0-shaped lead-bismuth heat exchange device

A heat exchange device, lead-bismuth technology, applied in cooling devices, reactors, greenhouse gas reduction, etc., can solve the problems of limited heat transfer capacity, large pressure drop loss of lead-bismuth fluid, etc., to achieve low manufacturing cost and pressure drop loss Small, easy-to-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

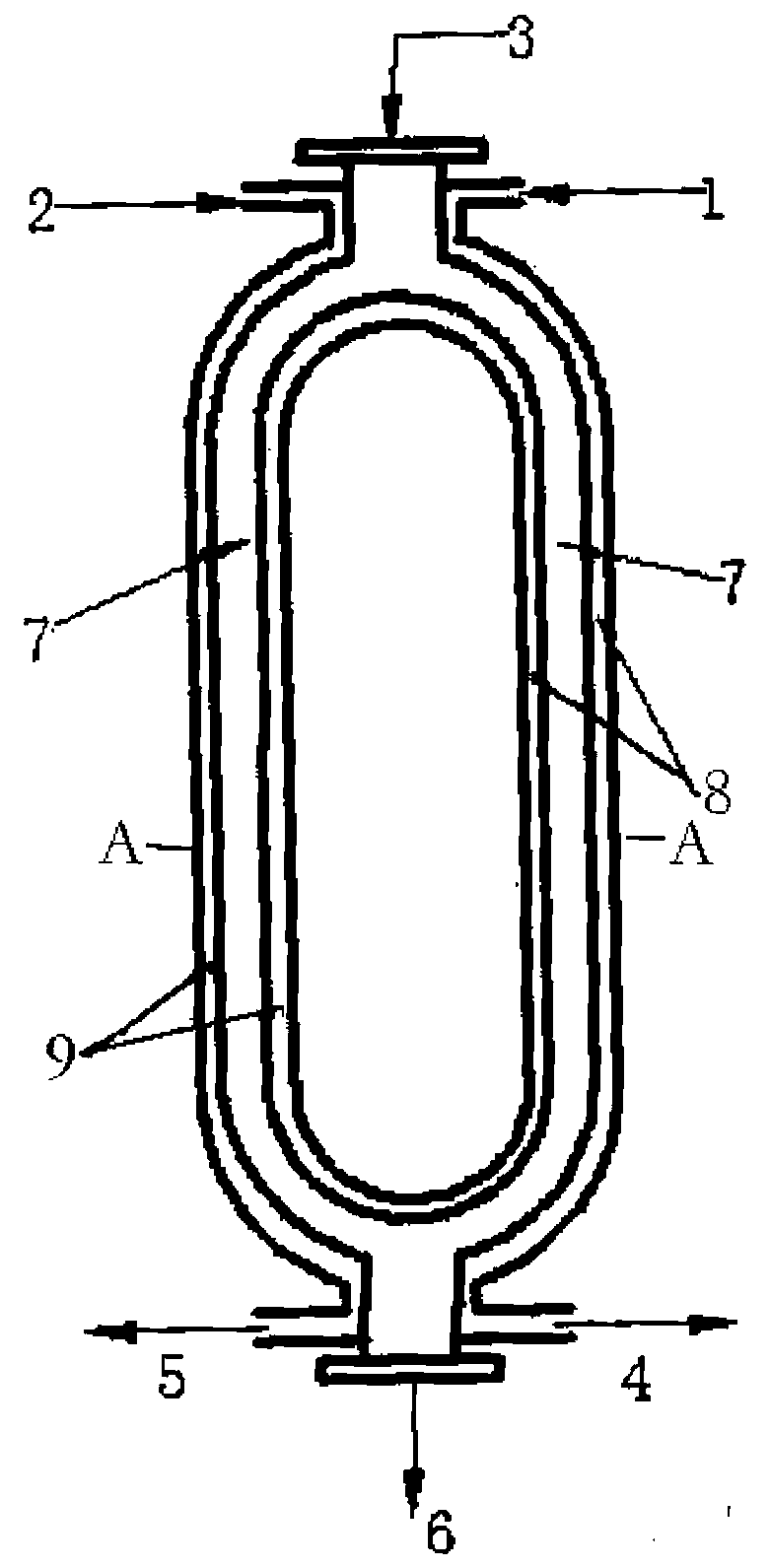

[0015] The invention provides a type 0 lead-bismuth heat exchange device. Be described below in conjunction with accompanying drawing.

