Isolated type H-bridge drive device

A driving device and isolated technology, applied in the field of power supply, can solve the problems of multiple design costs, inability to share ground, and low product reliability, and achieve the effect of increasing performance and electrical characteristics, wide application range, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

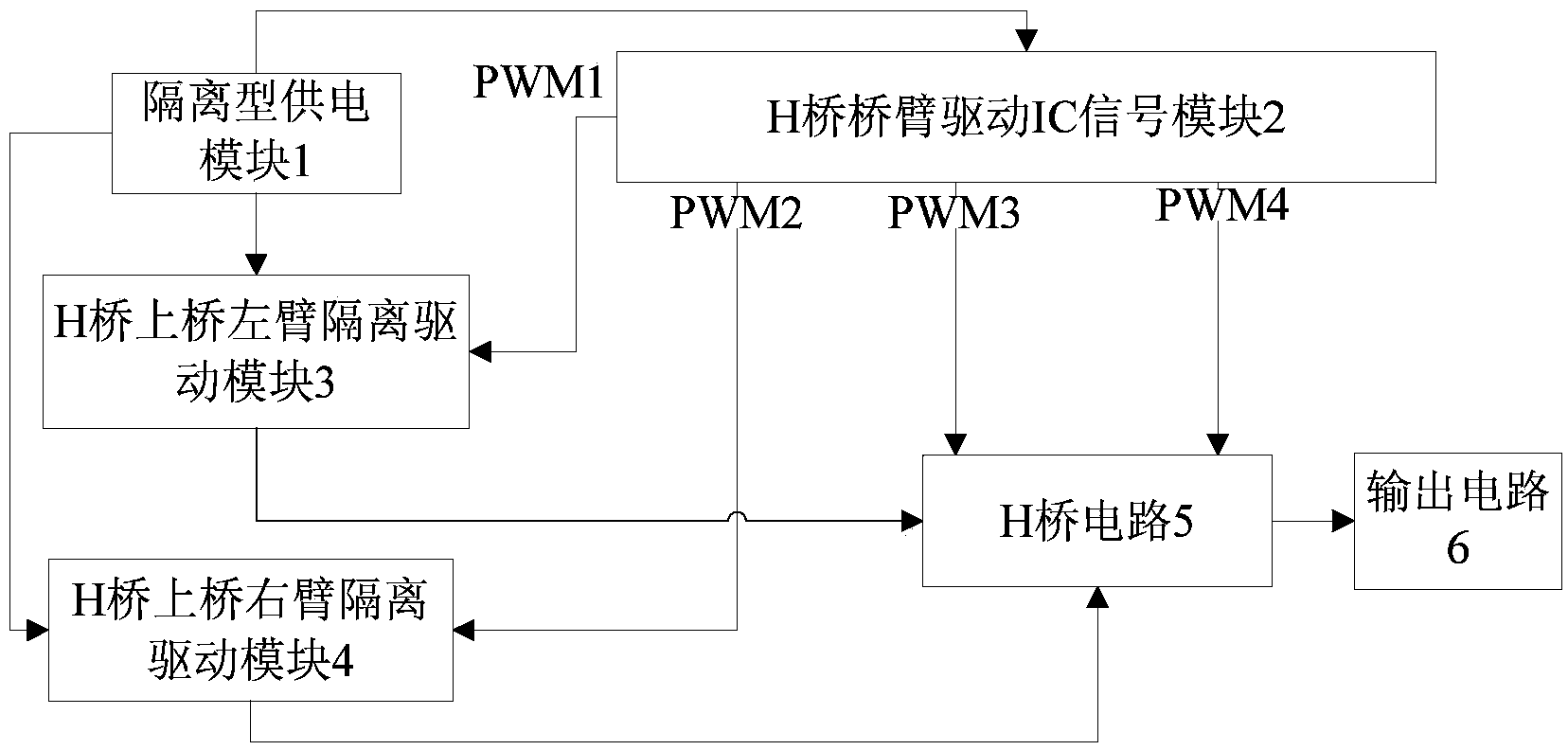

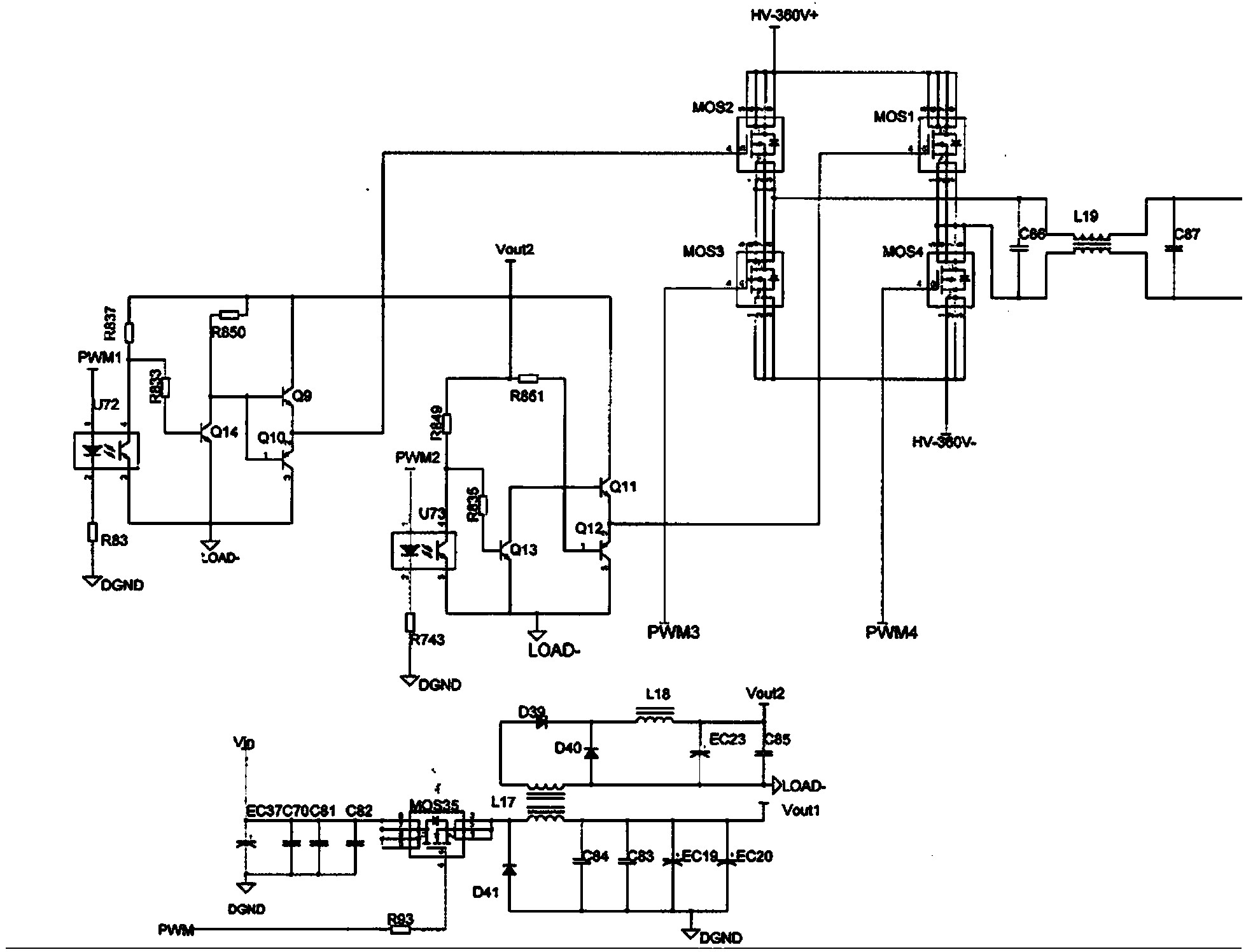

[0014] Such as figure 1 , 2 , an isolated H-bridge driving device, comprising an isolated power supply module 1, an H-bridge arm drive IC signal module 2, an isolated drive module 3 for the left arm of the upper bridge of the H bridge, an isolated drive module 4 for the right arm of the upper bridge of the H bridge, and an isolated drive module 4 for the upper arm of the H bridge. Bridge circuit 5 and output circuit 6;

[0015] The isolated power supply module 1 outputs two voltages, one voltage is connected to the driver IC signal module 2 of the H bridge arm, and the other voltage is connected to the left arm isolated driver module 3 of the upper bridge of the H bridge and the isolated driver module 4 of the right arm of the upper bridge of the H bridge ;

[0016] H-bridge arm drive IC signal mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com