Patents

Literature

37results about How to "Guarantee the quality of follow-up processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

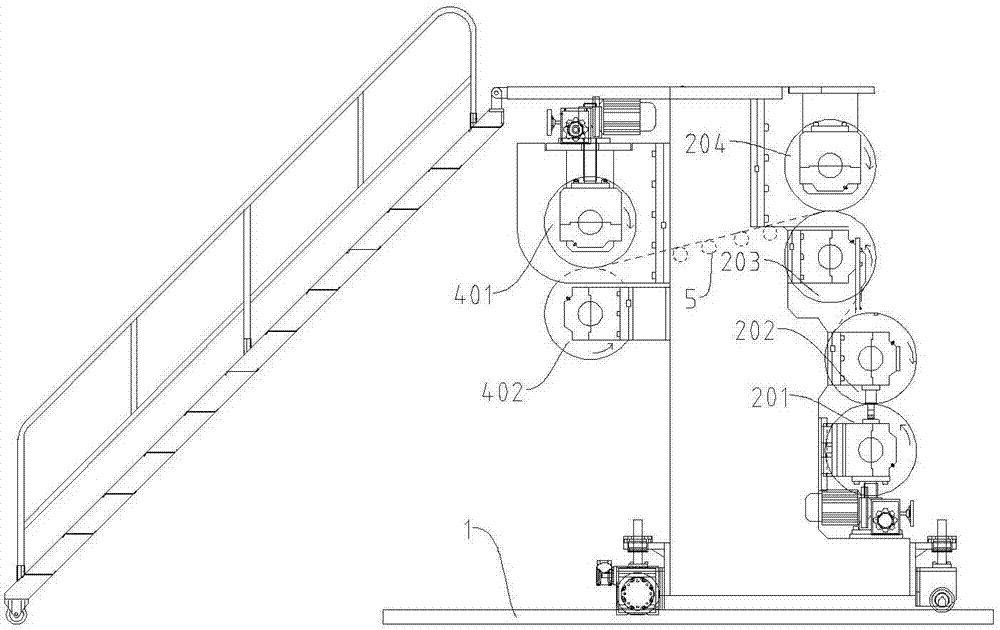

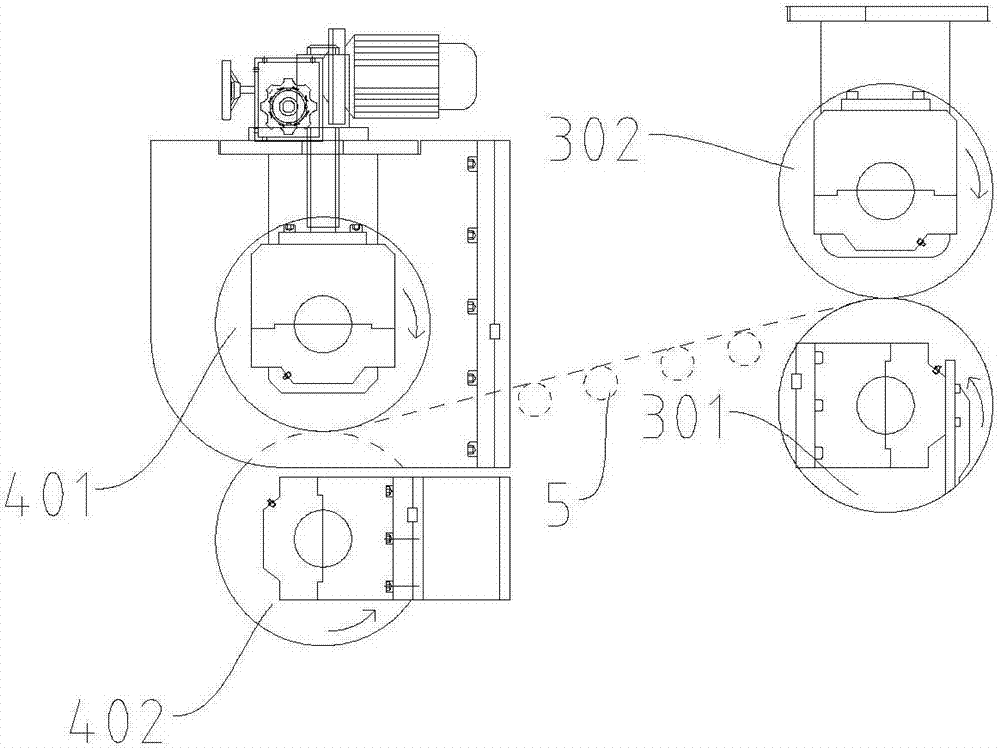

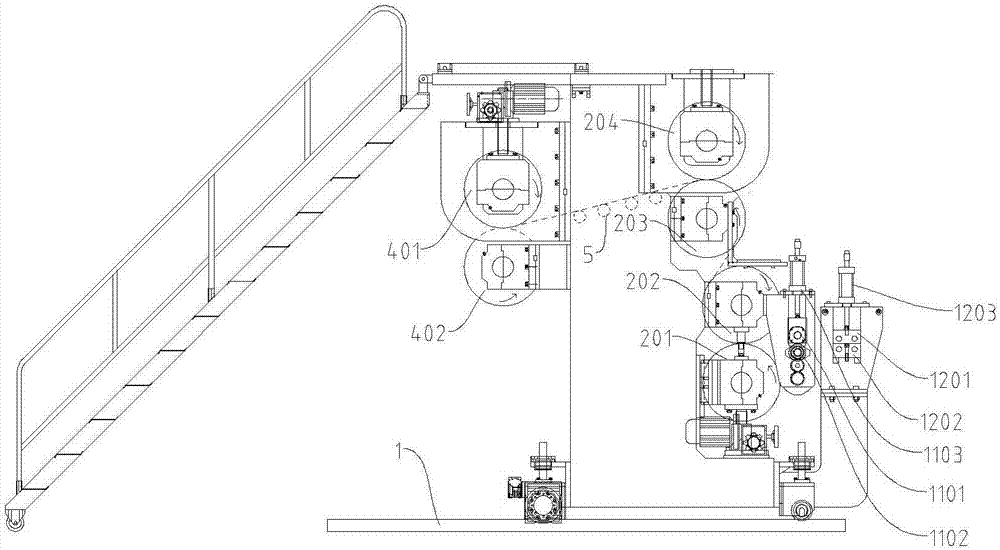

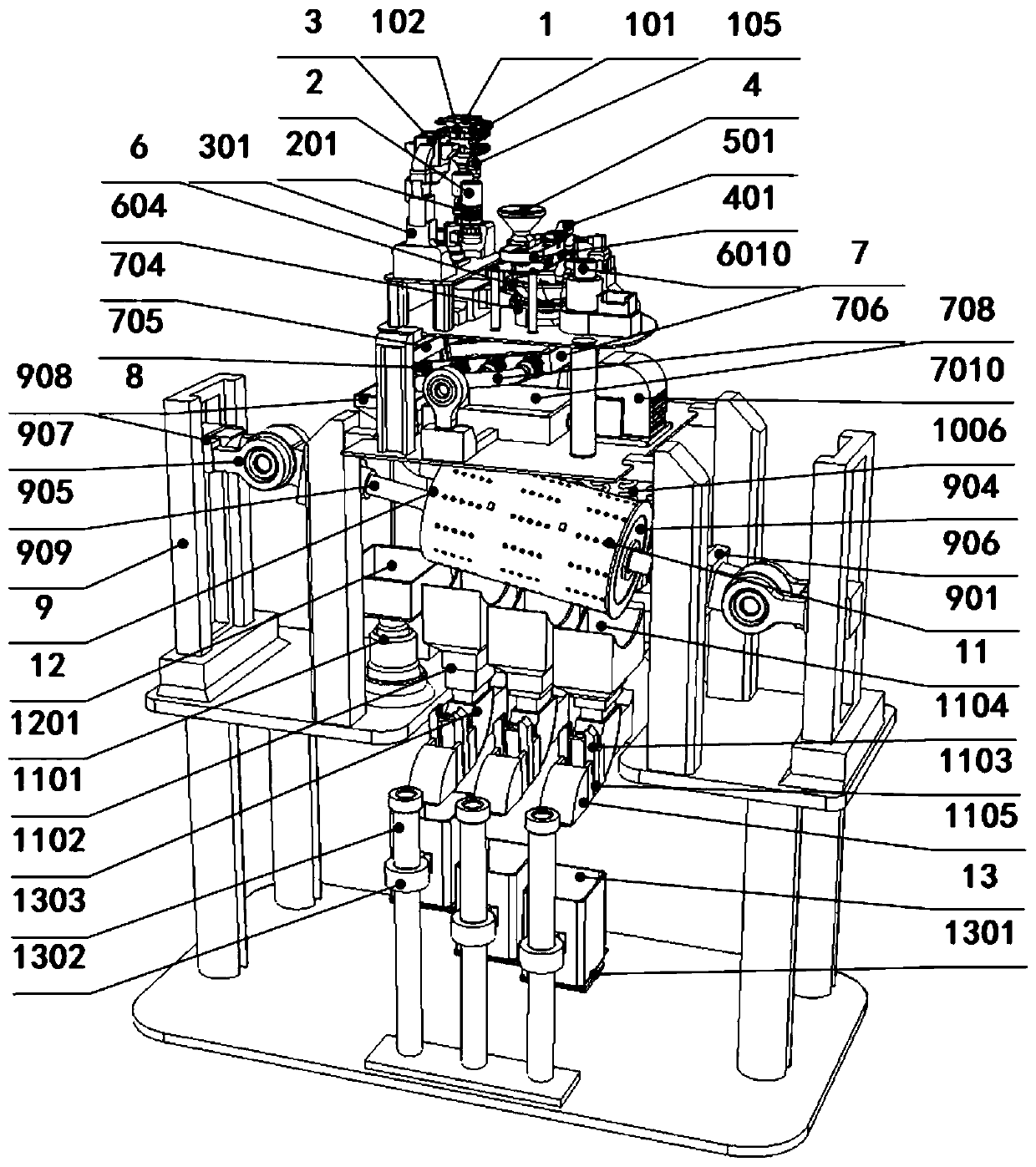

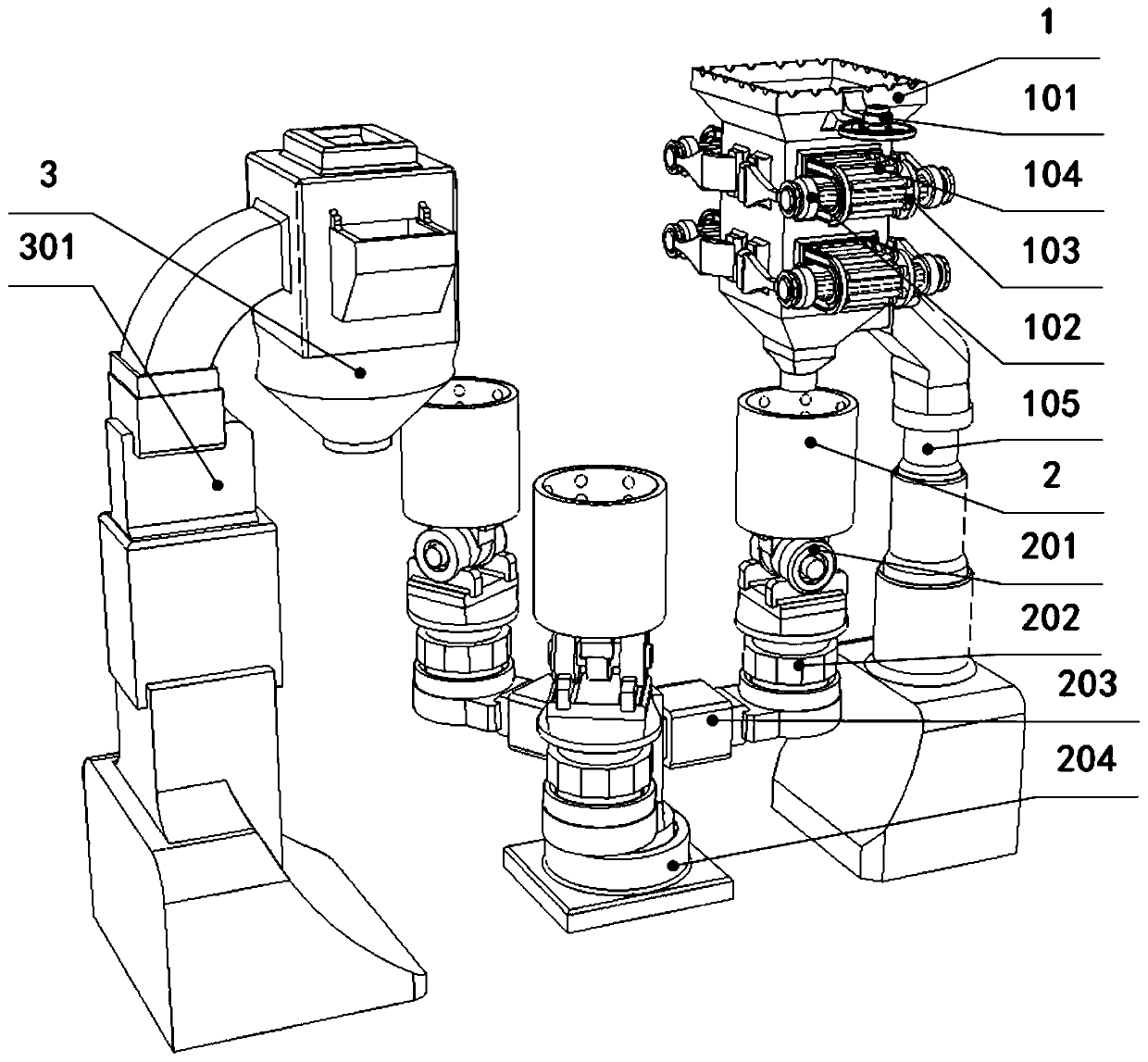

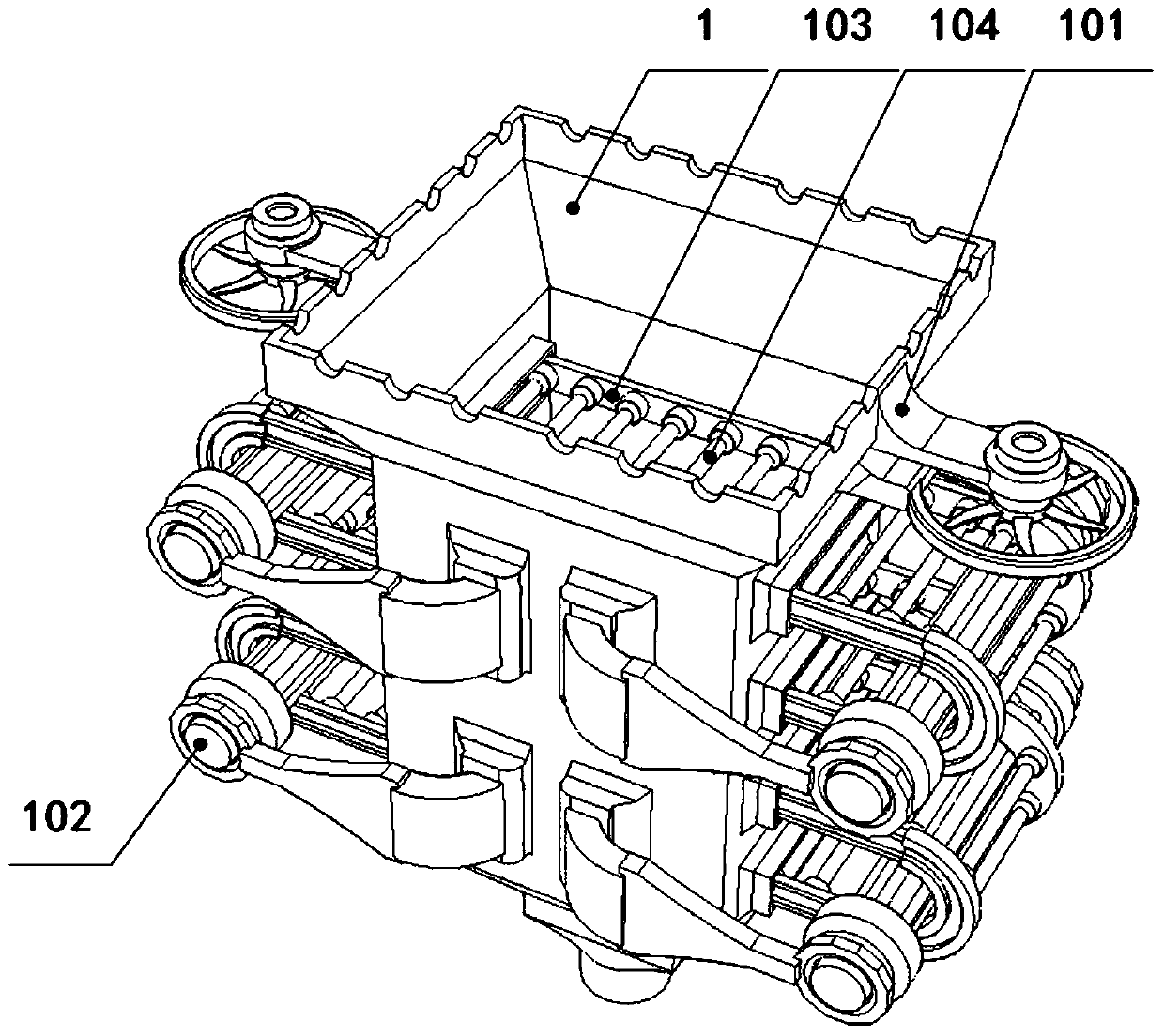

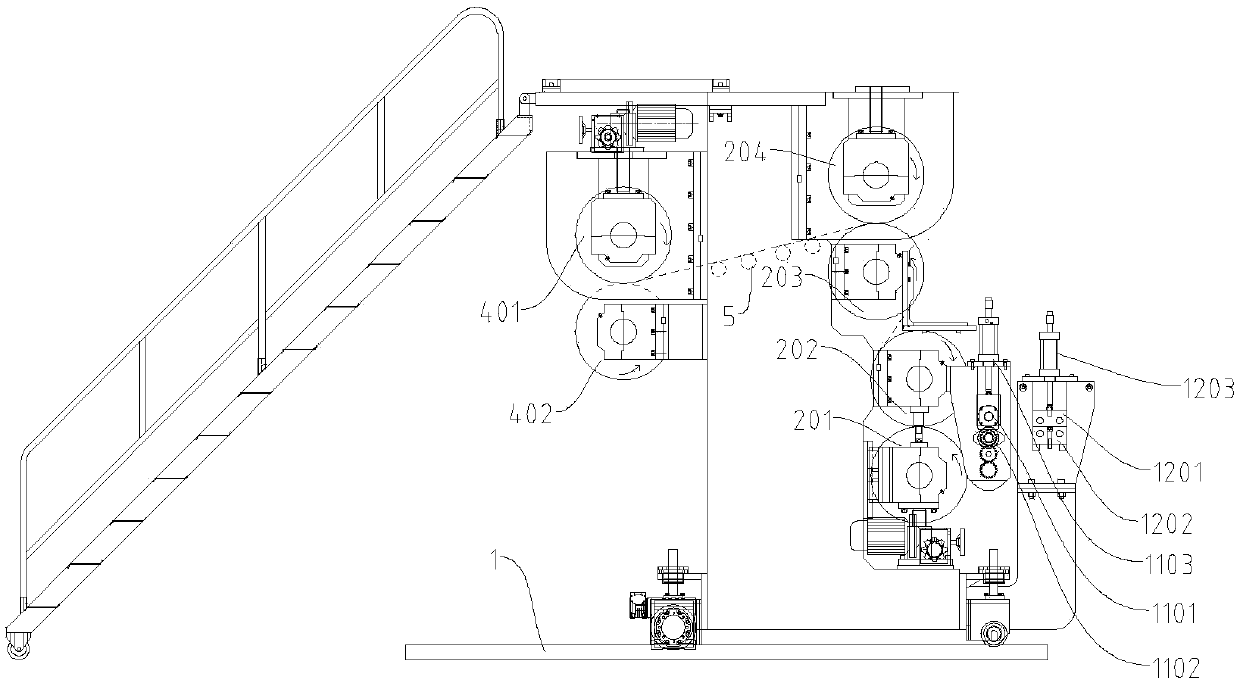

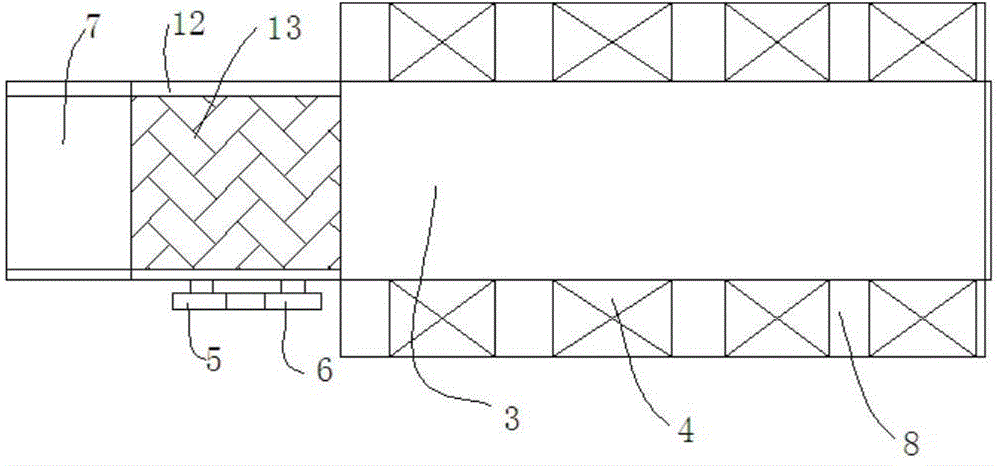

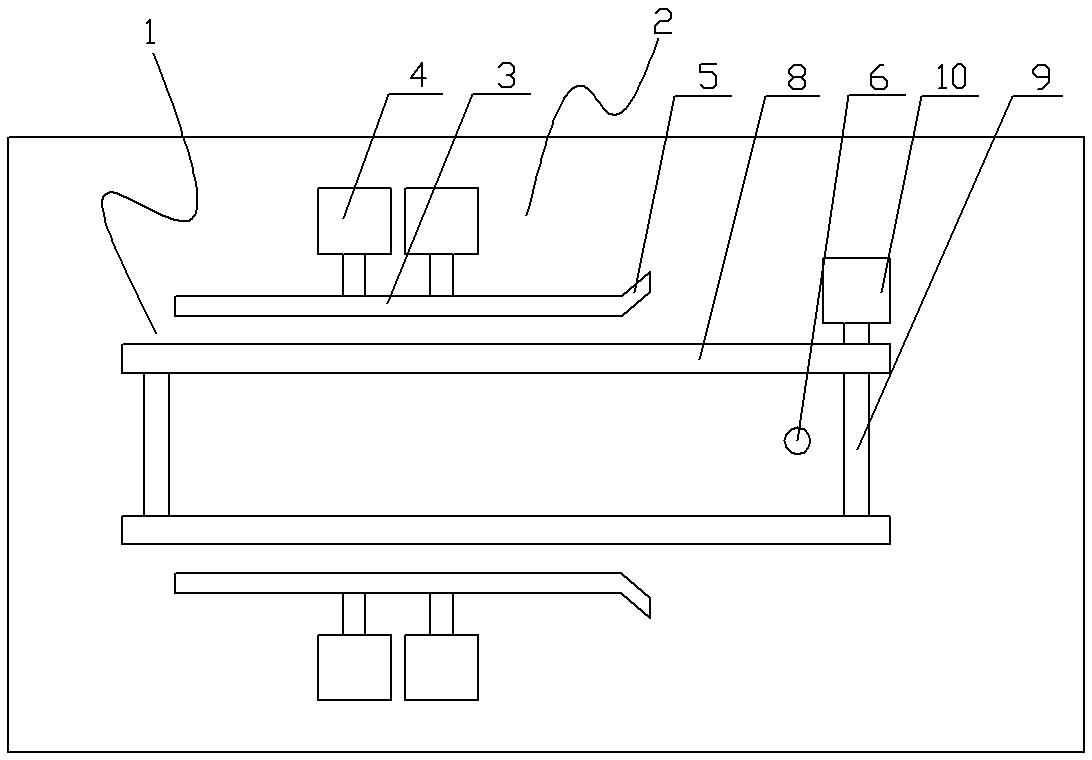

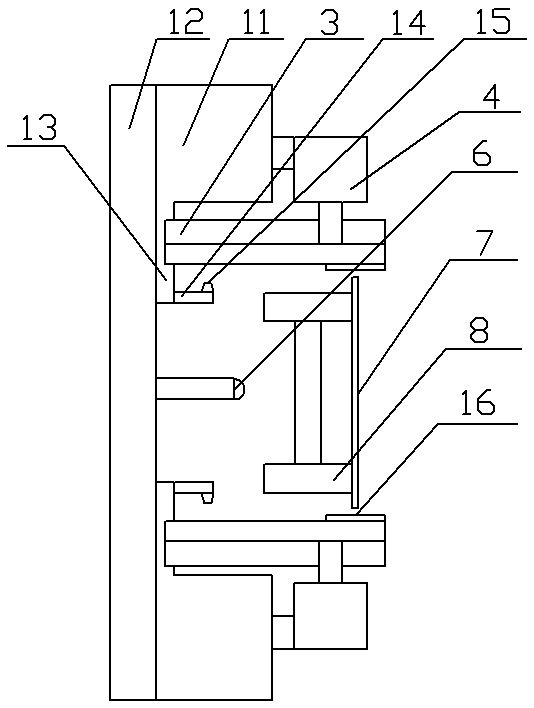

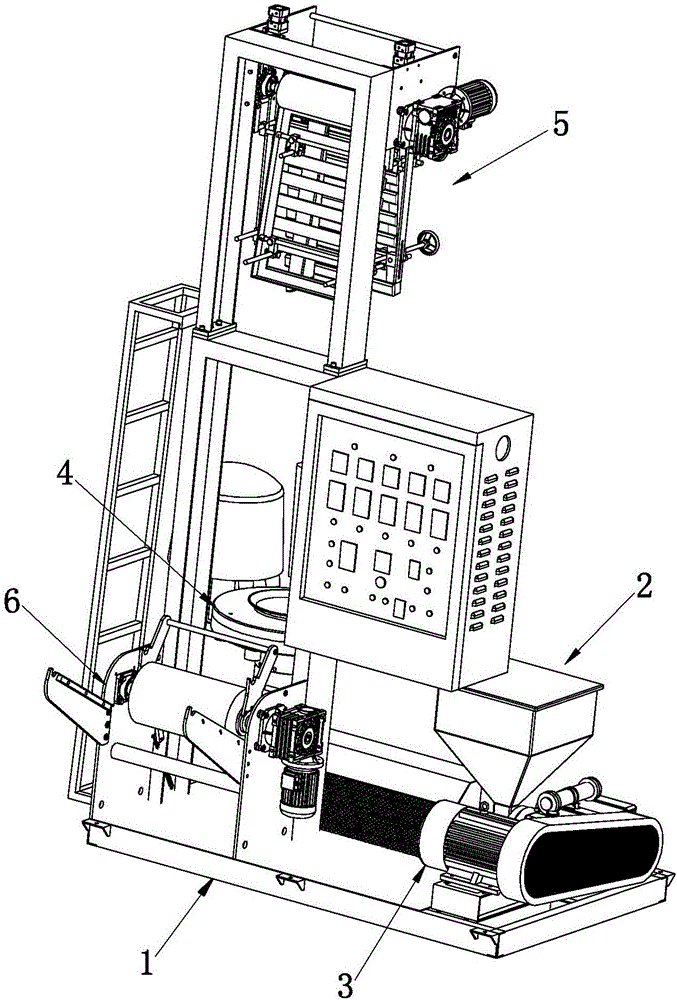

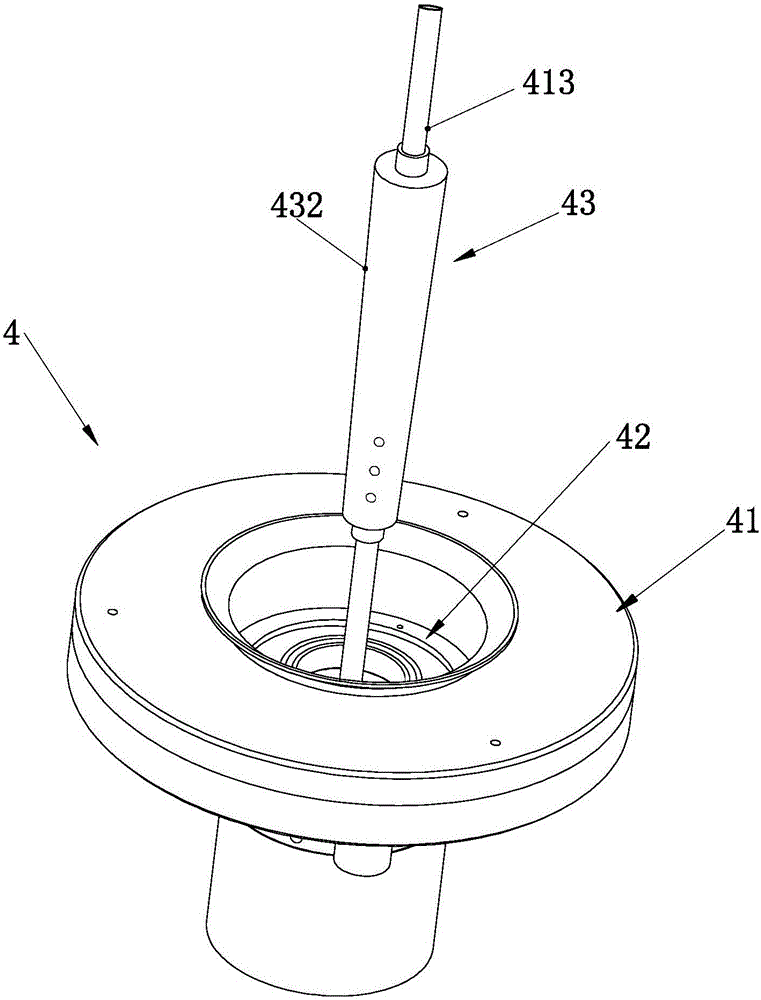

