Patents

Literature

206 results about "Particle charge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

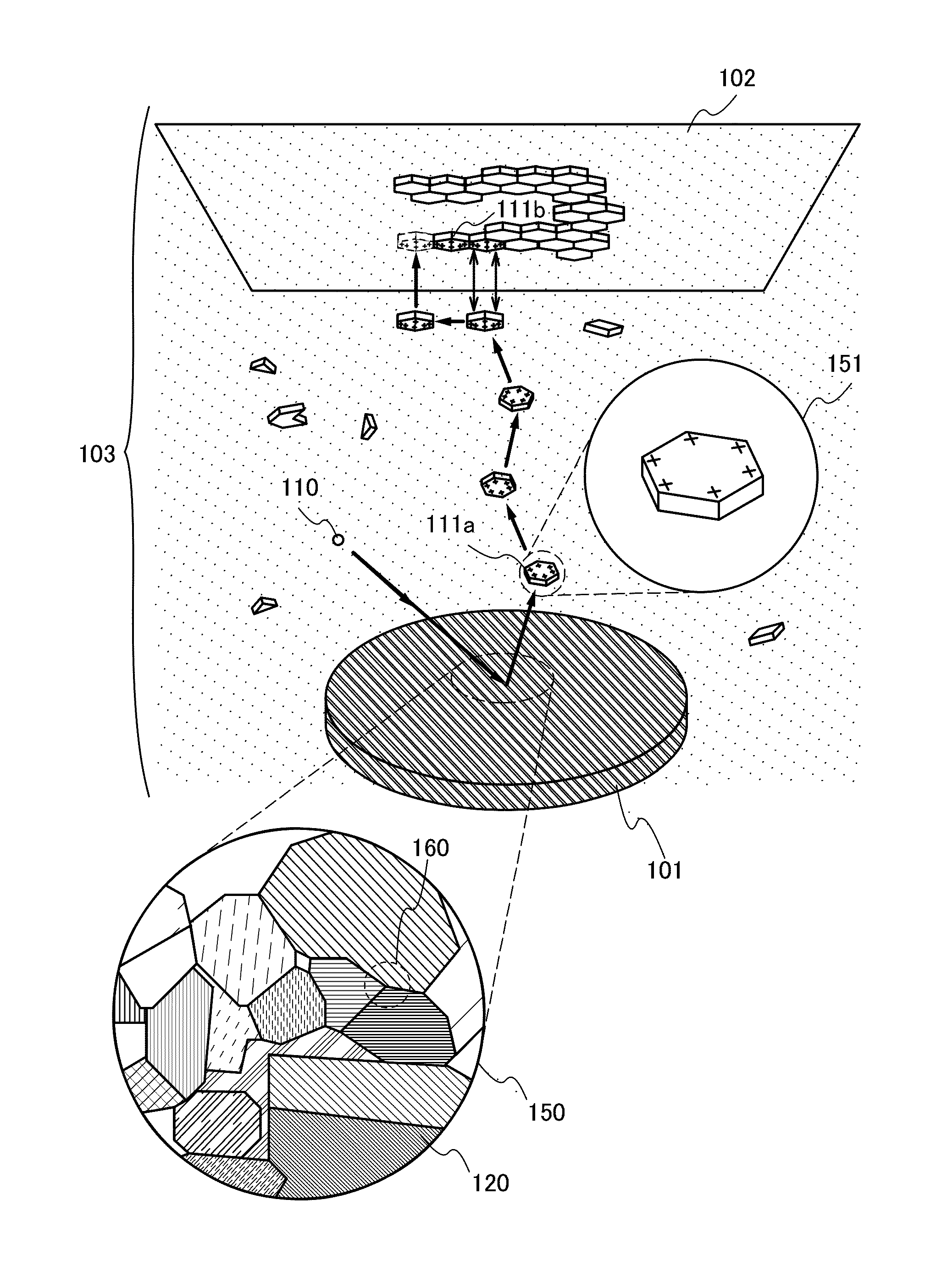

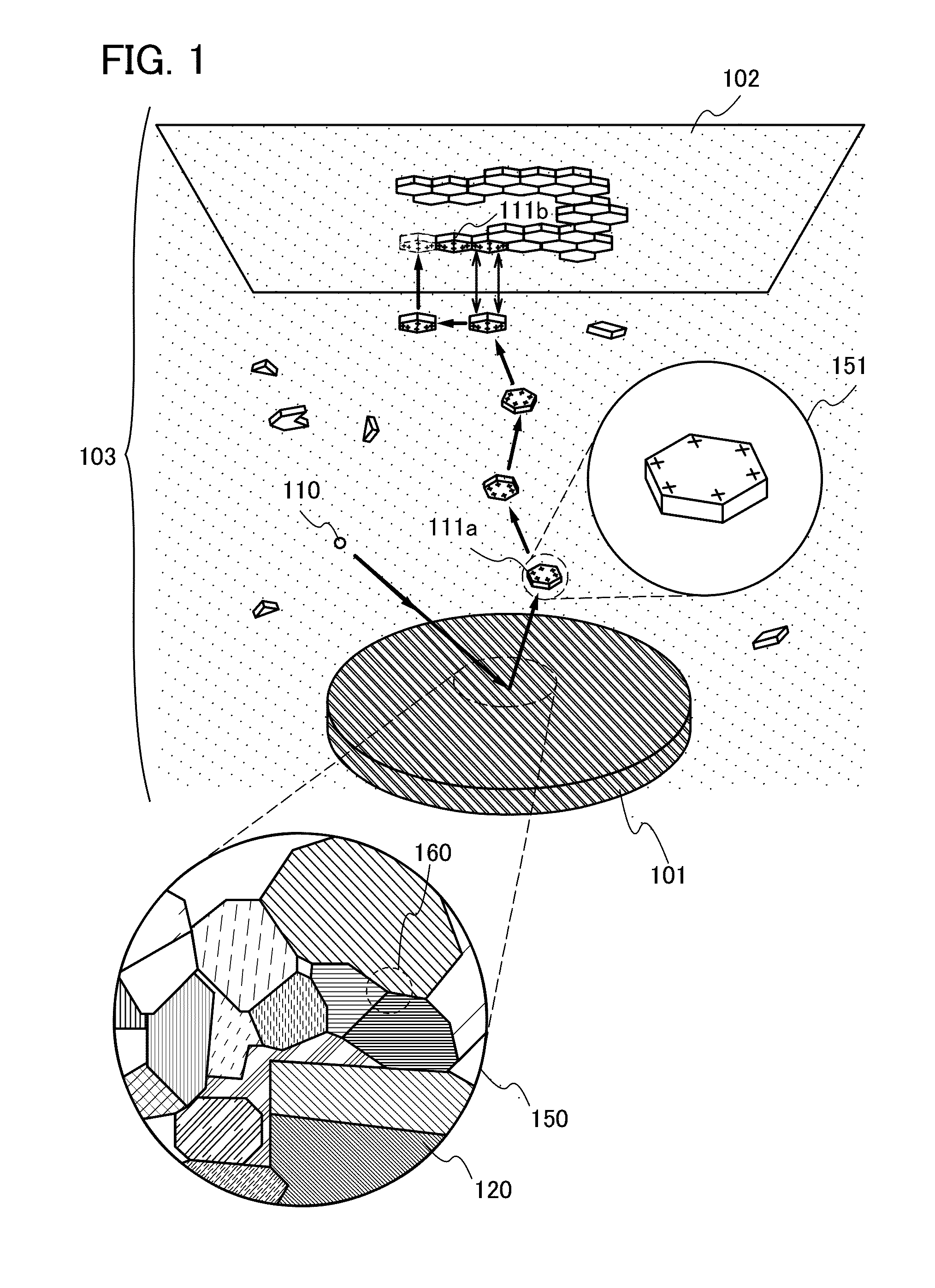

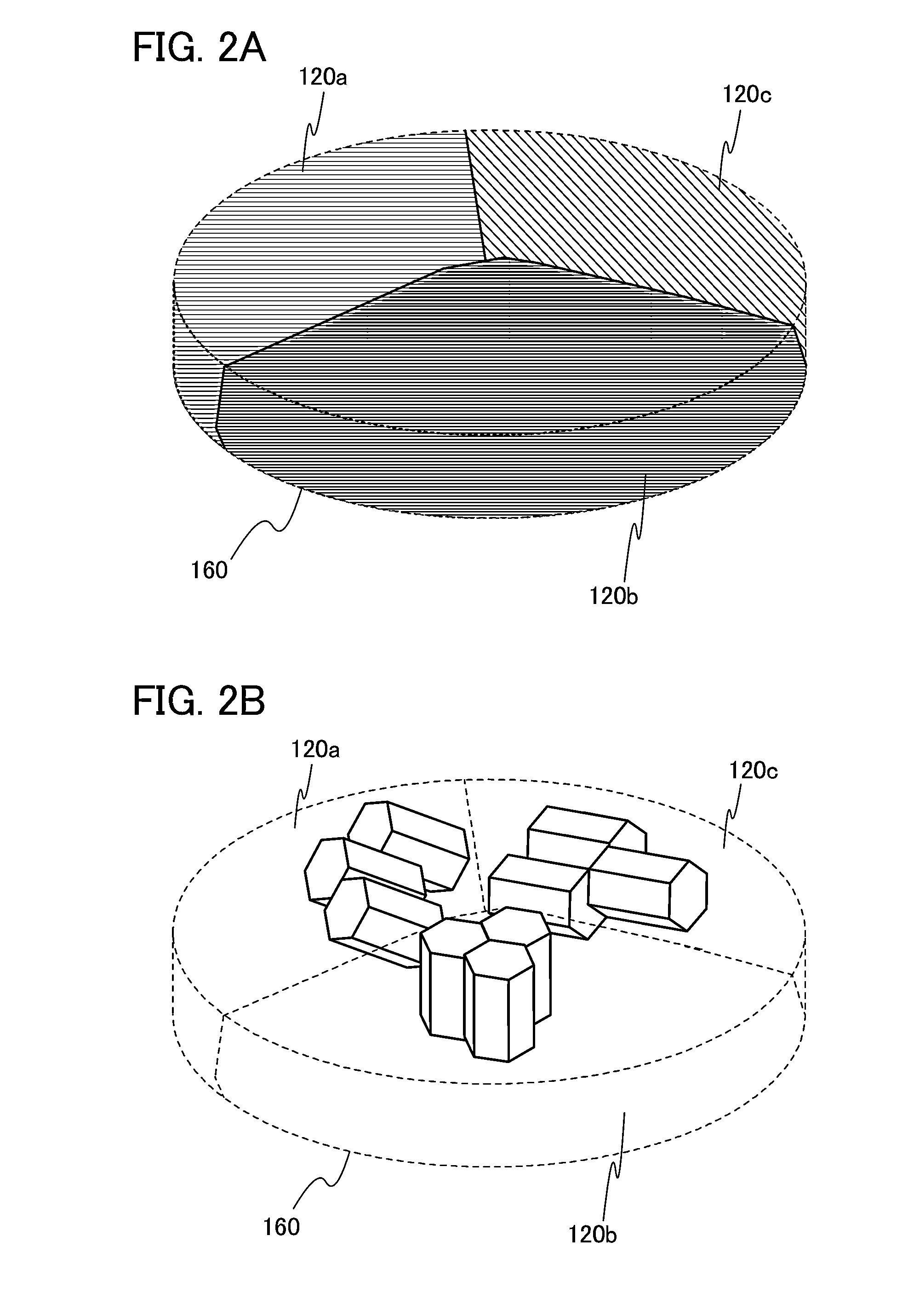

Method for using sputtering target and method for manufacturing oxide film

InactiveUS20140102877A1Favorable transistor characteristicImprove long-term reliabilityPolycrystalline material growthSolid-state devicesMaterials scienceInert gas

A plasma space containing an ionized inert gas is formed in contact with a deposition surface and a surface of a sputtering target containing a polycrystalline oxide including a plurality of crystal grains with randomly oriented c-axes. A flat-plate-like sputtered particle is separated from a cleavage plane corresponding to a-b planes of the plurality of crystal grains by collision of the ionized inert gas with the surface of the sputtering target. The flat-plate-like sputtered particle is transferred to the deposition surface through the plasma space with its flat-plate-like shape substantially maintained. The flat-plate-like sputtered particle and another flat-plate-like sputtered particle charged with the same polarity repel each other and are deposited on the deposition surface so as to be adjacent to each other on a plane such that the c-axes are substantially perpendicular to the deposition surface.

Owner:SEMICON ENERGY LAB CO LTD

Preparation and application of high-efficiency paint mist coagulant

InactiveCN102351286ALow costSimple processWater/sewage treatment by flocculation/precipitationAnti-Adhesion AgentSewage discharge

The invention relates to a paint mist coagulant. The paint mist coagulant has good anti-adhesion and coagulation effects on water-soluble and fat-soluble paints and is particularly applied to circulating water treatment of a wet paint mist removing system. The paint mist coagulant comprises an anti-adhesion agent A, a flotation agent B and a regulator C which are used simultaneously, wherein the anti-adhesion agent A is formed by combining water-soluble quaternary ammonium cationic polymer, amphoteric metal salt or polymer of the amphoteric metal salt, and a surfactant, has high electrical neutralization property, can quickly neutralize paint particle charges, and coats paint particles to make the viscosity of the paint particles lost; the flotation agent B is anionic polymer with the molecular weight of 8,000,000 to 25,000,000, has a strong coagulation effect, and can aggregate the paint particles of which the viscosity is lost; and the regulator C is used for regulating the pH of circulating water, controls the pH value of the circulating water to be between 7 and 10 commonly, and has small using amount. The paint mist coagulant is low in price, the process is stable, the total sewage discharge amount is small, and continuous production can be ensured.

Owner:YANCHENG INST OF TECH

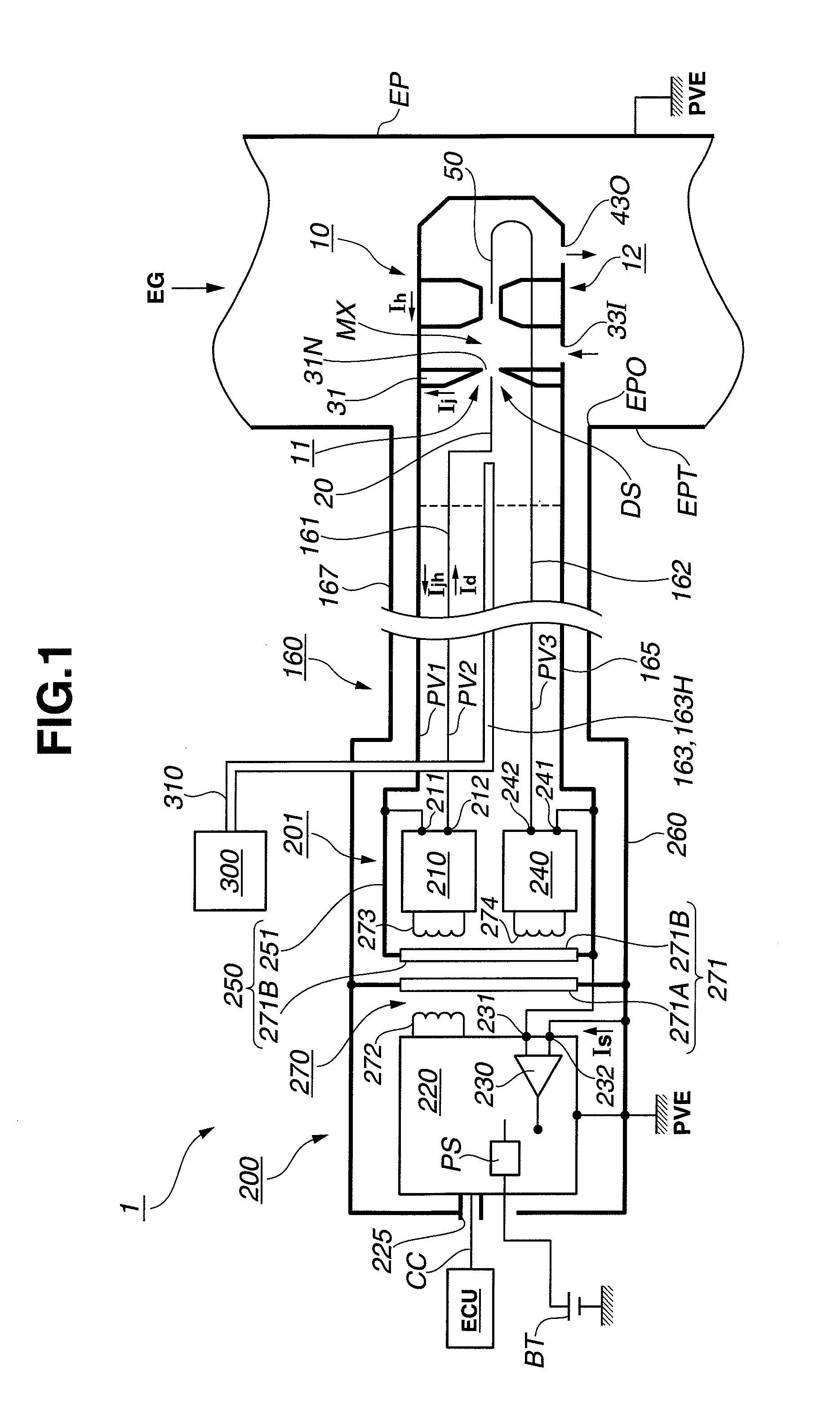

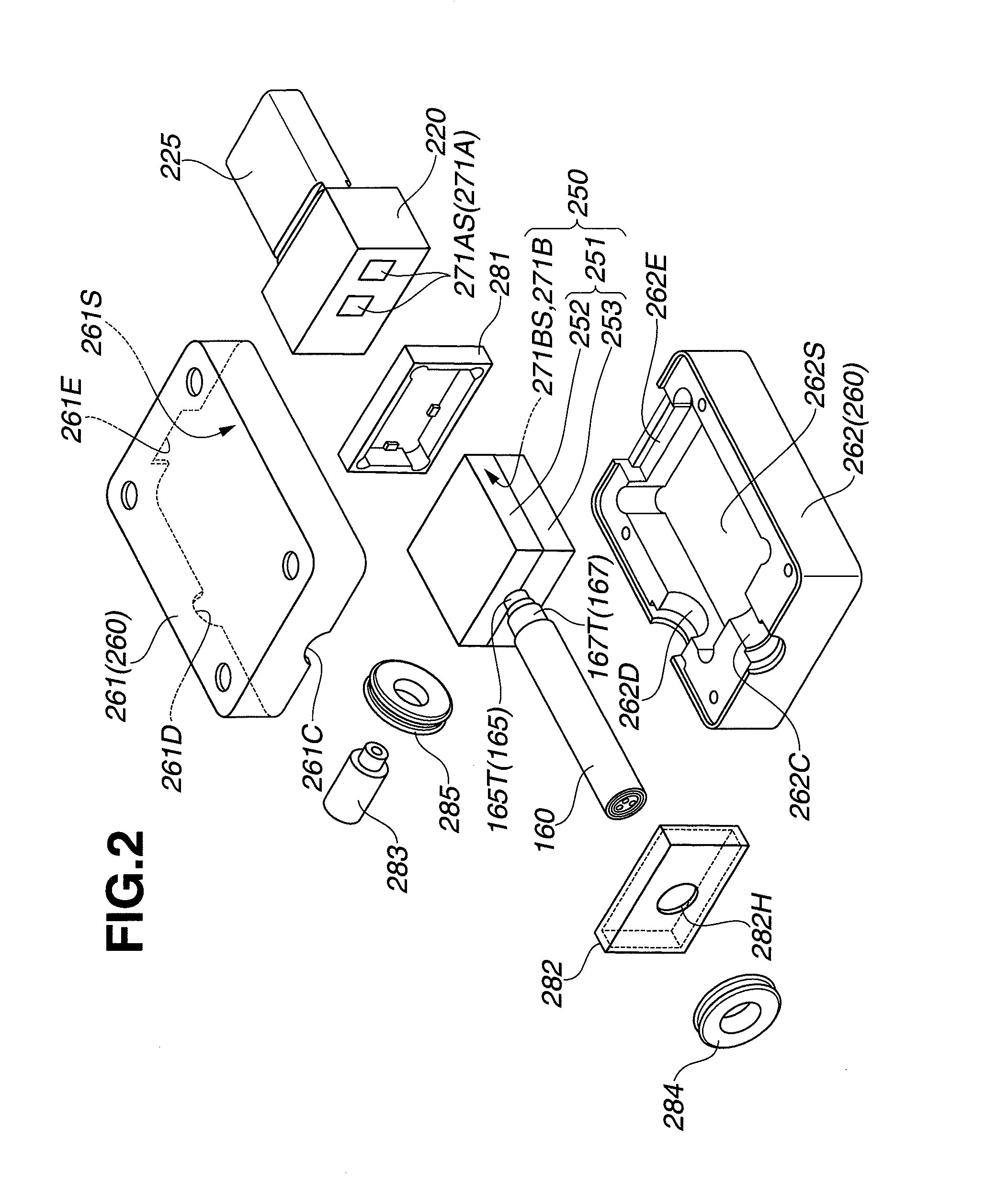

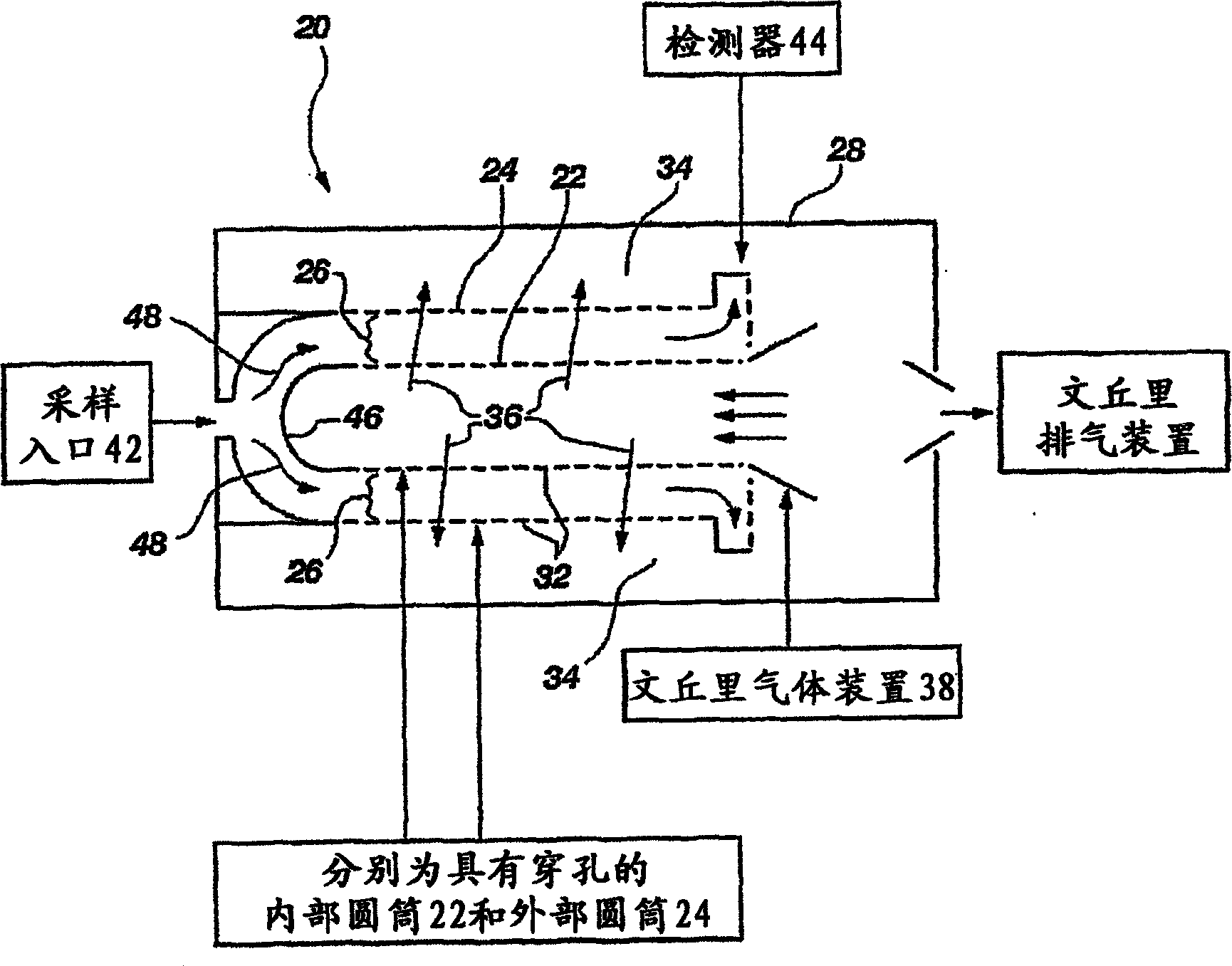

Fine particle detection system

ActiveUS20120262182A1Reduce intensityAccurate detectionExhaust apparatusMaterial analysis by electric/magnetic meansElectricityPower flow

There is provided a fine particle detection system with a fine particle sensor, a cable and a sensor drive control device. The fine particle sensor has an ion source unit with first and second electrodes, a particle charging unit and inner and outer sensor casings. The cable has a power supply wiring line connected to the second electrode, an inner shield line electrically continuous with the inner sensor casing and an outer shield line electrically continuous with the outer sensor casing. The sensor drive control device has an ion-source power supply circuit, a signal current detection circuit, an inner circuit casing electrically continuous with a first output terminal of the ion-source power supply circuit and surrounding the ion-source power supply circuit and an outer circuit casing connected to the ground potential and shielding the ion-source power supply circuit, the signal current detection circuit and the inner circuit casing.

