Printing and dyeing cloth anti-wrinkling rapid drying device

A technology of fast drying and cloth feeding device, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of low drying efficiency, slow drying speed, poor practicability, etc., to improve drying efficiency, Improve cloth quality and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

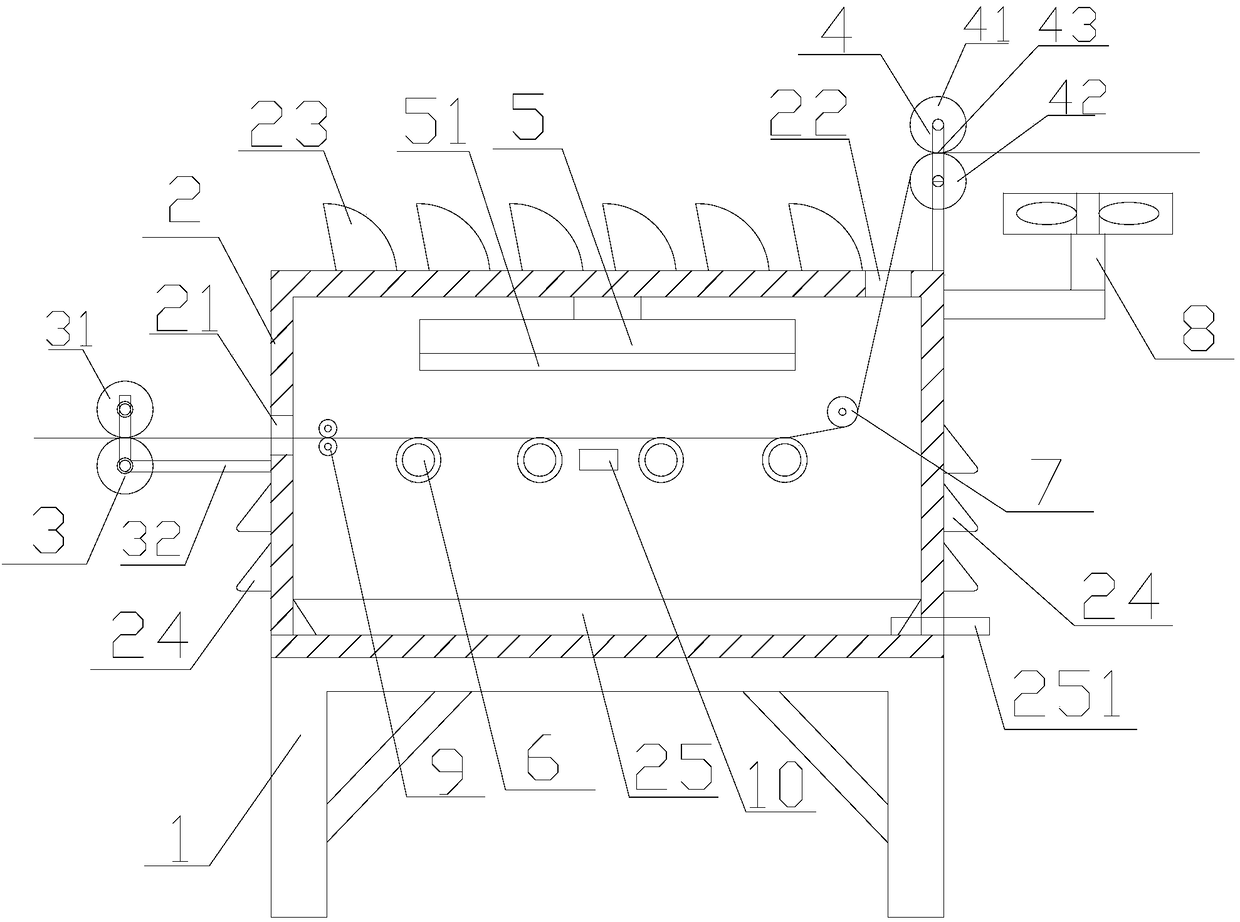

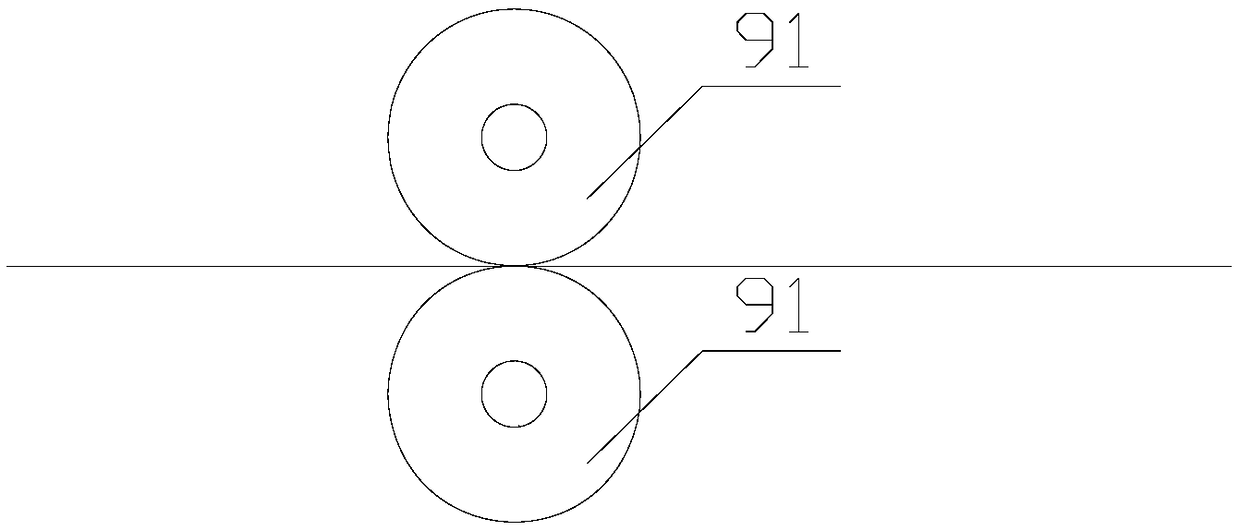

[0017] refer to figure 1 and figure 2 , an anti-wrinkle fast drying device for printed and dyed cloth of the present invention, comprising a frame 1, a drying box body 2, a cloth feeding device 3, a cloth discharging device 4, a drying fan 5, a heating rod 6, a cloth guide roller 7, a heat dissipation Fan 8, the upper end of the frame 1 is provided with a drying box 2, the drying box 2 is detachably connected with the frame 1, and the left side of the drying box 2 is provided with a cloth feeding device 3 , the drying box 2 is provided with a cloth inlet 21 that cooperates with the cloth feeding device 3, and the drying box 2 is provided with a drying fan 5, and the drying fan 5 is connected with the drying The top of the inner wall of the box body 2 is connected, and a number of heating rods 6 are evenly arranged in the drying box body 2. There are gaps between the heating rods 6, and guides are provided on the right side of the heating rods 6. Cloth roller 7, the top righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com