Nanofiltration membrane and preparation method thereof as well as preparation method of fluorescent graphene quantum dots

A technology of graphene quantum dots and nanofiltration membranes, applied in chemical instruments and methods, membrane technology, luminescent materials, etc., can solve problems such as difficulty in making size, high luminous efficiency fluorescent graphene quantum dots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

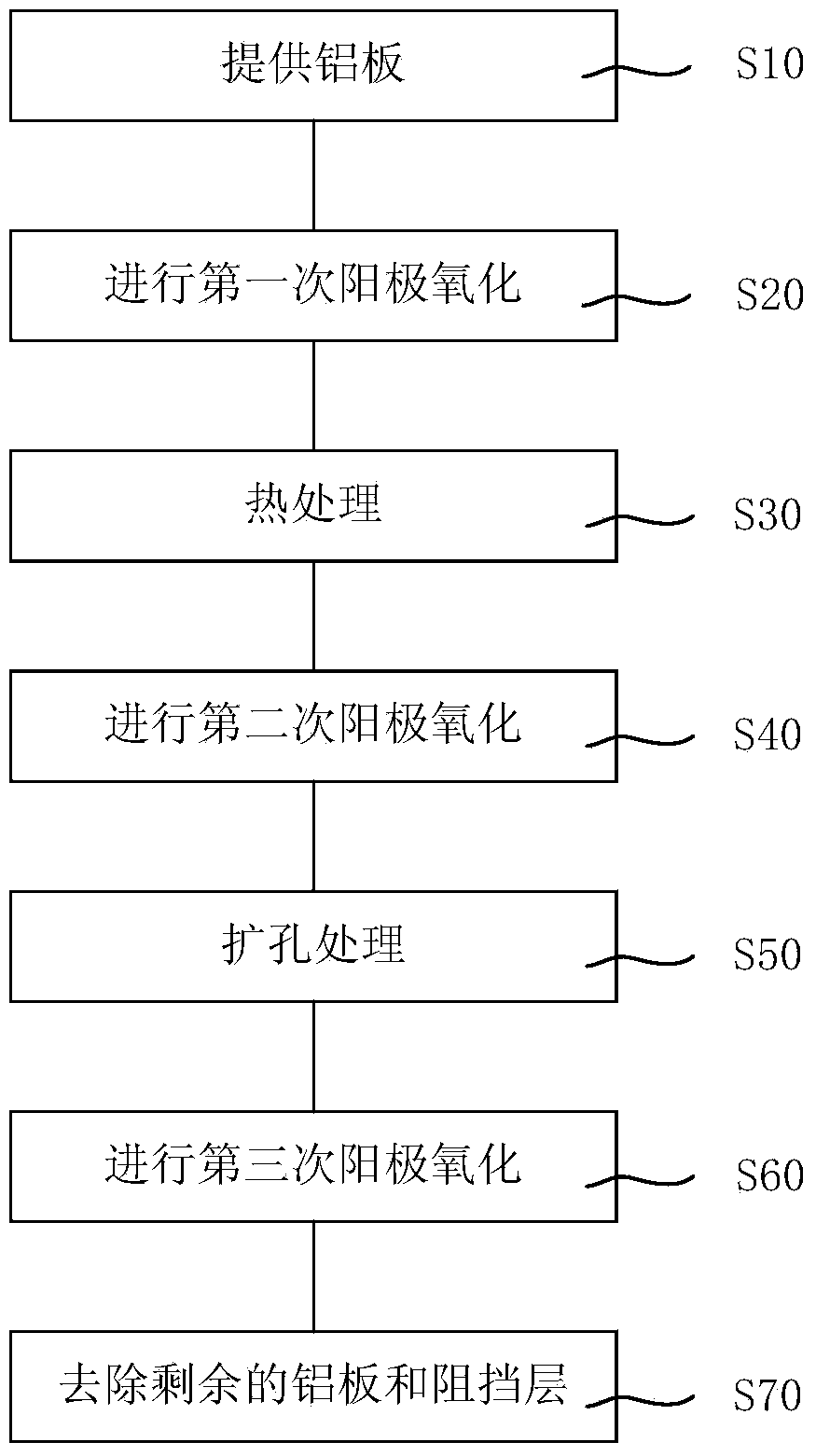

[0103] First, the preparation method of the nanofiltration membrane provided in this embodiment includes:

[0104] Provide high-purity aluminum plate;

[0105] Polishing treatment is carried out so that the high-purity aluminum plate has a clean and smooth surface. In the polishing treatment, the temperature is set at 0° C., and a voltage of 25V is applied in a mixed solution of perchloric acid and ethanol with a volume ratio of 1:4 to carry out The time is 10 minutes;