Owner:NGK SPARK PLUG CO LTD

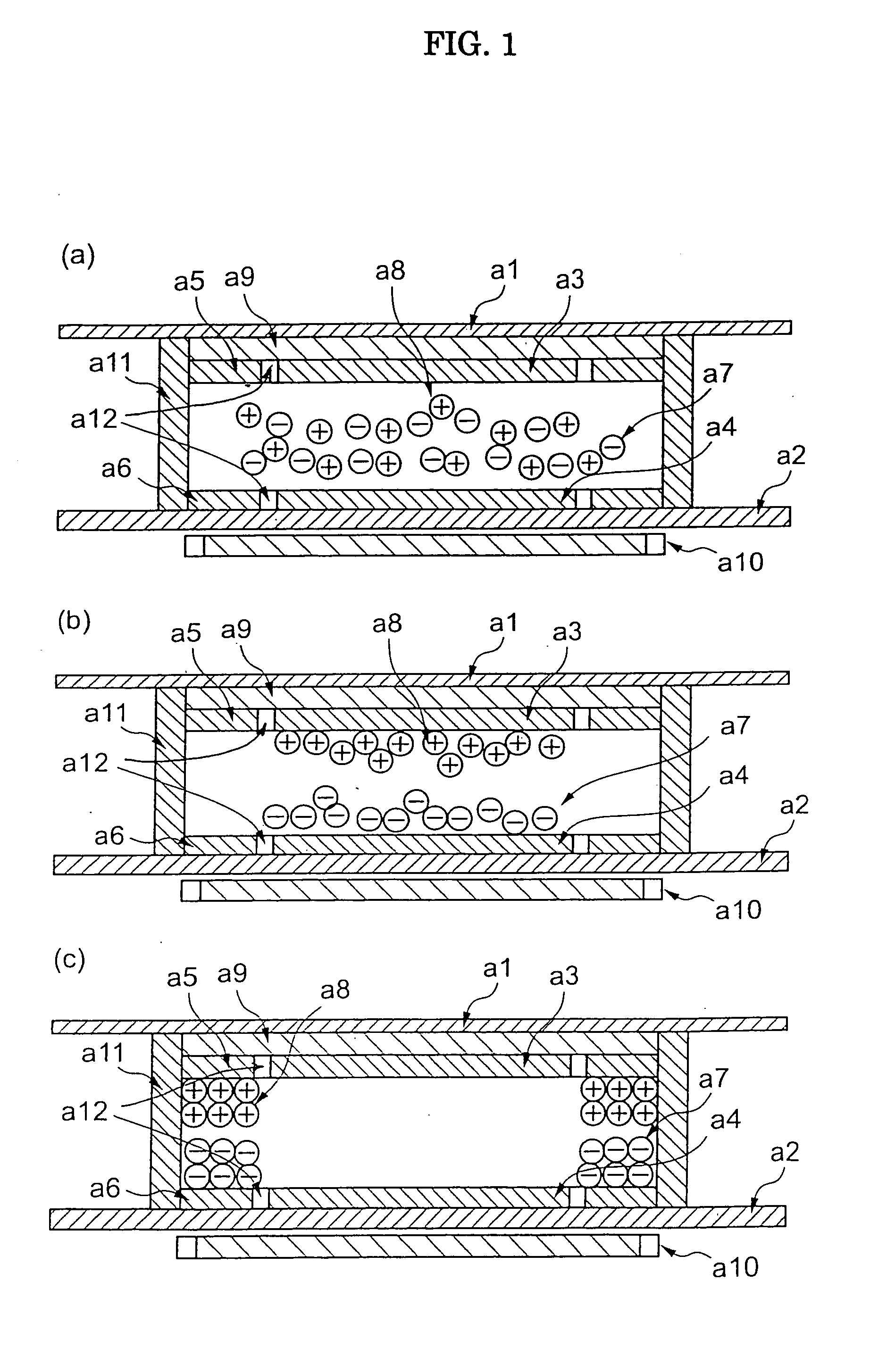

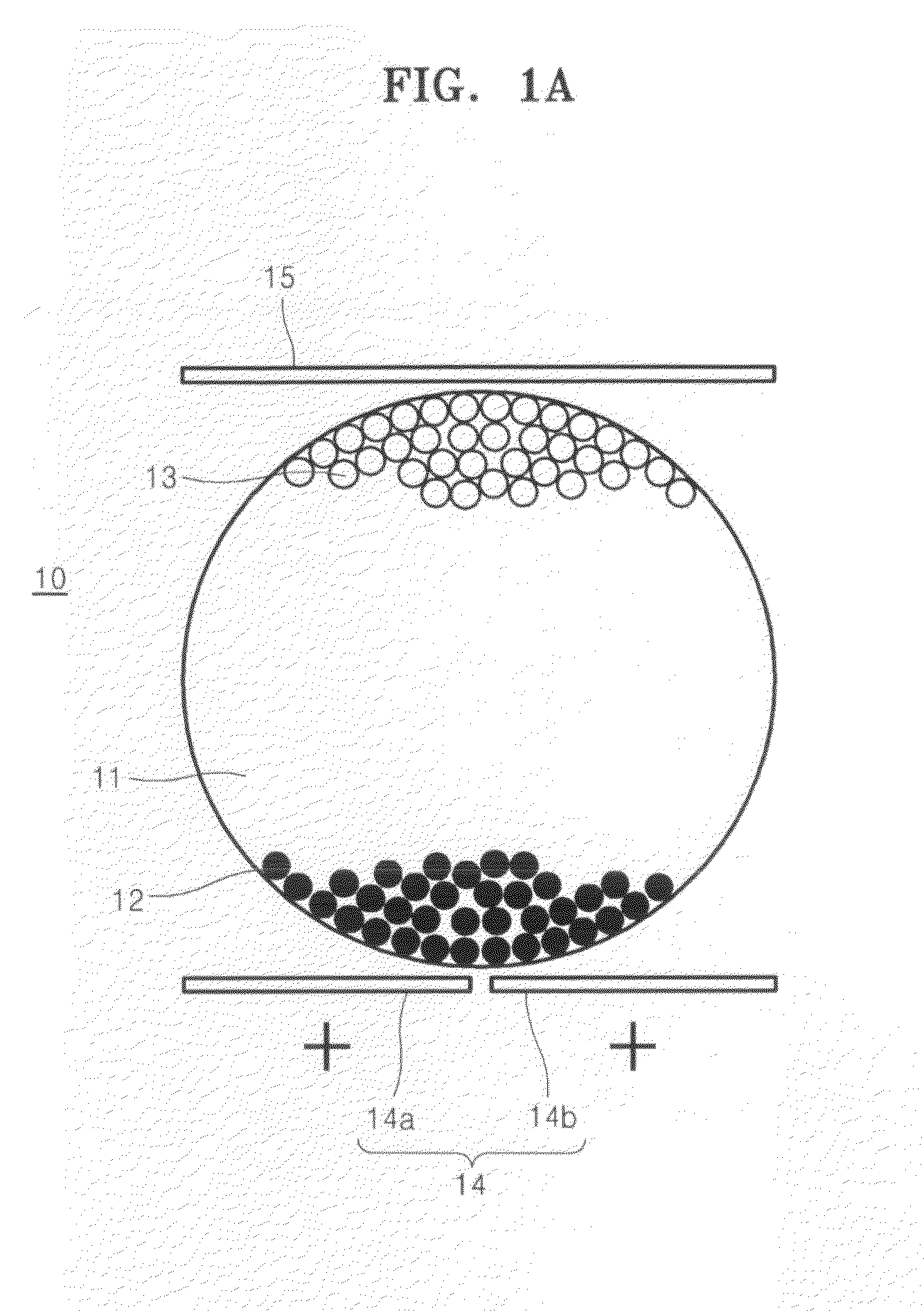

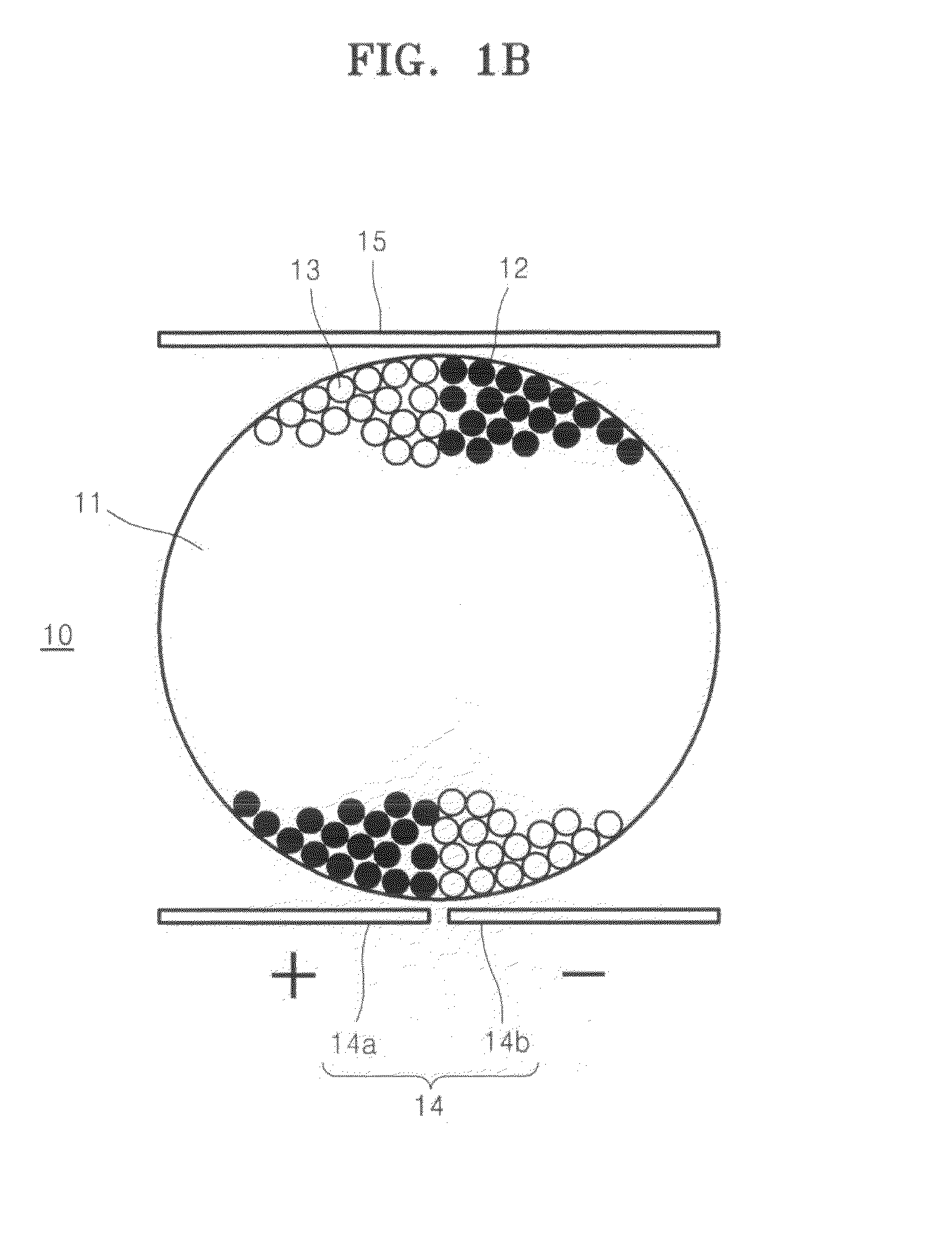

Reversible image display sheet and image display

InactiveUS20050052402A1Quick responseSimple structureStatic indicating devicesNon-linear opticsDisplay deviceColor charge

A reversible image display panel which comprises a pair of substrates one of which is transparent and a group of particles charged with single polarity, a group of particles with single color charged with single polarity, a group of particles having portions with different colors and different charge characteristics, or two groups of particles with different charge characteristics each enclosed between the substrates, characterized in applying an electric field across the substrates, and displaying images by flying and moving the particles. The reversible image display panel and the image display device in accordance with the invention have fast response speed and simple structure, being superior in stability and vividity. In an occasion of driving, generation of the strong electric field is unnecessary for them and accordingly, electric circuits can be assembled employing general purpose electronic materials.

Owner:BRIDGESTONE CORP

Preparation and application of paint waste water treatment agents

InactiveCN102351341AImprove processing efficiencyFast and effective detackificationMultistage water/sewage treatmentCompound organicSodium Bentonite

The invention relates to preparation and an application of paint waste water treatment agents. The paint waste water treatment agents comprise viscosity reducing agent A and flocculants B, wherein the viscosity reducing agent A is aqueous solution, is formed by compounding organic bentonite, 6501 nonionic surface active agents and high-molecular polymers prepared from formaldehyde and three kinds of organic compounds: aniline, urea and starch through reaction, has high electric neutrality and can fast neutralize paint particle charges, so dope loses the viscosity. The flocculants B is aqueous solution, is formed by compounding sodium alginate aqueous solution, sodium lignosulphonate aqueous solution and chitosan modified cation polyacrylamide aqueous solution with the molecular weight being 8 to 12 million, has high coacervation effect and can gather paint particles losing the viscosity. The paint waste water treatment agents have good viscosity reduction and coacervation effects on water-soluble and fat-soluble dope. When the paint flocculants are applied to paint spraying waste water treatment, the agent A and the agent B are sequentially added into paint-containing circulating water, more than 90 percent of paint in the waste water can be cleaned.