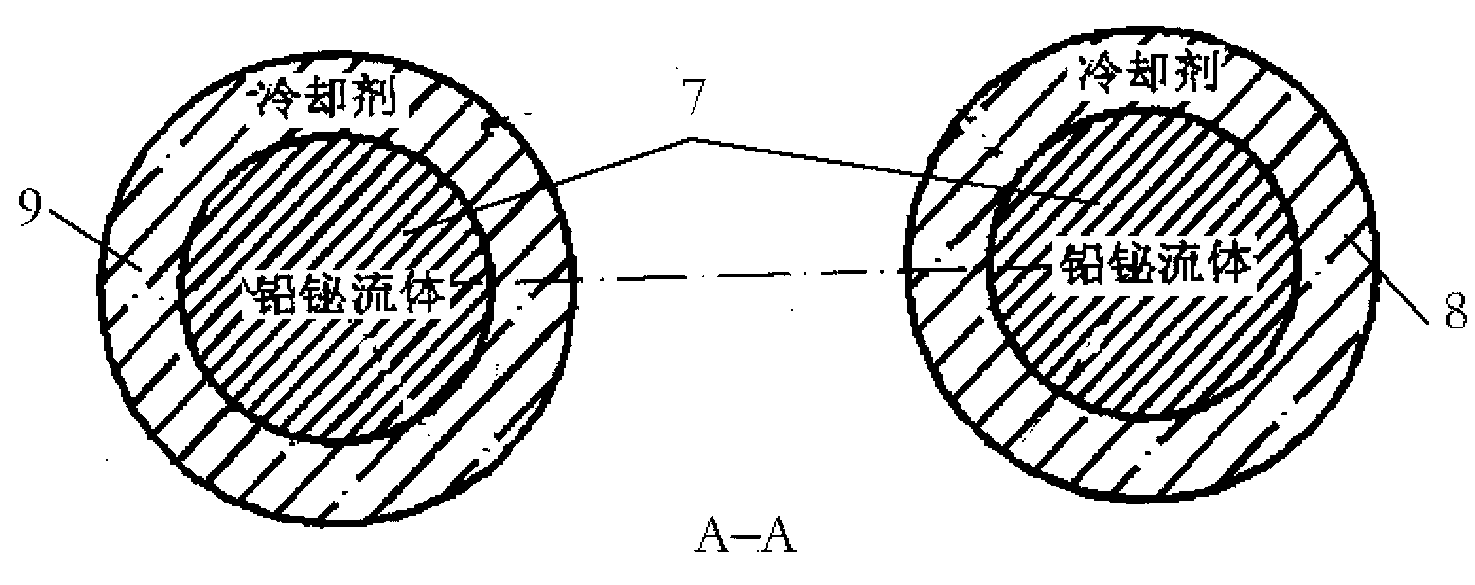

[0016] figure 1 It is a schematic diagram of "0" type lead-bismuth heat exchange device. The heat exchange device shown in the figure is a device for flow heat transfer on both sides. The shape of the whole heat exchanger is similar to the Arabic numeral "0"; the right ring sleeve of the "0" type lead-bismuth alloy flow channel The right ring coolant flow heat exchange channel 8 is welded on the outer circumference of the tube, the upper end is provided with the first coolant inlet 1, and the lower end is provided with the first coolant outlet 4; Weld the left ring coolant flow heat exchange channel 9 on the circumference, set the second coolant inlet 2 at the upper end, and set the second coolant outlet 5 at the lower end; set the lead-bismuth alloy fluid inlet at the top of the "0"-shaped lead-bismuth alloy flow channel 7 3. A lead-bismu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com