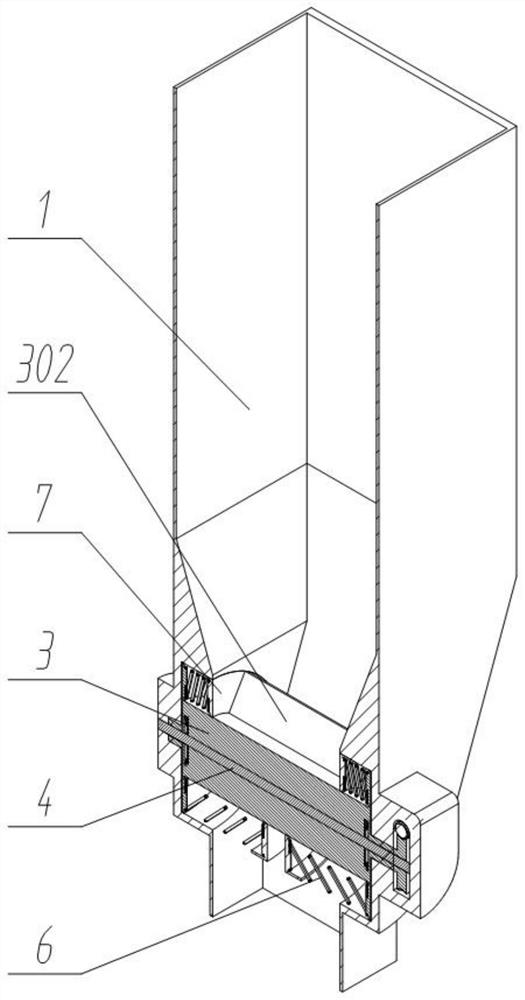

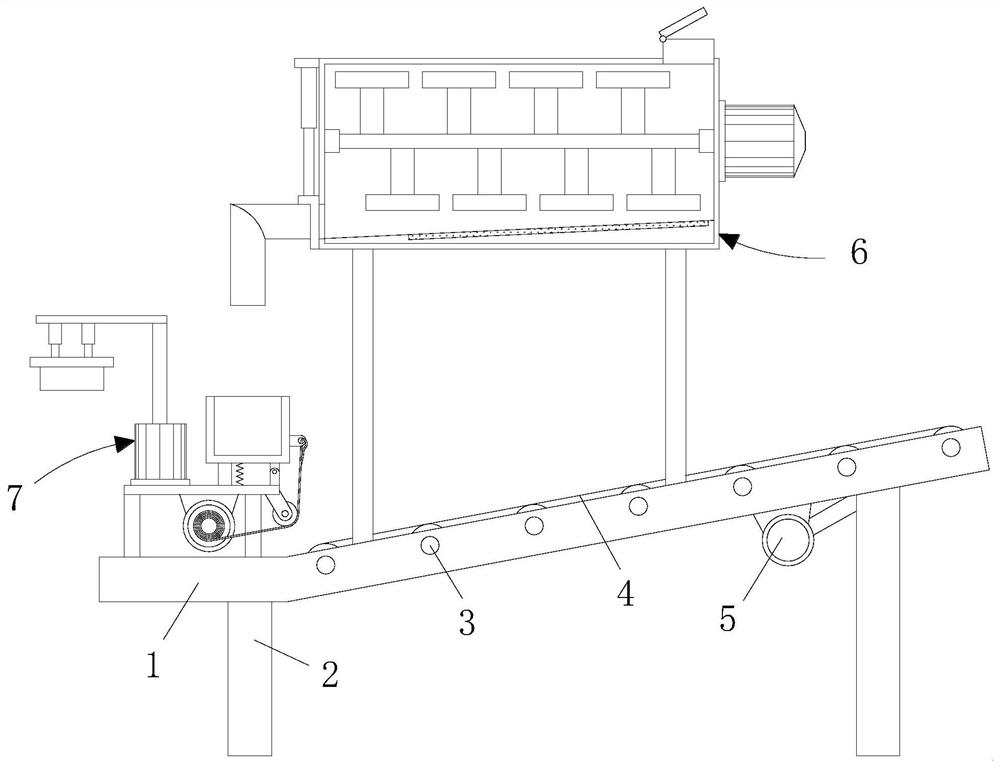

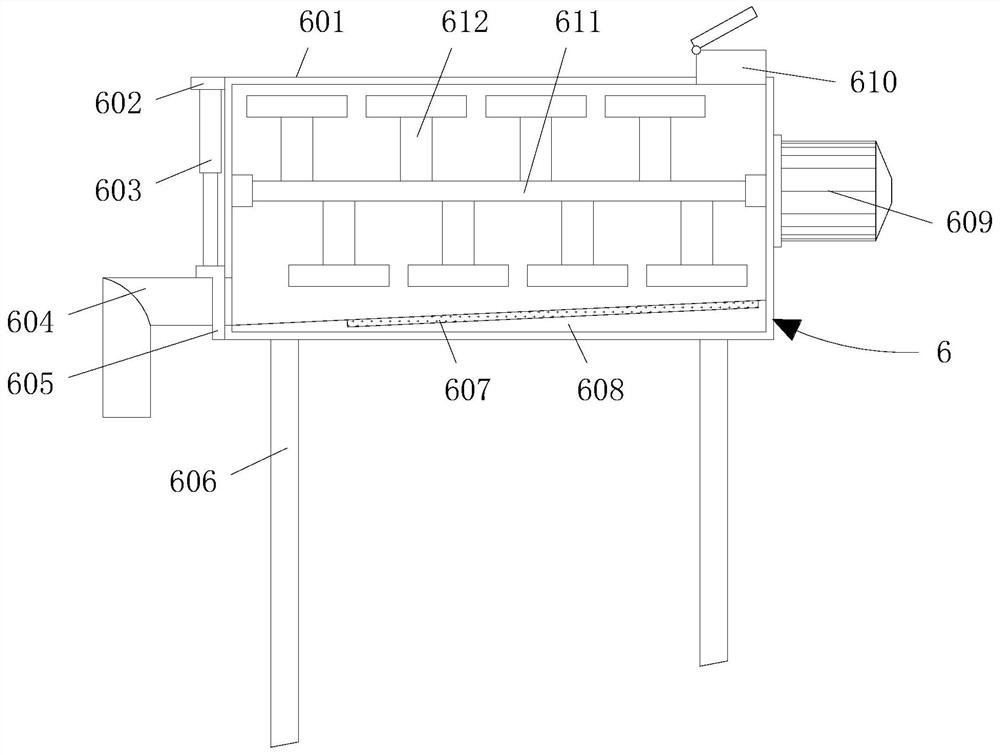

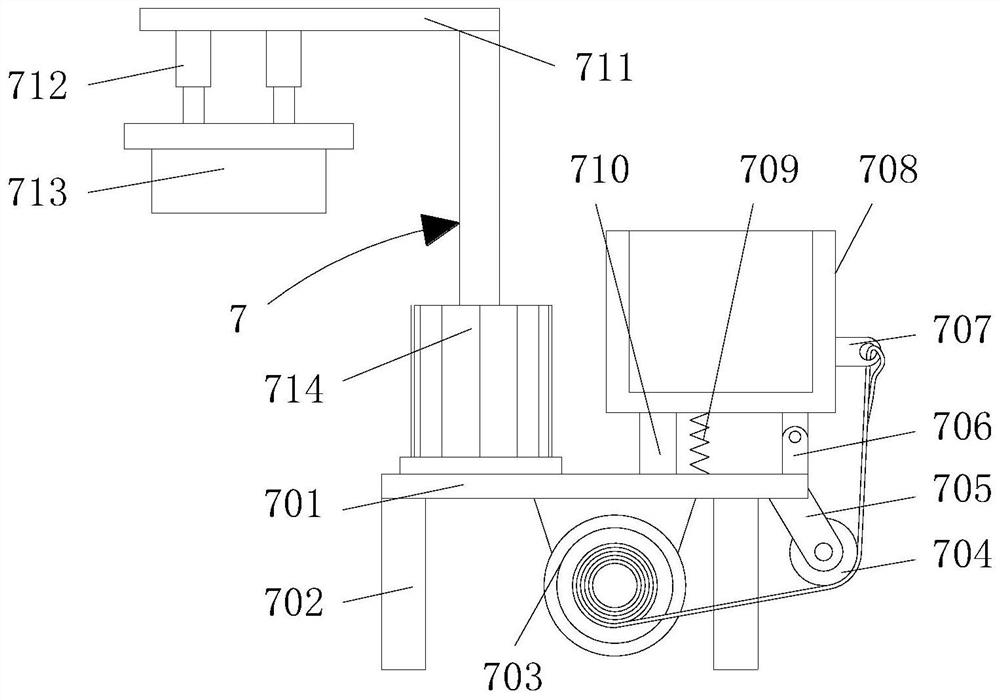

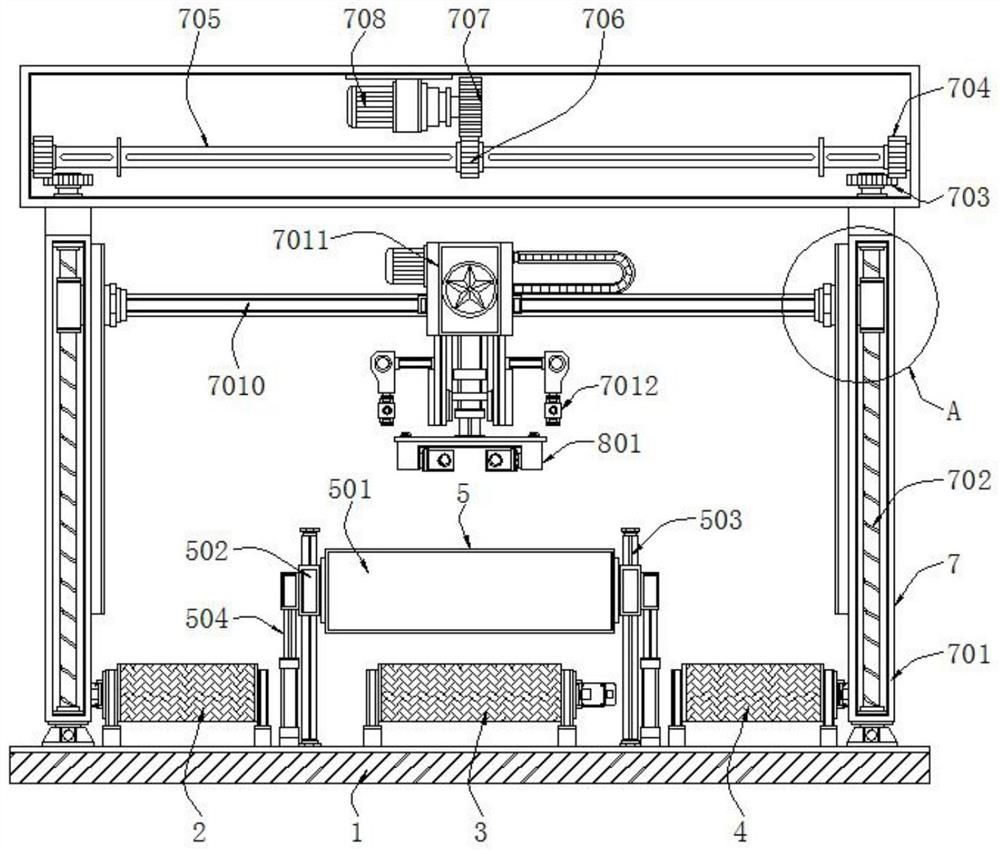

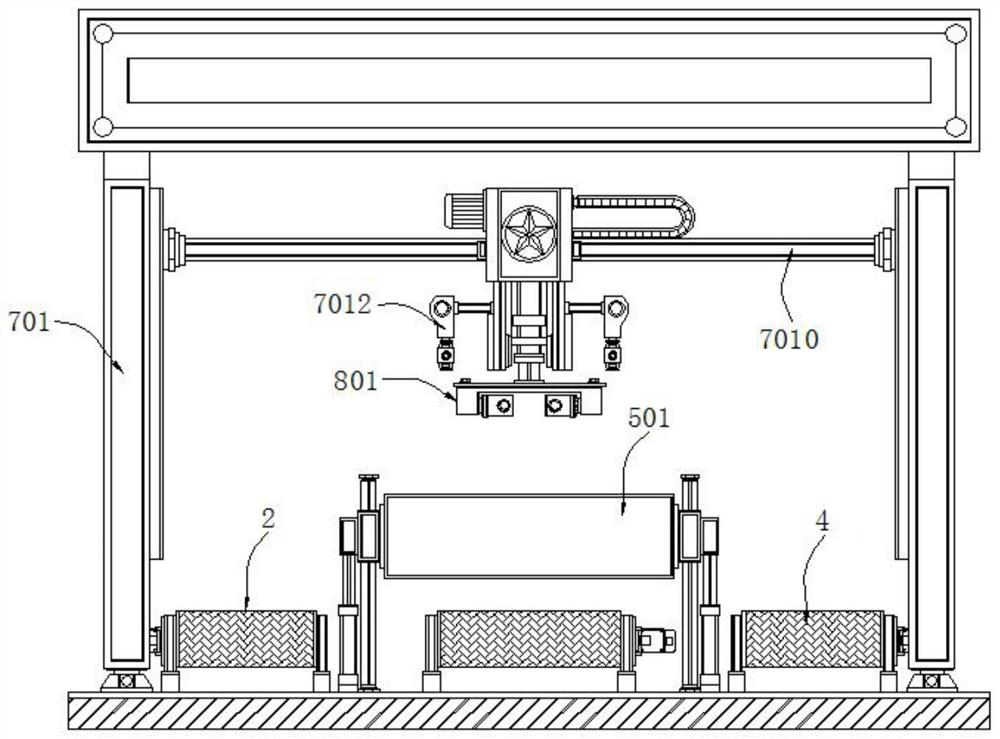

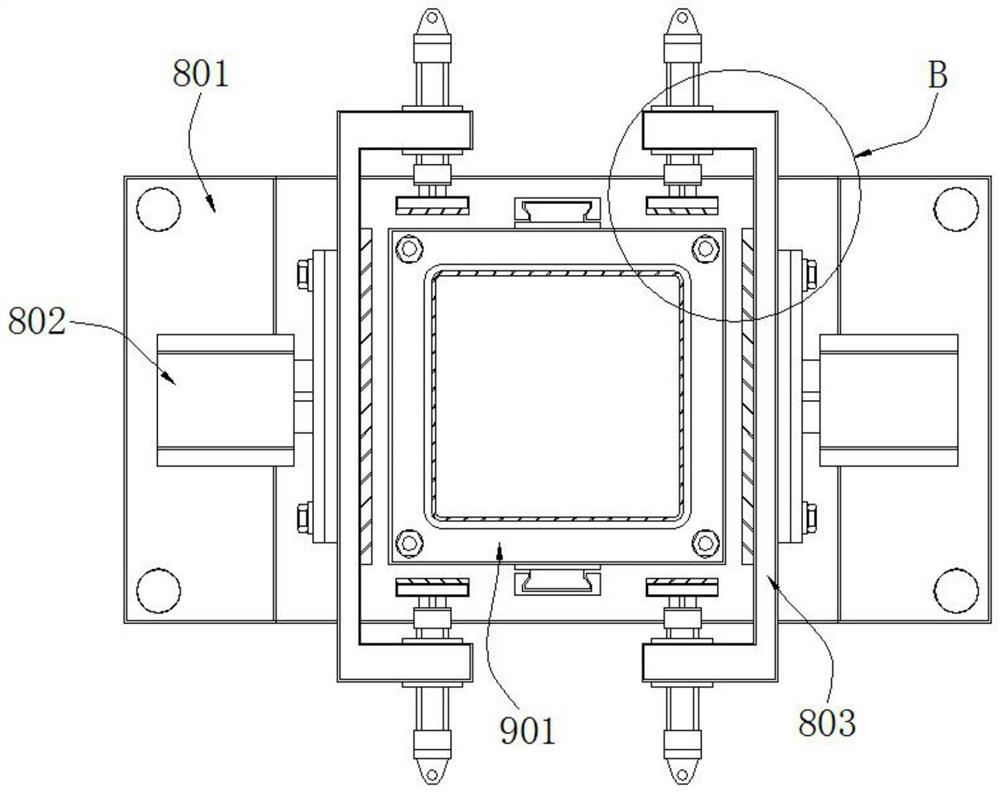

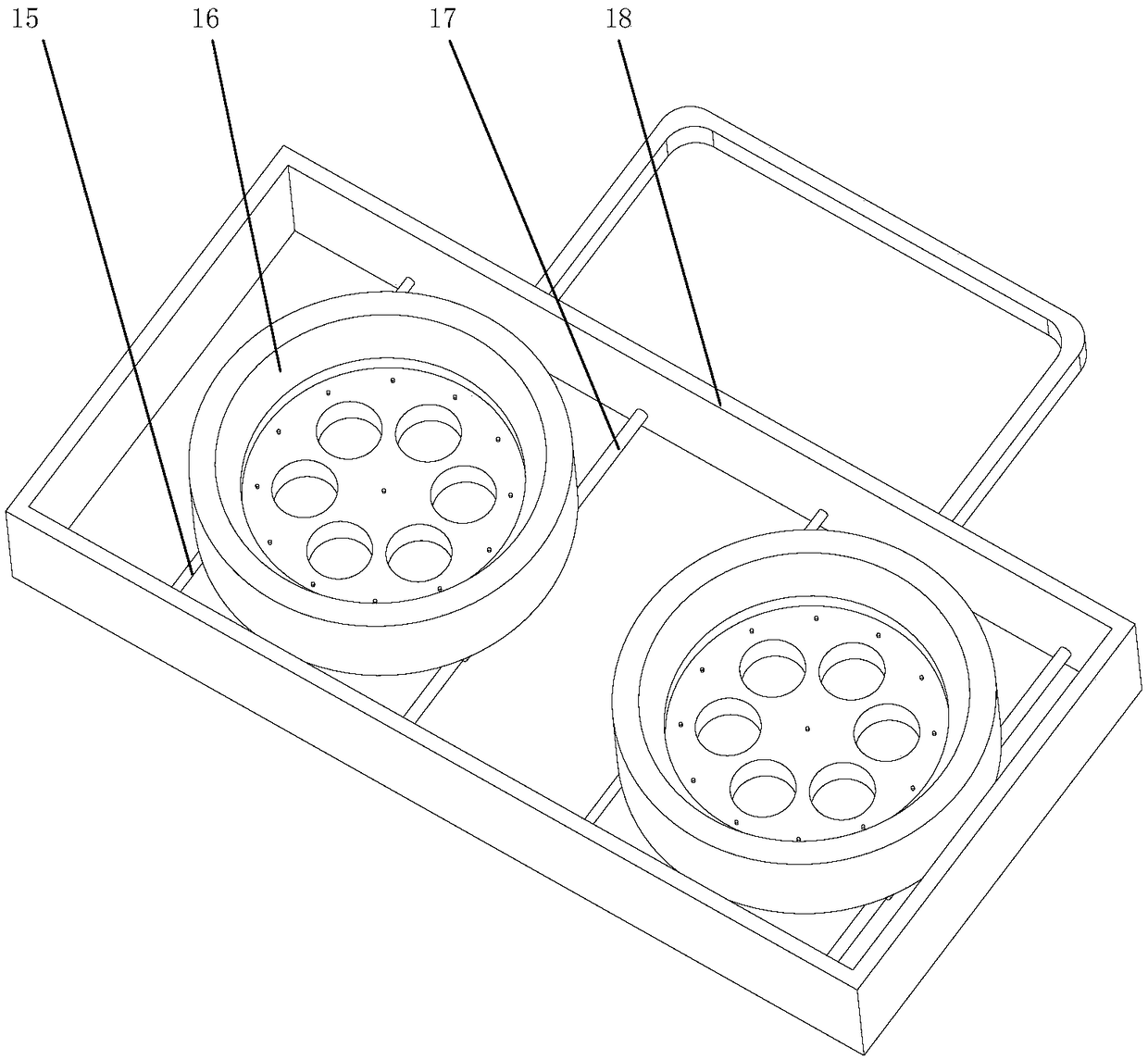

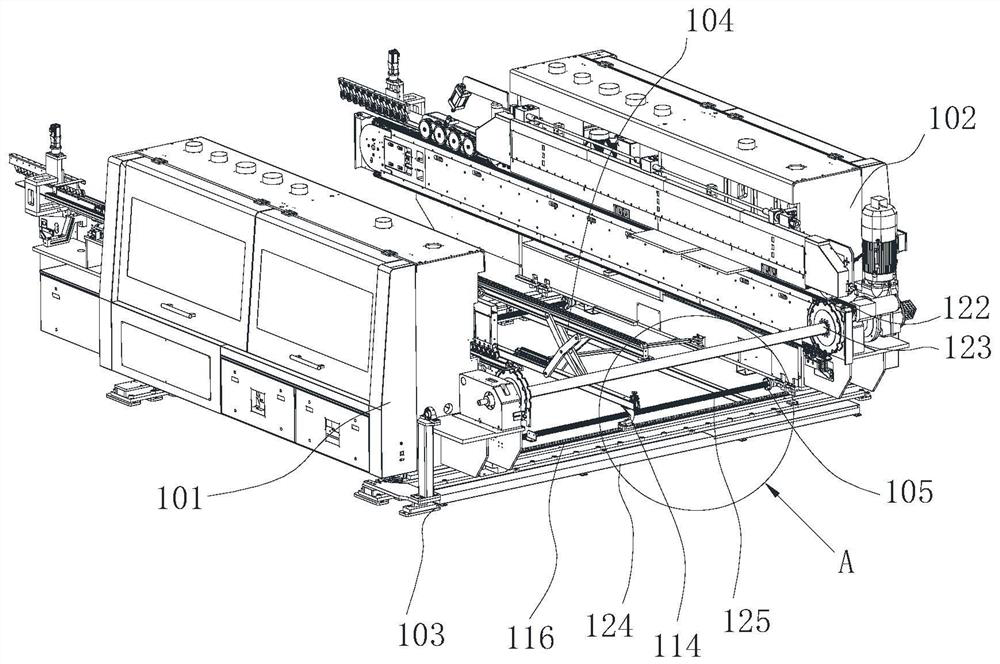

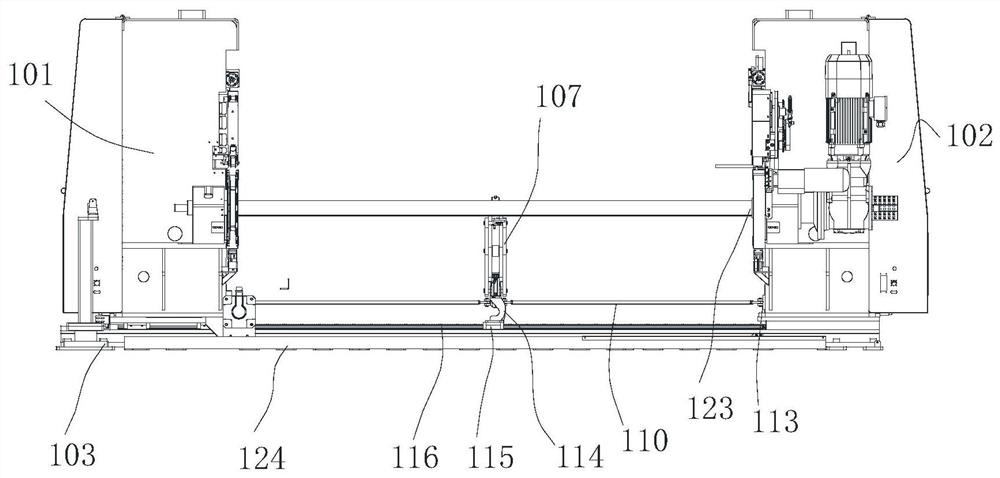

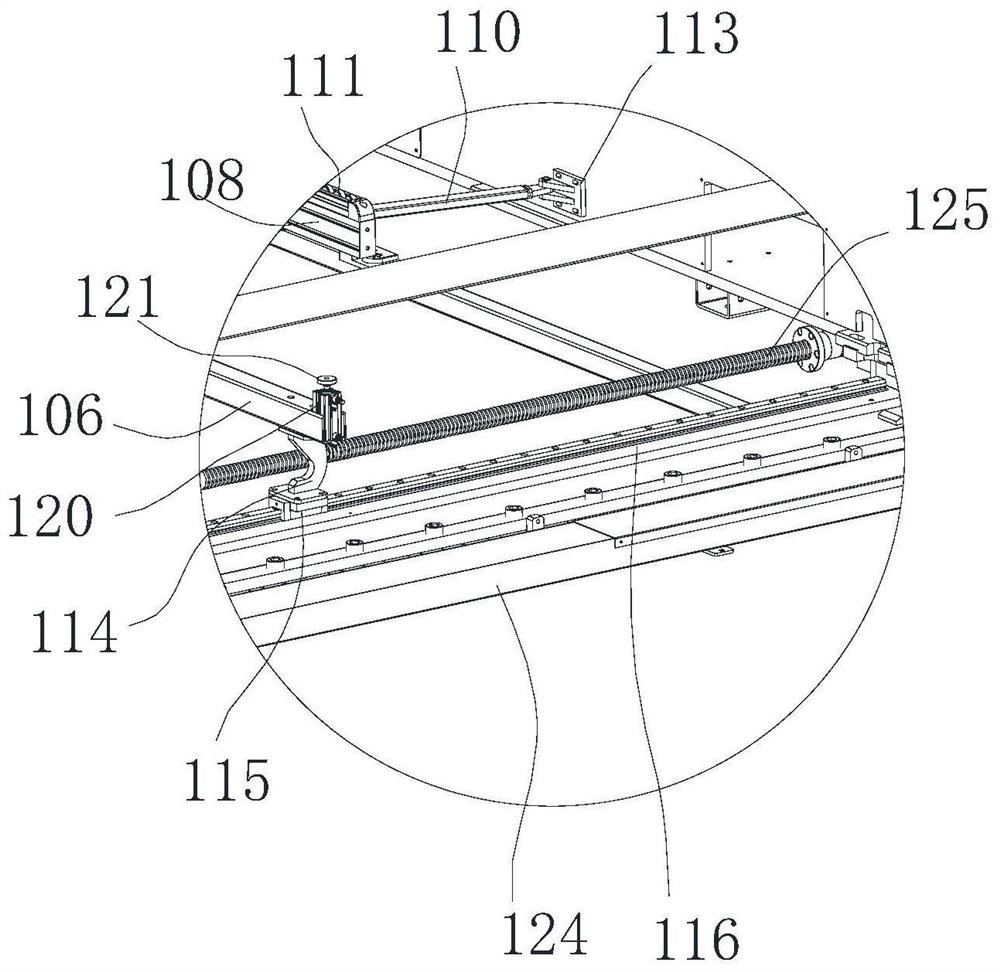

Calendar, foamed floor production line and one-time forming production process

InactiveCN107186937AReduce the temperatureGuarantee the quality of follow-up processingProduction linePulp and paper industry

