Outer-disk micro channel type thermal storage water tank for heat pump water heater

A heat storage tank and micro-channel technology, applied in fluid heaters, lighting and heating equipment, etc., to achieve the effects of increasing water storage, reducing heat transfer resistance, and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

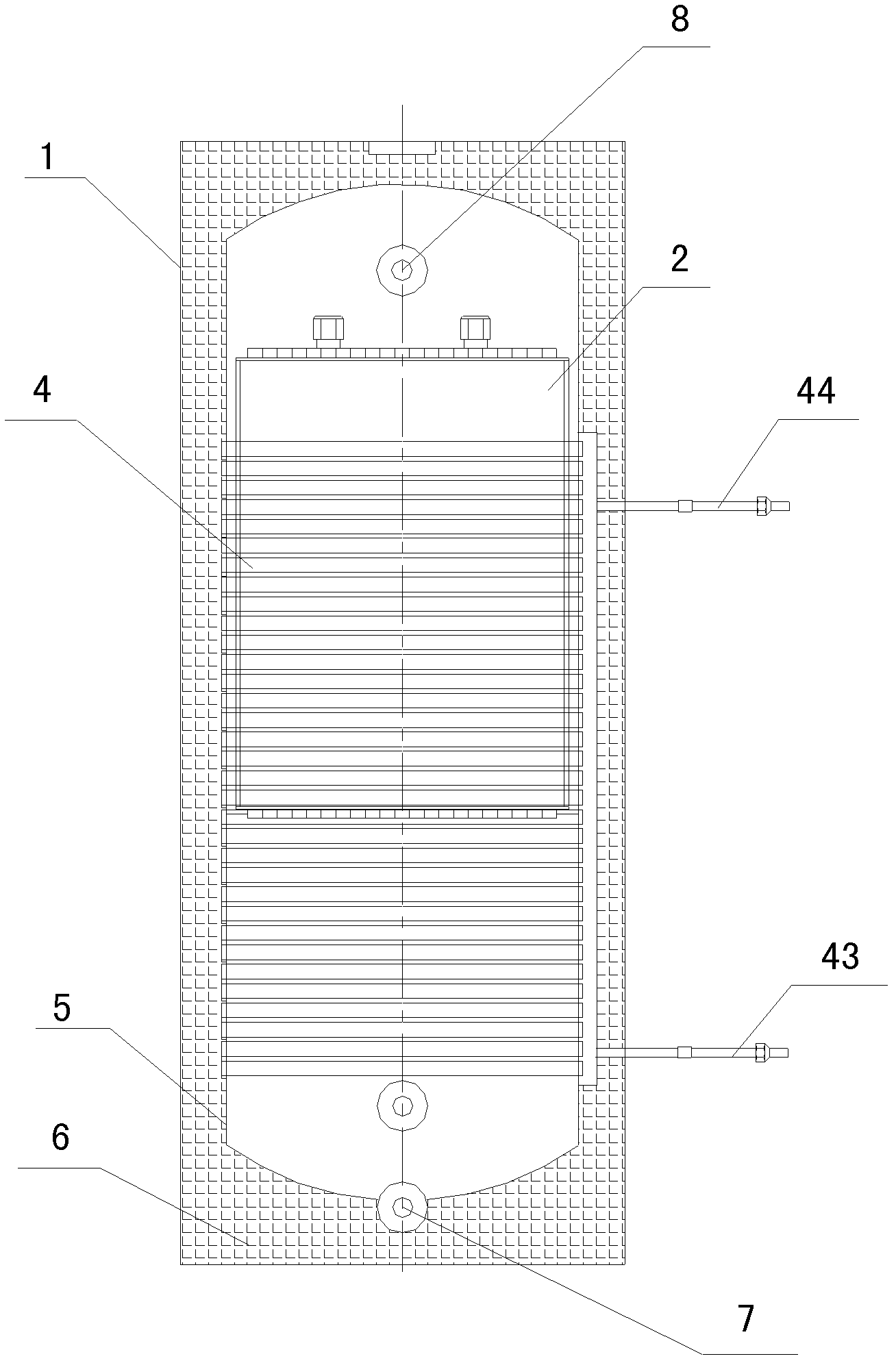

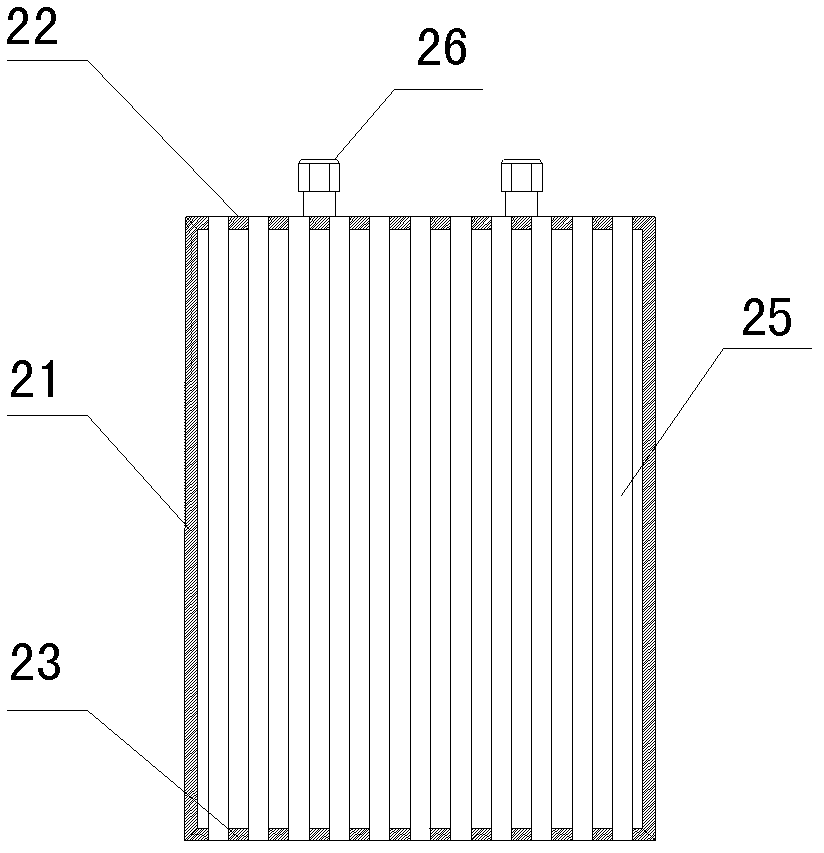

[0030] Such as figure 1 As shown, the hot water storage tank of the present invention includes a shell 1, a heat storage mold box 2, a heat storage material (not shown in the figure), a water tank liner 5, a condensing heat exchanger 4 and a thermal insulation material 6, and the heat storage material The phase change temperature point is between the water temperature of the water inlet and outlet. The heat storage mold box 2 is set inside the water tank liner 5, and the heat insulating material 6 is foamed between the outer shell 1 and the water tank liner 5. On the water tank liner 5 There are inlet and outlet ports 7 and 8. Such as image 3 , 4 As shown, the heat storage mold box 2 includes a cylinder side wall 21 and upper and lower end covers 22, 23, and the upper and lower end covers 22, 23 are provided with vertically opposite small holes 24, and in the vertically opposite two small A connecting pipe 25 is provided between the holes to form a water flow channel conne...

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 is:

