Solid heat storage device

A heat storage device and solid technology, applied in heating devices, solar thermal devices, solar heat storage, etc., can solve problems such as short service life, large heat loss in external pipeline insulation cycles, and limited heat transfer area between solids. Reach the effect of reducing the energy consumption of the system operation, ensuring the quality of heat output, and good overall heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the examples.

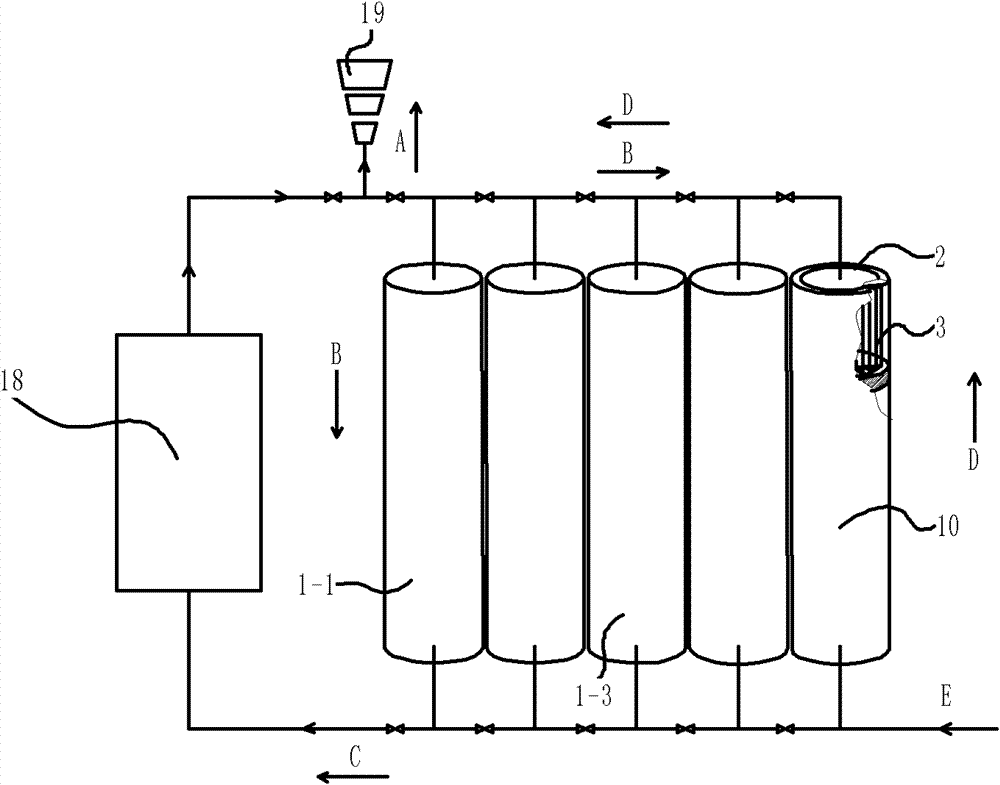

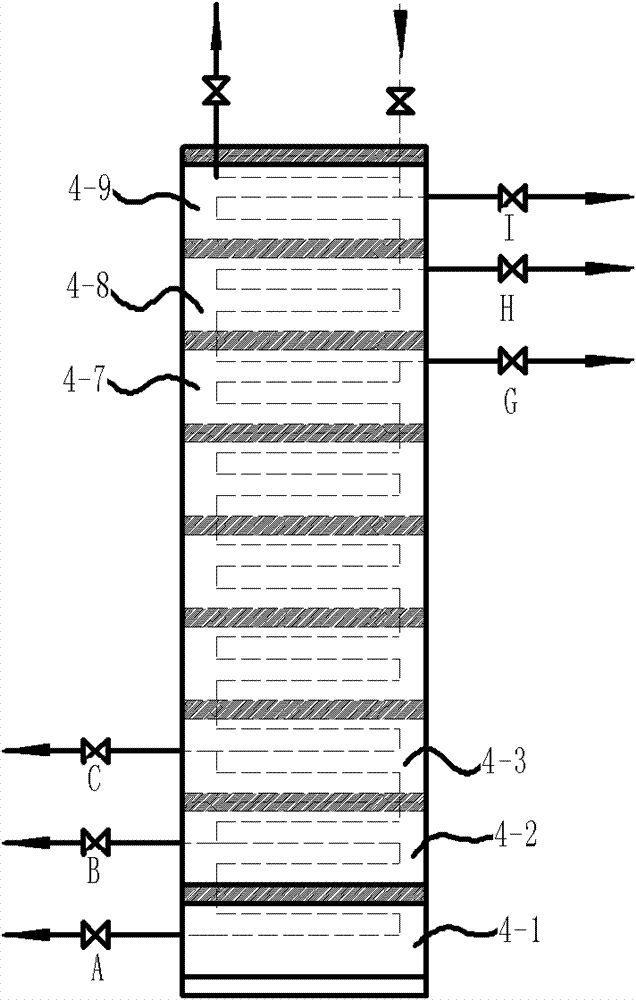

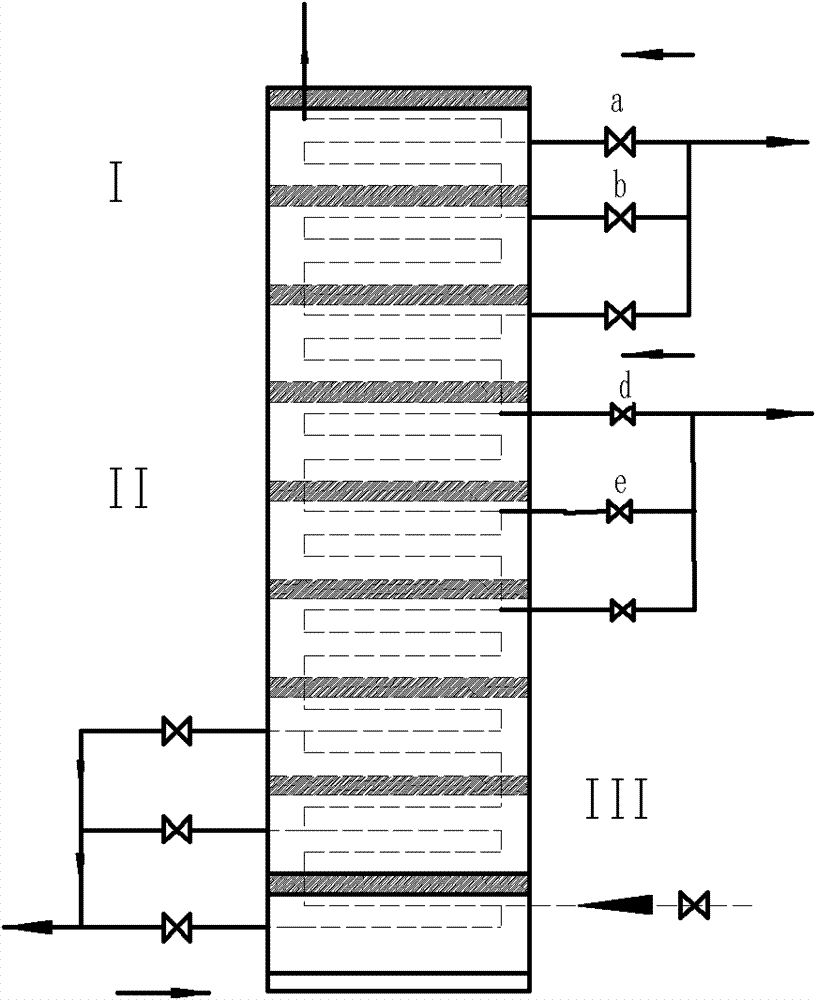

[0054] figure 1 It is a schematic diagram of the overall structure of an embodiment of a solid heat storage device of the present invention; the solid heat storage device is composed of a plurality of heat storage units, such as an array of heat storage units 1-1 and heat storage units 1-3; figure 1 As shown, the heat storage units 1-1 of the array are arranged vertically on the ground; each heat storage unit 1-1 includes a casing 2, a solid heat storage medium 3 arranged inside the casing 2, and an insulation layer 10 arranged outside the casing 2; The outer surface of the solid heat storage medium 3 is the heat exchange interface of the heat transfer medium, and the solid heat storage medium 3 is a dense material with a porosity of less than 10%; optimally, the surface of the solid heat storage medium 3 has an airtight layer to further reduce the heat transfer medium i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com