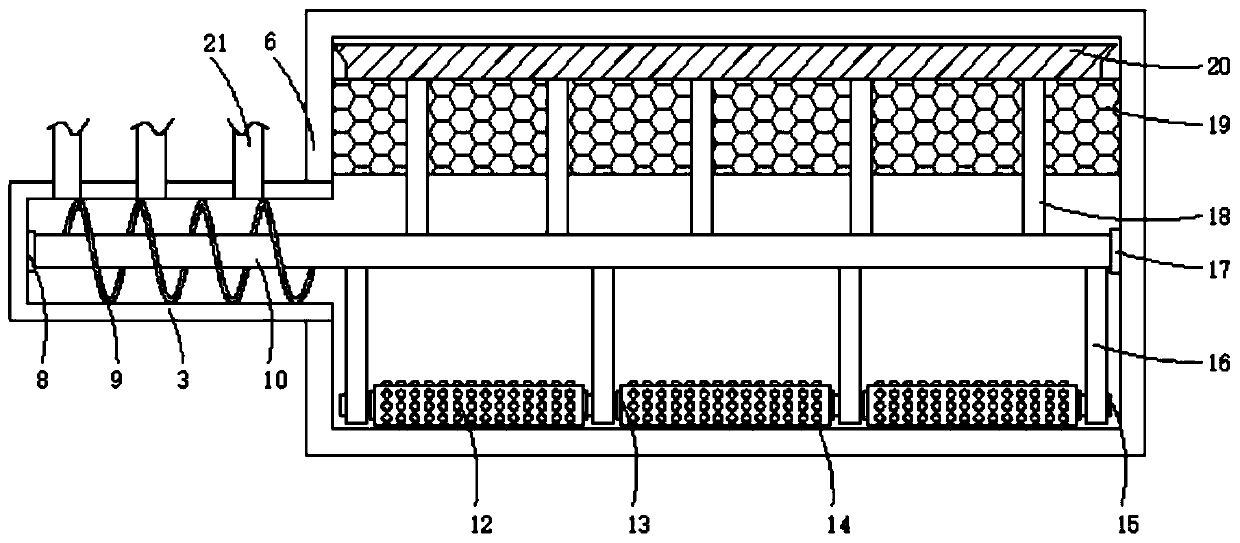

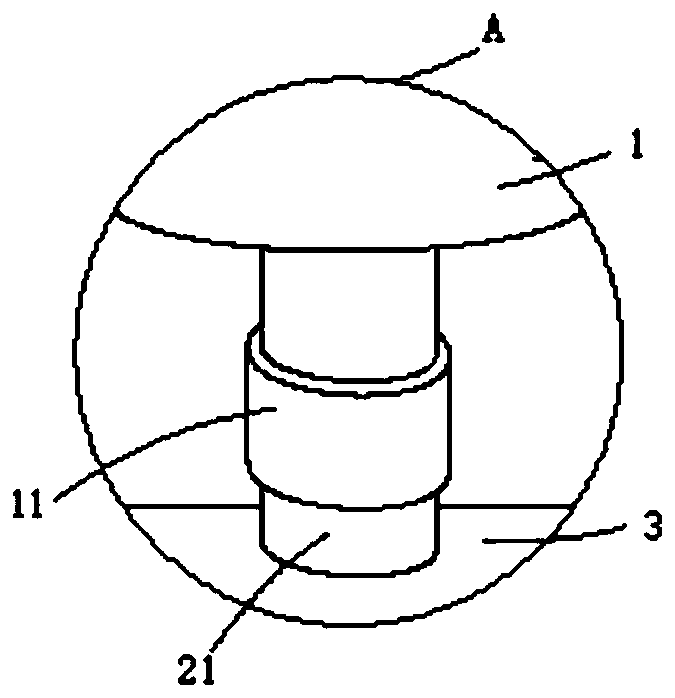

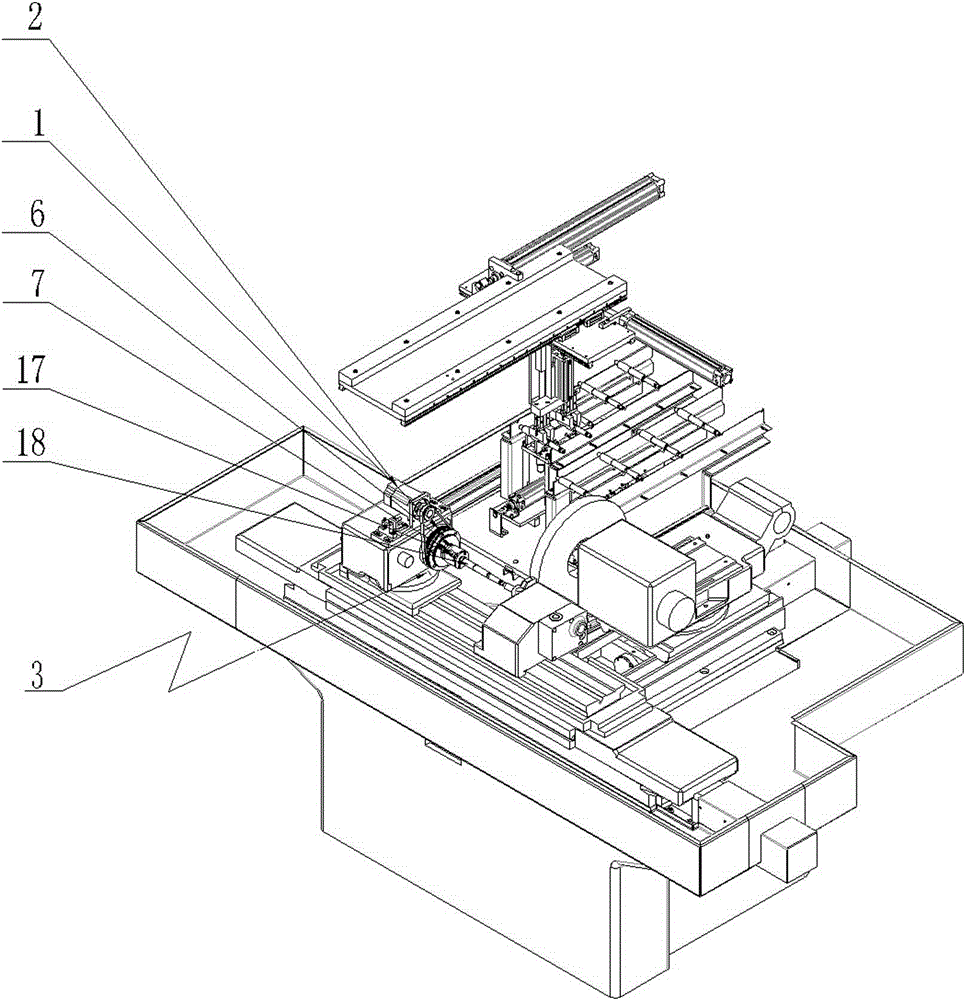

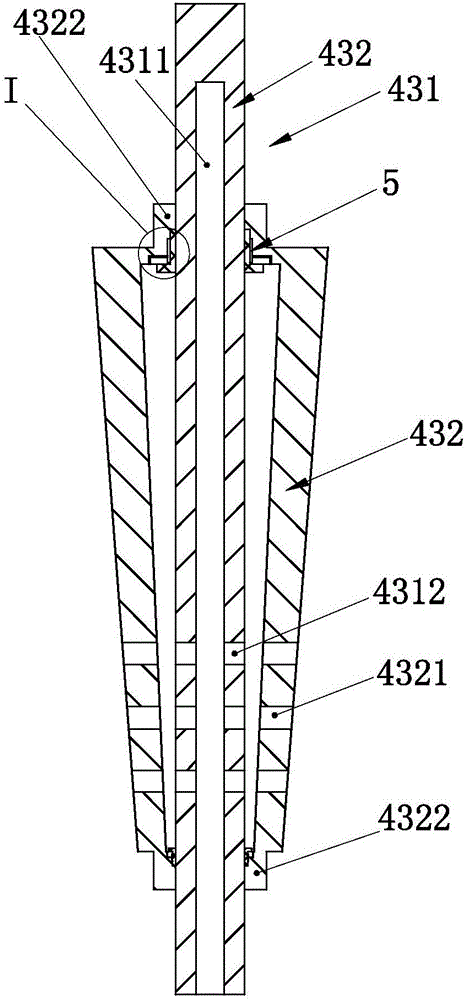

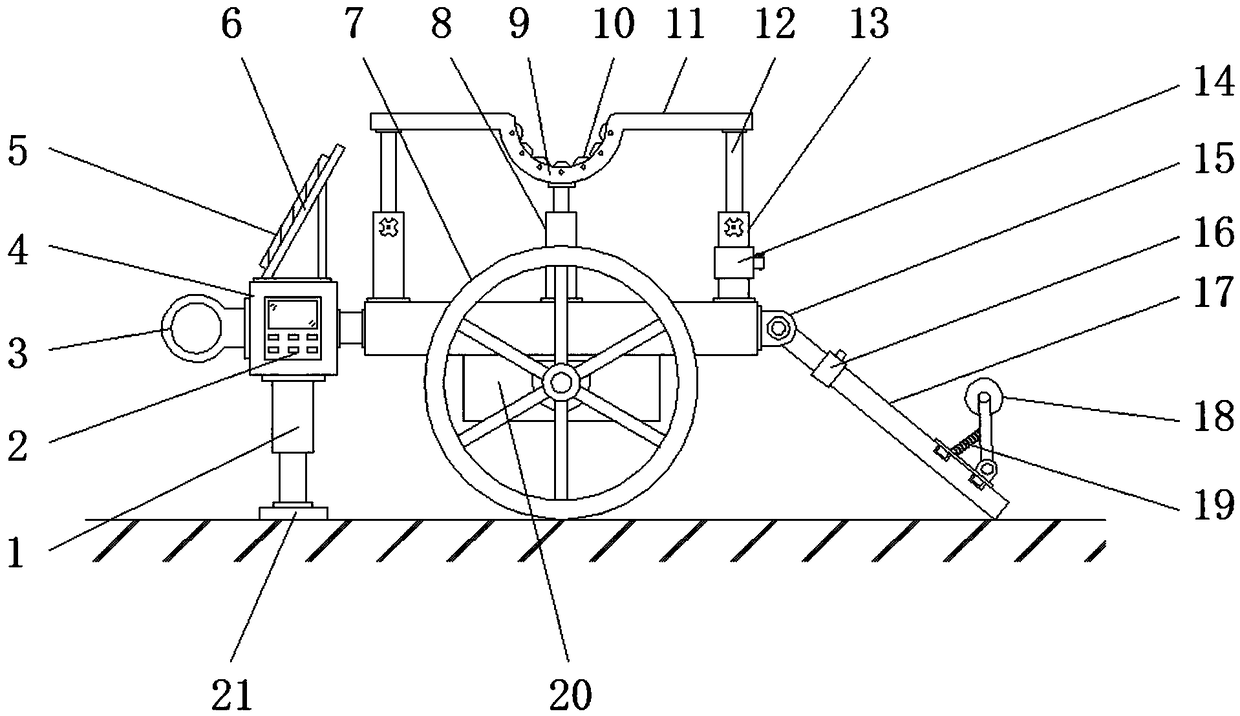

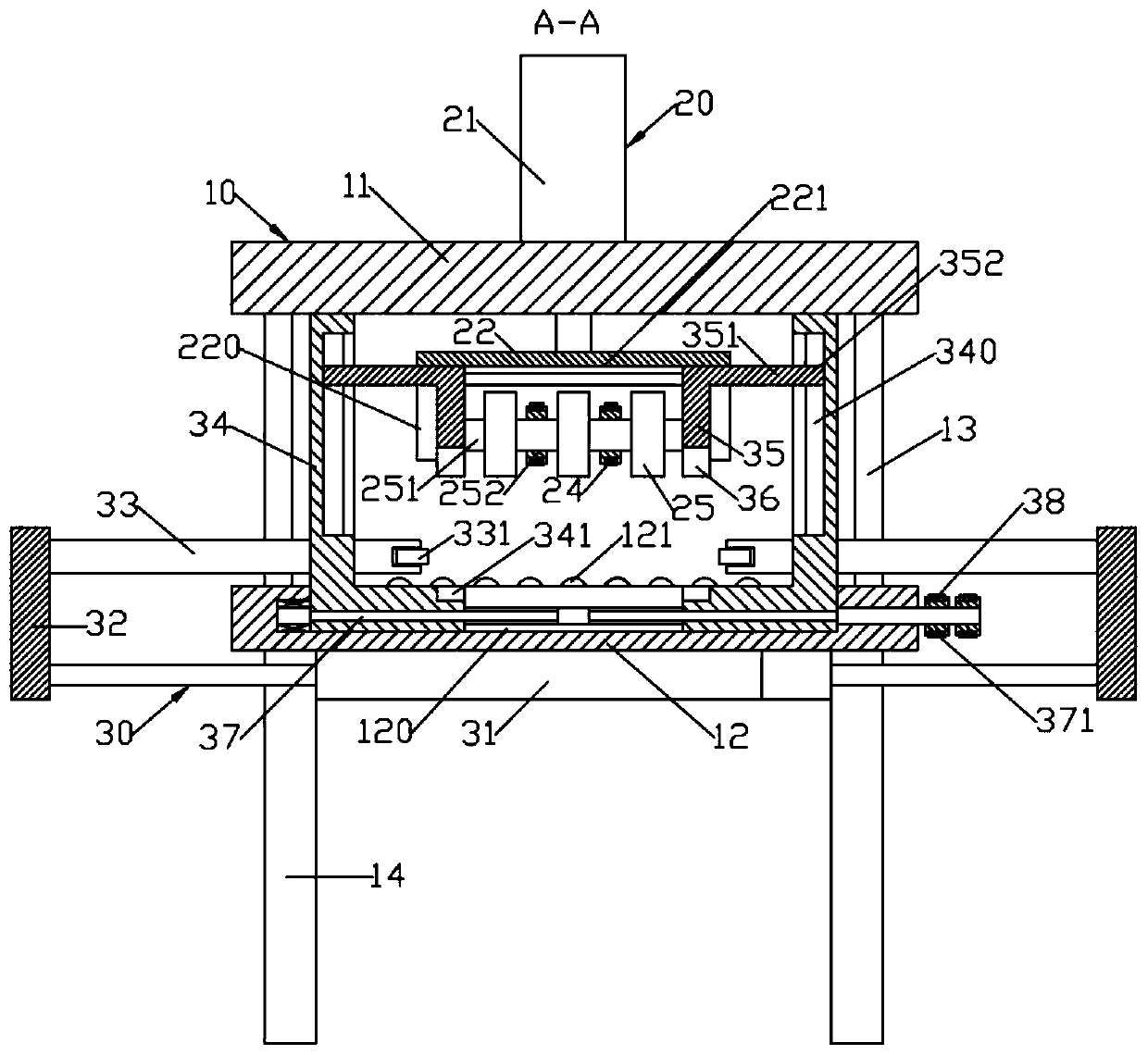

A calender, comprising a machine base and a set of calender rolls arranged on the base, characterized in that: the set of calender rolls includes a main set of calender rolls and a set of embossing rolls for embossing the material to be processed, the main set of calender rolls Calendering rollers and embossing rollers are spaced at a certain distance so that the material can be cooled before passing from one roller group to another. The calender mirror can achieve better embossing embossing effect. The calender is used in the production of foamed floor, which can realize the integrated production of foamed floor.

Owner:QINGDAO SANYI PLASTIC MACHINERY

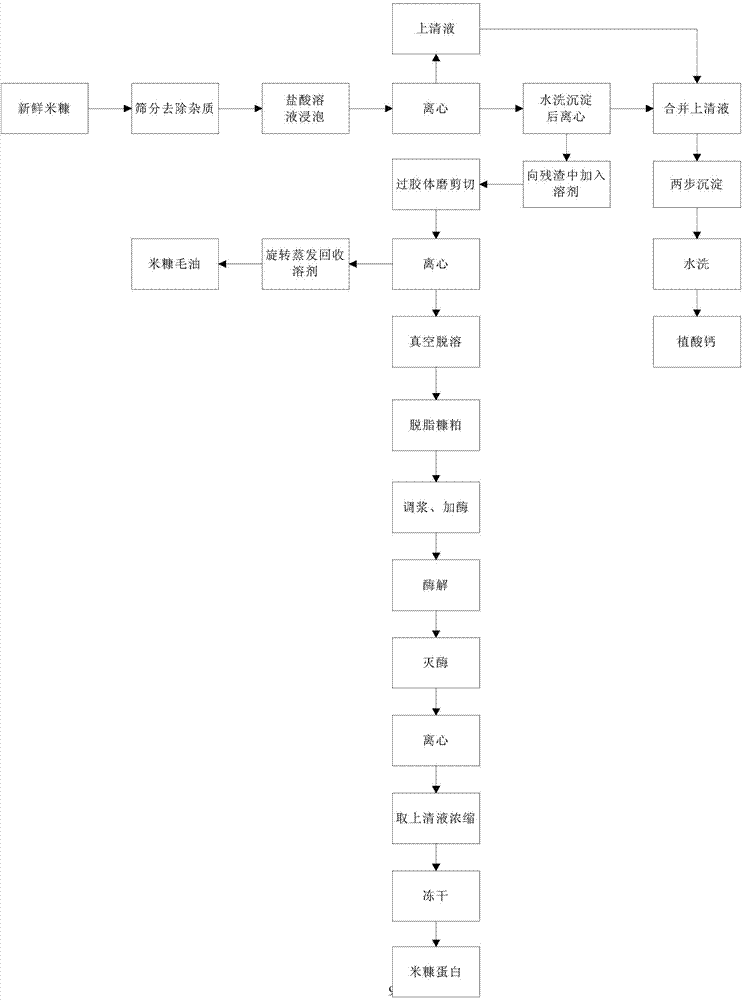

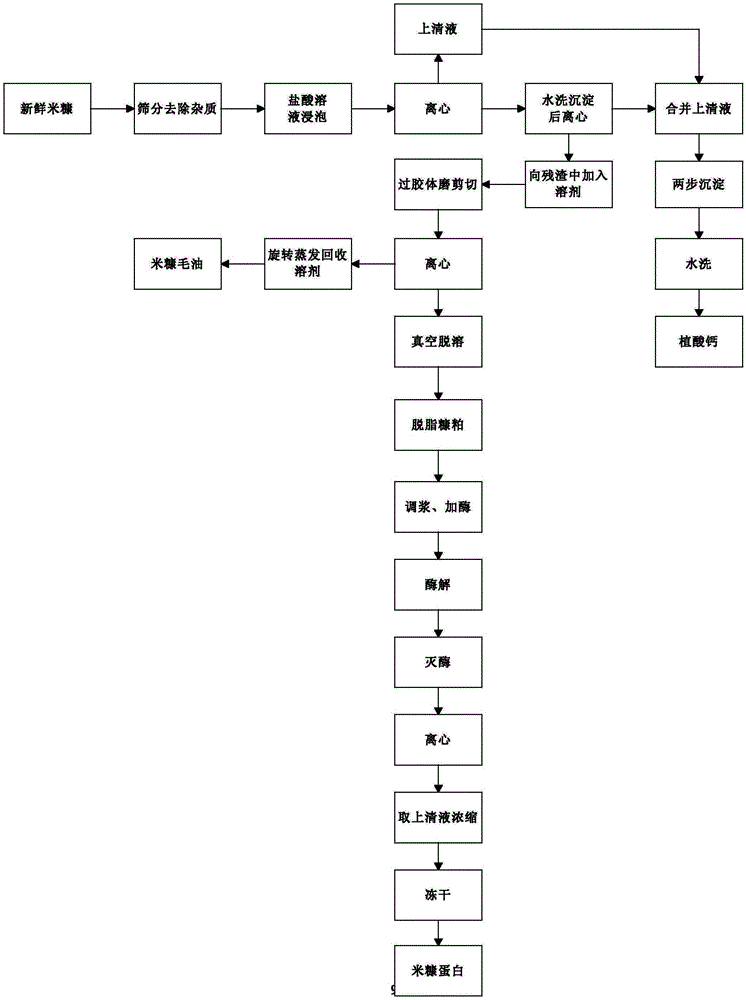

High-efficiency extraction method of nutritional and active substances of rice bran

ActiveCN103833786APrevent rancidityComponents are assignedGroup 5/15 element organic compoundsFatty-oils/fats productionPhytic acidSolvent

The invention provides a high-efficiency extraction method of nutritional and active substances of rice bran. The high-efficiency extraction method comprises the following steps of 1, full-fat rice bran screening impurity-removal, 2, phytic acid extraction by immersion in an acid, 3, rice bran crude oil extraction by high-speed shearing and a complex solvent, and 4, enzyme method-based extraction of a rice bran protein. The high-efficiency extraction method can realize high-efficiency extraction of phytic acid, fat and proteins of full-fat rice bran in an order, realize high-valued complete utilization of full-fat rice bran, improve an added value and avoid resource waste.

Owner:JIANGNAN UNIV

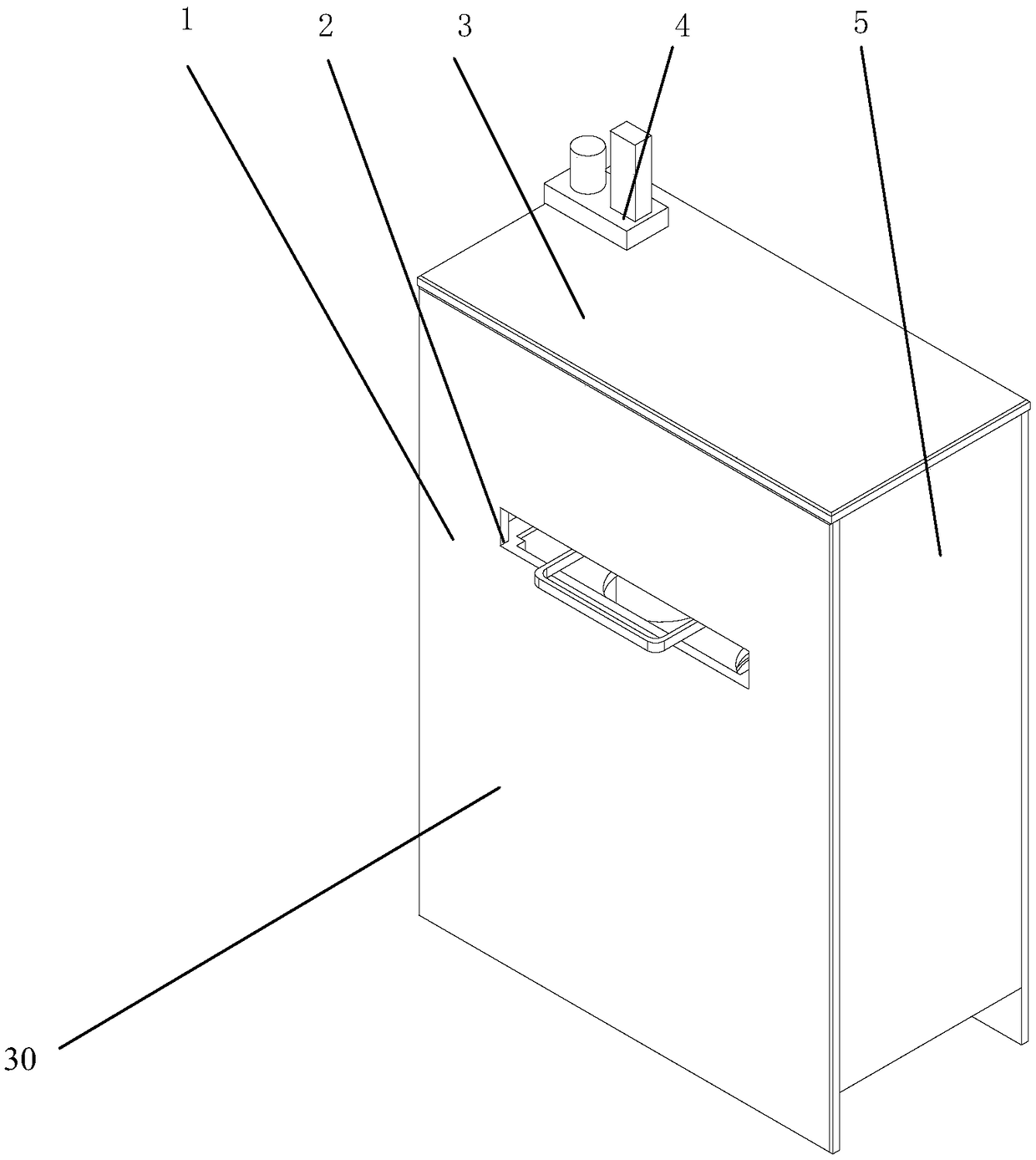

Wheat pretreatment device

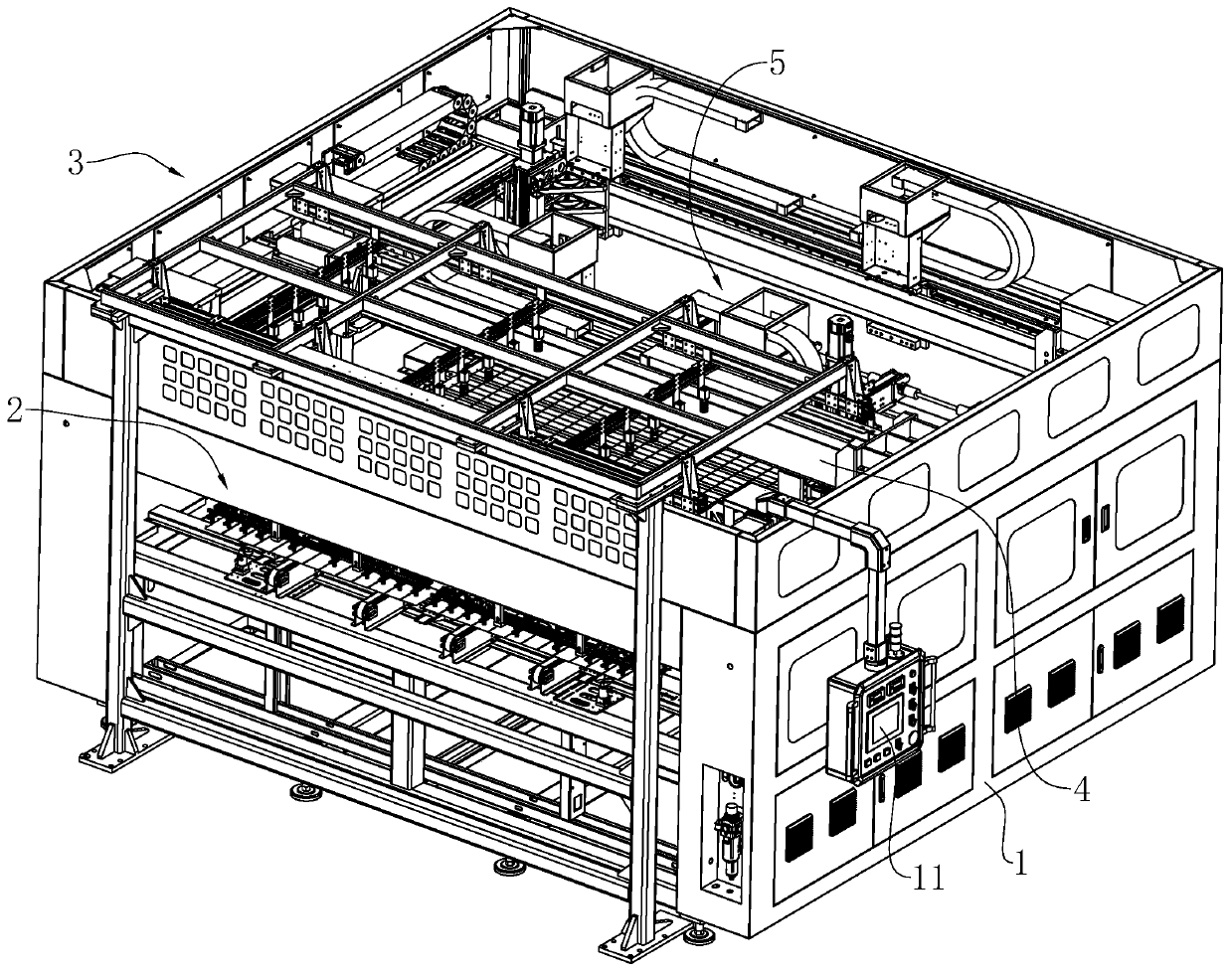

ActiveCN110560199AImprove processing efficiencyGuarantee the quality of follow-up processingGrain huskingGrain polishingWater rinsingEngineering

The invention discloses a wheat pretreatment device. The wheat pretreatment device comprises a weeding system, a grinding system, an impurity removal system and a screening system, wherein the weedingsystem, the grinding system, the impurity removal system and the screening system are arranged in sequence, and the impurity removal system comprises a water rinsing impurity removal mechanism and awater separation mechanism. According to the wheat pretreatment device, through the weeding system, weeds and other impurities in wheat can be removed, through the grinding system and the impurity removal system, the wheat can be thoroughly hulled, and can be cleaned while other light impurities are removed, then clean and impurity-free pure wheat is obtained, the treatment efficiency is high, andthe time and labor are saved. According to the wheat pretreatment device, the wheat can be divided into three grades for screening by the screening system according to the sizes of wheat grains, so that the wheat is thoroughly screened; meanwhile, through an air blowing mechanism, hot air can be blown to a screening cavity, the screening process is accelerated, the wheat can also be dried, subsequent quantitative collection is facilitated, the subsequent wheat processing quality is guaranteed, and the production benefits of enterprises are increased.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

