Patents

Literature

62results about How to "Reduce residual oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing palm oil decolorizing agent by attapulgite clay soybean oil decolorized waste residues

ActiveCN103055811AAchieve reuseActivate the microporous structureOther chemical processesFatty-oils/fats refiningActivated carbonOil and grease

The invention discloses a method for preparing a palm oil decolorizing agent by attapulgite clay soybean oil decolorization waste residues, which comprises the following steps of: firstly, carrying out soybean oil decolorization treatment by attapulgite clay; then spraying acid to attapulgite clay waste residues which adsorb grease; roasting at a temperature of 300 to 380 DEG C; and finally, washing, drying and sieving to obtain the attapulgite clay palm oil decolorizing agent loaded with activated carbon. The palm oil decolorizing agent prepared by the method utilizes a synergistic effect between the attapulgite clay and the activated carbon and not only realizes decolorization of palm oil, but also realizes recycling of the soybean oil decolorization waste residues; and the product has the advantages of high decolorization ratio, high filtering rate, oil damage and the like and is suitable for deeply decolorizing crude palm oil.

Owner:中国科学院兰州化学物理研究所盱眙凹土应用技术研发中心

Method for recovering oil-containing waste active white clay by dichloroethane

InactiveCN107185508AHigh extraction rateHigh recovery rateFatty oils/acids recovery from wasteOther chemical processesOil and greaseSlag

The invention relates to a method for recovering oil-containing waste active white clay by dichloroethane. The method comprises the following steps of (1) performing more than one time of digestion on the oil-containing waste active white clay or oil-containing waste kieselguhr by a solvent; after solid-liquid separation, obtaining filter slag and oil-containing ingredients, wherein the solvent is 1,1-dichloroethane; (2) drying the filter slag obtained in the step (1) to obtain the regenerated active white clay or the regenerated kieselguhr; (3) performing distillation on the oil-containing ingredients obtained in the step (1); separating fraction and grease. When the method is used for treating the oil-containing waste active white clay, the recovery rate of the grease and the active white clay is high; the process is simple; the investment cost is low; the used 1,1-dichloroethane has low toxicity; the separation and the recovery are easy; secondary pollution cannot be caused on the environment.

Owner:JIAOZUO CITY DIV OF RESOURCES COMPREHENSIVE UTILIZATION R & D +1

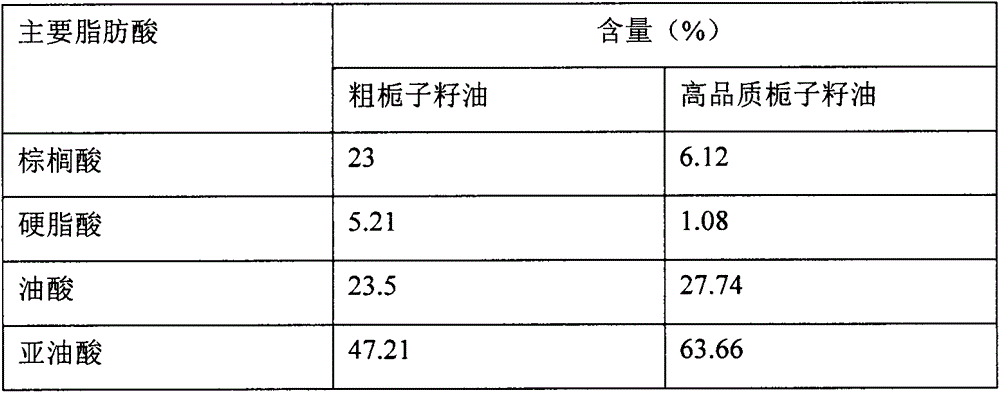

Preparation method of high-quality cape jasmine seed oil rich in linoleic acid

InactiveCN105112155AImprove qualityReduce residual oilFatty-oils/fats refiningFatty-oils/fats productionMicrowaveSolvent

The invention relates to a preparation method of high-quality cape jasmine seed oil rich in linoleic acid. Cape jasmine seeds are treated as raw materials, and the preparation method comprises the following steps: 1, conducting extraction, wherein microwave drying is conducted for drying the cape jasmine seeds, then the pulverization is conducted, subcriticality is adopted for conducting the extraction, and crude cape jasmine seed oil is obtained; 2, adopting different proportions of adsorption materials for conducting low-temperature decoloration and deodorization treatment, and the high-quality cape jasmine seed oil is obtained. The preparation method is easy to operate, the cape jasmine seed oil can be effectively extracted, no pollution is caused, no solvent residual exists, and the obtained cape jasmine seed oil is rich in the linoleic acid.

Owner:福建恒康生态农业发展有限公司 +1

Processing method for camellia seed oil

InactiveCN105219516AAdjustable granularityAdjustable temperatureFatty-oils/fats refiningFatty-oils/fats productionFlavorCamellia oleifera

The invention relates to the field of squeezing camellia seed oil, particularly a processing method for camellia seed oil. The method comprises: tedding cured camellia seeds in the sunshine, and putting the camellia seeds in a crusher to be crushed; carrying out flaking and adjusting treatment on the crushed camellia seed powder; carrying out cold-squeezing by use of a twin-screw oil press; separating a cold-squeezed oil-dreg mixture by use of a centrifugal separator; and finely filtering the separated oil and depositing the filtrate, and then filtering the filtrate to obtain the camellia seed oil. By carrying out flaking and adjusting treatment on the camellia seed powder, the grain size, the squeezing temperature and the water content and the like of the camellia seeds can be adjusted, so that the oil yield is increased. Meanwhile, the camellia seed meal is mixed with the dreg separated by the centrifugal separator, and the mixture is added with camellia seed oil and is subjected to filter pressing, so that part of nutrients in the camellia seed meal and the dreg are added into the camellia seed oil, the flavor and nutritional components of the final camellia seed oil can be increased; and moreover, the oil yield is further increased, and the residual oil can be reduced to be no greater than 5%.

Owner:HUNAN LYUBO AGRI & FORESTRY DEV CO LTD

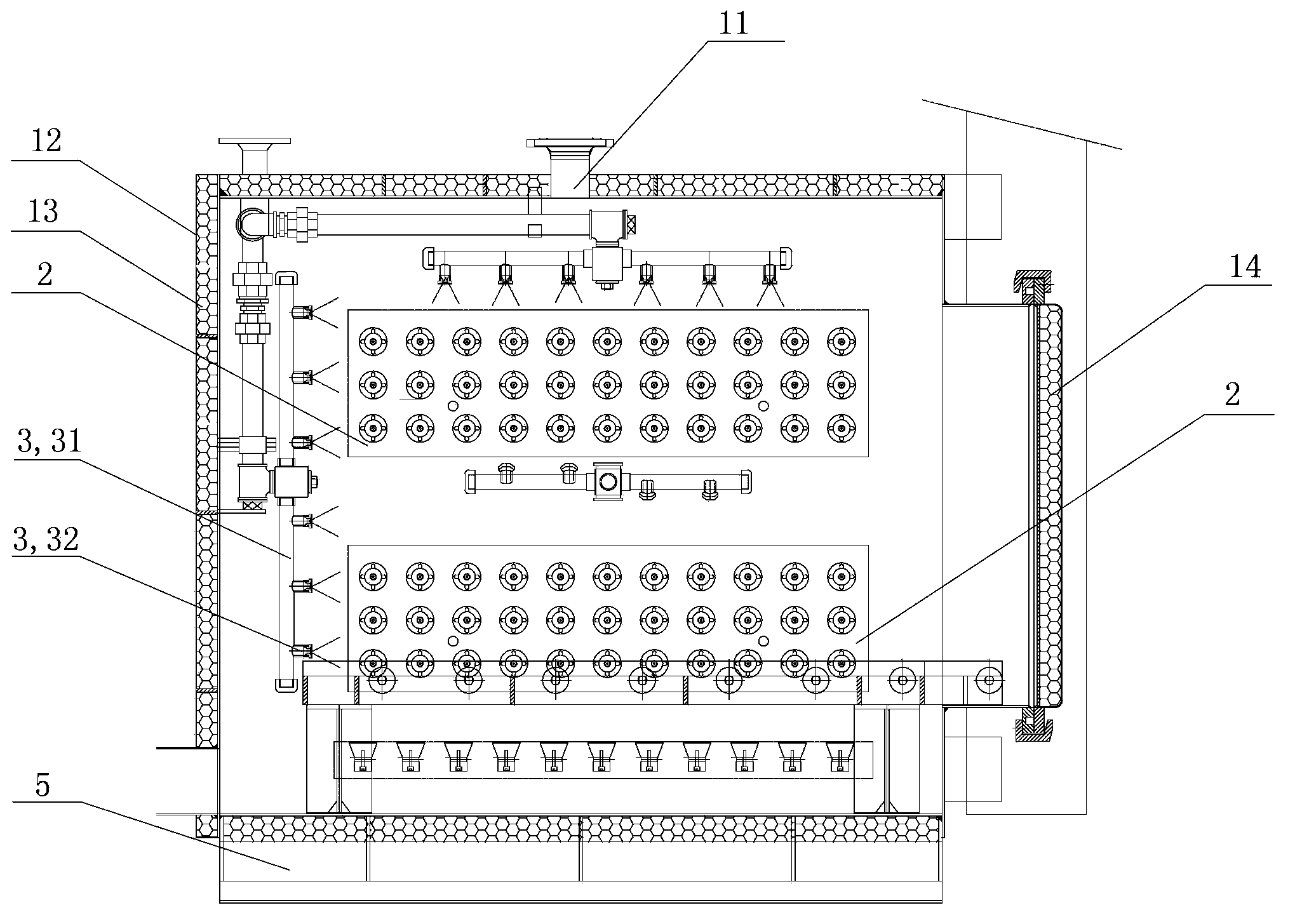

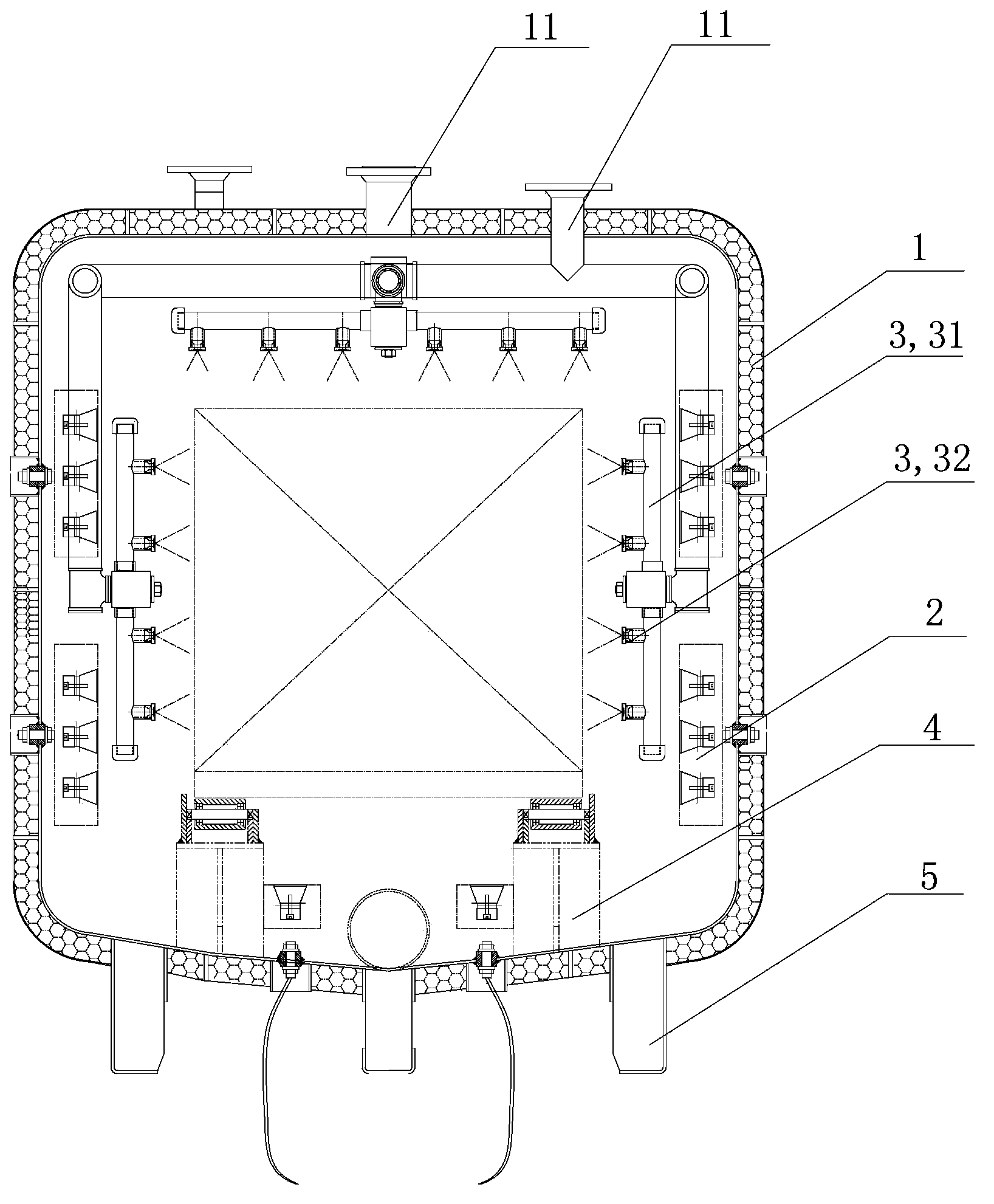

Vacuum cleaning chamber

InactiveCN103894366AReduce residual oilImprove cleanlinessCleaning using liquidsResidual oilEngineering

The invention relates to cleaning equipment for heat treatment, in particular to a vacuum cleaning chamber for heat treatment. The vacuum cleaning chamber comprises a cleaning chamber shell. A furnace door is arranged on a side of the cleaning chamber shell, a plurality of through holes are formed in the upper end of the cleaning chamber shell, and ultrasonic vibrating plates are arranged on the inner wall of the cleaning chamber shell and are connected with an external ultrasonic controller. The vacuum cleaning chamber has the advantages that heat treatment workpieces can be conveniently and automatically cleaned in a closed vacuum system, the vacuum cleaning chamber is high in cleaning degree, and accordingly the cleaning efficiency can be greatly improved; the ultrasonic vibrating plates are arranged in the cleaning chamber for assisting in cleaning the workpieces, so that stubborn dirt on the surfaces of the workpieces can be quickly removed, cleaning dead zones of complicated workpieces with holes, grooves and the like can be effectively cleaned, and the quantities of residual oil on the surfaces of the workpieces can be greatly reduced.

