Heat exchange plate with streamline structure, and printed circuit board heat exchanger with same

A heat exchange plate and streamlined technology, applied in the field of printed circuit board heat exchangers, can solve the problems of heat exchange performance and pressure drop loss that cannot meet actual needs, and achieve the effect of reducing pressure drop loss and improving heat exchange performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments.

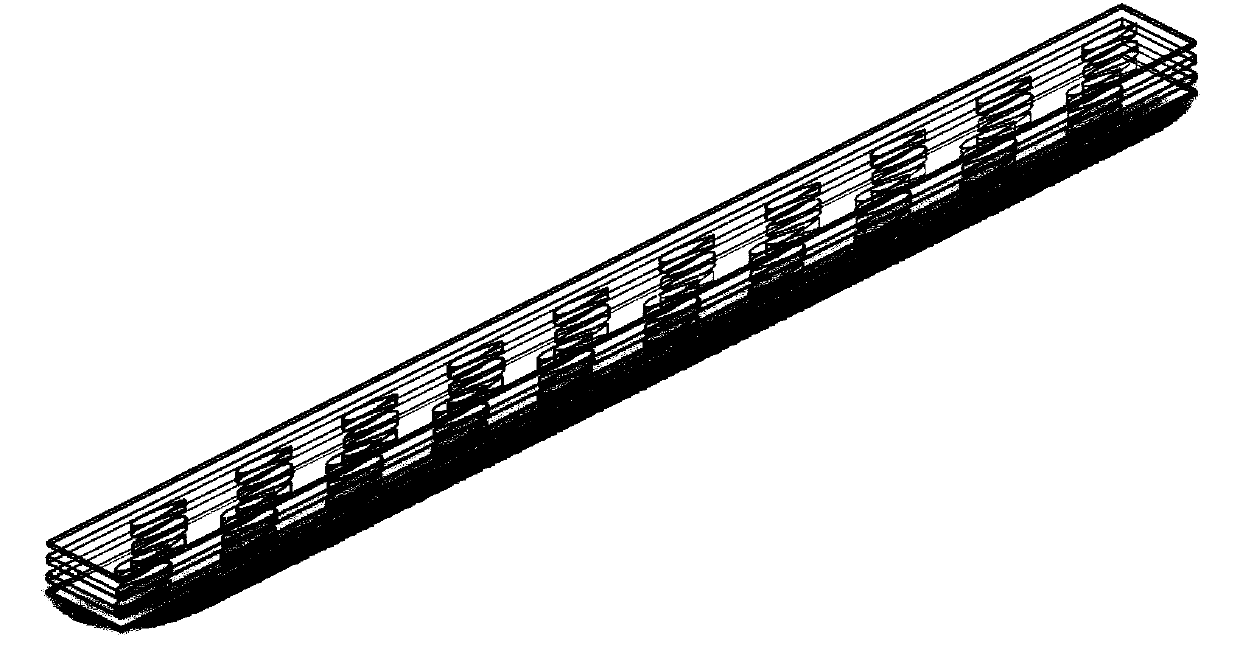

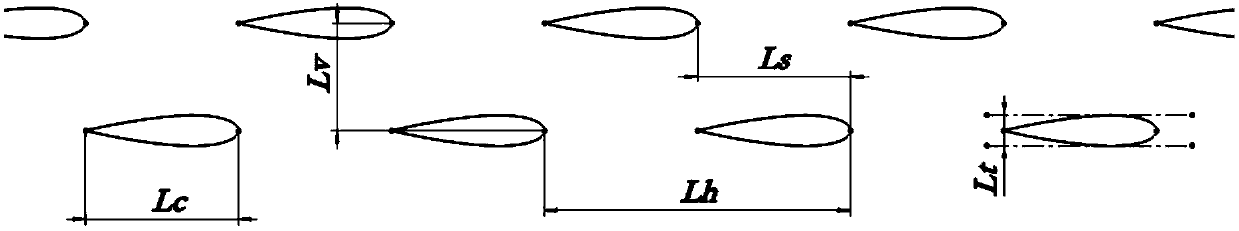

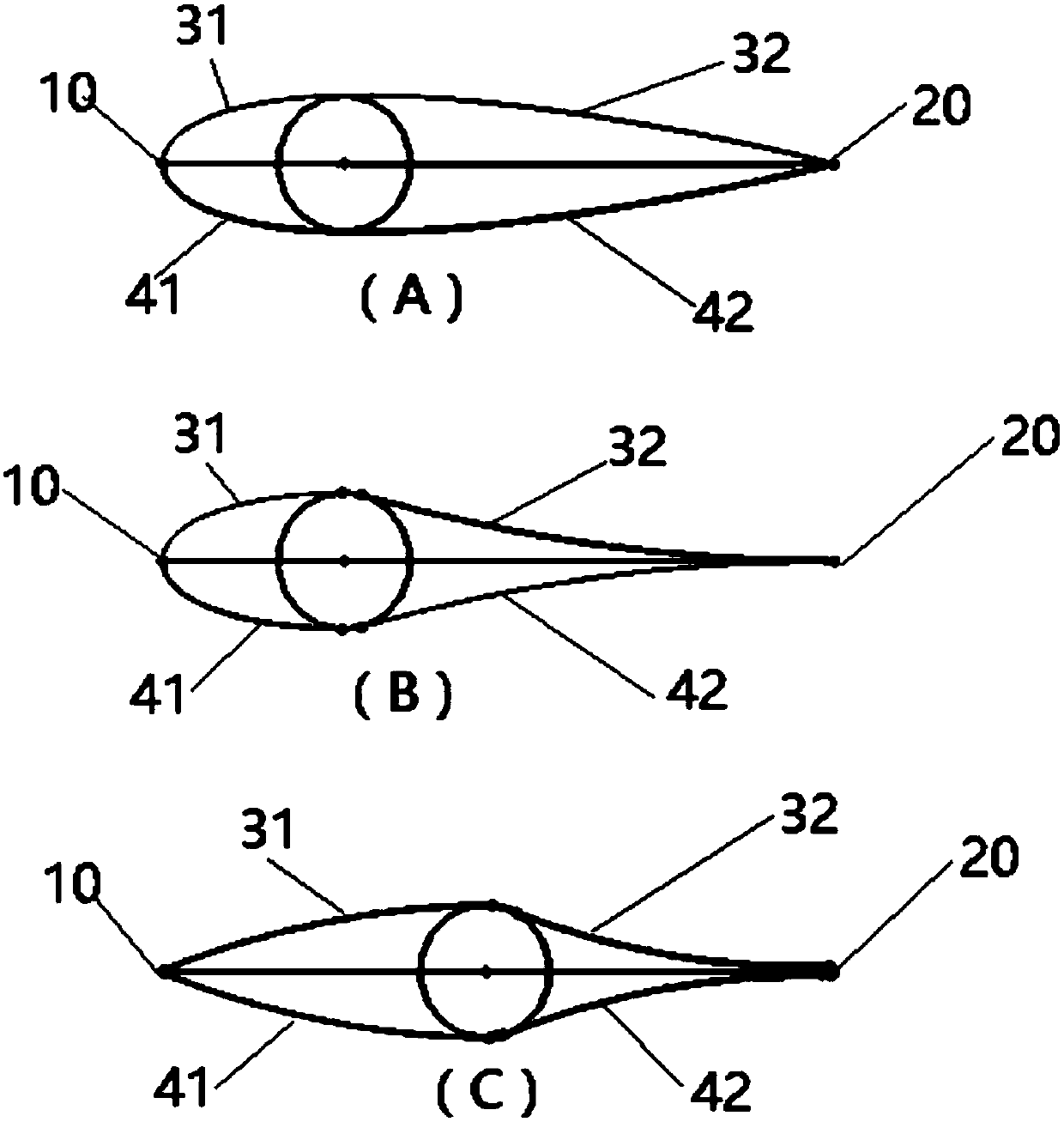

[0027] Such as image 3 , 4 As shown, the heat exchange plate with streamlined rib structure of the present invention includes a base plate and a plurality of streamline ribs arranged in rows and rows on the surface of the base plate. The cross section of the streamline ribs is roughly a symmetrical wing structure. Including the leading edge 10, the trailing edge 20, the upper arc lines 31, 32, and the lower arc lines 41, 42, the connecting line between the airfoil front edge 10 and the trailing edge 20 is formed as a wing-shaped middle arc line, the upper arc line and The lower arc is symmetrical about the middle arc. The maximum thickness of the airfoil is formed at the position of the largest inscribed circle of the upper and lower arcs. The cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com