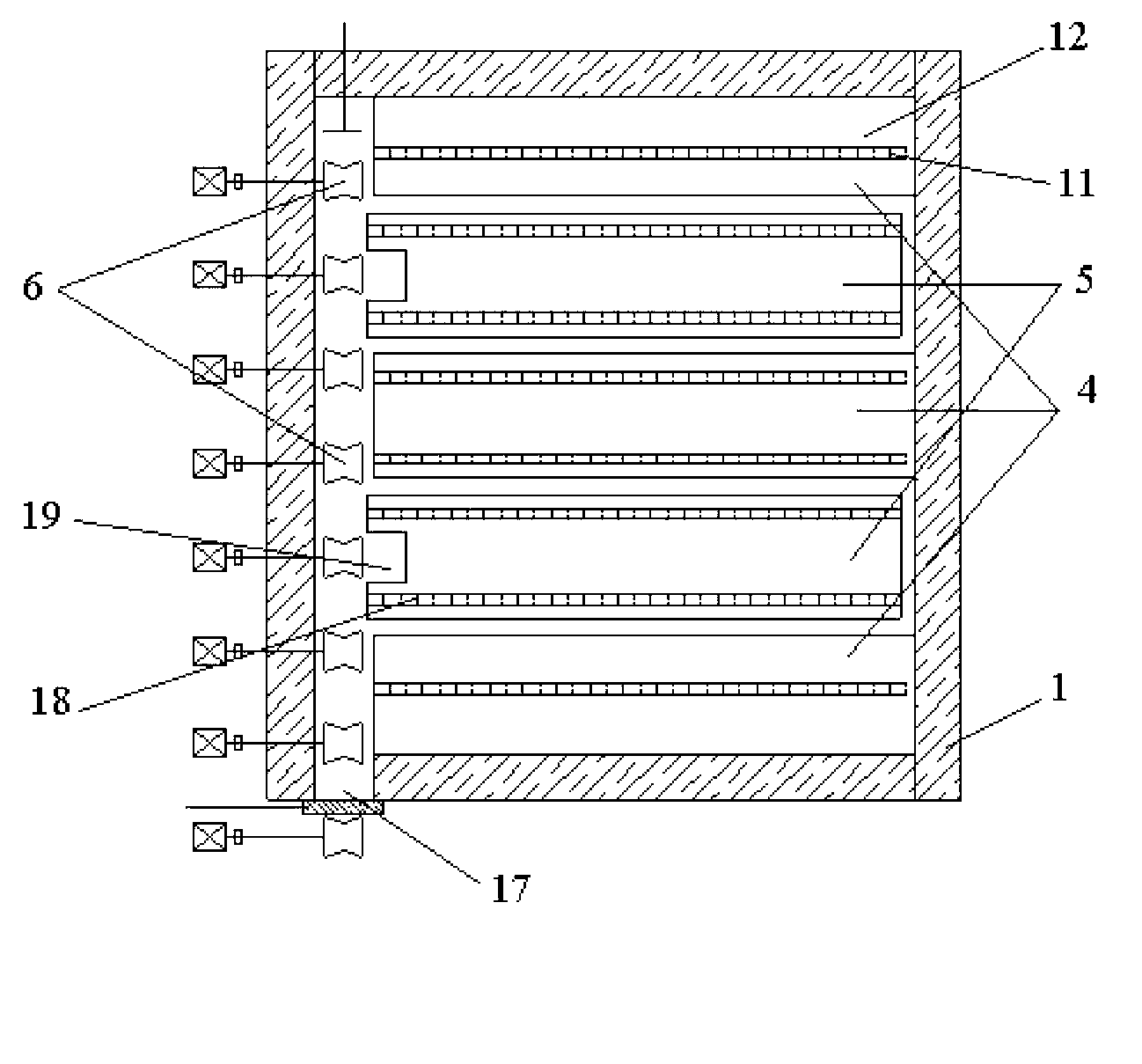

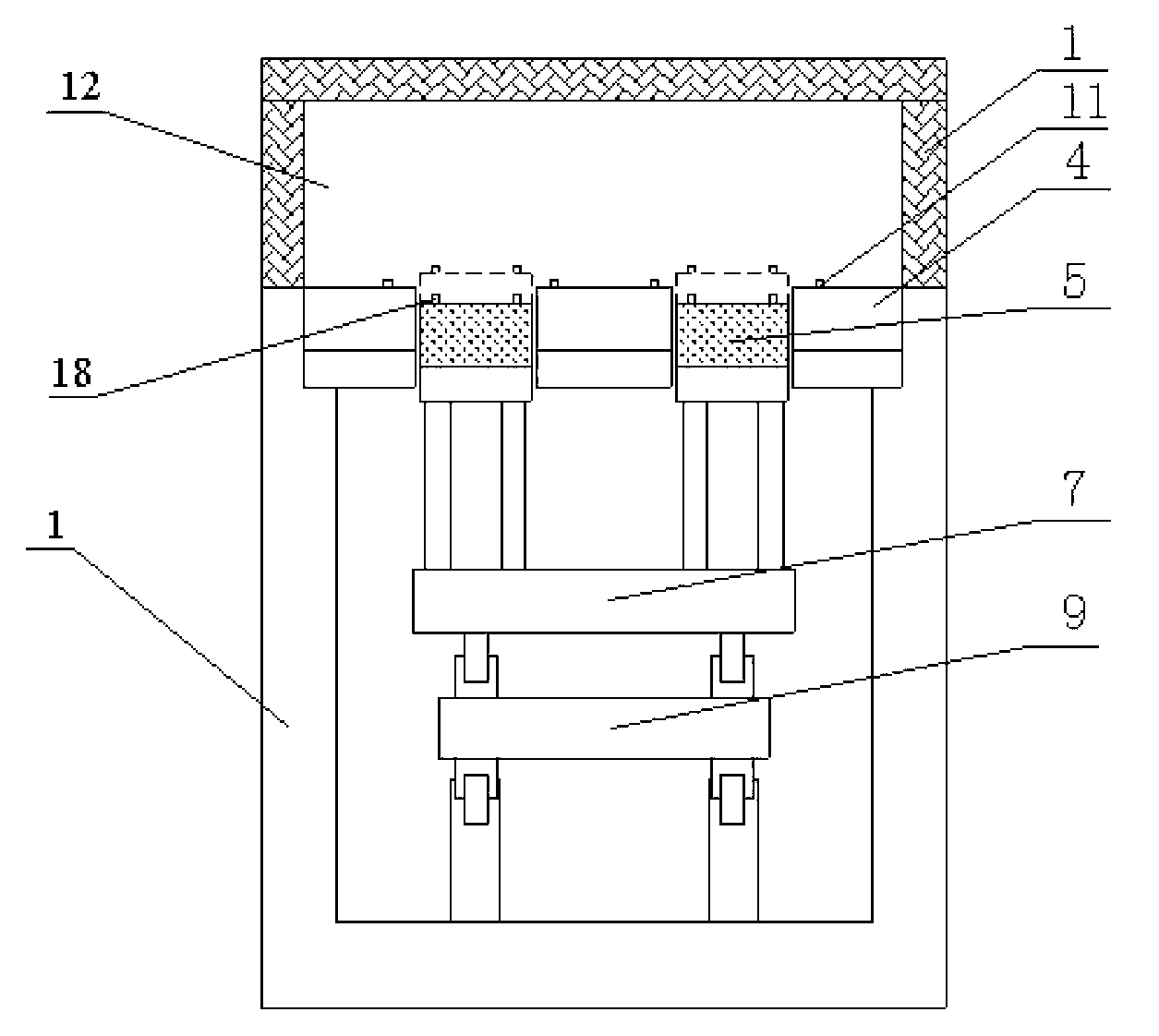

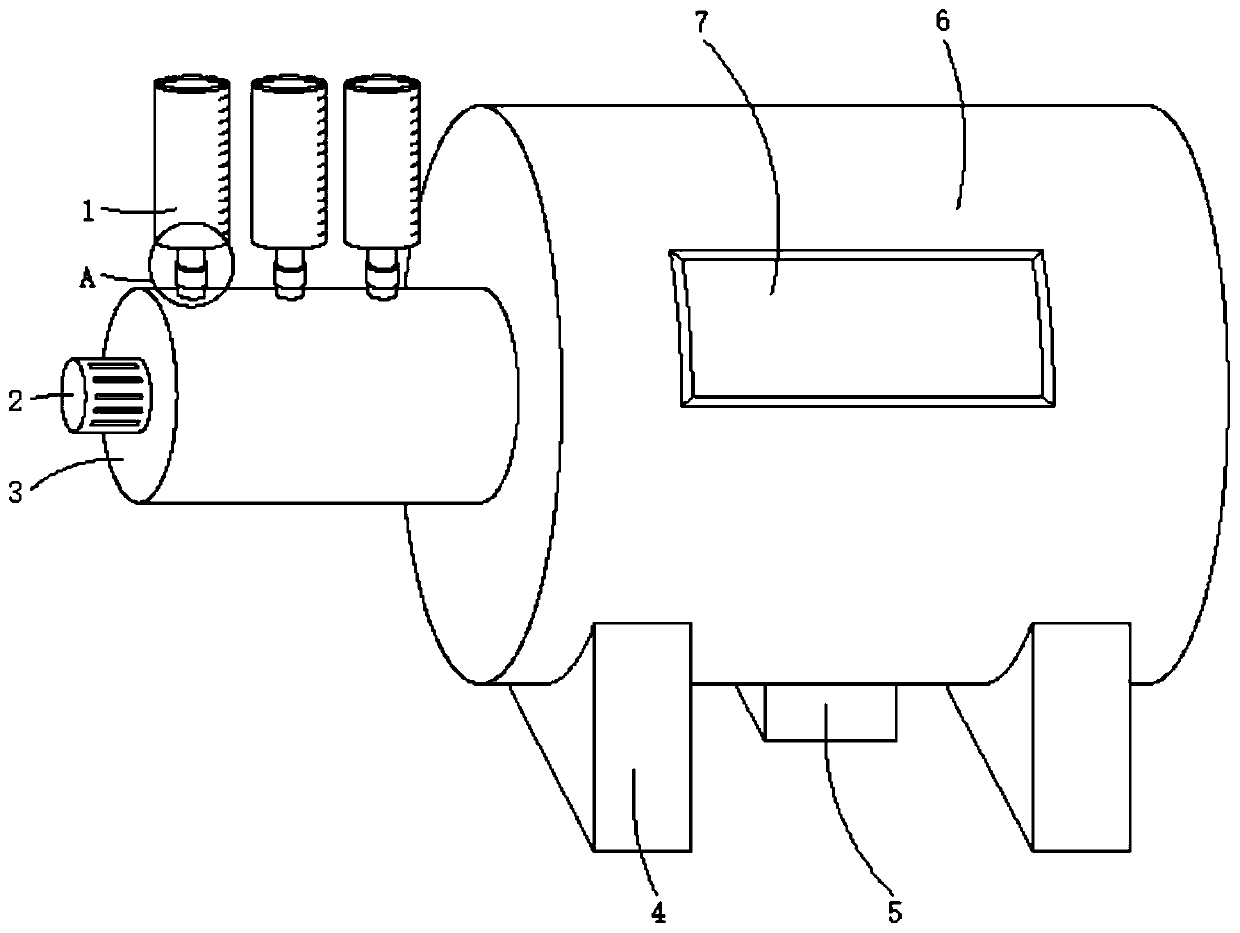

Stepping type automatic overturning heating furnace

ActiveCN103014287AHeating evenlyGuarantee the quality of follow-up processingFurnace typesHeat treatment process controlCombustionHearth

The invention provides a stepping type automatic overturning heating furnace, which is provided with a furnace body, wherein a hearth is arranged at the upper part of the furnace body and the upper part of the hearth is provided with a combustion nozzle; fixed beams are horizontally arranged at the bottom of the hearth along the transverse direction; a movable beam is arranged between the fixed beams; one row of cantilever rollers are horizontally arranged at the left side of the hearth in the vertical direction; the cantilever rollers are located between the furnace wall of the furnace body and the left end faces of the fixed beams and the movable beam; a hoisting mechanism is arranged at the bottom of the furnace body; the hoisting mechanism is provided with a translation mechanism; the movable beam is fixedly arranged above the translation mechanism; heat-resisting cushion blocks I are arranged on the fixed beams; and the upper end face of each heat-resisting cushion block I is a V-shaped inclined plane. According to the stepping type automatic overturning heating furnace, the heat-resisting cushion blocks with the rolling inclined planes are adopted to be matched with a hydraulic stepping mechanism to realize automatic material overturning; and titanium and a titanium alloy circular blank are heated uniformly so as to guarantee the subsequent machining quality of the titanium and the titanium alloy circular blank.

Owner:BAOJI TITANIUM IND

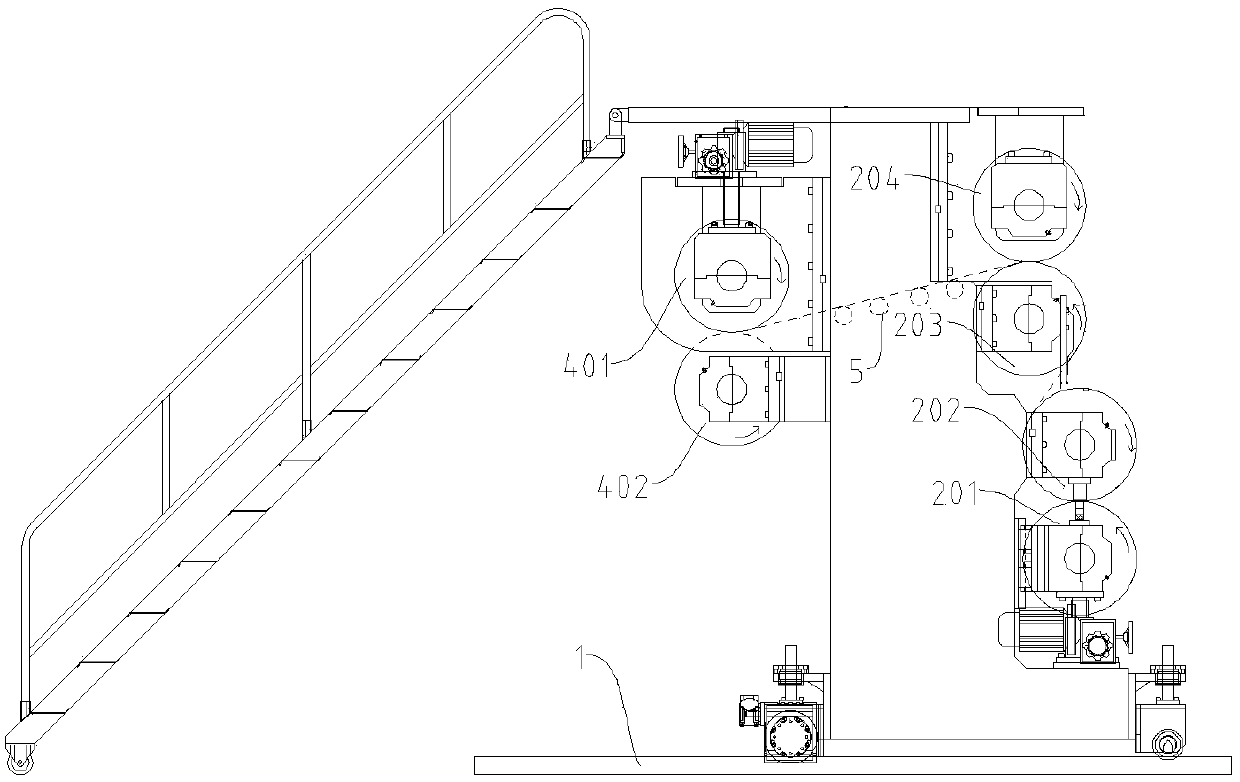

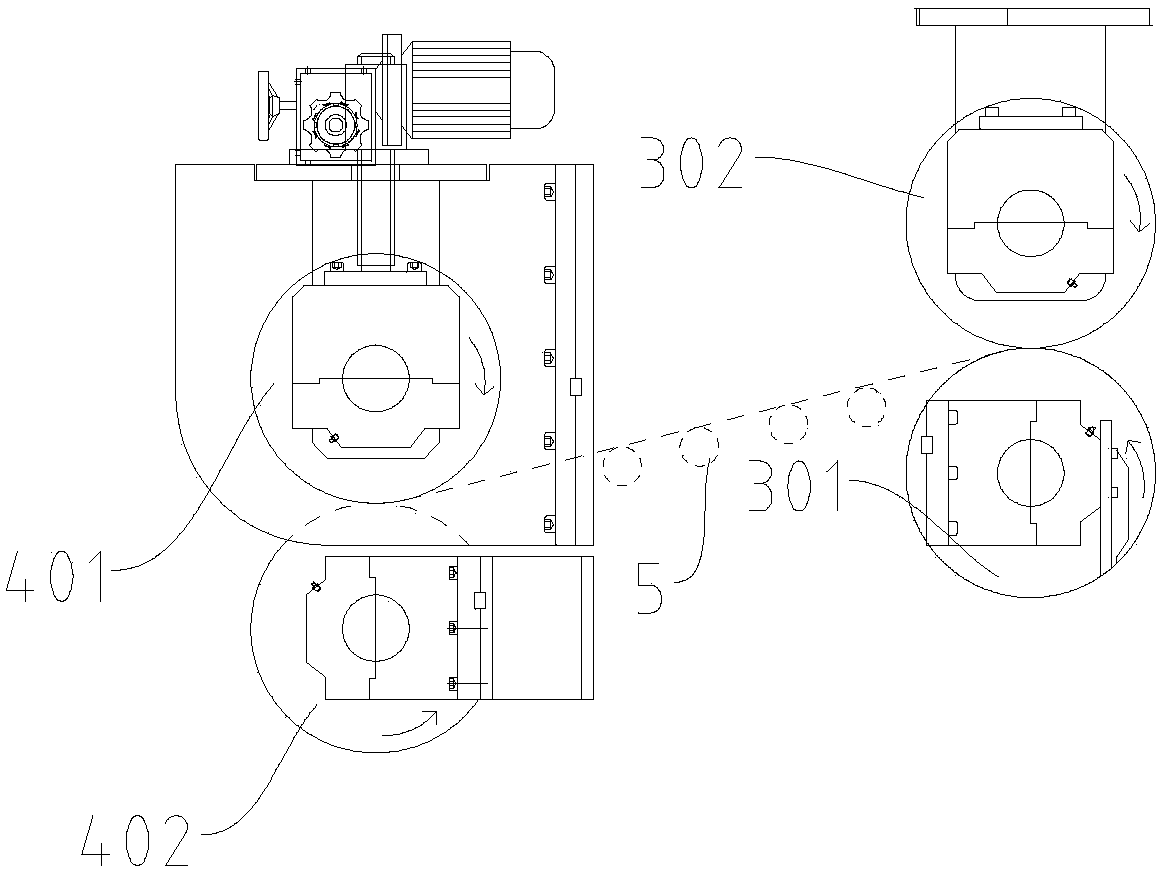

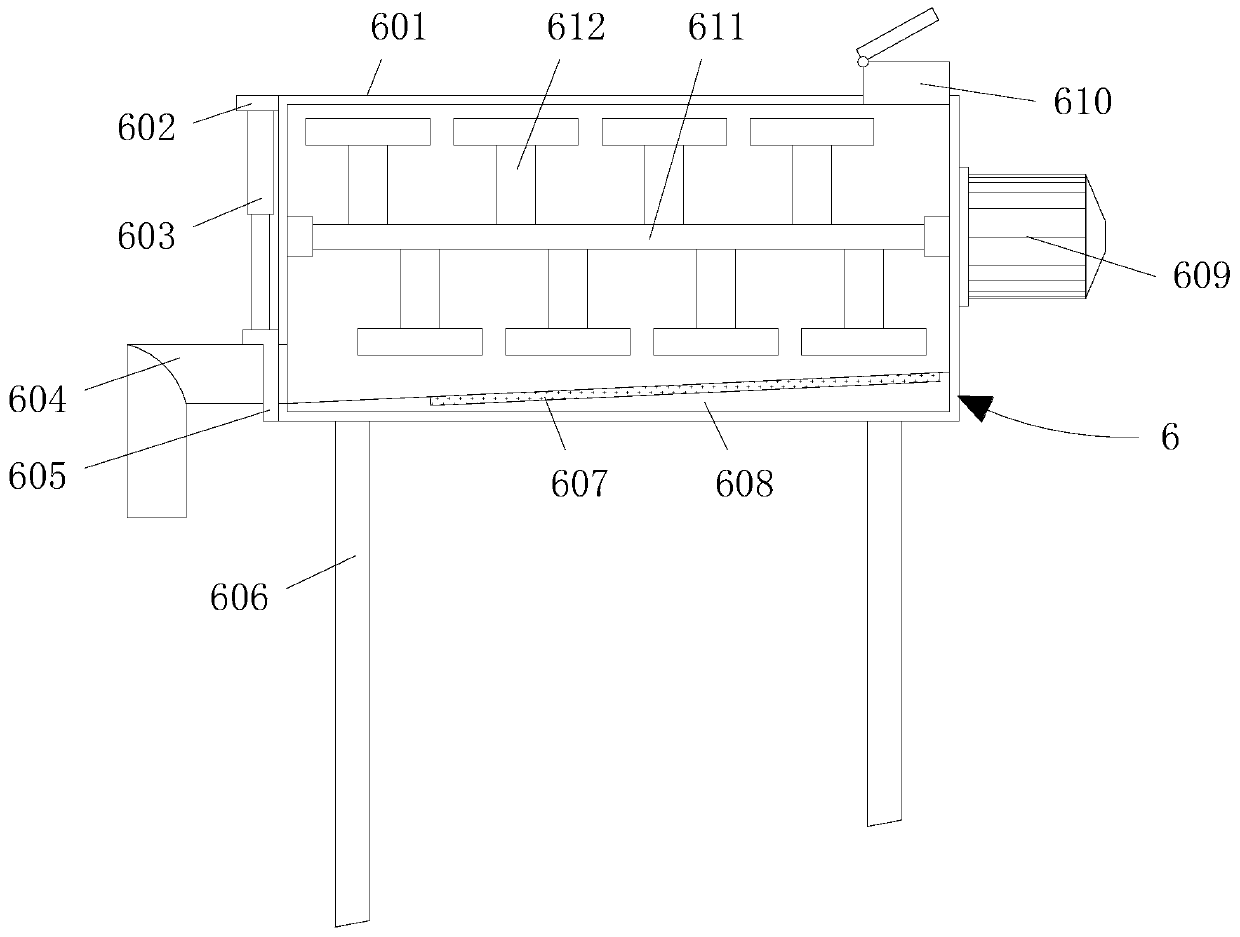

Calender, foaming floor production line and one-time forming production technology

PendingCN107738394AImprove environmental performanceReduce pollutionFlat articlesProduction linePulp and paper industry

A calender comprises a machine base and calender roller groups arrayed on the machine base. The calender is characterized in that each calender roller group comprises a main calender roller group andan embossing roller group for embossing to-be-machined materials; each main calender roller group and the corresponding embossing roller group are spaced at a certain distance so that the materials can be cooled before entering another roller group form one roller group. The calender can realize the better embossing effect. The calender is used for production of a foaming floor so that integratedproduction of the foaming floor can be realized.