Owner:HEPHAES HEAT TREATMENT SYST JIANGSU

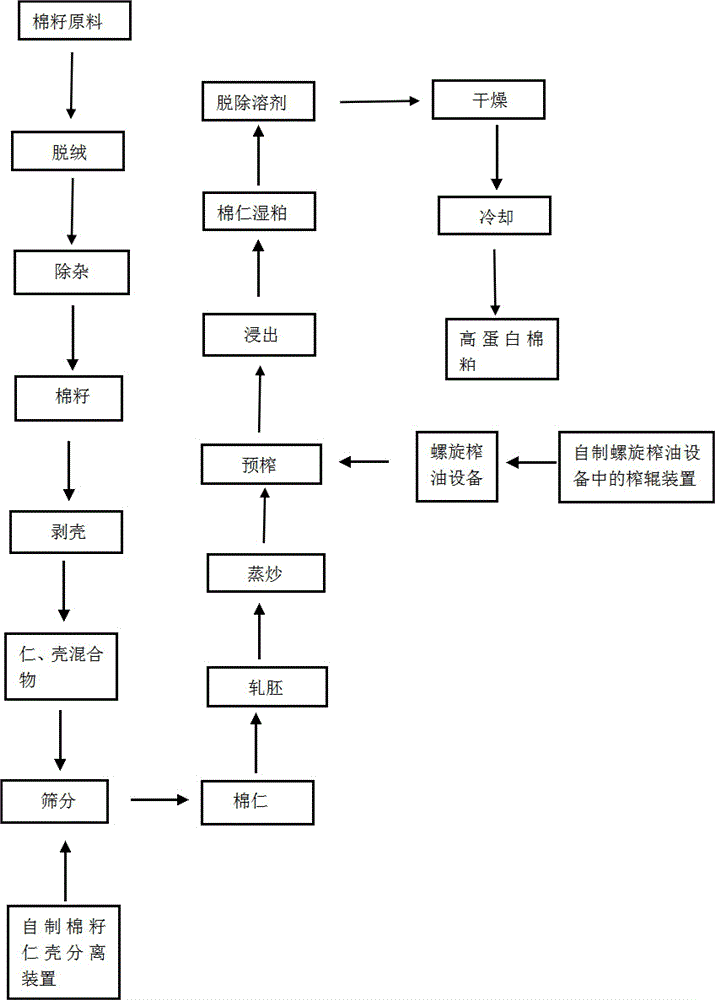

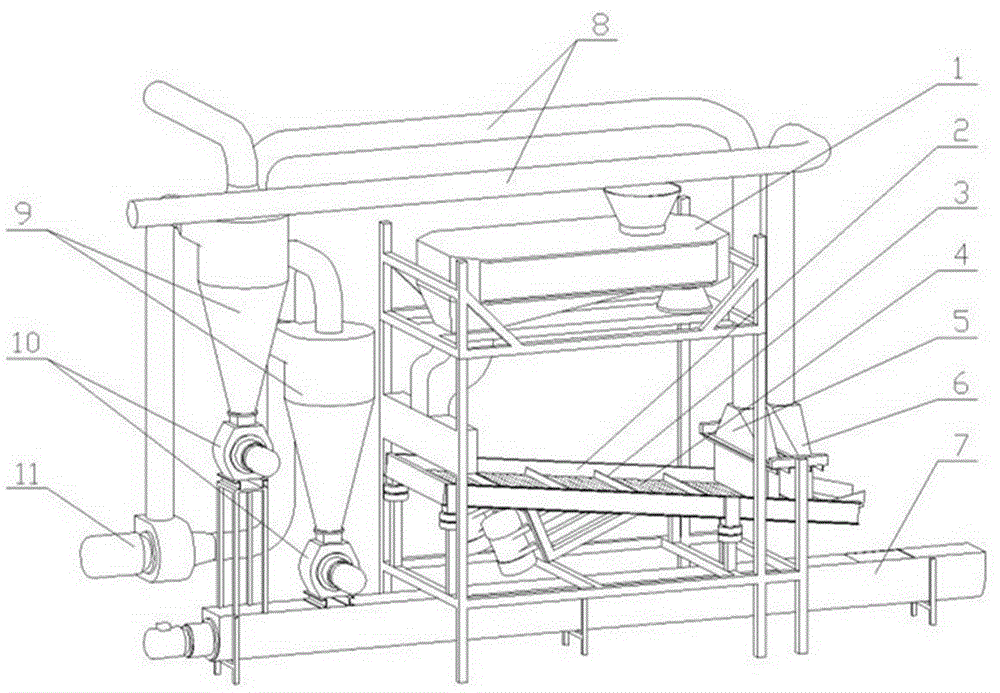

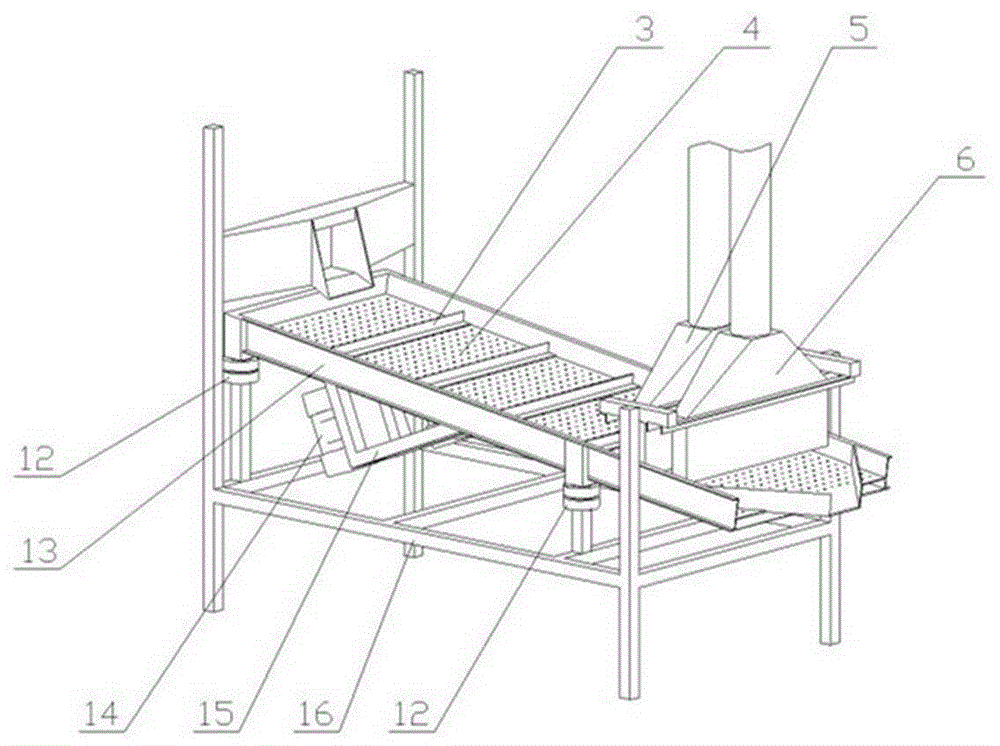

Preparation method for high protein cottonseed meal and selected device therefor

ActiveCN104544510AHigh in proteinEasy to separateGas current separationFeeding-stuffCrude fibreHigh protein

The invention discloses a preparation method for high protein cottonseed meal and a selected device therefor. The preparation method includes delinting cottonseeds, removing impurities of the cotton seeds, and husking; feeding into a husking roller uniformly by a variable frequency feeding device, putting the mixture of husks and kernels after husking into a cottonseed kernel and husk separation device, putting the fine selected cotton kernel into a double-roller flaking device, then putting into a layered cooker for wetting, steaming, frying to obtain cooked flakes, wherein a medium-temperature medium-wet technology is adopted in the steaming and frying step, so that the protein denaturation is avoided to the greatest extent while the free gossypol content is effectively reduced. Meanwhile a press screw device applicable to the cottonseed kernel and husk separation device and a spiral oil press is provided, so that the cottonseed husking efficiency is high, the prepared high protein cottonseed meal is high in quality, the prepared high protein cottonseed meal has the crude protein content of not less than 52%, the bottom oil of not more than 1.0%, the moisture of not more than 9.0%, the crude fiber of not more than 6.0%, the crude ash of not more than 7.5%, the NSI value of not less than 65% and the free gossypol of not more than 800ppm, and is wide in application and promotion values.

