Patents

Literature

49results about How to "Fast fermentation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

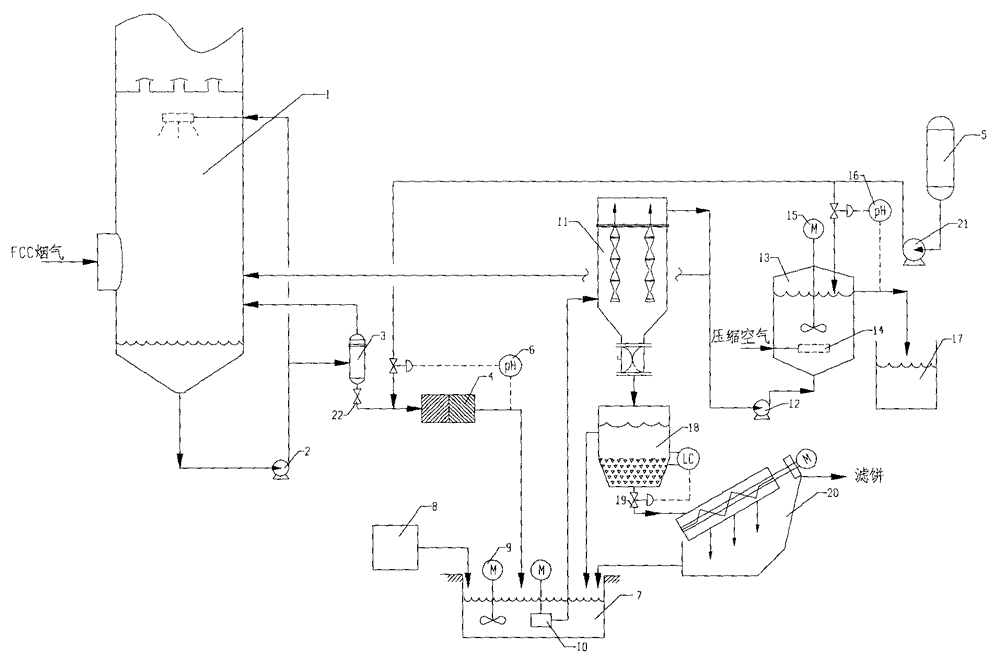

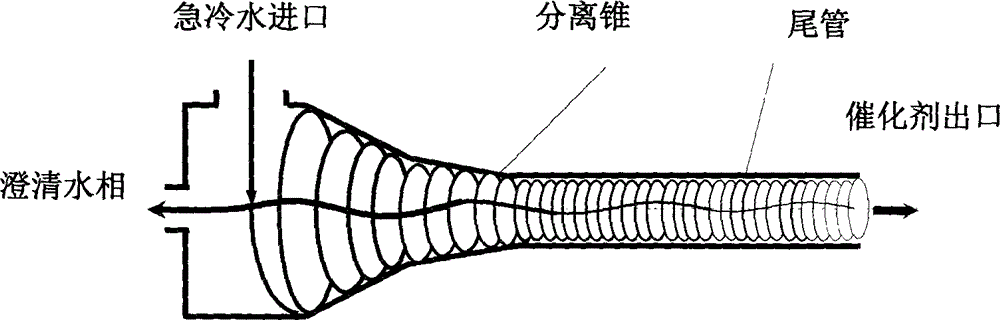

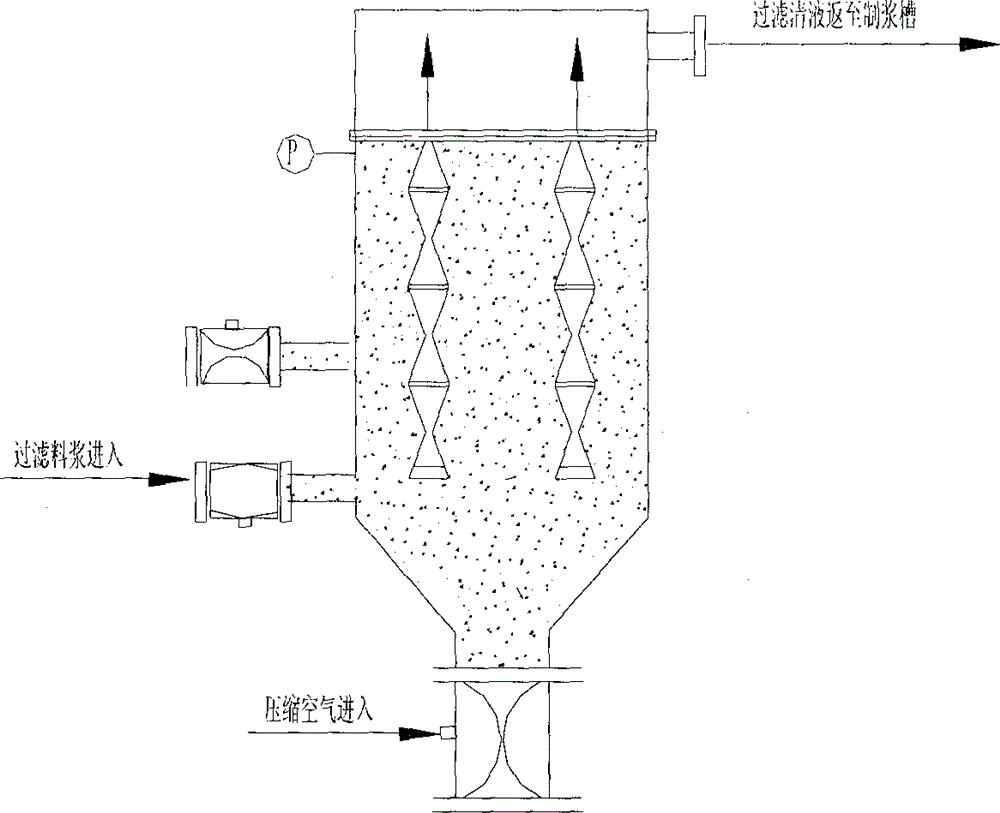

Process for treating waste liquid from catalytic cracking flue gas desulfurization

InactiveCN104418447AReduce dust concentrationReduce wearWater/sewage treatment by centrifugal separationSludge treatmentLiquid wasteSlurry

The invention provides a process for treating waste liquids from catalytic cracking flue gas desulfurization. The process comprises the following steps: enabling a part of waste liquids from a quenching washing tower to enter a hydraulic cyclone separator so as to be subjected to solid-liquid separation, returning the thin liquids to the quenching washing tower so as to be recycled, enabling the thick liquids to enter a neutralization reactor so as to be subjected to neutralization reaction, enabling the neutralized waste liquids to enter a slurry pond so as to be mixed with a flocculating agent uniformly, and enabling the mixture to enter an expansion-drum type filter so as to be subjected to solid-liquid separation with a thick slurry and a supernatant being obtained; returning part of the supernatant to the quenching washing tower so as to be recycled, discharging the remaining supernatant into an oxidation tank, removing the pseudo-COD containing sulfite roots and bisulfite roots by oxidizing, and directly discharging the qualified sewage; enabling the thick slurry to enter a settling pond from the bottom of the expansion-drum type filter so as to be further settled, feeding the thick slurry subjected to settlement into a dewatering machine so as to be concentrated and dewatered, directly transporting the filter cakes obtained by dewatering the thick slurry, returning the filtrate from the dewatering of the thick slurry to the slurry pond, and mixing the filtrate with the waste liquids so as to be retreated. The process provided by the invention has the advantages of a stable and efficient treatment effect, strong shock resistance, low investment and small floor area occupation and convenience of operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

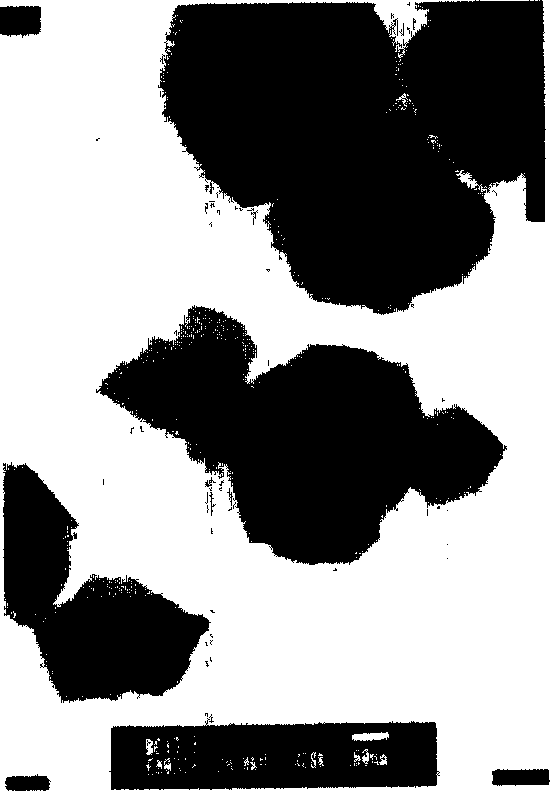

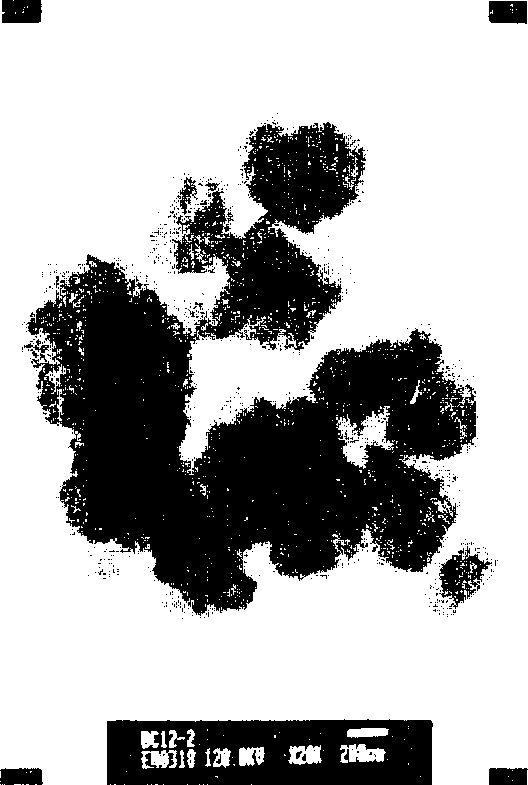

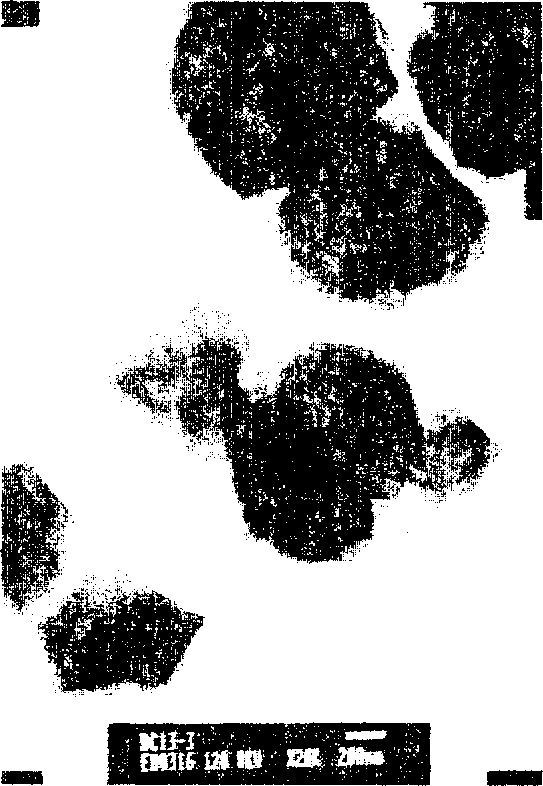

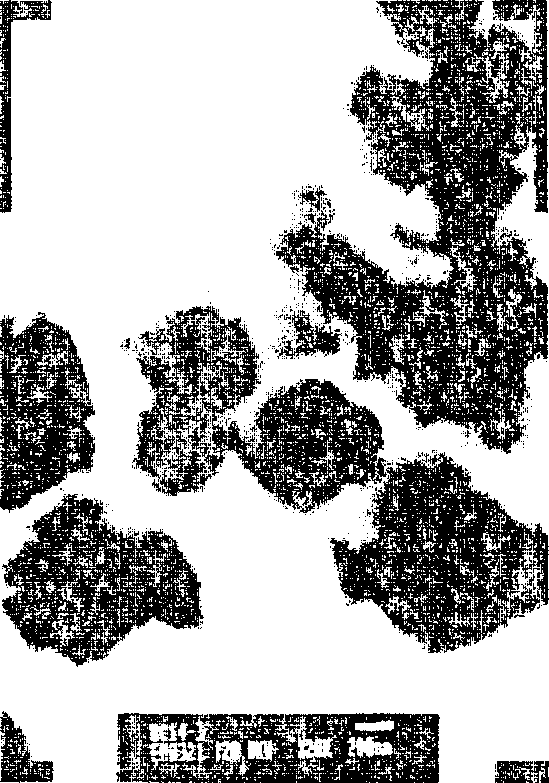

Process for preparing NaY molecular sieve by using synthetic mother liquor

ActiveCN1634764ATake advantage ofEmission reductionFaujasite aluminosilicate zeoliteMolecular sieveSilicon

The invention relates to a method for preparing NaY molecular sieve by using the synthesis mother liquor, comprising the following steps: 1. adding the aluminium salt solution into the synthesis mother liquor to form a precipitating silicon-aluminium gel, then filtering it to obtain a silicon-aluminium gel filter cake; 2. mixing the silicon-aluminium gel filter cake with the soluble silica resource, aluminium resource and guiding agent evenly, after that, pre-crystallizing it under 30 to 100 degrees centigrade for 0.5 to 30 hours; 3. mixing the pre-crystallized product with the soluble silica resource, aluminium resource to form a crystallization mixture, after that, crystallizing it under 90 to 100 degrees centigrade for 8 to 65 hours, then filtering, washing and drying to obtain a NaY molecular sieve with large crystal grain and large granule. The invention overcomes the bias of the existed techniques by adding the pre-crystallizing step before the conventional crystallizing step to prepare NaY molecular sieve with large crystal grain and large granule, and solves slow filtering rate in post treatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing palm oil decolorizing agent by attapulgite clay soybean oil decolorized waste residues

ActiveCN103055811AAchieve reuseActivate the microporous structureOther chemical processesFatty-oils/fats refiningActivated carbonOil and grease

The invention discloses a method for preparing a palm oil decolorizing agent by attapulgite clay soybean oil decolorization waste residues, which comprises the following steps of: firstly, carrying out soybean oil decolorization treatment by attapulgite clay; then spraying acid to attapulgite clay waste residues which adsorb grease; roasting at a temperature of 300 to 380 DEG C; and finally, washing, drying and sieving to obtain the attapulgite clay palm oil decolorizing agent loaded with activated carbon. The palm oil decolorizing agent prepared by the method utilizes a synergistic effect between the attapulgite clay and the activated carbon and not only realizes decolorization of palm oil, but also realizes recycling of the soybean oil decolorization waste residues; and the product has the advantages of high decolorization ratio, high filtering rate, oil damage and the like and is suitable for deeply decolorizing crude palm oil.

Owner:中国科学院兰州化学物理研究所盱眙凹土应用技术研发中心

Method for producing alcohol by mixing and fermenting raw materials and cooked materials

InactiveCN102586338AAvoid damagePromote growthBiofuelsMicroorganism based processesAlcoholEnergy consumption

The invention relates to a method for preparing alcohol by mixing and fermenting raw materials and cooked materials. The method comprises the following steps: adding or supplementing saccharified mash obtained by non-cooked raw material fermentation method into liquefied mash or saccharified mash in the traditional cooked alcohol fermentation process, namely dividing starchy materials into two parts, gelatinizing, liquefying and saccharifying one part of starchy materials by the conventional traditional cooking alcohol fermentation method, liquefying and saccharifying the other part of starchy materials by a non-cooked raw material alcohol fermentation method, liquefying or saccharifying the mash of the two processes, mixing and synchronously scaccharifying and fermenting to prepare the alcohol. According to the method, the preparation efficiency is equal to that of the complete cooking alcohol preparation process, equipment is not transformed, the preparation process is simplified partially, energy consumption is reduced partially, and market popularization is facilitated.

