Preparation method of high-power carbon-coated synthetic graphite negative electrode material

An artificial graphite negative electrode, carbon coating technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems affecting battery cycle performance, graphite layer peeling, pulverization, etc., achieve good application performance, reduce graphitization cost, Yield-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

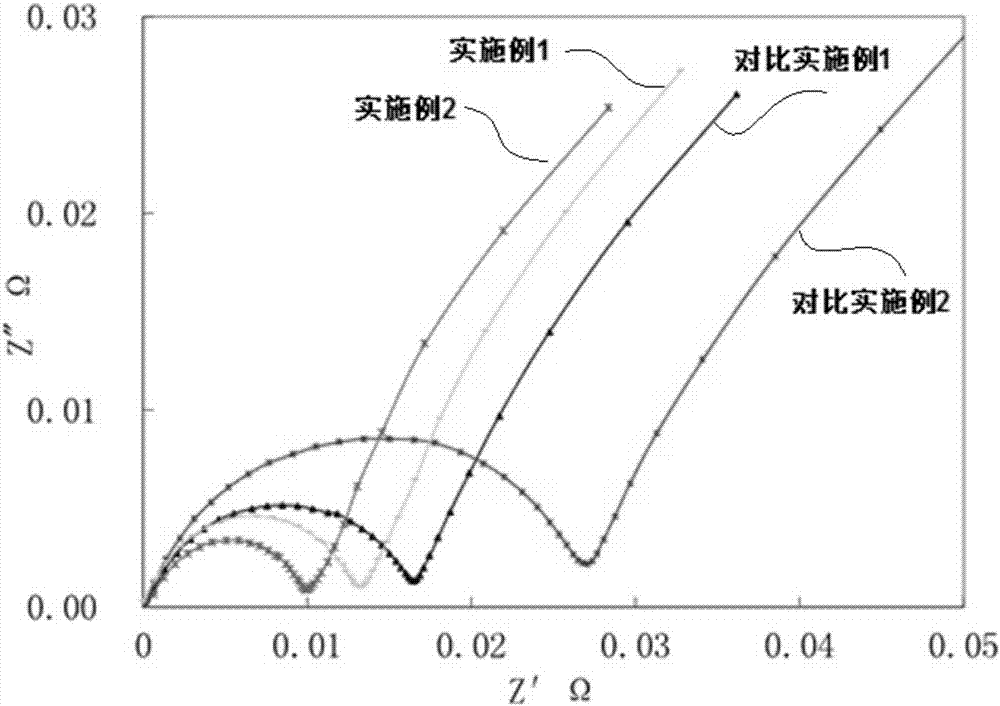

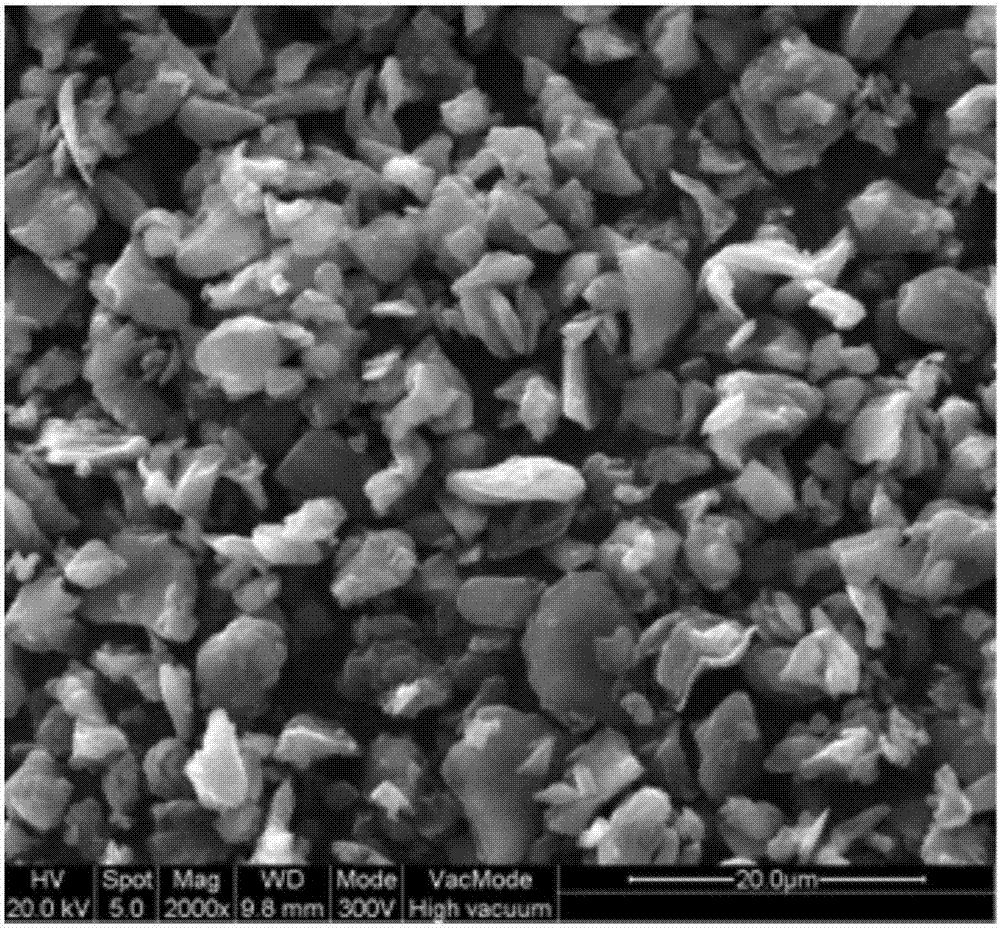

Embodiment 1

[0035] Weigh 100 kg of coal-based green coke raw material A, crush and process it to 5.0 μm.