Owner:新疆泰昆蛋白科技股份有限公司

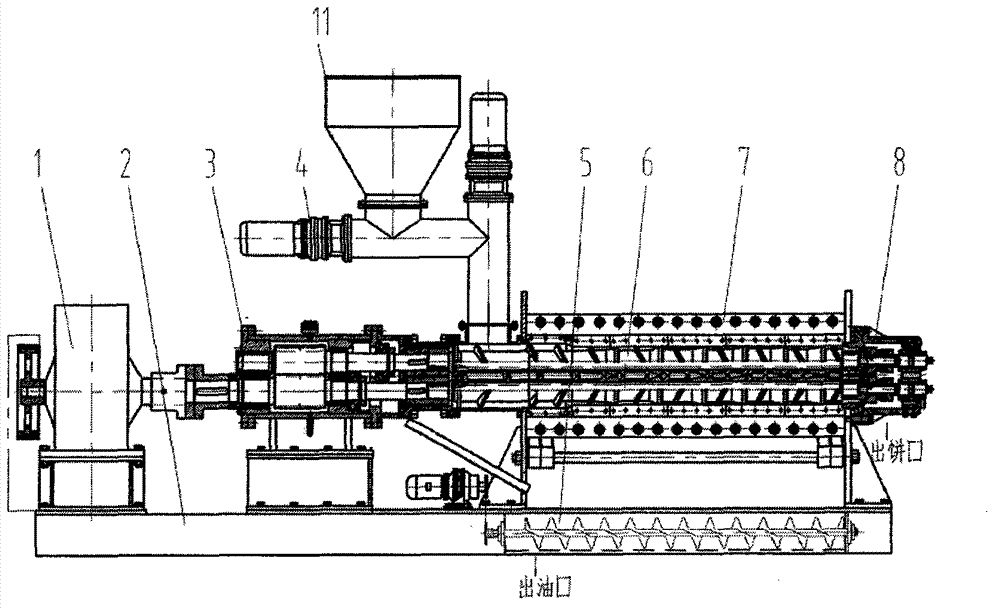

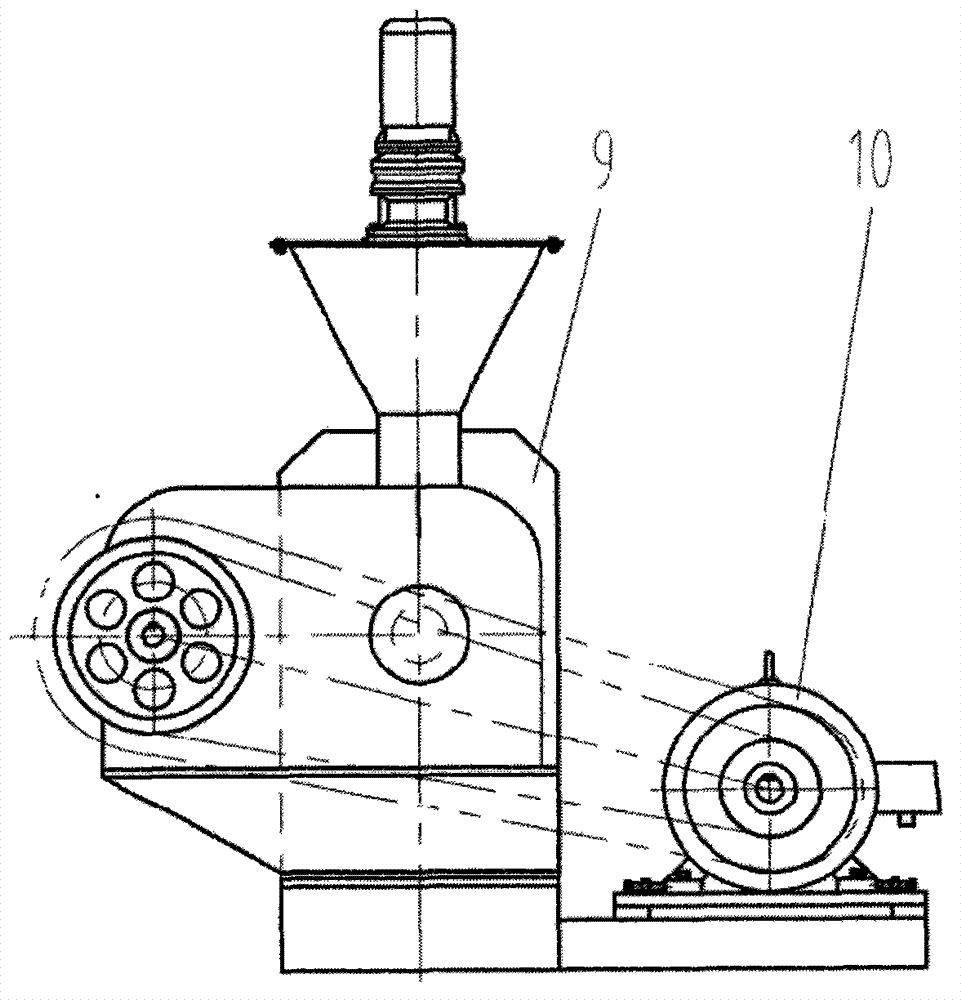

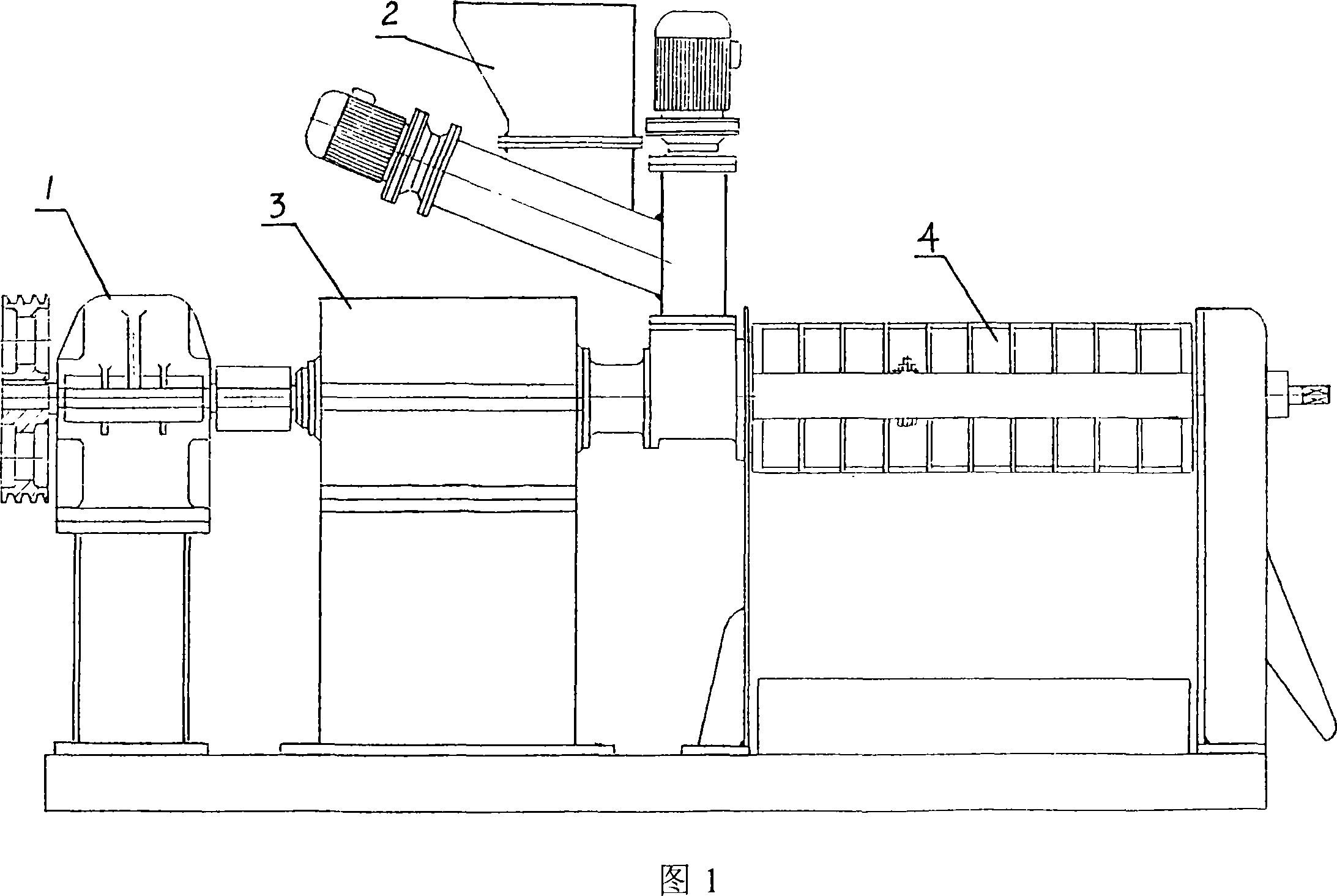

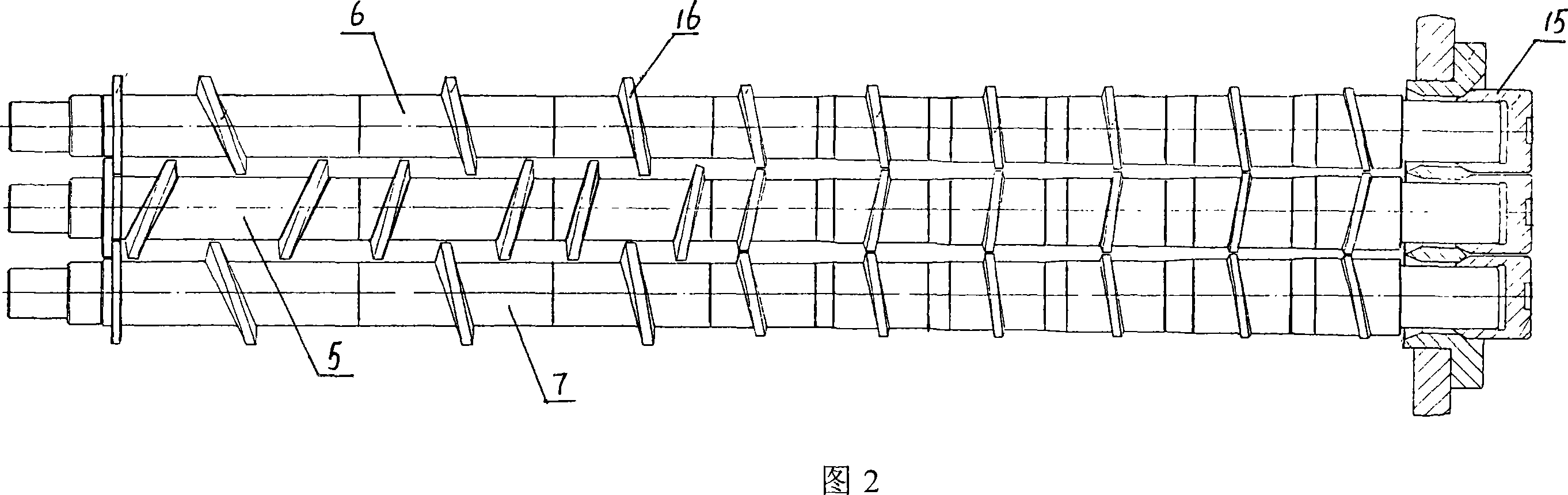

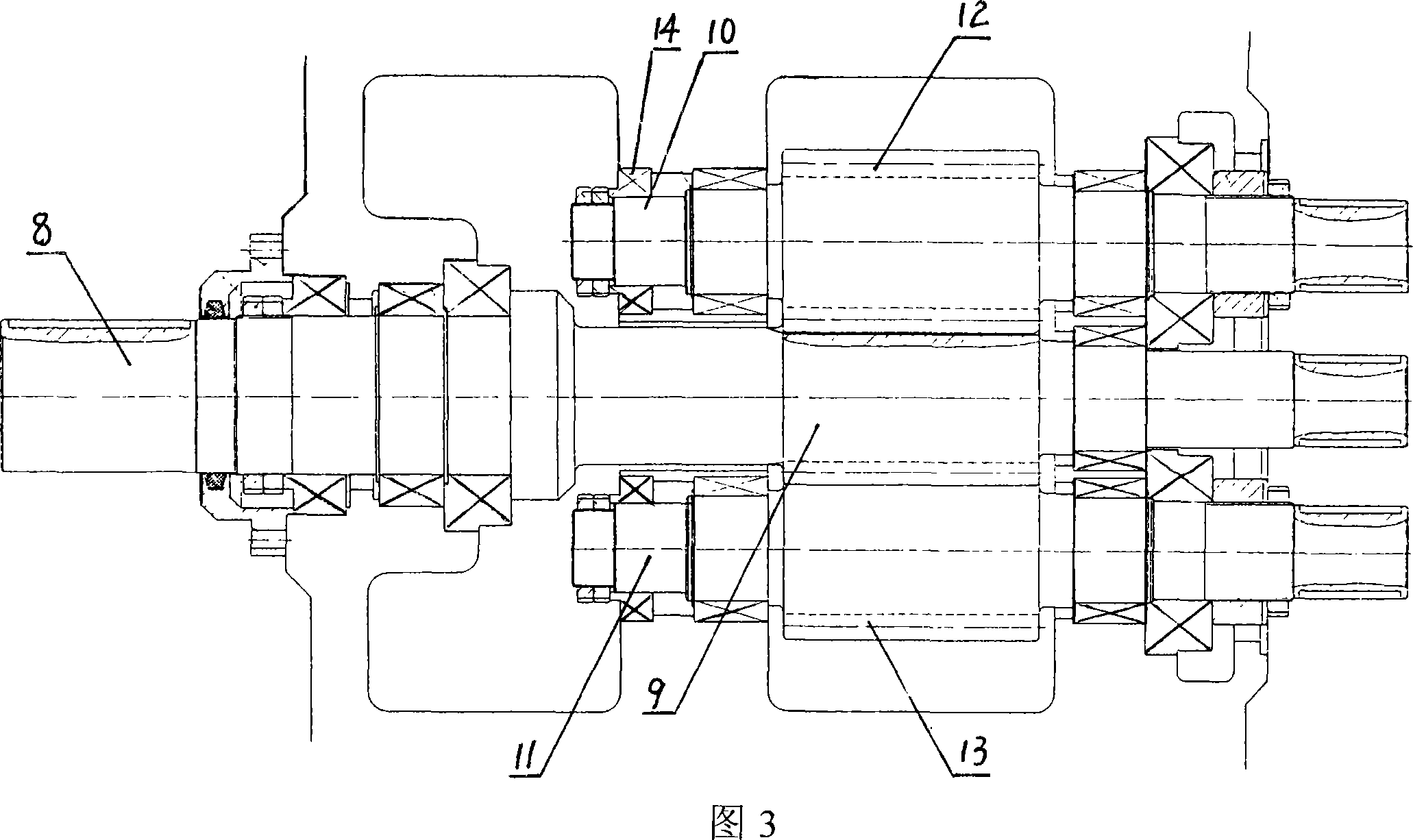

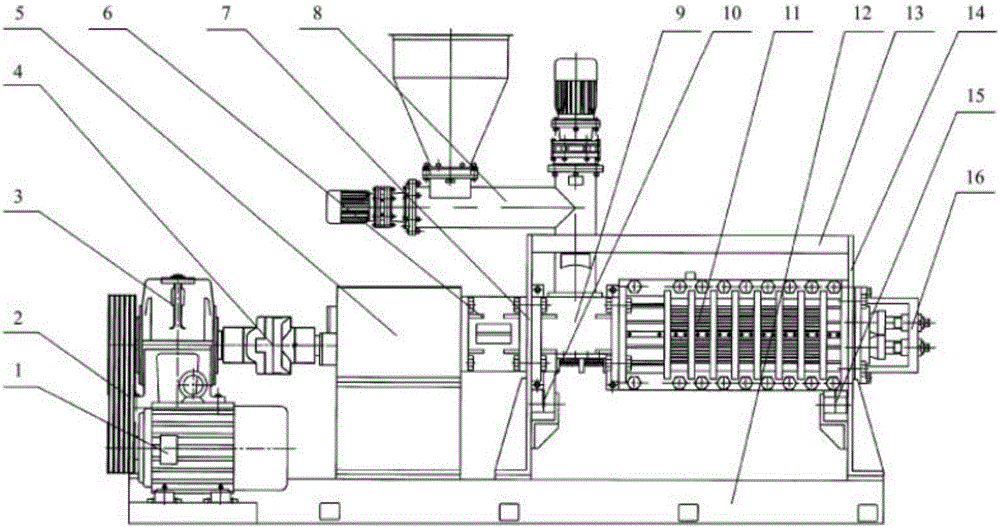

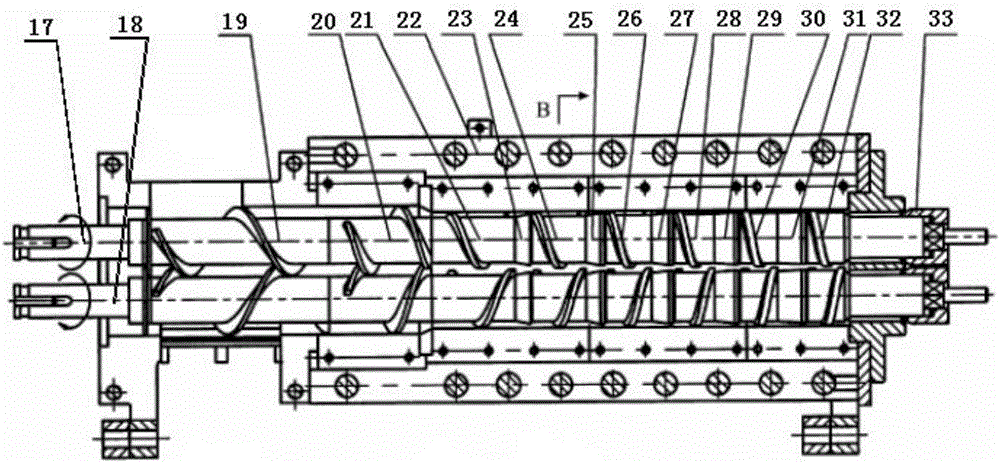

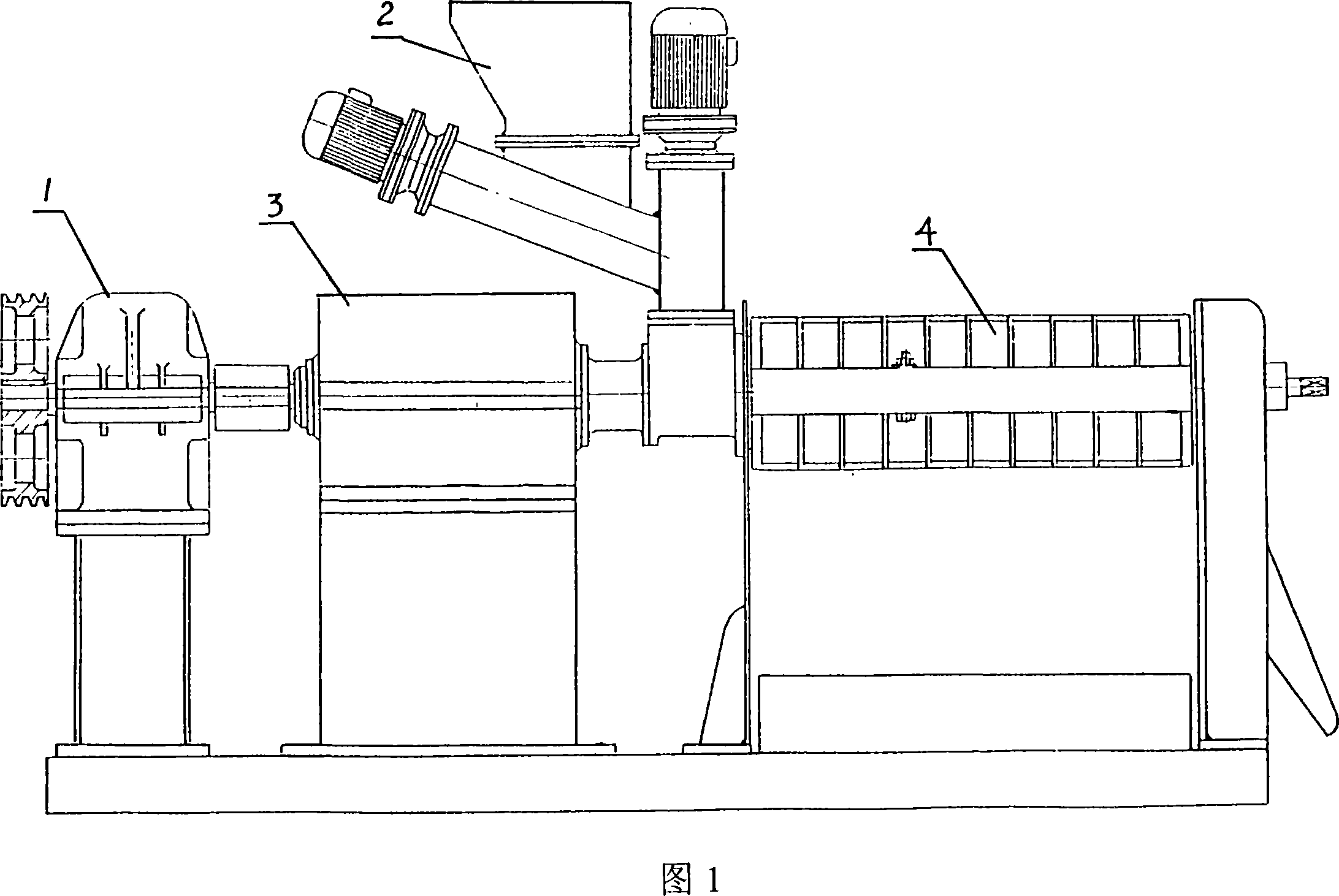

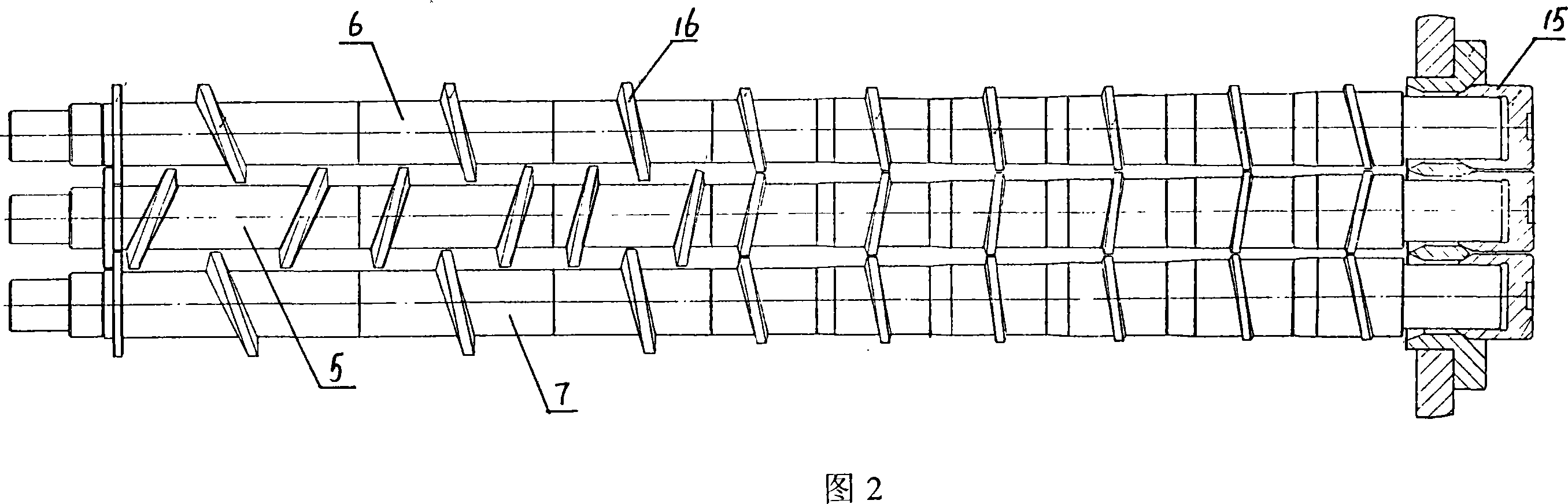

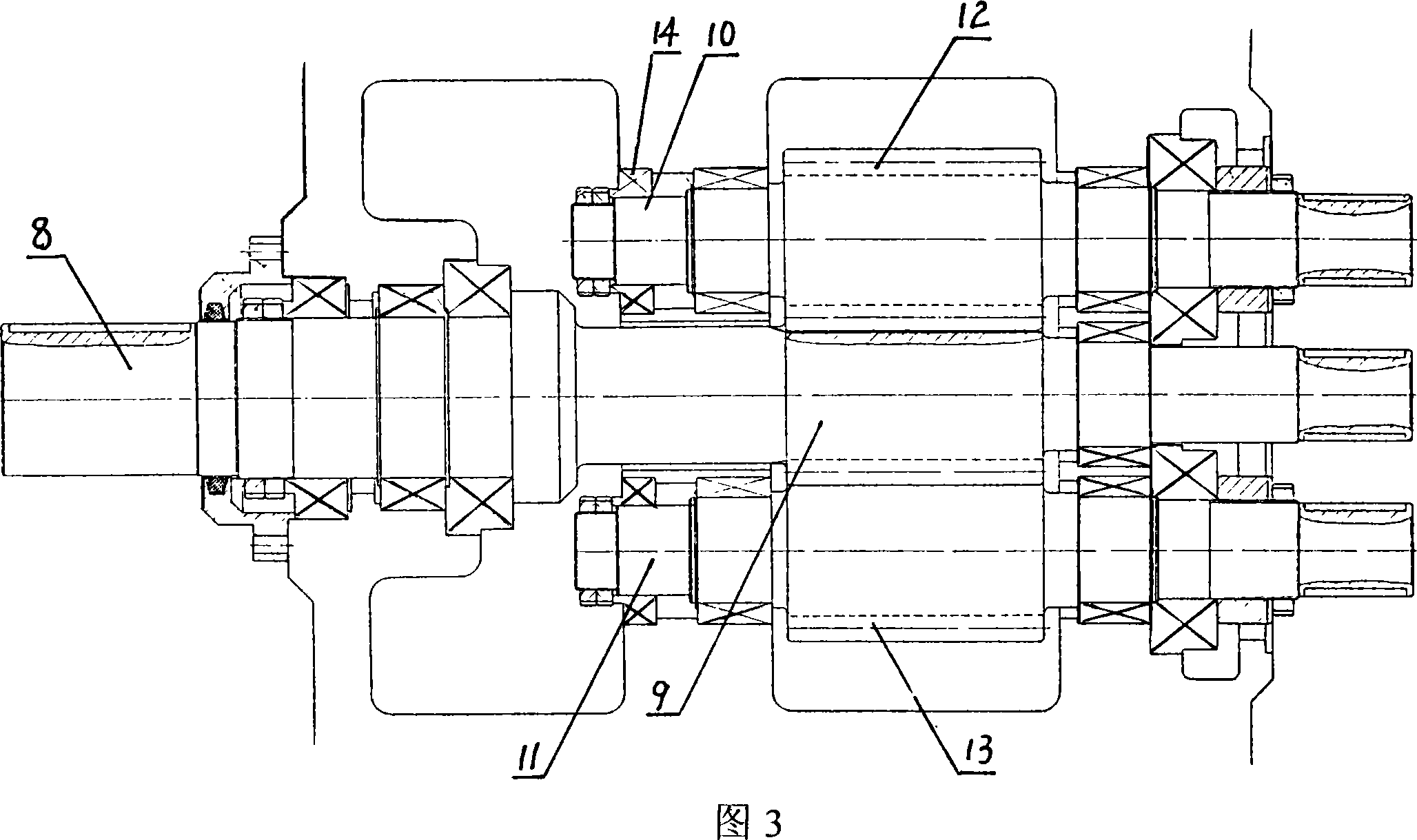

High oil plant loading double-helix oil press

InactiveCN102815009ASatisfy degree of transgenderMeet the industrialization requirements of low degree of denaturationPressesOil and greaseReduction drive

The invention discloses a high oil plant loading double-helix oil press comprising a feeding mechanism, a torque divider, a double-helix shaft, a press cage, a cake output mechanism and an oil discharging mechanism. The torque divider is connected with a driving motor via a speed reducer, the double-helix shaft comprises an upper spindle and a lower spindle which are mutually matched and provided with a plurality of press whorls and conical rings, an upper stop ring and a lower stop ring are respectively arranged on the upper spindle and the lower spindle at feed inlet ends of the double-helix shaft, the press cage is sleeved on the double-helix shaft and forms a press barrel with the same, two gear shafts of the torque divider are respectively connected with the upper spindle and the lower spindle of the double-helix shaft, and an discharge outlet of the feeding mechanism is connected with a feed inlet of the double-helix shaft. By the aid of the high oil plant loading double-helix oil press, oil in oil plants can be pressed out to the greatest extent, industrialization requirements on low oil pressing temperature, high oil output and low albuminous degeneration degree are met, and a base for follow-up full utilization of albumen is established.

Owner:中机康元粮油装备(北京)有限公司 +1

Pressing and aroma improving technical method of camellia seeds and tea seed oil obtained by method

ActiveCN108929769ALow acid valueRich flavorFatty-oils/fats refiningFatty-oils/fats productionCooking & bakingActivated carbon

The invention discloses a pressing and aroma improving technical method of camellia seeds. The technical method comprises the following technical steps: step one, baking and stir-frying tea seed kernels: husking fresh oil-tea fruits, drying the obtained camellia seeds, carrying out washing with water, completely removing shells, carrying out specific gravity separation, carrying out baking and stir-frying to obtain the tea seed kernels rich in fragrance; step two, curing tea seed kernels: husking fresh oil-tea fruits, drying the camellia seeds, drying the obtained camellia seeds, carrying outwashing with water, completely removing shells, carrying out specific gravity separation, carrying out curing to obtain the cured tea seed kernels; and step three, carrying out pressing: uniformly mixing 30-50 parts of the tea seed kernels obtained in the step one, 50-70 parts of the tea seed kernels obtained in the step two and 0.1-1 part of activated carbon particles, and feeding the obtained mixture into a presser for manufacturing oil to obtain the camellia oil with strong aroma. The method is simple in process, and the obtained tea oil has a low acid value, is rich in flavor, is nontoxicand safe, and is sanitary and nutrient.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

Method for producing grape seed oil from polyphenol-extracted grape seeds

ActiveCN103865637ALow densityLow viscosityFatty-oils/fats refiningFatty-oils/fats productionGrape seedExtracted grape seeds

Owner:河北丝路晨光油脂有限公司

Camellia essential oil extracting method

InactiveCN101294120ASimple processLess production equipmentEssential-oils/perfumesRoom temperatureSolvent

