Hydraulic torque converter which is provided with cooling blade and control oil passage and is capable of lowering working temperature

A technology for hydraulic torque converters and cooling blades, which is applied to belts/chains/gears, fluid transmission devices, mechanical equipment, etc., and can solve problems such as blade surface corrosion, hydraulic transmission oil viscosity damage, and poor cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

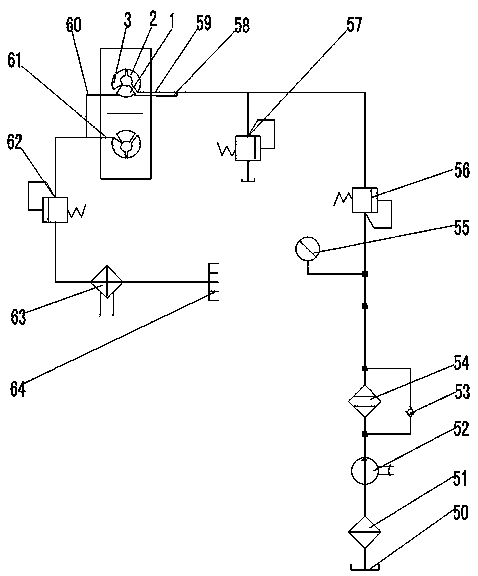

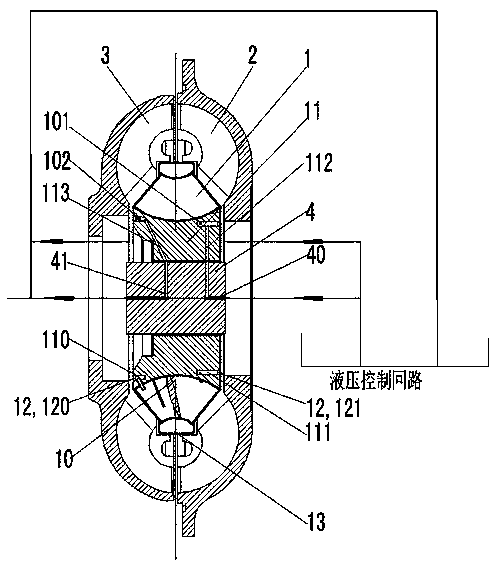

[0022] see Figure 1 to Figure 4 As shown, a hydraulic torque converter with cooling blades and control oil circuit can reduce the working temperature, including guide wheel 1, pump wheel 2, turbine 3, spline shaft 4, cooling circulation oil circuit and hydraulic torque converter Drive circulation oil circuit, guide wheel 1 is placed on spline shaft 4, pump wheel 2 and turbine wheel 3 are respectively placed on both sides of guide wheel 1, cooling circulation oil circuit flows through spline shaft 4 and guide wheel 1 internal cooling flow respectively The transmission circulation oil circuit of the hydraulic torque converter flows through the pump wheel 2, the turbine wheel 3 and the guide wheel 1 respectively;

[0023] The spline shaft 4 is provided with a first oil passage 40 and a second oil passage 41;

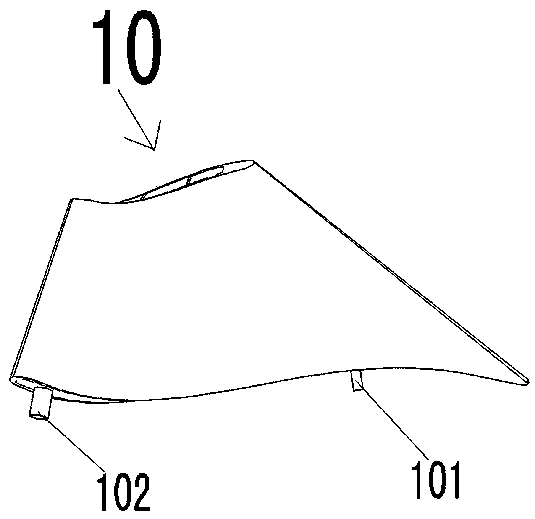

[0024] The guide wheel 1 comprises a plurality of guide wheel cooling blades 10, a guide wheel seat 11 (equivalent to the guide wheel outer ring), an oil deflector 12 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com