Easy-to-remove double-sided UV protective adhesive tape and preparation method of same

A protective tape, double-sided technology, applied in the direction of adhesives, film/sheet adhesives, adhesive types, etc. Problems such as difficult control of adhesive tape surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

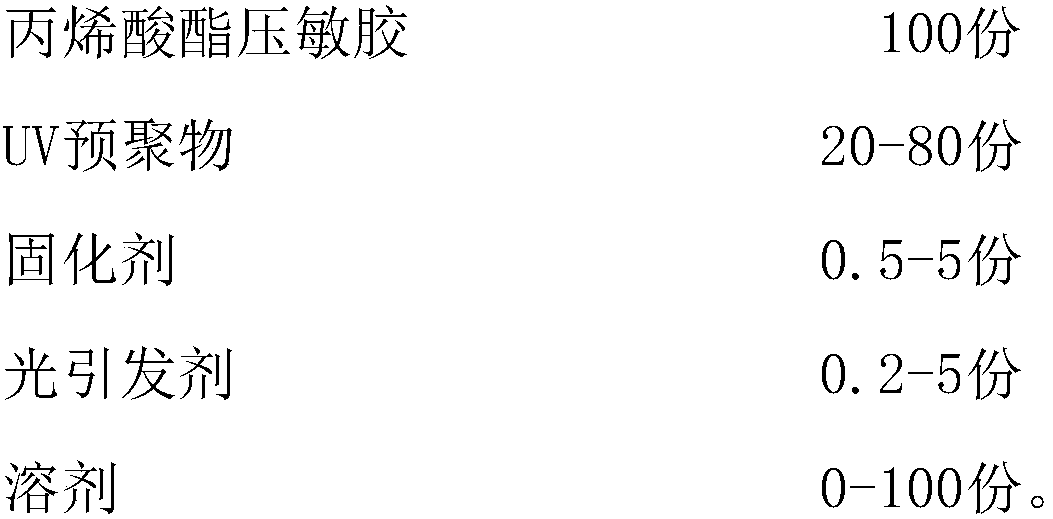

Method used

Image

Examples

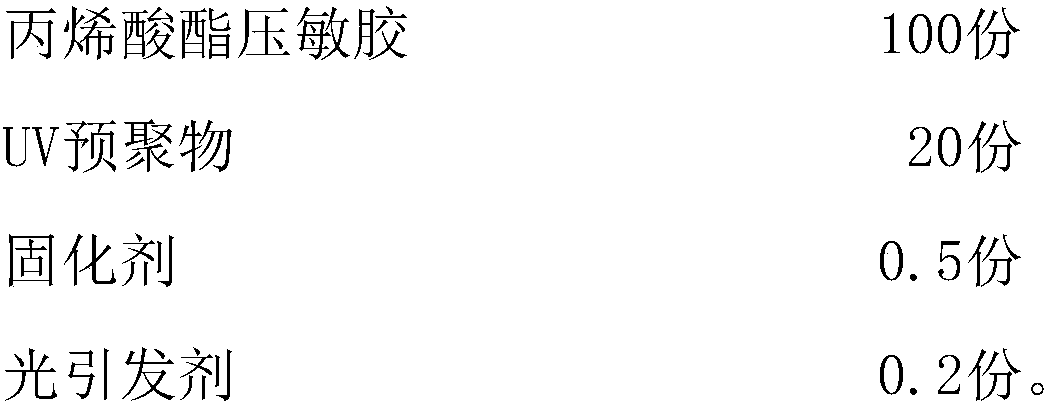

Embodiment 1

[0039] An easy-to-remove double-sided UV protective tape, comprising an upper release film, a first adhesive layer, a substrate film, a second adhesive layer and a lower release film arranged in sequence, and the substrate film is PET heat-shrinkable A film, the first adhesive layer is a pressure-sensitive adhesive layer, and the second adhesive layer is a UV adhesive-reducing layer.

[0040] The 180° peel force of the UV adhesive layer before UV irradiation is 0.5N / 25mm-0.8N / 25mm, and the 180° peel force of the UV adhesive layer after UV irradiation is 0.02-0.0.05N / 25mm; the 180° peel force of the pressure-sensitive adhesive layer is: 0.2N / 25mm-0.5N / 25mm.