The extraction method of camellia essential oil is characterized in that the method comprises the following steps: (1) adding edible salt by an amount of 5 to 15% weight of fresh camellias, kneading, adding into a container, compressing, fixing fragrance at room temperature for 1 to 7 days, adding No.4 solvent (butane or mixture of butane and propane) into the camellias after fragrance fixation at normal temperature and under a certain pressure, extracting to obtain camellia liquid, and distilling by conventional method to obtain the camellia essential oil; or (2) drying the fresh camellias under the sun or in an oven, extracting the dried camellias with carbon dioxide and methanol or ethanol at a weight ratio of 1:(30 to 50):(10 to 40) under a pressure of 30 to 50 MPa, and separating the extractive liquid to obtain the camellia essential oil. The invention provides the method for extracting the camellia essential oil from the camellias by using simple process and less production equipment to fill the blank in camellia utilization, and develops a path for deep development and utilization of the camellias.

Owner:黄宝生

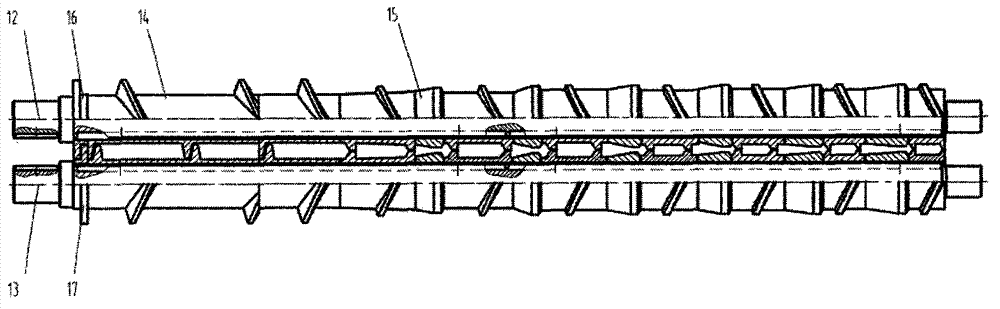

Triple screw extruder

InactiveCN101249728ASolve the smoothbore phenomenonSuitable for dehulling and cold pressingShaping pressOil and greaseDecortication procedure

The invention discloses an oil press, in particular to a three-screw oil press which is composed of a transmission device, a feeding device, a transmission case and a press chamber, and is characterized in that three parallel press screw shafts are arranged in the press chamber. The oil press has the advantages that the structure is simple, the compression ratio is high (20 to1), the residual oil content in the cake is low, and the temperature is low during the pressing process. The oil press thoroughly solves the oil seed sliding phenomenon in chamber, efficiently utilizes vegetable protein to prepare the original ecological high-level oil, and is particularly suitable for oil seed decortication and cold-pressing.

Owner:武汉新概念农业机械设备制造有限公司

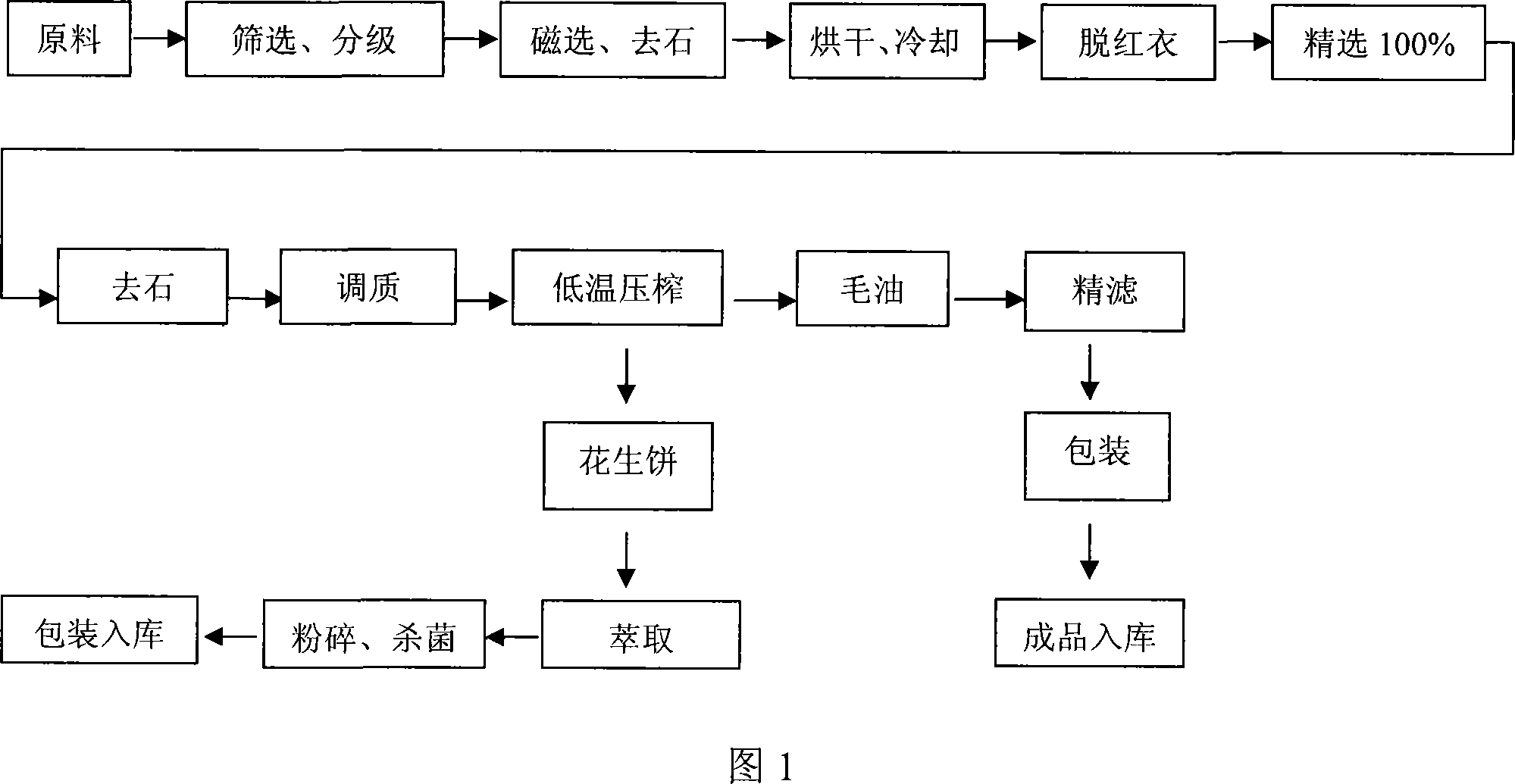

Process for preparing peanut oil and peanut protein powder synchronously

ActiveCN101095435AAflatoxin removalEfficient removalProtein composition from vegetable seedsEdible oils/fatsChemical compositionAdditive ingredient

The invention relates to a method for preparing peanut oil and peanut protein powder simultaneously, which comprises following steps: treating peanut at low temperature, pressing with oil expeller at low temperature and getting crude oil and cake; fine filtering the crude oil and getting peanut oil; extracting said cake at low temperature, ultra-micro disintegrating, disinfecting and getting peanut protein powder. The invention is characterized in that the process is carried out at low temperature, so the nutrition can be maximum retained, and the peanut oil is rich in unsaturated fatty acid, contains no cholesterol, color is light, the phosphatide content is low, and there is no toxic chemical component and residual. The protein is not degenerated, the residual oil content is lower than 1.5%, protein content is more than 55%, and the water and oil retaining property, emulsifying and gel performance are better. The application is wider.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP +1

Raw material oil pressing process with separated rapeseed shell and kernels

The rapeseed shell-kernel separating and raw material oil pressing process includes the steps of eliminating repeseed shell, separating rapessed shell from kernel, separated treatment of shell, squeezing oil with kernal at 35-80 deg.c and the condition of no change in protein property to obtain rapeseed cake and oil, and filtering oil to obtain product oil. The present invention is simple, low incost, high product quality and high in side product value.