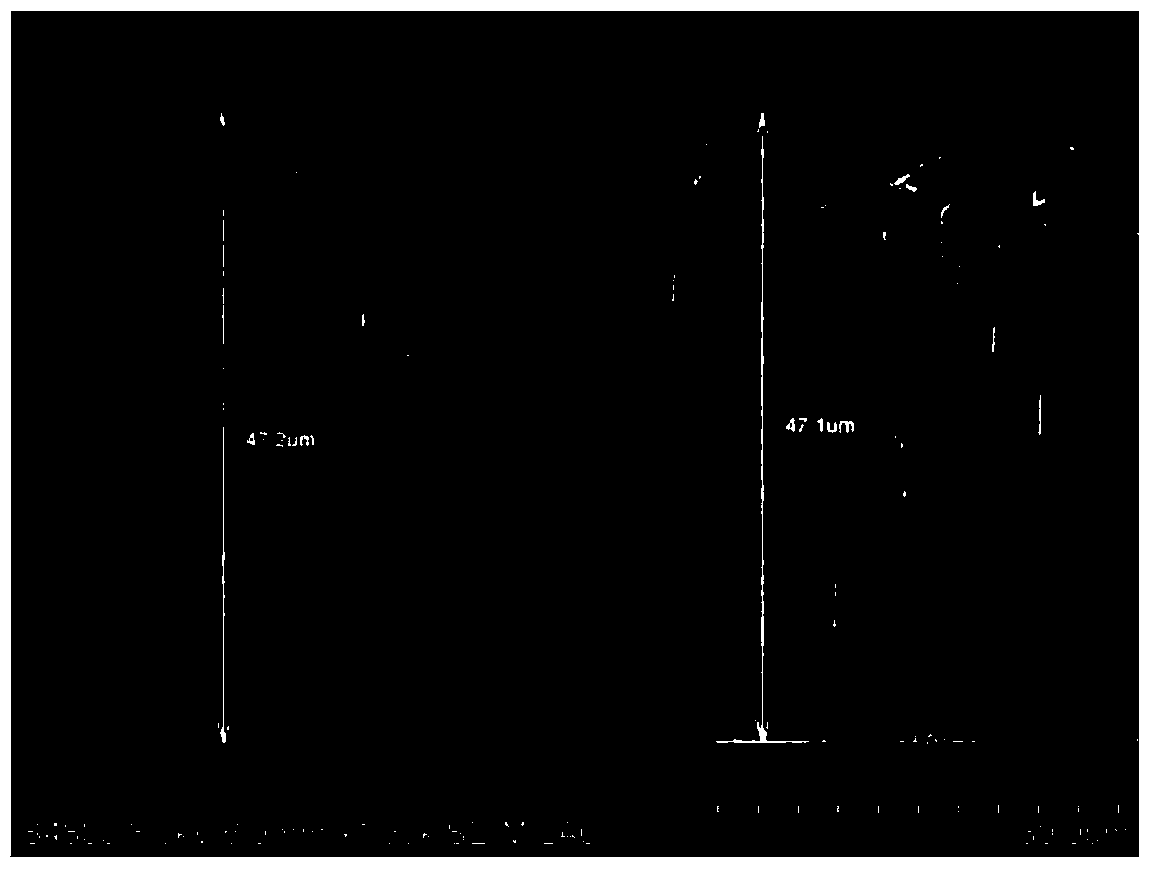

[0106] Carrying out the first anodic oxidation on the high-purity aluminum plate, the condition is to carry out in 0.3mol / L oxalic acid, the setting voltage is 50V, the temperature is 0°C, and the time is 2h to obtain the first aluminum oxide layer;

[0107] Putting the aluminum plate and the first aluminum oxide layer into chromic acid for heat treatment for 2 hours;

[0108] The second anodic oxidation of the high-purity aluminum plate is carried out in 0.3mol / L oxalic acid, the set voltage is 50V, the tem...

Embodiment 2

[0126] First, the preparation method of the nanofiltration membrane provided in this embodiment includes:

[0127] Provide high-purity aluminum plate;

[0128] Polishing treatment is carried out so that the high-purity aluminum plate has a clean and smooth surface. In the polishing treatment, the temperature is set at 0° C., and a voltage of 25V is applied in a mixed solution of perchloric acid and ethanol with a volume ratio of 1:4 to carry out The time is 10 minutes;

[0129] Carrying out the first anodic oxidation on the high-purity aluminum plate, the condition is to carry out in 0.3mol / L oxalic acid, set the voltage to 195V, the temperature is 0°C, and the time is 2h to obtain the first aluminum oxide layer;

[0130] Putting the aluminum plate and the first aluminum oxide layer into chromic acid for heat treatment for 2 hours;

[0131] Carry out the second anodic oxidation on the high-purity aluminum plate, the condition is to carry out in 0.3mol / L oxalic acid, set the ...

Embodiment 3

[0145] First, the preparation method of the nanofiltration membrane provided in this embodiment includes:

[0146] Provide high-purity aluminum plate;

[0147] Polishing treatment is carried out so that the high-purity aluminum plate has a clean and smooth surface. In the polishing treatment, the temperature is set at 0° C., and a voltage of 25V is applied in a mixed solution of perchloric acid and ethanol with a volume ratio of 1:4 to carry out The time is 10 minutes;

[0148] Carrying out the first anodic oxidation on the high-purity aluminum plate, the condition is to carry out in 0.3mol / L oxalic acid, the setting voltage is 50V, the temperature is 0°C, and the time is 2h to obtain the first aluminum oxide layer;

[0149] Putting the aluminum plate and the first aluminum oxide layer into chromic acid for heat treatment for 2 hours;

[0150] The second anodic oxidation of the high-purity aluminum plate is carried out in 0.3mol / L oxalic acid, the set voltage is 50V, the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com