UNIV

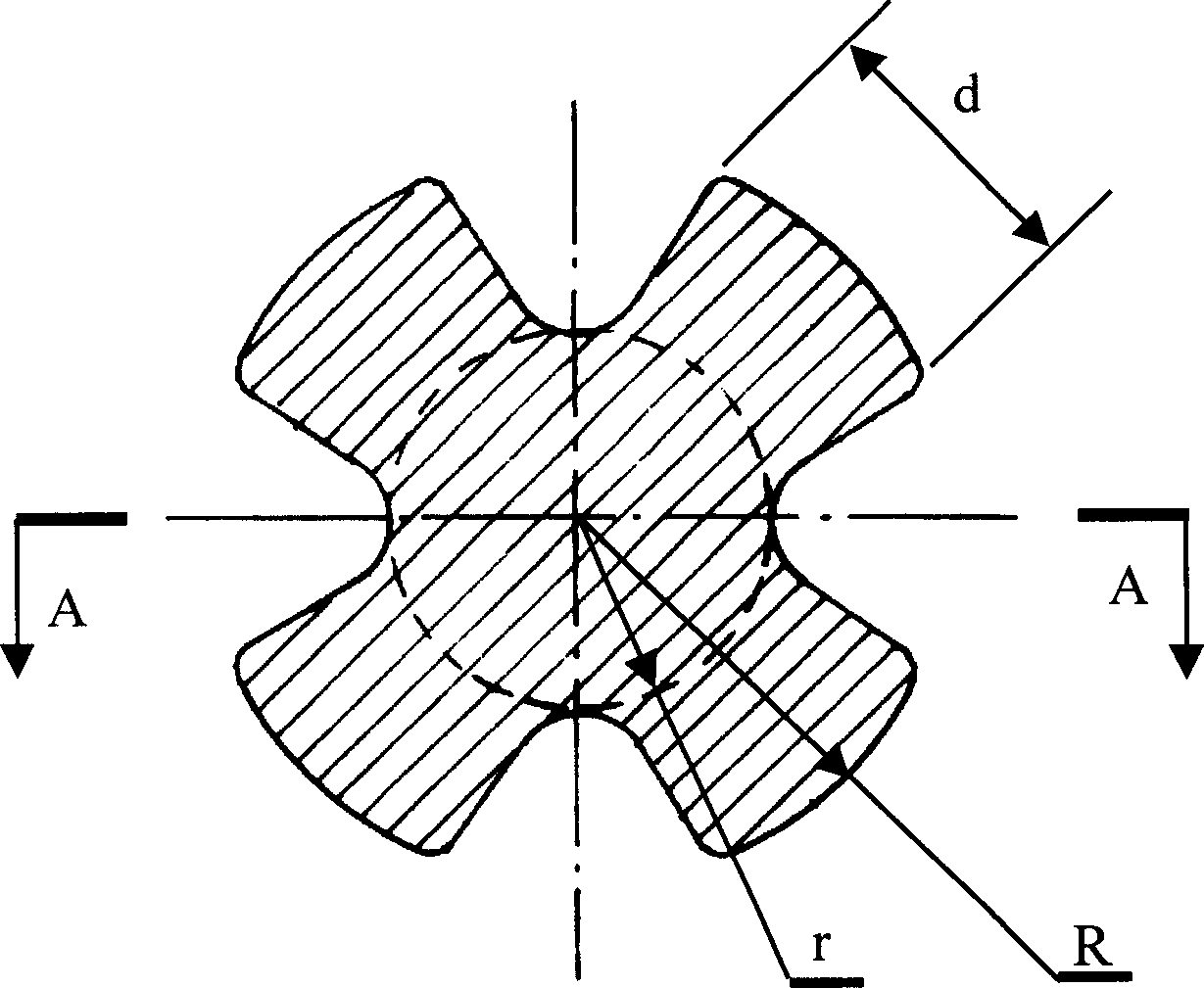

Catalyst for producing vinyl acetate

InactiveCN1428199ASuitable particle shapeSmall pressure drop lossOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsAcetic acidSpherical granule

The present invention relates to a catalyst for preparing vinyl acetate by using ethylene, acetic acid and oxygen gas or oxygen-containing gas as raw material and adopting gas-phase reaction. Its carrier is SiO2 or mixture of SiO2 and Al2O3, and the loaded active component contains Pd and KOAc, the active component is formed into egg-shell type non-uniform distribution, said catalyst is made into spherical granule, radium R of the sphere is 2-4 mm, and surrounding a central shaft of sphere, on the surface of the sphere 3-8 grooves whose cross-section is made into arched form are cut along the longitudinal direction, the groove is extended toward two ends of the central shaft from middle portion of the sphere and progressively exposed from surface of the sphere, and the distanced between grooves is greater than 1.5 mm. Said catalyst has high crushing strength, larger packing voidage and proper specific surface area.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com