Heat exchanger perforated fins

A plate-fin heat exchanger and fin technology, applied in the direction of indirect heat exchangers, heat exchanger types, heat transfer modification, etc., can solve the problems of not providing guidance, not showing perforation, etc., to reduce capital and Operating cost, overall capital and operating cost reduction, effect of reduced pressure drop loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

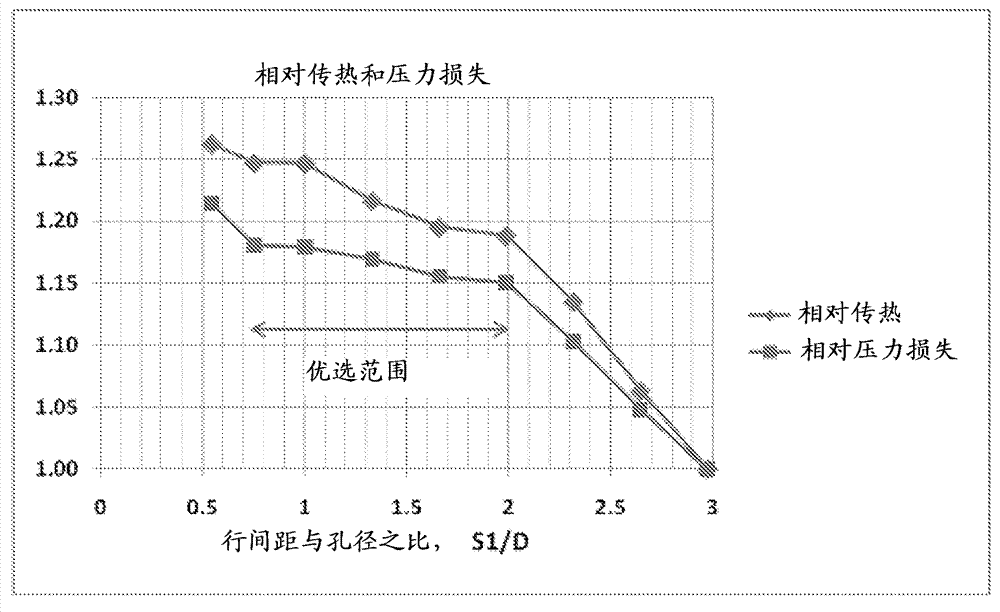

[0043] To better understand the effect of perforations within the fin geometry, several sample problems were solved using computer fluid dynamics (CFD). When using this technique, the computation is usually constrained to some repetitive structure in order to limit the computational size of the problem. However, the overall geometry of the heat exchanger is very complex when we try to quantify the effect of a specific perforation pattern, even when we restrict the problem to a single subchannel within the plate-fin passage. For this reason, different types of approximations are used.

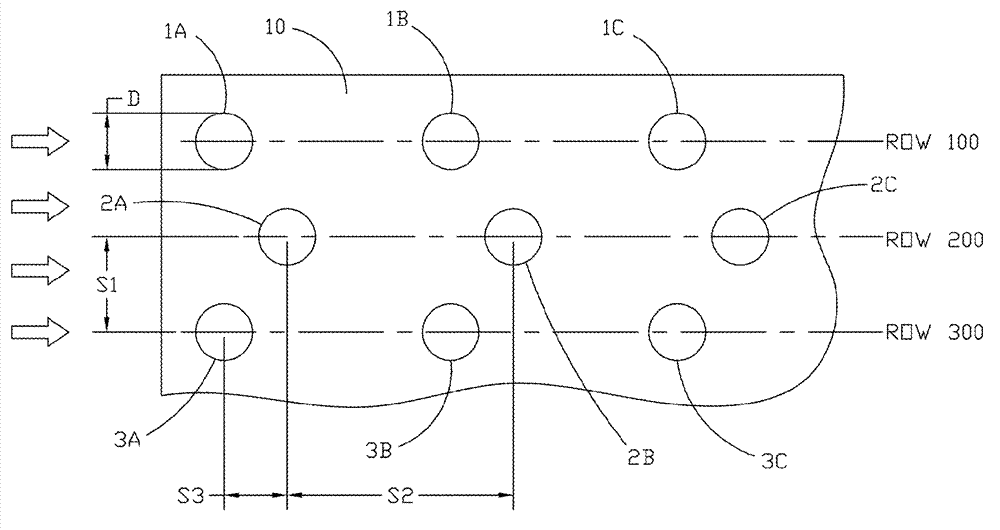

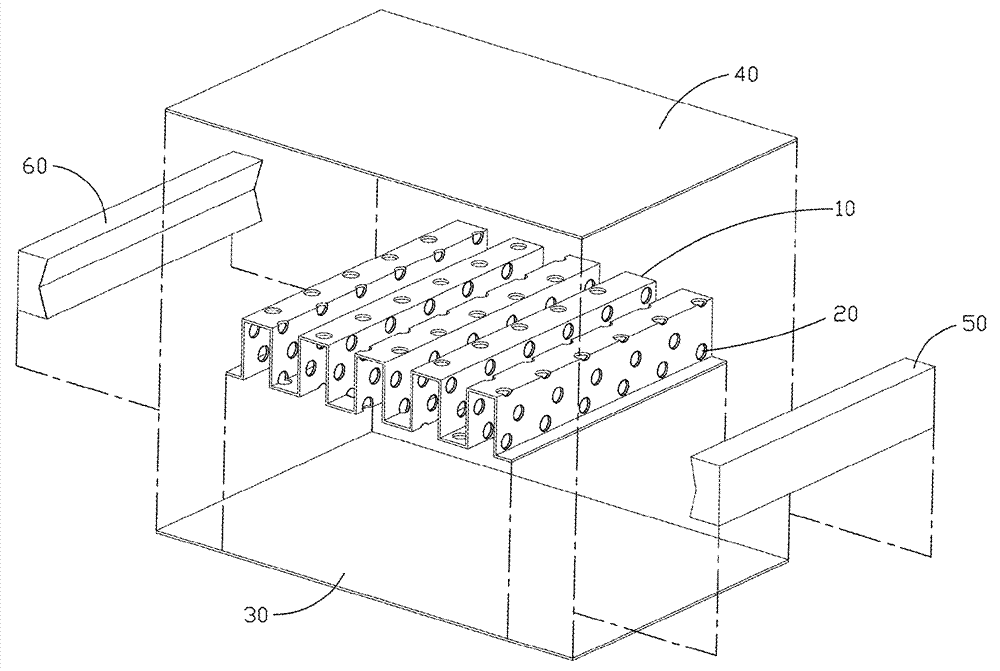

[0044]In most plate-fin exchangers, the secondary surface area tends to be the majority of the total area. As noted above, this is the area represented by the fin legs spanning and separating the divider plates or plates 30, 40 representing the major surface area. To understand the effect of the positioning of the perforations, a typical periodic area of two infinite parallel plates was mode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Perforation diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com