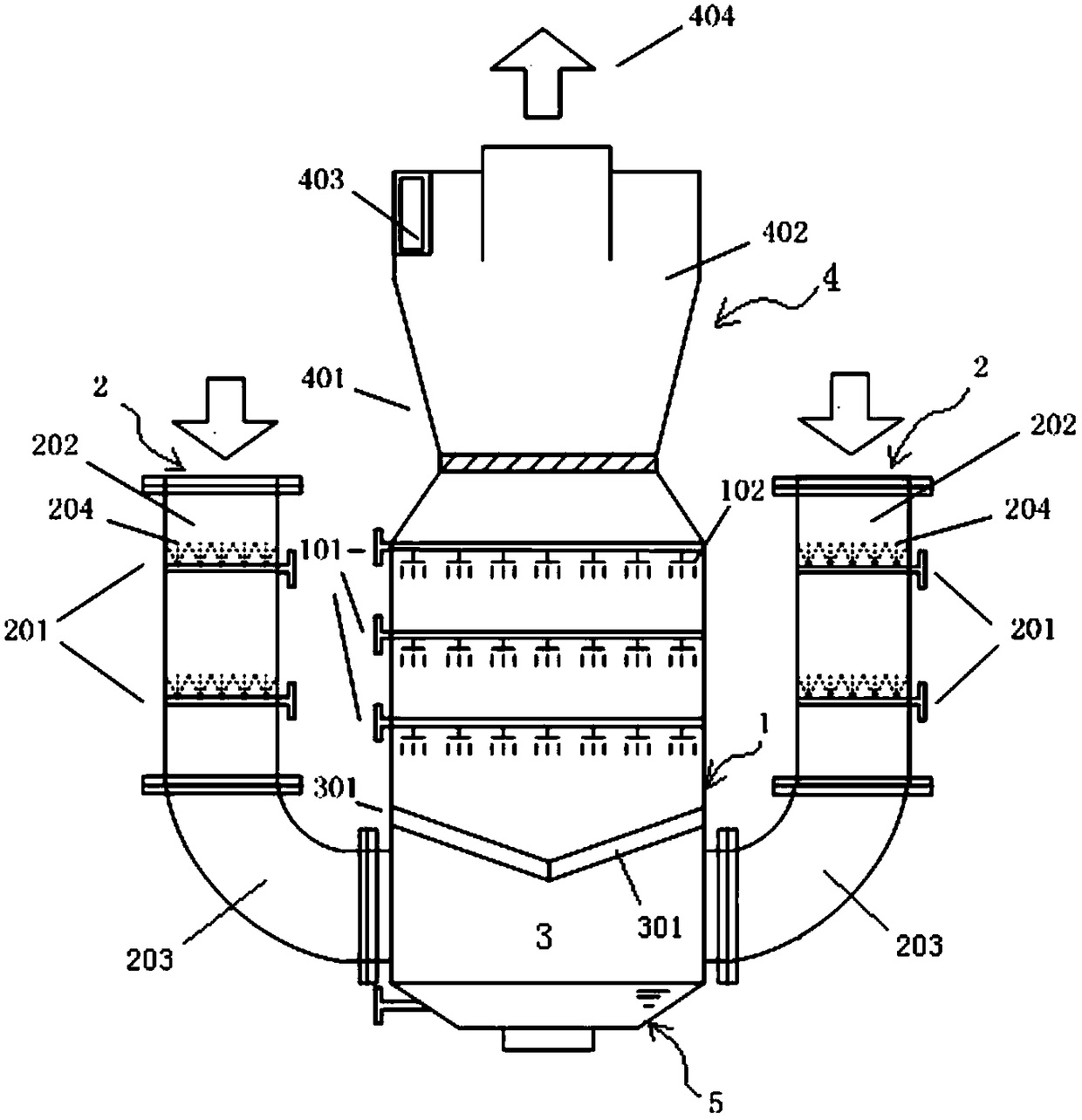

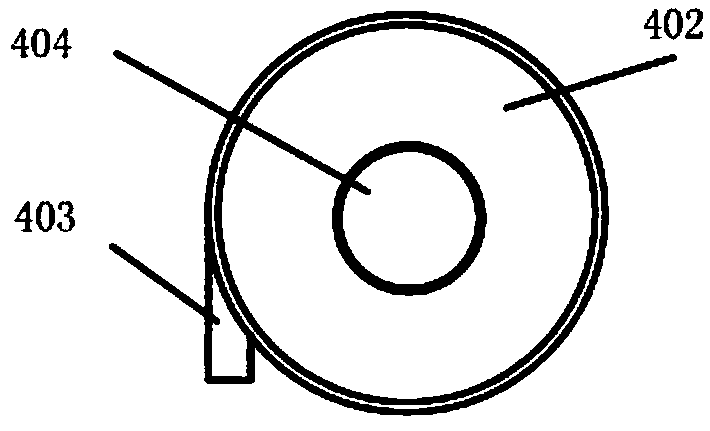

Ship exhaust gas desulfurization device

A desulfurization device, ship exhaust technology, applied in gas treatment, use of liquid separation agent, membrane technology, etc., can solve the problems of the stability of the ship's center of gravity, increase the weight of the desulfurization device, and move the center of gravity upward, so as to prolong the gas-liquid reaction time, The effect of reducing the footprint of the equipment and the space occupied by the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