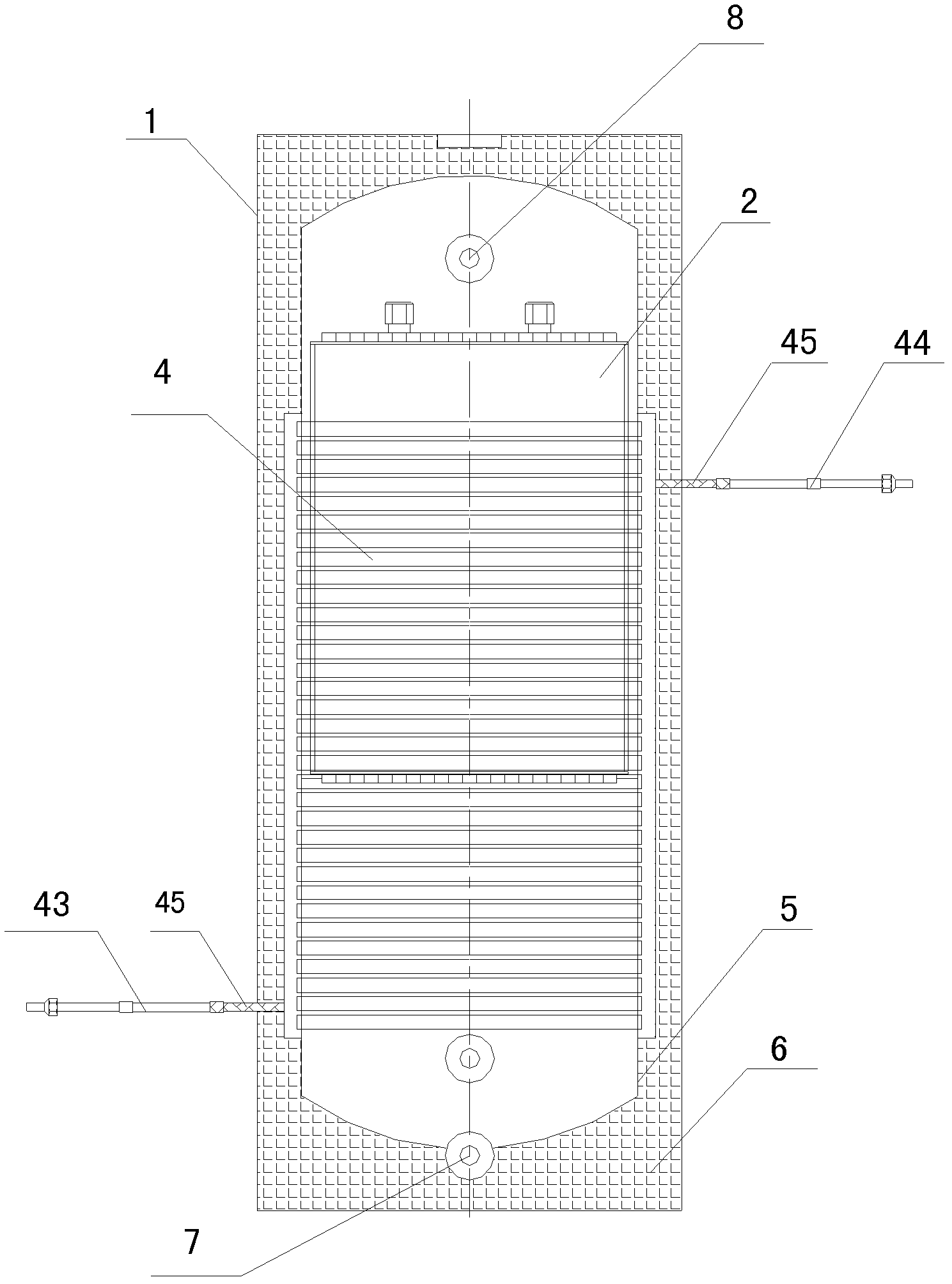

[0035] Such as figure 2 , 7 , 8, the condensing heat exchanger 4 is formed by connecting two microchannel condensers in parallel, the inlet headers 42 of the two microchannel condensers communicate through the refrigerant circulation pipe 45, and the outlets of the two microchannel condensers The headers 46 are communicated through the refrigerant circulation pipes 45, one of which is located at the lower part of the outlet header 46 and communicates with the refrigerant outlet pipe 43, and the other refrigerant circulation pipe is located at the upper part of the inlet header 42 and communicates with the Refrigerant inlet pipe 44.

Embodiment 3

[0037] The difference between this embodiment and embodiment 2 is:

[0038] A groove is arranged on the outer wall of the water tank liner 5, and the flat tube bundle 41 of the microchannel condenser is stuck in the groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com