Owner:上海天之冠可再生能源有限公司

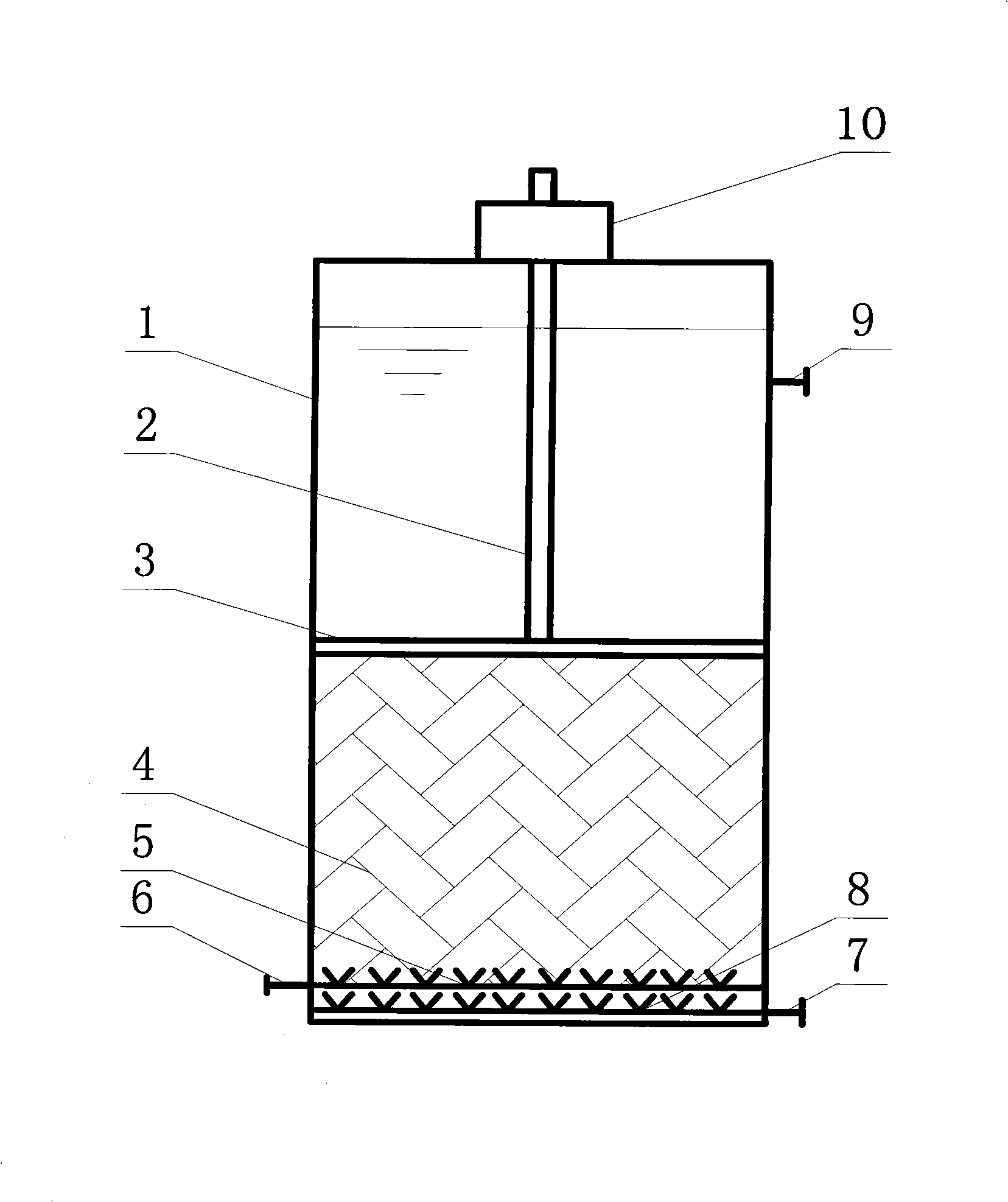

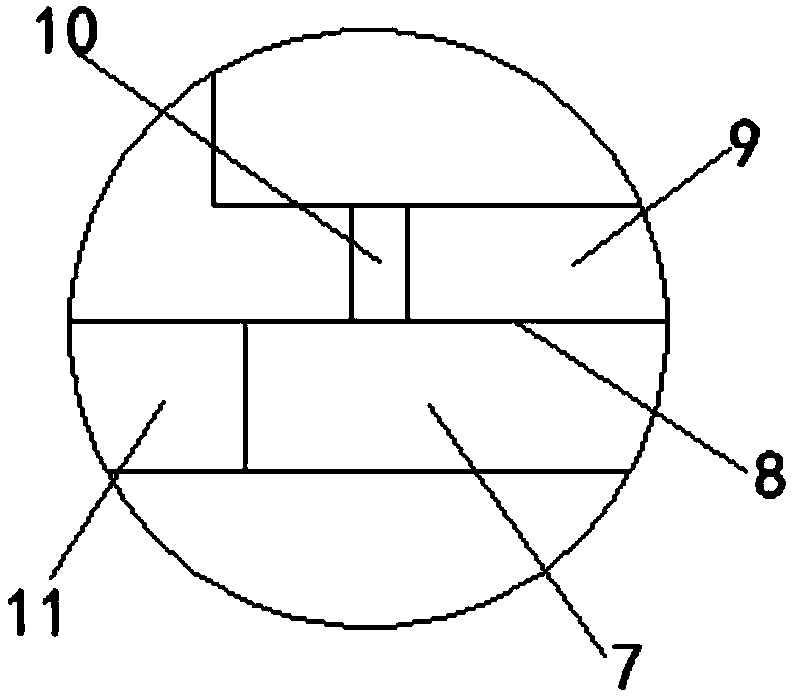

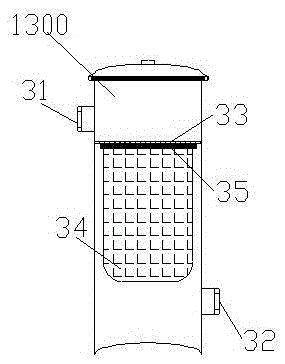

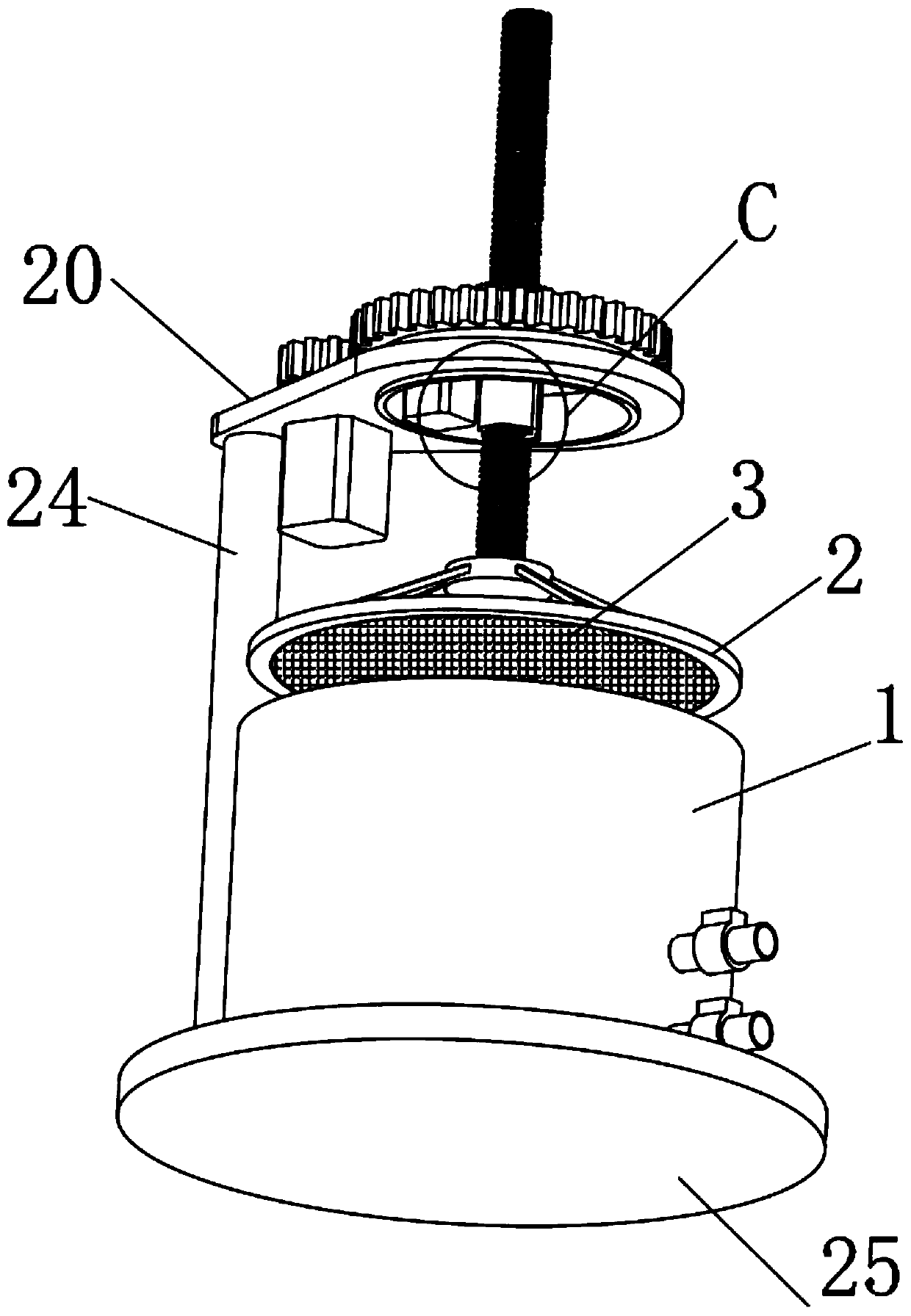

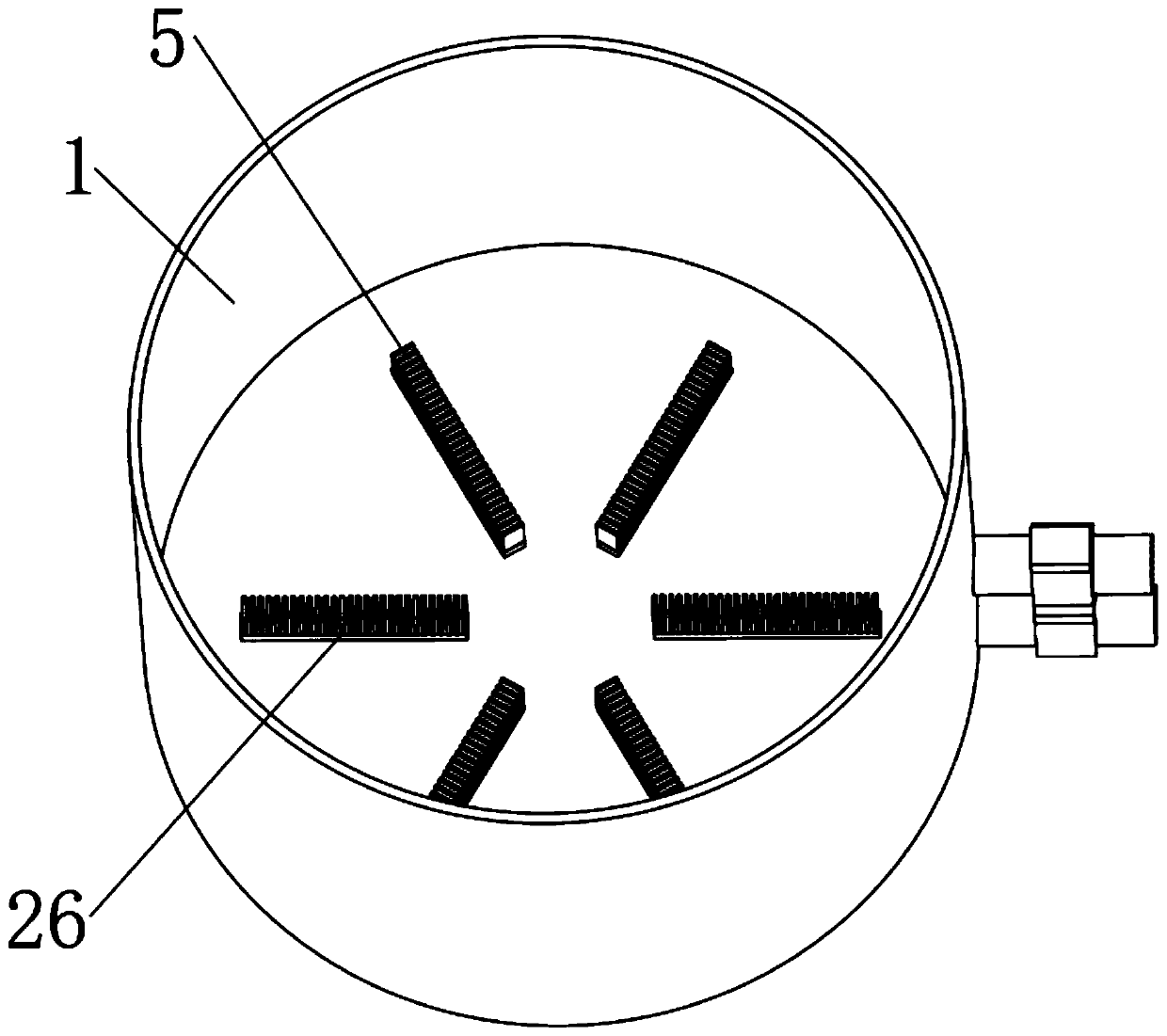

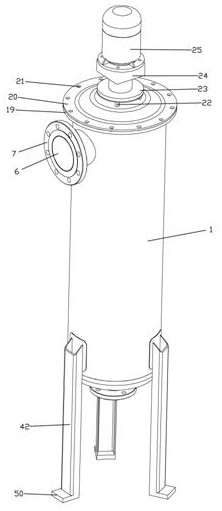

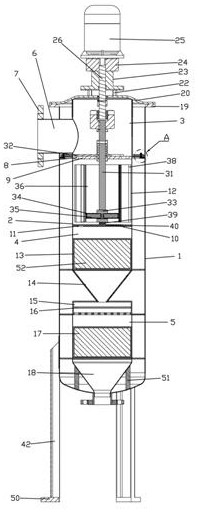

Variable-volume sewage interception and acceptance solid-liquid separator and method thereof

InactiveCN101337138AFast fermentation rateHigh interception capacityLoose filtering material filtersGravity filtersAutomatic controlFilter media

The present invention discloses a volume-variable solid-liquid separating device with functions of sewage capturing and dirt accepting, and a separating method thereof. The solid-liquid mixture to be separated flows(down-to-up or up-to-down) through the filtering medium which is compressed to have a height equal to 60% to 90% of the natural filling height. With the increase of captured solid phases, a shaft lifting driver drives a lifting shaft to lift a compress screen, and the height of the filtering medium increases gradually. When the height of the filtering medium reaches 90% of the natural filling height, the compress screen is lifted to the highest position, the filtering medium is loosened completely, at the same time, reverse flushing gas is charged from the intake pipe for a period of 10 to 15 minutes, after the reverse flushing, the compress screen is lowered to compress the filtering medium for refiltration. As a result, the invention has a fast filtering speed reaching a level of 45m / h, sewage capturing speed is increased while the pressure drop loss is decreased; the reverse flushing is complete while the water consuming is less; the operation is simple, and complete auto-control can be realized.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

