A kind of efficient extraction method of rice bran nutrition and active substances

A technology of active substances and extraction methods, which is applied in the field of deep processing of rice bran, can solve the problems of ignoring the purity of protein extraction and the destruction of rice bran structure, and achieve the effects of avoiding rancidity, low residual oil, and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

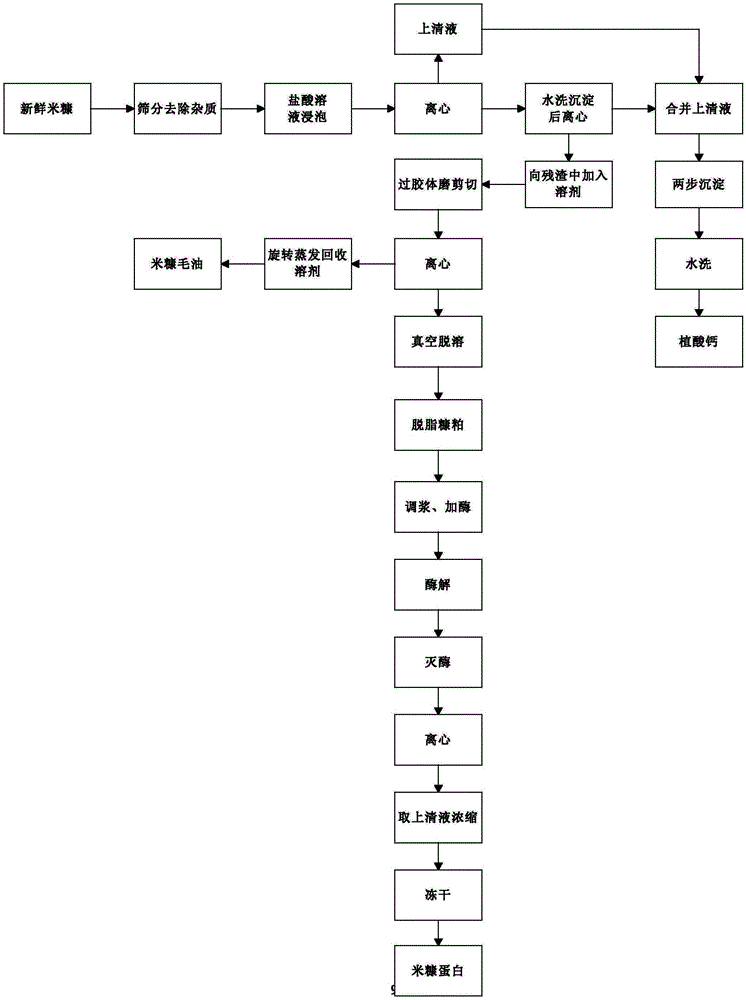

Method used

Image

Examples

Embodiment 1

[0030] Using fresh full-fat rice bran (product of Jiangxi Jinnong Biotechnology Co., Ltd.) as raw material, the extraction process steps in this example are as follows:

[0031] (1) Sieving and removing impurities: Pass 200g of fresh full-fat rice bran through a 20-mesh sieve to remove foreign matter, rice husk, broken rice and other impurities;

[0032] (2) Extraction of phytic acid by acid soaking: put the rice bran treated in step (1) in an enzyme reactor, add a hydrochloric acid solution with a concentration of 1.0wt% for soaking, the acid soaking time is 4 hours, the temperature is 50°C, and the solid-liquid ratio is 1:10, the stirring rate of the agitator is 180r / min; centrifuge at 3000r / min for 10min to obtain the residue and supernatant, add 1600mL water to wash the residue once, centrifuge again and combine the supernatant; add 100 mesh sieve to the supernatant Calcium hydroxide solution with a concentration of 10wt%, stir slowly while adding, adjust the pH value to 4...

Embodiment 2

[0038] Using fresh full-fat rice bran (same as above) as raw material, the extraction process steps in this example are as follows:

[0039] (1) Sieving and removing impurities: Pass 200g of fresh full-fat rice bran through a 20-mesh sieve to remove foreign matter, rice husk, broken rice and other impurities;

[0040] (2) Extraction of phytic acid by acid soaking: put the rice bran treated in step (1) in an enzyme reactor, add a hydrochloric acid solution with a concentration of 1.0wt% for soaking, the acid soaking time is 3 hours, the temperature is 60°C, and the solid-liquid ratio is 1:10, the stirring rate of the agitator is 180r / min; centrifuge at 3000r / min for 10min to obtain the residue and supernatant, add 1600mL water to wash the residue once, centrifuge again and combine the supernatant; add 100 mesh sieve to the supernatant Calcium hydroxide solution with a concentration of 10wt%, stir slowly while adding, adjust the pH value to 4.6, then add a sodium hydroxide solut...

Embodiment 3

[0046] Using fresh full-fat rice bran (same as above) as raw material, the extraction process steps in this example are as follows:

[0047] (1) Sieving and removing impurities: Pass 200g of fresh full-fat rice bran through a 20-mesh sieve to remove foreign matter, rice husk, broken rice and other impurities;

[0048] (2) Extraction of phytic acid by acid soaking: put the rice bran treated in step (1) in an enzyme reactor, add a hydrochloric acid solution with a concentration of 1.4wt% for soaking, the acid soaking time is 5 hours, the temperature is 40°C, and the solid-liquid ratio is 1:8, the stirring rate of the agitator is 180r / min; centrifuge at 3000r / min for 10min to obtain the residue and supernatant, add 1600mL water to wash the residue once, centrifuge again and combine the supernatant; add 100 mesh sieve to the supernatant Calcium hydroxide solution with a concentration of 10wt%, stir slowly while adding, adjust the pH value to 5.0, then add a sodium hydroxide soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com