Vacuum cleaning chamber

A technology for vacuum cleaning and cleaning chambers, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of soft spots, difficulty in cleaning furnaces, deterioration of workshop environment, etc., to ensure the cleaning effect. , The effect of improving cleaning efficiency and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

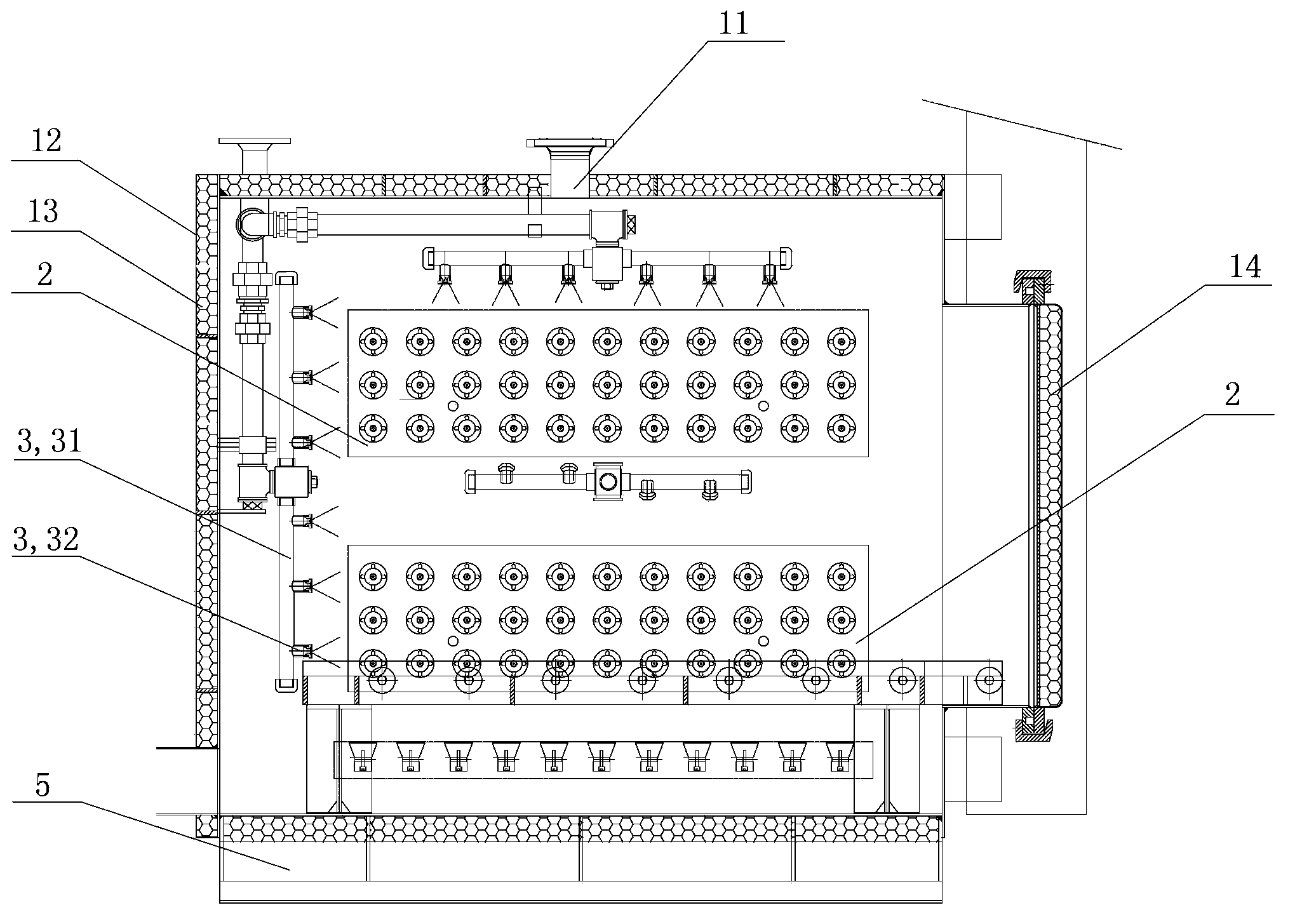

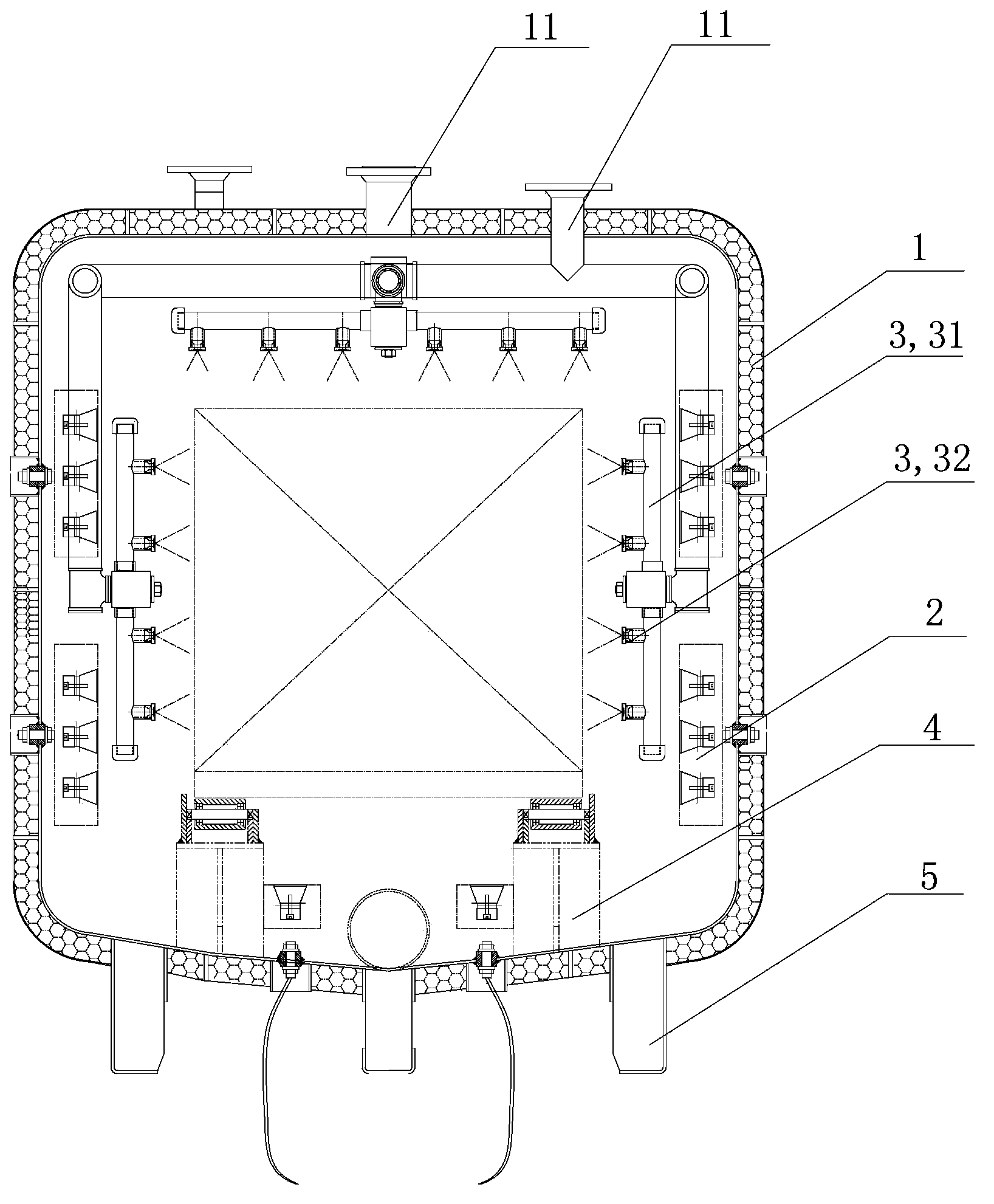

[0021] See figure 1 and figure 2 , the present invention has a cleaning chamber housing 1 with a furnace door 14 on one side, a plurality of through holes 11 are provided at the upper end of the cleaning chamber housing, and the vacuum piping system and the cleaning piping system can pass through the through holes 11 to enter the inside of the cleaning chamber. An ultrasonic vibrating plate 2 is arranged on the inner wall of the cleaning chamber shell 1, and the ultrasonic vibrating plate 2 is connected with an external ultrasonic controller.

[0022] Preferably, a spray device 3 is also provided on the outside of the cleaning chamber wall, and the spray device 3 includes a water spray pipe 31 and several spray ports 32 uniformly distributed on the top of the water spray pipe 31; The water pump is connected.

[0023] Preferably, the inner bottom surface of the vacuum cleaning chamber housing 1 is provided with a workpiece fixing bracket 4 for fixing the workpiece so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com