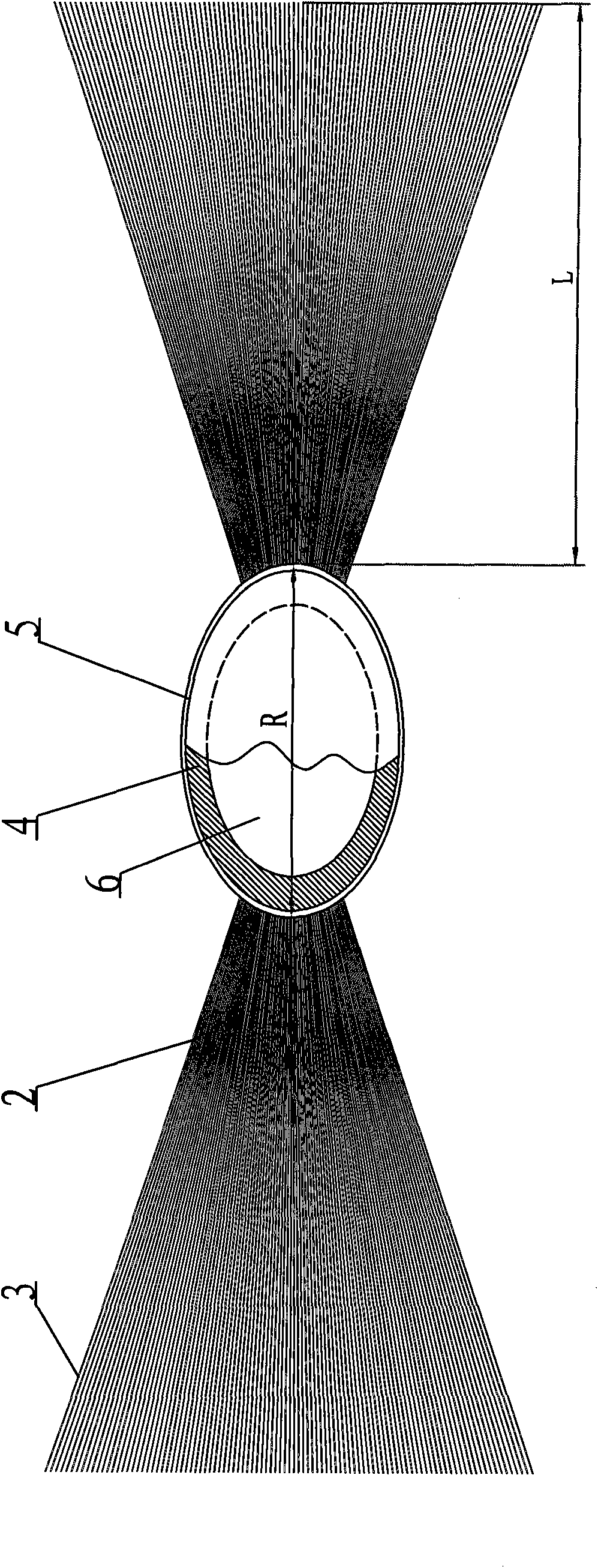

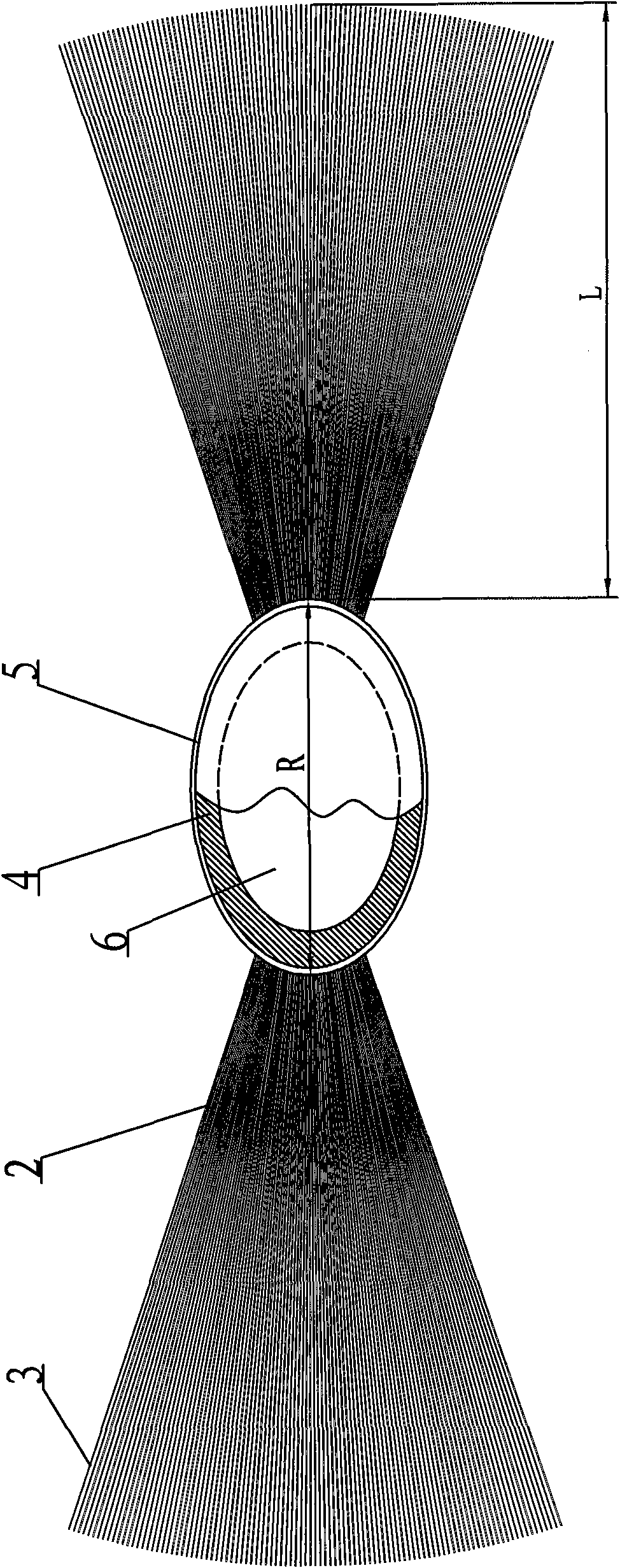

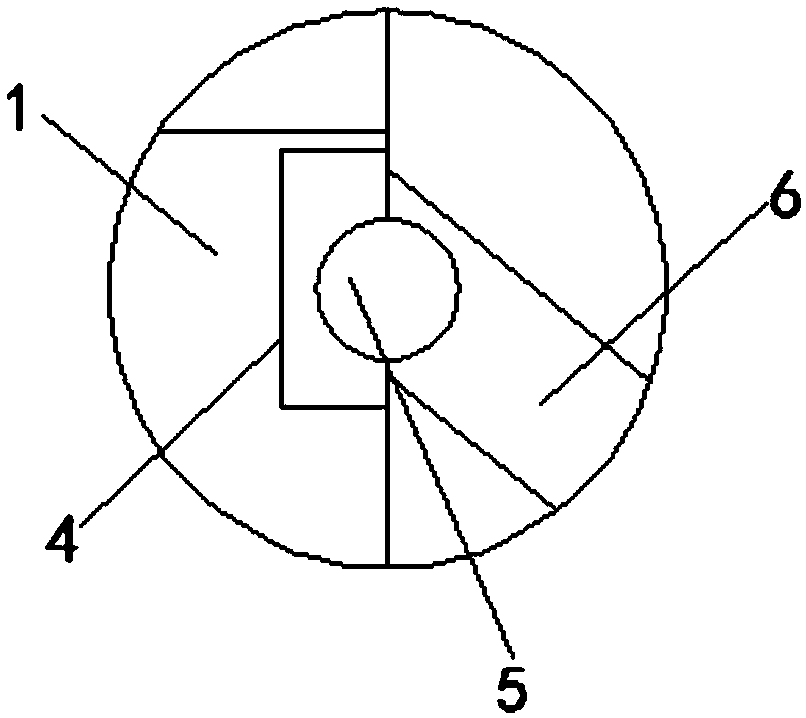

Butterfly high-efficiency self-adaptive plastic-fiber mixed filter material filter

ActiveCN101884860AHigh interception capacityHigh filtration precisionFiltration separationCorrosion resistantSmall footprint

The invention discloses a butterfly high-efficiency self-adaptive plastic-fiber mixed filter material filter. The filter consists of filter material monomers, wherein each filter material monomer is formed by connecting a weight-balancing core body and paired corrosion-resistant balancing filtering wing bodies in a matching way; the surface of the weight-balancing core body is made of plastic; the weight-balancing core body is ellipsoidal; the threshold of the average density p0 of the weight-balancing core body is between 1.30 and 1.50 g / cm<3>; the two ends of a long axis of the ellipsoidal weight-balancing core body are provided with balancing wing bodies respectively; each balancing wing body is made from fiber bundles consisting of artificial fiber yarns; and the inner ends of the artificial fiber yarns constituting each fiber bundle are fixedly connected to each end of the long axis of the weight-balancing core body and the other ends of the artificial fiber yarns are in a diffused state so as to form a whisker form. The filter has the technical advantages of high porosity, high filtering speed, high filtering accuracy, low resistance, high filth holding capacity, small backwashing water using amount, high periodic water yield, low operating cost, small floor area and high anti-load impact capacity.

Owner:新疆德安环保科技股份有限公司

Nanofiltration membrane and preparation method thereof as well as preparation method of fluorescent graphene quantum dots

ActiveCN103721574AGuaranteed separation effectAchieve separationSemi-permeable membranesLuminescent compositionsQuantum yieldEngineering

The invention provides a nanofiltration membrane and a preparation method thereof as well as a preparation method of fluorescent graphene quantum dots. The nanofiltration membrane at least comprises a function layer and a support layer, wherein the function layer comprises a plurality of first filter holes penetrating through the function layer; the support layer is connected with the function layer and comprises a plurality of second filter holes penetrating through the support layer; the apertures of the second filter holes are greater than those of the first filter holes; one second filter hole is communicated with at least one first filter hole. The nanofiltration membrane can effectively achieve separation of nanoscale particles, and the separated particles are uniform in size. The invention also provides a method for preparing fluorescent graphene quantum dots by the nanofiltration membrane, and the finally obtained fluorescent graphene quantum dots are high in luminous efficiency and high in quantum yield.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

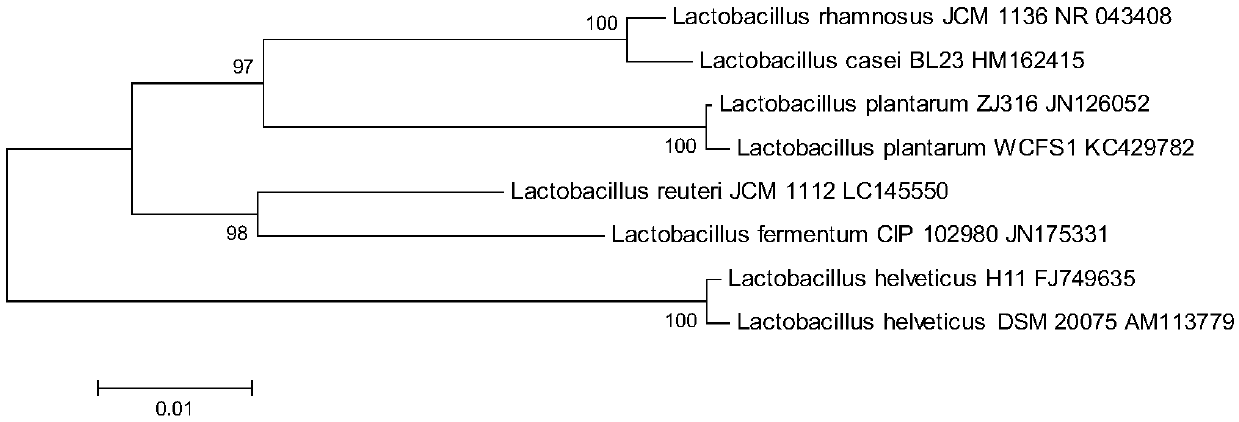

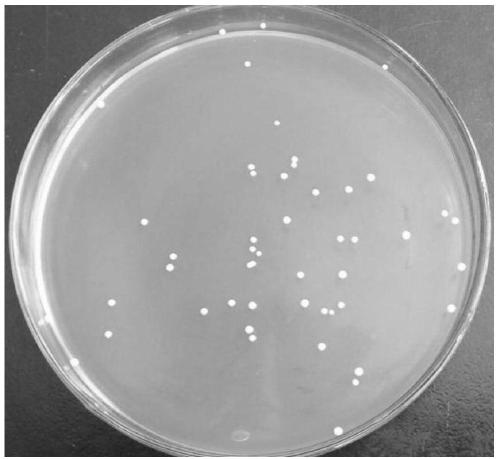

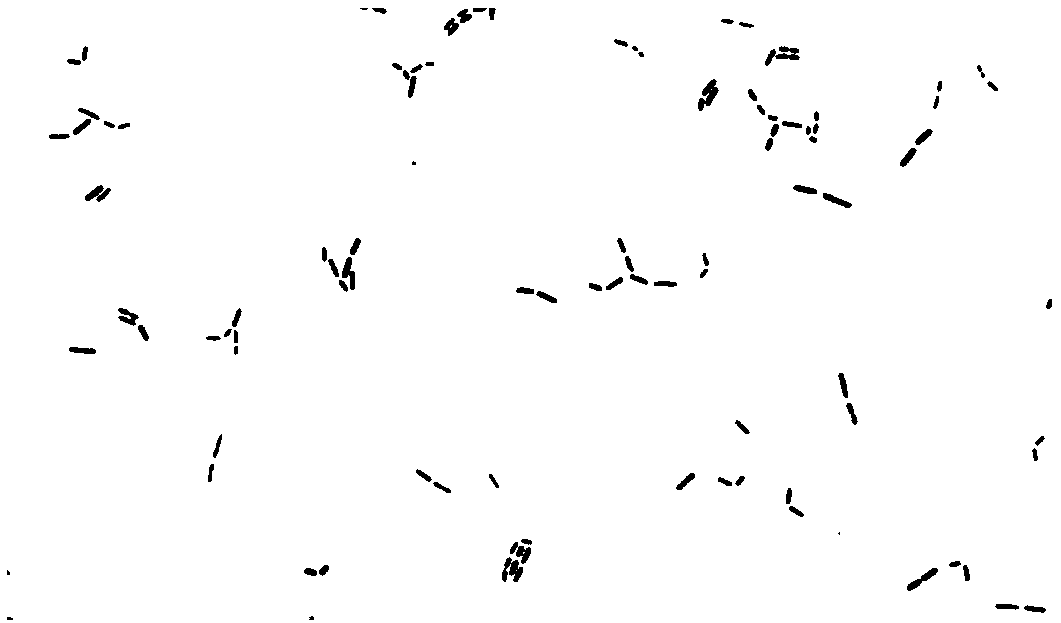

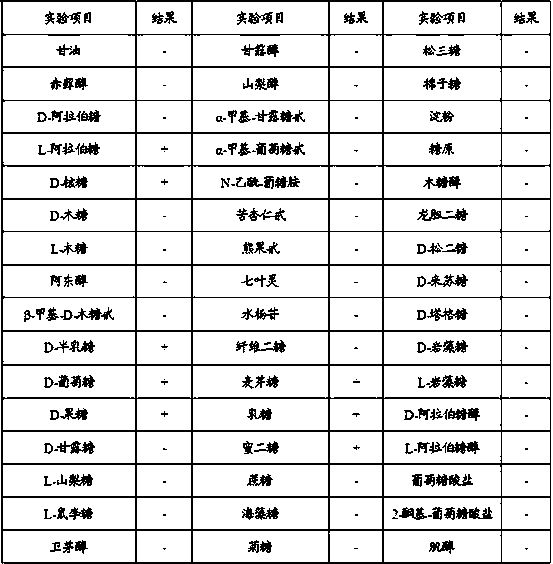

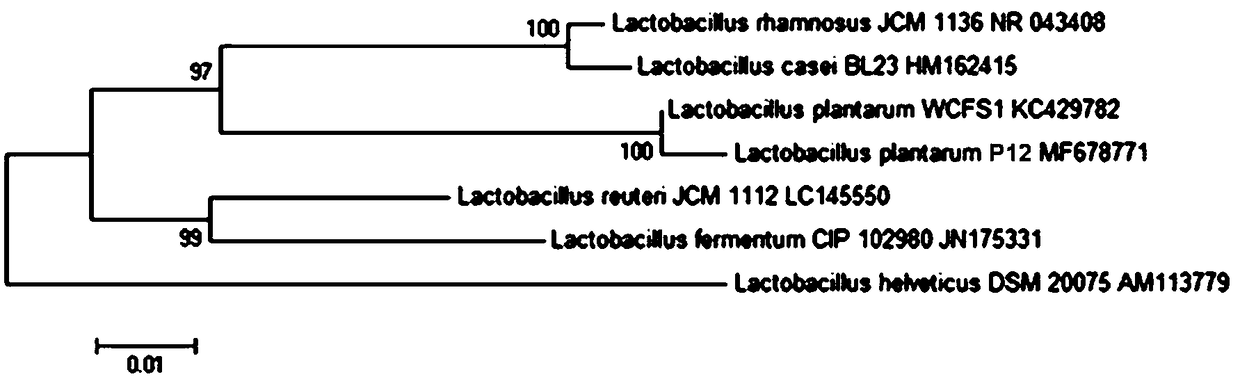

Lactobacillus helveticus H11 and application thereof

ActiveCN109517763AFast fermentation rateImprove survival rateMilk preparationBacteriaFlavorBacterial strain

The invention relates to a lactobacillus helveticus H11 and a method used for preparing a brown active milk beverage. The method comprises the following steps: preparing a MRS culture medium; activating bacterial strains; culturing bacterial strains; preparing separated milk containing glucose; preparing a brown active lactobacillus beverage, and the like. The invention has the advantages that theprepared brown active milk beverage is capable of reducing fermenting time and reducing fermenting cost, has nice taste and flavor during storage period and has higher stability. Peptides Val-Pro-Proand Ile-Pro-Pro with a function of reducing blood pressure, ACE inhibitor activity and biological activity are generated in the fermentation period, so that the functionality and healthcare propertyof milk beverage products can be enhanced.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Process for preparing NaY molecular sieve by using synthetic mother liquor

ActiveCN1286723CTake advantage ofEmission reductionFaujasite aluminosilicate zeoliteMolecular sieveSilicon

The invention relates to a method for preparing NaY molecular sieve by using the synthesis mother liquor, comprising the following steps: 1. adding the aluminium salt solution into the synthesis mother liquor to form a precipitating silicon-aluminium gel, then filtering it to obtain a silicon-aluminium gel filter cake; 2. mixing the silicon-aluminium gel filter cake with the soluble silica resource, aluminium resource and guiding agent evenly, after that, pre-crystallizing it under 30 to 100 degrees centigrade for 0.5 to 30 hours; 3. mixing the pre-crystallized product with the soluble silica resource, aluminium resource to form a crystallization mixture, after that, crystallizing it under 90 to 100 degrees centigrade for 8 to 65 hours, then filtering, washing and drying to obtain a NaY molecular sieve with large crystal grain and large granule. The invention overcomes the bias of the existed techniques by adding the pre-crystallizing step before the conventional crystallizing step to prepare NaY molecular sieve with large crystal grain and large granule, and solves slow filtering rate in post treatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