Owner:WUHAN UNIV OF TECH

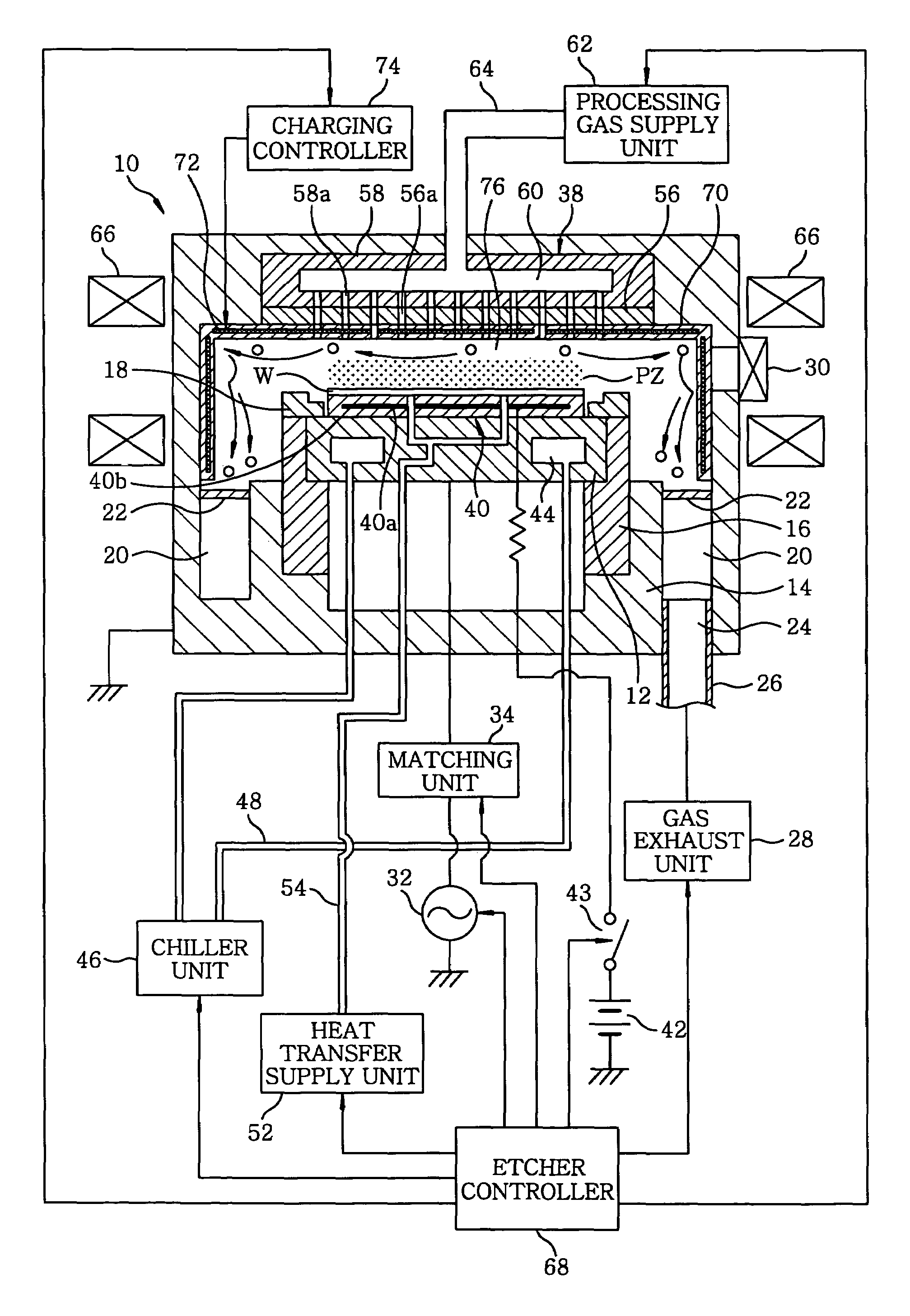

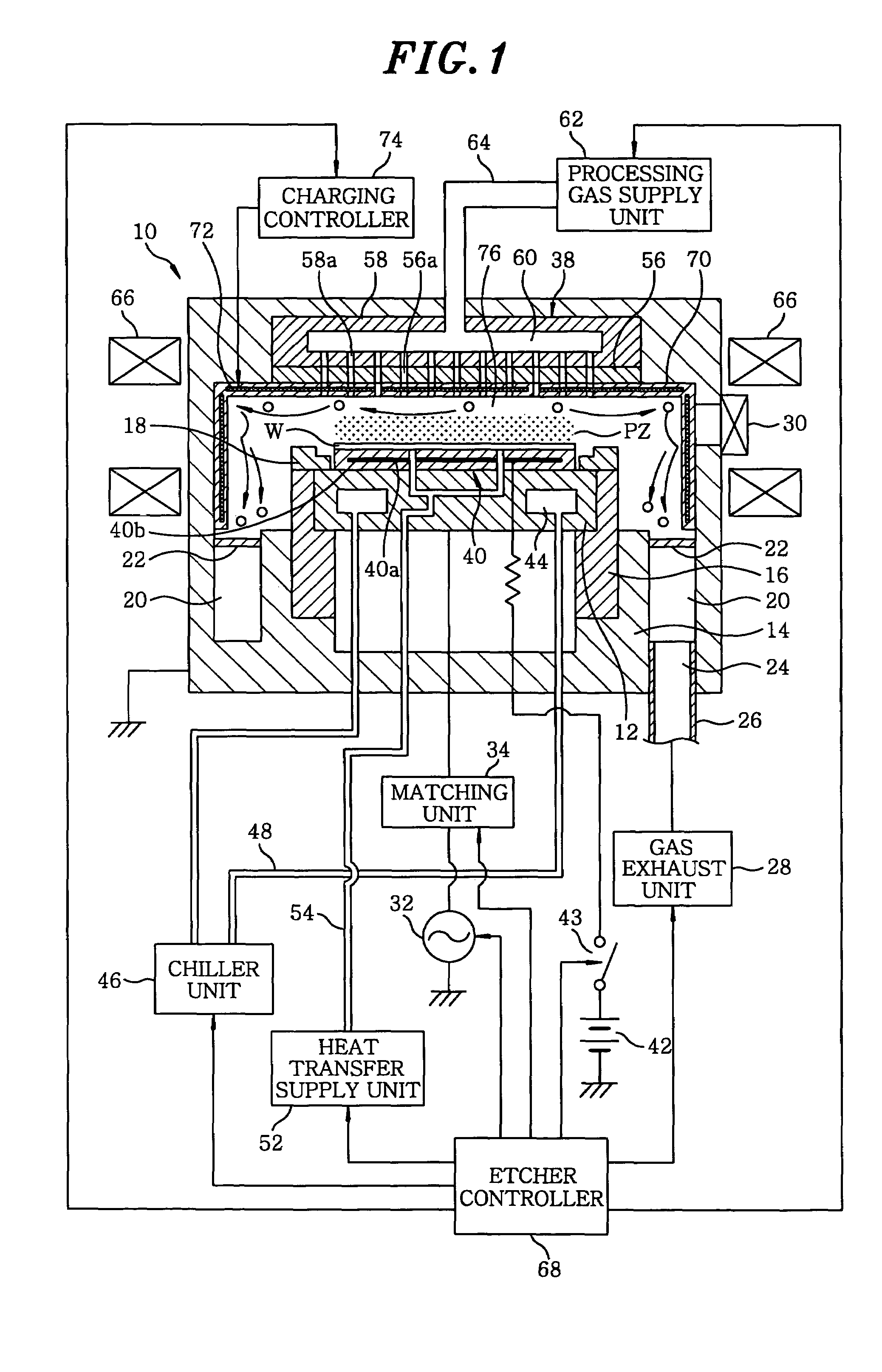

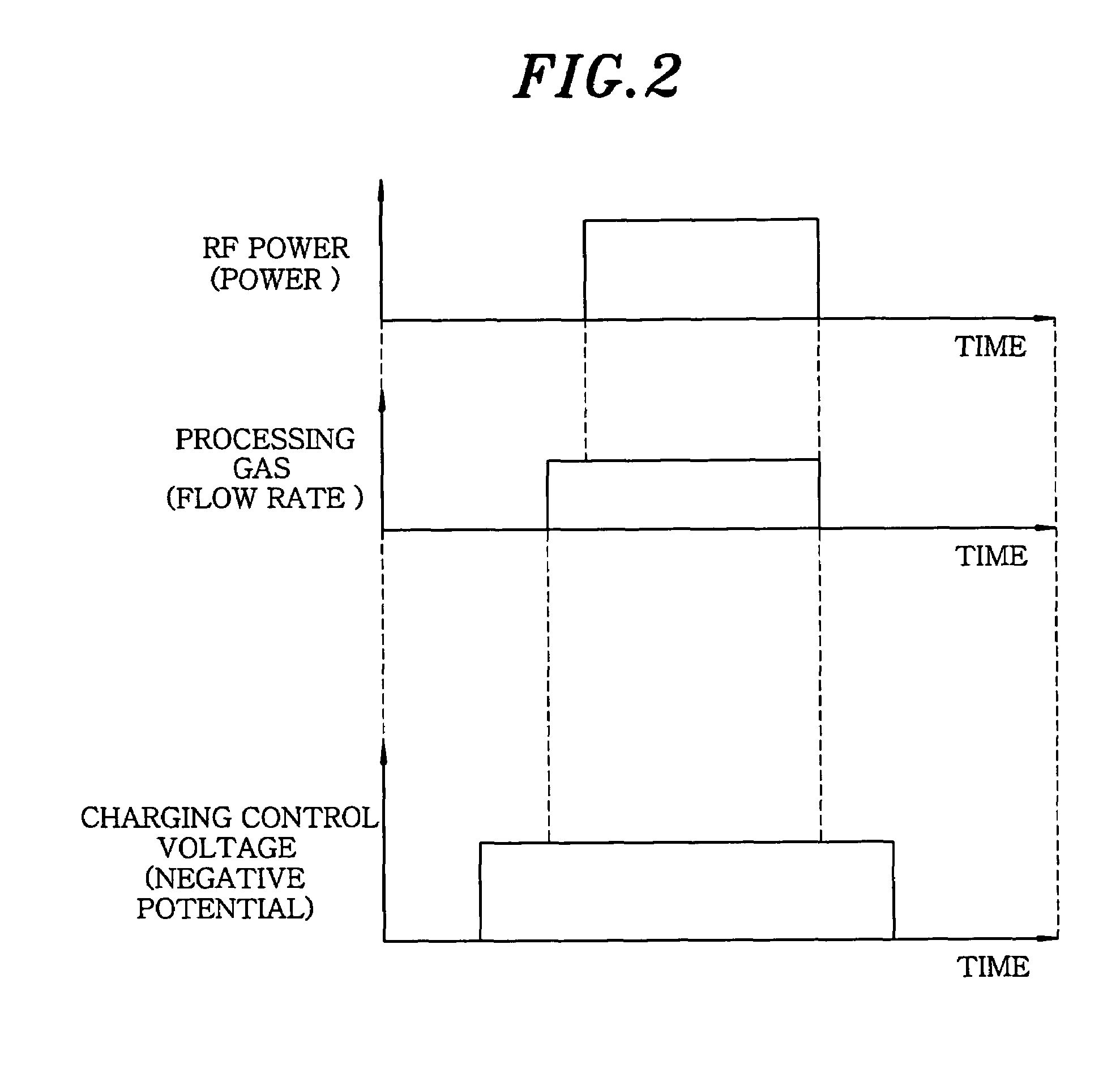

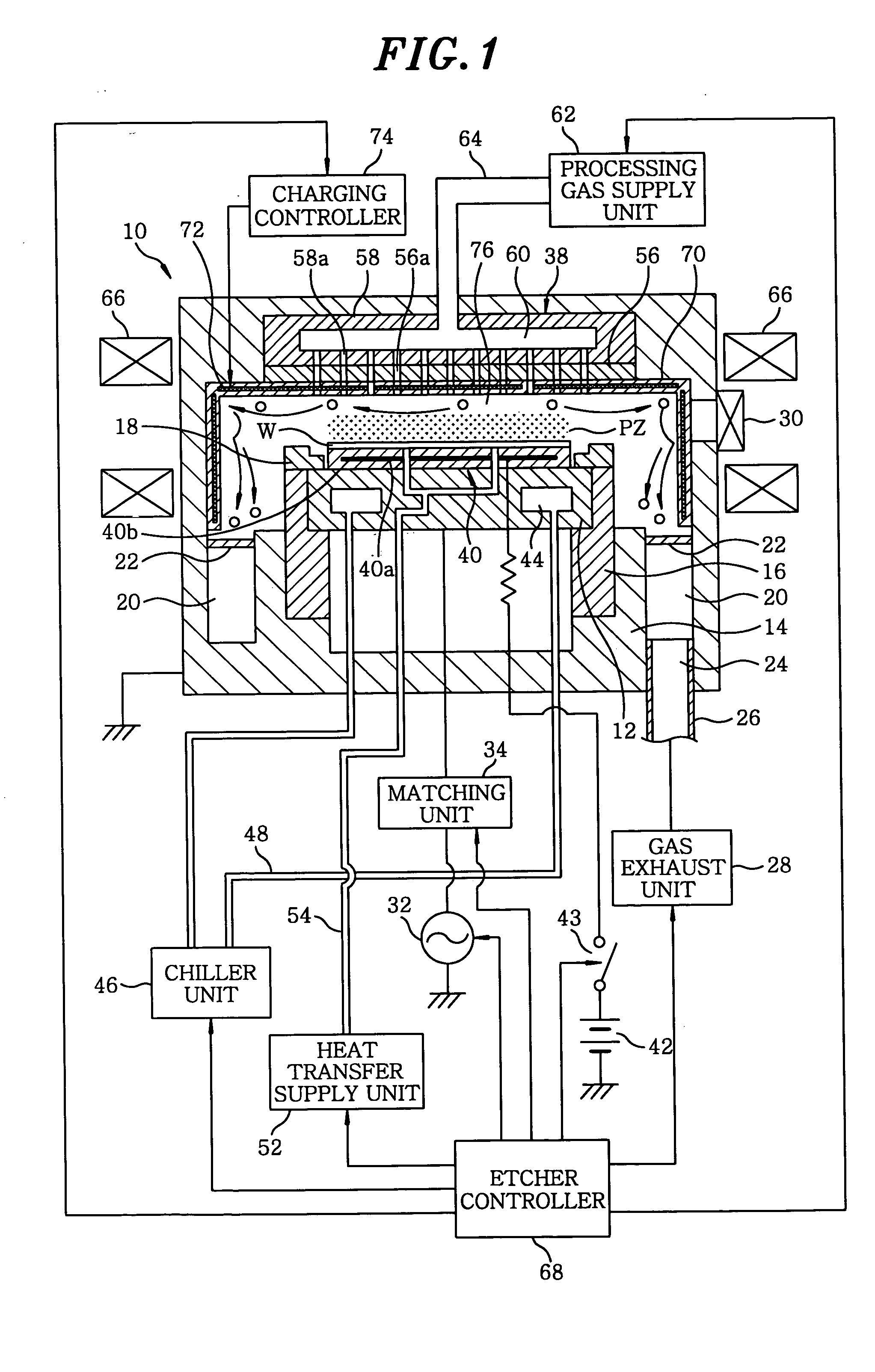

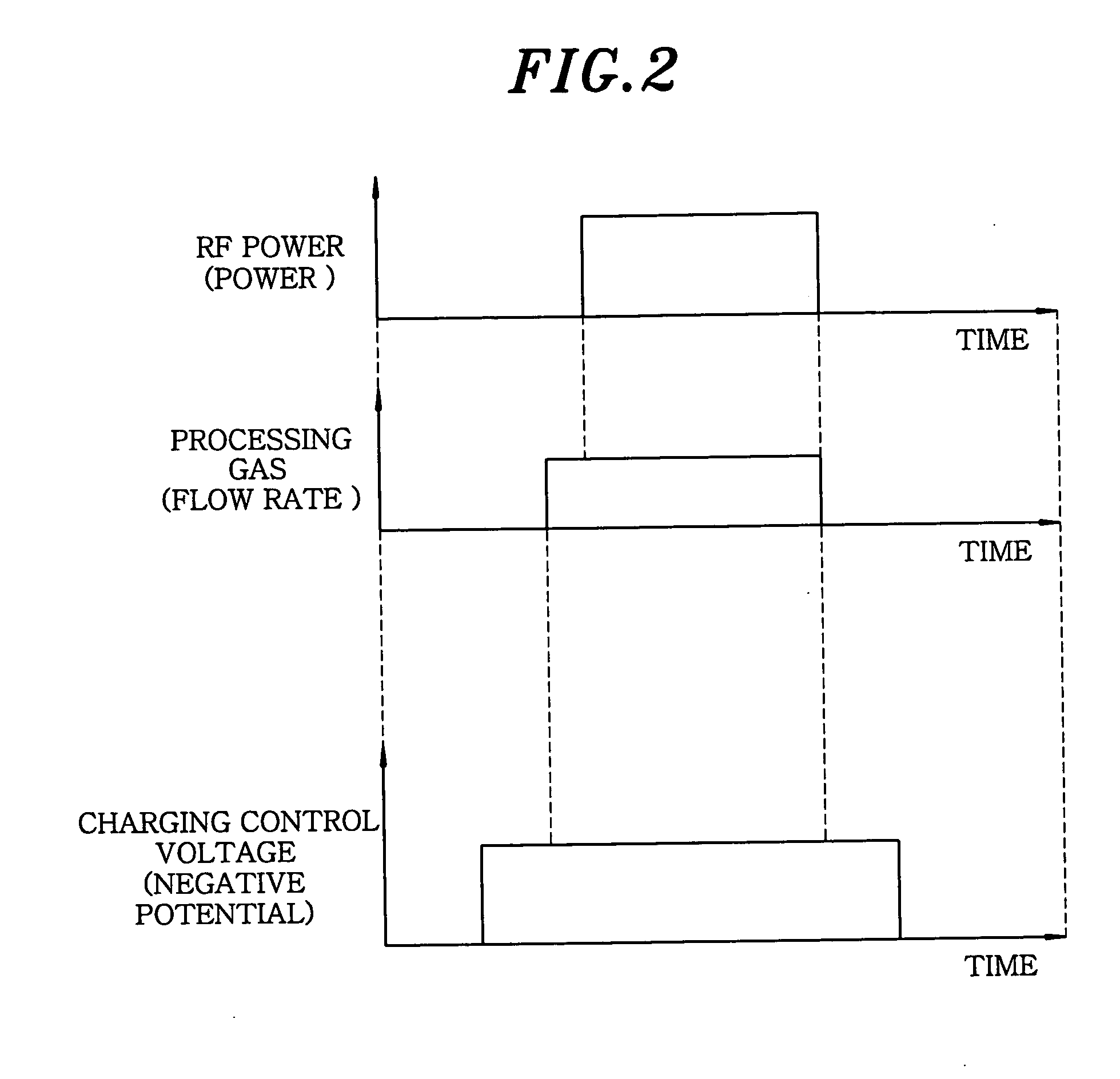

Particle removal apparatus and method and plasma processing apparatus

ActiveUS7651586B2Efficient removalElectric discharge tubesElectrostatic cleaningPositively charged particleMetal contamination

A particle removal apparatus for removing particles from a chamber of a plasma processing apparatus, wherein the chamber is connected to a gas exhaust port and a plasma of a processing gas is generated in the chamber to plasma process a substrate to be processed, includes a particle charging control member for positively charging particles generated within the chamber by positive ions of an ion sheath region formed in a region other than the vicinity of the substrate to be processed, wherein positively charged particles are discharged from the chamber via the gas exhaust port. Therefore, there is no plasma disturbance or metal contamination, and thus can be applied to a practical use.

Owner:TOKYO ELECTRON LTD

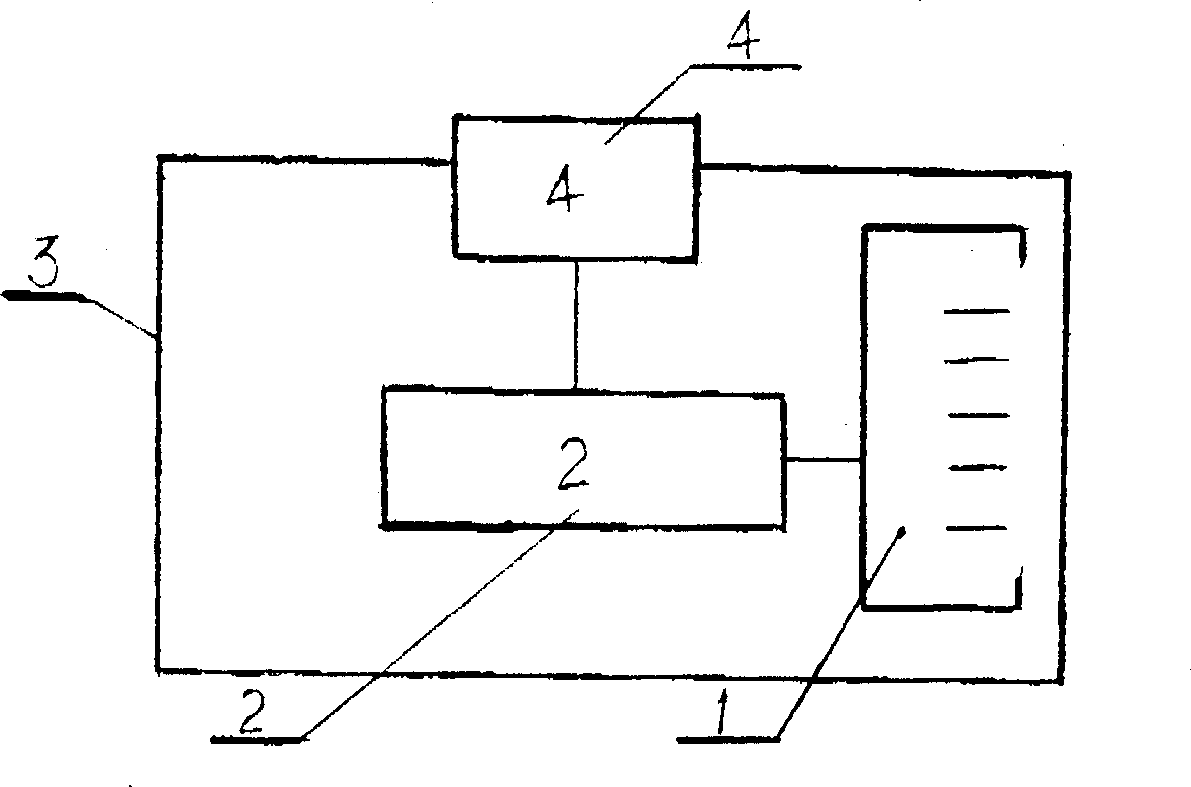

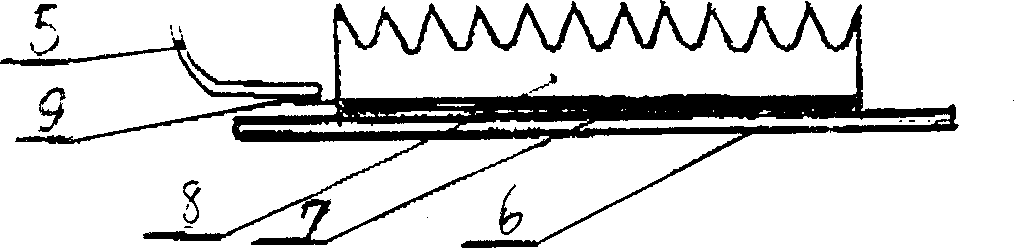

Washing machine dewatering device and washing machine

InactiveCN102733156AAvoid noiseAvoid breedingOther washing machinesTextiles and paperLaundry washing machineWater flow

The invention discloses a washing machine dewatering device and a washing machine. The washing machine comprises an outer barrel, an inner barrel and a wave wheel, wherein cleaning particles for cleaning the walls of the barrels are arranged between the inner barrel and the outer barrel, the dewatering device comprises a particle charging and discharging cavity for containing the cleaning particles during dewatering and automatically putting the cleaning particles between the inner barrel and the outer barrel to clean the walls of the barrels due to the buoyancy force when water enters and a dewatering cavity, and a filtering structure which baffles the cleaning particles and discharges line scraps and smaller impurities is arranged between the particle charging and discharging cavity and the dewatering cavity. The filtering structure comprises a particle baffling part, a filtering gap and a fracture crossed with the filtering gap, wherein the fracture is communicated with the filtering gap, so that the line scraps wound on the baffling part is washed by water flow and fallen off to be discharged out of the fracture, and a filtering surface of the filtering structure which corresponds to one side of the charging and discharging cavity is an arc surface / inclined surface flow guide structure which is concave to the other side at the position of the fracture. The washing machine dewatering device and the washing machine disclosed by the invention are simple in structure, and low in low, and prevents bacterial from growing caused by the dewatering blockage and the residual line scraps when the cleaning particles are intercepted.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

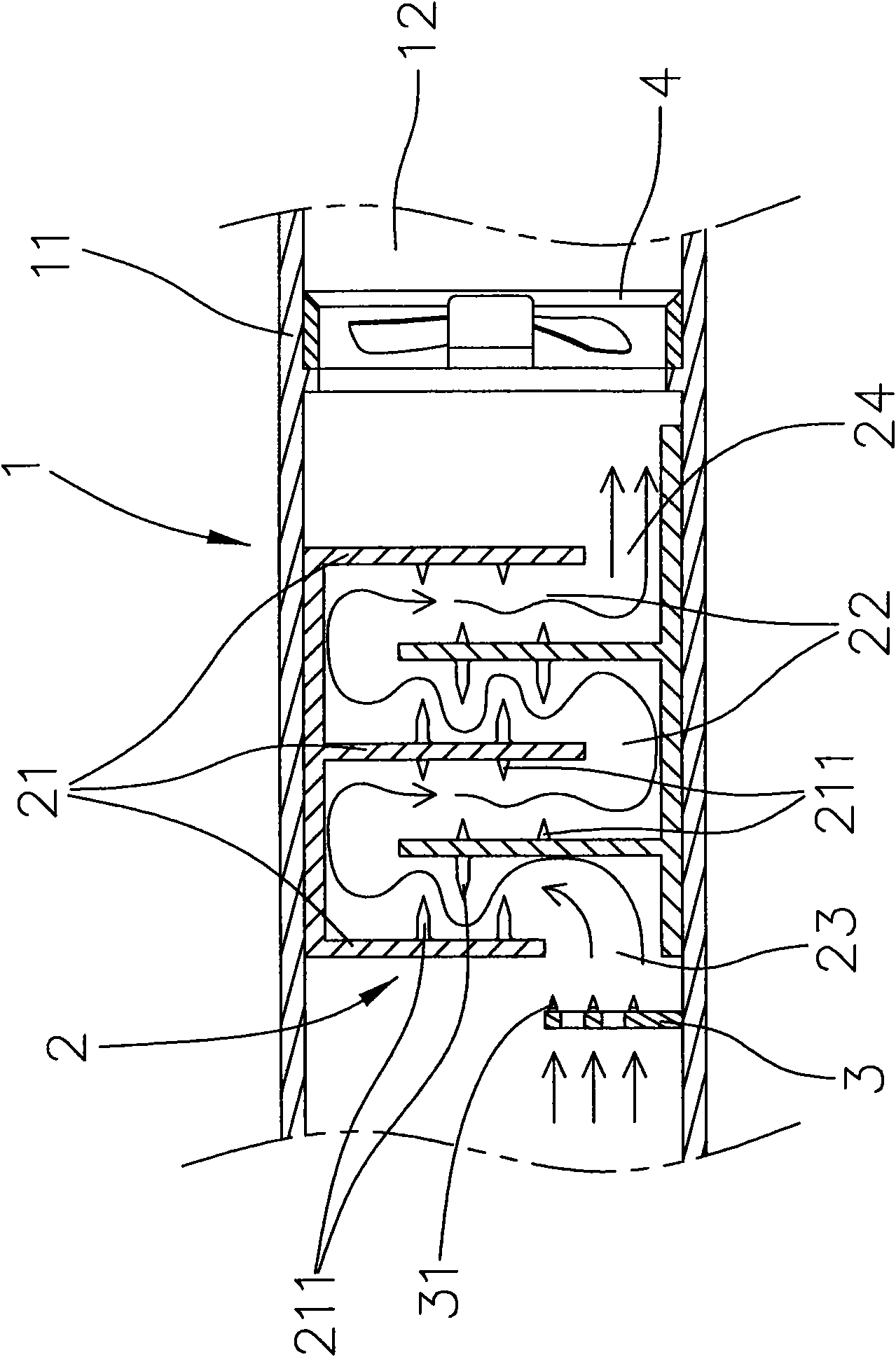

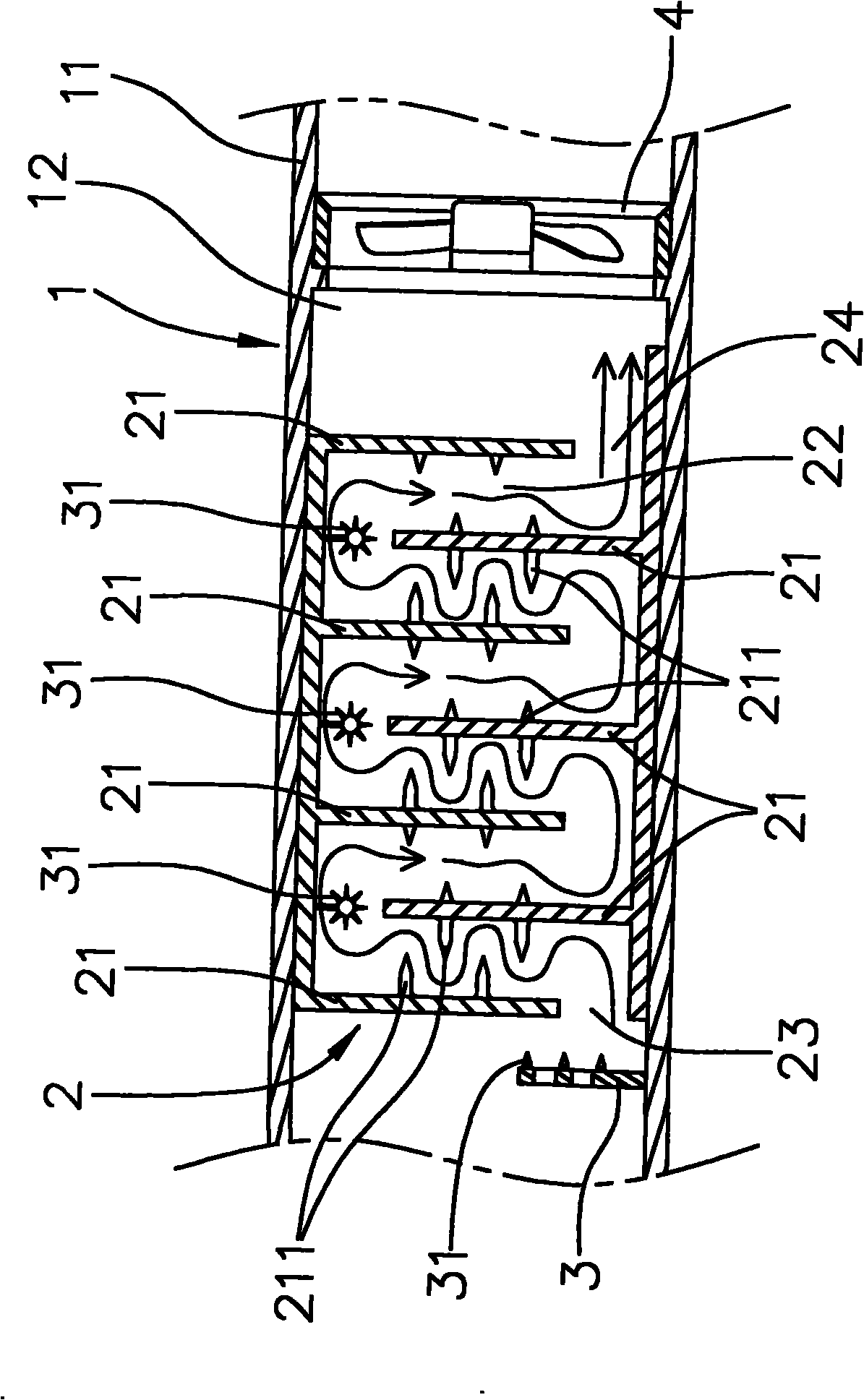

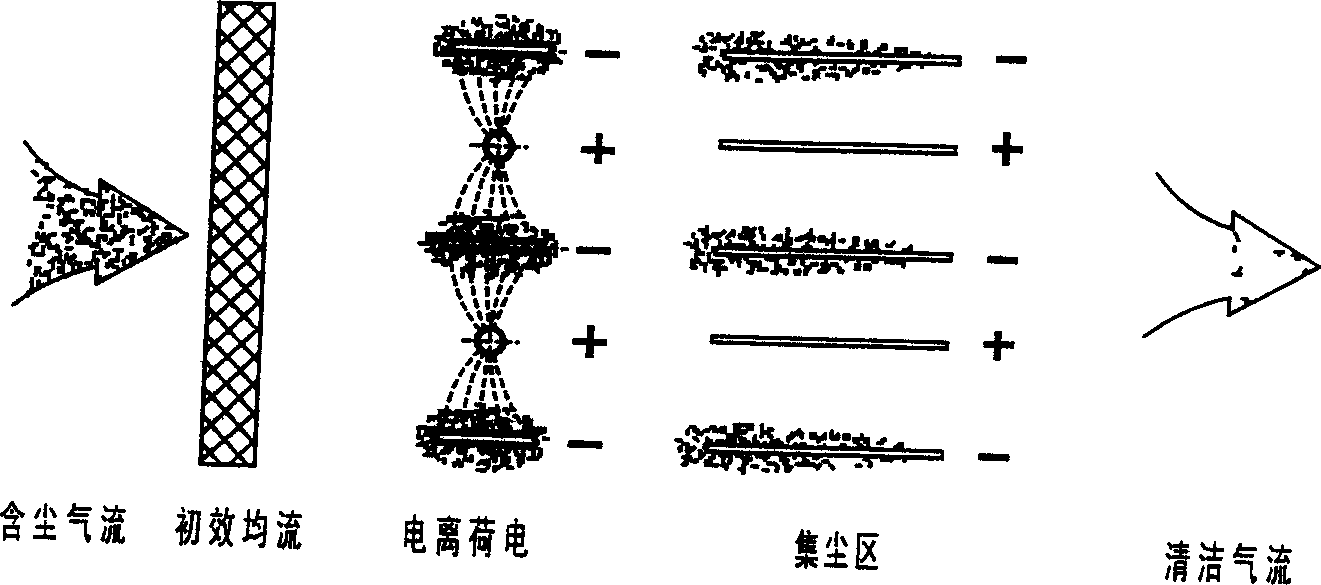

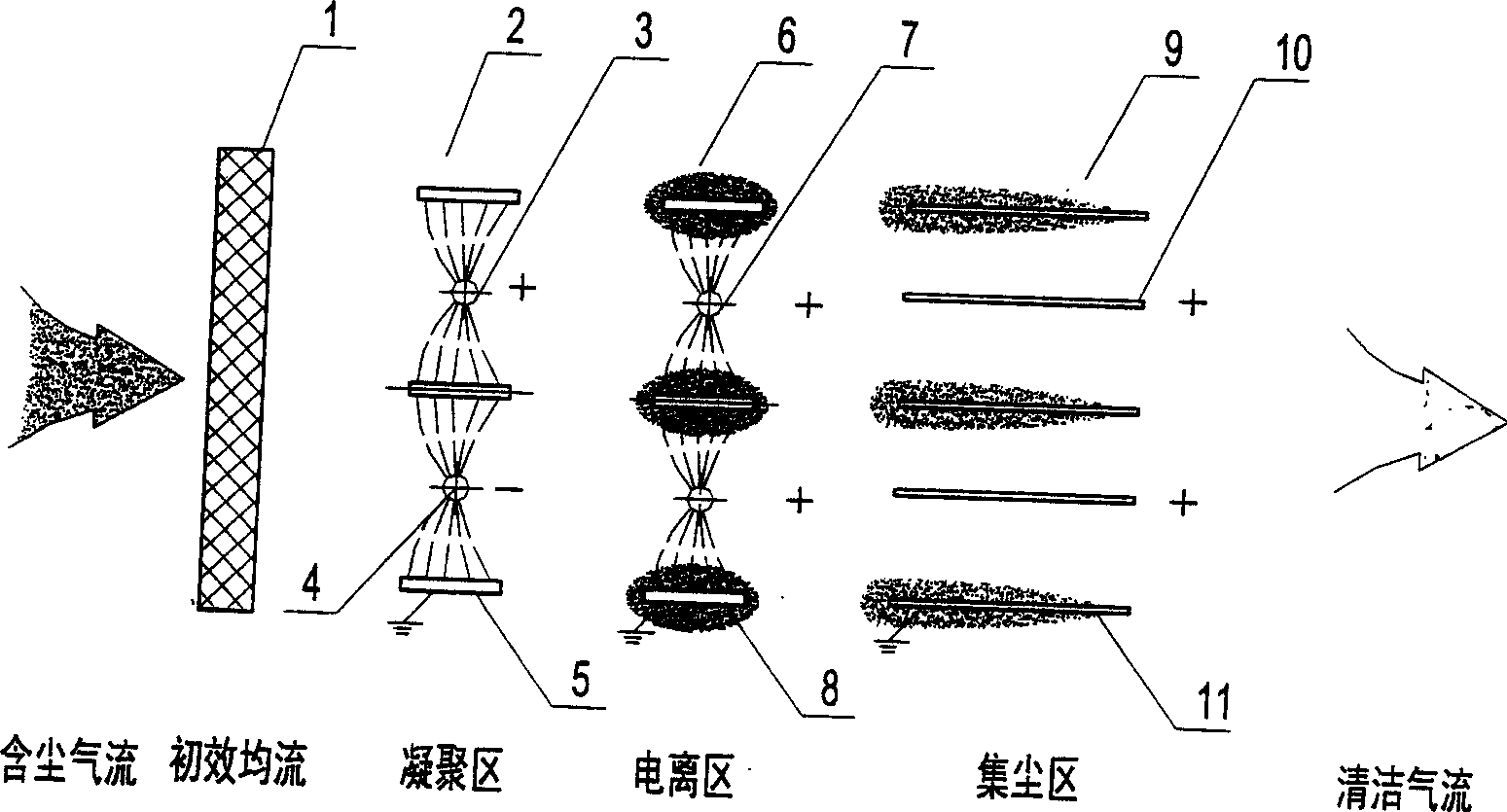

High-efficiency labyrinth type air treatment device

InactiveCN102039222AGood air purification effectMaintain physical healthExternal electric electrostatic seperatorElectrode constructionsElectricityAir Ionization

The invention relates to a high-efficiency labyrinth type air treatment device. The high-efficiency labyrinth type air treatment device is characterized in that a dust collecting unit is arranged in an air duct of a shell of the air treatment device and consists of at least more than one groups of dust collecting plates which are mutually and correspondingly intersected and arranged and charged positively (negatively); a labyrinth-shaped semienclosed air flow channel is formed in the dust collecting unit and is internally provided with a discharge transmitting end (wire) of an air ionization generator and a fan; and further the air is suctioned to be ionized close to the discharge transmitting end (wire) of the air ionization generator by means of the fan so as to enable the heterogeneous particles of the air to be charged positively (negatively), enable the heterogeneous particles charged positively (negatively) of the air to enter the labyrinth-shaped air flow channel in the dust collecting unit, enable the air to generate circuity in the labyrinth-shaped air flow channel in the dust collecting unit to collide with the dust collecting plate charged positively (negatively) and disturb the normal flowing state of the heterogeneous particles of the air, therefore, the purposes of changing the air flowing direction and improving the dust collecting effect of the dust collecting unit are achieved.