Owner:QINGDAO SANYI PLASTIC MACHINERY

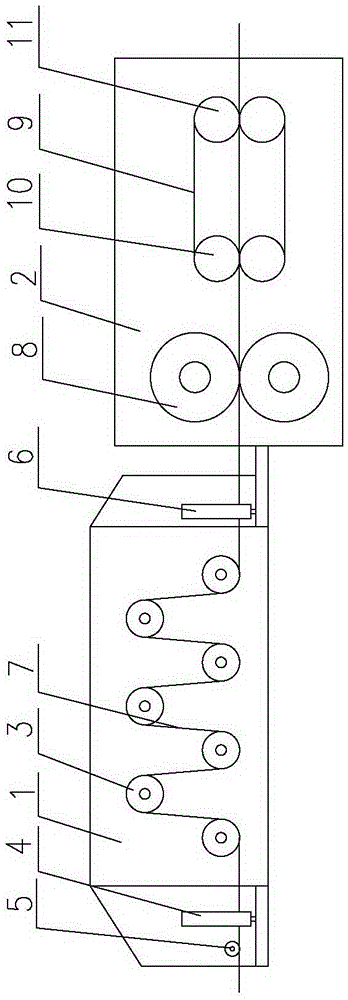

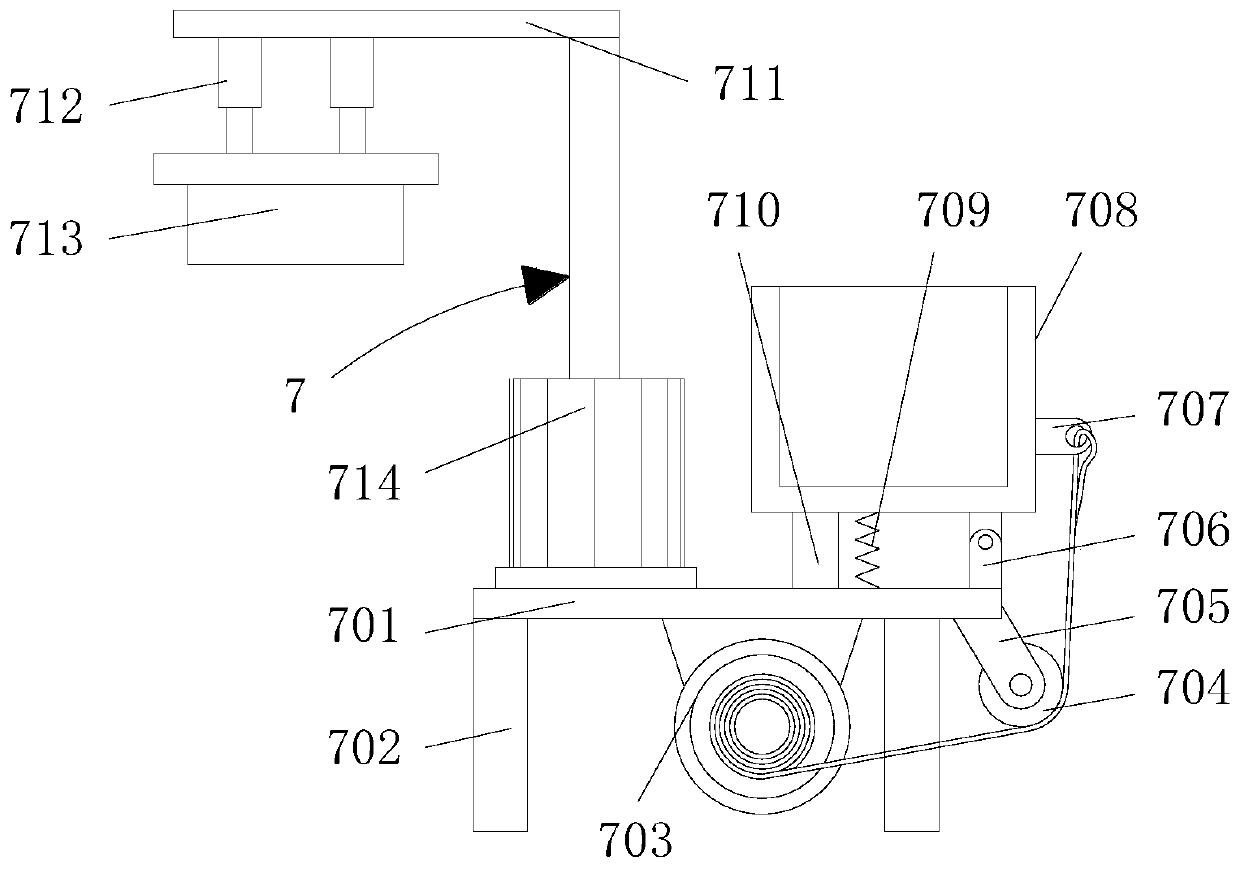

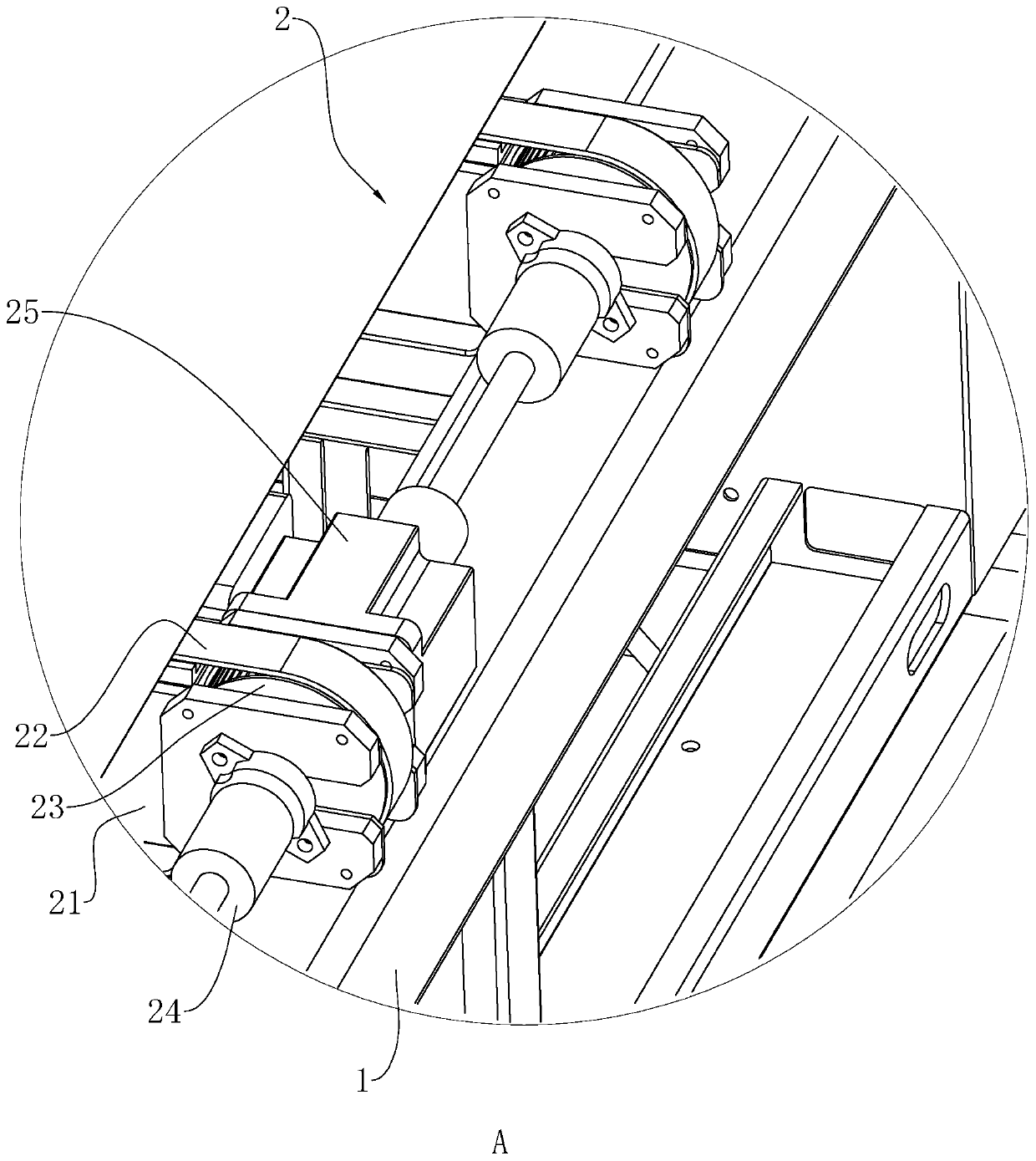

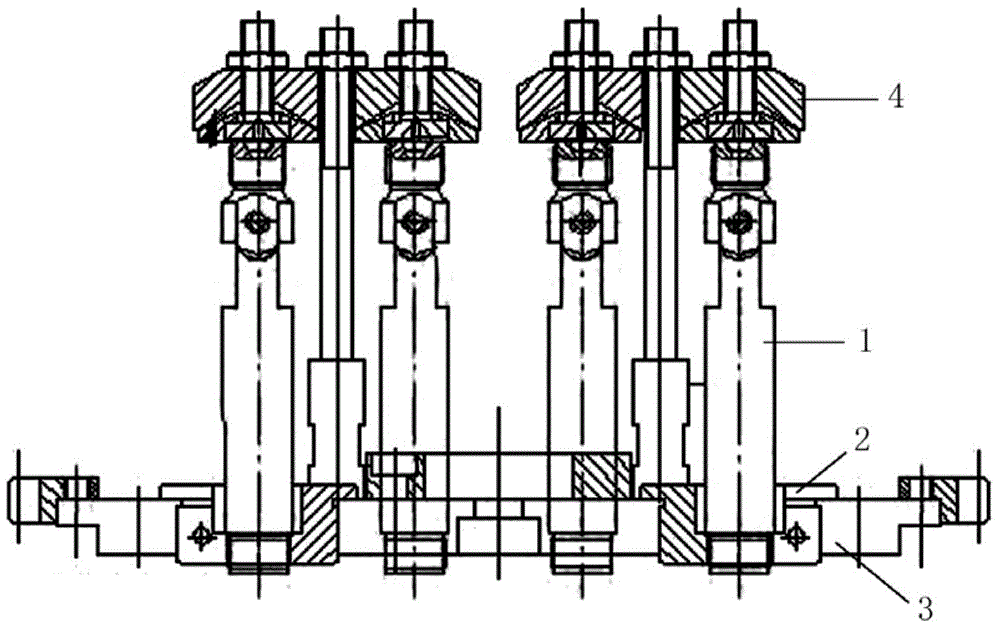

Electric wire middle conveying device

InactiveCN106516886AGuarantee the quality of follow-up processingFilament handlingElectric machineDrive motor

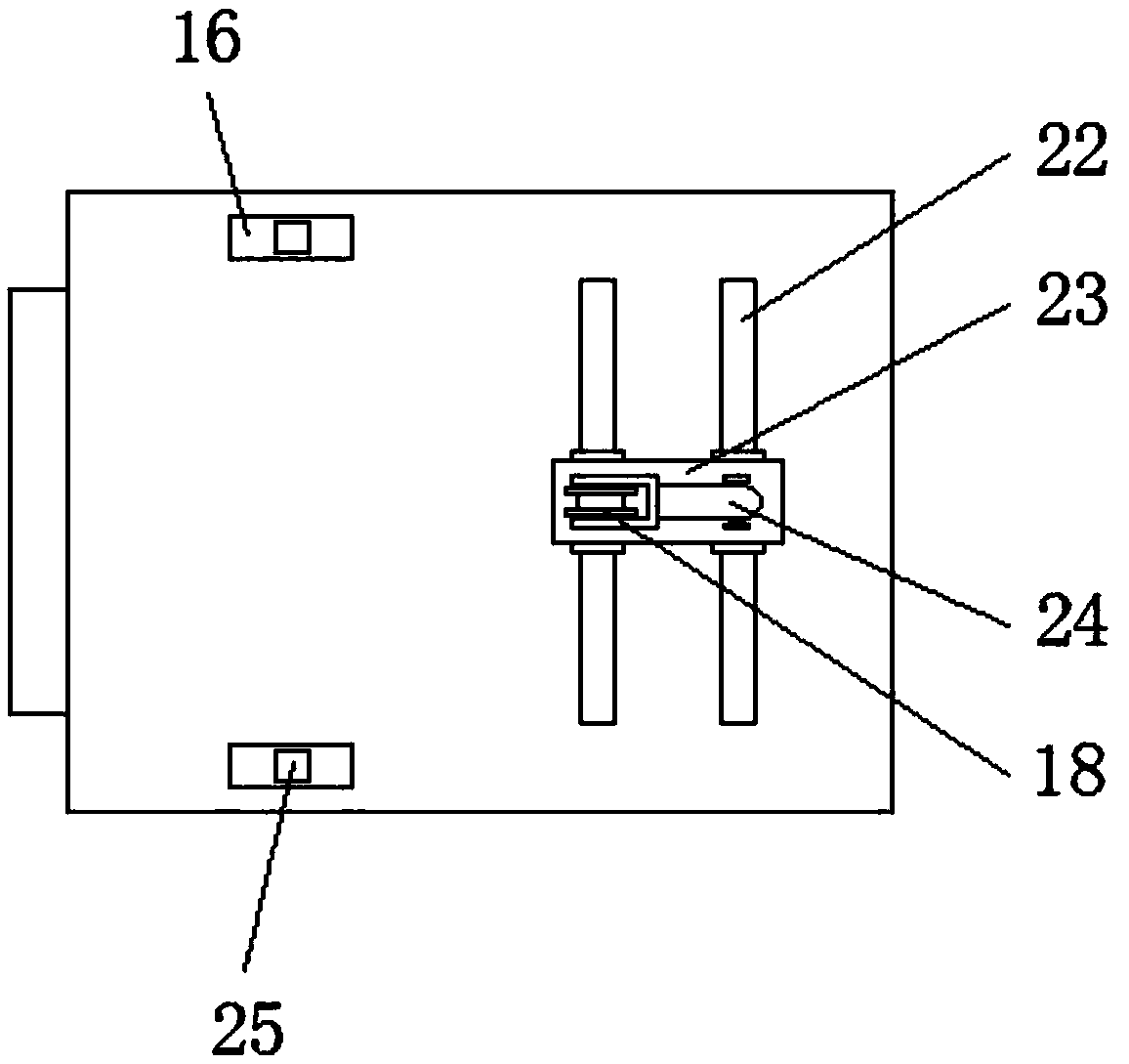

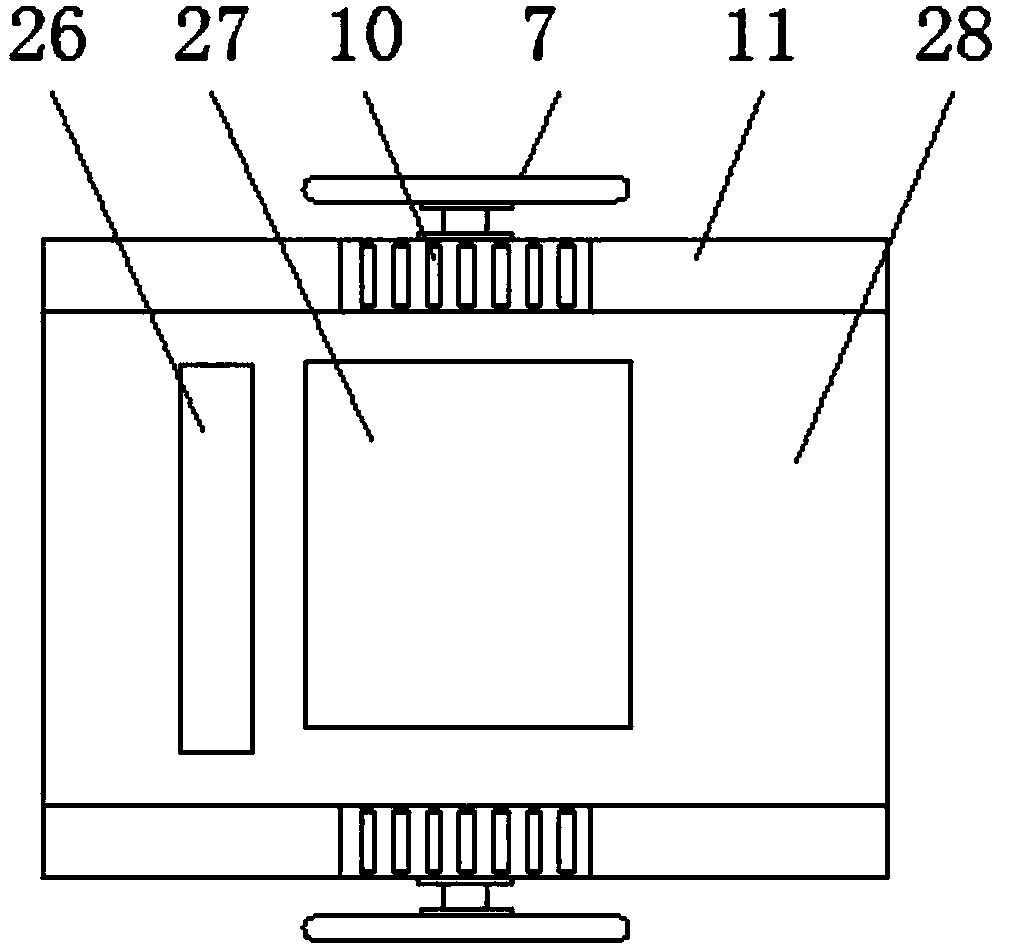

The invention relates to the field of electric wire conveying, in particular to an electric wire middle conveying device, which can effectively guarantee stable and reliable conveying of electric wires and guarantee subsequent machining quality. The electric wire middle conveying device comprises a front frame and a back frame; two rows of tension wheels are mounted on the front frame, and are staggered up and down; guide column mechanisms are respectively arranged on the left and right two sides of the two rows of tension wheels; the guide column mechanism on the left side includes two left side vertical guide columns arranged side by side, and a transverse guide column; the guide column mechanism on the right side includes two right side vertical guide columns arranged side by side; a gap between the two left side vertical guide columns and a gap between the two right side vertical guide columns are both equal to the diameters of the electric wires; two guide wheels and two guide conveying belts are arranged on the back frame in sequence, and are symmetrically distributed up and down; the guide conveying belts are mounted on a driving conveying wheel and a driven conveying wheel; the driving conveying wheel is connected with a driving motor; and a gap between the two guide wheels and a gap between the two guide conveying belts are both equal to the diameters of the electric wires.

Owner:WUXI VIGOROUS ELECTRIC

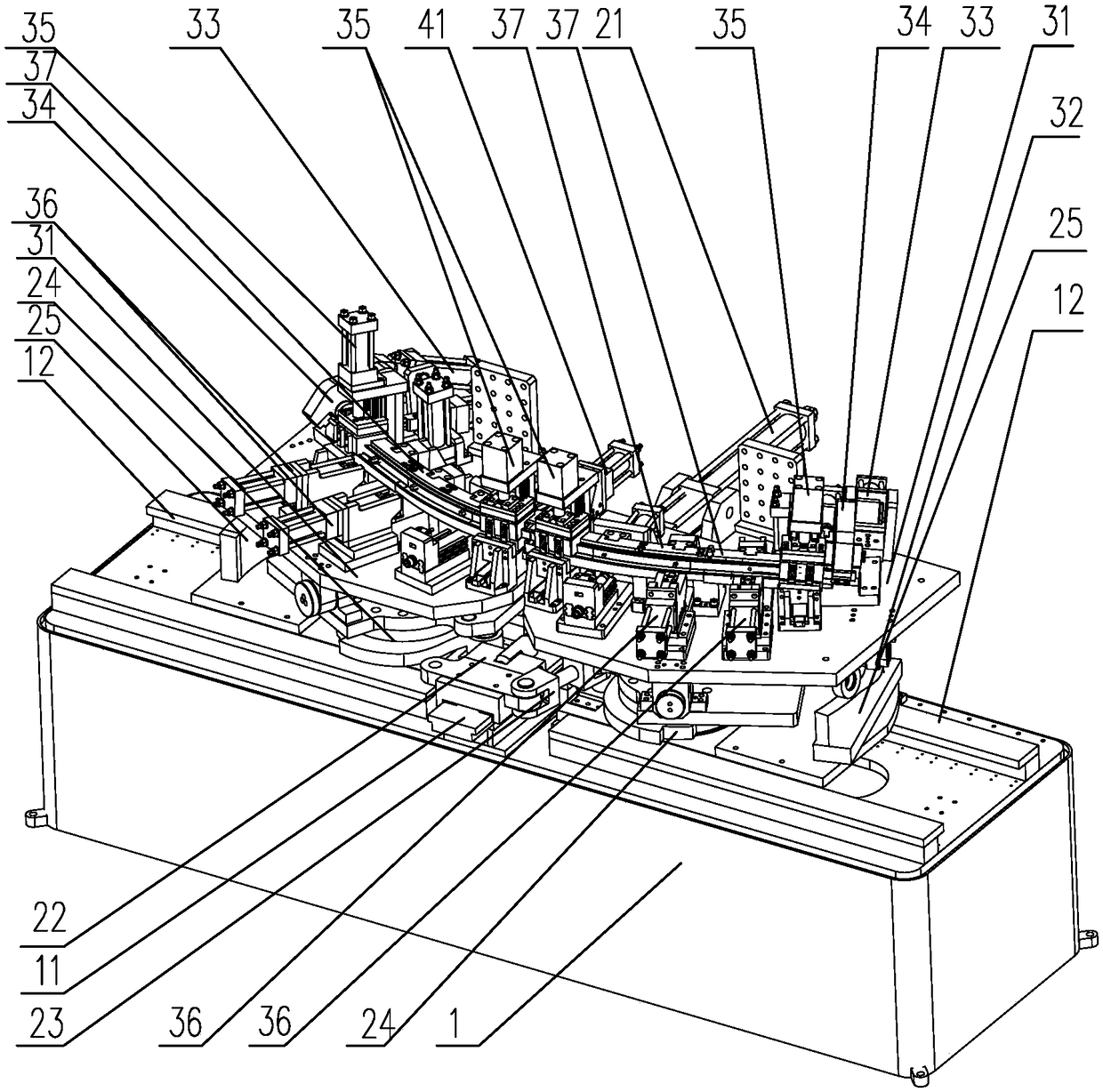

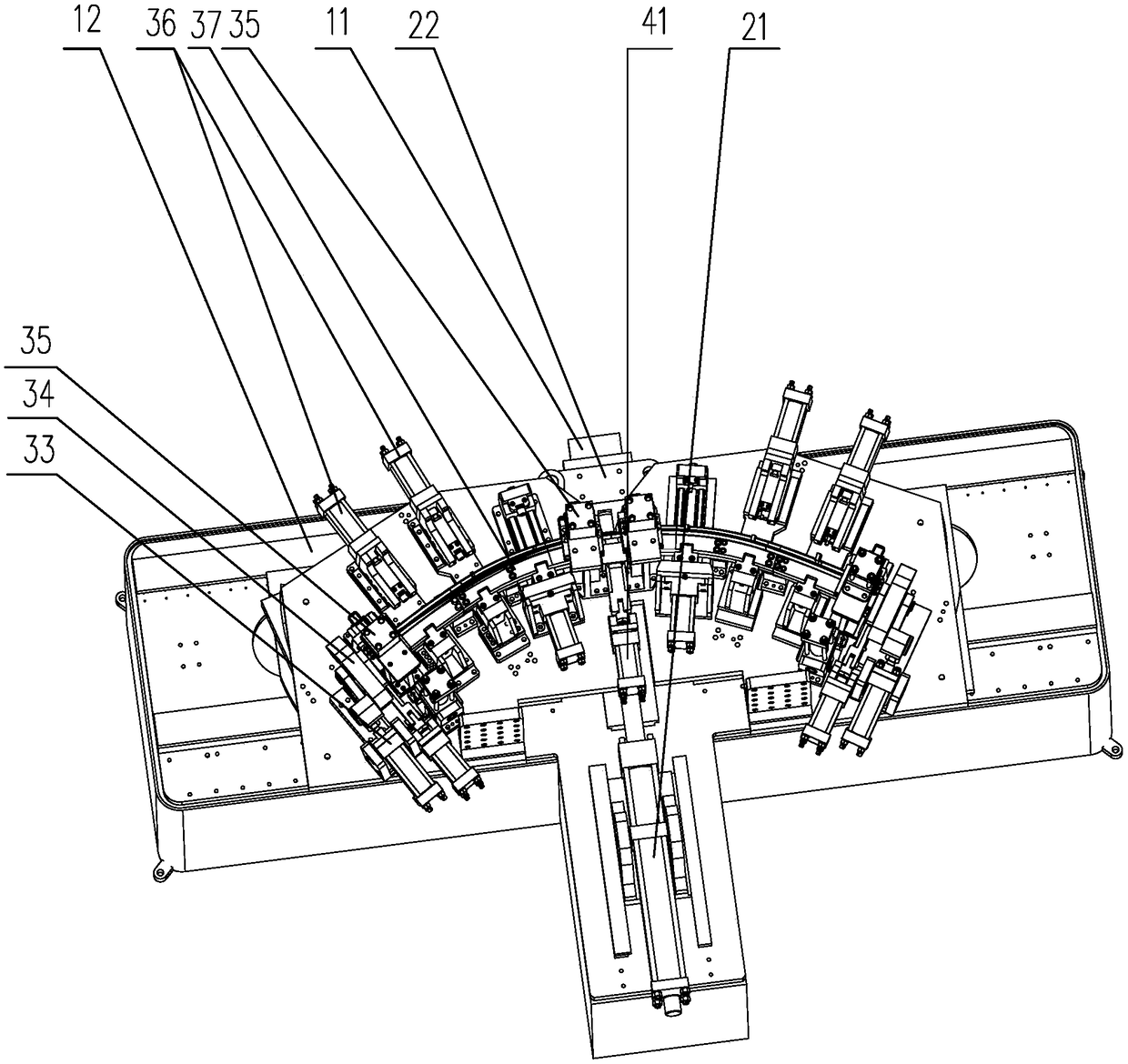

Car door sliding rail stretch bending machine

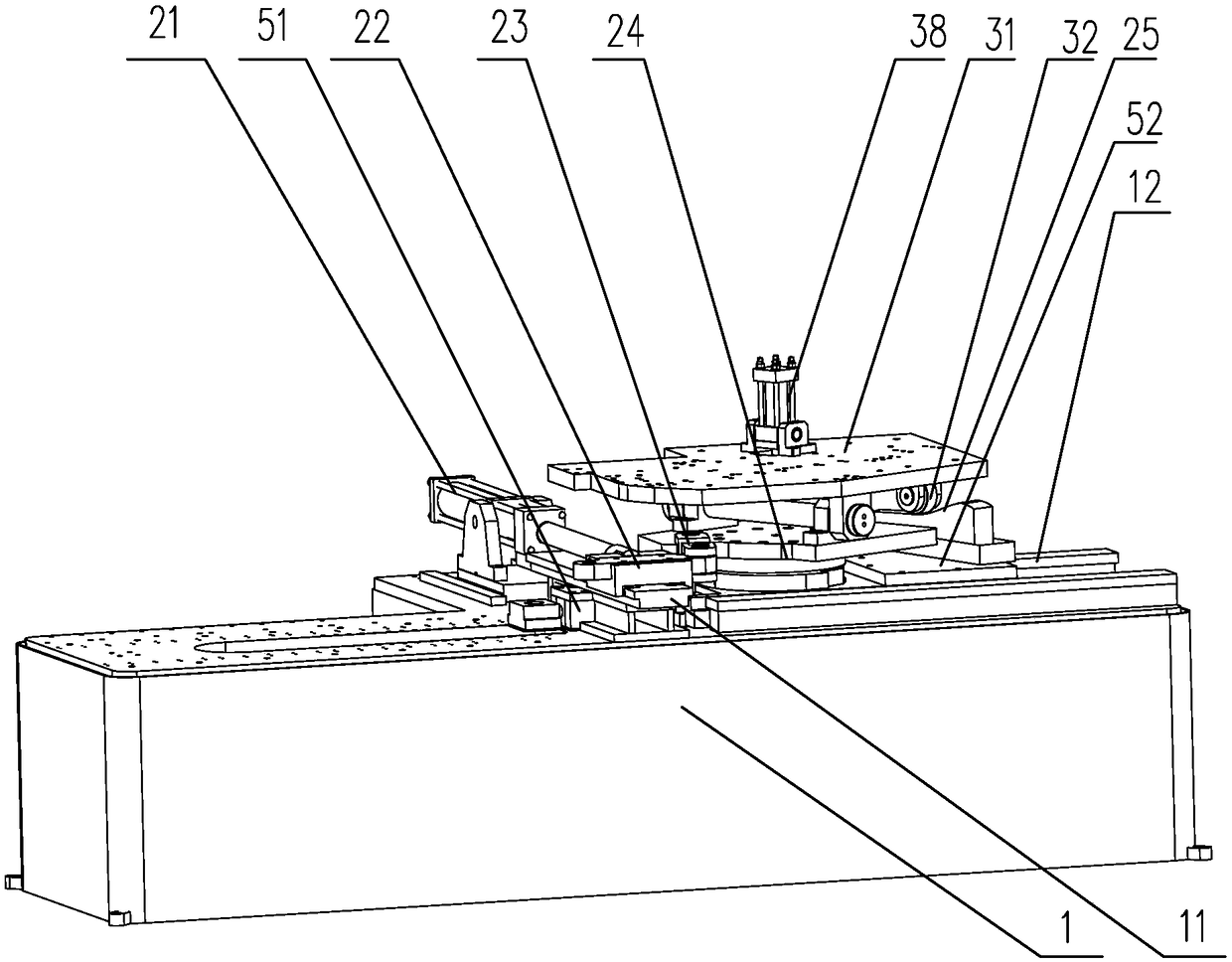

The invention discloses a car door sliding rail stretch bending machine. The car door sliding rail stretch bending machine comprises a support. Two stretch bending devices are arranged on the supportin a mirror image manner. Each stretch bending device comprises a movable platform and a drive mechanism, wherein the movable platform is arranged on the support and provided with an arc carrying track, and the movable platform is provided with a positioning device; and the drive mechanism comprises a steering disc, a lifting track and a steering drive piece, the position, corresponding to the movable platform, of the steering disc is rotationally arranged on the support, the steering disc is hinged to the movable platform, the lifting track is arranged on one side of the steering disc, the movable platform is provided with wheels, and the wheels and the lifting track are in sliding fit. A cropping device is arranged between the two stretch bending devices, and the support is further provided with an adjusting device for adjusting the distance between the two stretch bending devices. The improved structure of the car door sliding rail stretch bending machine is simple and reasonable, the whole machine structure is simple, stretch bending of a car door sliding rail in the vertical direction and the horizontal direction is effectively achieved, forming is fast, and the production efficiency is higher.