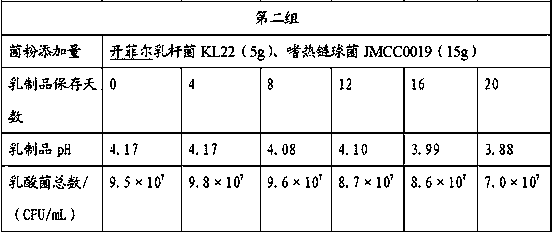

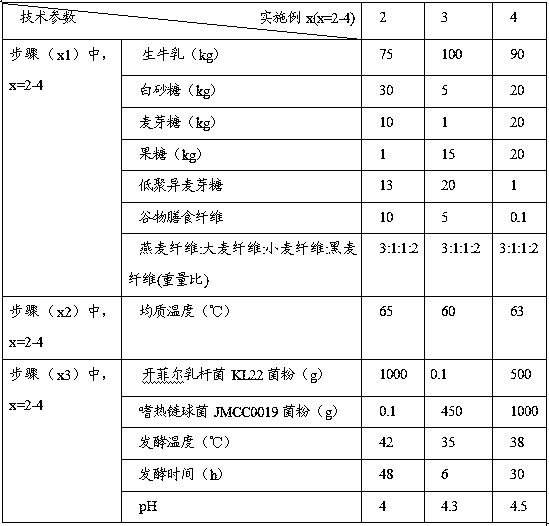

Fermented milk containing Lactobacillus kefir and preparation method of fermented milk

ActiveCN107927168ASoft tasteFull of nutritionMilk preparationStrepto/lacto-coccusNutrientStreptococcus thermophilus

The invention discloses fermented milk containing lactobacillus kefir. Lactobacillus kefir KL22 and Streptococcus thermophilus JMCC0019 are added into the fermented milk, the compatibility of ingredients of the fermented milk is reasonable, the fermented milk has soft taste, is rich in nutrients and high in viable count, can be planted through adhering suppressive enteric harmful bacteria and hasan intestine conditioning effect. The invention further provides a preparation method of the fermented milk containing lactobacillus kefir. The preparation method sequentially comprises the followingsteps: batching, homogenization, sterilization, fermentation, demulsification and the like. The preparation method has the beneficial effects that the preparation process is simple and easy to control, the fermentation period is short, lactobacillus kefir KL22 and Streptococcus thermophilus JMCC0019 can generate a synergistic effect in the fermentation process, the drawback that independent fermentation of lactobacillus kefir KL22 is slow is overcome, the fermentation speed is high, and the fermented milk has a mellow taste. The preparation method is suitable for preparing the fermented milk containing lactobacillus kefir.

Owner:JUNLEBAO DAIRY GRP CO LTD

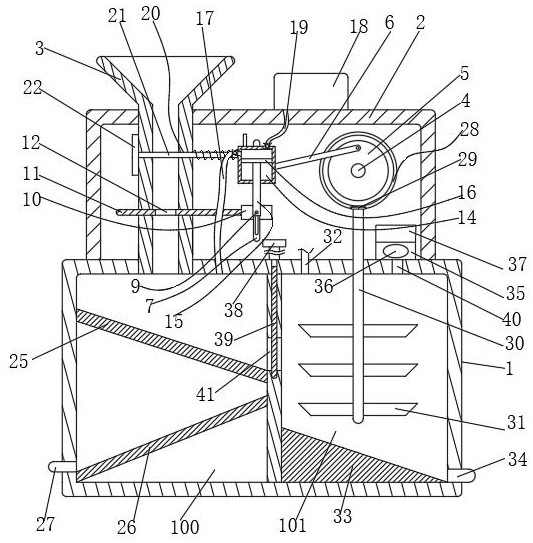

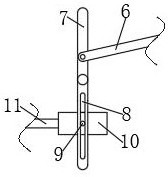

Environment-friendly pollution-free livestock and poultry manure recycling and treatment device

ActiveCN113277695AControllable reclosing timeTo achieve the effect of intermittent feedingSludge treatment by thermal conditioningInternal combustion piston enginesEnvironmental engineeringPoultry manure

The invention discloses an environment-friendly livestock and poultry manure pollution-free recycling and treatment device, and relates to the technical field of manure treatment. The left side of a moving block is fixedly connected with an insertion plate, the center part of a hopper is provided with an opening II through which the insertion plate passes and is in sliding connection with the insertion plate, the surface of the insertion plate is provided with a discharge port, a disinfection component for injecting high-temperature hot air into the separation cavity is arranged on the surface of a swing plate, and a stirring component and a circulating power generation component are arranged in a fermentation cavity. The device has the advantages that the condition that follow-up devices are blocked is avoided by means of intermittent discharging of manure, high-temperature gas is matched to sterilize the manure, the pollution-free effect is achieved, finally, biogas generated by fermentation is used for power generation, energy is provided for the device, the environment-friendly effect is achieved, and the device has the effect of better practicability.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

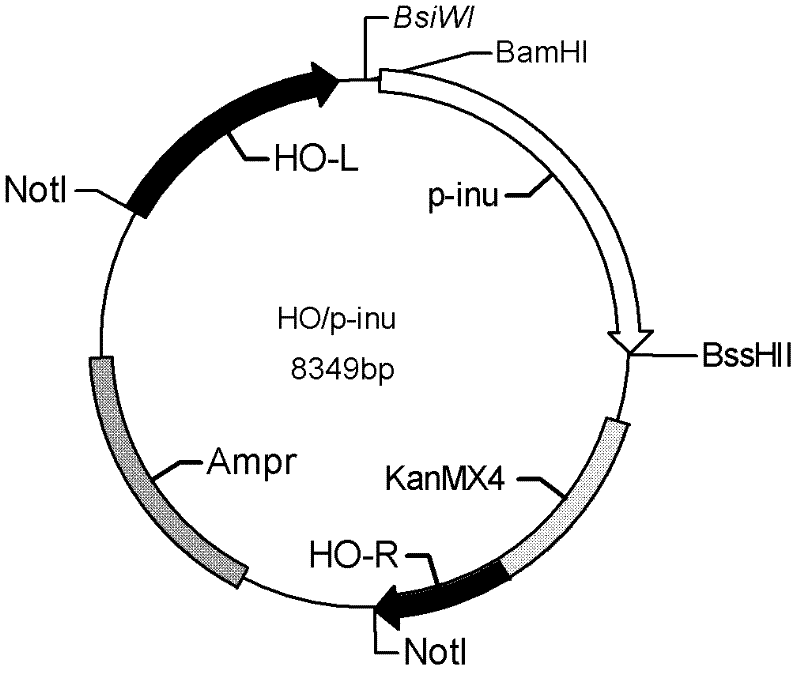

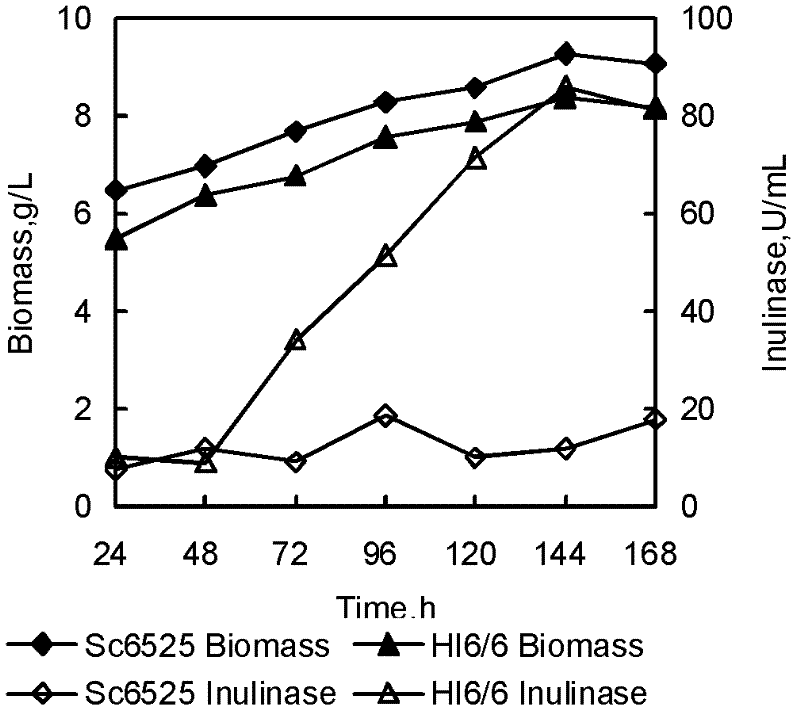

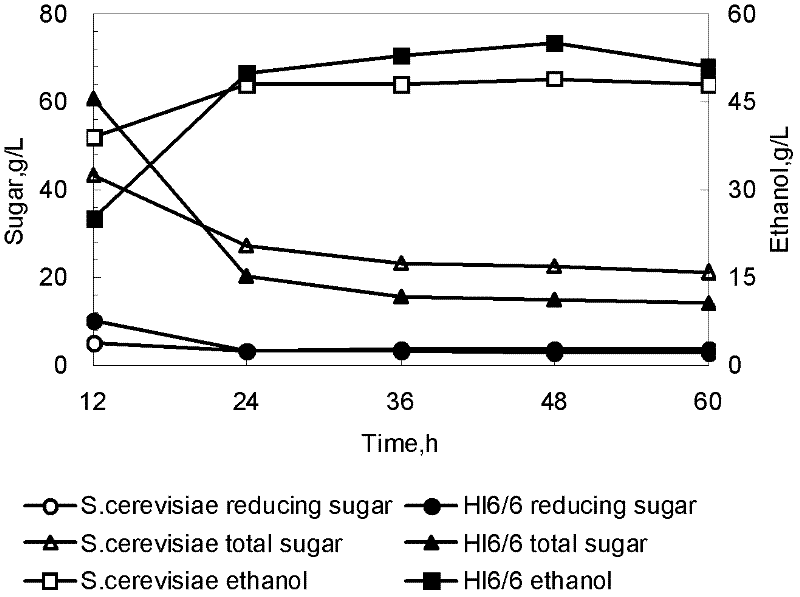

Method for preparing ethanol by fermenting jerusalem artichoke through recombinant saccharomyces cerevisiae

ActiveCN102229966AEthanol fermentation rate is fastLow residual sugarBiofuelsMicroorganism based processesChemistryEthanol fuel

The invention belongs to the field of biotechnology and discloses a method for preparing ethanol by fermenting jerusalem artichoke through recombinant saccharomyces cerevisiae. The method provided by the invention comprises the following steps of: taking the jerusalem artichoke powder as a culture medium and carrying out anaerobic fermentation by utilizing the recombinant saccharomyces cerevisiae to prepare the ethanol, wherein the fermentation concentration of the ethanol can be more than 9% in 60 hours. By utilizing the raw material and the fermenting method provided by the invention, corn meal, wheat meal and the like which are grain raw materials and are used in the traditional ethanol industrial production in China can be replaced and a foundation is laid for the non-grain-fuel ethanol production.