Owner:罗永宗

High-oil-content seed kernel cold-pressing oil-making machine

The invention relates to a high-oil-content seed kernel cold-pressing oil-making machine for pressing high-oil-content seed kernels and extracting fat. A hydraulic power system consists of a hydraulic pump station, an oil-pressing power hydraulic cylinder, a lifting sealing hydraulic cylinder and a material-loading and cake-unloading hydraulic cylinder; and a pressing and oil making system consists of a presser pulling force column shaft, a bearing lifting bottom support, a bearing lifting supporting arm guide sleeve, a double-pressure bearing, pressing cylinder bodies, a bearing press-stopping plate, a positioning lead, a positioning lead bolt, a pressing cylinder flange, a flow aid inclination angle pressing ring, a bearing sliding pressing plate, a pressing ring clamping key, a high-pressure oleophobic partition plate, a platform and the like. By using two material pressing cylinder bodies and three integrated and independent underlying hydraulic cylinders, operation and control can be more simply and conveniently performed; when any one pressing cylinder body is in position in a lifting sealing mode, the oil-pressing power hydraulic cylinder and the material-loading and cake-unloading hydraulic cylinder of the whole machine can be automatically positioned at the same time; and continuous operation production can be realized in the natural environment temperature during the four seasons.

Owner:LIAONING FERTILIZER

Tea seed seasoning oil and preparation method thereof

InactiveCN109679763ALow acid valueRich flavorFatty-oils/fats productionEdible oils/fatsCooking & bakingCamellia oleifera

The invention discloses tea seed seasoning oil and a preparation method of the tea seed seasoning oil. The preparation method comprises the following steps: (1) baking: airing fresh camellia seeds, husking the fresh camellia seeds to form camellia seed kernels, washing the camellia seed kernels with water, drying, crushing and baking the camellia seed kernels to form crushed tea seed kernels, (2)spicing: putting the crushed tea seed kernels obtained in the step (1) into a fresh spice, performing continuous baking, adding a mashed dry red pepper, performing continuous stir-frying, adding a dryspice, and continuing the baking, (3) flavoring: adding distiller grains for flavoring, and (4) pressing: pressing oil from an obtained mixture to form the tea seed seasoning oil, wherein the fresh spice comprises ginger pieces, green Chinese onions, garlic and onions; and the dry spice comprises myrcia, elettaria cardamomum, star anise, fennel, cassia bark and pricklyash peel. Materials of the method are simple, and the obtained tea seed seasoning oil is mellow and fragrant in flavor, and light red and clear in color. After the tea seed seasoning oil is used, a taste is soft, not scorched, slightly spicy, delicious, fragrant, not greasy, nontoxic, safe, hygienic and nutritive.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

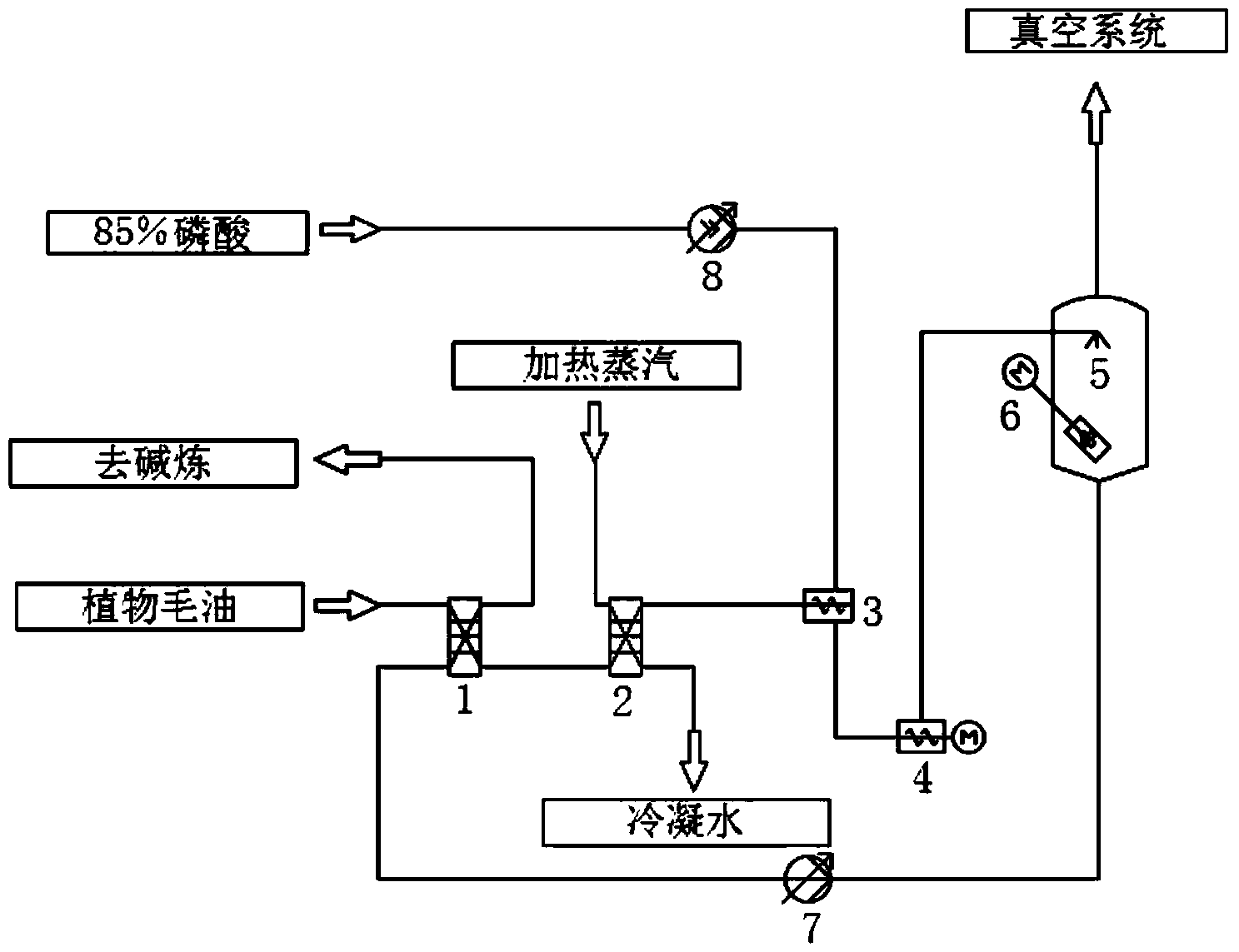

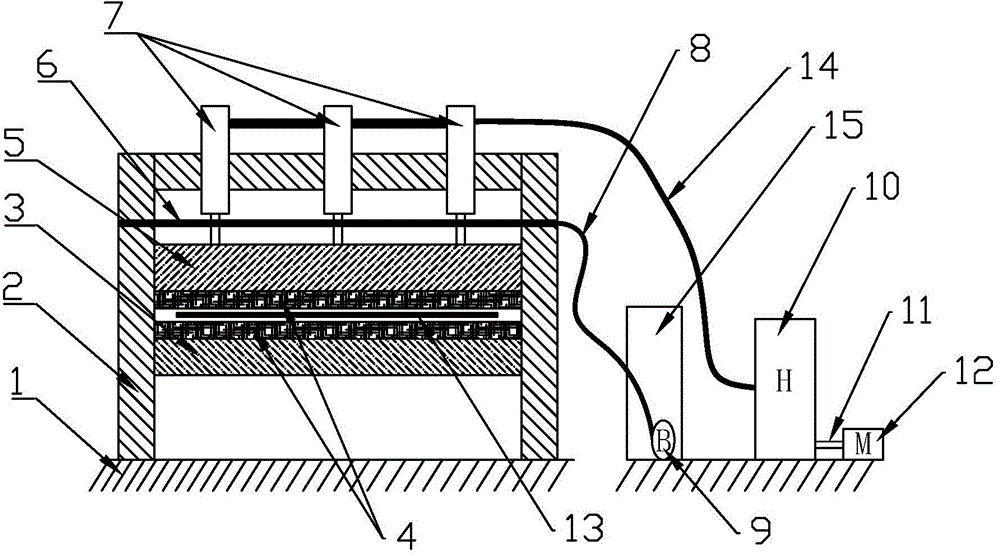

Method and special device for removing chlorophyll in vegetable oil

ActiveCN103849462AImprove qualityIncrease production capacityFatty-oils/fats refiningVegetable oilPhosphoric acid

The invention discloses a method and a special device for removing chlorophyll in vegetable oil. The device comprises a steam heater, a static mixer, a high shear mixer, a vacuum reactor and a stirrer arranged in the vacuum reactor, wherein the steamer heater, the static mixer, the high shear mixer and the vacuum reactor are sequentially connected; vegetable crude oil heated to 130-160 DEG C by virtue of the steam heater enters into the static mixer to be pre-mixed with 85% phosphoric acid in the static mixer, and is then conveyed to the high shear mixer to be fully mixed and then conveyed to the vacuum reactor to be reacted for 10-20 minutes under stirring of the stirrer. Vegetable oil in the upper layer of the reactor is extracted to enter into the next step. Compared with the prior art, the method disclosed by the invention further can be used for reducing the consumption of caustic soda and activated clay while being suitable for producing first-level oil products and fourth-level oil products of national standard, so that the production yield is improved, the quality of the oil products is improved and the discharge of solid wastes is reduced.