Owner:浙江创大汽车部件有限公司

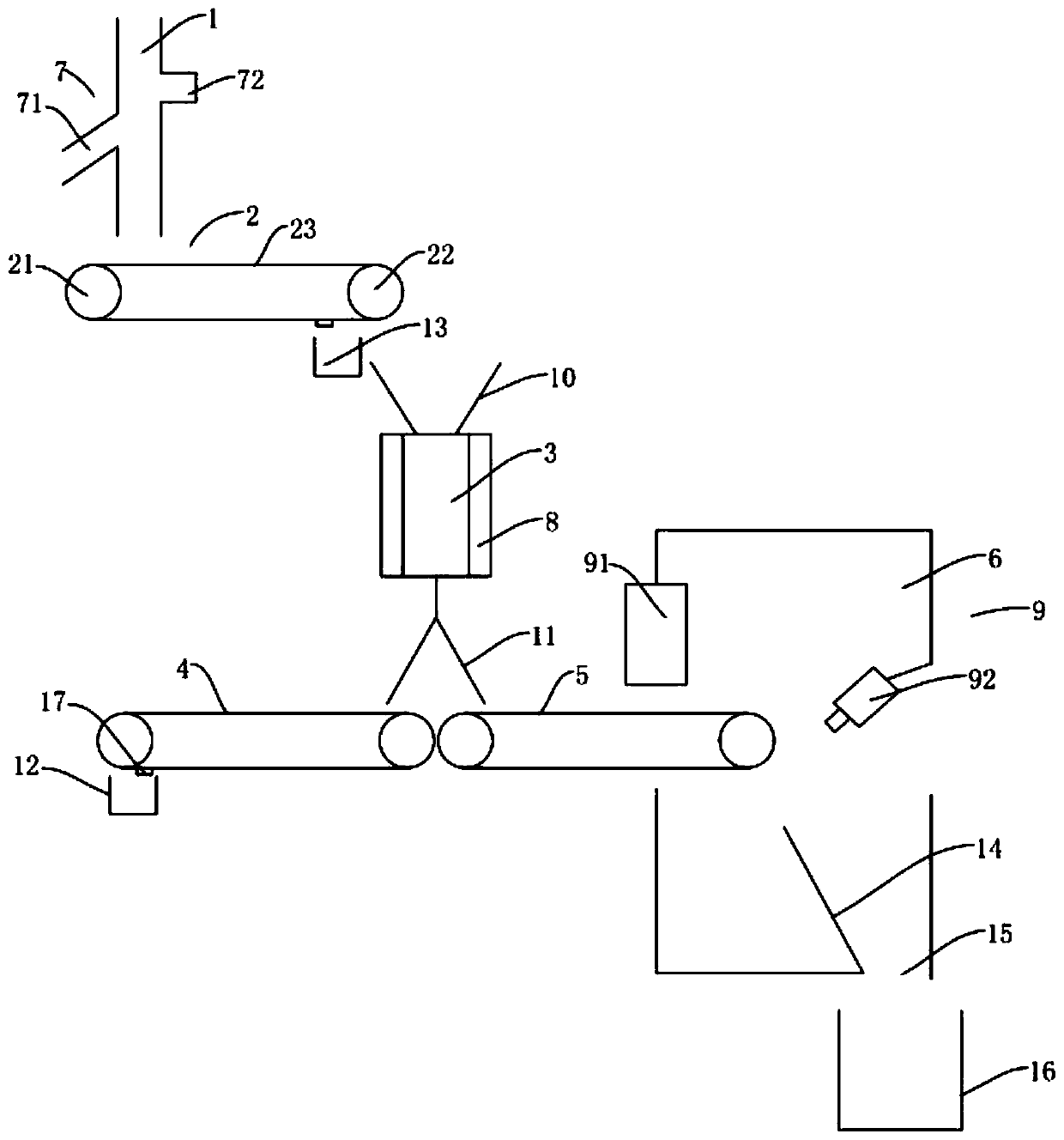

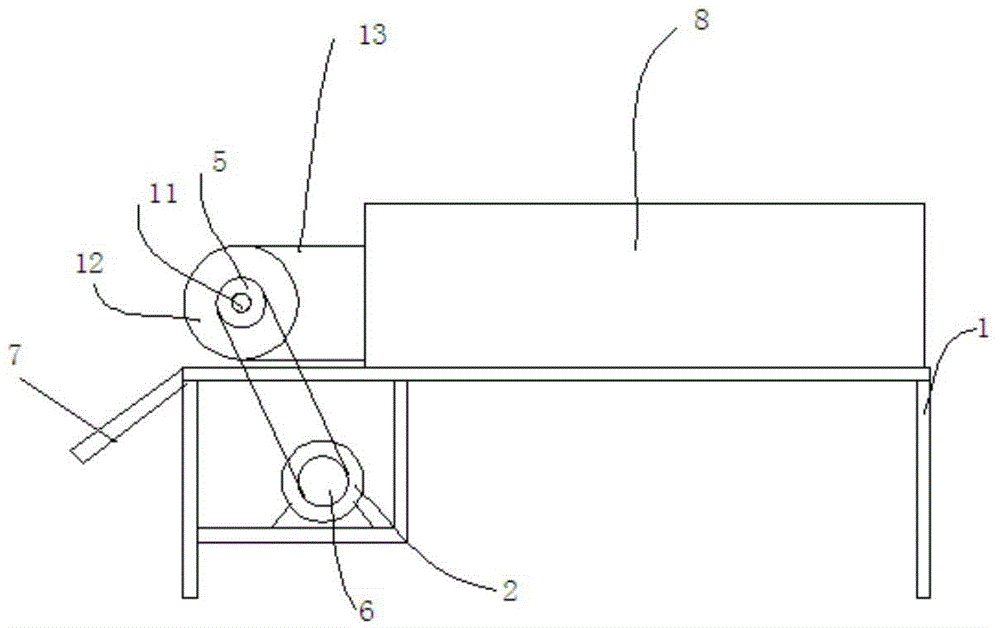

Polycrystalline silicon lump material selection device and selection method

InactiveCN111438053AAchieve FeaturedHigh efficiency in removing impuritiesGas current separationElectrostatic separationEngineeringMechanical engineering

The invention discloses a polycrystalline silicon lump material selection device and selection method, and relates to the field of polycrystalline silicon production equipment. The polycrystalline silicon lump material selection device comprises a feeding pipe, a first-stage conveying mechanism capable of conducting magnetic separation, a feeding pipe, a second-stage conveying mechanism, a third-stage conveying mechanism and a collecting box; a winnowing mechanism is installed in the feeding pipe, the outlet end of the feeding pipe is in butt joint with the output end of the first-stage conveying mechanism, and the output end of the first-stage conveying mechanism is in butt joint with an inlet of the feeding pipe; electrodes which are symmetrically distributed are mounted in the feeding pipe; the second-stage conveying mechanism and the third-stage conveying mechanism are symmetrically arranged, and the input end of the second-stage conveying mechanism and the input end of the third-stage conveying mechanism are both located between the two electrodes; and an inlet of the collecting box is in butt joint with an outlet of the third-level conveying mechanism, and a color sorting mechanism is further installed on the collecting box. According to the device, not only can impurities be automatically removed, but also the processing quality of the polycrystalline silicon lump material is ensured, and the fine selection of the polycrystalline silicon lump material is realized.

Owner:ASIA SILICON QINGHAI +1

Automatic forming device for rubber products processing and use method thereof

The invention discloses an automatic forming device for rubber products processing and a use method thereof. The automatic forming device comprises a supporting seat, the right end of the inner surface of the supporting seat is movably provided with a plurality of conveying rollers which are equidistantly distributed and are connected in a transmission manner through a conveyor belt, the right rear end of the bottom part of the supporting seat is fixedly provided with a conveying motor, and the output shaft of the conveying motor is connected with the conveying rollers at the most right end ofthe inner surface of the supporting seat a transmission manner through a belt. According to the automatic forming device for rubber products processing and the use method of the automatic forming device, a stirring and heating mechanism is arranged and has the function of stirring and heating materials, so that the solidification of the materials in the process is avoided, the subsequent processing quality is guaranteed; a forming mechanism is arranged and can carry out injection molding treatment of the materials, so that the forming efficiency is of the materials improved; and the conveyingrollers, the conveyor belt, the belt and the conveying motor are arranged, the conveying motor is started, the conveying motor drives the conveying rollers to rotate through the belt, then the conveying rollers drive the materials to move through the conveyor belt, so that the purpose of feeding is achieved.

Owner:浙江橡企科技有限公司

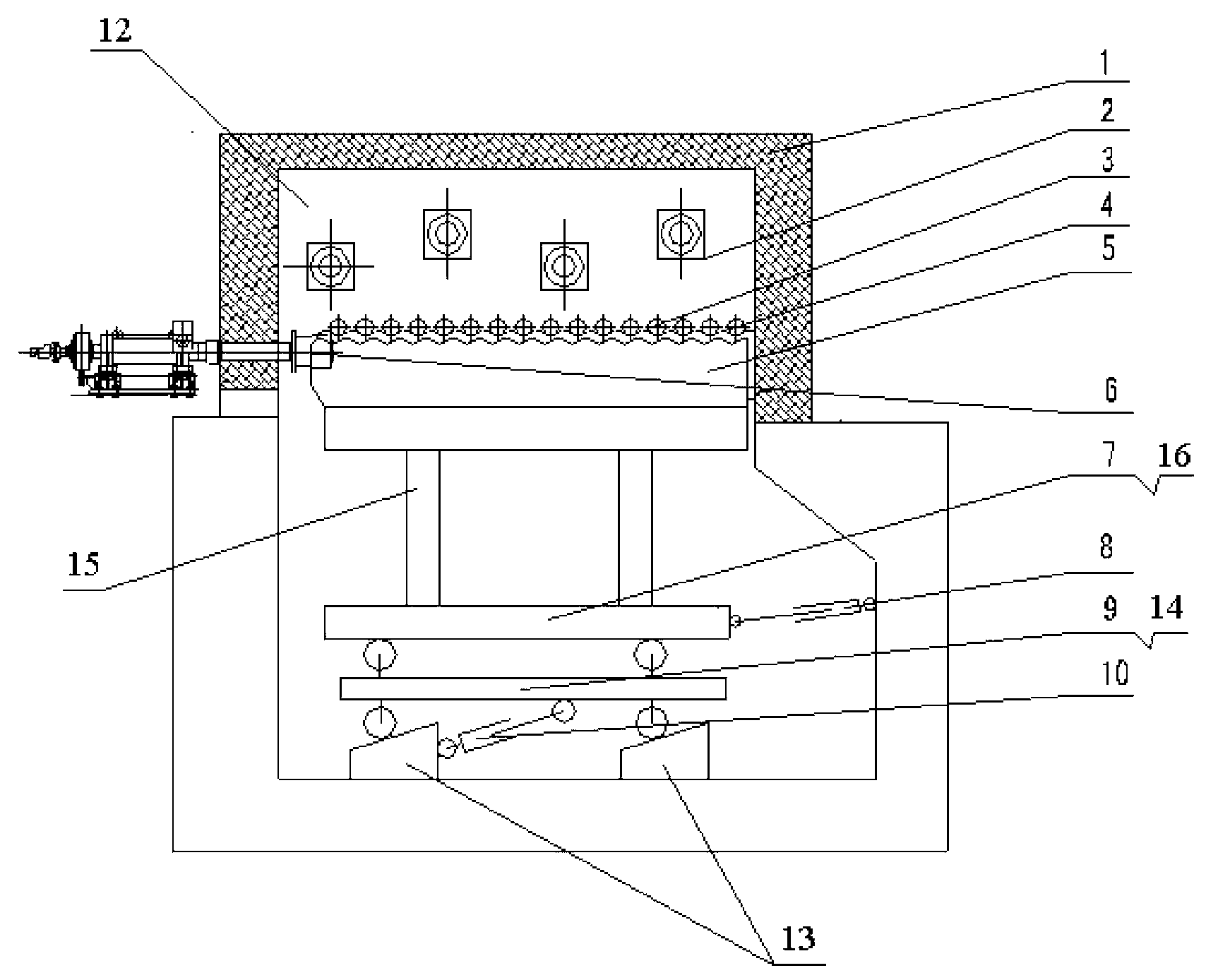

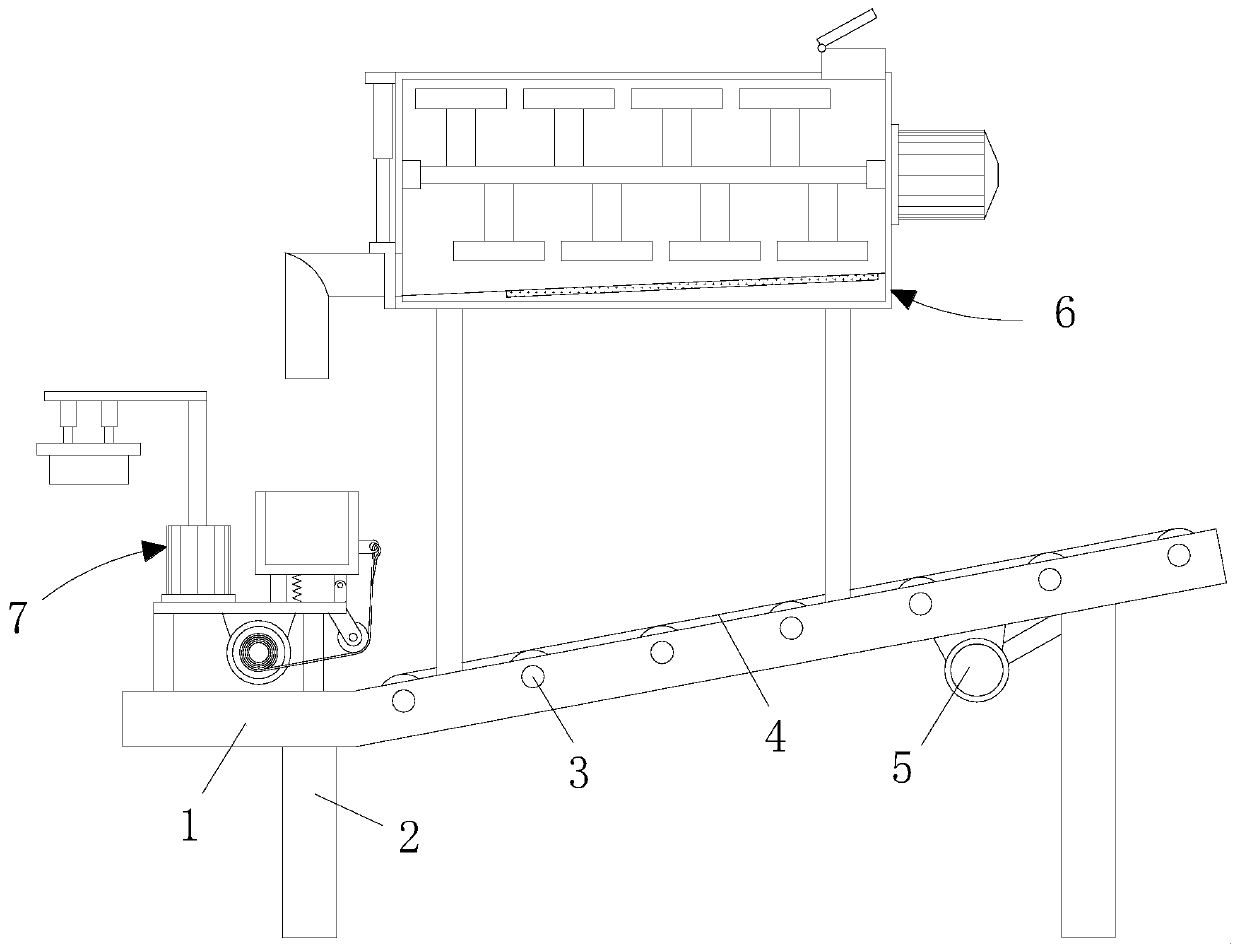

Air cooling equipment for machining engine connecting rod

InactiveCN104457081ANovel structureEasy to manufactureDomestic cooling apparatusLighting and heating apparatusCold airProduction line

The invention discloses air cooling equipment for machining an engine connecting rod. The air cooling equipment comprises a supporting frame, a chain conveying mechanism is installed on the supporting frame and connected with an output shaft of a motor, and the motor is fixed to the supporting frame. An outer shell is arranged above the chain conveying mechanism in a covering mode. Cooling air channels are formed in the upper portion of the outer shell, cooling fans are installed above the outer shell, and the lower portions of the cooling fans are located inside the cooling air channels. By the adoption of the structure, the temperature of the connecting rod is high after heating, rolling, forming, punching and edge trimming are performed on the connecting rod on a production line, and at the moment, the connecting rod high in temperature enters the outer shell under driving of the chain conveying mechanism; because the fans installed on the outer shell are in a working state, cold air enters the cooling air channels and cools the connecting rod.

Owner:CHONGQING PENGSHI TECH DEV

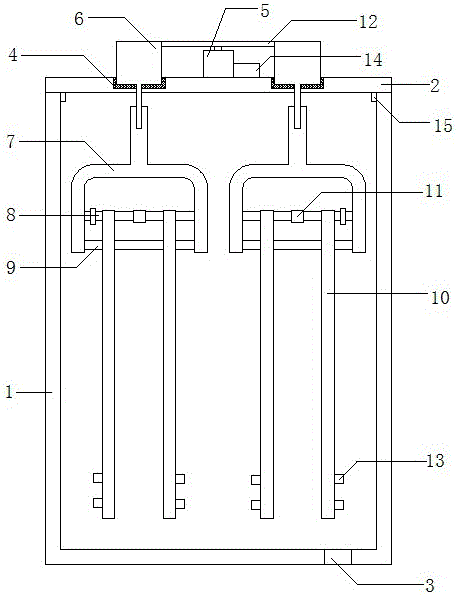

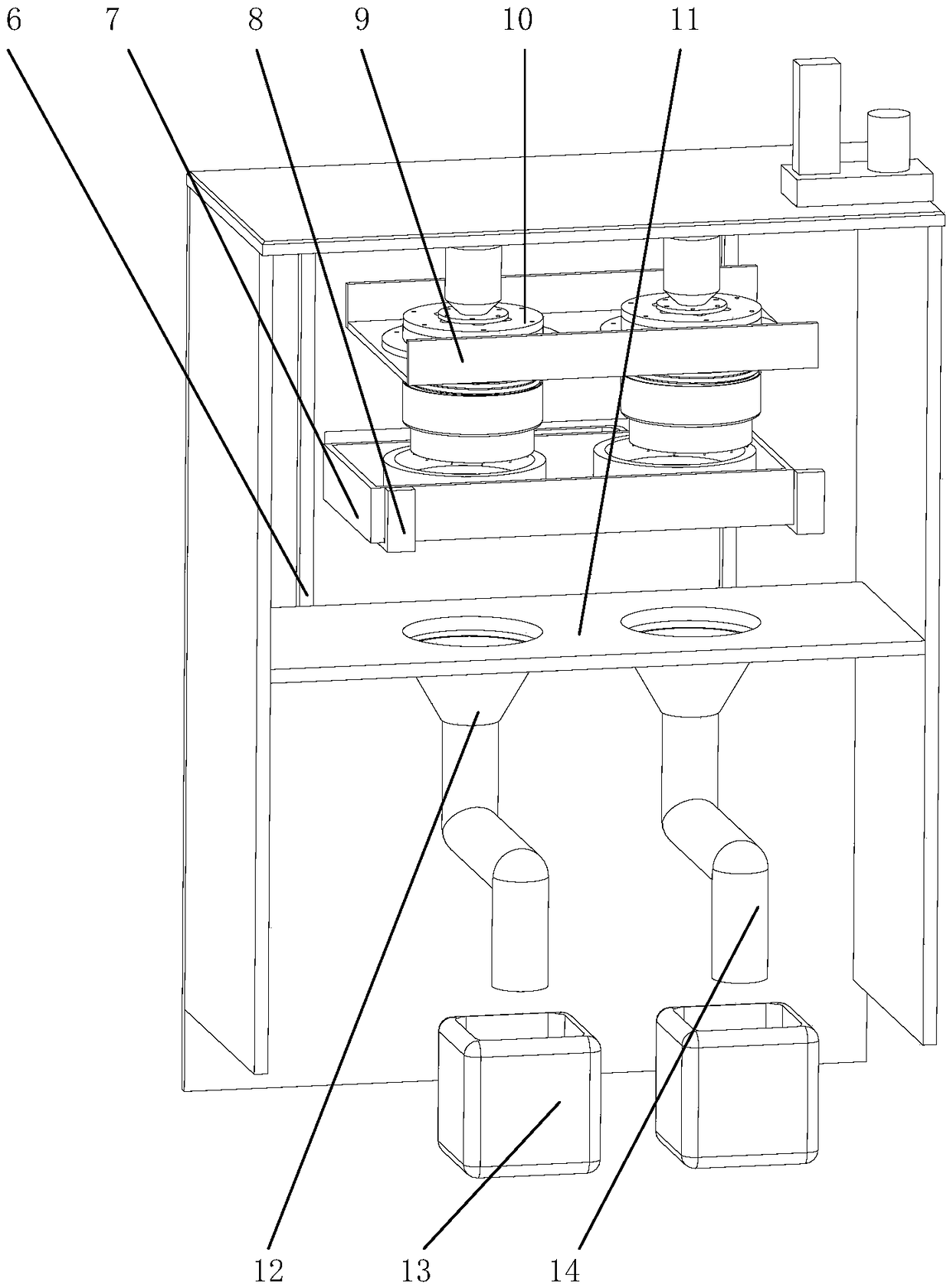

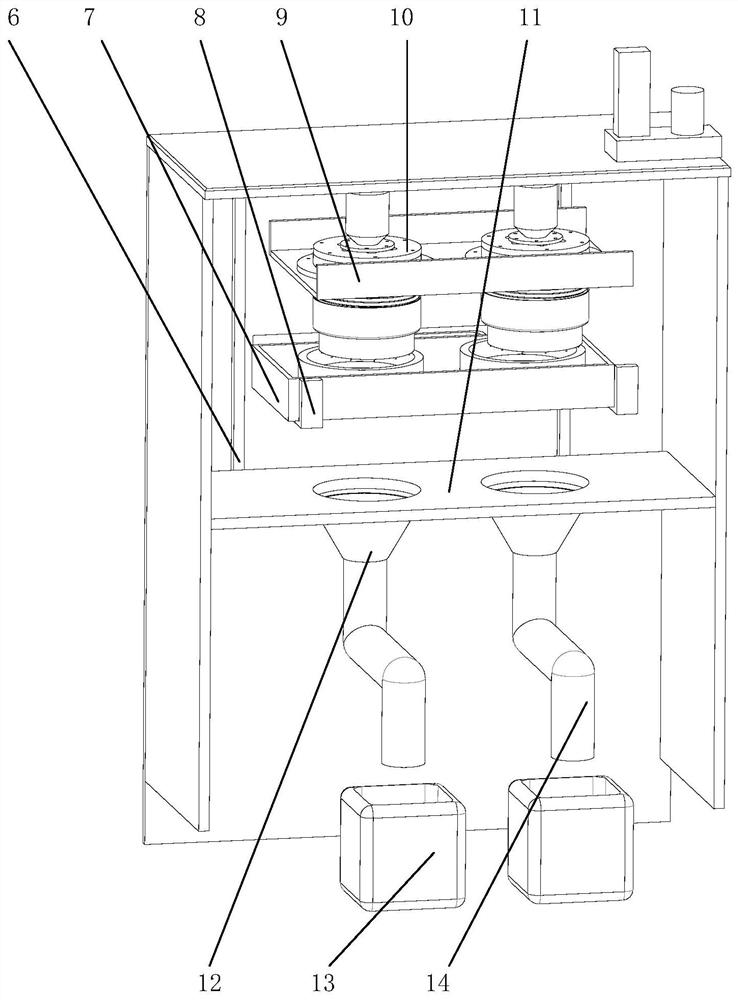

Quantiative mixing device for processing PVA starch granules

InactiveCN111267258AAvoid the problem of poor uniformity when mixingGuarantee the quality of follow-up processingHollow article cleaningGrain treatmentsElectric machineryProcess engineering

The invention discloses a quantiative mixing device for processing PVA starch granules and relates to the technical field of PVA starch granules. The quantiative mixing device comprises a mixing tank,wherein two symmetrical support seats are fixedly mounted on the outer surface of the mixing tank; a discharging component is fixedly mounted on the outer surface of the mixing tank and is positionedbetween the two support seats; and a feeding barrel is fixedly mounted on the left side face of the mixing tank. The quantiative mixing device is reasonable in designed structure; a stirring motor iselectrified to start to drive a rotary shaft to rotate; the rotary shaft drives a feeding component to rotate; fallen raw material is conveyed into the mixing tank under the action of the feeding component; the rotary shaft drives a stirring rod and a hairbrush component to rotate to overturn and mix the raw material; the rotary shaft drives a third sealed bearing and a support rod to rotate, sothat the third sealed bearing is in contact with the inner wall of the mixing tank to grind and crush the raw material, the starch granules are prevented from adhesion under the external factors, theproblem that the uniformity of the starch granules is poorer during the mixing process is avoided, and the following processing quality is ensured.

Owner:浙江巨创新材料科技股份有限公司

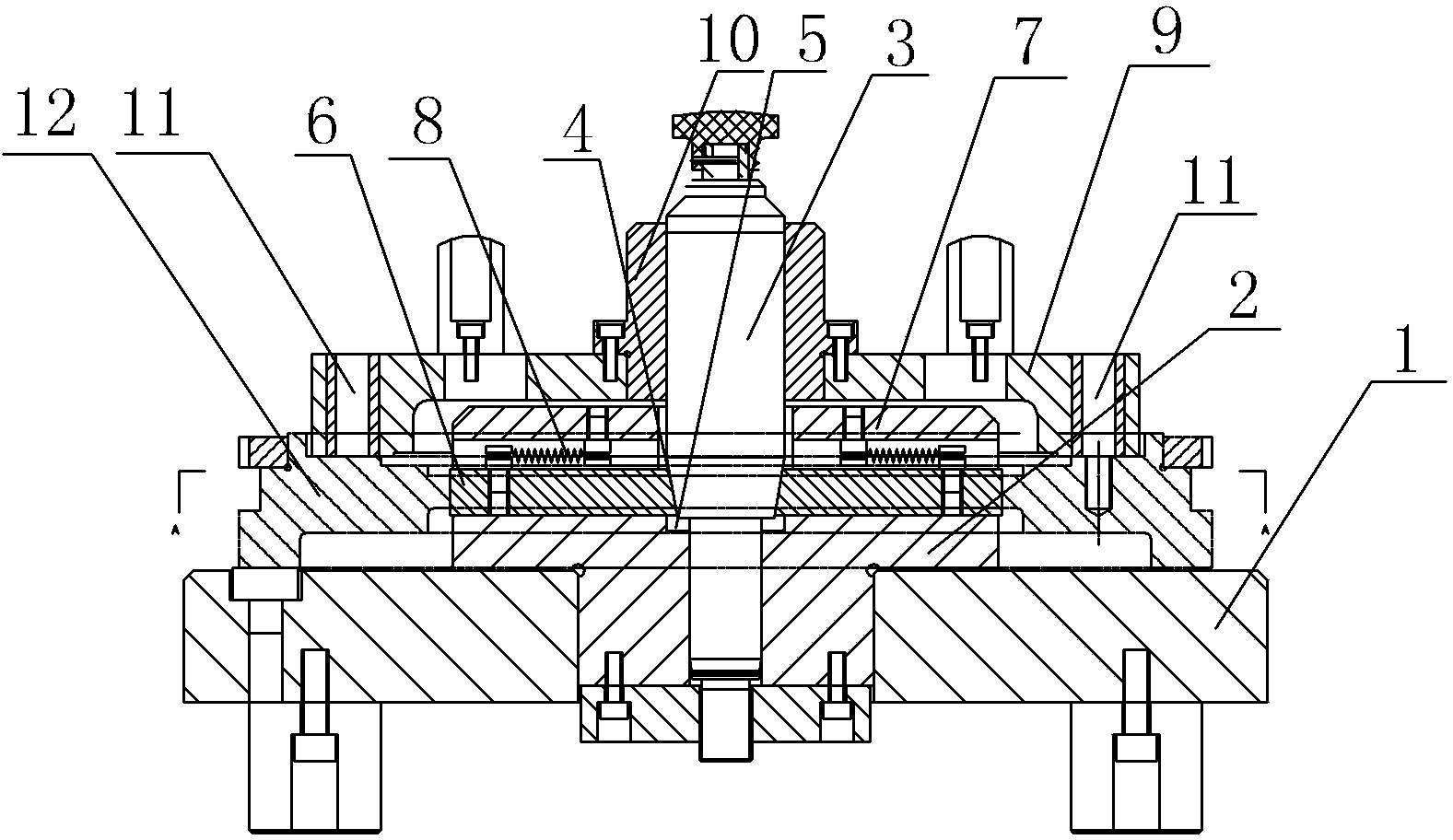

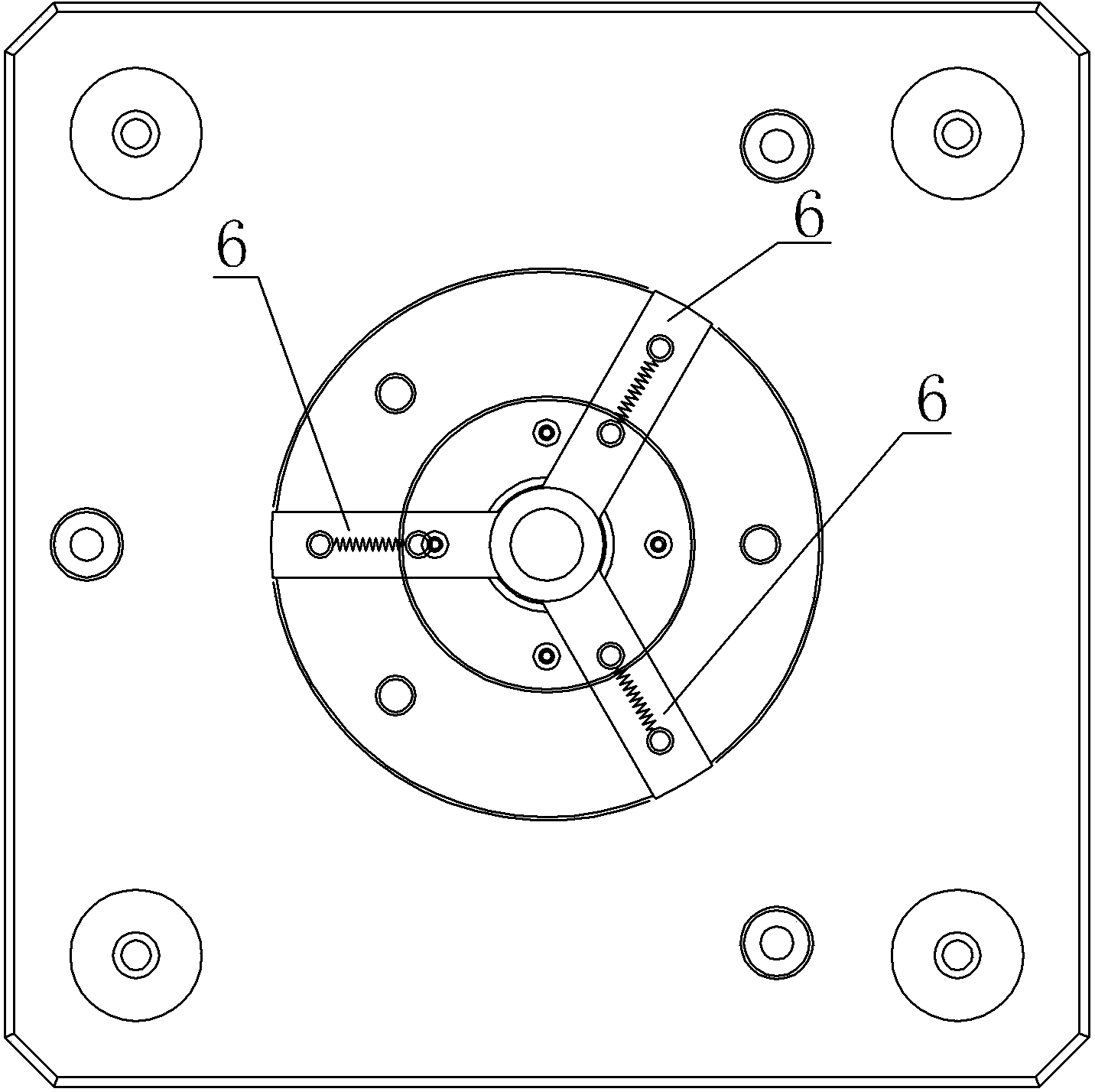

Automatic clamping device for workpieces

InactiveCN105171464AGuaranteed clamping qualityGuarantee the quality of follow-up processingPositioning apparatusMetal-working holdersEngineeringAutomation