Owner:吴福吉

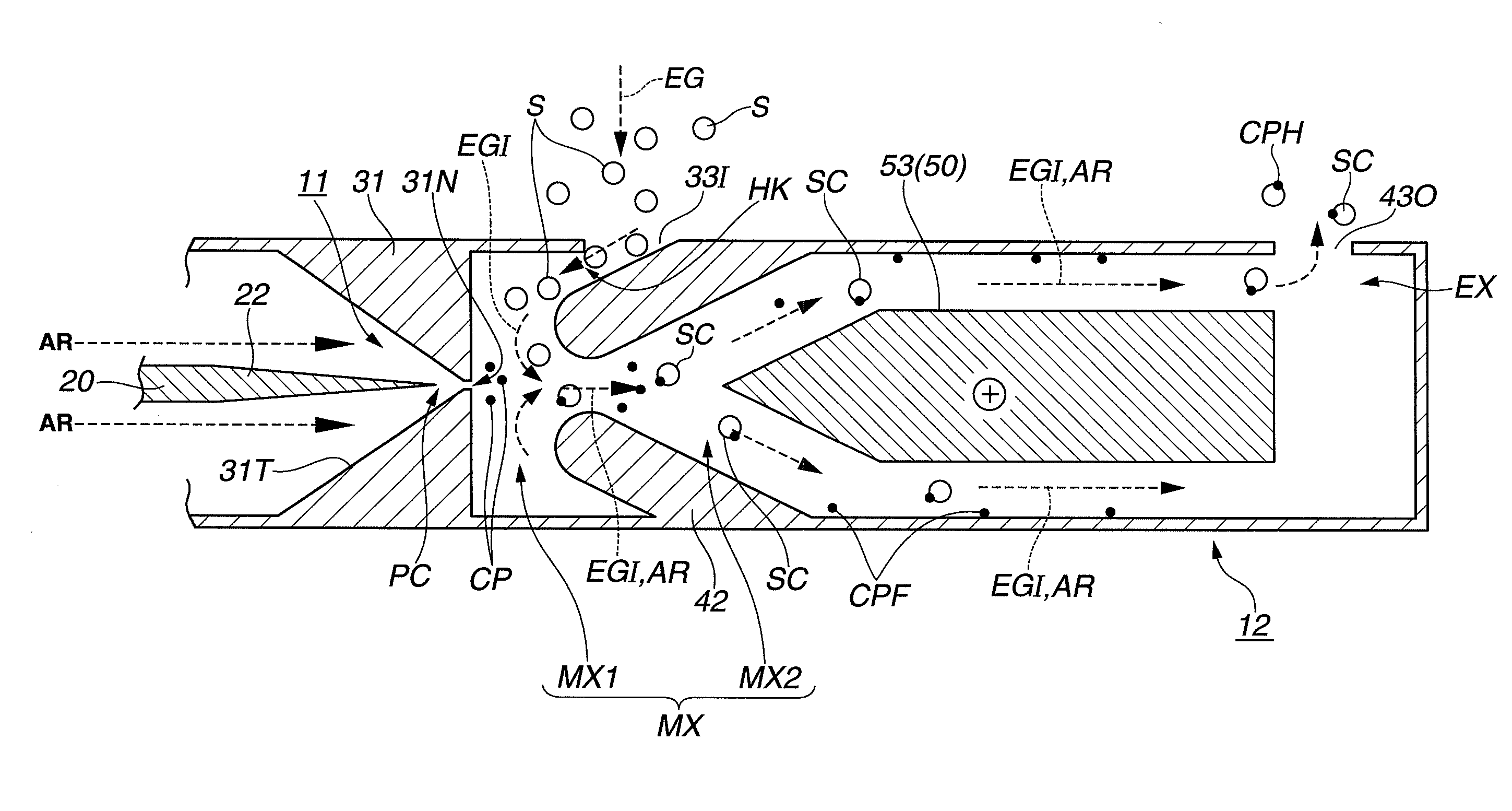

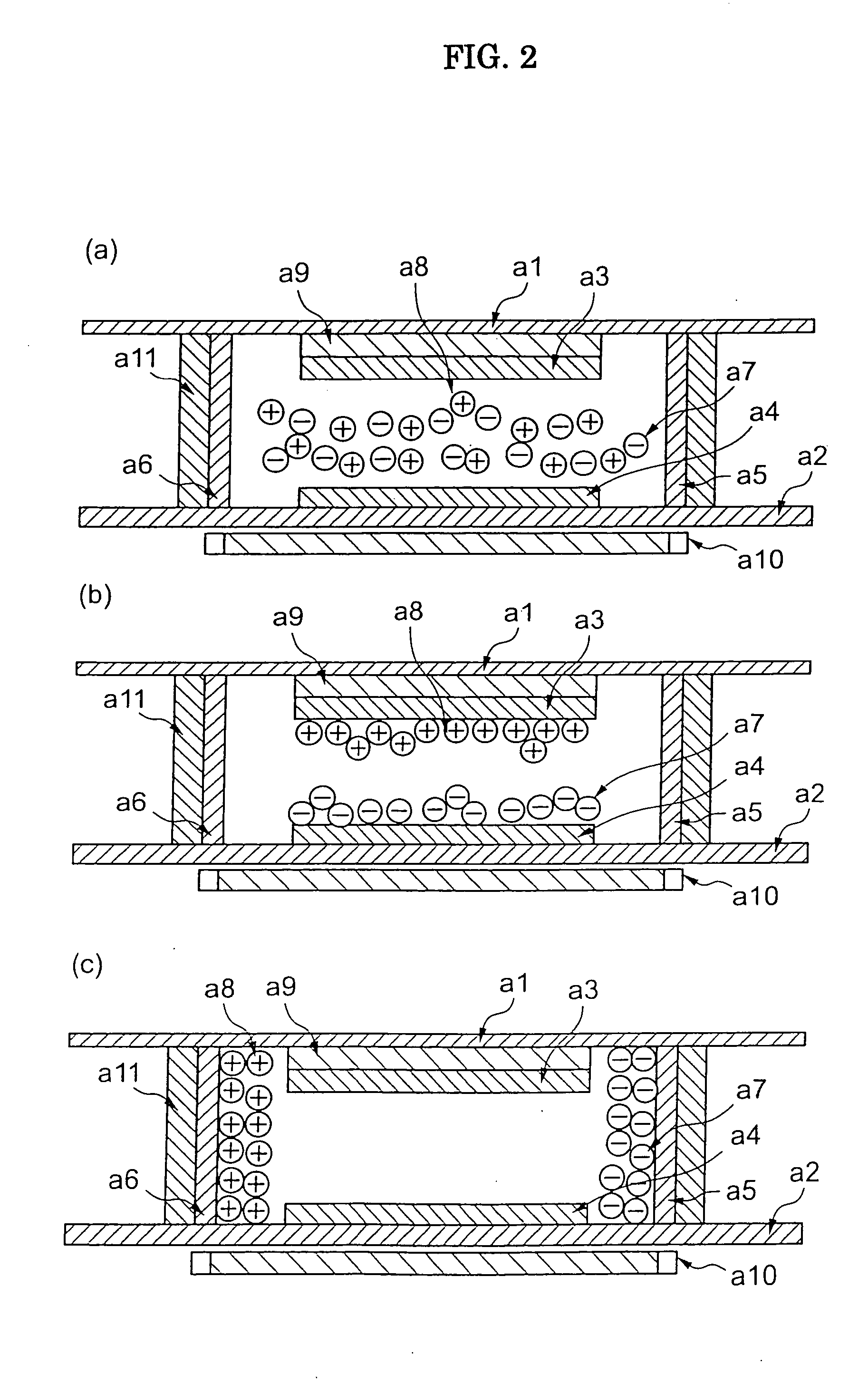

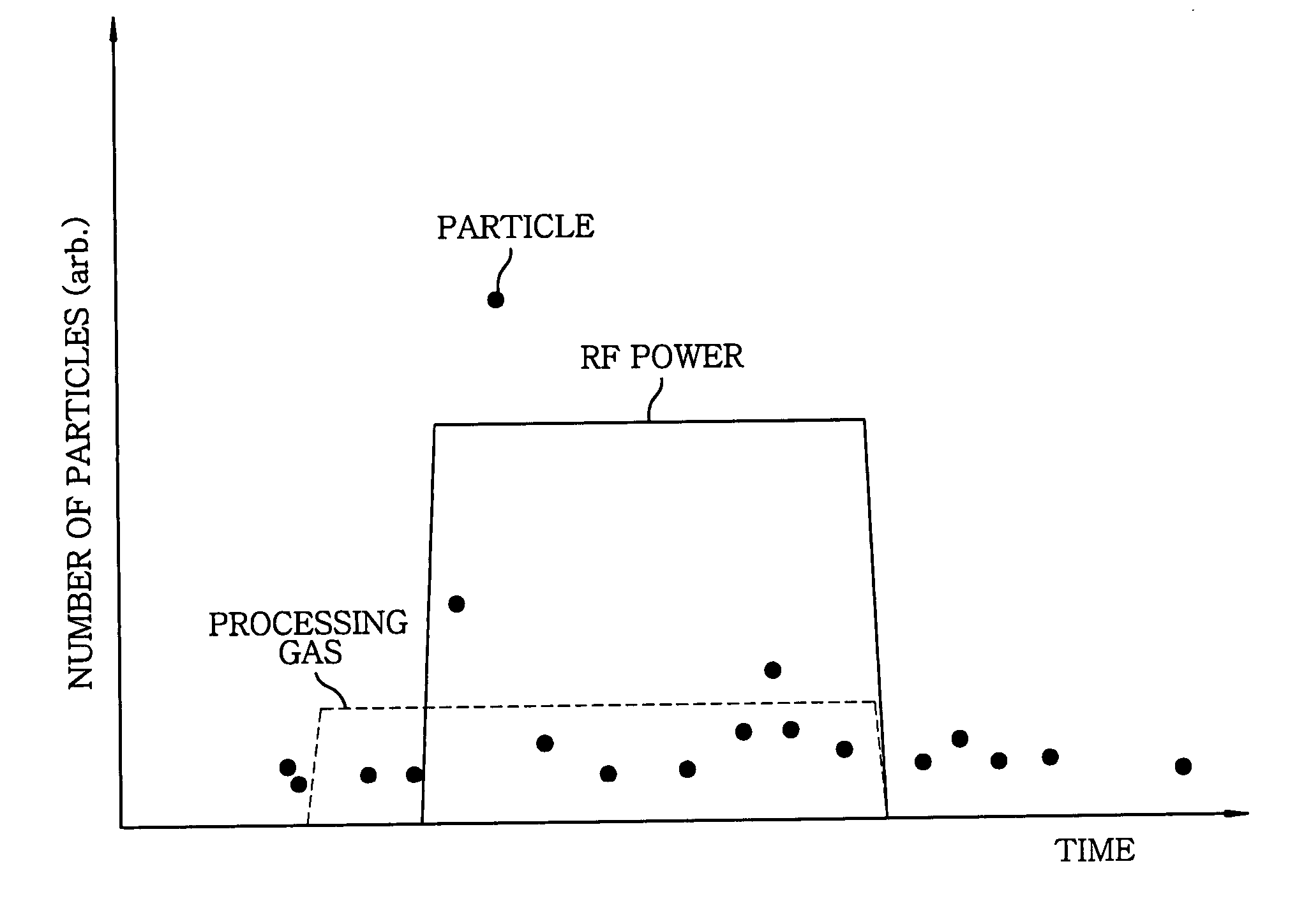

Particle removal apparatus and method and plasma processing apparatus

ActiveUS20050039773A1Efficient removalElectric discharge tubesElectrostatic cleaningPositively charged particleMetal contamination

A particle removal apparatus for removing particles from a chamber of a plasma processing apparatus, wherein the chamber is connected to a gas exhaust port and a plasma of a processing gas is generated in the chamber to plasma process a substrate to be processed, includes a particle charging control member for positively charging particles generated within the chamber by positive ions of an ion sheath region formed in a region other than the vicinity of the substrate to be processed, wherein positively charged particles are discharged from the chamber via the gas exhaust port. Therefore, there is no plasma disturbance or metal contamination, and thus can be applied to a practical use.

Owner:TOKYO ELECTRON LTD

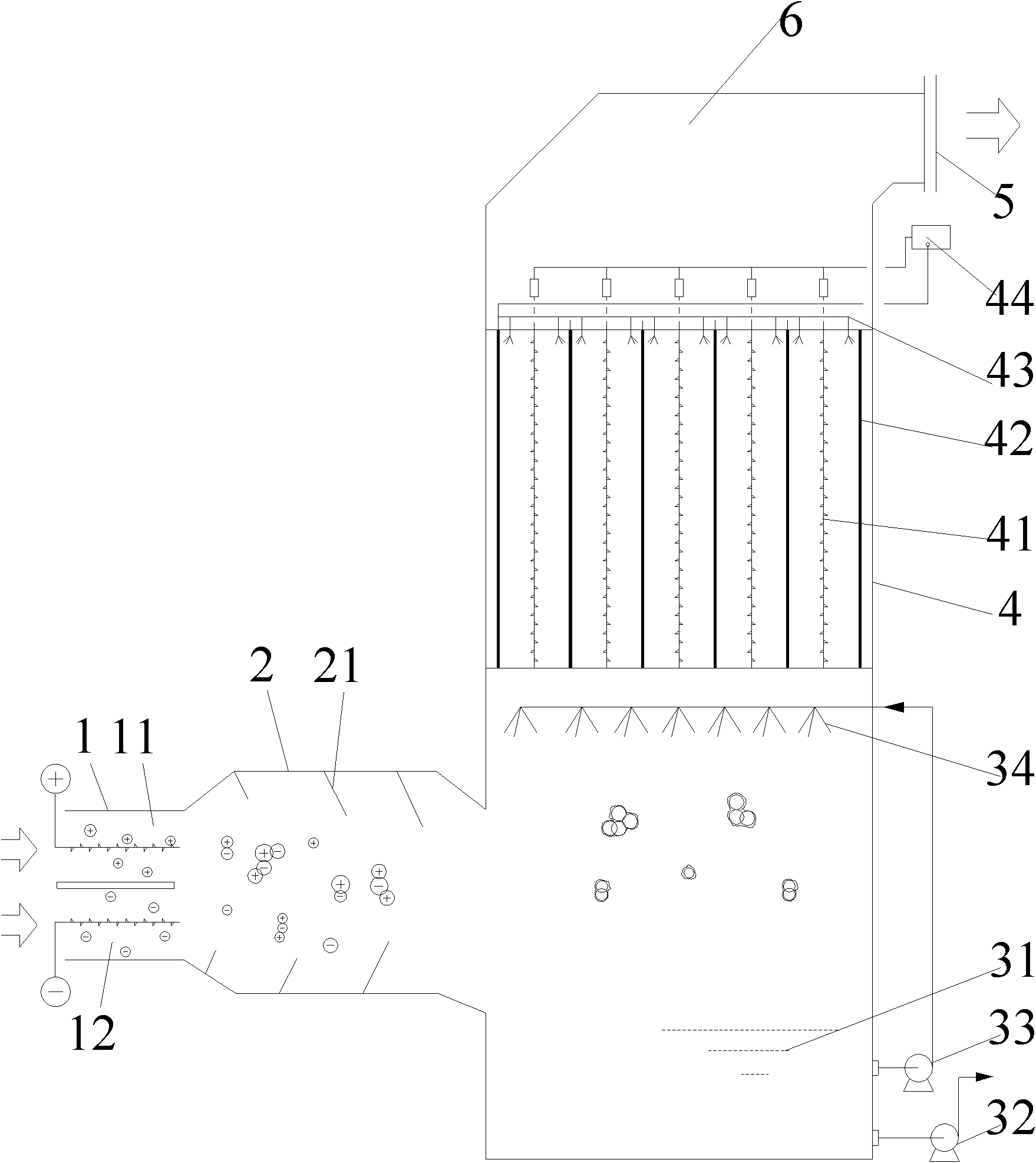

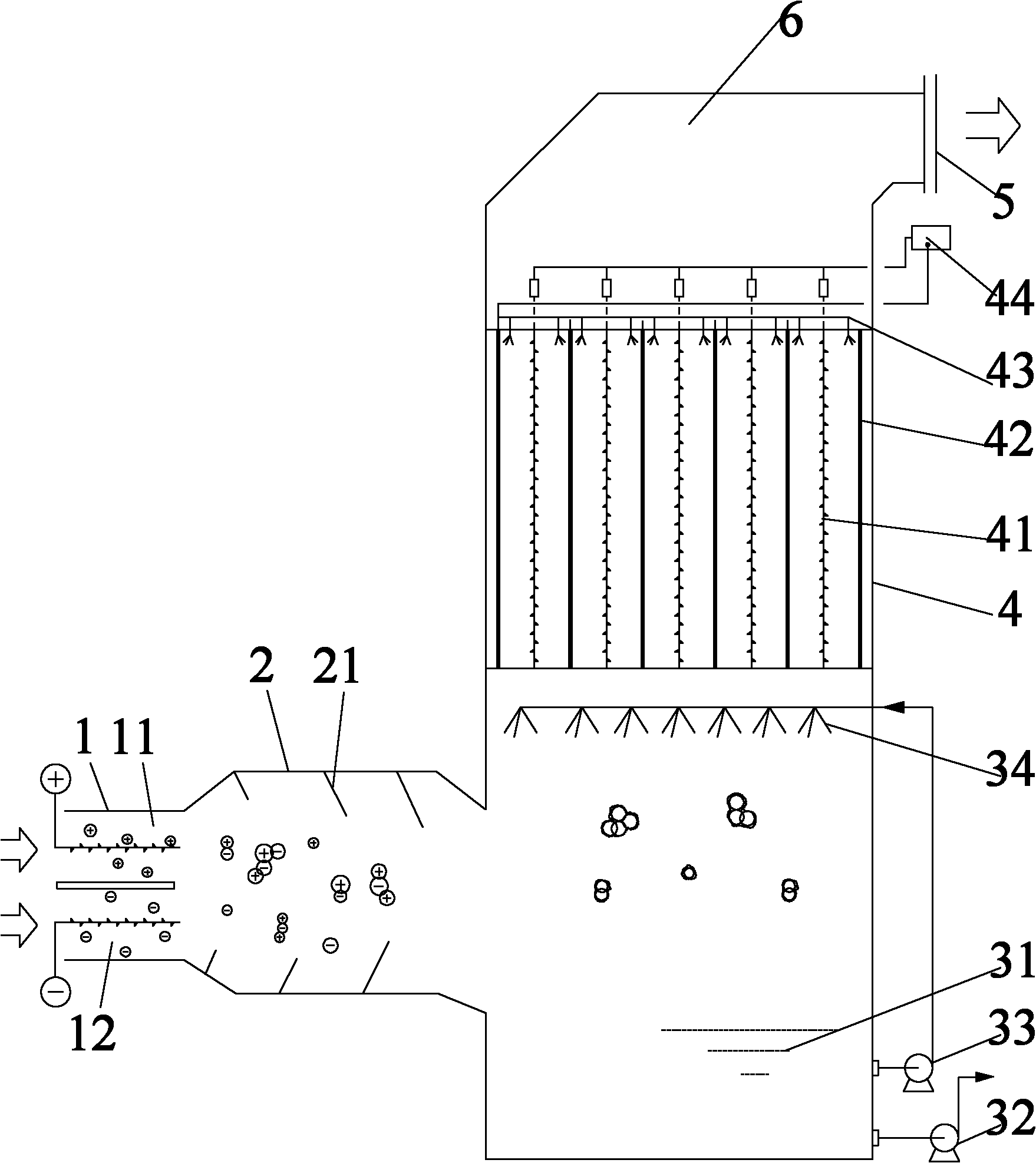

Device and method for removing PM 2.5 from smoke

InactiveCN102430478AExternal electric electrostatic seperatorElectrostatic separation detailsCorona dischargeEngineering

The invention discloses a device for removing PM 2.5 from a smoke. The device is characterized in that: the device comprises a removing tower, a wet electrical dust precipitator and one or more wetting spray apparatuses; the lower part of the removing tower is provided with a smoke inlet end; the smoke inlet end of the removing tower is provided with a particle charging zone and a mixing coagulation zone; the particle charging zone is divided into a positive corona discharging zone and a negative corona discharging zone; an anode is arranged in the positive corona discharging zone; a cathode is arranged in the negative corona discharging zone; at least one stage of wetting spray apparatus is arranged in the removing tower which is above the smoke inlet end; the wet electrical dust precipitator is arranged in the removing tower which is above the wetting spray apparatus; and the top of the removing tower is provided with a smoke outlet. The invention also discloses a method for removing PM2.5 from the smoke. The method sequentially comprises steps of particle charging, mixing coagulation, dust wetting tempering, and wet electrical precipitation. The device and the method have the following advantages: fine dust PM2.5 can be removed from fire coal; fine particles of acid mist, heavy metal particles and the like can be removed from the smoke; and the PM2.5 removal rate is equal to or greater than 95%.

Owner:浙江菲达脱硫工程有限公司 +1

Paint mist coagulant

InactiveCN101830548AImprove processing efficiencyCoagulation and floating effect is goodWater/sewage treatment by flocculation/precipitationLacquerWastewater

The invention relates to a paint mist coagulant which has excellent adhesion eliminating and coagulating effects on water-soluble and fat-soluble paints and is particularly suitable for treating spraying paint waste water produced in a conventional coating process. The paint mist coagulant comprises an adhesion eliminating agent A and a floating agent B, wherein the adhesion eliminating agent A is a linear high polymer which contains a -NH- group and is generated by reacting an organic nitrogen-containing compound with aldehyde, has very high charge neutralization and can rapidly neutralize paint particle charge to make over 90 percent of paint lose adhesion within 1 to 10 minutes; and the floating agent B is solution which is formed by compounding an amide polymer having the molecular weight of between 9 and 10 million with modified sodium salt, has very strong coagulation and can aggregate paint particles which lose adhesion. When the paint mist coagulant is applied to treating the spraying paint waste water, the pH value of the waste water is adjusted to between 7 and 9 and the agent A and the agent B are added into paint-containing circulating water, so that over 95 percent of paint mist in the waste water is cleared.

Owner:WUHAN UNIV OF TECH

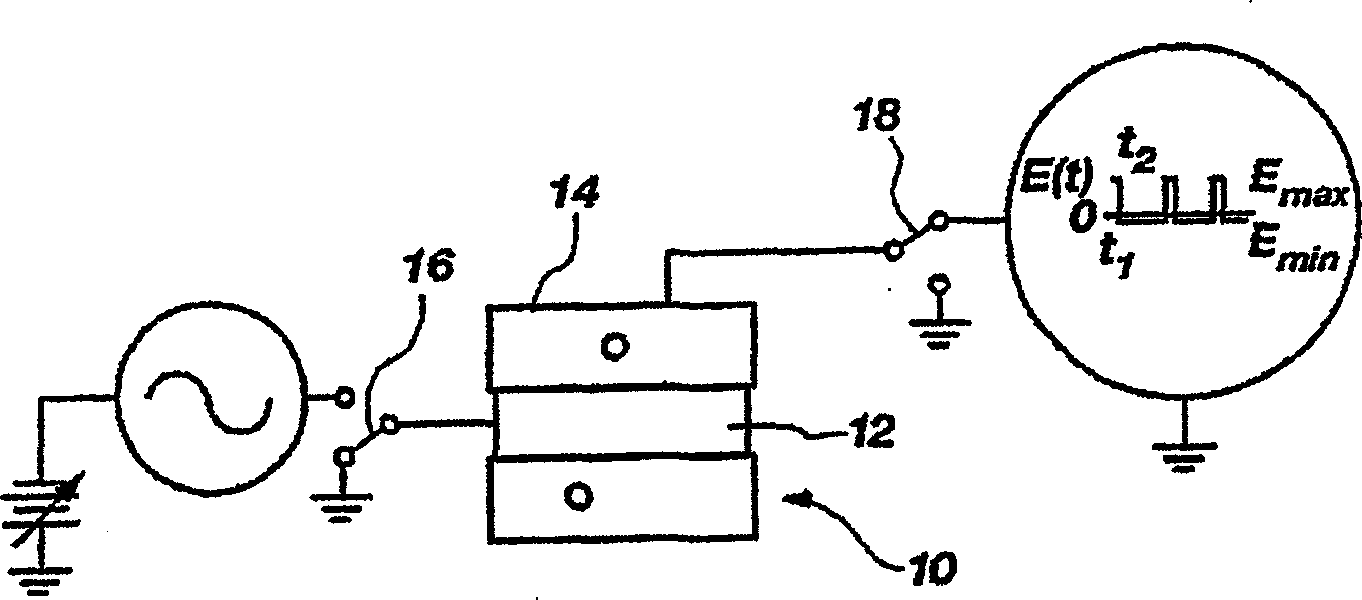

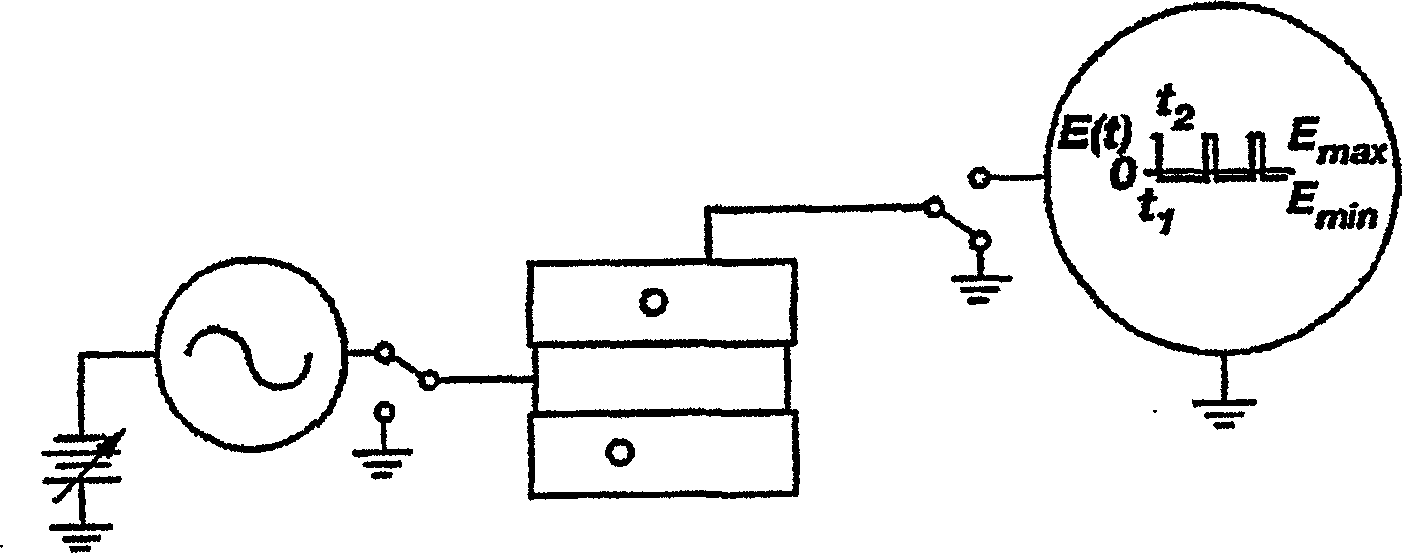

Single device for ion mobility and ion trap mass spectrometry

ActiveCN1829911AEasy to carryGood for hand-held operationStability-of-path spectrometersTime-of-flight spectrometersSubatomic particleIon trap mass spectrometry

A set of electrodes to which different potentials are applied at different time periods to perform ion mobility-based spectroscopy and mass spectrometry (MS) on an ion sample by performing any number of ion mobility-based Spectroscopy and mass spectrometry to process ions and are performed as separate or overlapping steps to capture, separate and analyze charged particles and charged particles originating from atoms, molecules, particles, subatomic particles and ions.

