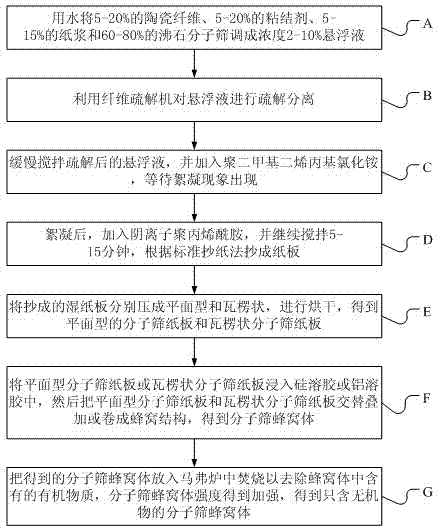

Manufacture method of molecular sieve honeycomb body for absorbing volatile organic compounds

A technology for volatile organic compounds and manufacturing methods, applied in separation methods, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high cost, easy peeling of molecular sieves, low adsorption efficiency, etc., and achieves simple manufacturing process and hydrothermal stability. Good, small pressure drop loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

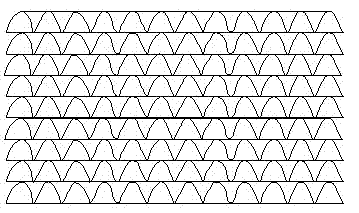

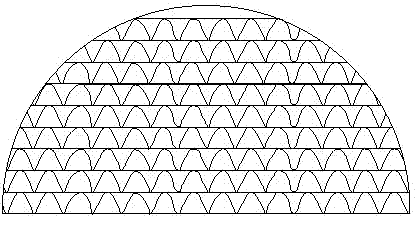

Embodiment 1

[0047] At room temperature, add 10g of NaY molecular sieve, 1g of pulp, 1.1g of ceramic fiber, and 3g of attapulgite clay into a 3L glass beaker, then add 300 mL of water to make a suspension, and use a fiber decomposer for 15 minutes to decompose. Add 0.07g of polydimethyldiallyl ammonium chloride under stirring, add 0.15g of anionic polyacrylamide after flocculation, add the suspension to dilute it into a 0.3% suspension, and then weigh 250g / m 2 Wet cardboard, after 5 minutes under pressure at 350kPa, 105 o C baked for 30 minutes to obtain a flat molecular sieve cardboard. Or heat-press the wet paperboard into a corrugated shape, and obtain a corrugated molecular sieve paperboard after drying, with a wave height of 1.8mm and a wave number of 30 / 10cm. Immerse the above-mentioned plane and corrugated molecular sieve paperboards into silica sol for 10 minutes, then alternately stack or roll the plane molecular sieve paperboards and corrugated molecular sieve paperboards into...

Embodiment 2

[0049] At room temperature, add 12g of hydrophobic Y-type molecular sieve, 1.5g of pulp, 1.5g of ceramic fiber, and 3g of attapulgite clay into a 3L glass beaker, then add 500 mL of water to make a suspension, and use a fiber decomposer for 20 minutes , add 0.10g of polydimethyldiallylammonium chloride under slow stirring state, add 0.21g of anionic polyacrylamide after flocculation, add the suspension to dilute it into a 0.5% suspension, and then weigh 300g / m 2 Wet cardboard, after 5 minutes under pressure at 350kPa, 105 o C baked for 30 minutes to obtain a flat molecular sieve cardboard. Or heat-press the wet cardboard into a corrugated shape, and obtain a corrugated molecular sieve cardboard after drying, with a wave height of 1.9mm and a wave number of 32 / 10cm. Immerse the above-mentioned plane and corrugated molecular sieve paperboards into silica sol for 20 minutes, then alternately stack or roll the plane molecular sieve paperboards and corrugated molecular sieve pape...

Embodiment 3

[0051] At room temperature, add 15g of ZSM-5 molecular sieve, 2g of pulp, 2.5g of ceramic fiber, and 3.5g of attapulgite clay into a 3L glass beaker, then add 500 mL of water to make a suspension, and use a fiber decomposer to decompose for 20 minutes. Add 0.25g of polydimethyldiallylammonium chloride under slow stirring state, add 0.41g of anionic polyacrylamide after flocculation phenomenon, add and dilute the suspension into 0.5% suspension, and then the gram weight is 220g / m 2 Wet cardboard, after 5 minutes under pressure at 350kPa, 105 o C baked for 30 minutes to obtain a flat molecular sieve cardboard. Or heat-press the wet cardboard into a corrugated shape, and obtain a corrugated molecular sieve cardboard after drying, with a wave height of 1.7 mm and a wave number of 32 / 10 cm. Immerse the above-mentioned plane and corrugated molecular sieve paperboards into silica sol for 20 minutes, then alternately stack or roll the plane molecular sieve paperboards and corrugated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com