Split type sealing weld mechanism

A split-type, body-based technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of non-compactness, inconvenient use and maintenance, and lack of alarm, etc., to reduce the loss of line pressure drop , easy to use and maintain, and reduce the loss of lead wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

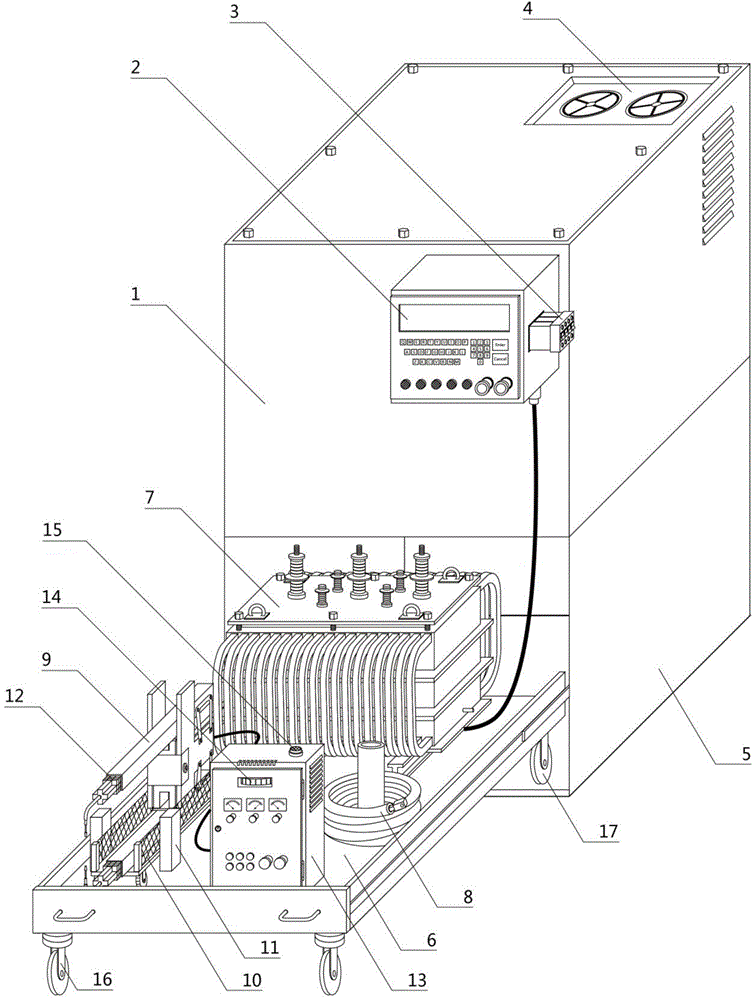

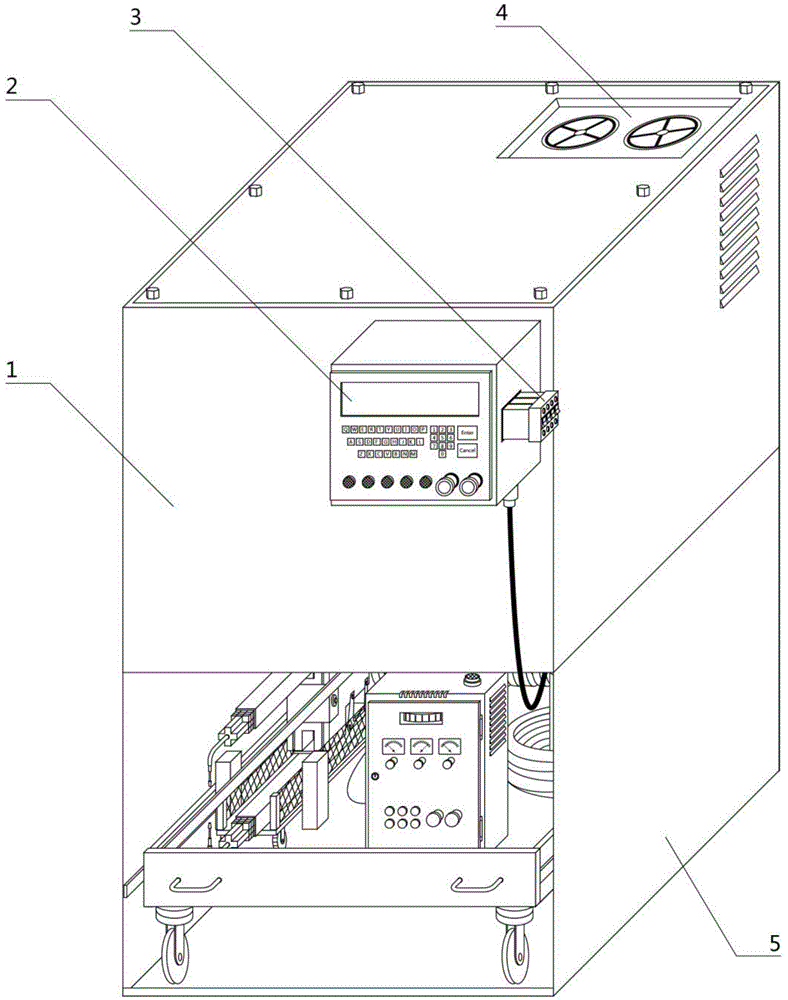

[0024] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

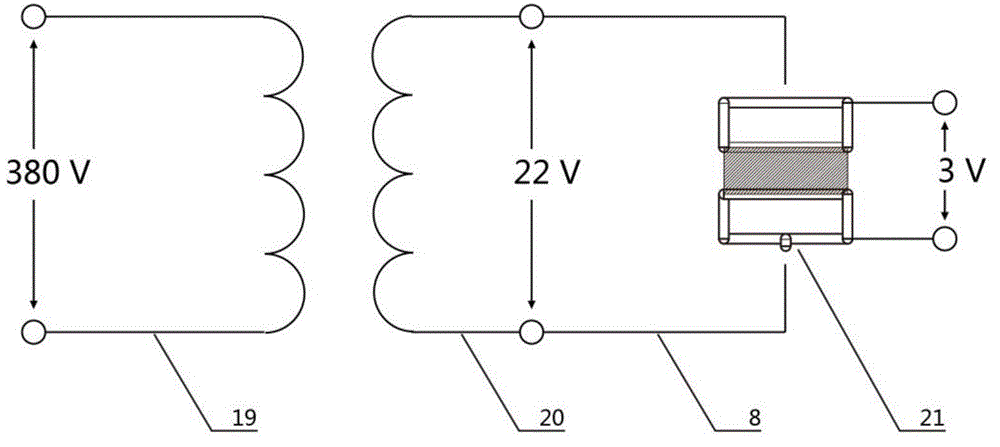

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5A split-type sealing and welding mechanism is shown, which is characterized in that it includes a body 1, a power switch 2 and a component storage compartment 5, the power switch 2 is located on one side of the body 1, and the power switch 2 is fixedly connected to the body 1 , the power switch 2 is also provided with an AC contactor 3, the AC contactor 3 is located on one side of the power switch 2, the AC contactor 3 is fixedly connected to the power switch 2, and the body 1 is also provided with There is a heat dissipation device 4, the heat dissipation device 4 is located inside the body 1, the heat dissipation device 4 is fixedly connected to the body 1, the component placement cabin 5 is located at the bottom of the body 1, and the component placement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com