Owner:BRIGHAM YOUNG UNIV

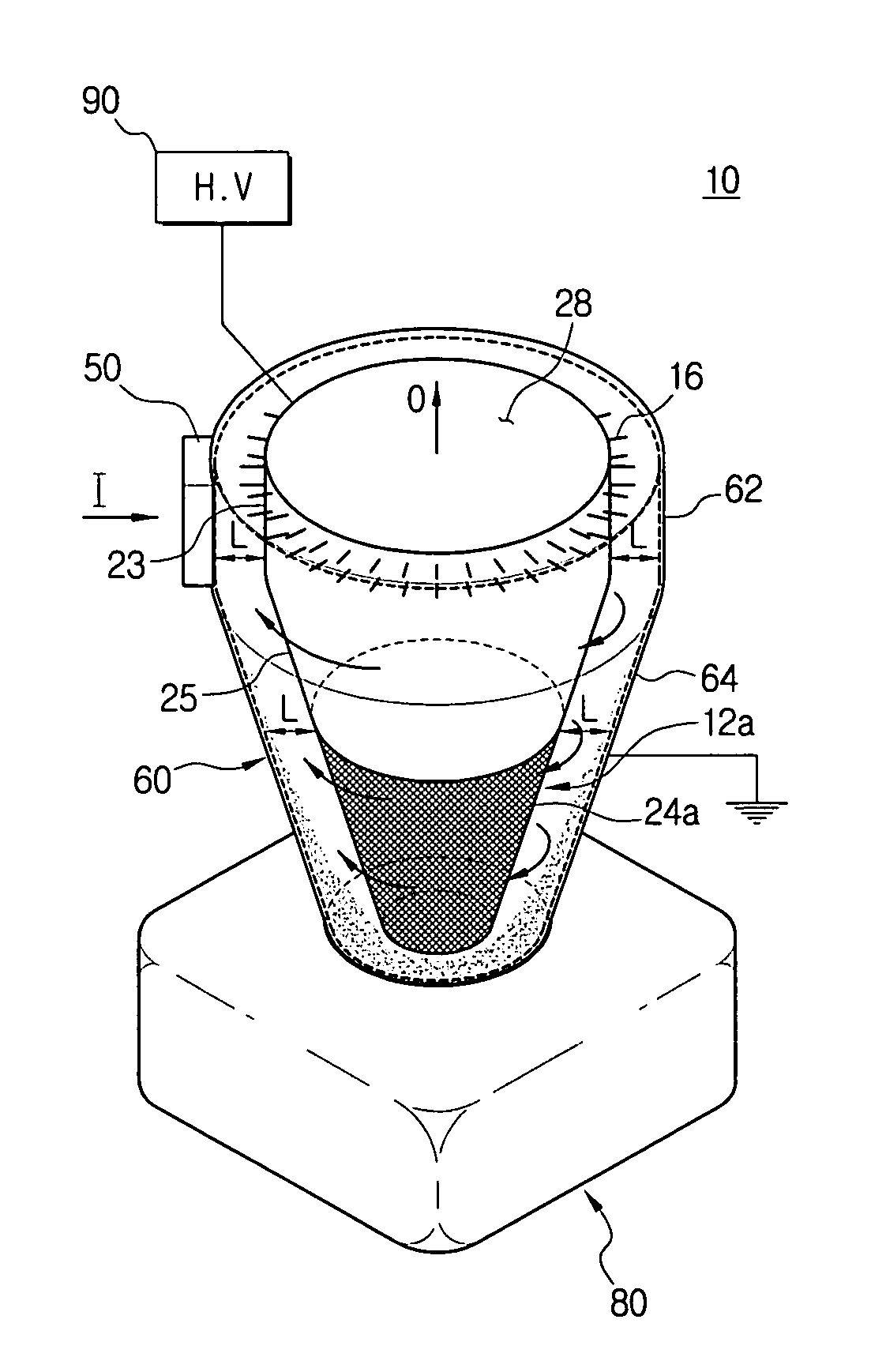

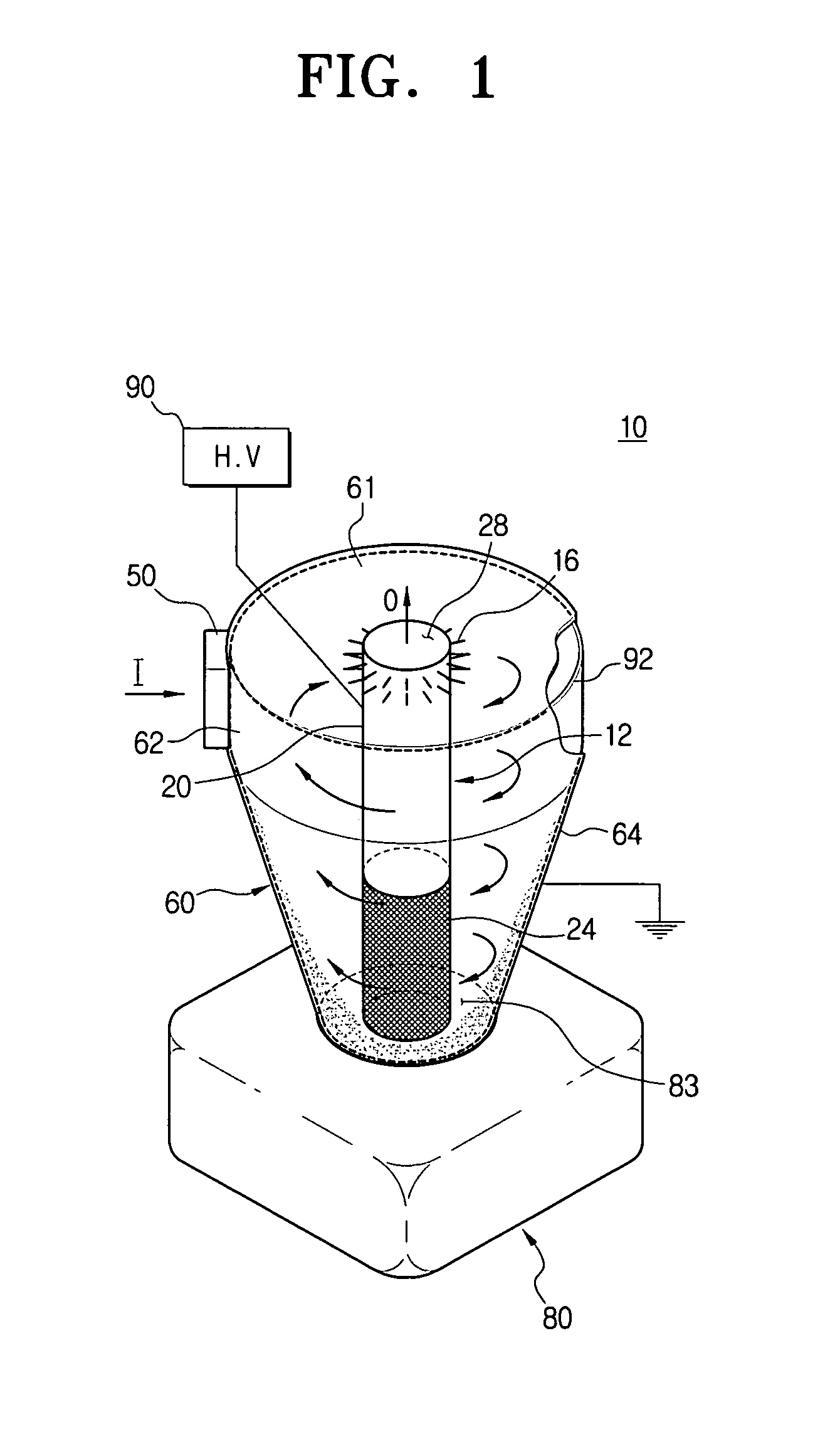

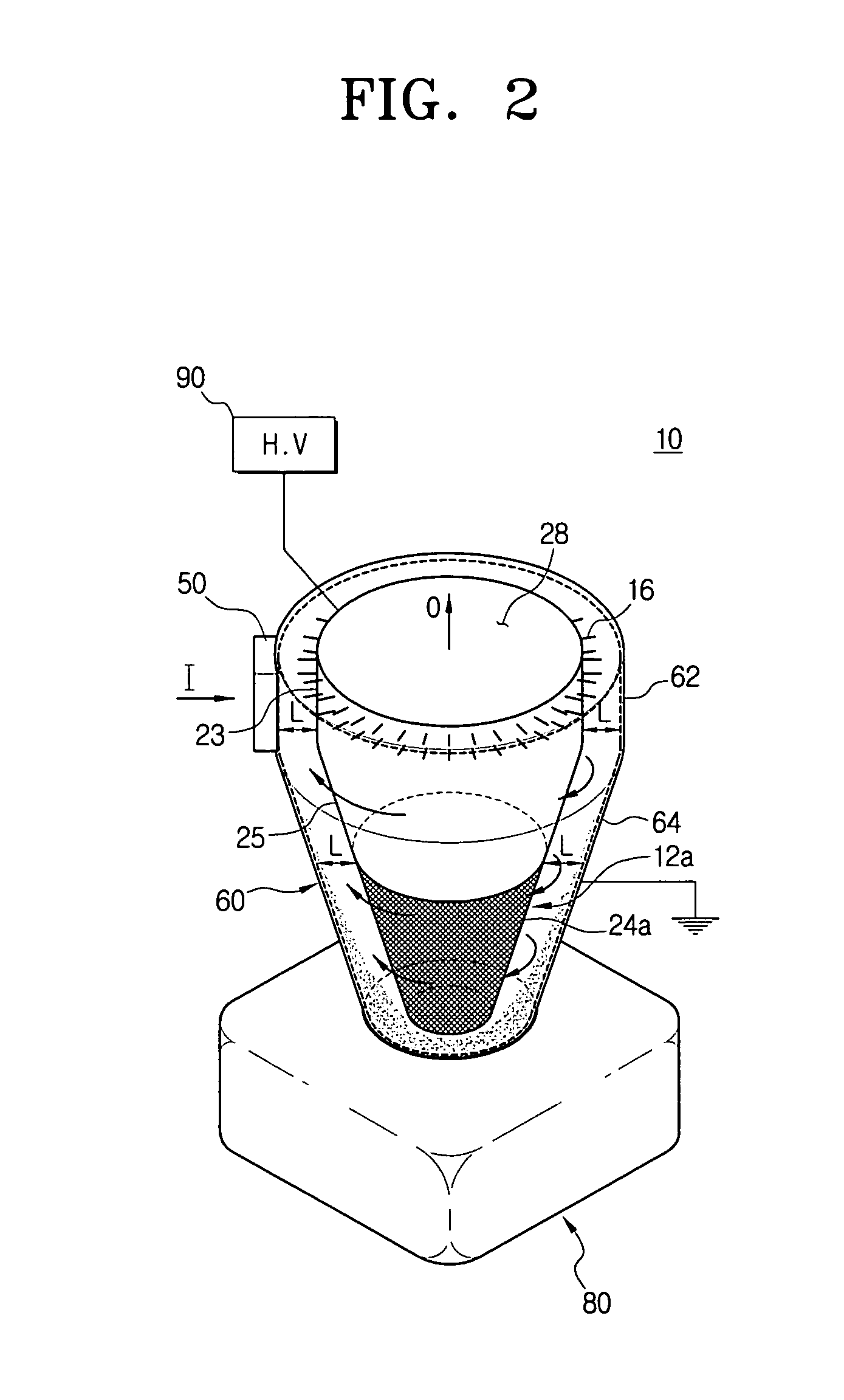

Cyclone dust-separating apparatus with discharge electrodes

InactiveUS7381248B2Improve efficiencyEvenly distributedCombination devicesAuxillary pretreatmentElectricityHigh pressure

A cyclone dust-separating apparatus in which the electrical field and particle charge can be uniform and stable. The cyclone dust-separating apparatus comprises: a cyclone body; an air intake pipe, through which air flows from outside into the cyclone body; an air exhaust pipe, through which air flows out of the cyclone body; a grounding member installed on the inside surface of the cyclone body; a plurality of discharge electrode members installed on the air exhaust pipe; and a high voltage power source connected to the air exhaust pipe. The air exhaust pipe conducts electricity, and the discharge electrode members are installed on one or more sides of the air exhaust pipe, are needle-shaped, and protrude from the outer surface of the air exhaust pipe so as to form a uniform and stable electrical field.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

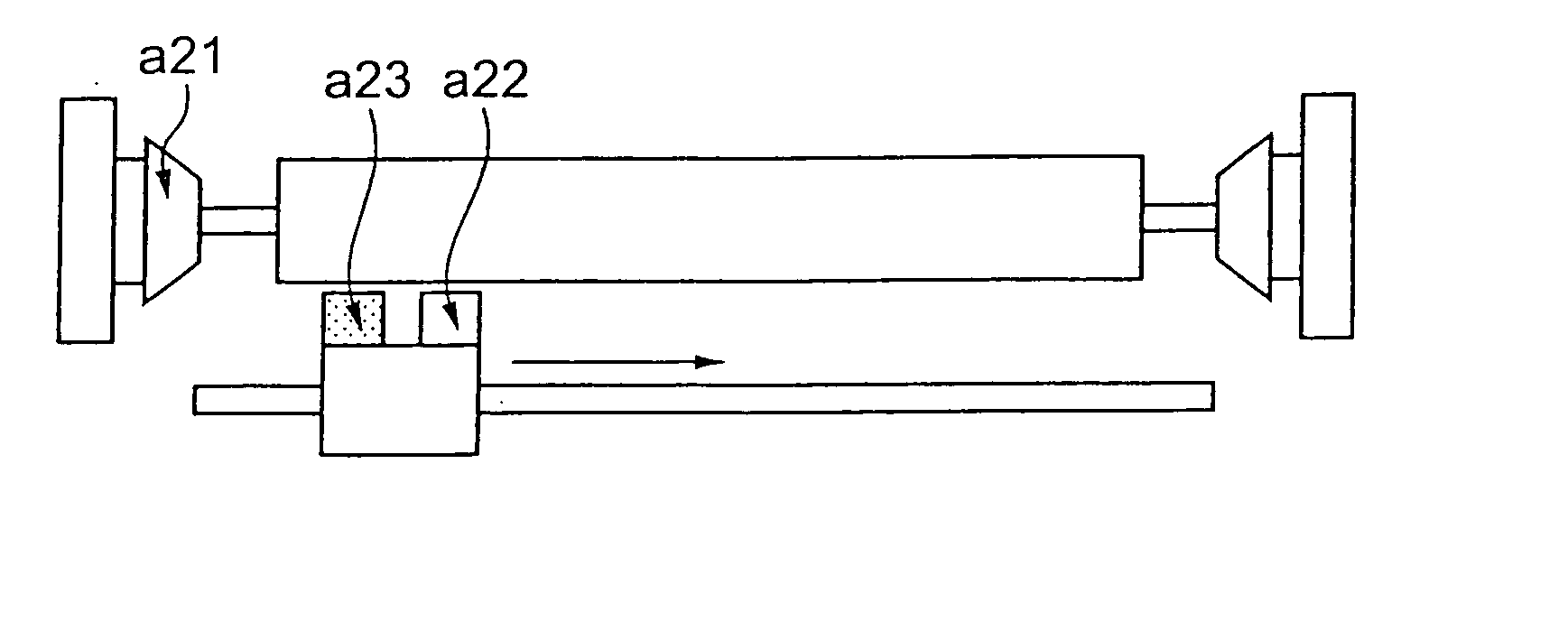

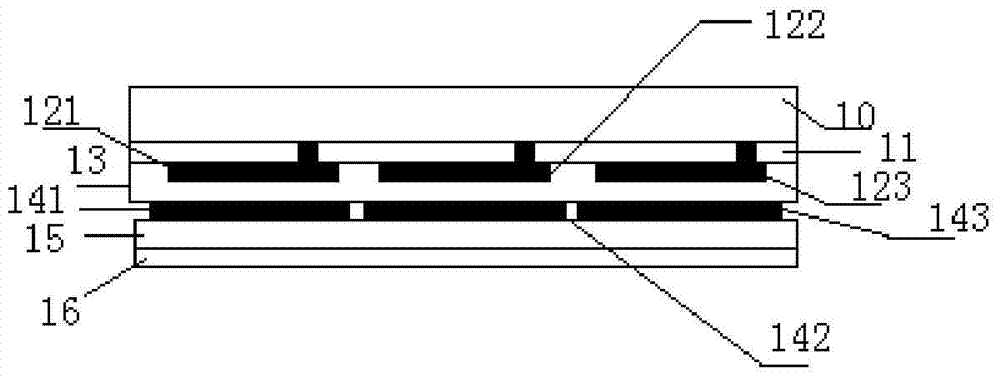

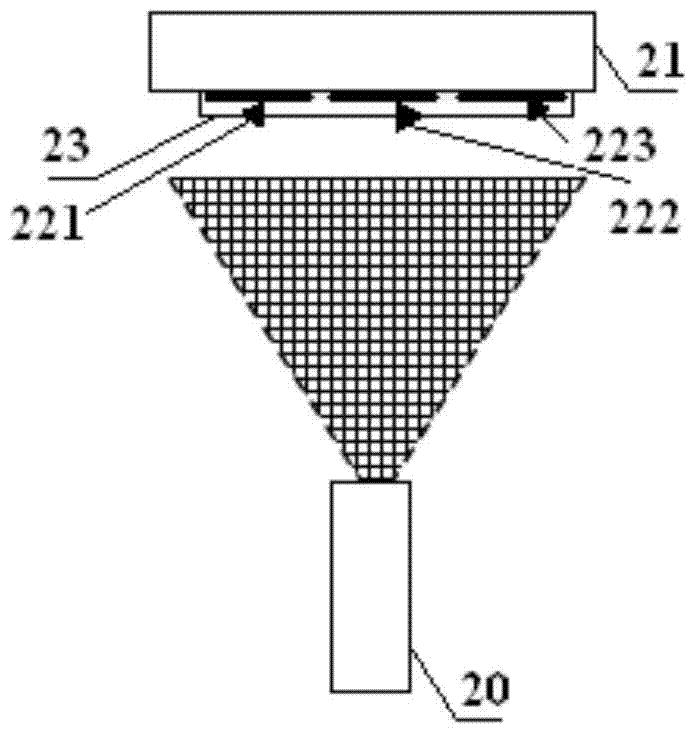

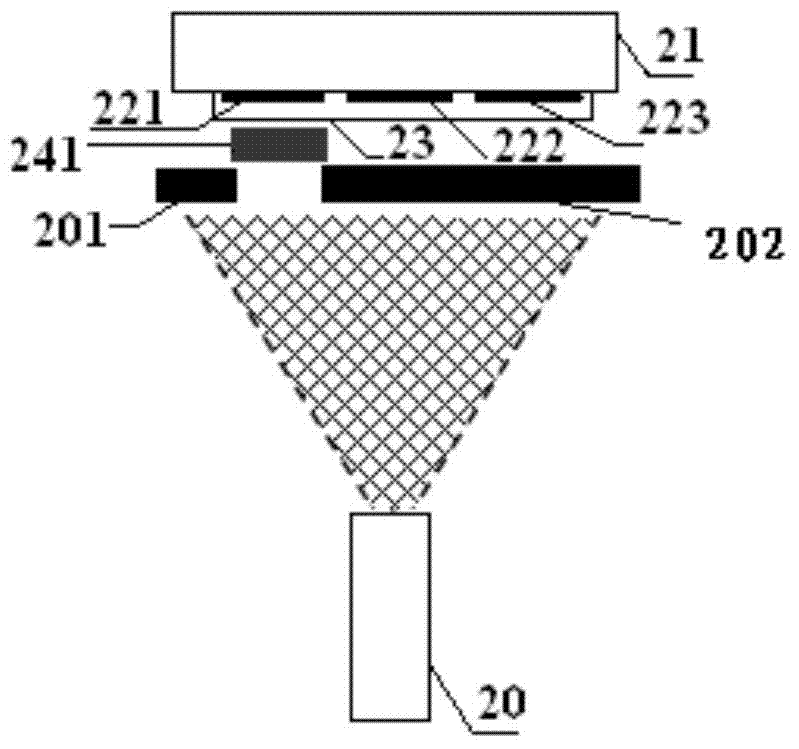

Electrostatic vapor deposition method and device for OEL (organic electroluminescence) display materials

InactiveCN103700780AHigh precisionTake advantage ofSolid-state devicesVacuum evaporation coatingEvaporationOrganic electroluminescence

The invention provides an electrostatic vapor deposition method for OEL (organic electroluminescence) display materials. The method comprises the following steps that an OEL material evaporation source outputs OEL material particles; a particle charging and transportation module controls the OEL material particles to carry charges with the specific polarity, in addition, the OEL material particles carrying the charges with the specific polarity can be directionally transported to an OLED (organic light emitting diode) display back plate; a guide electric field forming module forms a guide electric field among sub pixel electrodes in different colors, so the OEL material particles carrying the charges with the specific polarity can be deposited into a region, corresponding to the sub pixel electrodes in the set color, on the OLED display back plate. The method and the device provided by the invention have the advantages that the deposition positions of the OEL material particles of illumination layers of each sub pixel correspond to the positions of each sub pixel electrode, and patterns formed by the deposition of the OEL material particles of the lamination layers of each sub pixel can be consistent with the shape of the sub pixel electrodes.