[0041] The release force of the upper release film is less than the release force of the lower release film; the release force of the upper release film is 5-6gf / 25mm, and the release force of the lower release film is 10- 12gf / 25mm.

[0042] Preferably, the thickness of the PET heat-shrinkable film is 20um, and the hea...

Embodiment 2

[0058] An easy-to-remove double-sided UV protective tape, comprising an upper release film, a first adhesive layer, a substrate film, a second adhesive layer and a lower release film arranged in sequence, and the substrate film is PET heat-shrinkable A film, the first adhesive layer is a pressure-sensitive adhesive layer, and the second adhesive layer is a UV adhesive-reducing layer.

[0059] The 180° peel force of the UV adhesive layer before UV irradiation is 0.8N / 25mm-1.5N / 25mm, and the 180° peel force of the UV adhesive layer after UV irradiation is 0.05-0.1N / 25mm ; The 180° peel force of the pressure-sensitive adhesive layer is: 0.5N / 25mm-1N / 25mm.

[0060] The release force of the upper release film is less than the release force of the lower release film; the release force of the upper release film is 8-9gf / 25mm, and the release force of the lower release film is 25- 27gf / 25mm.

[0061] The thickness of the PET heat-shrinkable film is 40um, and the heat-shrinkage tempe...

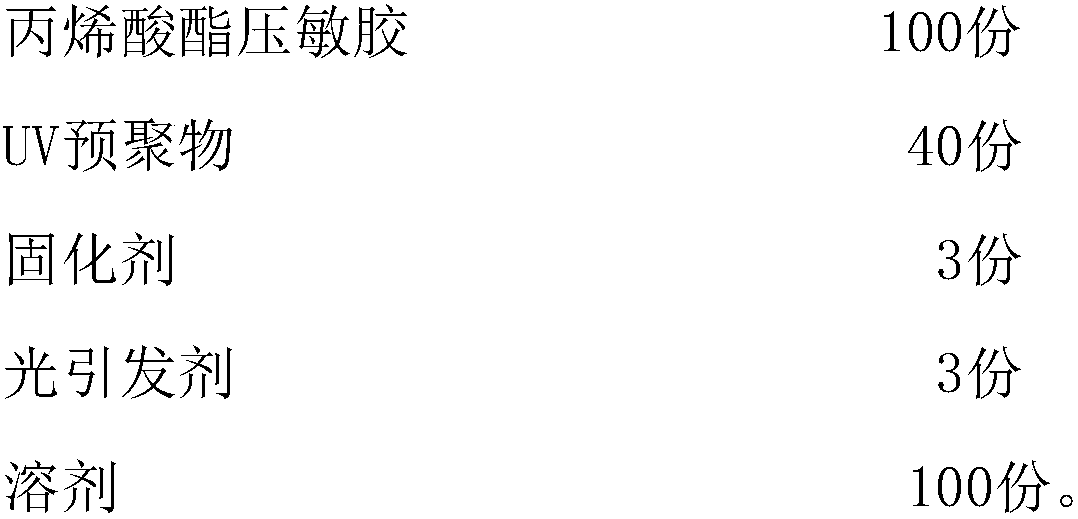

Embodiment 3

[0077] An easy-to-remove double-sided UV protective tape, comprising an upper release film, a first adhesive layer, a substrate film, a second adhesive layer and a lower release film arranged in sequence, and the substrate film is PET heat-shrinkable A film, the first adhesive layer is a pressure-sensitive adhesive layer, and the second adhesive layer is a UV adhesive-reducing layer.

[0078] The 180° peeling force of the UV adhesive layer before UV irradiation is 2N / 25mm-2.5N / 25mm, and the 180° peeling force of the UV adhesive layer after UV irradiation is 0.1-0.15N / 25mm; The 180° peel force of the pressure-sensitive adhesive layer is: 1N / 25mm-2N / 25mm.

[0079] The release force of the upper release film is less than the release force of the lower release film; the release force of the upper release film is 13-14gf / 25mm, and the release force of the lower release film is 35- 37gf / 25mm.

[0080] The thickness of the PET heat-shrinkable film is 60um, and the heat-shrinkage te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel force | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com