Owner:WUXI NAIBO ROBOT TECH CO LTD

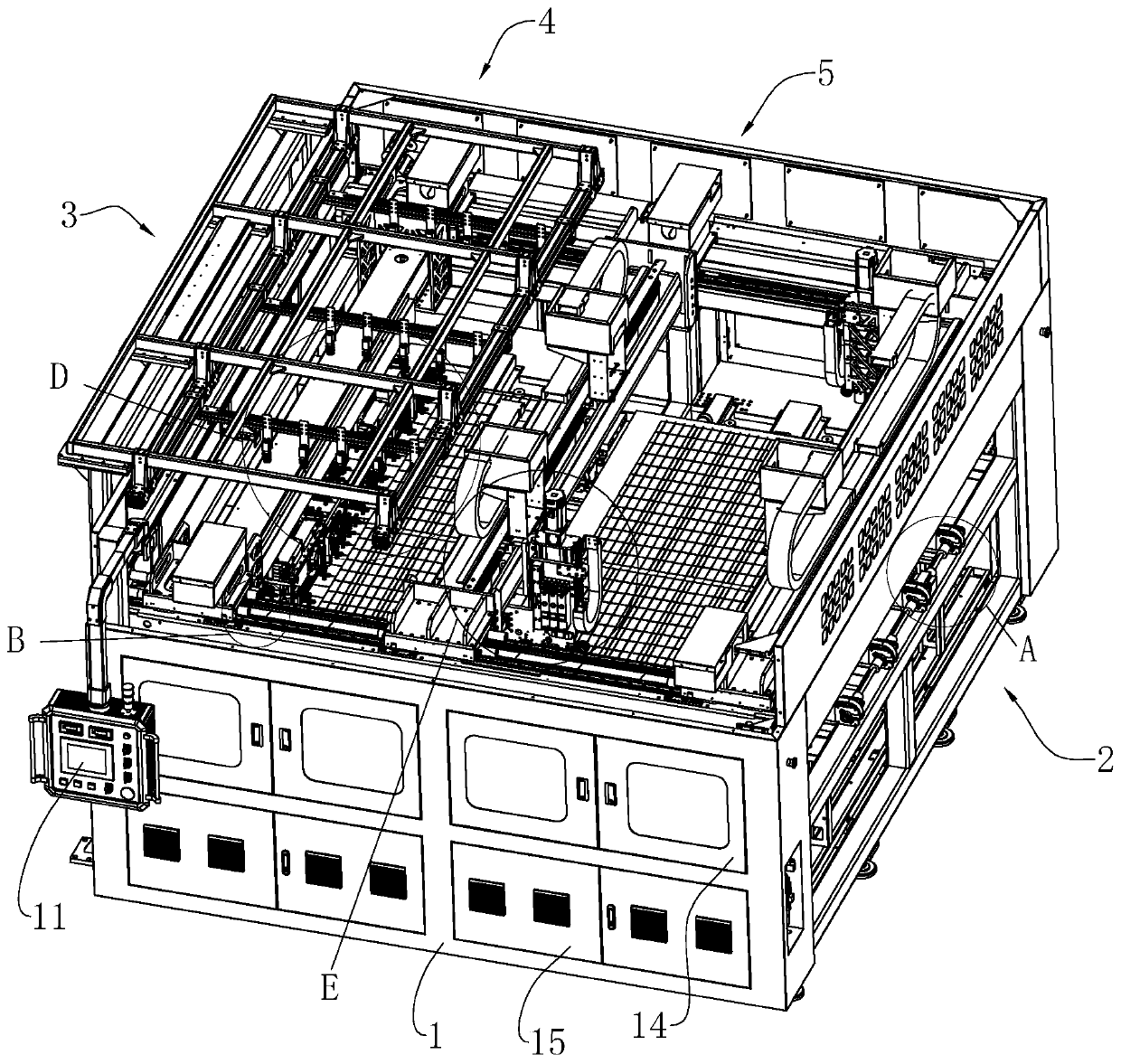

Typesetting and glue pasting device for solar battery strings

ActiveCN111086916ASmall footprintHigh adjustment accuracyElectrical componentsArticle deliveryAdhesive beltEngineering

The invention relates to a typesetting and glue pasting device for solar battery strings. The device comprises a rack, wherein a conveying mechanism for driving the battery strings to move, a detection mechanism for detecting position information of the battery strings, a deviation rectifying mechanism for placing the battery strings, a glue pasting mechanism for fixing the position of the adjacent battery strings and a controller for controlling each mechanism in the rack to act are arranged on the rack, the glue pasting mechanism comprises a glue pasting cross beam, a plurality of sets of glue pasting assemblies are arranged on the glue pasting cross beam, each glue pasting assembly comprises a material containing plate for placing high-temperature adhesive tape reels, comprises a material pasting block for finishing pasting adhesive taps and finishing pressing the adhesive tapes simultaneously, and comprises a transmission shaft for driving the material pasting block to rotate and amaterial cutting assembly for cutting the high-temperature adhesive tapes, the glue pasting mechanism simultaneously finishes the three actions of pasting the adhesive tapes, pressing the adhesive tapes and cutting the adhesive tapes, and in the rotating process of the transmission shaft, the two actions of pulling the adhesive tapes and adjusting the position of the material pasting block are finished. The typesetting and glue pasting device has the effects of being low in battery string re-typesetting rate, high in deviation rectifying and glue pasting processing efficiency of the battery strings.

Owner:SUZHOU HUIBANG AUTOMATION SYST

Solar silicon wafer centring device

PendingCN107680926AEasy accessGuarantee the quality of follow-up processingSemiconductor/solid-state device manufacturingConveyor partsElectric controlEngineering physics

The invention relates to the field of solar silicon wafer processing equipment, in particular to a solar silicon wafer centring device. According to the solar silicon wafer centring device, centring of a solar silicon wafer in the conveying process can be conveniently achieved to ensure the subsequent processing quality. The solar silicon wafer centring device comprises a conveyer belt mechanism;the solar silicon wafer centring device is characterized in that push devices are symmetrically arranged at two sides of the conveyer belt mechanism; each push device comprises a push plate; the outerside of each push plate is connected with drive air cylinders; a guide plate which is turned over outwards is arranged at one end of each push plate; and a photoelectric sensor is arranged in the middle of the conveyer belt mechanism at one side of each guide plate and is connected with the drive air cylinders through electric control.

Owner:无锡联晟光伏科技有限公司

Water-soluble wax mold forming technology

The invention relates to the technical field of complex part wax injection, in particular to a water-soluble wax mold forming technology. The surface of a produced water-soluble wax mold core is smooth and free of pocking, subsequent processing quality is guaranteed, fibers with the length equal to 3 mm are added to the wax mold raw materials, the fibers account for 1.5% of the total quantity of the wax mold raw materials, the wax mold raw materials are put into a wax vat and heated to 70-80 DEG C for wax melting, melt wax is stirred, the stirring time is 2-3 h, wax injection is conducted after stirring is completed, water-soluble wax is formed, blanking of the water-soluble wax is conducted, and the water-soluble wax mold core is formed by injecting the water-soluble wax into a mold through a wax injection nozzle.

Owner:鹰普(中国)有限公司

Film blowing equipment

The invention relates to film machining equipment, in particular to film blowing equipment. According to the technical scheme, the film blowing equipment comprises a machine body, a plastic particle charging hopper arranged on the machine body, a plastic particle heating melting device, a film blowing device, a stretching tidying device and a rolling device. The film blowing device comprises a film blowing barrel and a die. A die rod extending to the outside is arranged in the film blowing barrel and comprises a rod body connected with the film blowing barrel, and a guiding sleeve. The stretching tidying device comprises a support and a plurality of adjustable roll shafts erected on the support. The rod body is a hollow rod body and is internally provided with an air way. The rod body is provided with a plurality of air holes communicating with the inner air way of the rod body. Communicating through holes corresponding to the positions of the air holes are formed in the lower portion of the guiding sleeve, and a sealing assembly is arranged between each of the two axial ends of the guiding sleeve and the rod body. By the adoption of the above technical scheme, the film blowing equipment preventing bonding of a film and the roll shafts, preventing film damage, making film guidance stable and improving the machining quality is provided.

Owner:瑞安市铭德机械有限公司

Paying off device for cable production

InactiveCN108428515ARealize automatic tensioningGuarantee the quality of follow-up processingApparatus for feeding conductors/cablesArchitectural engineeringEngineering

Owner:安徽协创科技产业园有限公司

A kind of efficient extraction method of rice bran nutrition and active substances

ActiveCN103833786BGuarantee the quality of follow-up processingPrevent rancidityGroup 5/15 element organic compoundsFatty-oils/fats productionPhytic acidSolvent

The invention provides a high-efficiency extraction method of nutritional and active substances of rice bran. The high-efficiency extraction method comprises the following steps of 1, full-fat rice bran screening impurity-removal, 2, phytic acid extraction by immersion in an acid, 3, rice bran crude oil extraction by high-speed shearing and a complex solvent, and 4, enzyme method-based extraction of a rice bran protein. The high-efficiency extraction method can realize high-efficiency extraction of phytic acid, fat and proteins of full-fat rice bran in an order, realize high-valued complete utilization of full-fat rice bran, improve an added value and avoid resource waste.

Owner:JIANGNAN UNIV

Washing device for wirelike material

The invention provides a washing device for a wirelike material. The washing device comprises a washing barrel and a washing mechanism. The washing barrel comprises a barrel body and a barrel cover. The bottom of the barrel body is provided with a water outlet, the barrel cover is matched with a barrel body opening, and sector ring-shaped washing guide rails are symmetrically arranged on the surface of the barrel cover. The washing mechanism comprises a moving motor, washing motors and a wirelike material stirring shaft. The number of the washing motors corresponds to the number of the washing guide rails, and the washing motors are matched and installed in the washing guide rails vertically downwards. The wirelike material stirring shaft comprises a supporting shaft, a lead screw, a sliding rod and a wirelike material roller. The moving motor is installed at the position of the center of the barrel cover, a moving rod is horizontally fixed to an output shaft of the moving motor, and the two ends of the moving rod are fixed to the washing motors respectively. According to the washing device, the wirelike material is supported and stretched while the wirelike material is washed, washing efficiency of the wirelike material is greatly improved, follow-up processing quality is ensured, and the washing device is simple in structure, operates stably and is suitable for popularization.

Owner:XINCHANG JIAXIANG ELECTRONICS TECH CO LTD

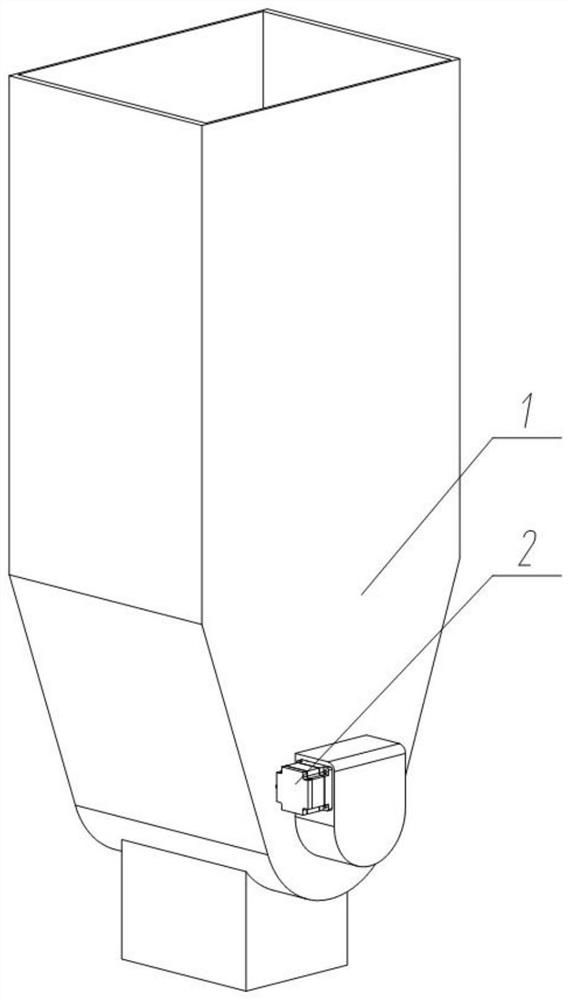

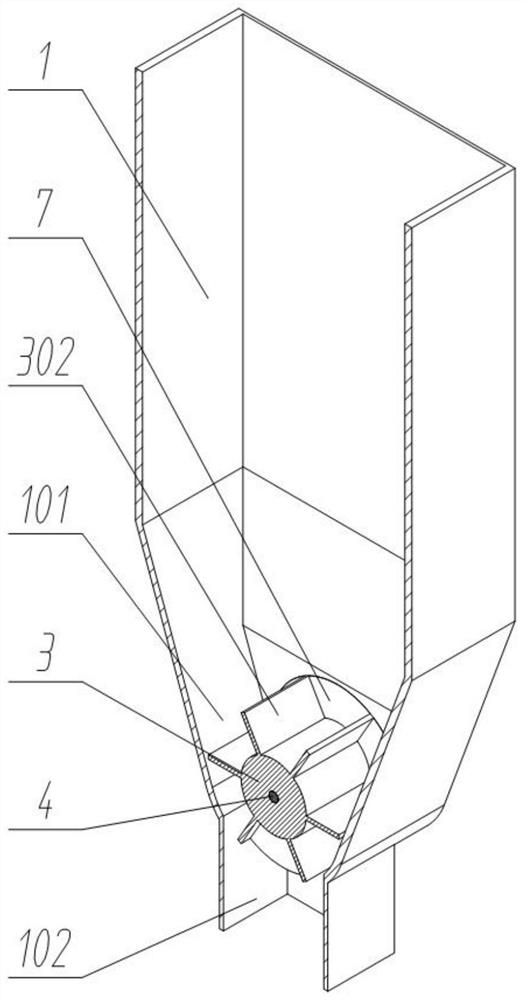

Clinker discharging device for cement production and processing

ActiveCN114684631AAvoid cloggingControl the output speedLarge containersLoading/unloadingProcess engineeringMechanical engineering

The invention provides a clinker discharging device for cement production and processing, and relates to the technical field of cement production. The discharging speed control part is rotationally connected to the lower part of the interior of the clinker discharging hopper; the discharging transmission mechanism is arranged in the right side of the clinker discharging hopper; the cleaning push plates are arranged in pairs, the six pairs of cleaning push plates are arranged, and the six pairs of cleaning push plates are distributed in a circumferential array mode and are slidably connected to the left side and the right side of the clinker discharging hopper; and the cleaning driving mechanism is arranged in the discharging speed control piece, and the discharging speed control piece drives the cleaning push plate to slide left and right through the cleaning driving mechanism. The discharging speed is effectively controlled, materials are effectively prevented from being hardened and blocking the discharging port, smooth discharging is guaranteed, the discharging speed is increased, the follow-up machining quality is guaranteed, and the problems that the discharging speed of an existing clinker bin is difficult to control, and the materials are prone to being hardened and blocking the discharging port to affect the discharging effect are solved.

Owner:GUANGYUAN GUANGWANG LUJIABA CEMENT

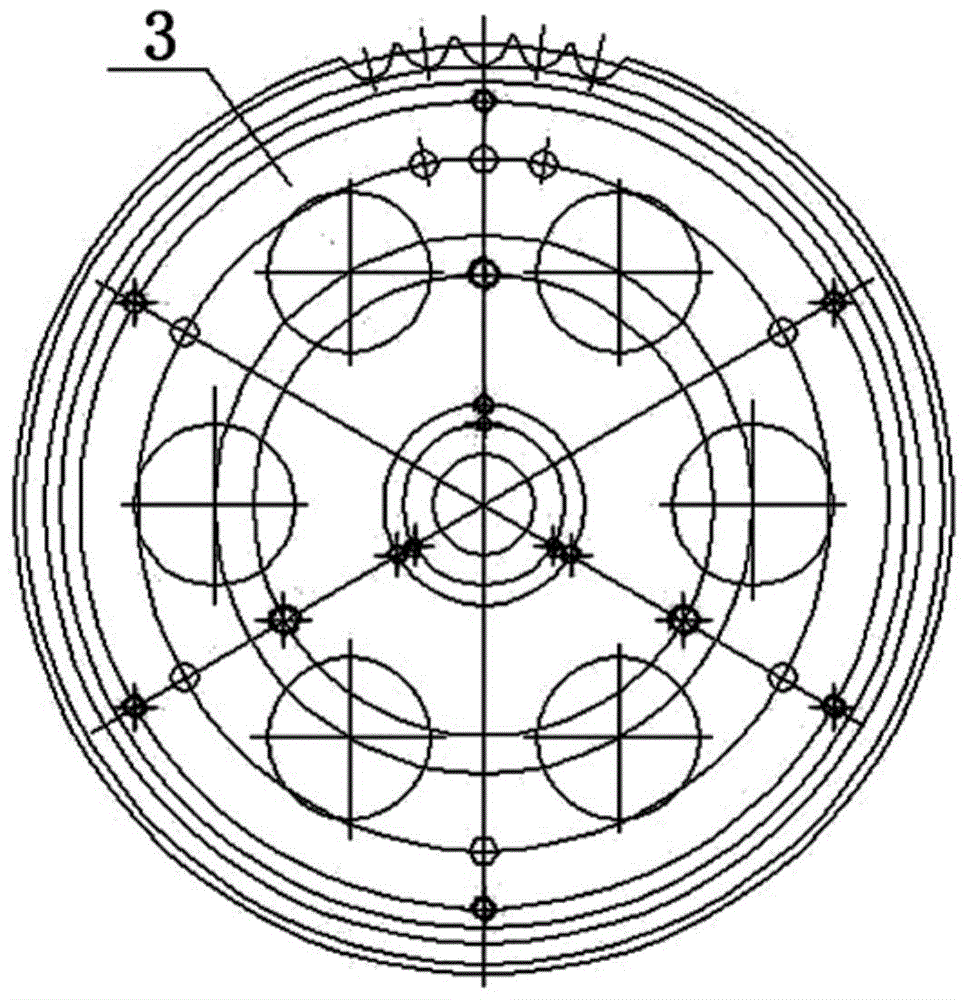

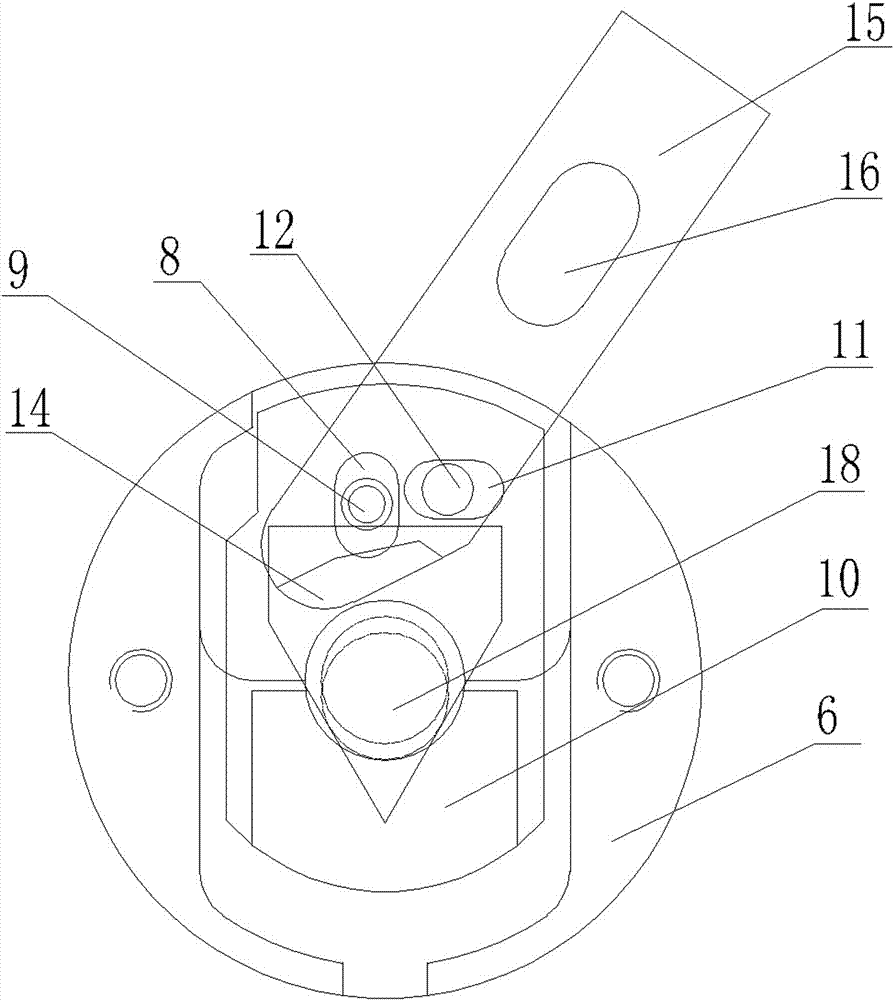

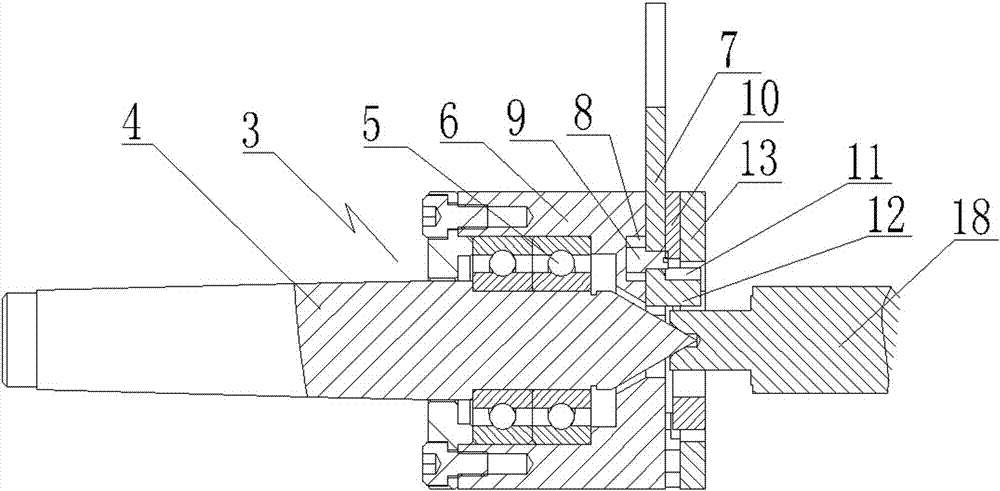

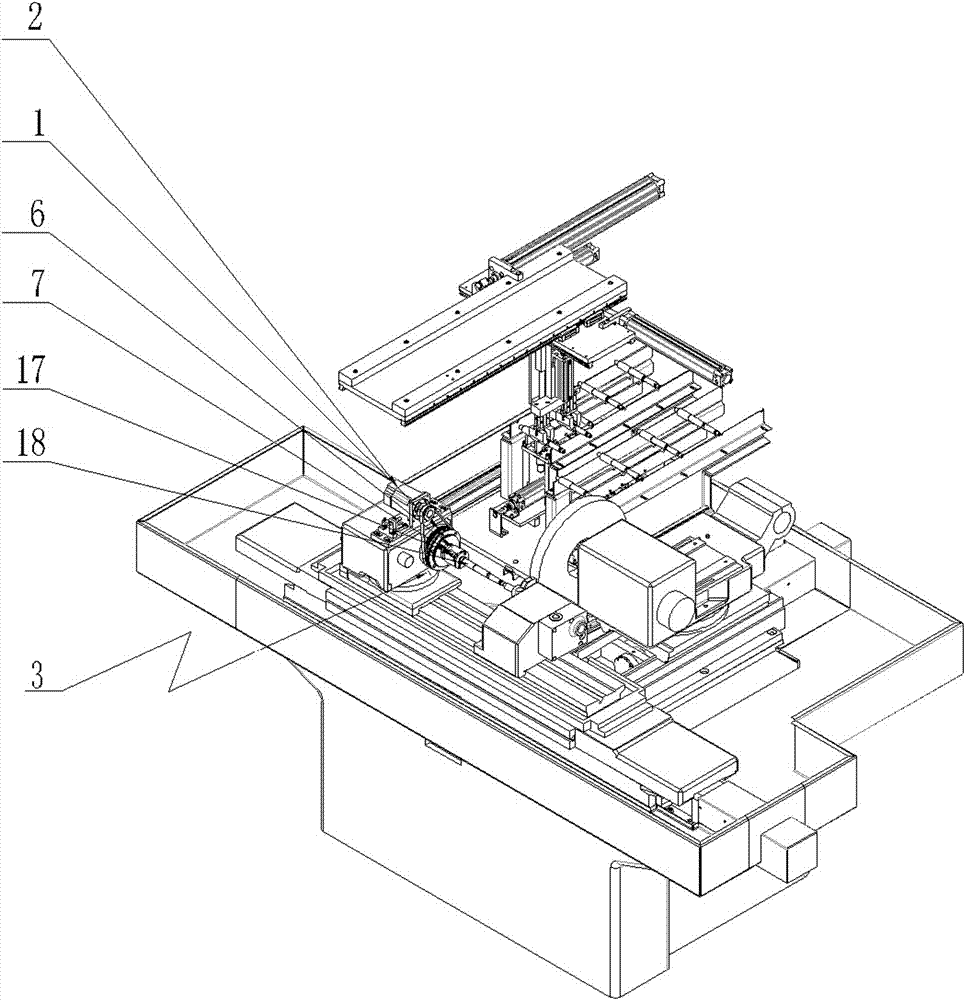

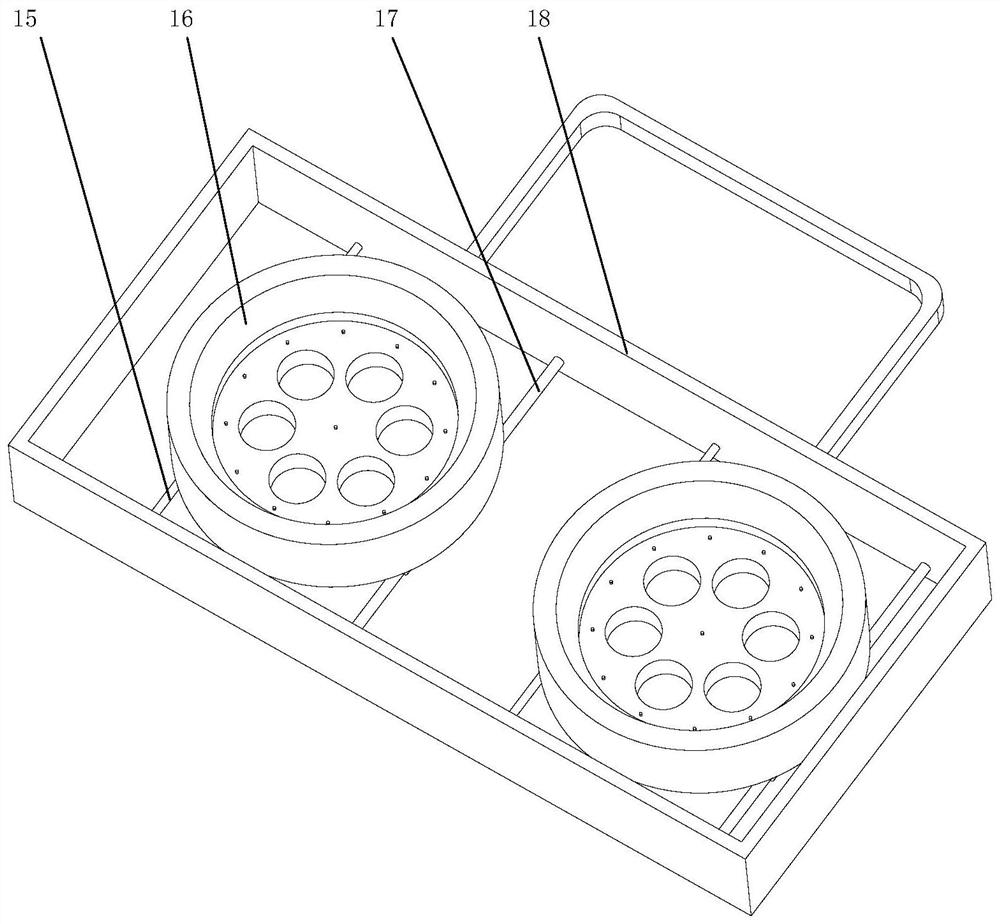

Clamp for oil atomizer body end face grinding procedure

InactiveCN104589209AIncrease the number ofSimple and fast operationGrinding work supportsEngineeringMechanical engineering