Owner:BOE TECH GRP CO LTD

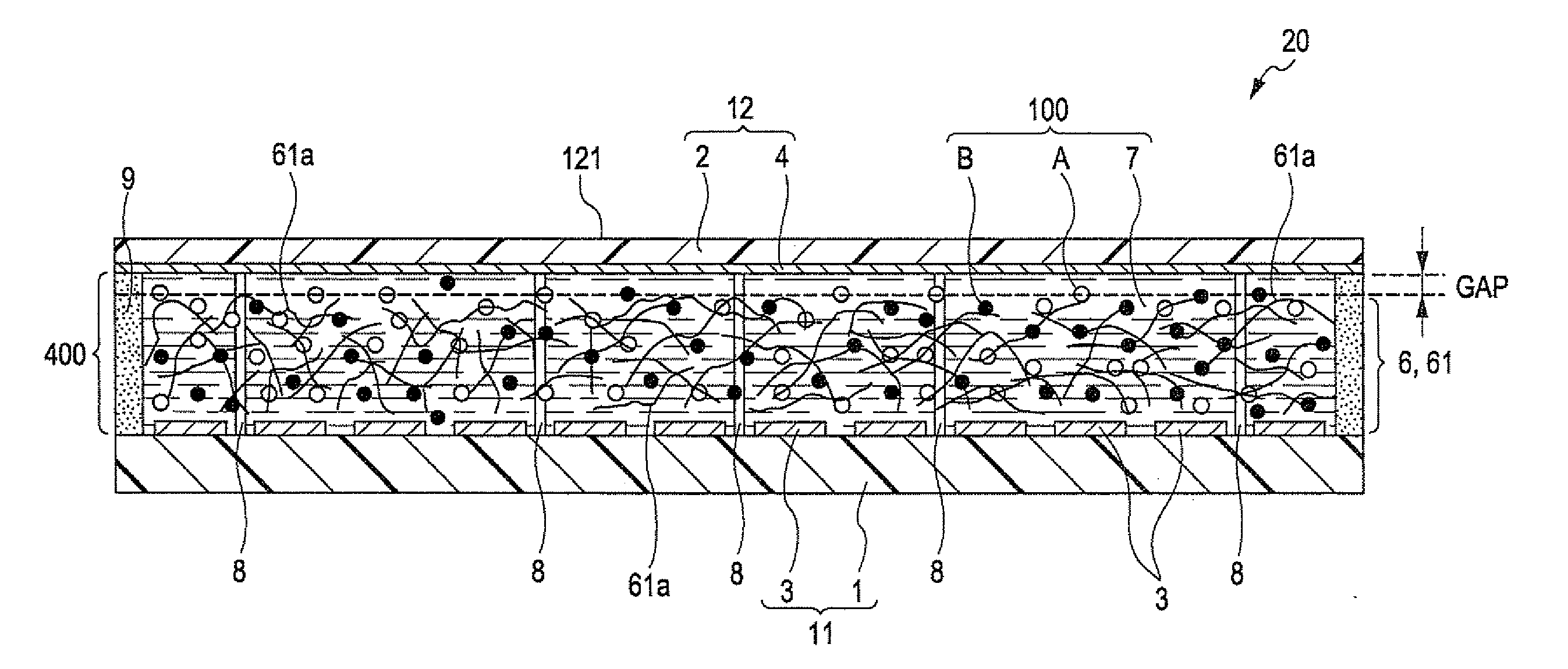

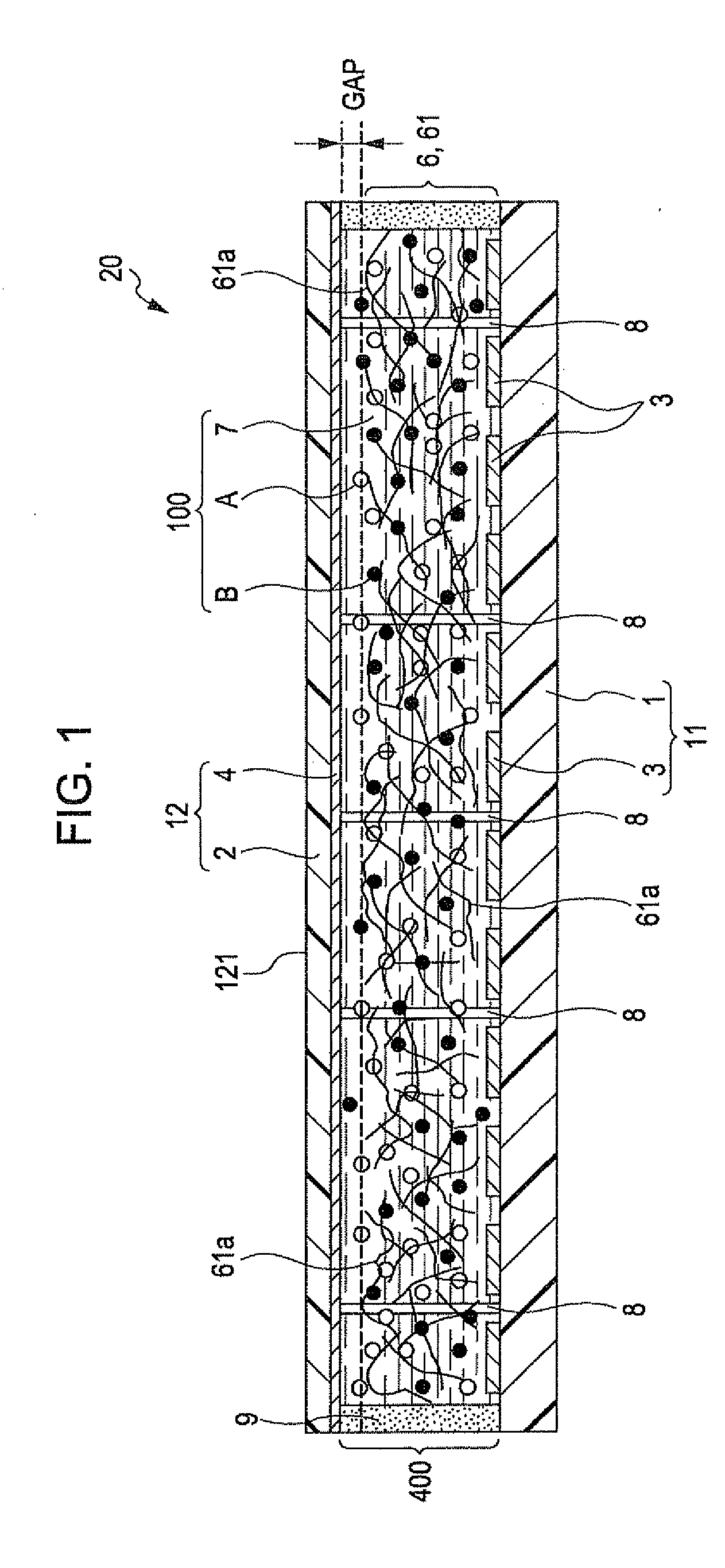

Display sheet, display device, and electronic apparatus

ActiveUS20120099182A1Improve reliabilityImprove display characteristicsNon-linear opticsOptical elementsIn planeDisplay device

A display device includes: a substrate provided on a side of the display surface; a counter substrate disposed to face the substrate; a display layer provided between the substrate and the counter substrate and filled with a dispersion liquid formed of a dispersion medium in which white particles and black particles charged with polarities opposite to each other are dispersed; and a particle constrained layer provided in the display layer, and suppresses the white particles and the black particles from moving in an in-plane direction of the display layer, while allowing the particles to move in the thickness direction of the display layer. In the display device, a particle constrained layer is provided to be separated from the substrate.

Owner:E INK CORPORATION

Highly effective air electronic filter

InactiveCN1565750AAccelerated ionization velocityImprove filtration efficiencyElectrode constructionsIndoor air qualityFiltration

A high performance electronic air filter comprising an ionized region and a dust collecting region is characterized in that: the filter also comprises a condensation region, said condensation region is on the air inlet side, the dust collecting region is on the air outlet side, the ionized region is in the middle, and there is condensation electrode assembly comprising multi-direct current anode and cathode coronas in the condensation region. The filtration efficiency can be improved by arranging a particle charge condensing region above the ionized region. The air filter can filter submicro particles in air, cleaning air, and improve air quality.

Owner:敖顺荣

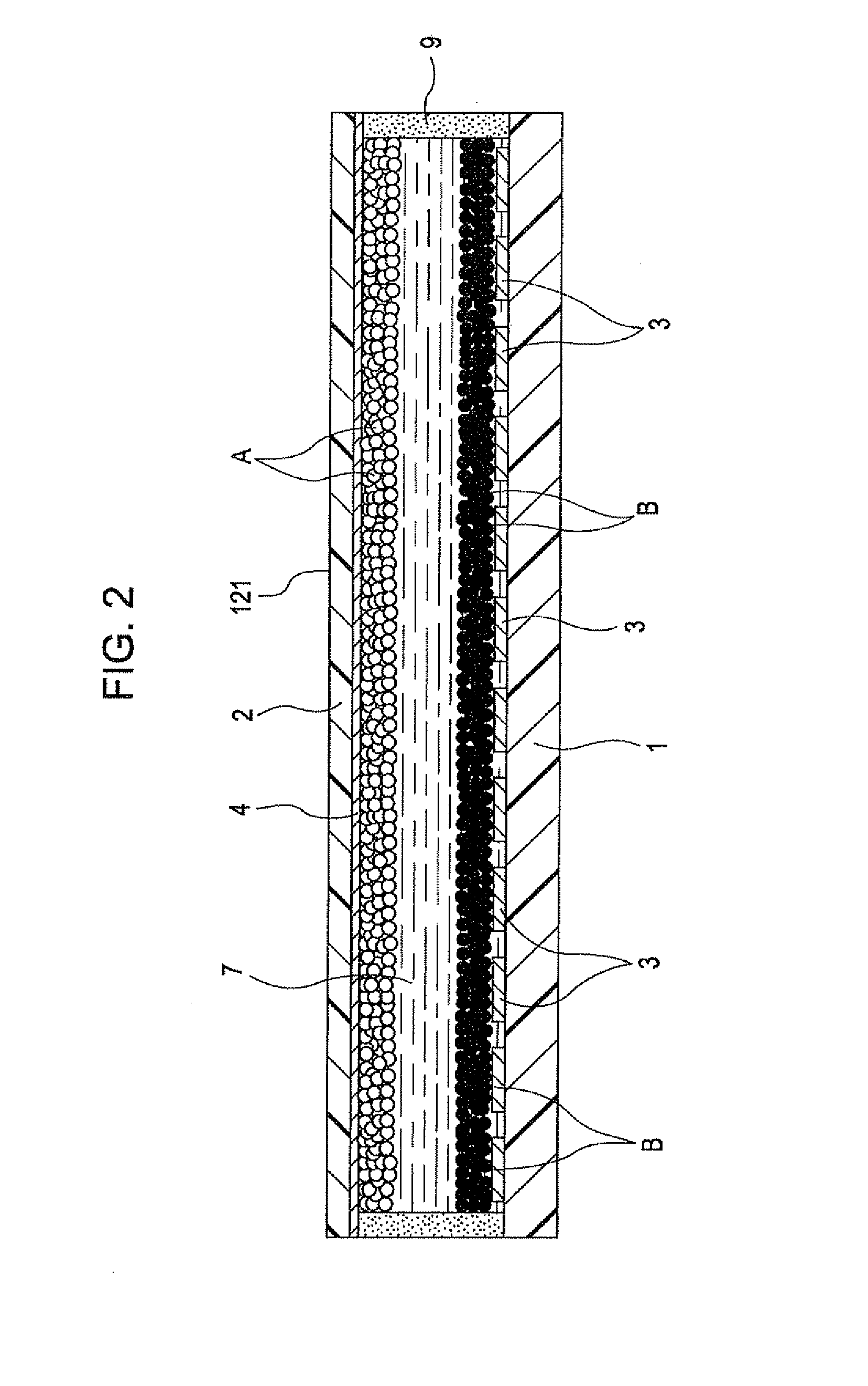

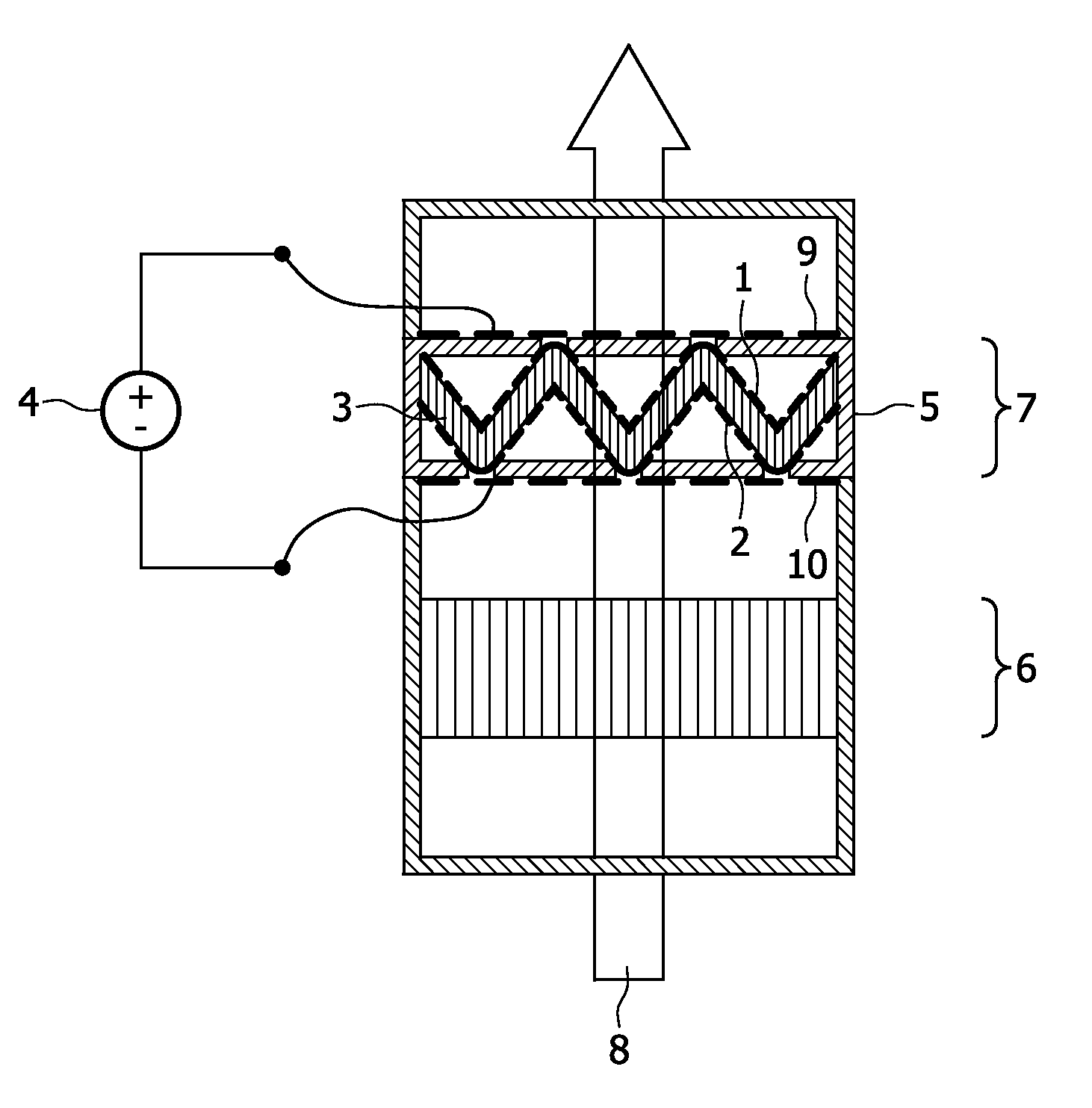

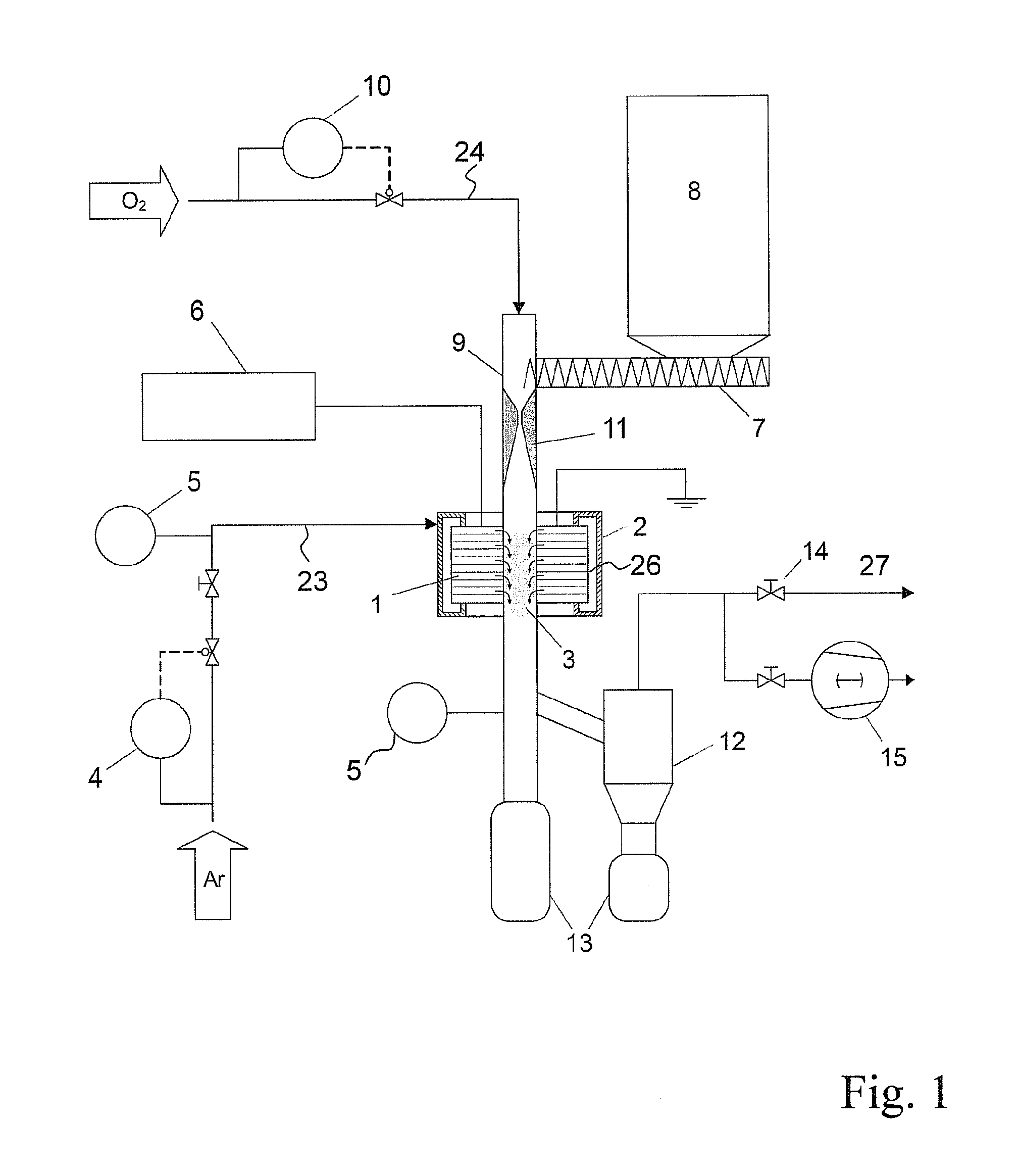

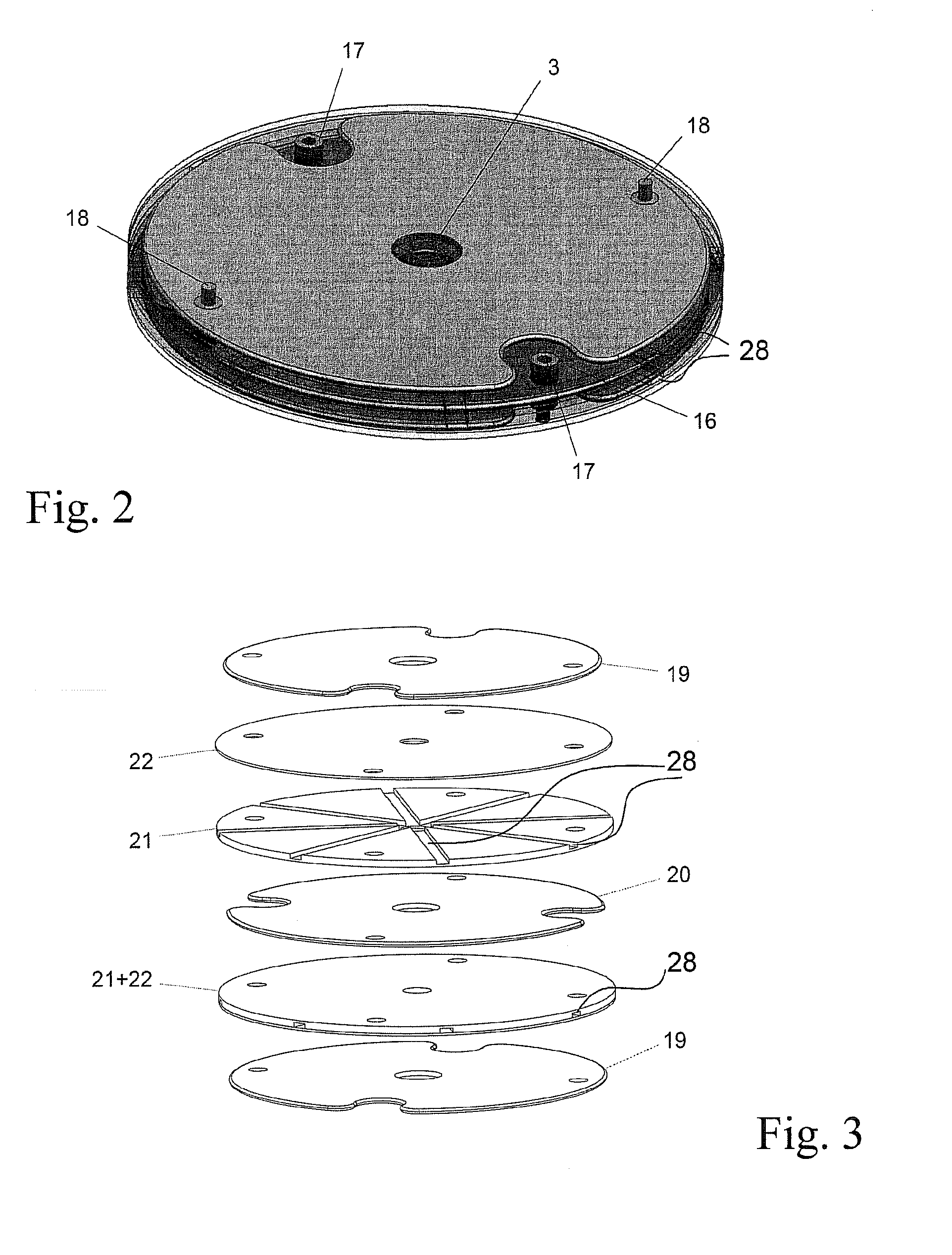

Electrostatic particle filter

InactiveUS8123840B2Particle charging/ionising stationsExternal electric electrostatic seperatorBoundary valuesFilter media

The invention relates to an electrostatic particle filter for removing particles from air. The electrostatic particle filter includes a filter medium (3) with first and second opposite sides, a first electrode (1) and a second electrode (2), the first electrode (1) and second electrode (2) being conformally provided on the first and second sides of the filter medium (3), respectively. The first electrode (1), the second electrode (2), and the filter medium (3) are arranged to allow an electrical conduction current through the filter medium (3). The first electrode (1) is a moderately-conductive electrode having a sheet resistance in a range with a lower boundary value of about 106 Ohm per square and an upper boundary value of about 1012 Ohm per square, at a relative humidity of 30%. The invention also relates to an electrostatic filtration system including the electrostatic particle filter, and a particle charging section (6).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

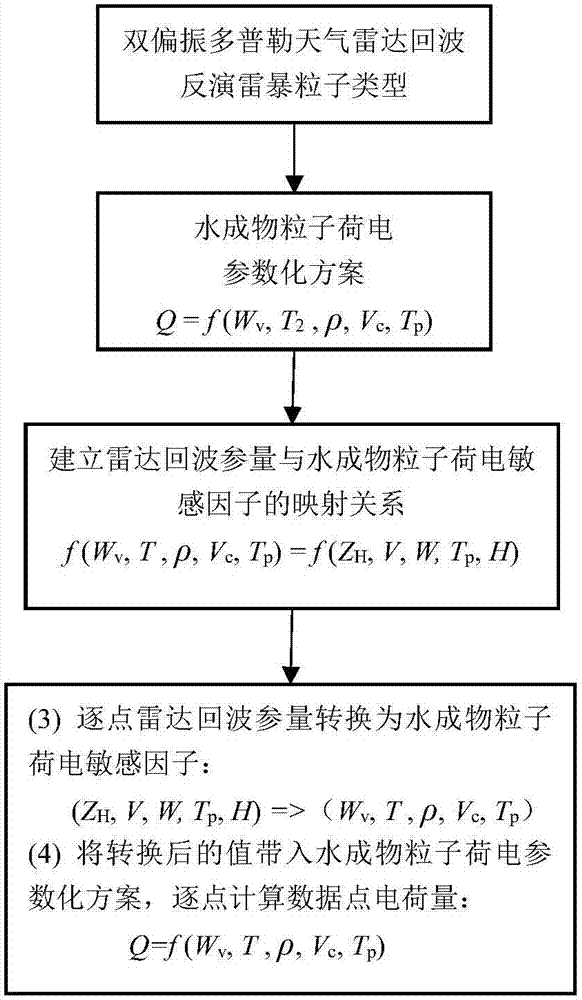

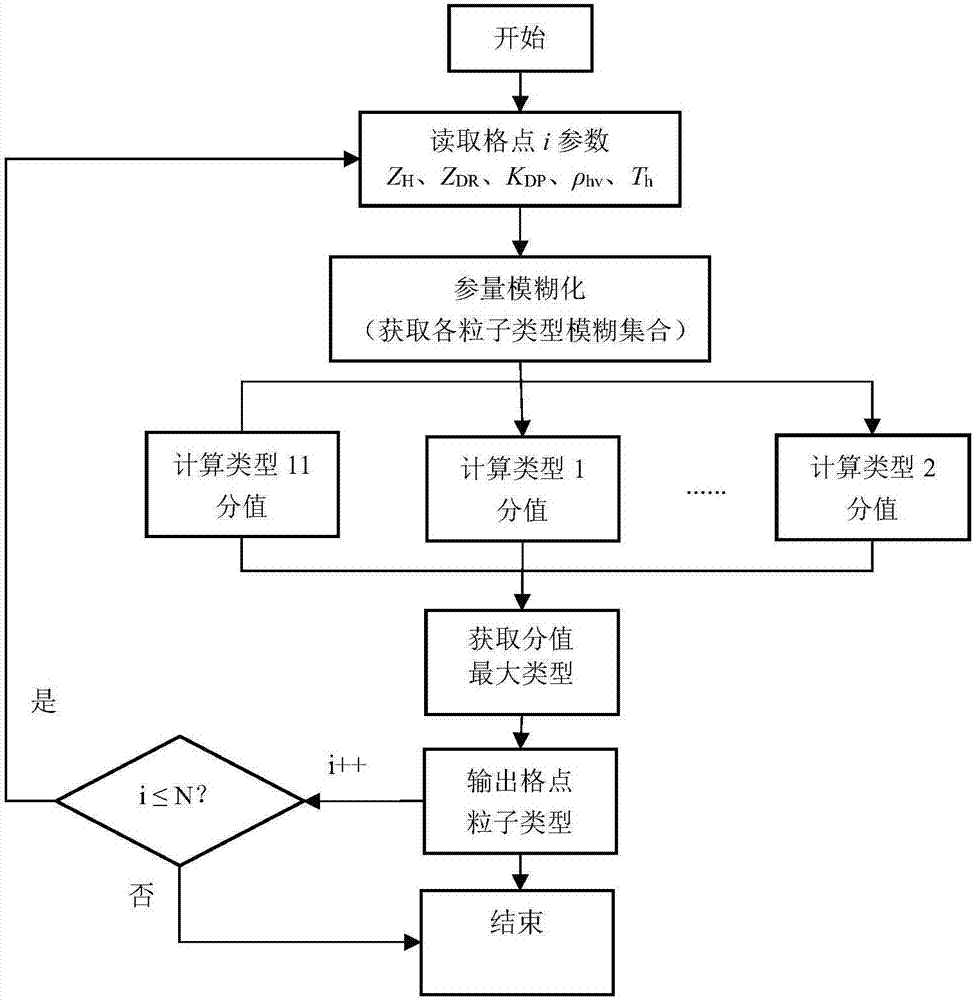

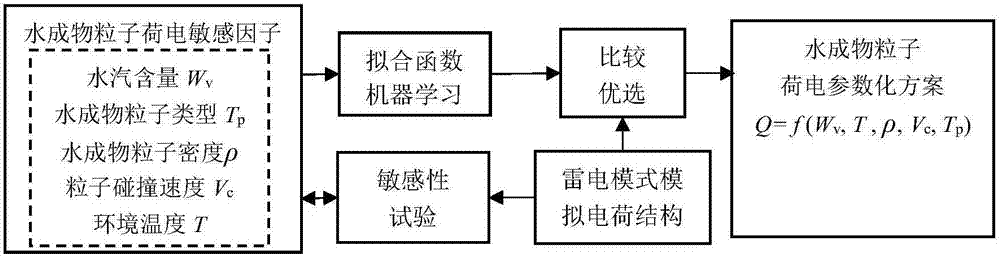

Inversion method of thunderstorm charge distribution by means of dual-polarization Doppler weather radar echo

InactiveCN107238826AAdd secondary productsImprove real-time performanceRadio wave reradiation/reflectionICT adaptationWeather radarRadar detection

The invention discloses an inversion method of thunderstorm charge distribution by means of dual-polarization Doppler weather radar echo. The inversion method of thunderstorm charge distribution by means of dual-polarization Doppler weather radar echo includes the steps: establishing the mapping relation between a dual-polarization Doppler weather radar echo parameter and a hydrometeor particle charge sensitive factor; and according to the mapping relation, converting the radar echo parameter information, such as the reflectivity factor, the Doppler velocity, the spectral width, the hydrometeor particle type and the height, into the related parameters, such as the hydrometeor particle type required by a hydrometeor particle charge parameterization scheme, bringing the result after conversion to the hydrometeor particle charge parameterization scheme, calculating the charge amount of each echo data point, point by point, and realizing inversion of thunderstorm charge distribution. The inversion method of thunderstorm charge distribution by means of dual-polarization Doppler weather radar echo integrates the electrification theory of thunderstorm, the charge structure model and the dual-polarization Doppler weather radar detection technology into one body to realize detection of thunderstorm charge distribution by means of the dual-polarization Doppler weather radar, thus being able to improve the monitoring capability of the dual-polarization Doppler weather radar for thunderstorm.