Owner:SHANGHAI JIAOER ENG TECH

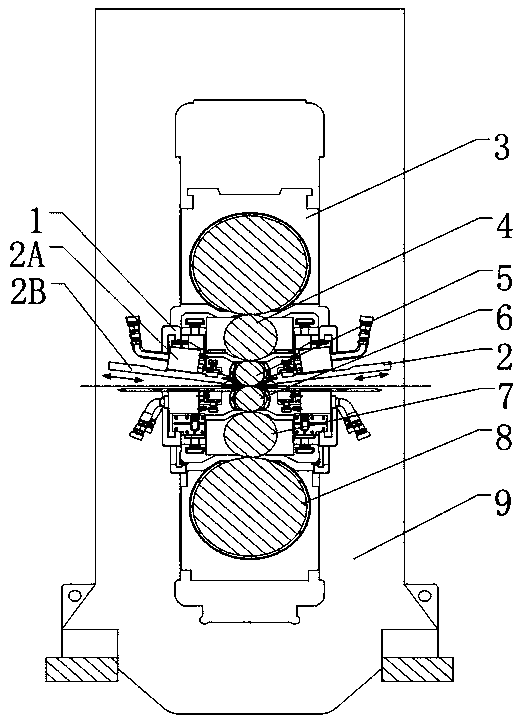

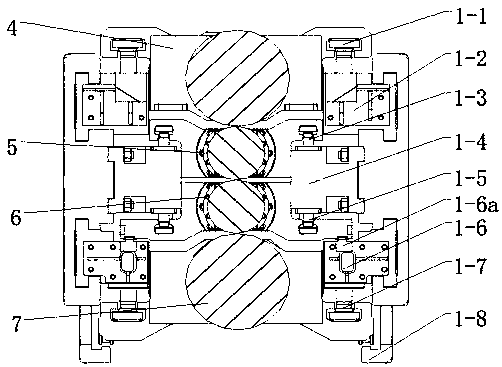

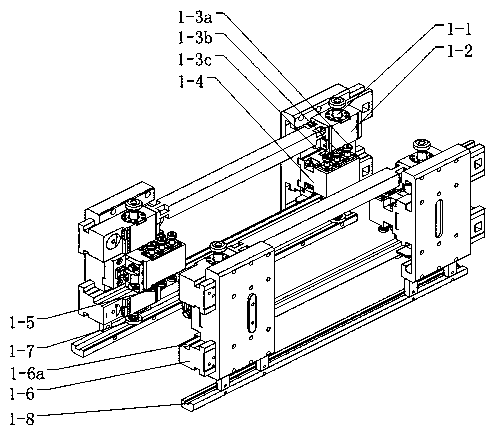

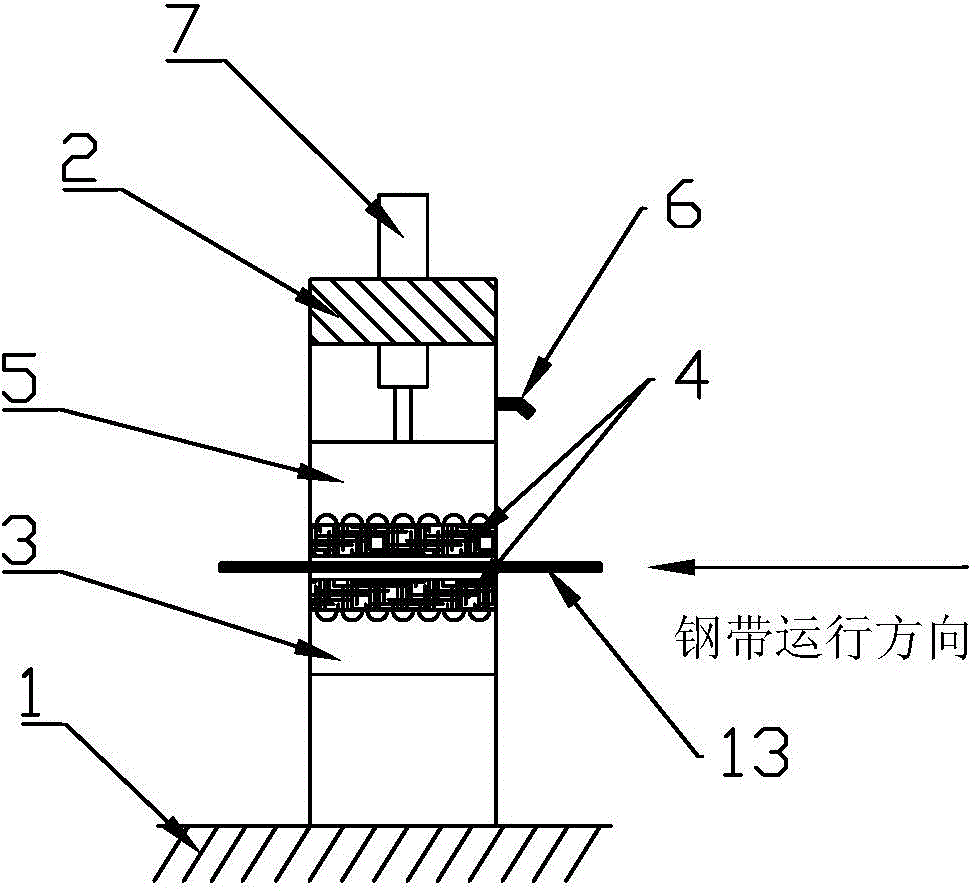

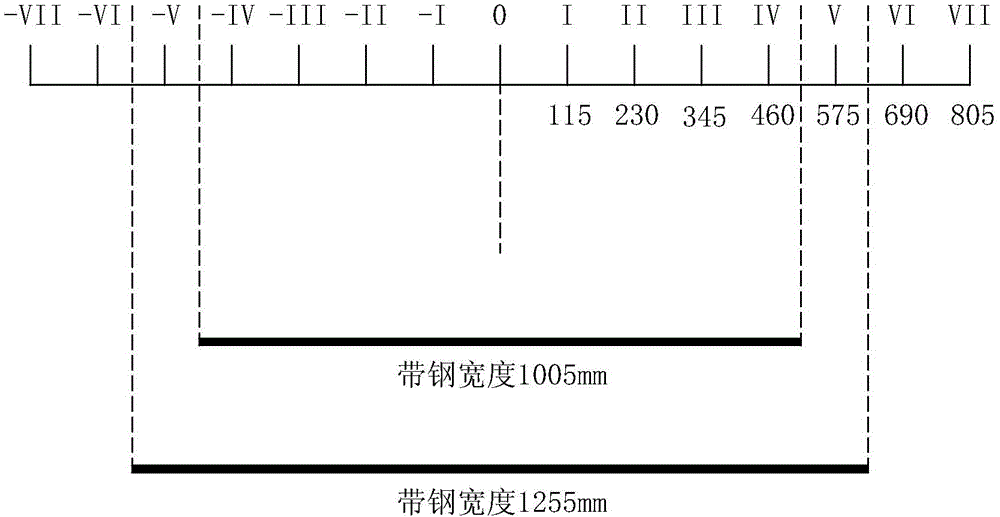

Compact type six-roller rolling mill and work method

PendingCN108817087AReduce residual oilCompact structureMetal rolling stand detailsMetal rolling arrangementsEngineeringCylinder block

The invention relates to a compact type six-roller rolling mill and a work method. The compact type six-roller rolling mill comprises a work roller and intermediate roller bending cylinder block, spraying beam and oil stopping guide plate parts, an upper bearing roller assembly, an upper intermediate roller assembly, an upper work roller assembly, a lower work roller assembly, a lower intermediateroller assembly, a lower bearing roller assembly and a rack. According to the compact type six-roller rolling mill and the work method, plate shape condition means such as intermediate roller positive and negative roller bending, work roller smooth transition positive and negative roller bending and intermediate roller channeling are achieved; the inner structure of the rack is compact, the spraying beam and oil stopping guide plate parts are arranged in the small space strip inlet and outlet direction, the outlet strip surface residual oil is reduced, and residual oil sprayed to the outlet strip surface from the empty space between the intermediate roller diameter part and a work roller during intermediate roller channeling can be greatly reduced.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Preparation method of idesia polycarpa crude oil

The invention provides a preparation method of idesia polycarpa crude oil, and solves the problems of high cost, low safety, high residual oil rate and poor quality of the prepared crude oil in the existing idesia polycarpa crude oil production technology. The preparation method of the idesia polycarpa crude oil comprises the following steps: (1) microwave coupled drum-type hot air frying pretreatment; (2) grinding; (3) slurry blending; (4) primary extraction; and (5) secondary extraction. According to the preparation method of the idesia polycarpa crude oil, potential safety hazards in the preparation process can be reduced, the cost of raw materials is saved, the utilization rate of the raw materials is increased, the residual oil rate is reduced, the oil yield is increased, and the quality of the produced crude oil is guaranteed.

Owner:四川中海茂农业开发有限公司

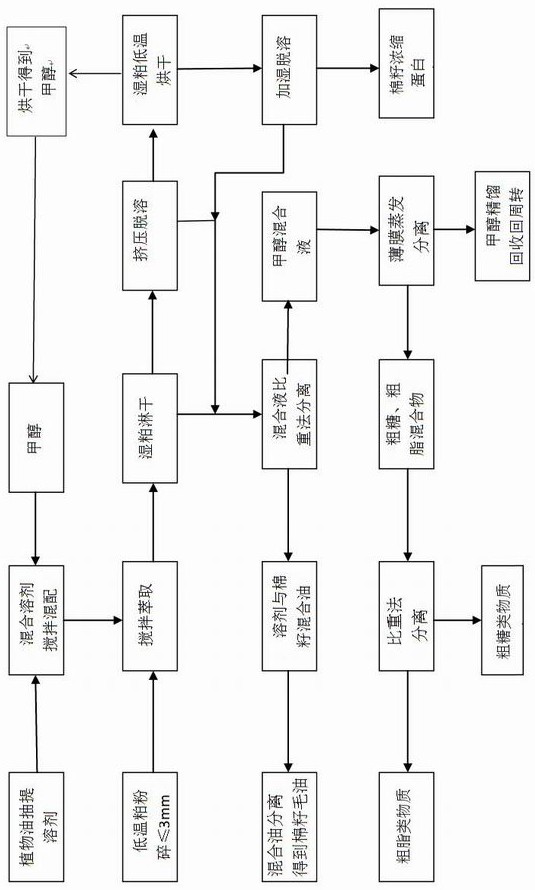

A cottonseed protein production method capable of extracting various by-products

ActiveCN107011411BImprove economyHigh protein contentPeptide preparation methodsFatty-oils/fats productionVegetable oilCottonseed oil

A cottonseed protein production method capable of extracting various by-products includes the steps: stirring and extracting meal powder under the action of solvents; separating materials from the solvents after extraction to obtain wet meal; desolventizing the wet meal; drying the wet meal at low temperature; adjusting the water content of the wet meal and continuing removing residual solvents to form a cottonseed protein concentrate product meeting requirements; separating the separated solvents to obtain methanol mixed liquid and cottonseed mixed oil containing solvents for vegetable oil extraction; continuing separating the methanol mixed liquid, recovering methanol and keeping the remaining, namely raw sugar and crude fat mixture; separating the raw sugar and crude fat mixture to obtain raw sugar substances and crude fat substances. The solvents are mixed solvents of methanol solution and the solvents for vegetable oil extraction. Cottonseed meal processed and produced at the low temperature serves as a raw material and can be extracted to obtain cottonseed protein concentrate and raw sugar, the raw fat substances with the yield exceeding raw sugar yield can be obtained, cottonseed oil can be further extracted, and residual oil in the meal is further reduced, so that the field of cottonseed processing has better economical efficiency.

Owner:济南中棉生物科技有限公司

Processing method of corn oil nigre

ActiveCN103451023AReduce shipping costsReduce lossFatty oils/acids recovery from wasteFatty-oils/fats refiningSolventAnimal feed

The invention relates to a processing method of corn oil nigre. The processing method comprises the following steps: mixing corn oil nigre and corn germ meal; granulating and forming a mixture of the corn oil nigre and the corn germ meal; leaching a material after granulating and forming; evaporating leached oil; condensing and recycling a solvent. According to the processing method of the corn oil nigre, more than 80% of grease in the corn oil nigre can be extracted, and the loss of the oil and fat during the refining process is reduced; solid meal after the grease are completely extracted can be taken as an animal feed, so that the nigre is completely utilized, the processing process is free of pollution, and the environment-friendly cost of processing the nigre by enterprises is reduced.

Owner:SHANDONG SANXING CORN IND SCI CO LTD

Efficient energy-saving twin-screw rod oil press

The invention discloses an efficient energy-saving twin-screw rod oil press which comprises a machine frame base, a motor, a speed reducer, a torque distributor, a feeding device, a feeding device base, a left wallboard, a right wallboard, a pressing cage assembly and a cake adjusting mechanism; the pressing cage assembly comprises a pressing cage, a first screw rod and a second screw rod; both the first screw rod and the second screw rod are formed by combining eight sections of pressing bolts and five taper rings inserted among the pressing bolts. By utilizing the efficient energy-saving twin-screw rod oil press disclosed by the invention, the retention time of a pressing material in a pressing chamber can be greatly prolonged, the pressing characteristics are effectively improved, the oil yield is improved, and residual oil in a cake is reduced.

Owner:JIANGNAN UNIV

Method for improving surface clearness of cold-strip steel and dedicated device thereof

InactiveCN104438382AReduce residual iron contentImprove cleanlinessWork treatment devicesMetal rolling arrangementsAlcoholSpray nozzle

The invention discloses a method for improving surface clearness of cold-strip steel and a dedicated device of the method. The method comprises the steps that the upper surface and the lower surface of the strip steel are cleaned through a chemical agent, and the chemical agent is composed of, by volume, 85 percent to 93 percent of glycolic acid, five percent to 10 percent of ethyl alcohol, one percent to three percent of hydroxyethylidene diphosphonate and one percent to two percent of polyoxyethylene nonionic surfactant. The dedicated device comprises a frame workshop, a fixed plate guide table and a strip pressing plate capable of moving vertically are arranged in the frame workshop, and adjacent faces of the fixed plate guide table and the strip pressing plate are parallel and are each coated with a layer of degreasing cotton. A liquid spray collecting pipe and nozzle system is further arranged on the frame workshop. The surfaces of the cold-strip steel can be cleaned with high speed and high efficiency.