Owner:DALIAN UNIV OF TECH

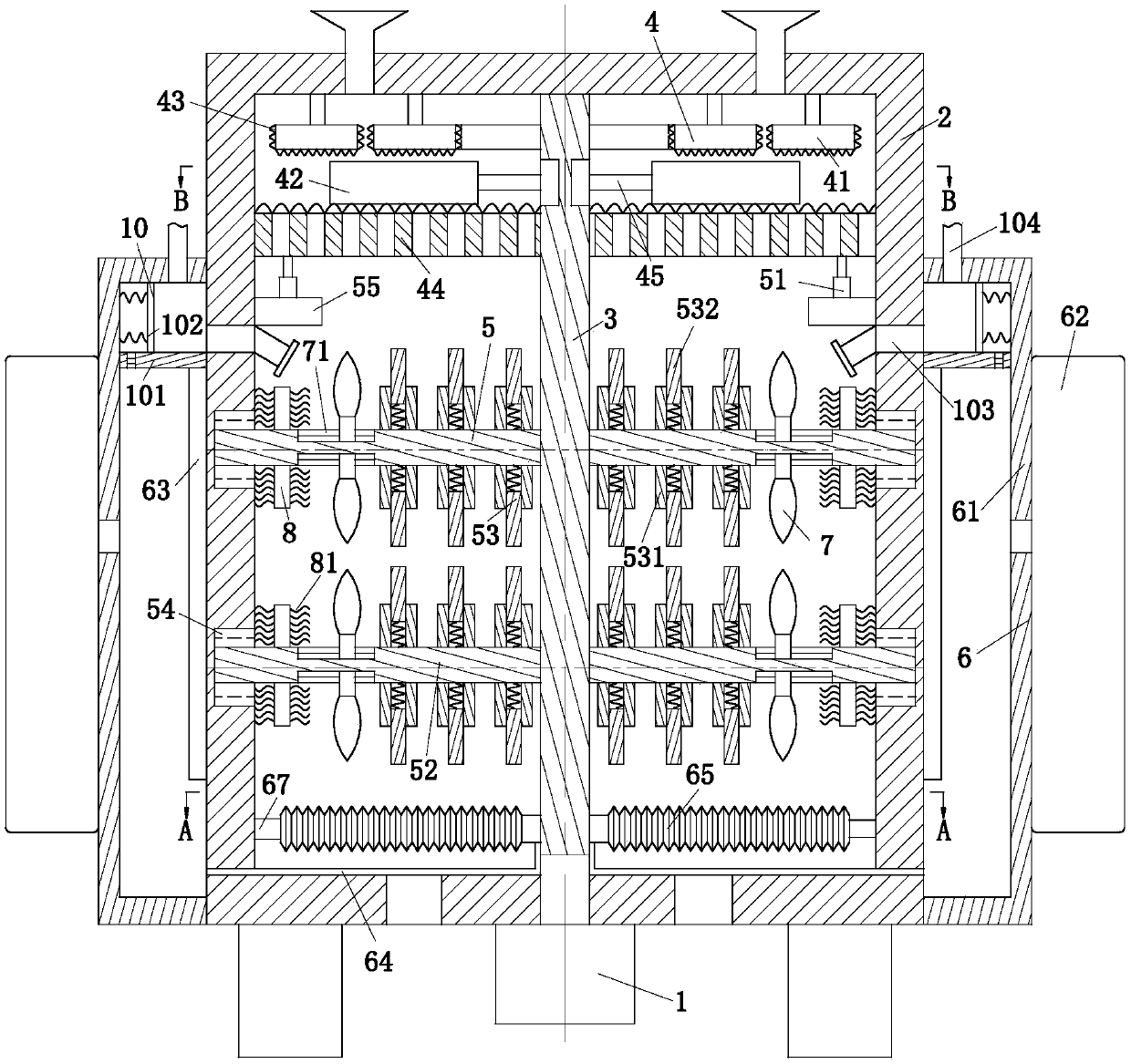

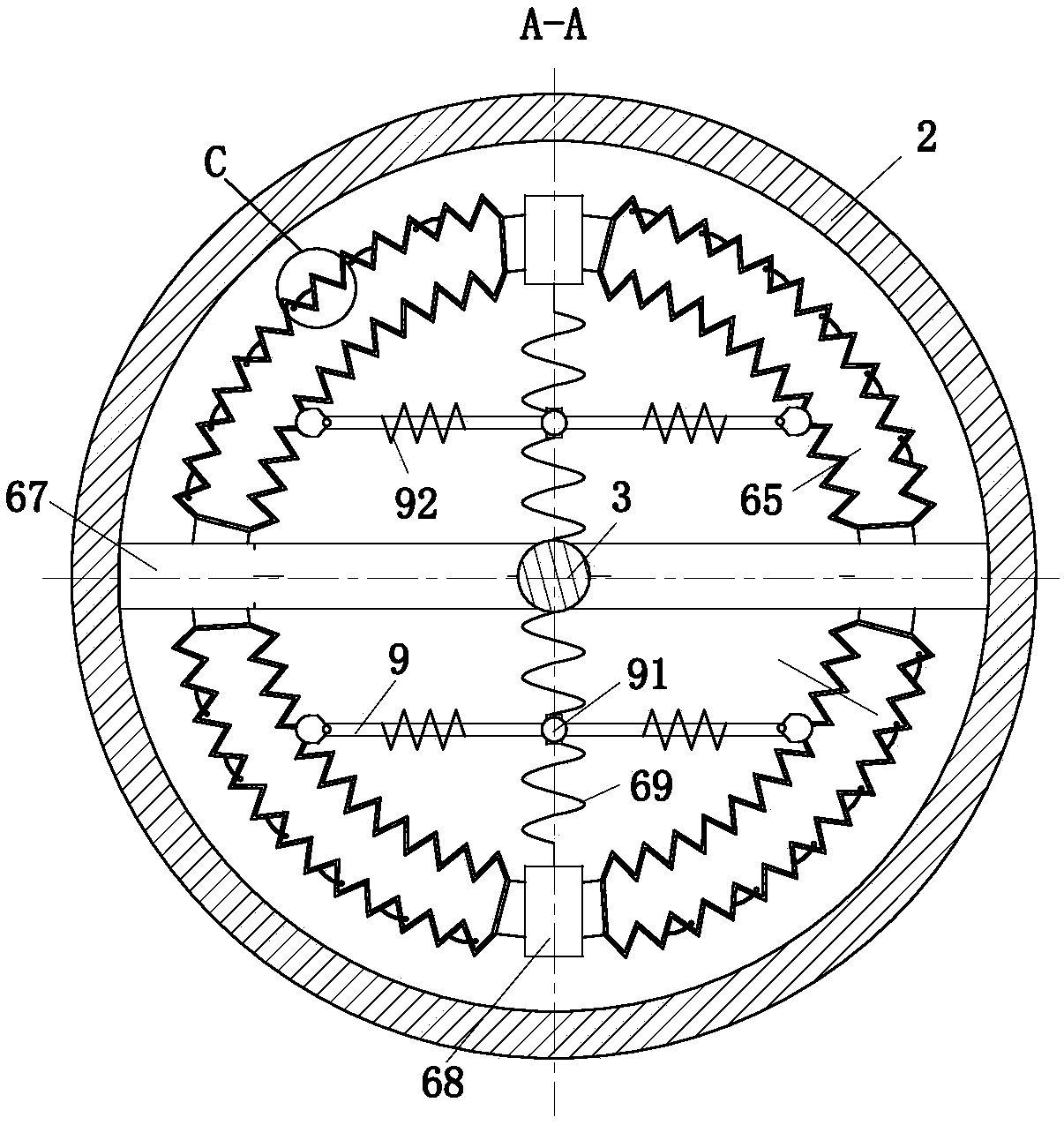

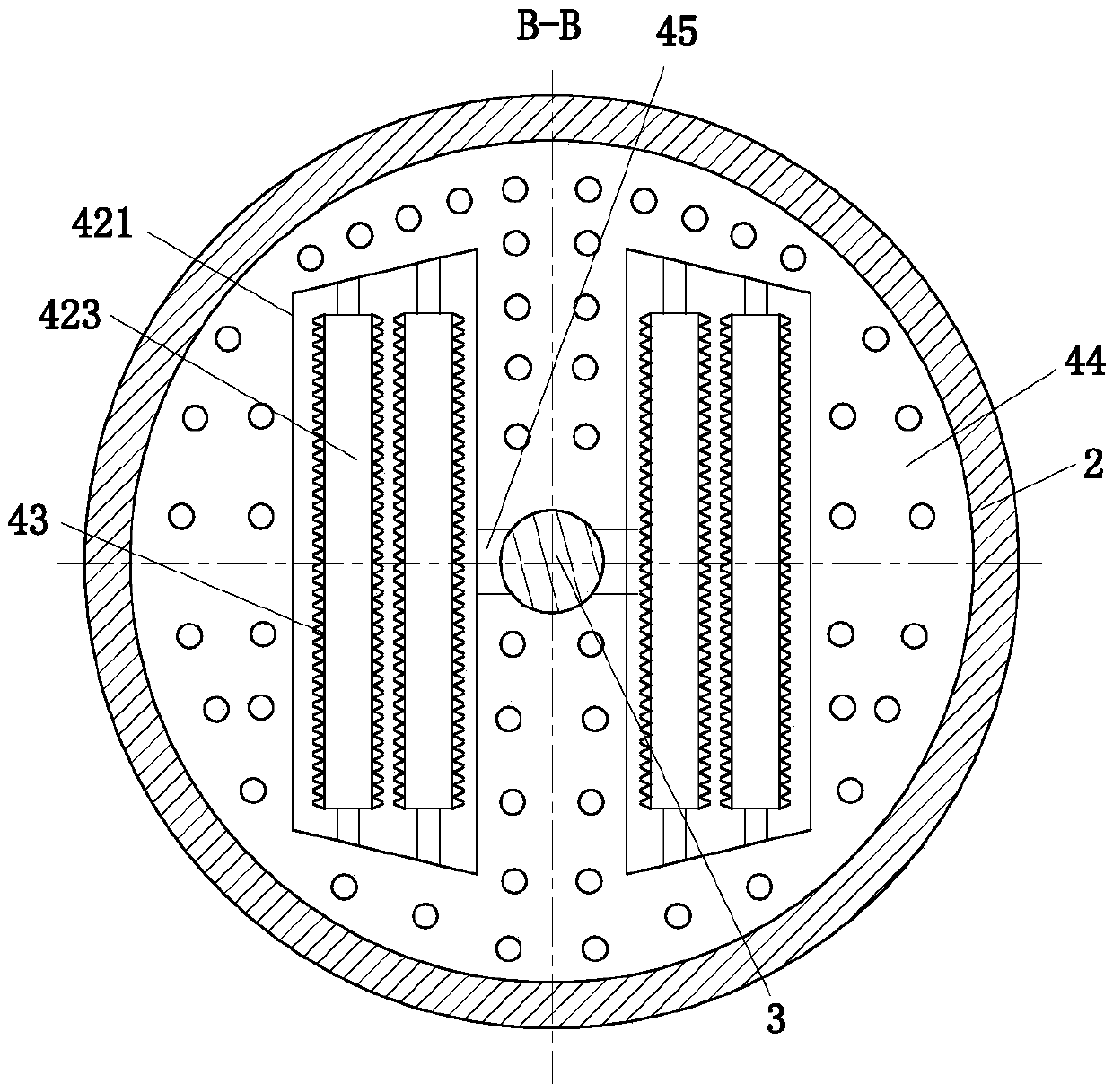

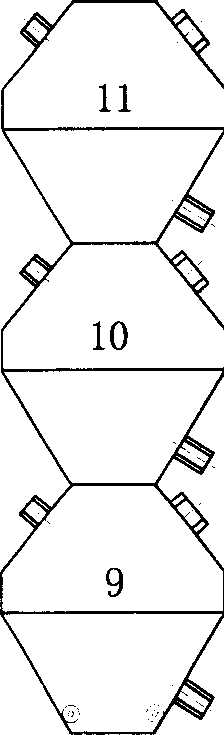

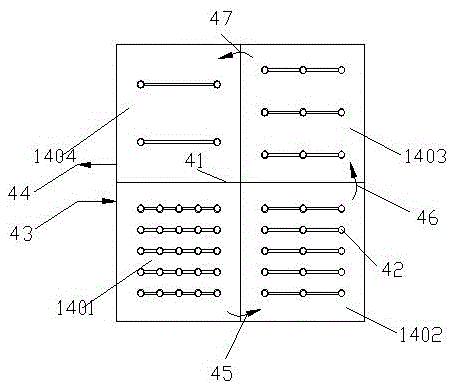

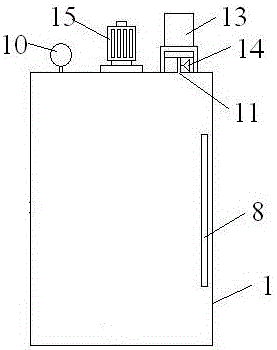

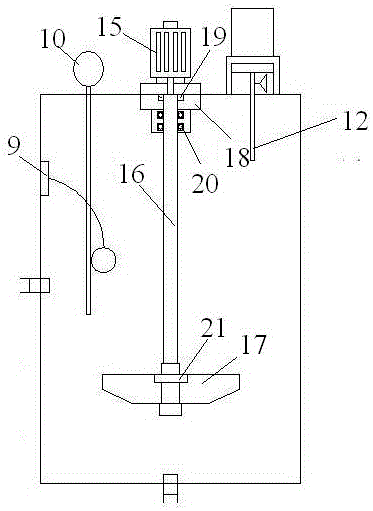

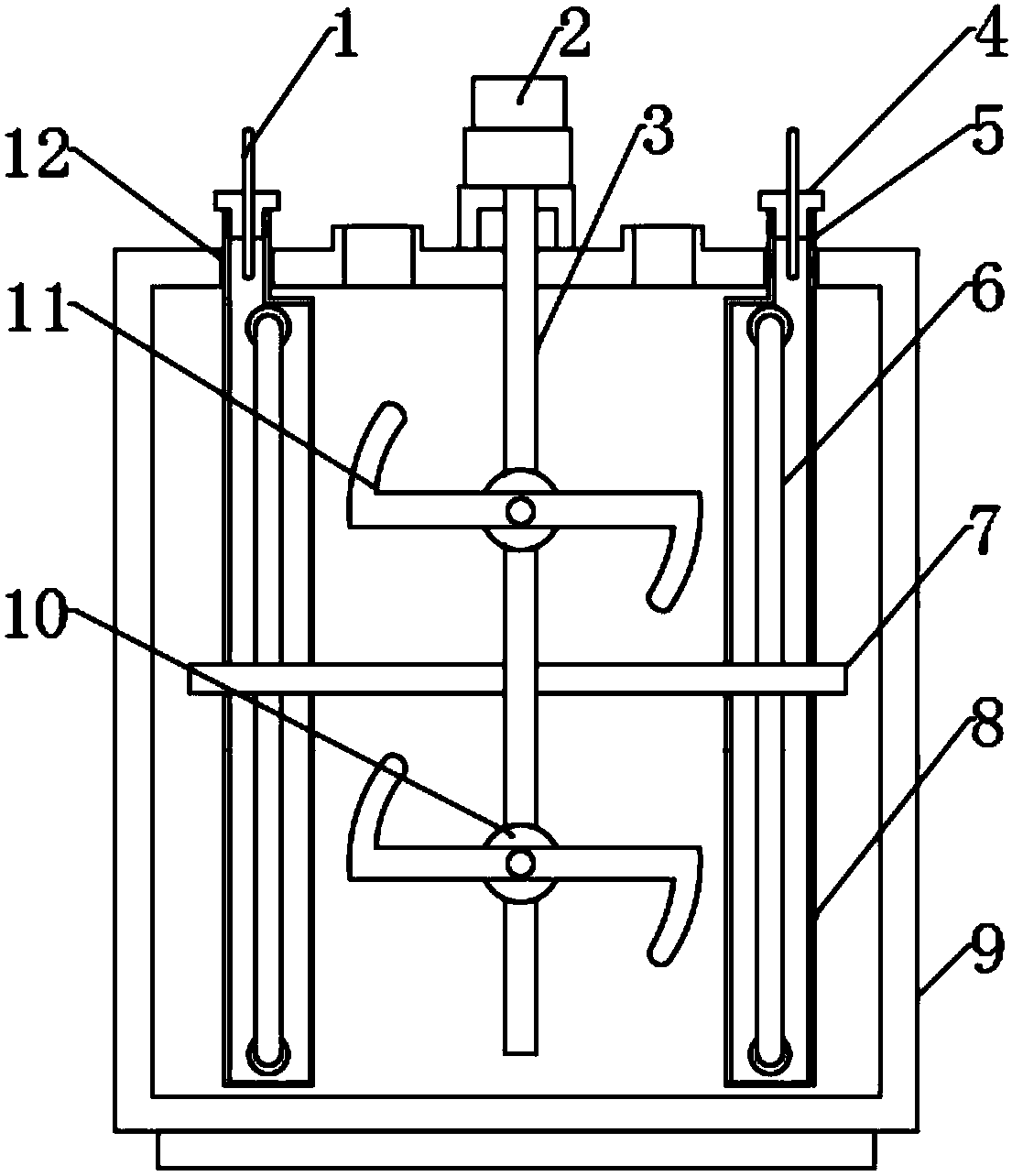

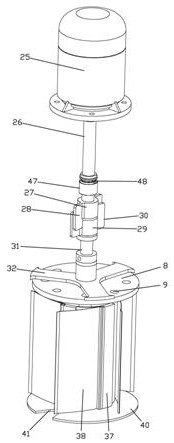

Energy-saving and environment-friendly microbial fermentation system

InactiveCN109609343AFast fermentation rateIncrease profitBioreactor/fermenter combinationsBiological substance pretreatmentsUtilization rateIndustrial engineering

The invention belongs to the technical field of microbial fermentation, and in particular to an energy-saving and environment-friendly microbial fermentation system. The system comprises feeding ports, discharge ports, a motor, a work box, a support base and a controller. The support base and the bottom of the work box are fixedly connected; the motor is located at the bottom of the work box, andthe output end of the motor passes through the bottom of the work box; a drive shaft is fixedly connected the output end of the motor located in the work box; the end, away from the output end of themotor, of the drive shaft and the top of the work box are in rotating connection; crushing units are arranged on the upper part in the working box; stirring units are arranged below the crushing units; and an aeration unit is arranged outside the working box. The microbial fermentation system has high microbial fermentation rate, and high utilization rate of fermentation raw materials.

Owner:WEIHAI OCEAN VOCATIONAL COLLEGE

Anti-blockage filtering device for petroleum

InactiveCN108034452ASimple structureEasy to useTreatment with plural serial refining stagesMagnetic separationPetroleumFilter effect

The invention relates to the technical field of petroleum gathering and transporting, and discloses an anti-blockage filtering device for petroleum. The upper end of the left side of a shell is fixedly connected with a petroleum inlet pipe which is communicated with the upper end of the left side of the shell; a rotating groove is formed in each of the positions, below the petroleum inlet pipe, ofthe left side and the right side of the inner wall of the shell; the inner wall of each of the two rotating grooves is fixedly connected with a rotating rod; the surface of each of the two rotating rods is connected with a down-flow plate in a sleeving manner; the positions, below the down-flow plates, of the inner wall of the shell are fixedly connected with a filtering plate; a sliding groove is formed in the top of the filtering plate; the inner wall of the sliding groove is connected with a settling box in a sliding manner; petroleum outlet holes are formed in the surface of the settlingbox; filtering holes are formed in the top of the filtering plate; the filtering holes are communicated with the sliding groove. The anti-blockage filtering device for the petroleum is simple in structure, can perform multi-stage filtering treatment on the petroleum and ensure a better filtering effect, and can also clean filtered residues to prevent petroleum filtering from blockage, so that thefiltering efficiency and the purity of the petroleum become higher.

Owner:盛江

Method for organic surface modification of nanometer attapulgite

InactiveCN105219126AEasy to precipitate and stratifyEasy separationPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSURFACTANT BLENDSurface modification

The invention provides a method for organic surface modification of nanometer attapulgite. The method comprises the following steps: (1) inorganic surface modification of nanometer attapulgite: a step of heating dispersed and purified nanometer attapulgite aqueous dispersion to 40 to 100 DEG C and carrying out inorganic surface modification on nanometer attapulgite under stirring, wherein a surface coating substance of nanometer attapulgite is one, two or three selected from the group consisting of ZnO hydrate, Al2O3 hydrate and MgO hydrate, and in terms of oxide, a mass ratio of the inorganic coating substance to nanometer attapulgite is 5 to 30%; (2) organic surface modification of nanometer attapulgite: a step of the pH value of the inorganic surface coated nanometer attapulgite aqueous dispersion so as to allow the surface of nanometer attapulgite to be positively charged, then adding desired anionic surfactant under stirring, wherein a mass ratio of the anionic surfactant to nanometer attapulgite is 3% to 20% and the anionic surfactant is added after dissolving in deionized water, and continuing stirring for 5 to 600 min after completion of addition; and (3) post-treatment: a step of subjecting a product to solid-liquid separation, washing, drying and crushing after completion of a reaction so as to eventually obtain the anionic surfactant surface modified nanometer attapulgite.