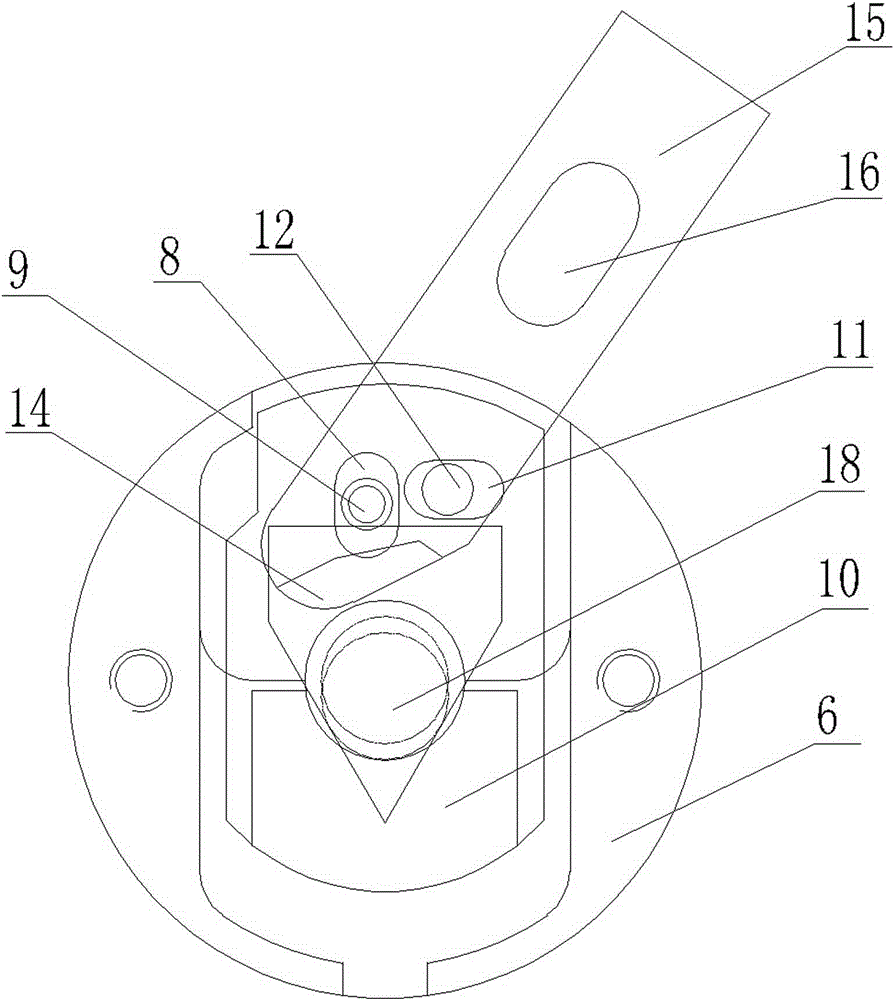

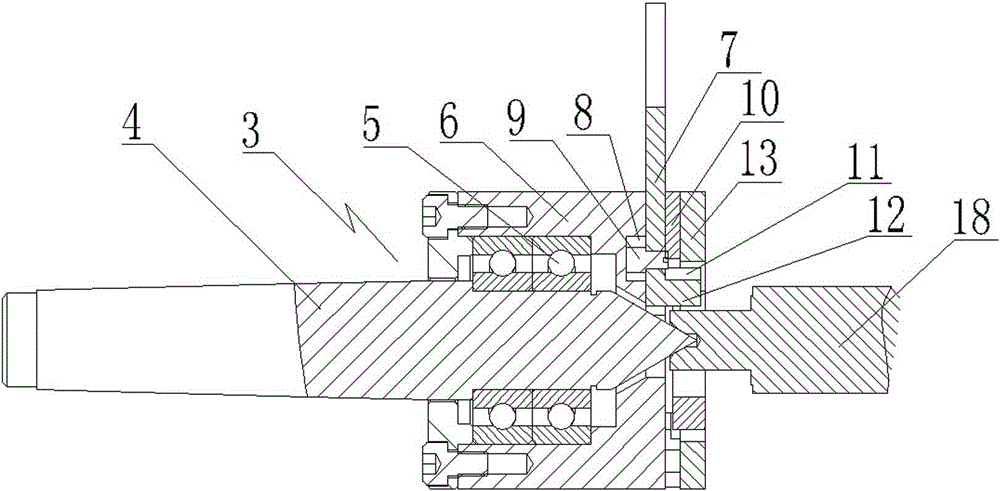

The invention discloses a clamp for an oil atomizer body end face grinding procedure. The clamp is characterized in that the clamp comprises a locating disc component, a meteor disc and a clamping component, the locating disc component comprises a locating disc and at least four short locating pins connected with the locating disc in a threaded mode, and the end faces of the short locating pins are located on the same plane; the clamping component comprises H-shaped locating bocks, first clamping bocks and second clamping blocks, and the first clamping blocks and the second clamping blocks are distributed on the two sides of the locating blocks, in a V shape and fixed on the two sides of the locating blocks through bolts. The clamp has the advantages that the mode that oil atomizer body end faces are located and the V-shaped clamping blocks are used for clamping oil atomizer bodies is adopted, locating swivel nuts are omitted, operation is more convenient, locating is more accurate, size consistency is good, the number of workpieces clamped at a time is multiplied, production efficiency is greatly improved, quality of the procedure is improved, and subsequent machining quality is better guaranteed.

Owner:YANTAI FUER PRECISION MACHINERY

An automatic molding device for rubber product processing and its use method

The invention discloses an automatic molding device for processing rubber products and a method for using the same. The right rear end of the bottom is fixedly equipped with a conveying motor whose output shaft is driven and connected with the conveying roller located at the rightmost end of the inner surface of the support through a belt. The invention is equipped with a stirring and heating mechanism, which can play the role of stirring and heating the material, so as to avoid the phenomenon of solidification of the material in the process, ensure the quality of subsequent processing, and set up a molding mechanism, which can perform injection molding on the material Processing, so as to improve its molding efficiency, set up the conveying roller, conveyor belt, belt and conveying motor, start the conveying motor, the conveying motor drives the conveying roller to rotate through the belt, and the conveying roller drives the material to move through the conveying belt, so as to achieve the purpose of feeding.

Owner:浙江橡企科技有限公司

Part carrying device with reinforcing structure for mechanical equipment manufacturing

PendingCN114377981AImplement automatic detectionConditions affecting manufacturing qualitySortingMechanical componentsMechanical equipment

The invention discloses a part carrying device used for mechanical equipment manufacturing and provided with a reinforcing structure, and relates to the technical field of mechanical equipment manufacturing, the part carrying device comprises a base and a clamping assembly, and the upper end of the base is sequentially provided with a first conveying belt, a main conveying belt and a second conveying belt from left to right; an overturning assembly used for overturning parts is distributed at the upper end of the main conveying belt, and detection assemblies used for detecting the parts are arranged in the middles of the front end and the rear end of the inner side of the overturning assembly. Through mutual cooperation of a plurality of assemblies, automatic detection, classification and carrying of mechanical parts are achieved, appearance detection work can be conducted on the carried parts, damaged and damaged parts are prevented from being assembled, parts which are detected to be unqualified can be conveyed in a classified mode, meanwhile, a very good reinforcing structure is achieved, and the production efficiency is improved. The stability of the parts in the carrying process is guaranteed, the situation that the parts fall off and are damaged is avoided, and the safety and continuity of the device in the part carrying process are guaranteed.

Owner:徐州邦克工程机械有限公司

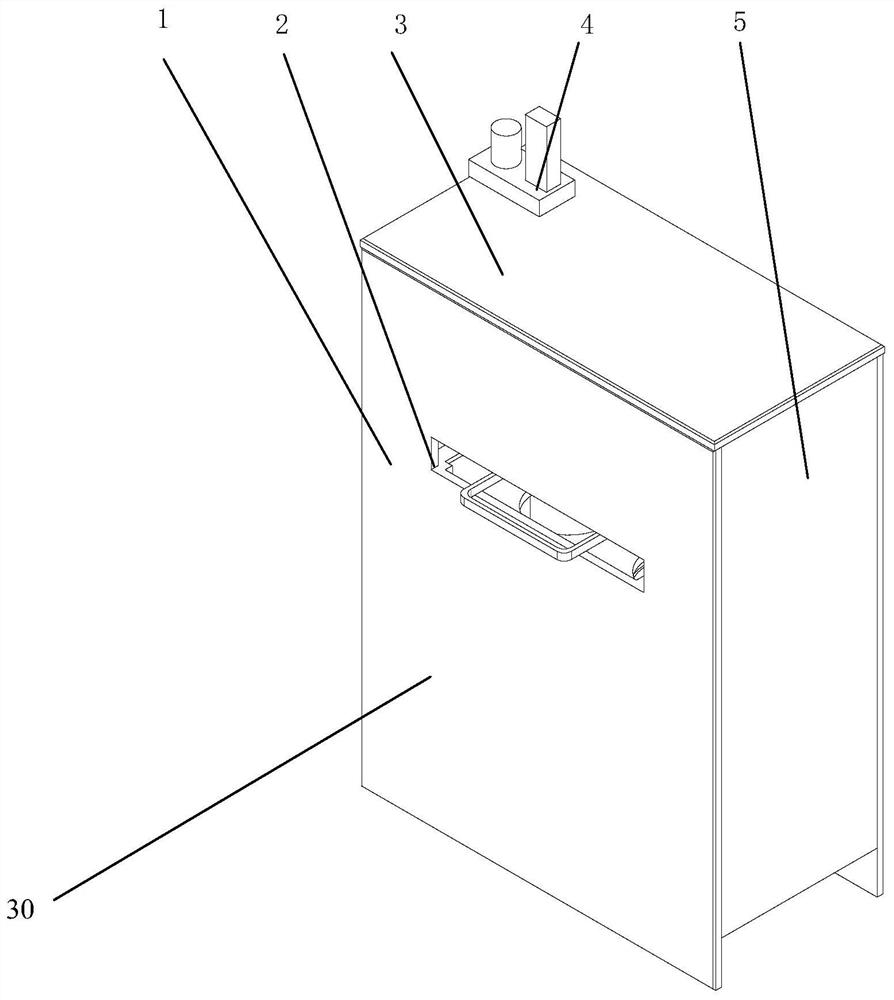

Automatic fruit ball digging device

The invention discloses an automatic fruit ball digging device. The automatic fruit ball digging device can replace a handheld manual ball digging device to carry out high-strength repetitive work, and can be applied to various fruit can production lines for fruit ball digging; the automatic fruit ball digging device comprises a shell, a forming part, a bracket mechanism and an assisting mechanism, wherein the shell comprises large side plates, small side plates and a top plate, and a working hole is formed in the shell; the forming part comprises an electric cylinder, guiding rails, a slidingframe and forming part bodies; the bracket mechanism comprises assisting rods, trays, fixed shafts and a bracket; the assisting mechanism comprises a fixed plate, hoppers, collectors and special-shape pipes. According to the automatic fruit ball digging device, the cost can be reduced, and the production efficiency is high; the automatic fruit ball digging device is simple in structure, small insize and convenient to move; further, due to automatic operation, the sanitary condition is good, it can be guaranteed that shapes of finished fruits are basically consistent, the appearance of pulpsafter ball digging is attractive, and the following processing quality of the pulps can be guaranteed.

Owner:YANSHAN UNIV

A workpiece automatic clamping device

InactiveCN105171464BGuaranteed clamping qualityGuarantee the quality of follow-up processingPositioning apparatusMetal-working holdersEngineeringAutomation

The invention provides an automatic clamping device for workpieces. Through the adoption of the clamping device disclosed by the invention, the clamping efficiency of clamping the workpieces is well improved, the automation of the workpiece clamping is realized, and besides, the clamping quality for the workpieces is also well guaranteed. The clamping device is characterized by comprising a clamping head structure, wherein the clamping head structure comprises a top; the top is connected with a base through bearings; an eccentric plate pressing assembly is movably connected to the base; a vertical long-shaped groove is formed in the base; a first pin is arranged on the eccentric plate pressing assembly; the first pin is matched with the vertical long-shaped groove; the eccentric plate pressing assembly is movably connected with a V-shaped block; a lateral long-shaped groove is formed in the V-shaped block; a second pin is arranged on the eccentric plate pressing assembly; the second pin is matched with the lateral long-shaped groove; the V-shaped block is connected with the base through a cover board; the eccentric plate pressing assembly comprises a fastening end and a driving end, wherein the fastening end is a bevel; the driving end is connected with the base; the fastening end is the bevel with a circular arc, and the driving end is connected with the base through cooperation between the long-shaped groove and the screw rod.

Owner:WUXI NAIBO ROBOT TECH CO LTD

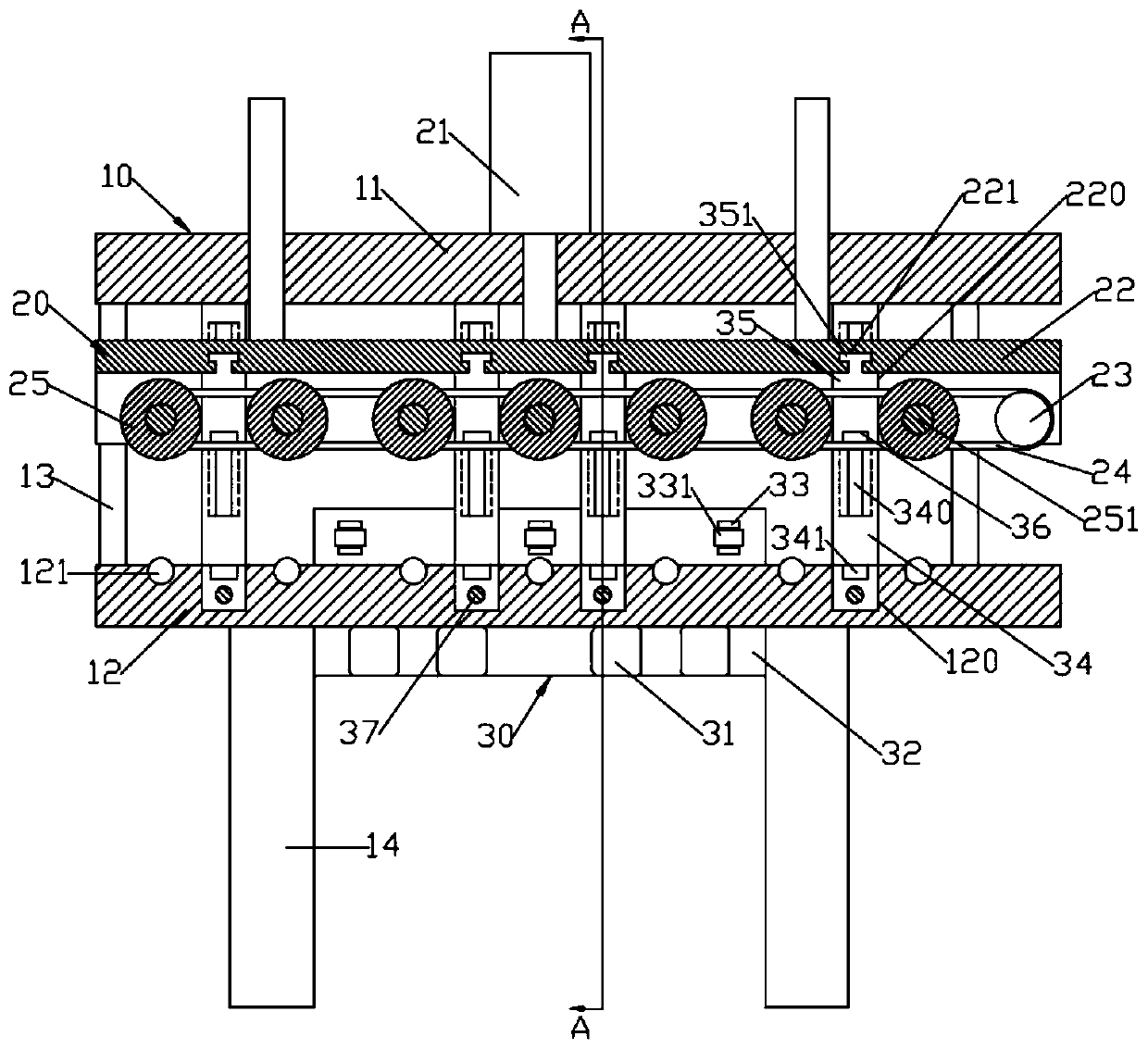

Double-end milling equipment

ActiveCN113199570ANovel structureIngenious designMulti-purpose machinesProfiling/shaping machinesEngineeringStructural engineering

The invention relates to the technical field of wood-working machinery, in particular to double-end milling equipment which comprises a left-direction milling machine rack, a right-direction milling machine rack, a bearing mechanism and a middle joist mechanism located between the left-direction milling machine rack and the right-direction milling machine rack. The left-direction milling machine rack and the right-direction milling machine rack are both arranged on the bearing mechanism; and the left-direction milling machine rack and the right-direction milling machine rack are each sequentially provided with a smashing device and a milling device in the machining direction of the left-direction milling machine rack and the right-direction milling machine rack. The double-end milling equipment is novel in structure, the middle joist mechanism is kept to be located in the middle between the left-direction milling machine rack and the right-direction milling machine rack all the time, stable conveying and supporting of plates are facilitated, and the structure is reliable; the capability of machining long-width plates and short-width plates is achieved; and when the plates pass through the equipment, the margins of the two sides and the front angle of each plate can be reduced through smashing and cutting, and the follow-up machining quality is guaranteed.

Owner:NANXING MACHINERY CO LTD

Board feeding mechanism for woodworking machinery

InactiveCN111231011ACorrect shipping directionGuarantee the quality of follow-up processingWood feeding arangementsFeeding devicesEngineeringWoodworking machinery

The invention discloses a board feeding mechanism for woodworking machinery. The mechanism comprises a rectifying device; the rectifying device comprises multiple pairs of light emitting body supportplates, multiple pairs of photoelectric sensing support plates and a pair of rectifying drive plates; the light emitting body support plates on the front and back sides approach each other or leave away from each other at the same time; light emitting bodies are mounted on the lower end surfaces of the light emitting body support plates; multiple front and back sliding grooves are formed in the upper end surfaces of upper support plates; the pair of photoelectric sensing support plates is arranged in the front and back sliding grooves in a front-back sliding manner; photoelectric sensors are mounted on the photoelectric sensing support plates; the photoelectric sensing support plates and the light emitting body support plates on the corresponding sides slide at the same time; the pair of rectifying drive plates is respectively arranged on the front and back sides of lower support plates, and approaches each other or leaves away from each other at the same time; multiple rectifying pushrods arranged in the front-back direction are formed in the approaching end surfaces of the pair of rectifying drive plates; and photoelectric sensors are used for controlling the pair of rectifyingdrive plates to approach each other or leave away from each other.

Owner:苏州超烁再生资源有限公司

An automatic fruit ball digging device

The invention discloses an automatic fruit balling device for fruit balling, which can replace a hand-held manual baller for high-intensity repetitive work and can be applied to various canned fruit production lines. The fruit poaching device according to the present invention includes a housing, a forming part, a bracket mechanism and an auxiliary mechanism. Among them, the housing includes a large side plate, a small side plate and a top plate; and, the housing is provided with a working hole; the forming part includes an electric cylinder, a guide rail, a sliding bracket and a forming part; the bracket mechanism includes an auxiliary rod, a tray, and a fixed shaft and brackets; auxiliary mechanisms include fixed plates, funnels, collectors and special-shaped pipes. The fruit ball digging device according to the present invention can save costs and has high production efficiency; the device of the present invention has a simple structure, small volume, and is convenient to move; further, due to automatic operation, the hygienic conditions are good, and it can ensure that the shape of the finished fruit is basically the same, so that The appearance of the pulp after balling is beautiful, and the subsequent processing quality of the pulp can be guaranteed.

Owner:YANSHAN UNIV

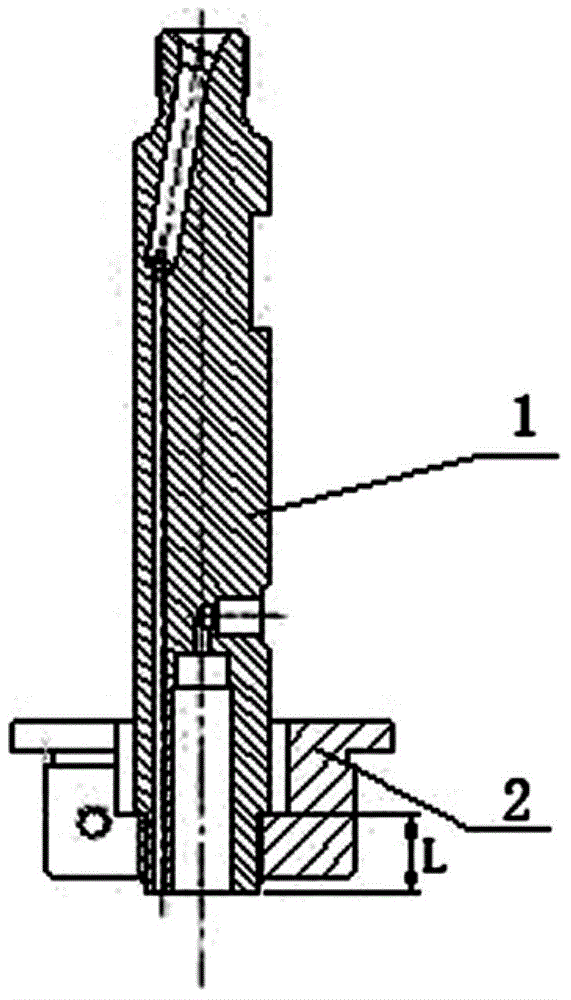

Macroporous part position accuracy detection positioner

The invention provides a macroporous part position accuracy detection positioner which can ensure the symmetry of the centers of holes, ensures position accuracy detection of the holes in a macroporous part, and ensures detection quality of a workpiece, thereby ensuring subsequent processing quality of the workpiece. The positioner is characterized by comprising a base plate. A flange is sleeved on the base plate; a positioning column moving up and down is sleeved on the flange; the positioning column comprises a cone column structure; the upper end, which is corresponding to the cone column structure, of the flange is uniformly provided with slide blocks; the upper ends of the slide blocks are provided with a cover plate; the cover plate is sleeved on the positioning column; the slide blocks are connected with the cover plate through an extension spring; the cover plate is provided with a template; and the template is sleeved on the positioning column.

Owner:MT PRECISION MACHINERY MFG

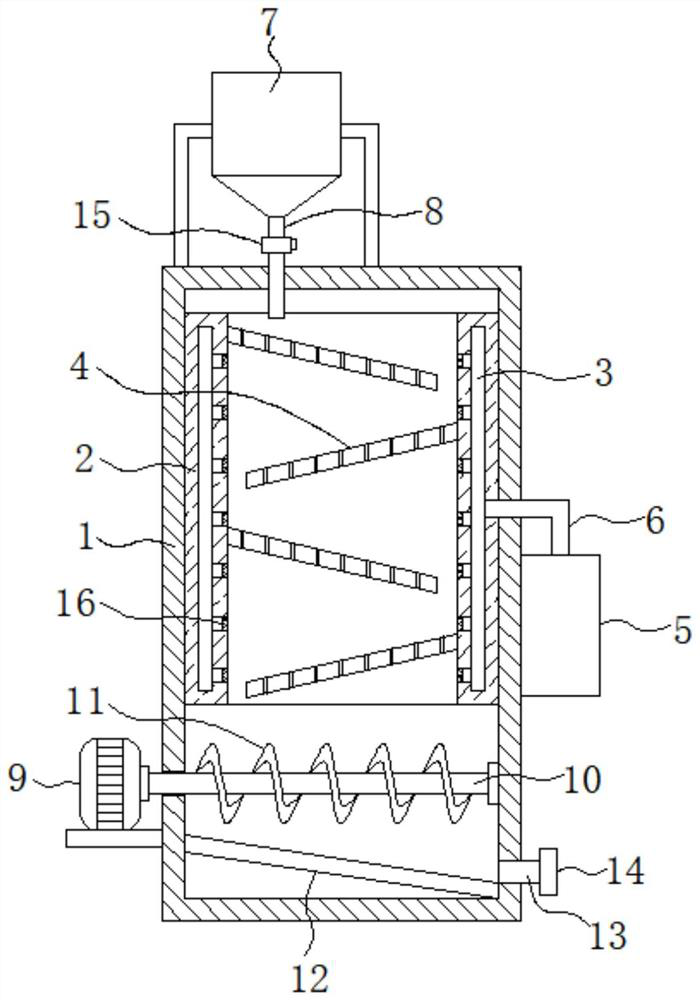

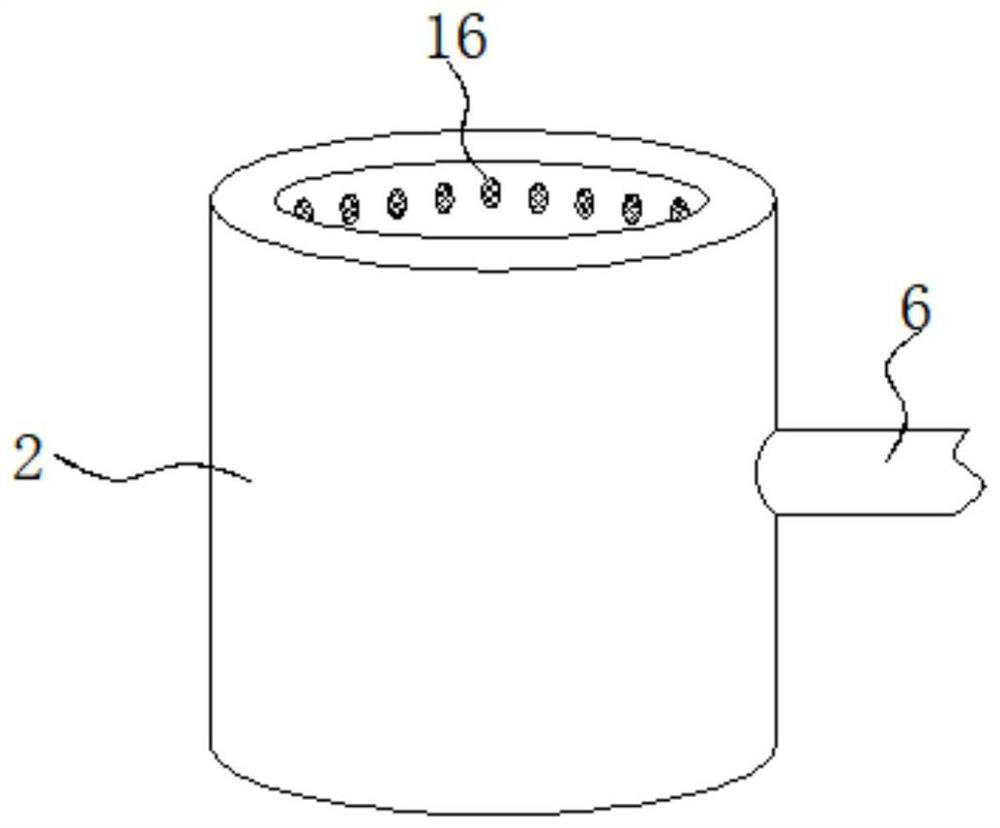

Drying device for tea oil processing pretreatment

InactiveCN112284116AEasy to dryExtension of timeDrying gas arrangementsDrying chambers/containersOil processingThermodynamics

The invention relates to the technical field of tea oil processing, and discloses a drying device for tea oil processing pretreatment. The drying device comprises a drying box, a drying cylinder withopenings formed in the two ends is fixedly connected into the drying box, an air guide cavity is formed in the cylinder wall of the drying cylinder, and a plurality of evenly-distributed air outlet holes are formed in the inner cylinder wall of the drying cylinder and communicate with the air guide cavity. A plurality of flow slowing plates which are evenly distributed in a staggered mode are fixedly connected to the inner wall of the drying cylinder, an air heater is fixedly installed on the outer side wall of the drying box, the output end of the air heater fixedly communicates with a hot air pipe, and the other end of the hot air pipe penetrates through the side wall of the drying box and fixedly communicates with the air guide cavity. A secondary drying mechanism is installed at the position, close to the bottom end, of the drying box, and a hopper is fixedly installed at the top of the drying box through a support. According to the drying device, multi-stage comprehensive and uniform drying treatment is conveniently conducted on tea oil seeds, the drying effect is effectively guaranteed, and therefore the subsequent processing quality of tea oil is guaranteed.

Owner:贵州大亨油茶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com