Owner:SHANDONG IRON & STEEL CO LTD

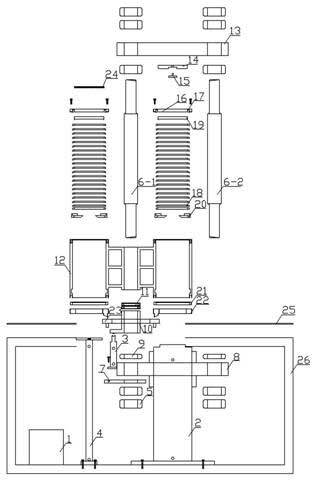

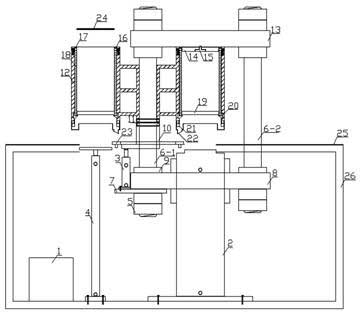

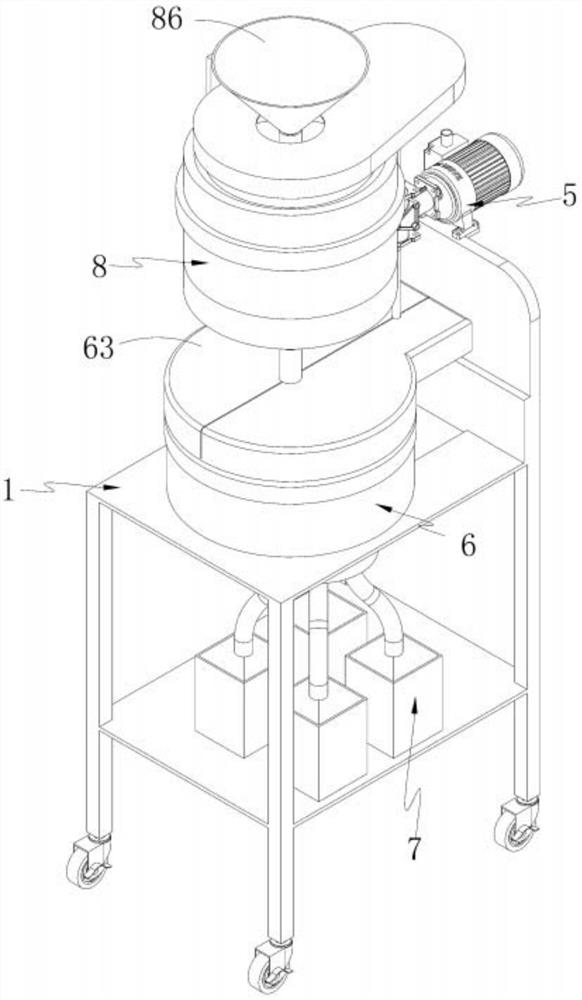

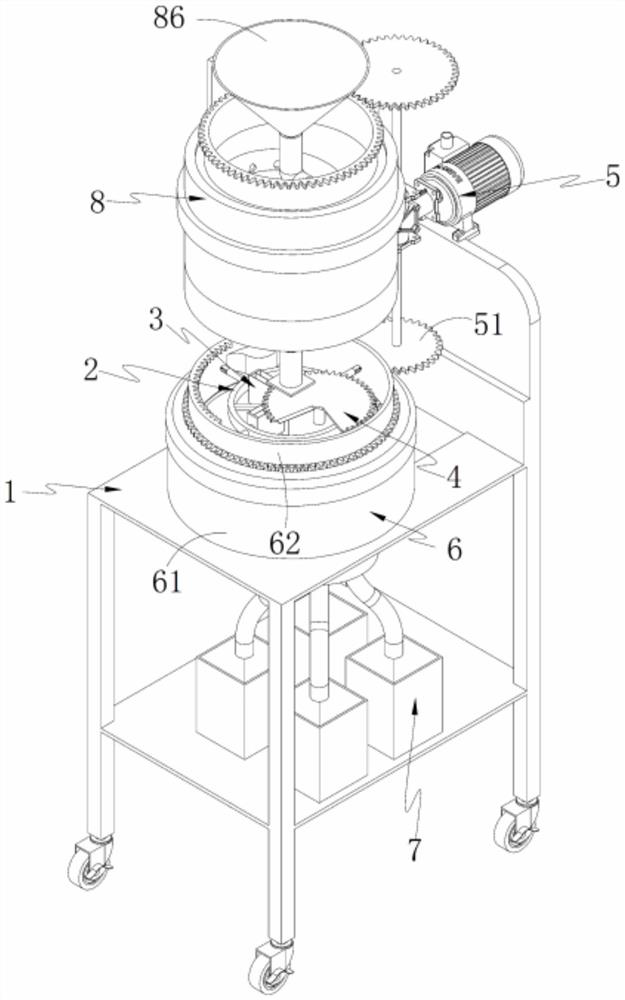

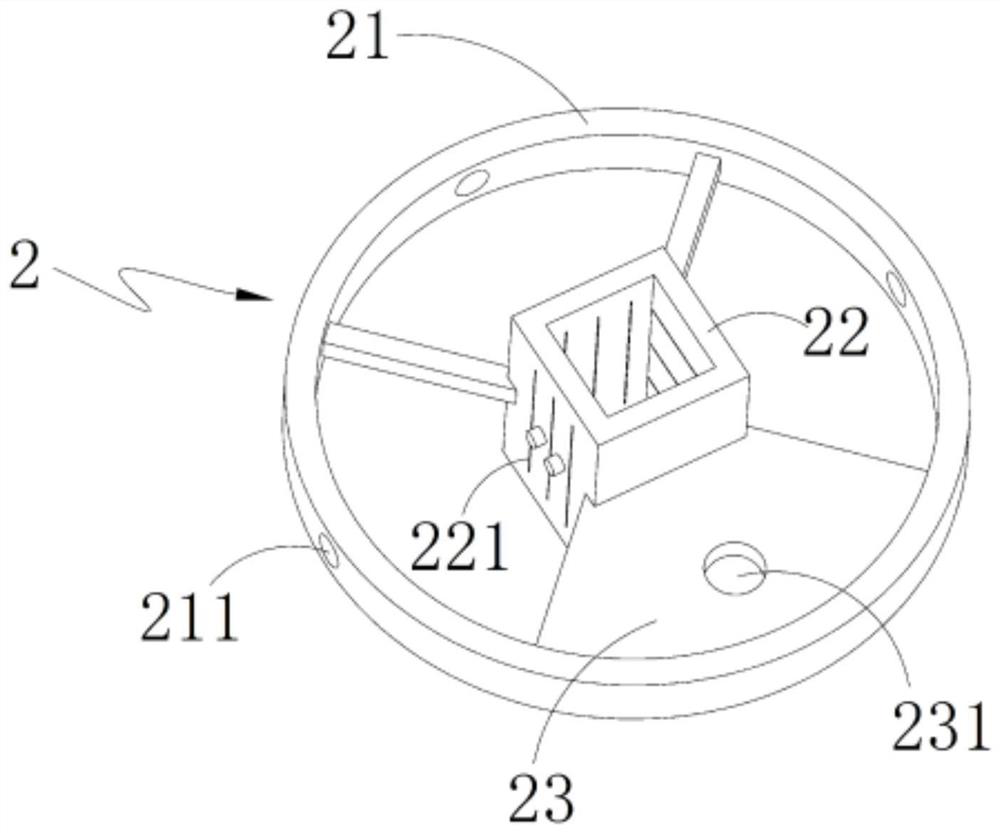

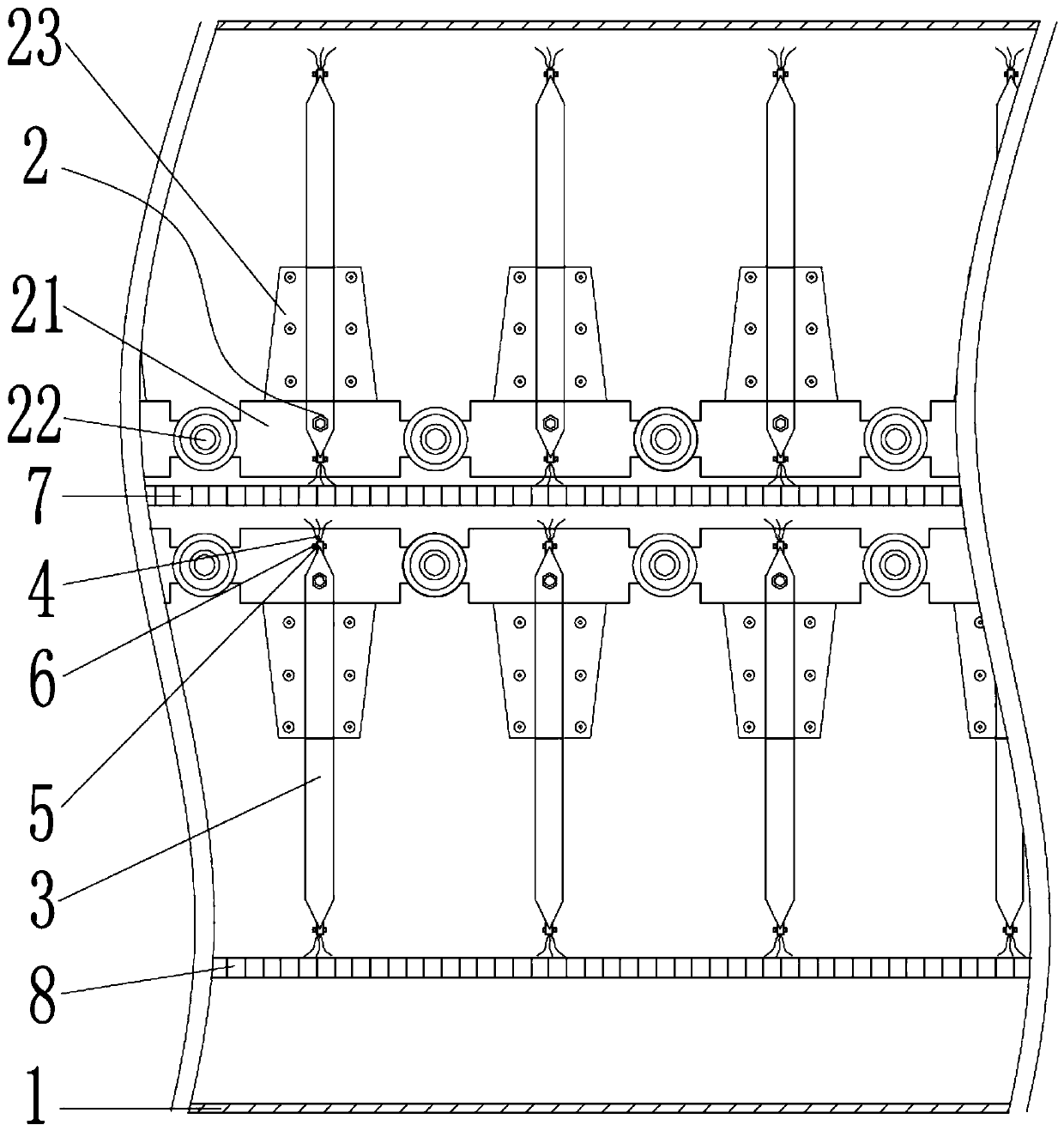

Crushed peanut processing equipment capable of reducing residual oil

ActiveCN112718142ASynchronous cuttingReduce residual oilRotary centrifugesGrain treatmentsAgricultural engineeringProcess engineering

The invention provides crushed peanut processing equipment capable of reducing residual oil. The equipment comprises a rack, a knife rest unit, a cutter, a feeding control unit, a driving unit, a material cutting control unit, a material receiving unit and an oil draining unit, and is characterized in that a spiral oil draining pipe of which a spiral direction is opposite to a rotating direction of a conical rotating disc is arranged on the oil draining unit, so that oil draining and sorting of fried peanuts are achieved, and the peanuts subjected to oil draining sequentially enter a knife rest; the feeding control unit, the knife rest unit, the cutter and the material cutting control unit cooperate with one another, so that the peanuts are cut according to a required particle size, and the problem that the particle uniformity of crushed peanuts is poor due to the fact that the crushed peanuts are produced in a crushing mode is solved; and the crushed peanuts with different particle sizes are classified and collected by means of the material receiving unit, the crushed peanuts with the different particle sizes are independently packaged and sold, the requirements of different customers are met, and a yield of the crushed peanuts is increased.

Owner:阜阳佰恩得新材料技术有限公司

Three-screw oil press

InactiveCN101088749ASolve the smoothbore phenomenonSuitable for dehulling and cold pressingShaping pressDecortication procedureResidual oil

The present invention discloses oil press, and is especially one kind of three-screw oil press. The three-screw oil press consists of one driving mechanism, one feeding mechanism, one driving box and one pressing cavity, and features the pressing cavity with three parallel pressing screws. The present invention has the advantages of simple structure, great compression ratio, low residual oil rate and low pressing temperature. The present invention is especially suitable for the decortication and cold pressing of plant oil material.

Owner:武汉新概念农业机械设备制造有限公司

Processing method of corn oil nigre

ActiveCN103451023BNo pollutionNo emissionsFatty oils/acids recovery from wasteFatty-oils/fats refiningOil and greaseSolvent

The invention relates to a processing method of corn oil nigre. The processing method comprises the following steps: mixing corn oil nigre and corn germ meal; granulating and forming a mixture of the corn oil nigre and the corn germ meal; leaching a material after granulating and forming; evaporating leached oil; condensing and recycling a solvent. According to the processing method of the corn oil nigre, more than 80% of grease in the corn oil nigre can be extracted, and the loss of the oil and fat during the refining process is reduced; solid meal after the grease are completely extracted can be taken as an animal feed, so that the nigre is completely utilized, the processing process is free of pollution, and the environment-friendly cost of processing the nigre by enterprises is reduced.

Owner:SHANDONG SANXING CORN IND SCI CO LTD

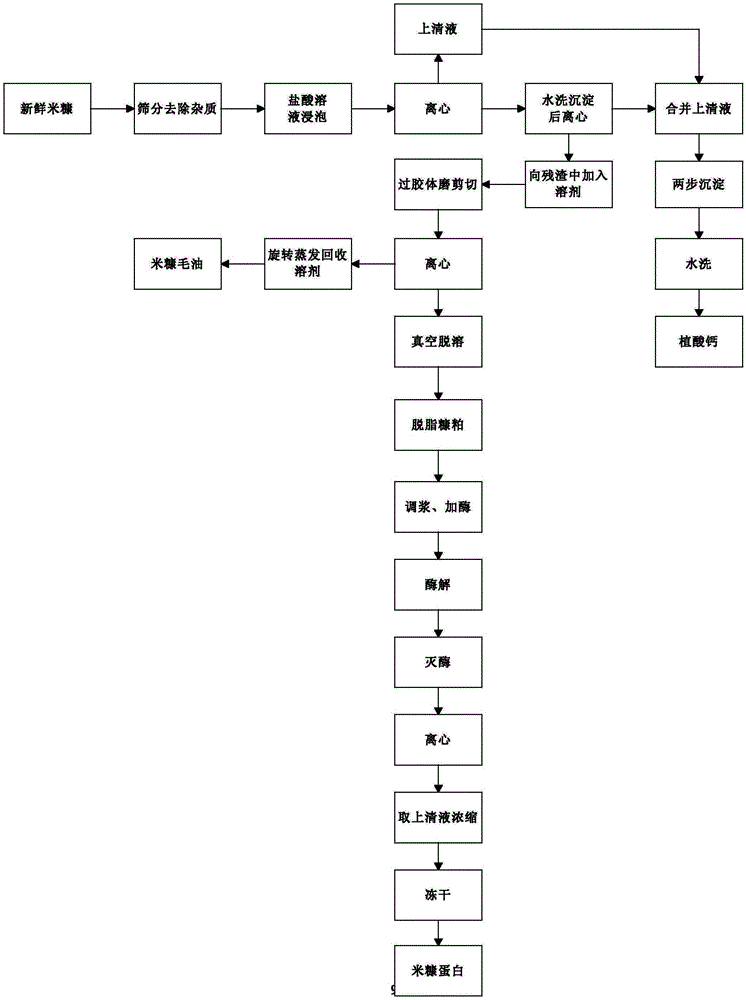

A kind of efficient extraction method of rice bran nutrition and active substances

ActiveCN103833786BGuarantee the quality of follow-up processingPrevent rancidityGroup 5/15 element organic compoundsFatty-oils/fats productionPhytic acidSolvent

The invention provides a high-efficiency extraction method of nutritional and active substances of rice bran. The high-efficiency extraction method comprises the following steps of 1, full-fat rice bran screening impurity-removal, 2, phytic acid extraction by immersion in an acid, 3, rice bran crude oil extraction by high-speed shearing and a complex solvent, and 4, enzyme method-based extraction of a rice bran protein. The high-efficiency extraction method can realize high-efficiency extraction of phytic acid, fat and proteins of full-fat rice bran in an order, realize high-valued complete utilization of full-fat rice bran, improve an added value and avoid resource waste.