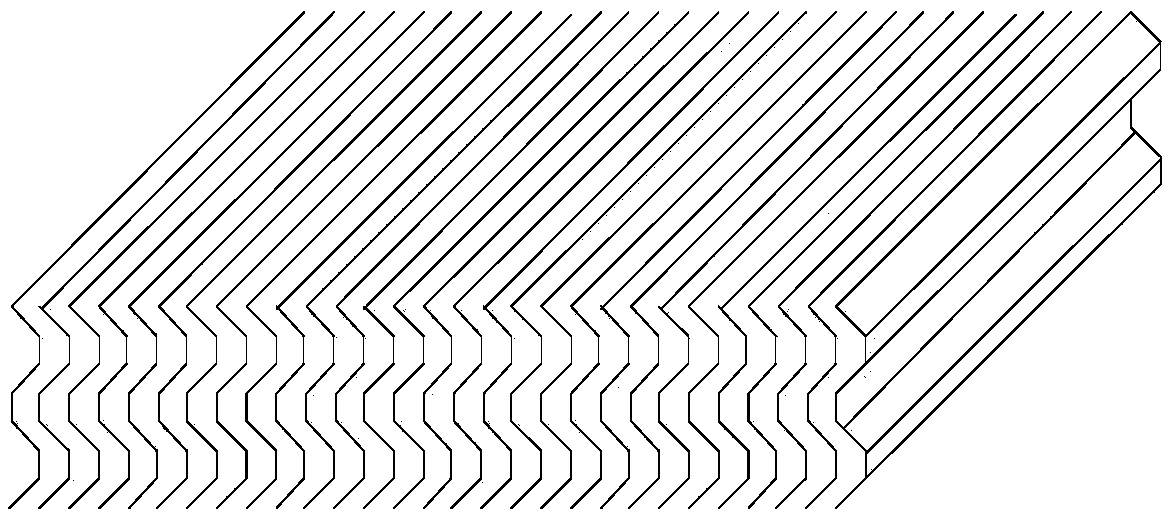

[0028] In a desulfurization device with a diameter of 3m and a height of 8m, the diameter of the flue gas inlet is 1m, and the working conditions are that the inlet flue gas temperature is 60°C, the flue gas flow rate is 77350kg / h, and the flue gas sulfur content is 1500ppm. The parameters are set as follows: the spray particle size of the spray section is 1 mm, the spray angle of the spray section is 120°, the atomization particle size of the pre-spray section is 140 μm, the atomization cone angle of the pre-spray section is 80°, and the liquid-gas ratio is 9L / m 3 , in this case the sulfur content of the outlet flue gas is about 557ppm, the desulfurization efficiency can reach 62.9%, and the desulfurization effect is better.

Embodiment 2

[0030] In a desulfurization device with a diameter of 3m and a height of 8m, the diameter of the flue gas inlet is 1m, and the working conditions are that the inlet flue gas temperature is 60°C, the flue gas flow rate is 77350kg / h, and the flue gas sulfur content is 1500ppm. The parameters are set as follows: the spray particle size of the spray section is 3 mm, the spray angle of the spray section is 120°, the atomization particle size of the pre-spray section is 140 μm, the atomization cone angle of the pre-spray section is 80°, and the liquid-gas ratio is 9L / m 3 In this case, the sulfur content of the outlet flue gas is about 182ppm, the desulfurization efficiency can reach 87.8%, and the desulfurization effect is the best.

Embodiment 3

[0032]In a desulfurization device with a diameter of 3m and a height of 8m, the diameter of the flue gas inlet is 1m, and the working conditions are that the inlet flue gas temperature is 60°C, the flue gas flow rate is 77350kg / h, and the flue gas sulfur content is 1500ppm. The parameters are set as follows: the spray particle diameter of the spray section is 5 mm, the spray angle of the spray section is 120°, the atomization particle diameter of the pre-spray section is 140 μm, the atomization cone angle of the pre-spray section is 80°, and the liquid-gas ratio is 9L / m 3 In this case, the sulfur content of the outlet flue gas is about 265ppm, the desulfurization efficiency can reach 82.3%, and the desulfurization effect is very good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com