[0036] The raw material B of coal tar pitch was weighed, crushed and classified to form a fine powder with a particle size of 2.5 μm.

[0037] The pulverized fine powder of material A is modified at a temperature of 630°C, and then graphitized at room temperature at 2700-2800°C for 50 hours in a resistance graphitization furnace.

[0038] The graphitized material is dispersed and graded to obtain a single particle of artificial graphite with a particle size of 5.0-5.5 μm.

[0039] Weigh 15kg of 5.0-5.5μm single-particle artificial graphite, add 0.6kg of pulverized raw material B, mix well and put it into the fusion machine, modify it at a frequency of 45Hz for 4.5min, and the modified material is processed in a pusher kiln. Medium temperature carbonization treatment at 1150°C for 12 hours to cure the cladding layer.

[0040] The carbonized material is mixed and classified with a co...

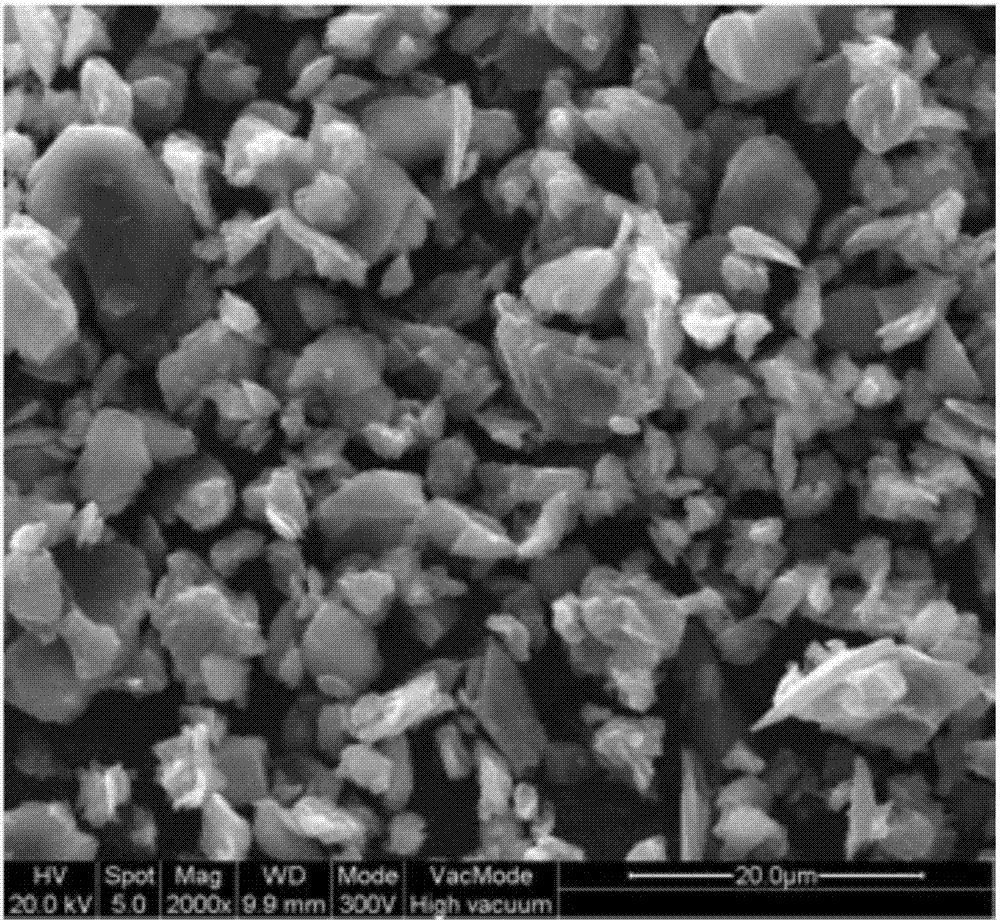

Embodiment 2

[0046] Weigh 100 kg of coal-based green coke raw material A, crush and process it to 7.0 μm.

[0047] The raw material B of coal tar pitch was weighed, crushed and classified to form a fine powder with a particle size of 2.5 μm.

[0048] The pulverized fine powder of material A is modified at a temperature of 630°C, and then graphitized at room temperature at 2700-2800°C for 50 hours in a resistance graphitization furnace.

[0049] The graphitized material is dispersed and graded to obtain a single particle of artificial graphite with a particle size of 7.0-7.5 μm.

[0050] The graphitized materials were dispersed and graded. Weighed 15kg of the graded materials, added 0.6kg of pulverized raw material B, mixed evenly and put them into the fusion machine, and modified them at a frequency of 45Hz for 4.5min. After modification, The material is carbonized at a temperature of 1150°C for 12 hours in a pusher kiln to solidify the coating layer.

[0051] The carbonized material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com