Owner:JIANGNAN UNIV

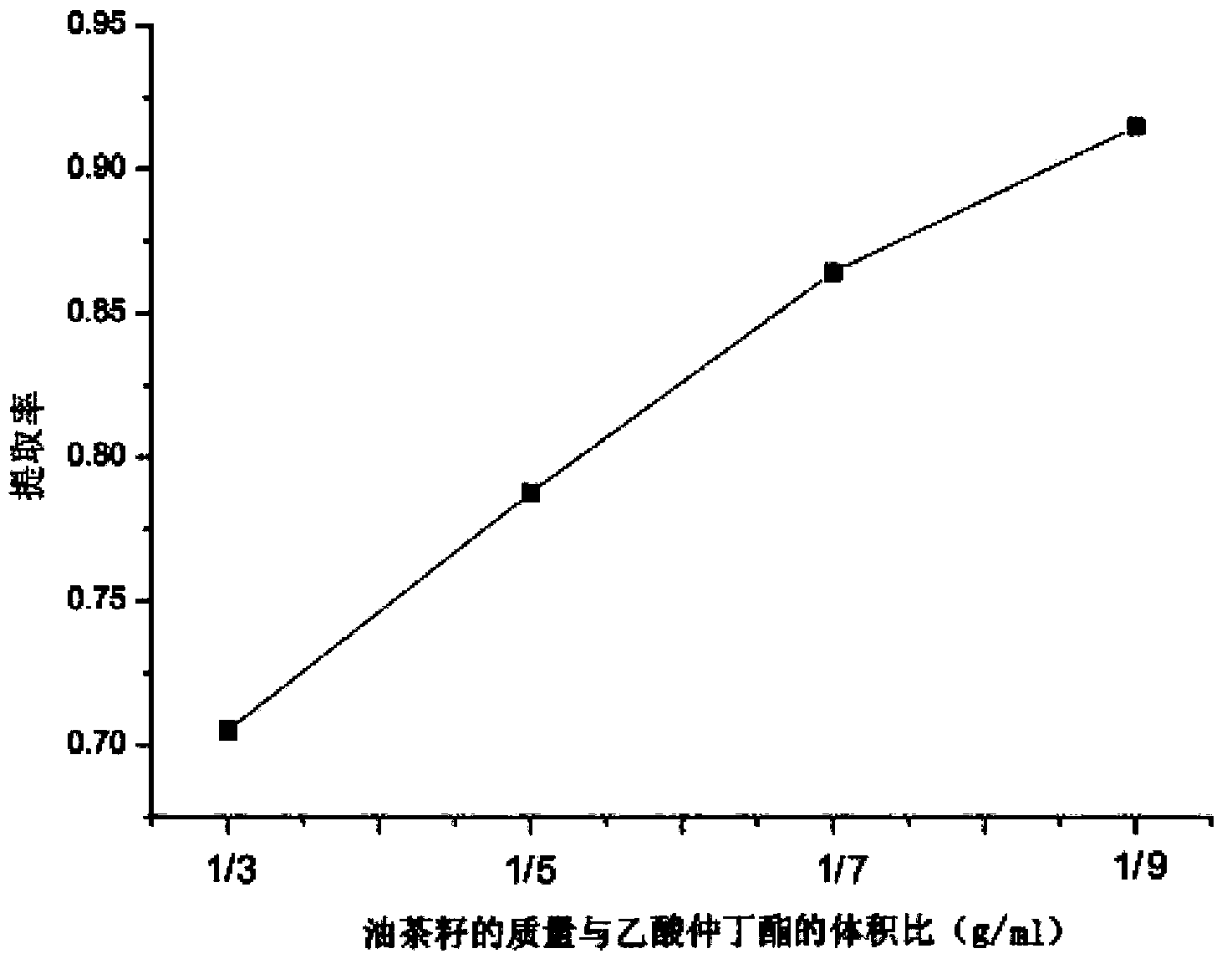

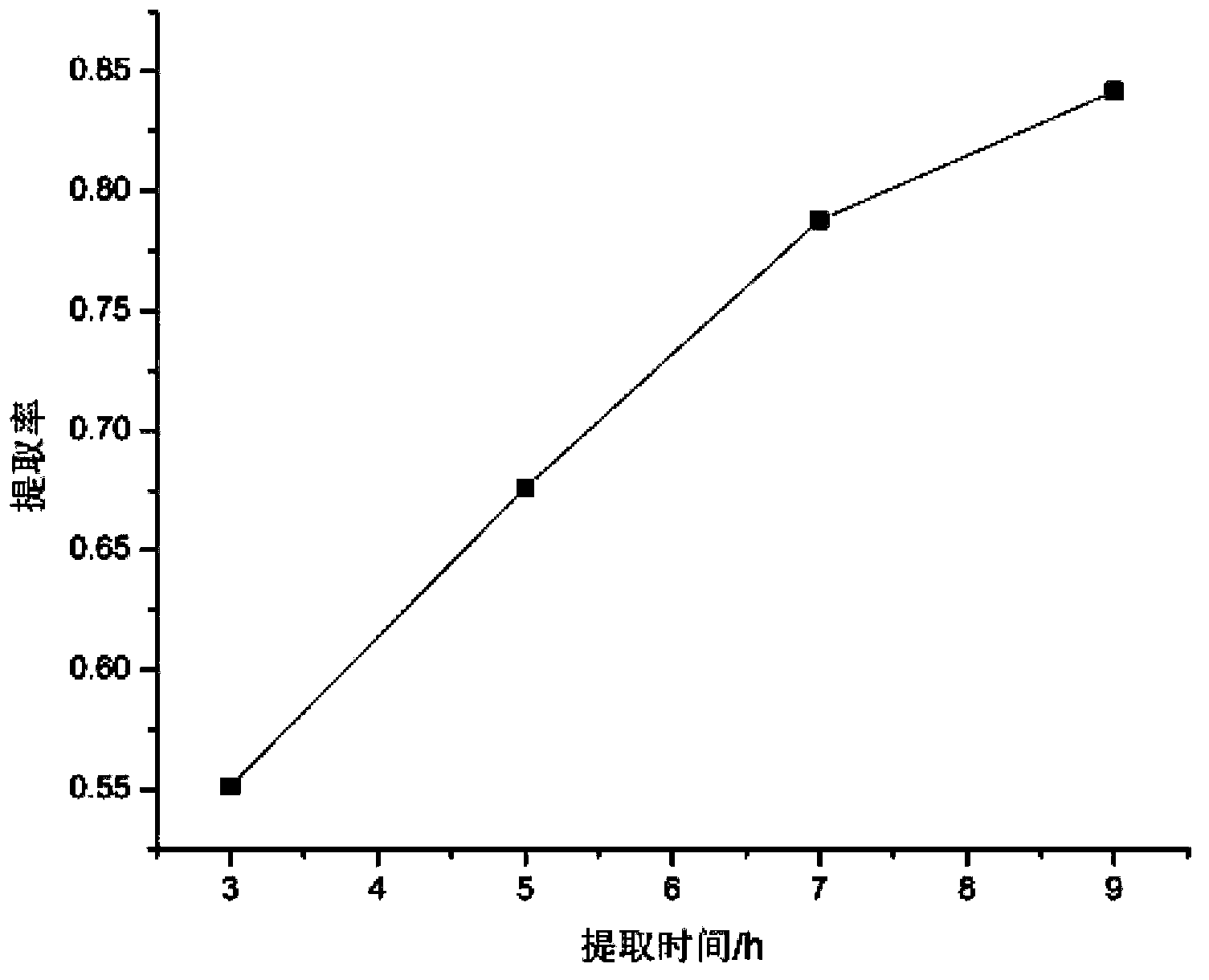

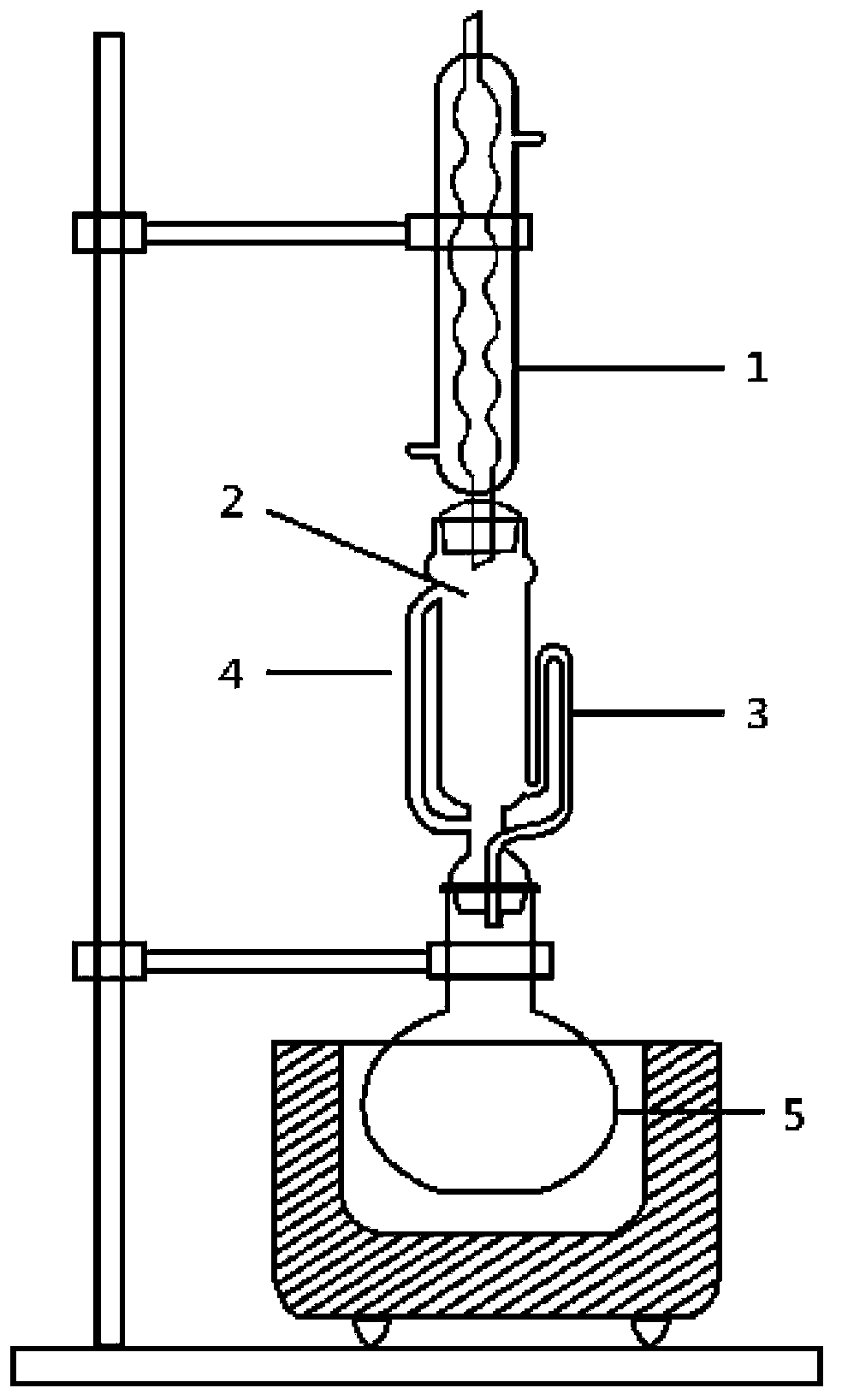

A kind of tea seed oil extraction method

The invention discloses a tea-seed oil extraction method which comprises the following steps that (1), pretreatment is performed: oil-tea camellia seeds are smashed, and (2), sec-butyl acetate is taken as a solvent, and tea-seed oil is extracted with a soxhlet extraction method or a mixing extraction method. The tea-seed oil extraction method takes the oil-tea camellia seeds as raw materials and sec-butyl acetate as the leaching solvent, and sec-butyl acetate is a green and environment-friendly solvent completely free from arene and sulfur, so that compared with the existing commonly-used leaching solvent, the extracted tea-seed oil is safer to eat due to the environment-friendly characteristic of sec-butyl acetate; sec-butyl acetate is free from sulfur, so that corrosion to a system is reduced, and the service life of equipment can be prolonged; the purity of adopted sec-butyl acetate is higher; the extracted tea-seed oil is few in impurity; the quality of the tea-seed oil is ensured; in addition, sec-butyl acetate is an ester solvent, and has better solubility to oil, so that the extracting power to the tea-seed oil is improved; the content of residual oil in pulp can be reduced; a yield of the oil is increased; and the extraction cost is lowered.

Owner:HUIZHOU YUSSEN CHEM CO LTD

Scraping plate device of corn germ extractor

InactiveCN111500362AImprove passabilityPromote circulationFatty-oils/fats productionEngineeringChain link

The invention relates to the field of corn germ processing, in particular to a scraping plate device of a corn germ extractor. The scraping plate device comprises an annular scraping plate chain and scraping plates, wherein the scraping plates are fixedly mounted on the annular scraping plate chain; the annular scraping plate chain is arranged around an upper extractor grid plate in the extractorand is positioned above a lower extractor grid plate; the annular scraping plate chain comprises a plurality of chain links, every two adjacent chain links are connected through a chain shaft, each chain link is provided with a scraping plate, and the chain links and the scraping plates are fixedly connected through scraping plate fixing pieces; and steel wire brushes are installed at the tops andthe bottoms of the scraping plates and fixedly connected with the scraping plates through wire brush pressing strips and pressing strip fasteners. According to such a technical scheme, when corn germs are processed by using an oil-making leaching method, the permeation of a leaching solvent passing through the grid plates is improved, and the circulation amount of the leaching solvent can be increased by 35%; and furthermore, residual oil in corn germ meal obtained by production is reduced by 12%.

Owner:河北惠典油脂有限公司

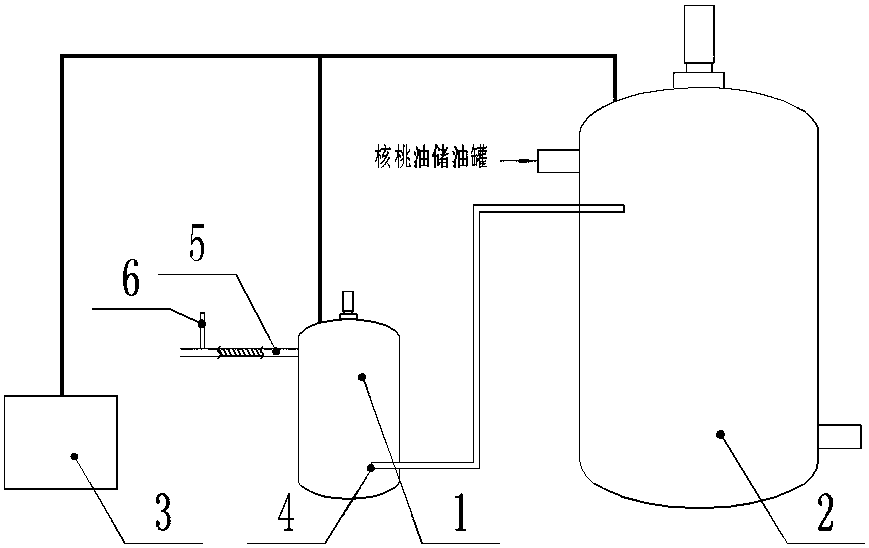

Walnut blend oil capable of preventing high blood pressure, high blood sugar and high blood lipid and preventing senile dementia, and preparation method and equipment

InactiveCN108338219ARaise the ratioEnhance blood lipid lowering effectFatty substance preservation using additivesFatty-oils/fats refiningOxidation resistantHigh pressure

The invention specifically relates to walnut blend oil having the efficacy of preventing high blood pressure, high blood sugar and high blood lipid and preventing senile dementia, and a preparation method and production equipment of the blend oil. The invention aims to overcome the defects that in the prior art, in the preparation course of walnut oil, oxidation resistant protection is not comprehensive and thorough enough and the stability of nutrition quality is poor, and provides high-quality walnut oil with a whole course having comprehensive oxidation prevention and control and being stable in nutrition quality, and a processing and preparing technology of nutritive walnut blend oil prepared by the high-quality walnut oil. The formula of the walnut blend oil having the efficacy of preventing high blood pressure, high blood sugar and high blood lipid and preventing senile dementia provided by the invention comprises the following raw materials in parts by mass of 45-55 parts of walnut oil, 5-9 parts of almond oil, 25-30 parts of olive oil, 1-4 parts of linseed oil, 0.5-1.4 parts of coconut oil, 2.5-5.5 parts of palm oil, 5-9 parts of grape seed oil and 1.5-3 parts of DHA. The preparation method and equipment of the walnut blend oil are also disclosed.

Owner:山西一果食品有限公司

Preparation method for high-purity rice bran oil

InactiveCN107868699AHigh in nutrientsKeep the scentFatty-oils/fats productionOil processingVitamin C

The invention mainly relates to the technical field of oil processing, and discloses a preparation method for high-purity rice bran oil. The preparation method comprises the following steps: soaking,lactic acid fermentation, yeast fermentation, drying and squeezing. The method is simple and is convenient to operate, and the obtained rice bran oil is relatively high in purity, and a later-stage purifying process does not need to perform, so that production cost is reduced by 18.7%. The preparation method specifically comprises the following steps: adding a vitamin C solution into rice bran tokeep nutritional ingredients in rice bran and prevent color of rice bran from being darkened; and introducing lactic acid bacteria into the rice branch to ferment to decompose colloids and wax in therice bran. The method is simple, increases nutritional ingredients of small molecules, avoids adding a chemical reagent at a later stage to perform degumming and dewaxing, is silent and environmentally friendly, saves energy resources, reduces the production cost, and keeps flavor and nutrients of the rice bran oil; angel brewer's yeast is added to perform high-temperature fermentation after lactic acid fermentation, so that activity of glucosidase is improved, and free fatty acid and dark-color components in rice bran are decomposed, and therefore, the preparation method is efficient and quick, is green and environmentally friendly, and reduces a great deal of production cost.

Owner:CHUZHOU YINSHI GREASE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com