Owner:蒋寿悟

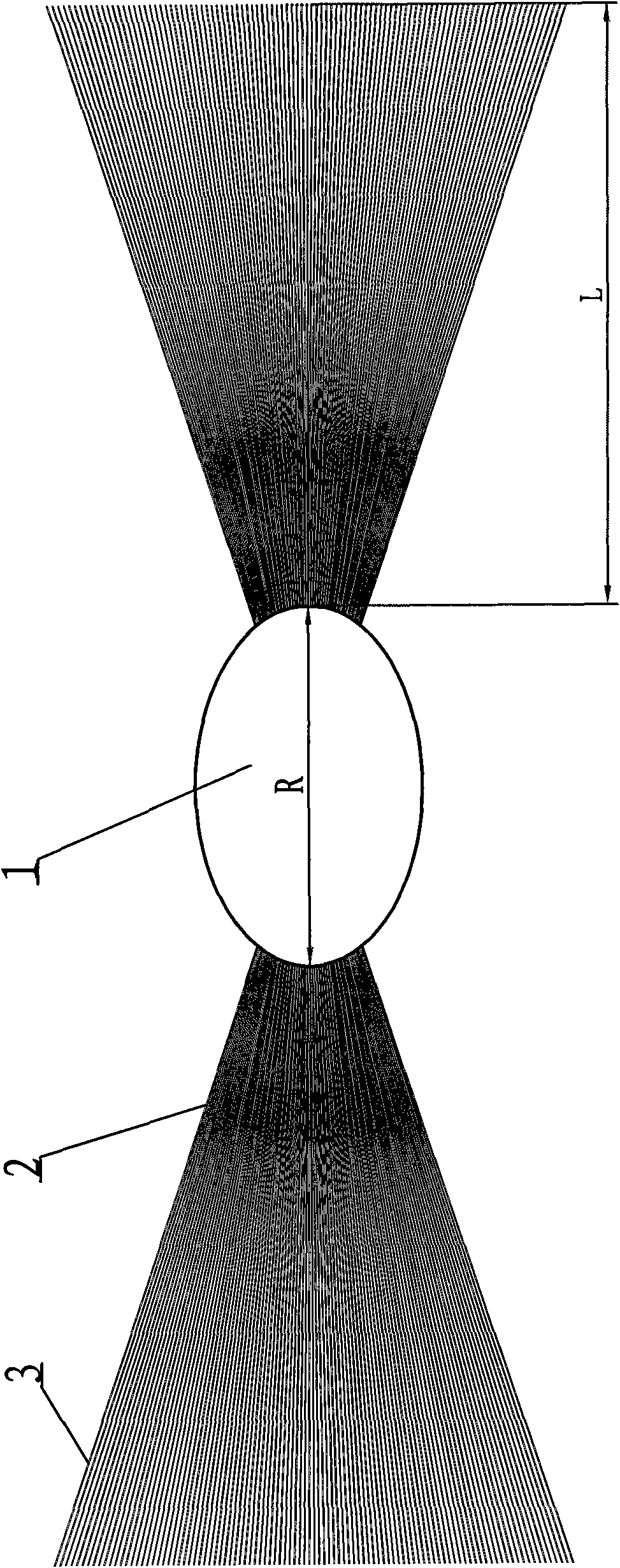

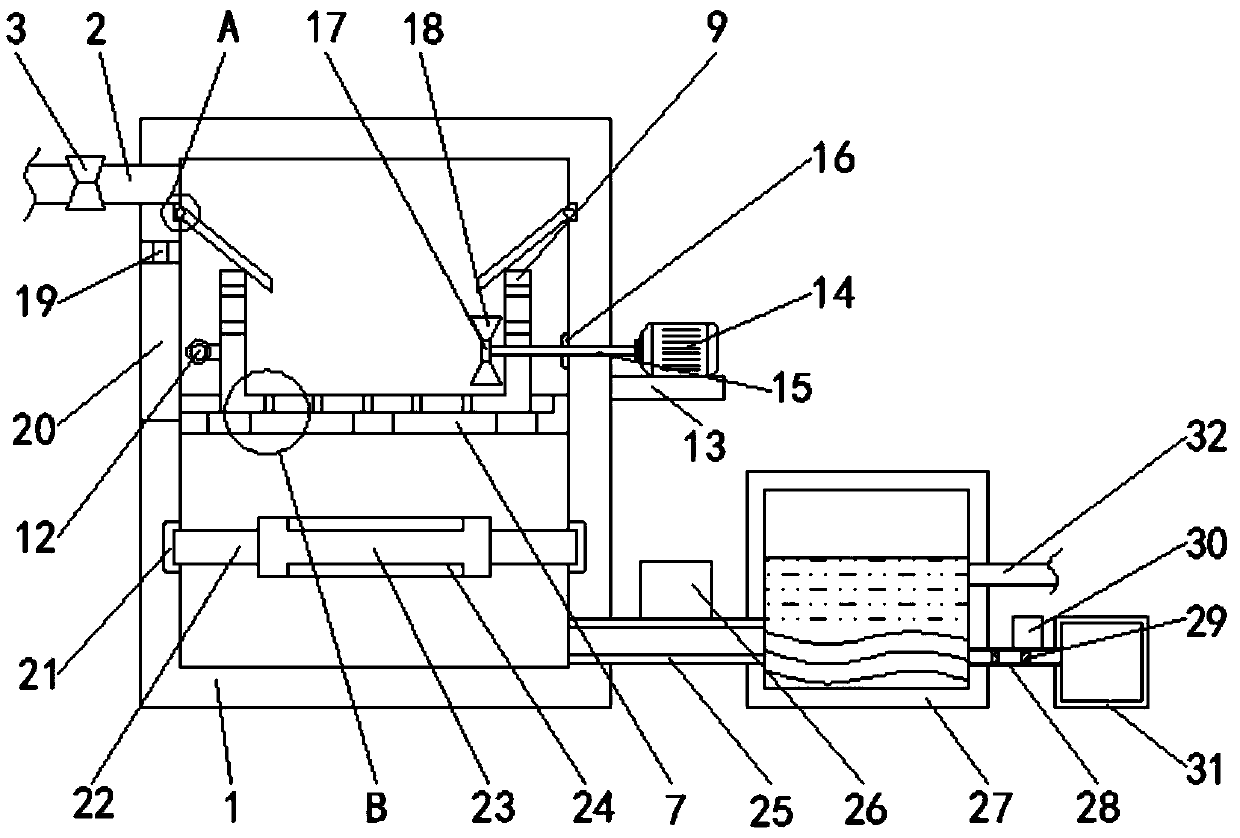

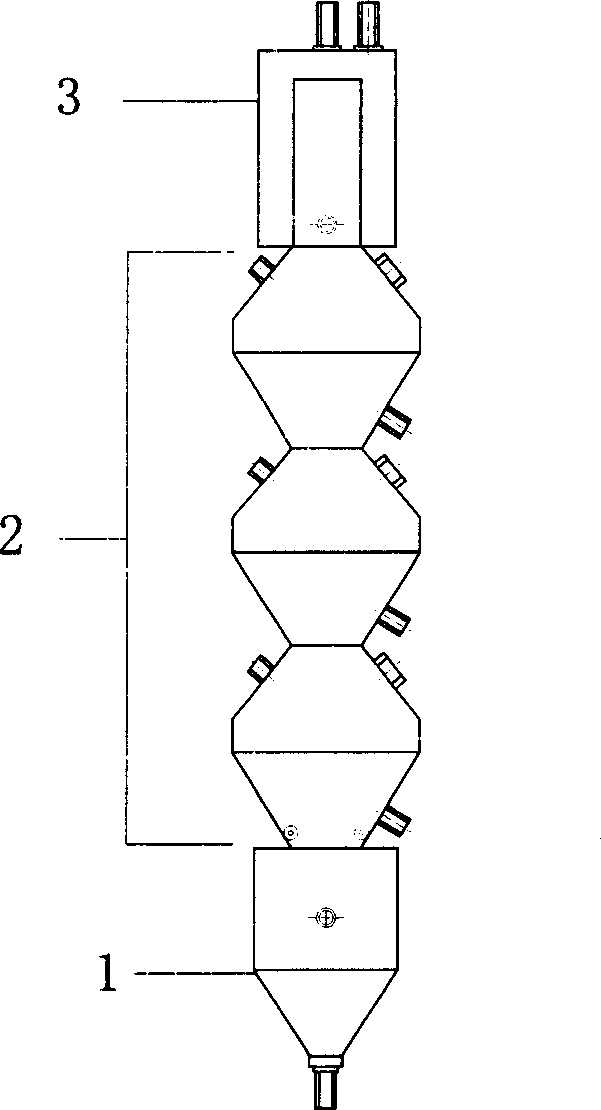

Three-stage alcohol fermentation bioreactor with fluidized-bed for fixed yeast

InactiveCN1840645AVigorous fermentation reactionLow shearBioreactor/fermenter combinationsBiological substance pretreatmentsYeastAlcohol

The three-stage fluid bed fixing barm alcohol fermentation bio-reactor comprises: a gas holder, a three-stage fusiformate fermentation body, and a storage chamber for fermented glutinour rice; all vertically connected in turn by flange. This invention is simple, needs low consumption and land area, and improves material utility.

Owner:SHANGHAI JIAO TONG UNIV

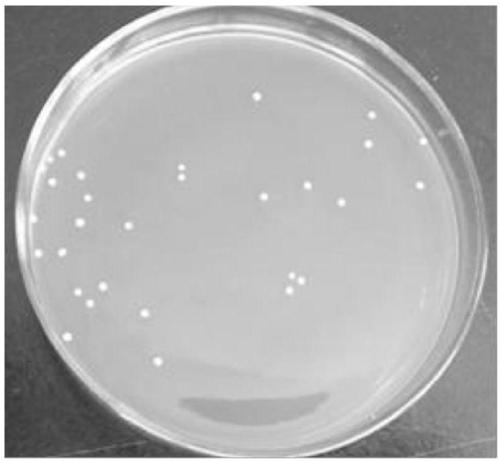

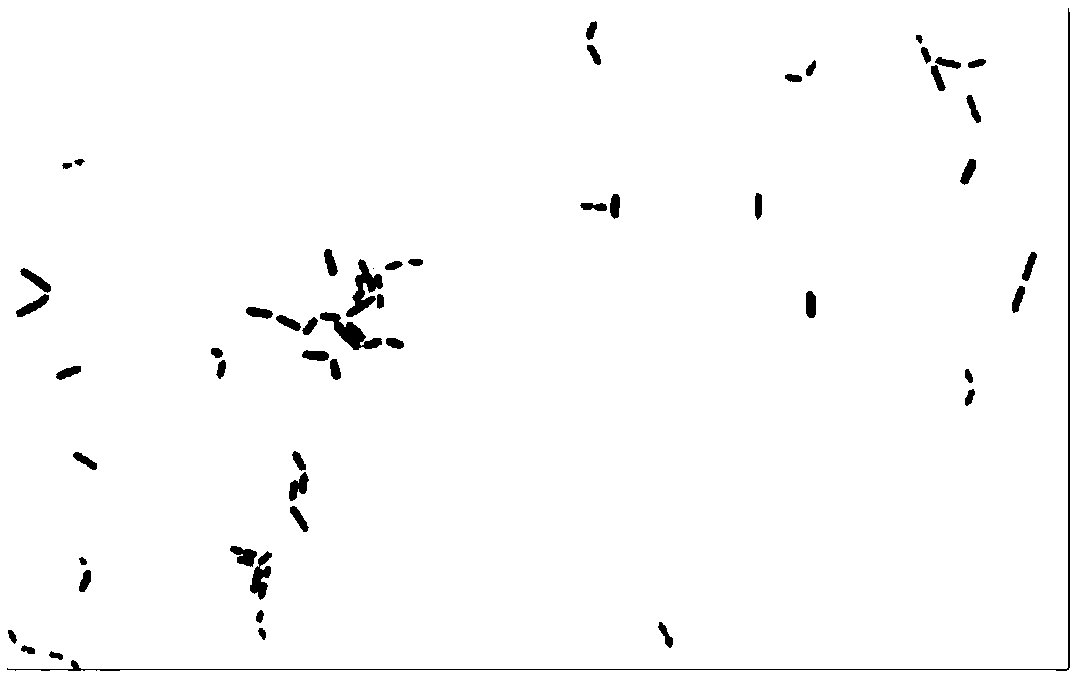

Lactobacillus plantarum P12 and application thereof

ActiveCN109504636AFast fermentation rateImprove survival rateBacteriaMicroorganism based processesLactic acid bacteriumEmulsion

The invention relates to Lactobacillus plantarum P12 and application thereof. A method for preparing a brown active milk beverage by the Lactobacillus plantarum P12 comprises the steps of: preparing an MRS culture medium, activating strains, culturing the strains, preparing degreasing emulsion containing glucose, and preparing a brown active lactic acid bacteria beverage. The brown active lactic acid bacteria beverage has significantly higher ACE inhibitory activity than commercial leavening agents and has good storage stability. The bacterium has relatively higher survival rate in the gastrointestinal fluid, thereby proving that the bacterium has excellent probiotic characteristics and has relatively strong viability in human body.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

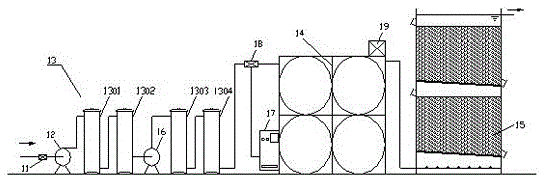

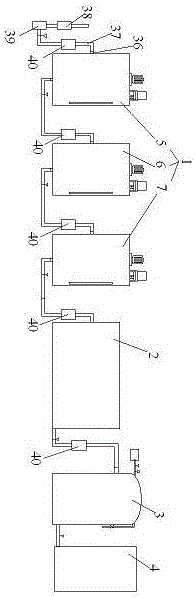

Integrated process and equipment for eutrophic water body control

ActiveCN105565541AQuick filterIncrease dissolved oxygenSpecific water treatment objectivesWater contaminantsEngineeringOxygen

The invention discloses an integrated process and equipment for eutrophic water body control. The process comprises multiple stages of fast filtering work procedures, a strong oxidation work procedure and a deep adsorption work procedure, wherein the multiple stages of fast filtering work procedures operate in a serial connection way. Suspended substances and algae cells in the water body can be fast filtered; phycotoxin, nitrogen and phosphorus nutrients and organic contaminants can be effectively removed; meanwhile, the effect of improving the water body dissolved oxygen can be achieved, so that the control effect of resolving the current problems and eliminating the root causes is achieved. In addition, through technology integration, the developed equipment is portable and intensive; the moving and the transportation are convenient; the process and the equipment are particularly applicable to the prevention and the emergency treatment of slight eutrophic water body algae bloom in urban view and scape lakes, medium-and-small-sized reservoirs and semi-sealed gulfs.

Owner:SHENZHEN ACAD OF ENVIRONMENTAL SCI

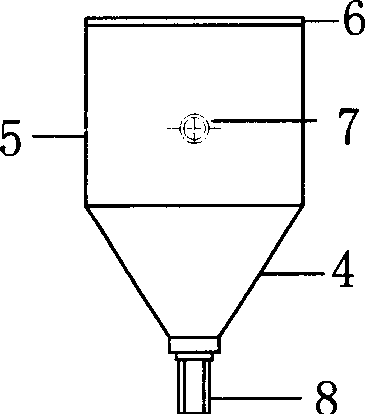

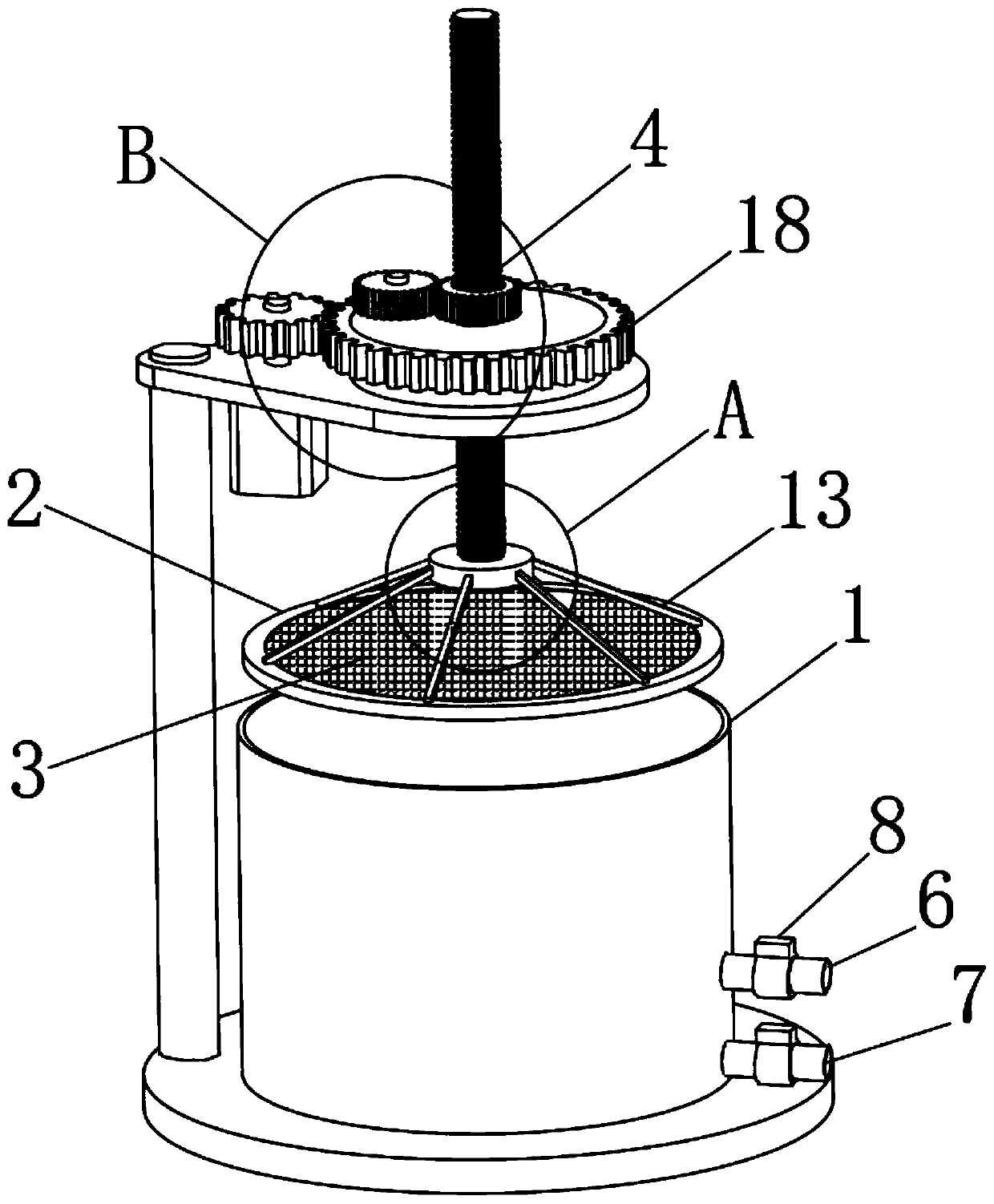

Oil residue separation equipment for oil-tea production

InactiveCN110760378AAvoid cloggingFast fermentation rateFatty-oils/fats refiningMoving filtering element filtersCamellia oleiferaPetroleum engineering

The invention discloses oil residue separation equipment for oil-tea production. The oil residue separation equipment for oil-tea production comprises an oil barrel, an annular plate and a filtering net; the filtering net is fixed in the annular plate; the annular plate is matched with the inner wall of the oil barrel; a pressurizing device is arranged at the top of the annular plate a cleaning device for removing impurities from the surface of the filtering net is arranged at the bottom of the inner side of the oil barrel; and a first oil outlet pipe and a second oil outlet pipe are arrangedat the bottom of the oil barrel sequentially along a vertical direction. According to the oil residue separation equipment for oil-tea production, the filtering net moves into the oil barrel through the pressurizing device and continuously moves downwards in the oil barrel to arrive at the bottom of the oil barrel, the filtering net filters impurities, which the tea oil contains, in the oil barrelin the moving process, and the filtering net is subjected to a constant pushing force in the moving process, so the filtering speed of the tea oil is high; and oil residues attached to the filteringnet can be eliminated by a cleaning device, so that blockage of the filtering net by the oil residues is avoided.