Owner:杨波 +4

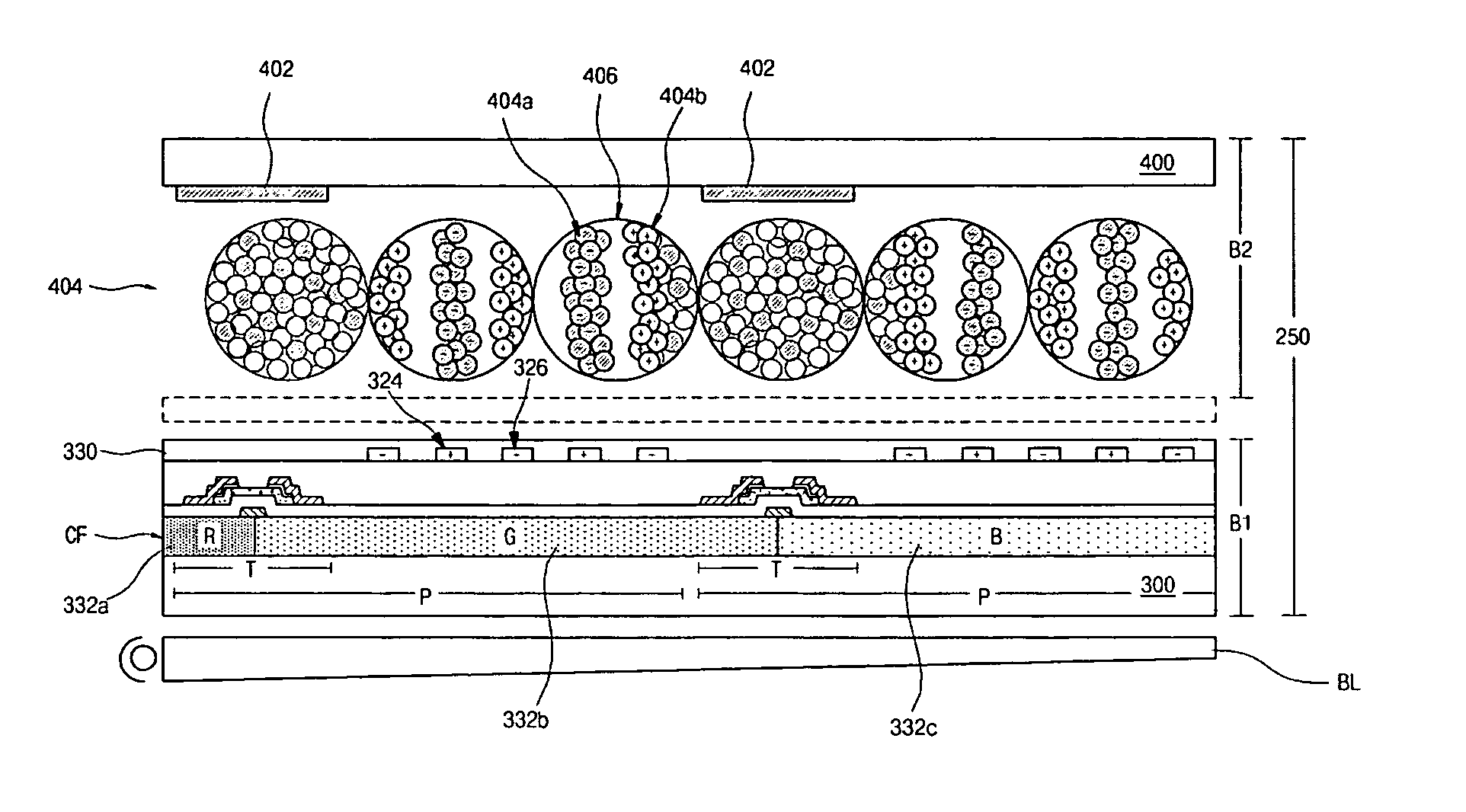

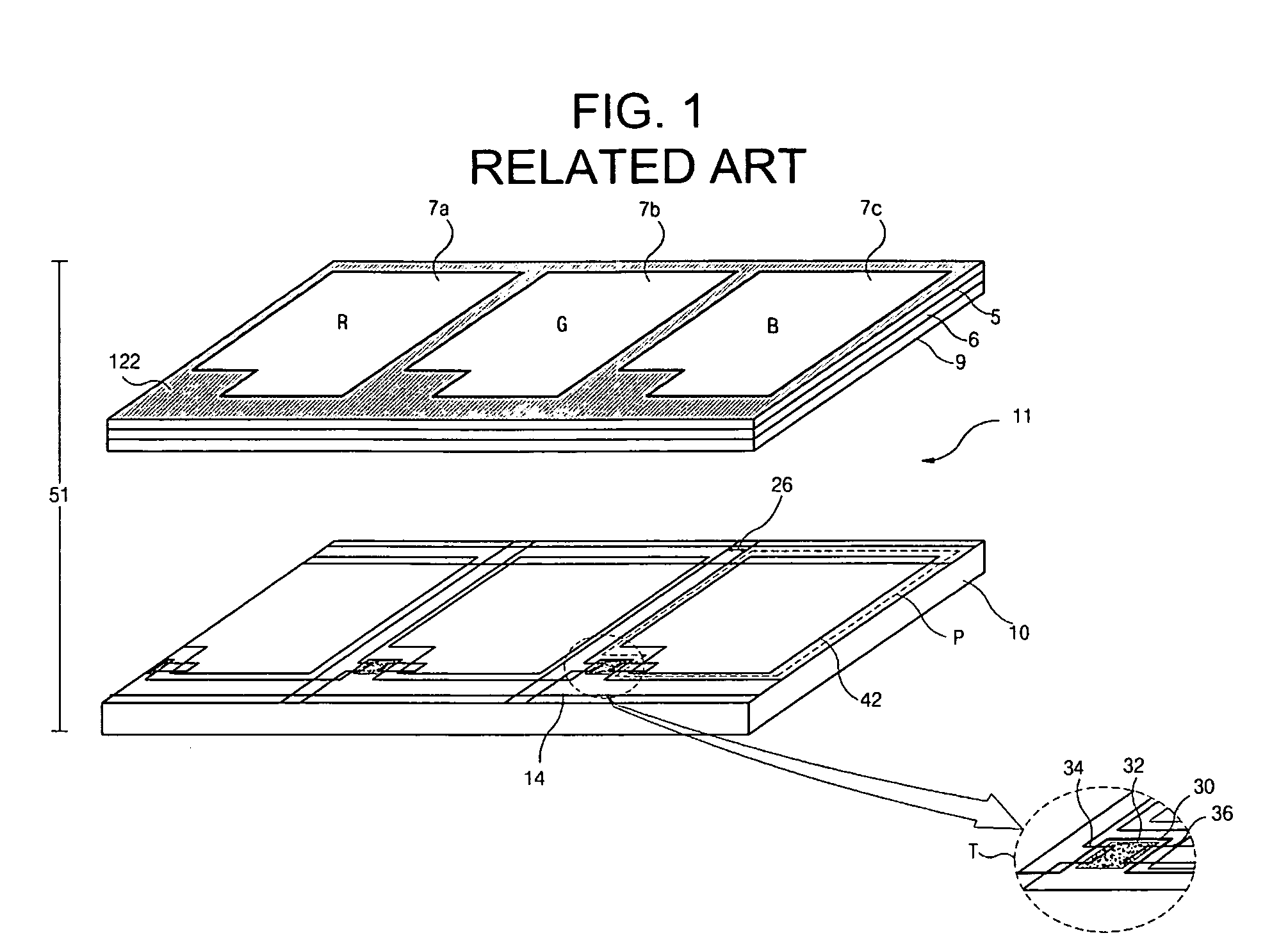

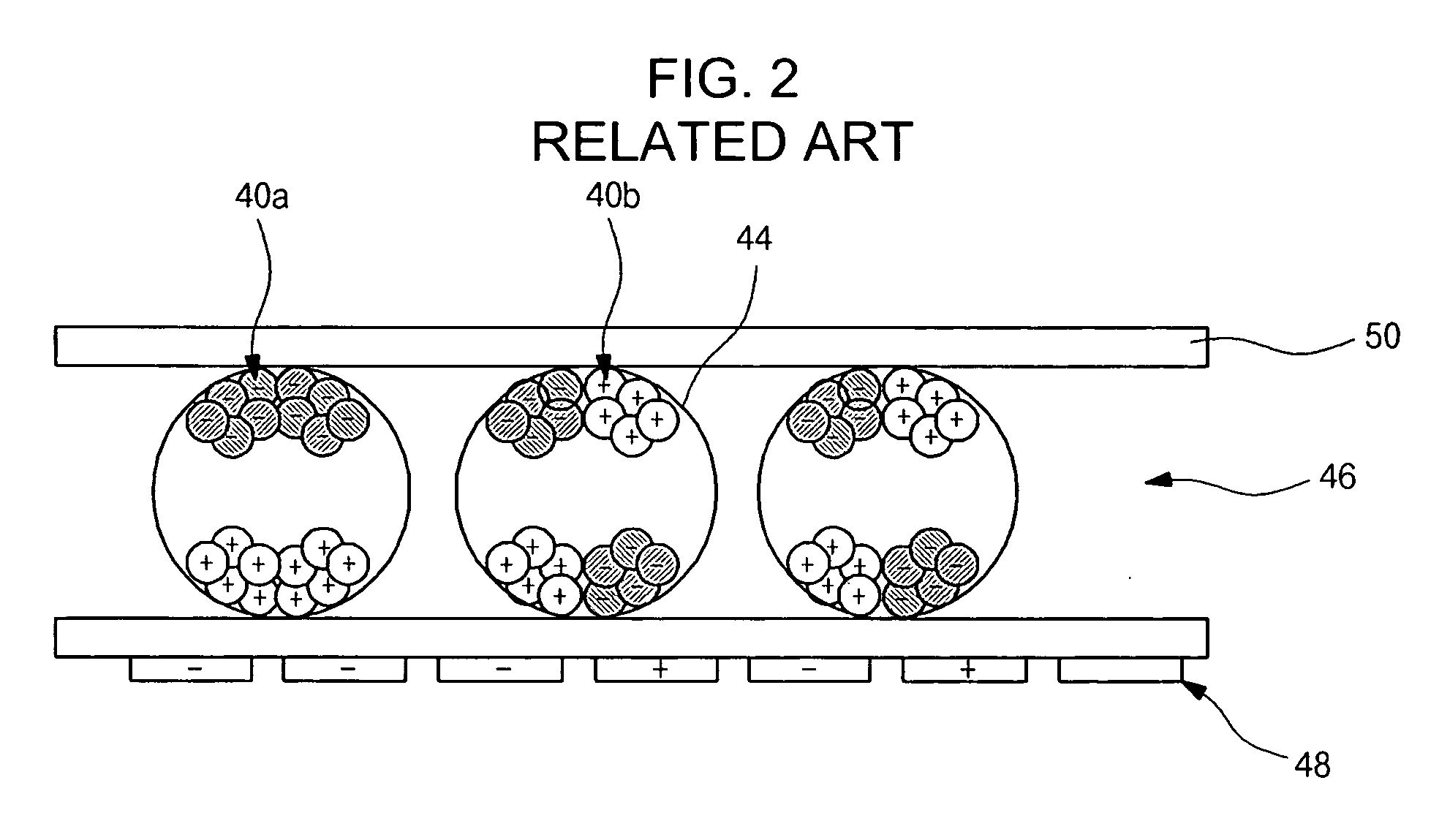

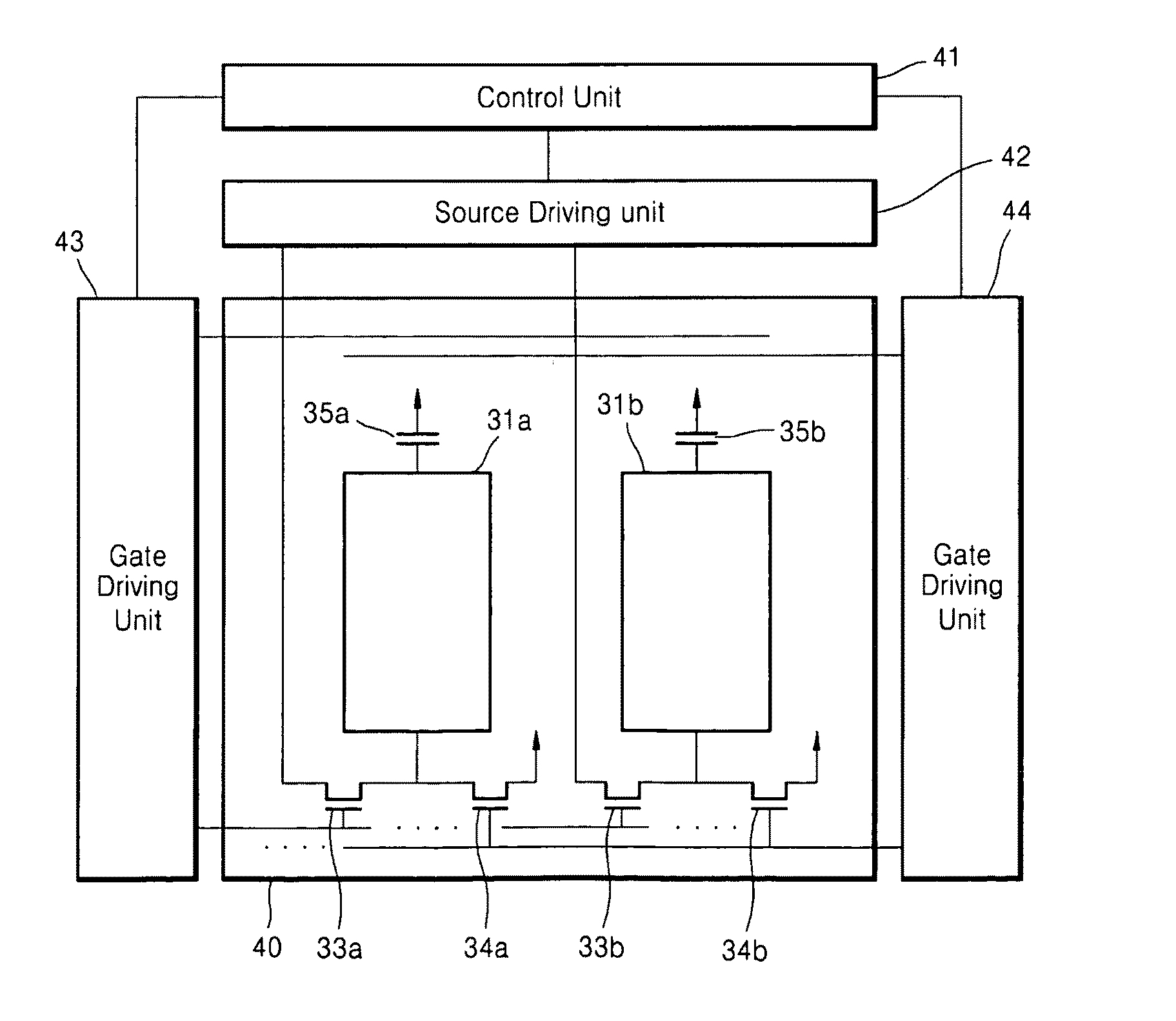

Electrophoresis type display device and method of fabricating and driving the same

ActiveUS20070132713A1Eliminate the problemStatic indicating devicesNon-linear opticsIn planeElectrophoresis

Provided is a electrophoresis type display device includes a pixel electrode and a common electrode on a substrate and inducing an in-plane electric field; an electric charge layer on the pixel electrode and common electrode and having a plurality of first particles and a plurality of second particles, the first and second particles charged with opposite polarities; and a backlight unit supplying light toward the substrate.

Owner:E INK CORPORATION

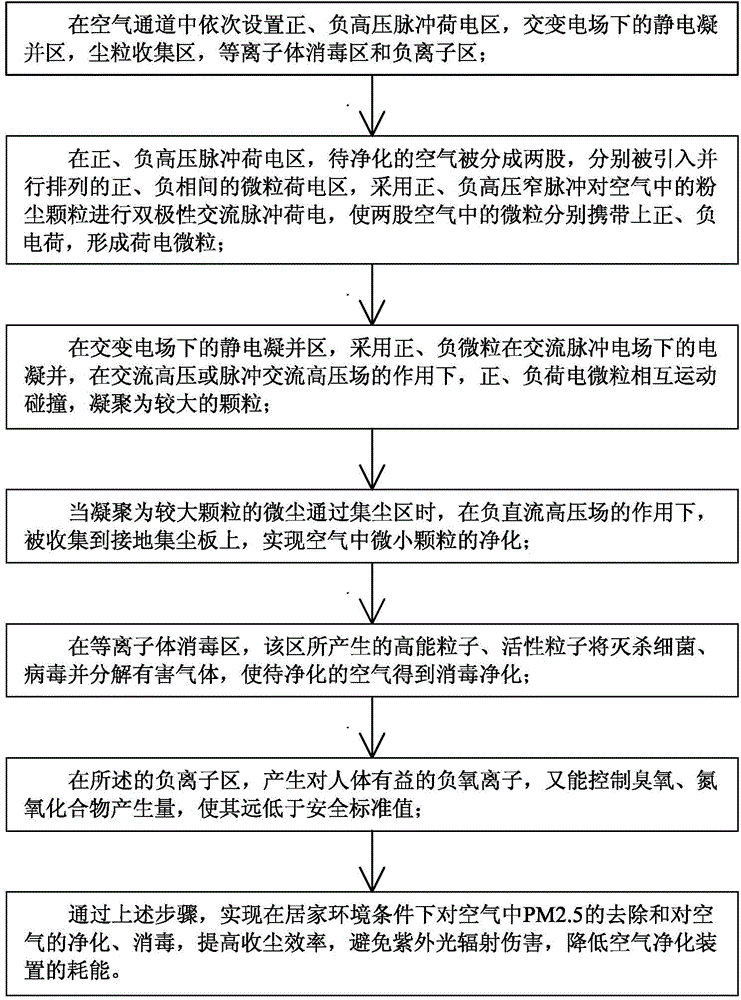

Method for removing fine particulate matters in air under condition of home environment

ActiveCN104588209AAchieve removalAchieve purificationElectrostatic separationHome environmentFine particulate

The invention relates to a method for removing fine particulate matters in the air under the condition of home environment, belonging to the field of purifying treatment. A positive and negative high-voltage pulse charged area, an electrostatic coagulation area under the alternating electric field, a dust particle collection area, a plasma sterilization area and a negative ion area are sequentially arranged in an air channel; in the positive and negative high-voltage pulse charged area, the air to be purified is divided into two parts which are respectively introduced into particle charged areas, and the particle charged areas respectively have the positive and negative charges and are arranged in parallel, so that the positive and negative charges are respectively carried by the particles in the two parts of air, and charge particles can be formed; under the action of alternating current (AC) high-voltage or pulse AC high-voltage field, the positive and negative charge particles have motion collision with one another, and larger particles are coagulated; when passing through the dust particle collection area, the larger-particle dust is collected onto a grounding dust collection plate, so that the fine particulate matters in the air can be purified. After the method is used, in the home environment, the collection efficiency of the fine particulate matters with the particle sizes of less than 10mu m reaches more than 90%.

Owner:上海安平静电科技有限公司

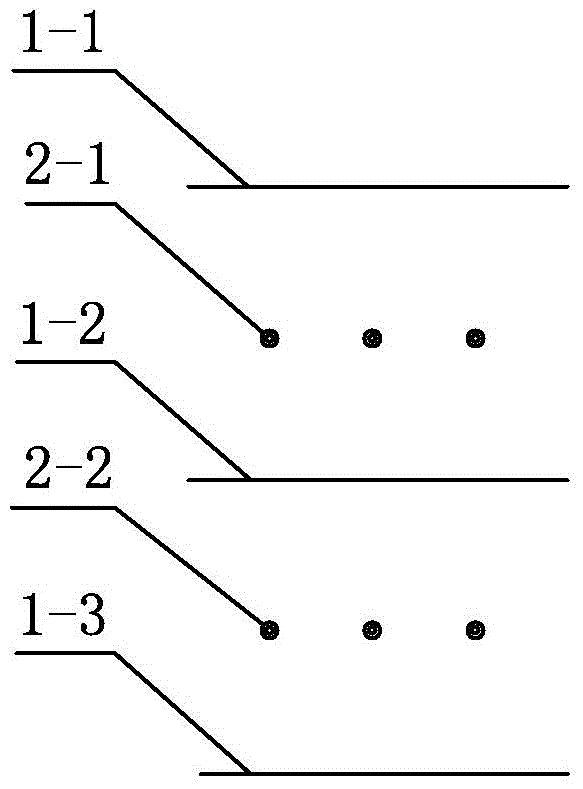

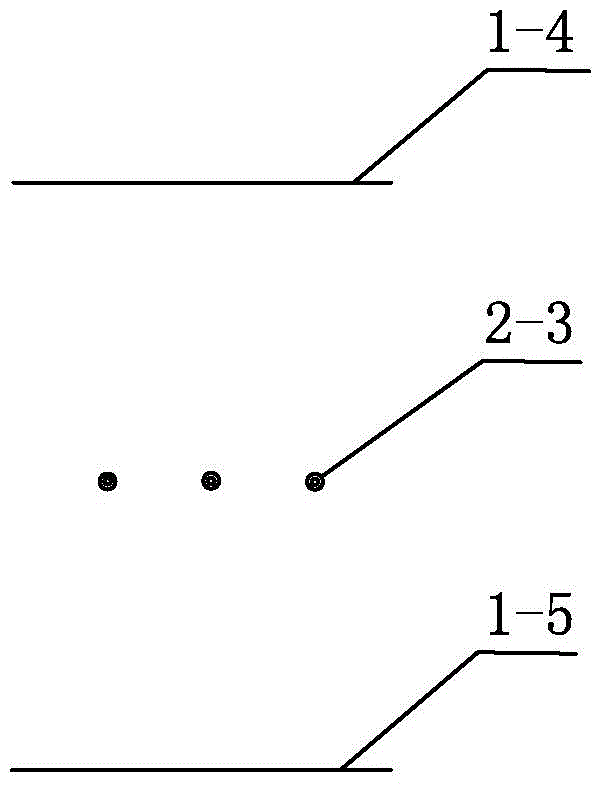

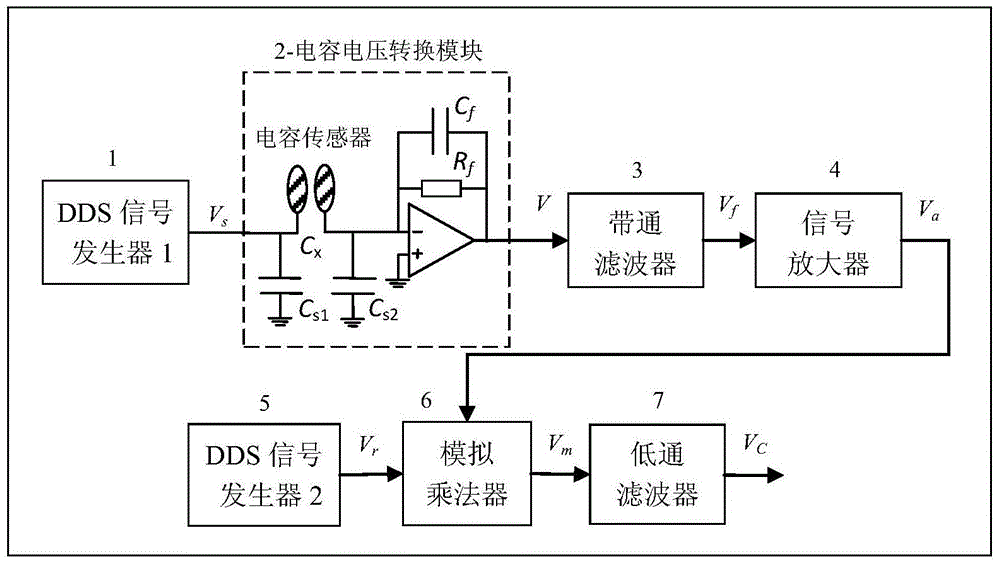

Electrostatic interference preventing capacitance measuring circuit and method

ActiveCN104597328AResolve interferenceDoes not cause measurement biasResistance/reactance/impedenceMaterial capacitancePhase differenceLow-pass filter

The invention discloses electrostatic interference preventing capacitance measuring circuit and method. The measuring circuit comprises a first signal generator, a second signal generator, a capacitance and voltage conversion module, a band-pass filter, a signal amplifier, an analog multiplier and a low-pass filter; the capacitance and voltage conversion module comprises a capacitance sensor, and a converting module for converting the capacitance detected by the capacitance sensor into voltage; the first signal generator is connected with an exciting electrode of the capacitance sensor; the band-pass filter, the signal amplifier, the analog multiplier and the low-pass filter are sequentially connected in series with the output end of the conversion module; the second signal generator is connected to another signal input port of the analog multiplier; an output signal of the second signal generator has the same frequency with the output siganl of the first signal generator, and the phase difference of the two output signals is zero. Compared with the prior art, the circuit has the advantages that the problem of particle charge interference during charge injection, zero drifting and air and solid flowing as the measuring objects can be overcome, and therefore, measurement deviation can be avoided.

