Film blowing equipment

A technology of equipment and film cylinder, applied in the field of film blowing equipment, can solve problems such as film damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

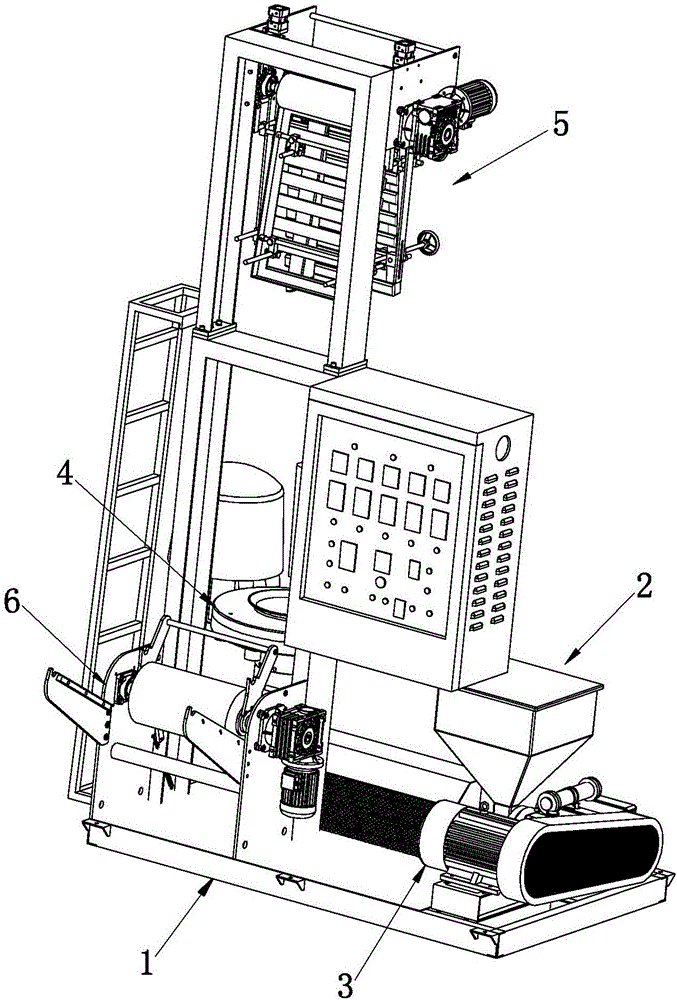

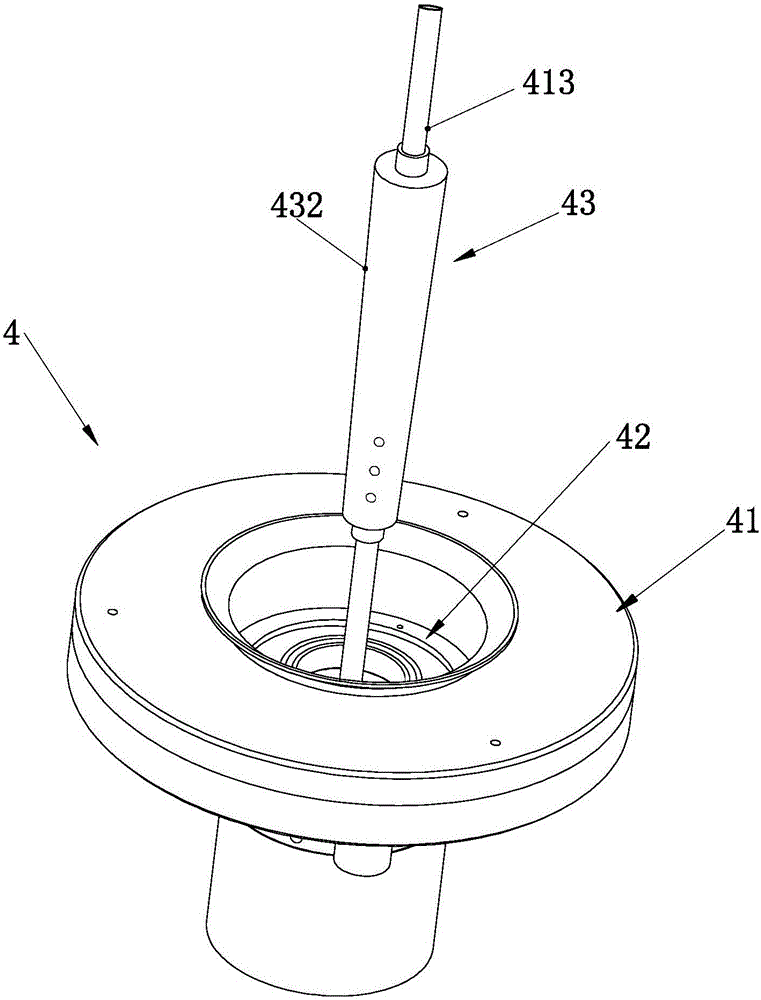

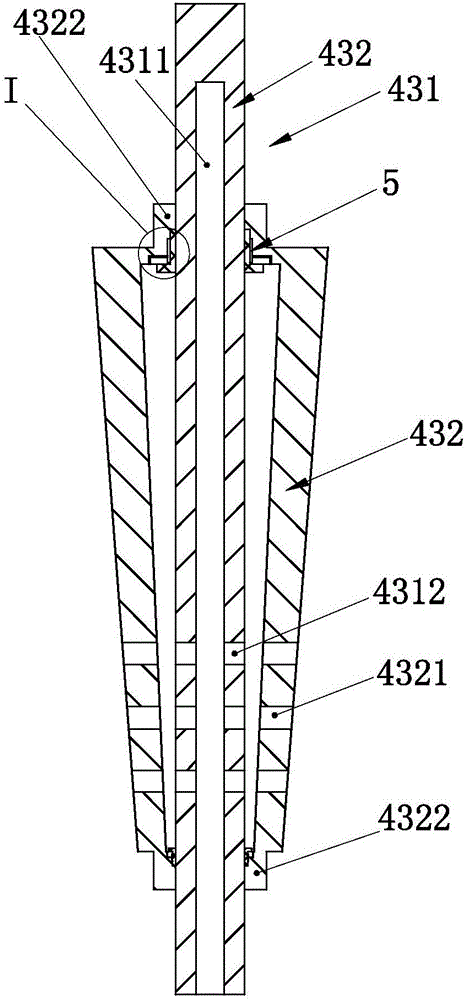

[0026] like figure 1 — Figure 8 The blown film equipment shown includes an organism 1, a plastic particle feeding hopper 2 arranged on the body 1, a plastic particle heating and melting device 3 connected with the plastic particle feeding hopper 2, and a blowing device connected with the plastic particle heating and melting device 3. The film device 4, the stretching finishing device 5 connected with the blown film device 4 and the winding device 6 connected with the stretching finishing device 5, the blown film device 4 includes a blown film cylinder 41 and a mold located in the blown film cylinder 41 42. The film blowing cylinder 41 is provided with a mold rod 43 extending to the outside. The mold rod 43 includes a rod body 431 connected to the blowing mold cylinder 41 and a guide sleeve 432 sleeved outside the rod body 431. The stretching finishing device 5 includes Support 51, some adjustable roller shafts erected on the support 51, the rod body 431 is a hollow rod body,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com