Steam-water separator and steam generator simulation body

A steam-water separator and steam generator technology, which is applied to steam separation devices and other directions, can solve the problems of large resistance coefficient, large pressure drop loss and inability to meet the requirements, and achieve the effects of low cost, reduced pressure drop loss and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

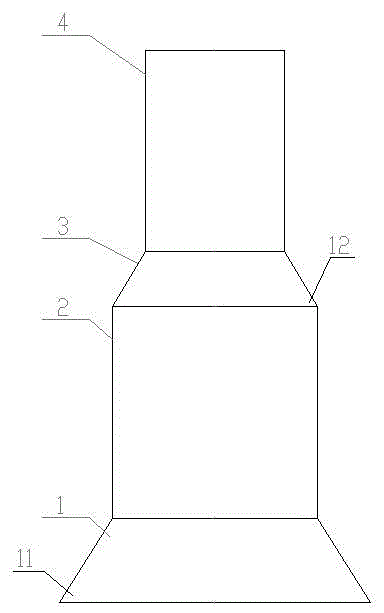

[0038] Such as figure 1 As shown, the steam-water separator is composed of the lower cone section 1, the lower section 2 of the ascending cylinder, the upper cone section 3 and the upper section 4 of the ascending cylinder. The lower cone section 1 and the upper cone section 3 have a wide bottom and a narrow structure. The upper end is connected with the lower end of the lower section 2 of the ascending section, the upper end of the lower section 3 of the ascending section is connected with the lower end of the upper cone section 3, and the upper end of the upper cone section 3 is connected with the lower end of the upper section 4 of the ascending section.

[0039] The diameter of the lower section 2 of the ascending cylinder is greater than the diameter of the upper section 4 of the ascending cylinder.

[0040] The lower cone section 1 is used for introducing the soda-water mixture into the lower section 2 of the ascending cylinder, and the upper cone section 3 is used for i...

Embodiment 2

[0043] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, the angle A11 of the bottom surface of the lower cone section 1 is preferably set to 45°, so that the resistance generated by the soda-water mixture passing through the lower cone section 1 is minimal.

Embodiment 3

[0045] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1 or Embodiment 2, the angle B12 of the bottom surface of the upper cone section 3 is preferably set to 45°, so that the resistance generated by the soda mixture passing through the upper cone section 3 is the minimum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com