Owner:湖南省康多利油脂有限公司

A method for efficiently separating and purifying palladium and rhodium from alloy flakes containing palladium and rhodium alloy

ActiveCN109609783BFast fermentation rateTo achieve the purpose of purificationProcess efficiency improvementSulfatePotassium manganate

The invention provides a method for efficient separation and purification of palladium and rhodium from an alloy sheet containing palladium-rhodium alloy. The method comprises the steps that the palladium-rhodium alloy sheet is dissolved with a nitromurlatic acid solution, then palladium is dissolved in the nitromurlatic acid solution, while rhodium resistant to corrosion from the nitromurlatic acid solution is not dissolved and deposits at the bottom of a container in the form of fine powder, so that palladium and rhodium are separated; potassium permanganate and ammonium chloride are added into the solution containing palladium, so that red palladium sediment is obtained to realize purification, and then a chemical reagent is added to generate dichlorodiamminepalladium which is used as araw material for synthesizing tetraamminepalladium sulfate; and the insoluble rhodium is roasted together with sodium peroxide and is then soaked in acid to be dissolved to obtain rhodium-containingliquor, and rhodium powder with the purity of 99.95% is obtained after purification and reduction.

Owner:KANFORT JIANGMEN ENVIRONMENTAL TECH CO LTD

Complete equipment for treating chromium wastewater

ActiveCN106630250AImprove processing efficiencyEasy to handleWater treatment parameter controlWater contaminantsLiquid wasteWater source

The invention provides complete equipment for treating chromium wastewater. The complete equipment comprises a reaction tank, a pressure filter, a mechanical filter and an activated carbon absorber, wherein the reaction tank is provided with a water level meter, a float switch, a pH sensor, a chemical inlet and stirring equipment, the mechanical filter is provided with a high-pressure gas inlet pipe and a gas outlet pipe, and the interior of the mechanical filter is divided into an upper coarse filtering layer and a lower refined filtering layer. The complete equipment has the advantages that the complete equipment is simple in structure, reasonable in design, capable of lowering equipment operation cost, increasing chromium wastewater treatment efficiency and effect and effectively controlling feeding quantity, visual in liquid level, fast in wastewater filtering and high in safety; filtered water is quite clean after being absorbed by activated carbon and can be directly used by other working procedures or used for cleaning, environment pollution is avoided, water resource utilization rate is increased, and waste is avoided.

Owner:JIANGSU HUAXING ELECTRICAL TECH

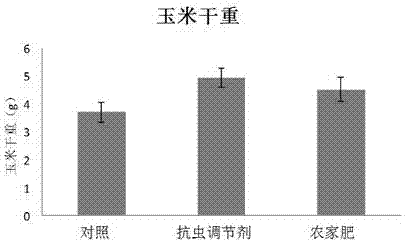

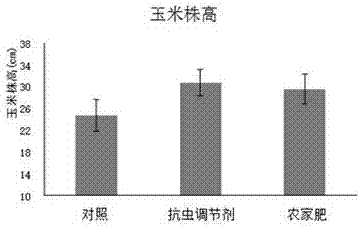

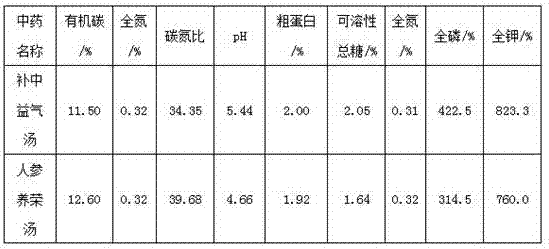

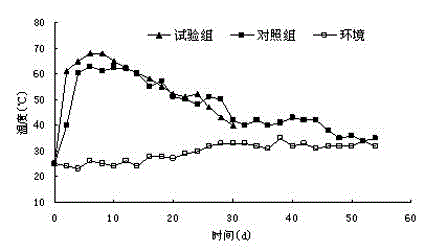

Insect-resistant soil regulator taking traditional Chinese medicine wastes as matrix and production method of soil regulator

InactiveCN107446955AShort fermentation cycleFast fermentation rateCalcareous fertilisersMicroorganismsDiseaseSaccharum

The invention relates to an insect-resistant soil regulator taking traditional Chinese medicine wastes as a matrix and a production method of the soil regulator. The production method comprises the following steps: inoculating green muscardine fungus to a seed medium, and preparing a fermentation seed solution, wherein the seed medium comprises glucose, yeast powder, peptone and a potato liquid; and inoculating the fermentation seed solution to a solid-phase medium, wherein the inoculation amount is 10-15%, and standing and fermenting in a shallow tray solid fermentation apparatus at the temperature of 25-30 DEG C, wherein the solid-phase medium comprises the traditional Chinese medicine wastes, saccharose, maize syrup powder, bean pulp, Ca(OH)2 and wood vinegar. The fermentation method in the invention is short in fermentation cycle, mild in conditions and easy to control and amplify, the provided solid-phase fermentation matrix is high in fermentation rate, and the fermented soil regulator has an insect-resistant effect; and meanwhile, the functional substance wood vinegar can provide the characteristics of promoting growth, resisting diseases and the like.

Owner:MICROBIOLOGY INST OF SHAANXI +1

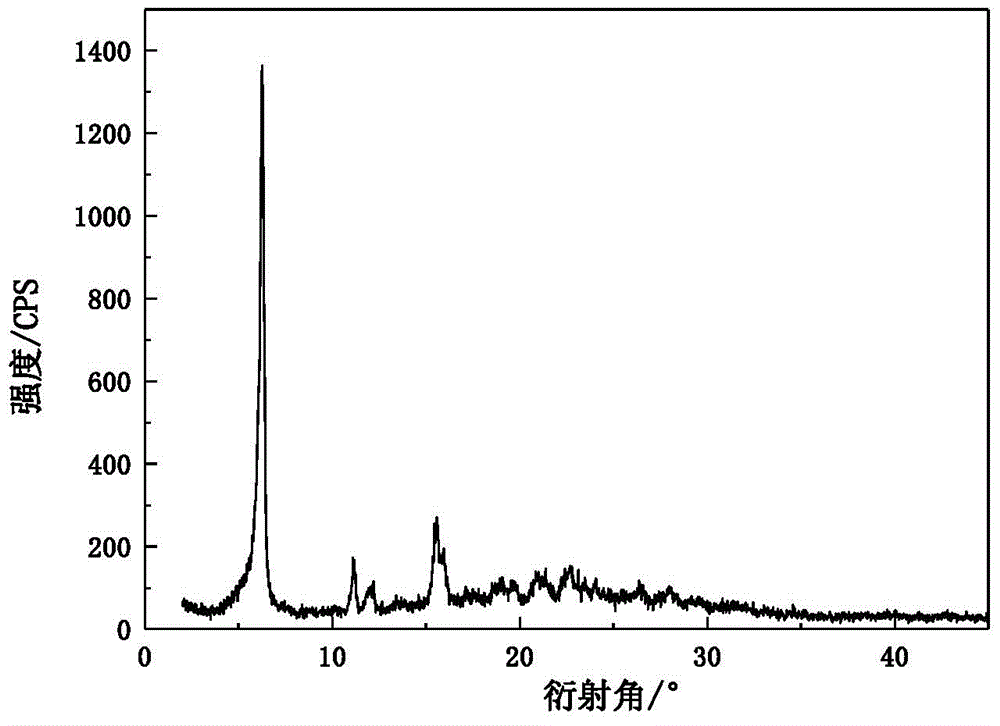

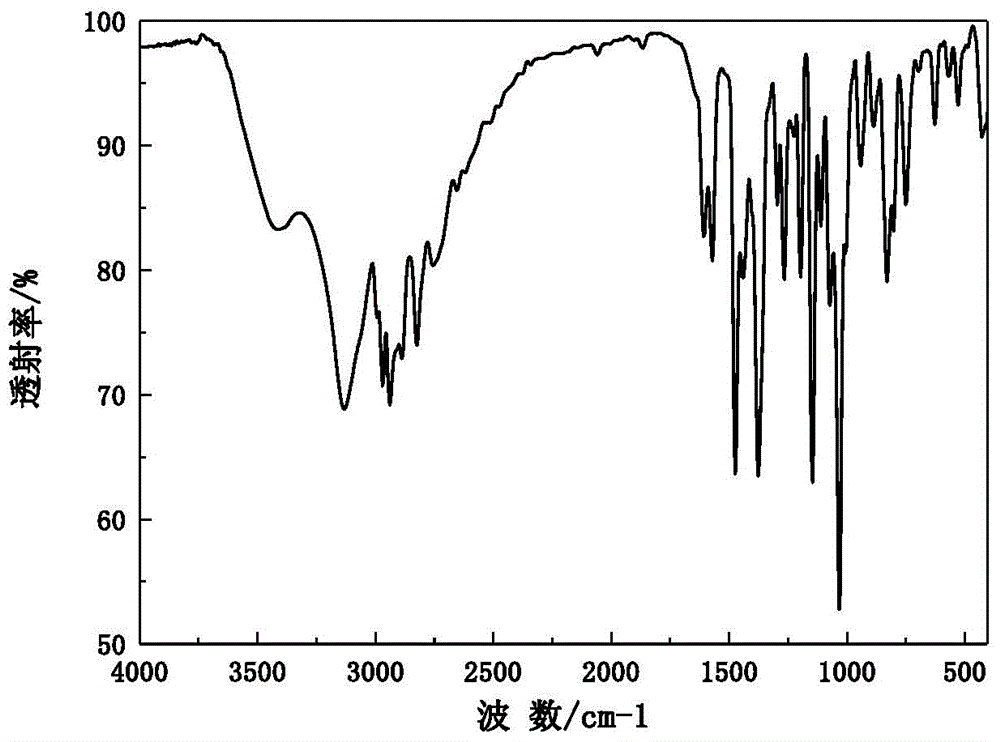

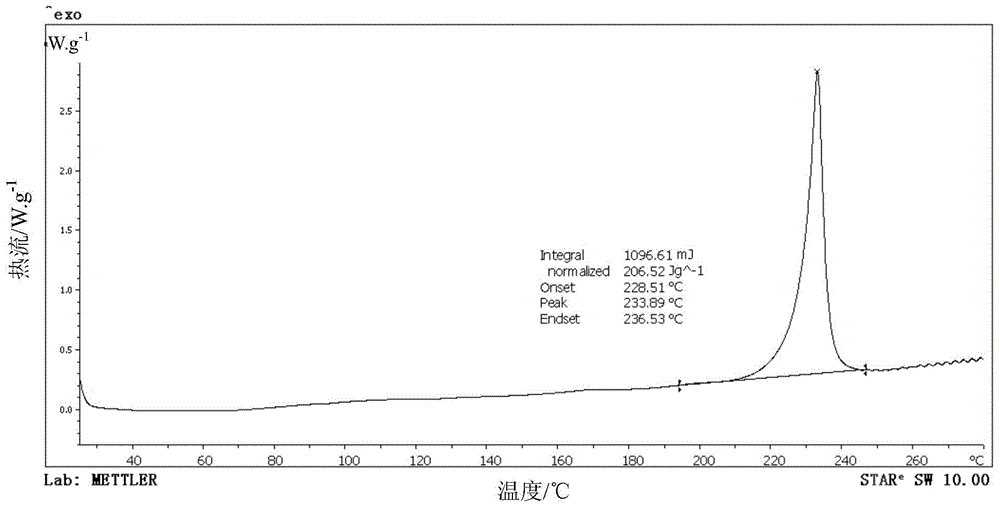

Omeprazole sodium semihydrate and preparation method thereof

ActiveCN104788426AShort timeImprove efficiencyOrganic chemistry methodsOmeprazole SodiumOrganic solvent

The invention discloses omeprazole sodium semihydrate and a preparation method thereof. Every mole of omeprazole sodium semihydrate contains 0.5 mole of water, and an X-ray diffraction spectrum has characteristic peaks at diffraction angles 2Theta of 6.26+ / -0.1 degrees, 11.10+ / -0.1 degrees, 12.20+ / -0.1 degrees, 15.58+ / -0.1 degrees, 16.02+ / -0.1 degrees, 17.12+ / 0.1 degrees, 19.08+ / 0.1 degrees, 21.00+ / 0.1 degrees, 22.68+ / -0.1 degrees, 23.48+ / -0.1 degrees, 24.08+ / -0.1 degrees, 26.52+ / -0.1 degrees and 28.08+ / -0.1 degrees. The omeprazole sodium semihydrate is obtained by adding a raw material omeprazole sodium hydrate into an organic solvent, stirring the mixture for 2 to 9 hours at constant temperature of 25 to 60 DEG C and performing filtration and drying. The omeprazole sodium semihydrate is high in purity, stability and flowability and low in agglomeration rate, and has broader application prospect.

Owner:TIANJIN UNIV +1

Microbial agent and preparation method as well as application thereof

ActiveCN103304285BImprove proliferative abilityPhosphorus dissolving ability is strongBio-organic fraction processingOrganic fertiliser preparationMicroorganismMicrobial agent

The invention relates to a microbial agent and a preparation method as well as an application of the microbial agent. The microbial agent comprises functional bacteria and an adsorbent and is characterized in that the functional bacteria comprise bacillus subtilis, bacillus megatherium, trichoderma longibrachiatum and aspergillus niger, wherein the mass ratio of the microbial fermentations of the bacillus subtilis, the bacillus megatherium, the trichoderma longibrachiatum and the aspergillus niger in a mixture is 0.5-2:0.5-2:0.5-2:0.5-2. The microbial agent is prepared by carrying out the processes of slant culture, shake-flask culture, seeding tank fermentation, fermentation tank fermentation, microbial fermentation mixing, absorbent absorption, and low-temperature drying, and the microbial agent can be applied to the production of straw manure.

Owner:南京宁粮生物工程有限公司

Fermentation tank for cultivating edible fungi

PendingCN107557272AEasy to assemble and disassembleEasy to cleanBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyElectric machinery

The invention discloses a fermentation tank for cultivating edible fungi. The fermentation tank comprises heating pipes and stirring paddles, wherein the heating pipes and the stirring paddles are arranged in a fermentation tank body, the fermentation tank body is of a drum structure, a stirring shaft is arranged in the middle of the fermentation tank body, the upper end of the stirring shaft penetrates through the upper surface of the fermentation tank body, a deceleration motor is connected with the upper end of the stirring shaft, and small motors are fixed at the lower end of the stirringshaft. The stirring paddles on the stirring shaft are convenient to disassemble and clean, and reduced fermentation rate or fermentation failure can be avoided; the stirring paddles are connected withthe small motors, and the stirring paddles can rotate vertically when the stirring shaft drives the stirring paddles to rotate transversely, so that a material is fully stirred; the heating pipes arearranged in a water tank, heat is transmitted to a fermented substance through the water tank, the phenomenon that part of the fermented substance is dead due to overheat is prevented, and the cost is saved; the fermentation temperature can be stably controlled within a certain range through the water tank, and the fermentation rate of the fermented substance is high; the fermentation tank is suitable for being popularized.

Owner:重庆市永川区佳诚食用菌种植专业合作社

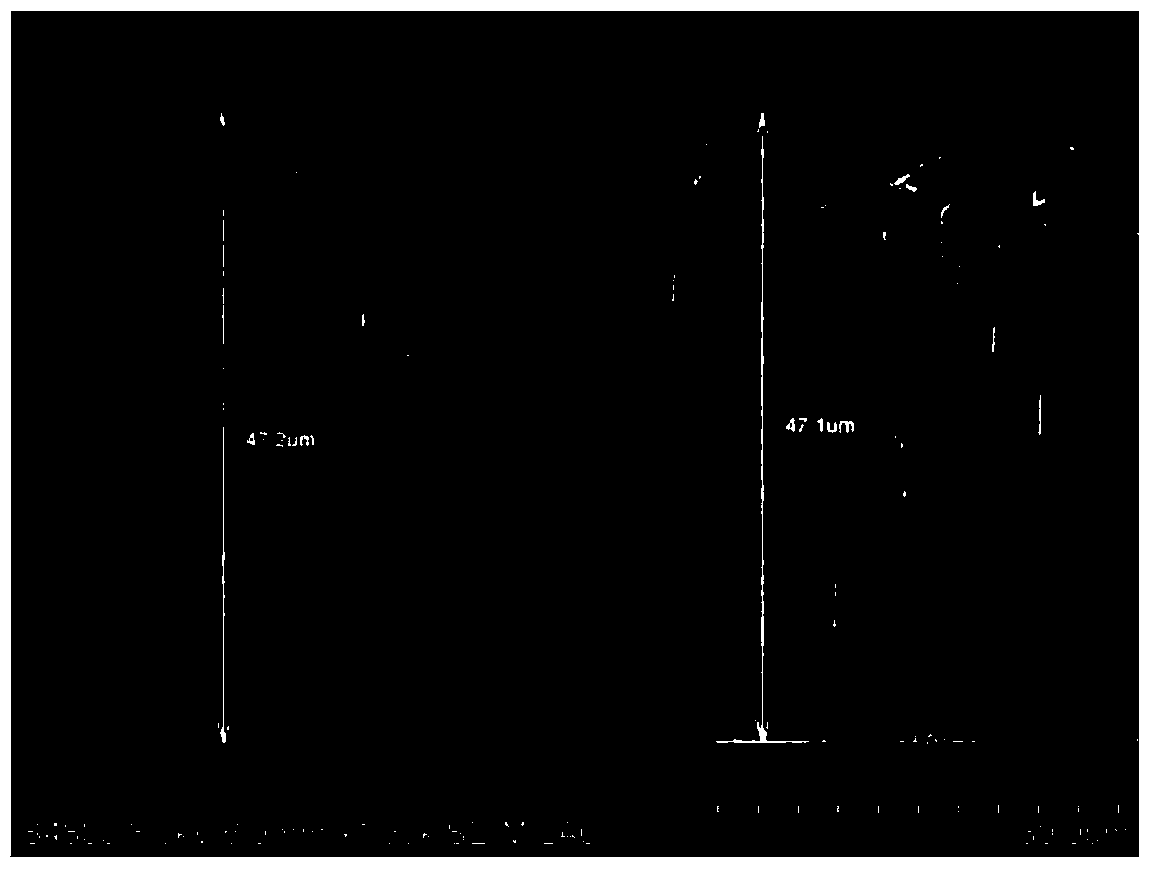

Sewage treatment method based on MBR process

ActiveCN112939227AHigh removal rateLarge particlesWater treatment parameter controlWater/sewage treatment bu osmosis/dialysisSludgeTotal nitrogen

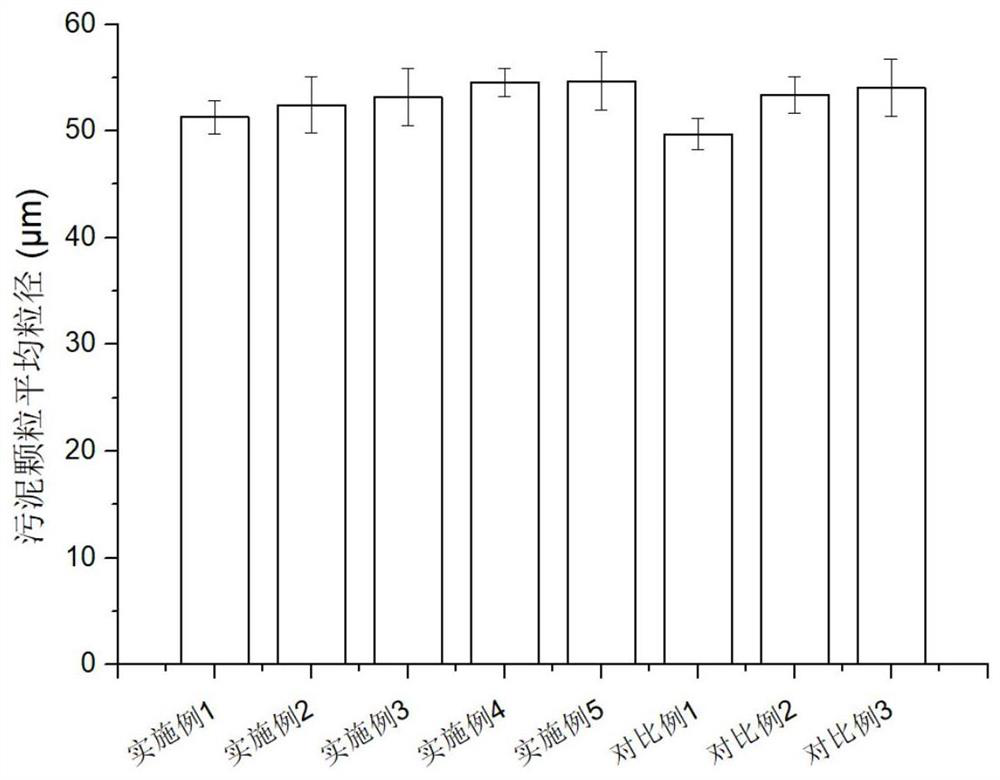

The invention discloses a sewage treatment method based on an MBR technology, and belongs to the technical field of MBR sewage treatment. The sewage treatment method comprises the steps that perishable garbage is fermented to obtain perishable garbage fermentation liquor, the COD in the perishable garbage fermentation liquor is 100-200 g / L, and the SCOD in the perishable garbage fermentation liquor is 60-120 g / L; the perishable garbage fermentation liquor is used for treating sewage in the MBR process, the MBR process comprises anaerobic section treatment, aerobic section treatment and membrane section biochemical treatment, and in order to improve the sewage treatment effect, bergenin can also be added in sewage treatment. Clear water obtained after the sewage obtained by the method is treated is high in the COD removal rate, and the COD removal rate after the sewage is treated is 93% or above; clear water obtained after sewage treatment is high in the total nitrogen removal rate, and the total nitrogen removal rate after sewage treatment is 72% or above; and the obtained sludge particles are large, pollution to the membrane is reduced, the average particle size of the sludge particles in the aerobic tank is 50-55 microns, and the d10 value of the sludge is 6.5-8.0 microns.

Owner:HANGZHOU NAXI ECOLOGICAL TECH CO LTD

Polyether glycol and preparation method thereof, and waterborne polyurethane emulsion

The invention discloses polyether glycol and a preparation method thereof, and a waterborne polyurethane emulsion. The preparation method comprises the following steps that: polyether monoalcohol R-(O-CH2-CH2-)n-OH reacts with a halogenating reagent to prepare halogen-terminated polyether R-(O-CH2-CH2-)n-X, then the halogen-terminated polyether R-(O-CH2-CH2-)n-X reacts with a compound defined in the specification to obtain end-capped polyether defined in the specification. In the refining process, an adsorbent and an auxiliary agent cooperate, the material adsorption amount in a filter cake is reduced, and the product loss is further reduced; the end-capped polyether is subjected to a ring-opening reaction in the presence of an acid catalyst to obtain a product polyether glycol defined in the specification, wherein n is 3-220, preferably 14-87, and the molecular weight distribution is 1.01-1.25, preferably 1.05-1.15. The preparation process is simple and efficient, the raw materials are low in cost and wide in source, and the industrial prospect is good. The polyether glycol is used for preparing the waterborne polyurethane emulsion and has the beneficial effect of reducing the viscosity.

Owner:WANHUA CHEM GRP

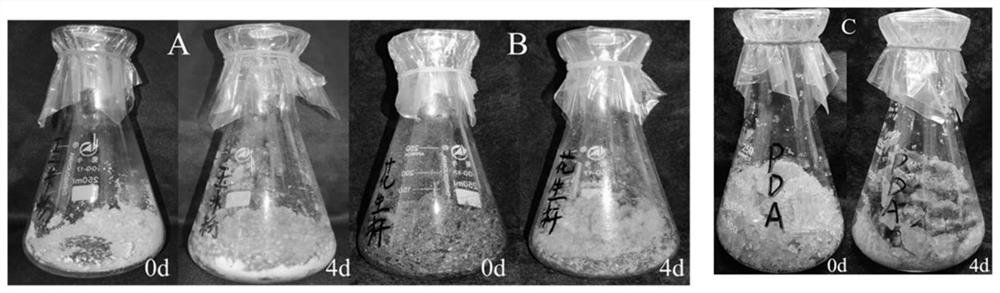

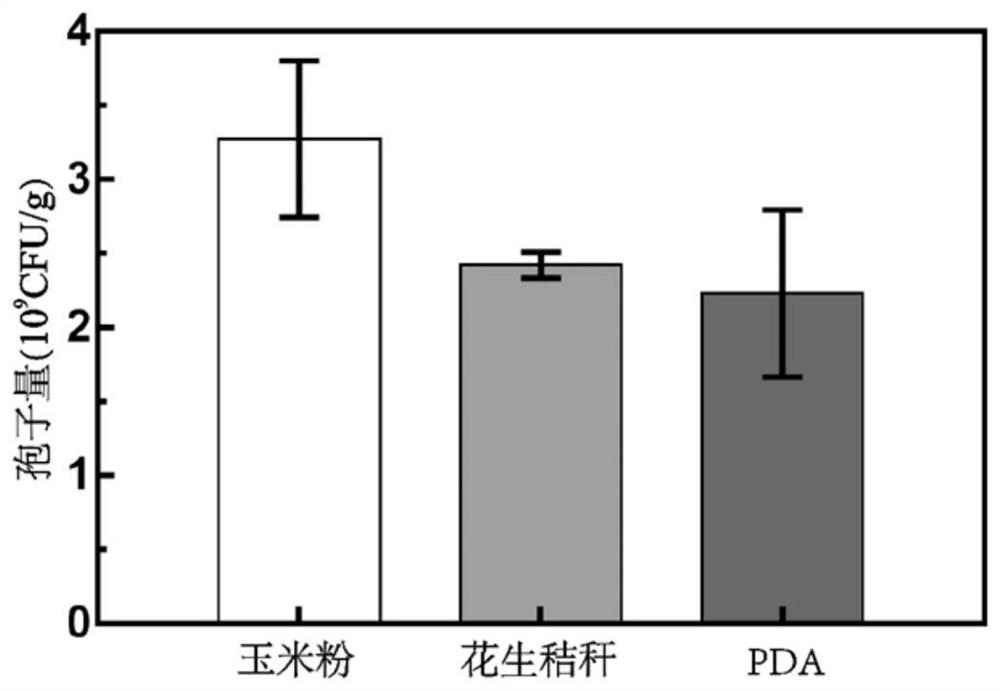

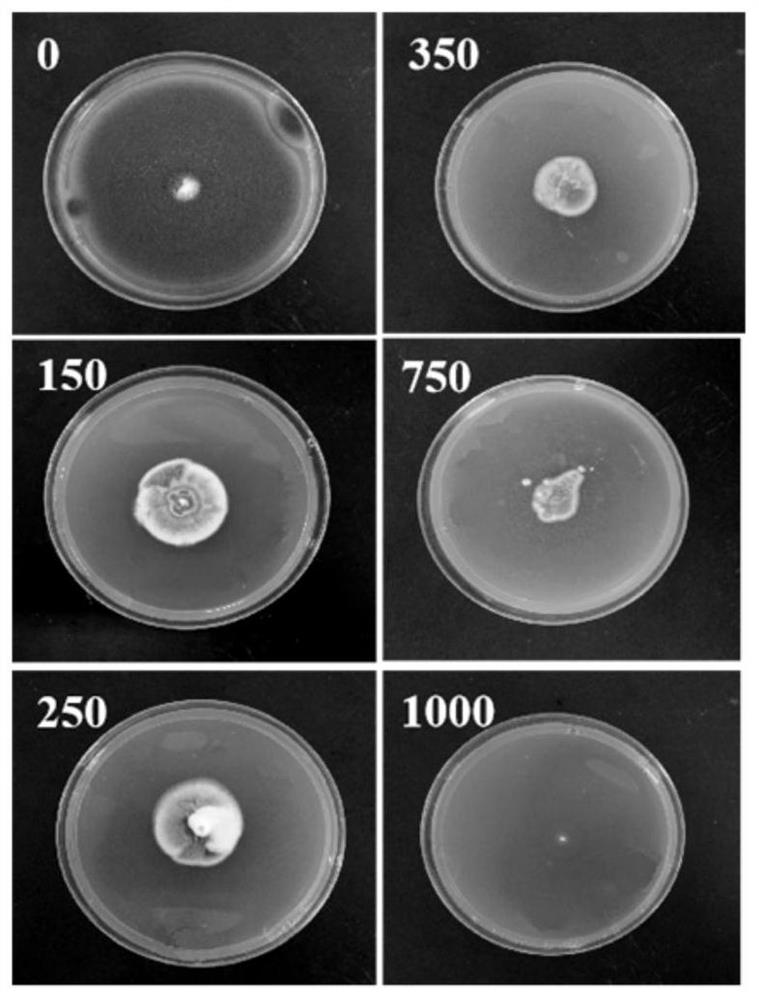

A kind of solid fermentation of Penicillium oxalicum and its method for efficiently decomposing phosphorus and removing lead

ActiveCN113333459BEfficient removalRealize solid fermentationClimate change adaptationContaminated soil reclamationBiotechnologyOxalate

The invention discloses a solid fermentation of Penicillium oxalicum, and the Penicillium oxalicum PSF‑4 is used for the degradation of phosphorus and lead. The present invention adopts the above-mentioned solid fermentation of Penicillium oxalicum and its high-efficiency method for decomposing phosphorus and removing lead, which can realize the function of decomposing phosphorus and removing heavy metals at the same time, and the cost is low. Soil fertility and ecotoxicity.

Owner:XIANGTAN UNIV

Activated carbon filtering device utilizing water-soluble silicon

ActiveCN112209533AImprove purification effectQuick purificationTreatment involving filtrationMultistage water/sewage treatmentActivated carbon filtrationStructural engineering

The invention discloses an activated carbon filtering device utilizing water-soluble silicon. The device comprises a barrel, an inner barrel is installed in the barrel and comprises a water inlet barrel, a mixed adsorption barrel and a filtering barrel, a leakage plate is connected to the bottom of the water inlet barrel, the bottom of the water inlet barrel is connected with the mixed adsorptionbarrel, a partition plate is connected into the mixed adsorption barrel, and water holes are formed in the partition plate. The mixed adsorption barrel forms a mixing layer through cooperation of thepartition plate and the leakage plate, the lower side in the mixed adsorption barrel is connected with an adsorption box, the bottom of the mixed adsorption barrel is connected with a guide sleeve, the guide sleeve is of a horn-shaped structure with the large upper portion and the small lower portion, and the bottom of the guide sleeve is connected with a composite filter box. The bottom of the composite filter box is connected with a filter cartridge, an activated carbon filter layer is arranged in the filter cartridge, the bottom of the filter cartridge is connected with a water outlet guidesleeve, the bottom of the water outlet guide sleeve penetrates through the barrel and extends to the lower side of the barrel, the top of the barrel is fixedly connected with a mounting ring and a barrel cover is connected to the top of the mounting ring.

Owner:SHENZHEN HONGYANG EPE CO LTD

Method for preparing palm oil decolorizing agent by attapulgite clay soybean oil decolorized waste residues

ActiveCN103055811BAchieve reuseTake full advantage of the adsorptionOther chemical processesFatty-oils/fats refiningActivated carbonOil and grease

The invention discloses a method for preparing a palm oil decolorizing agent by attapulgite clay soybean oil decolorization waste residues, which comprises the following steps of: firstly, carrying out soybean oil decolorization treatment by attapulgite clay; then spraying acid to attapulgite clay waste residues which adsorb grease; roasting at a temperature of 300 to 380 DEG C; and finally, washing, drying and sieving to obtain the attapulgite clay palm oil decolorizing agent loaded with activated carbon. The palm oil decolorizing agent prepared by the method utilizes a synergistic effect between the attapulgite clay and the activated carbon and not only realizes decolorization of palm oil, but also realizes recycling of the soybean oil decolorization waste residues; and the product has the advantages of high decolorization ratio, high filtering rate, oil damage and the like and is suitable for deeply decolorizing crude palm oil.

Owner:中国科学院兰州化学物理研究所盱眙凹土应用技术研发中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com