Owner:SOUTHEAST UNIV

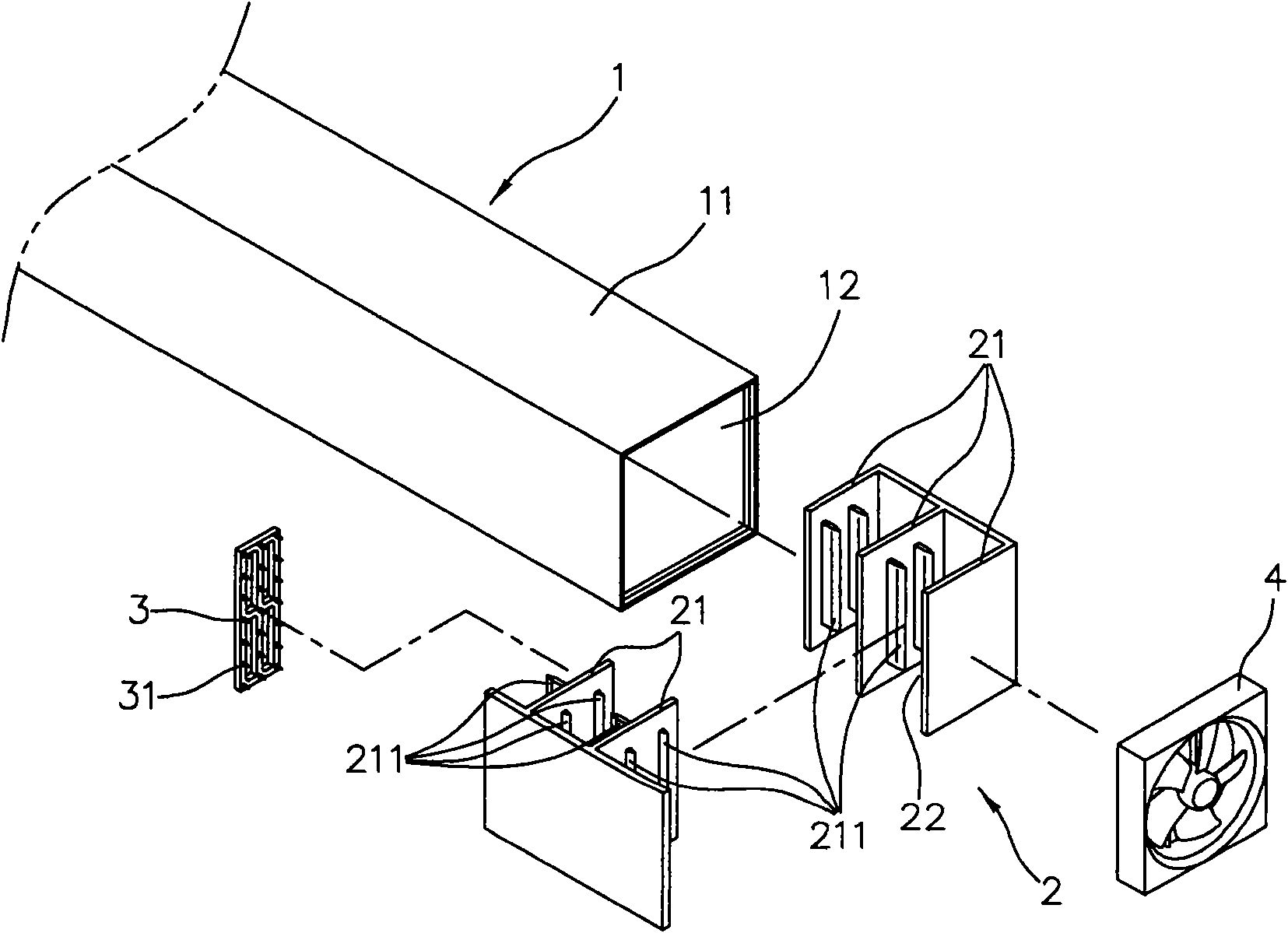

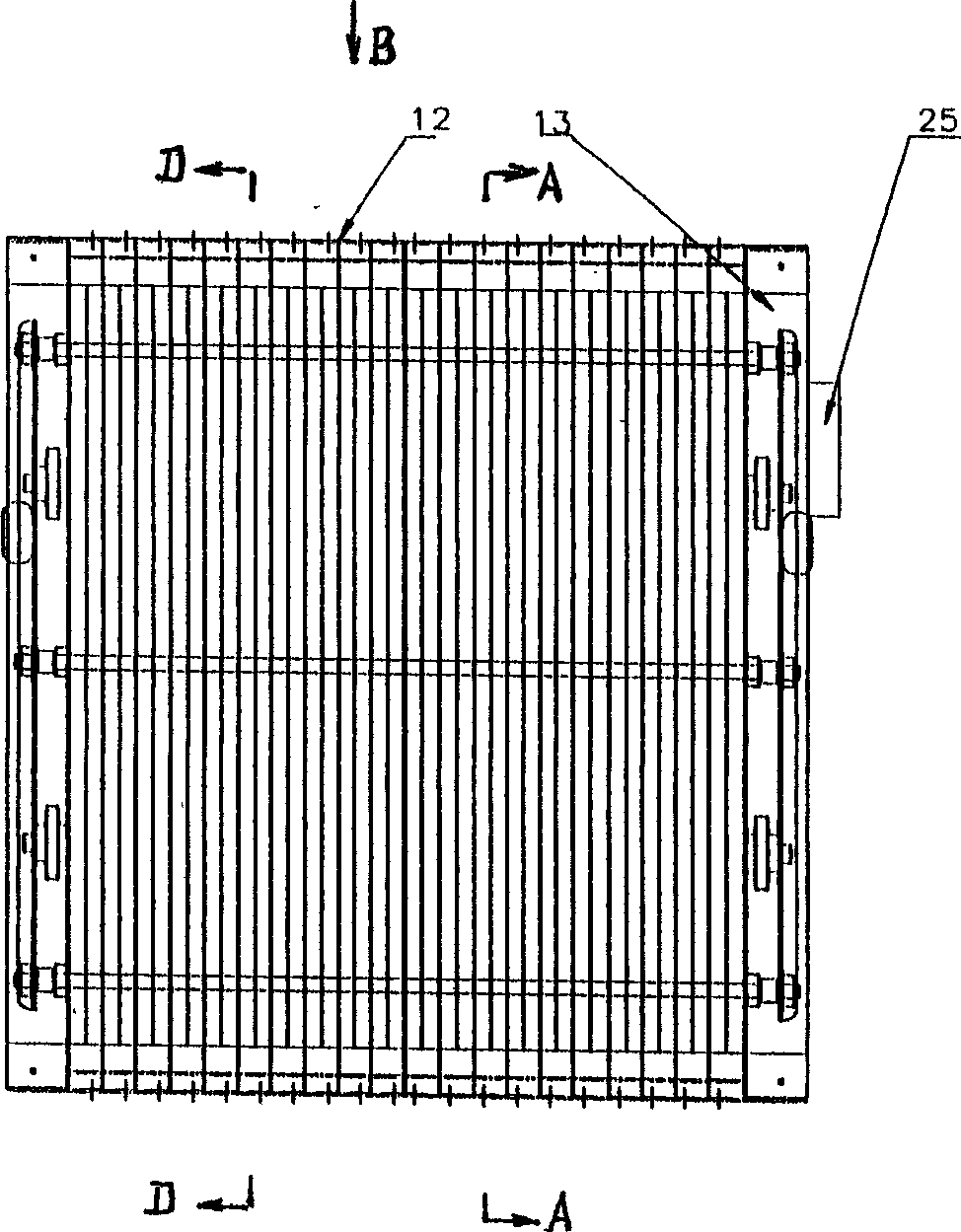

Air filtration system

InactiveUS20090044703A1Add supportEasy to disassembleCombination devicesElectrode carrying meansAir filtrationDielectric

An intense field dielectric air filtration system includes a perimeter frame for wall or ceiling mounting at the inlet of a return air duct for an air conditioning apparatus. A door including a grille disposed thereon is mounted for movement on the frame between working and non-working positions for access to an air filter unit, a pre-filter unit and an intense field particle charging unit. Contacts on the filter unit and the field charging unit engage cooperating contacts on an enclosure mounted on the frame when the door is closed to supply electrical power. An interlock is provided to interrupt power when the door is moved to an open position or the grille is removed. A control system disposed in the enclosure includes user control features accessible when the door is in an open position. An alternate embodiment includes a support frame for positioning the filtration system in ductwork or the like other than a return air inlet.

Owner:TRANE INT INC

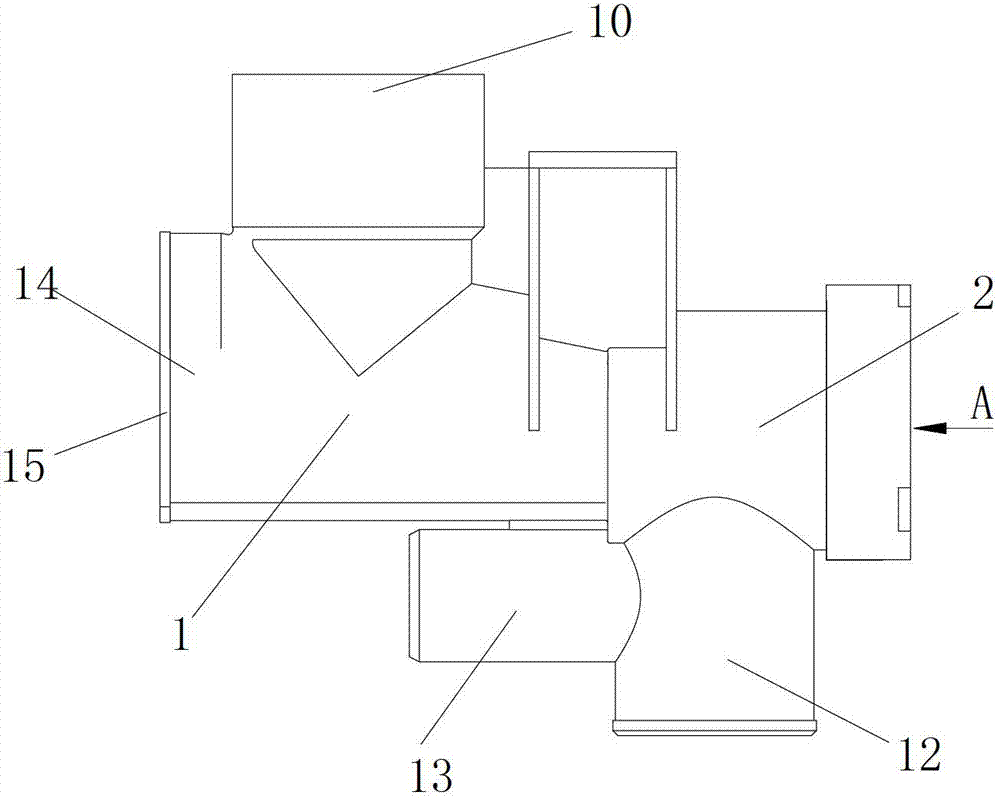

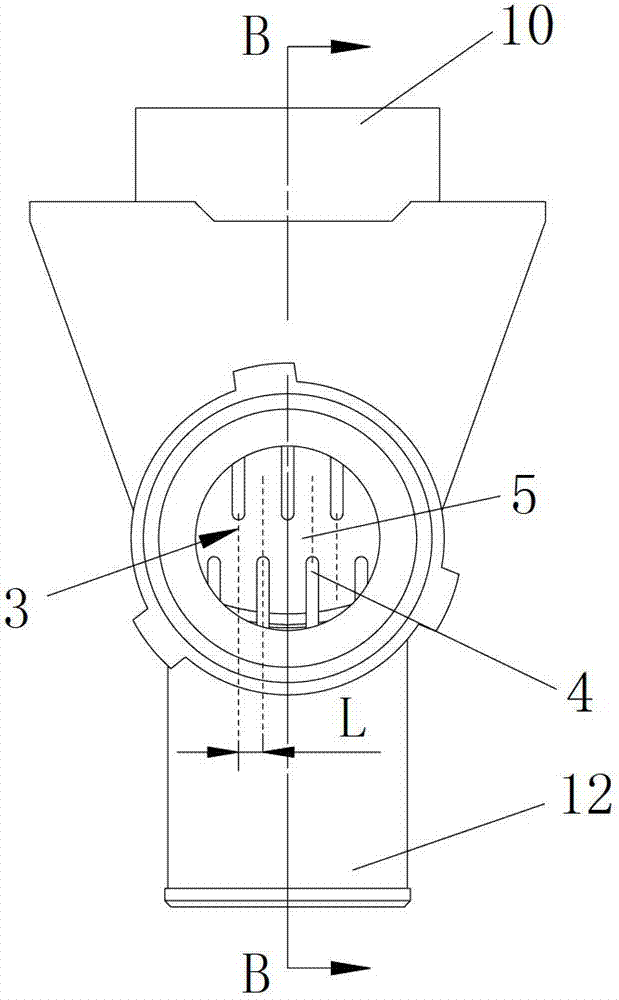

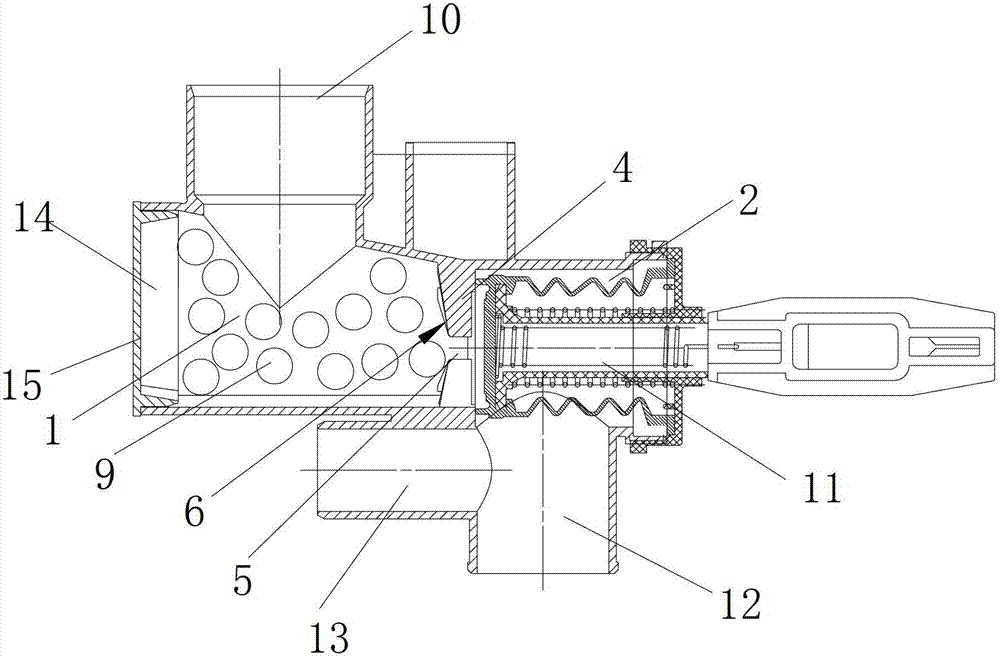

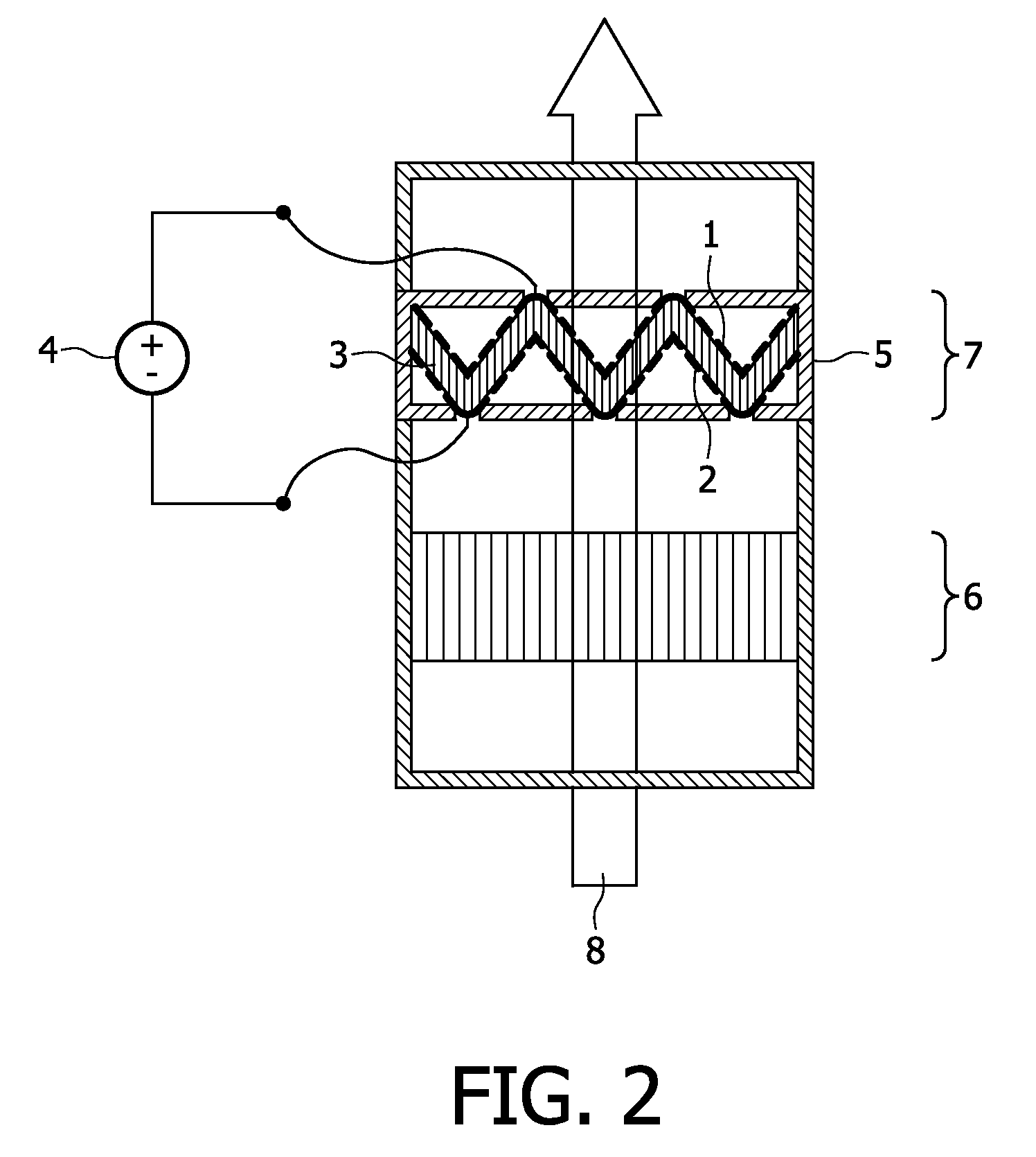

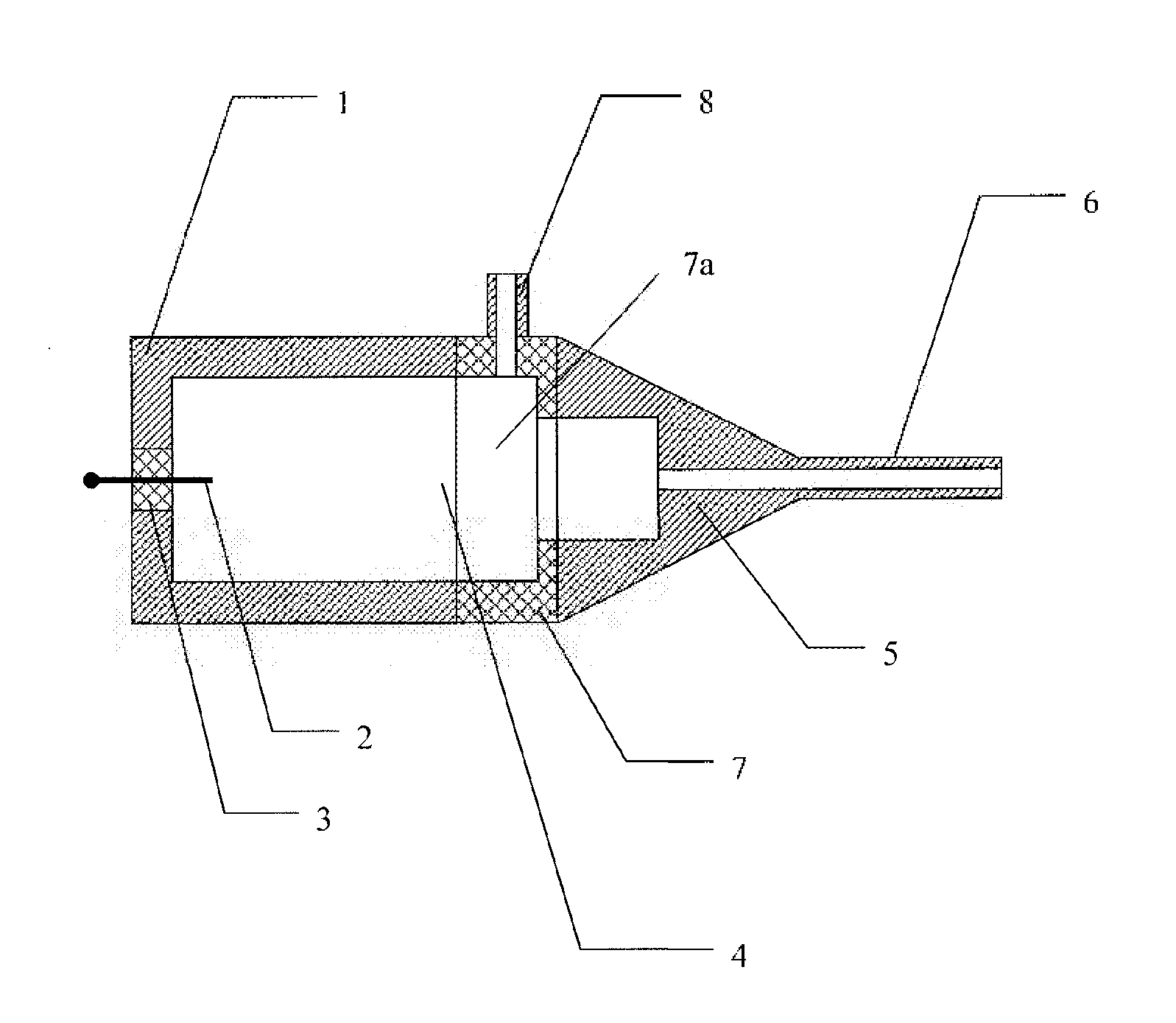

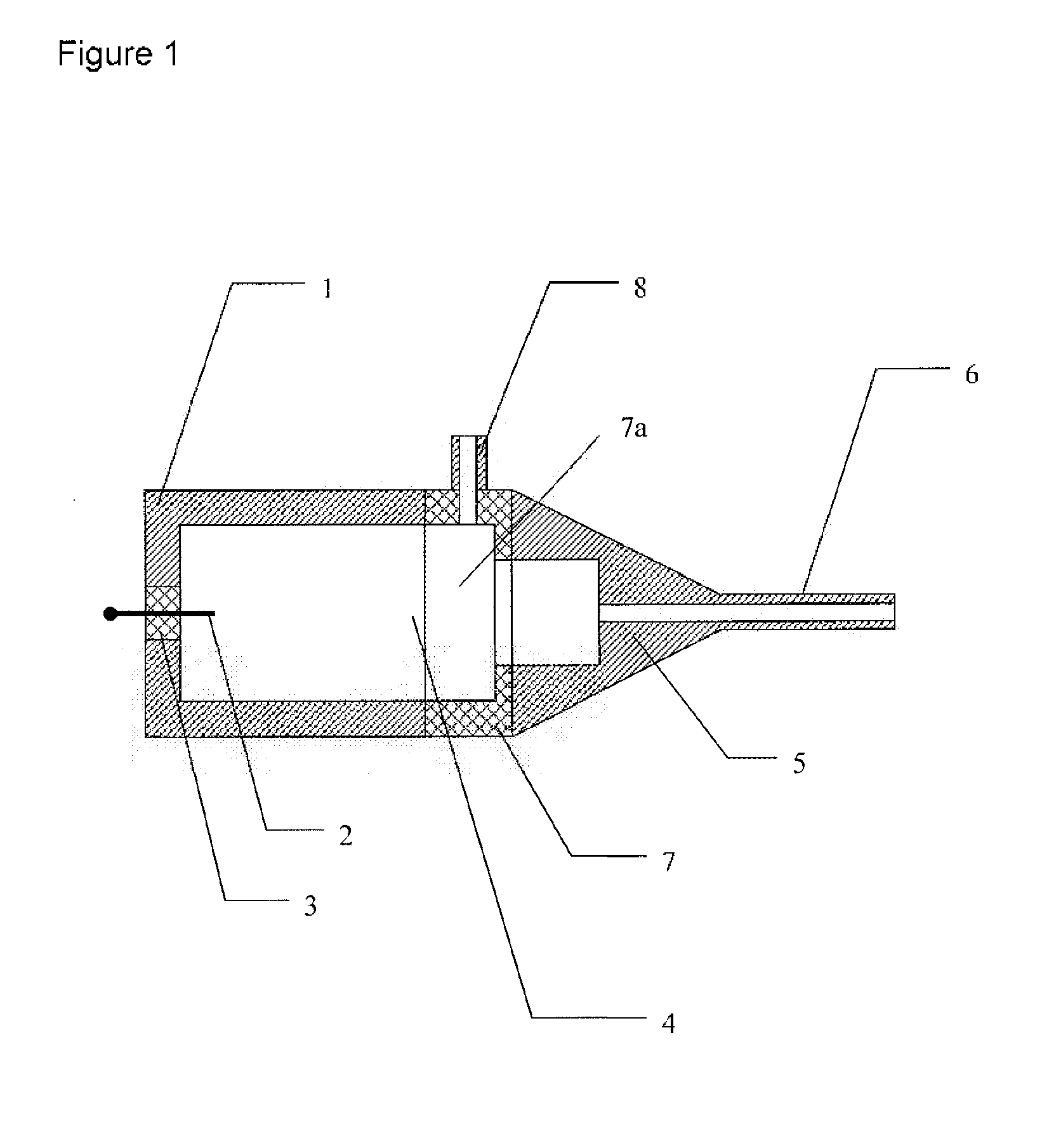

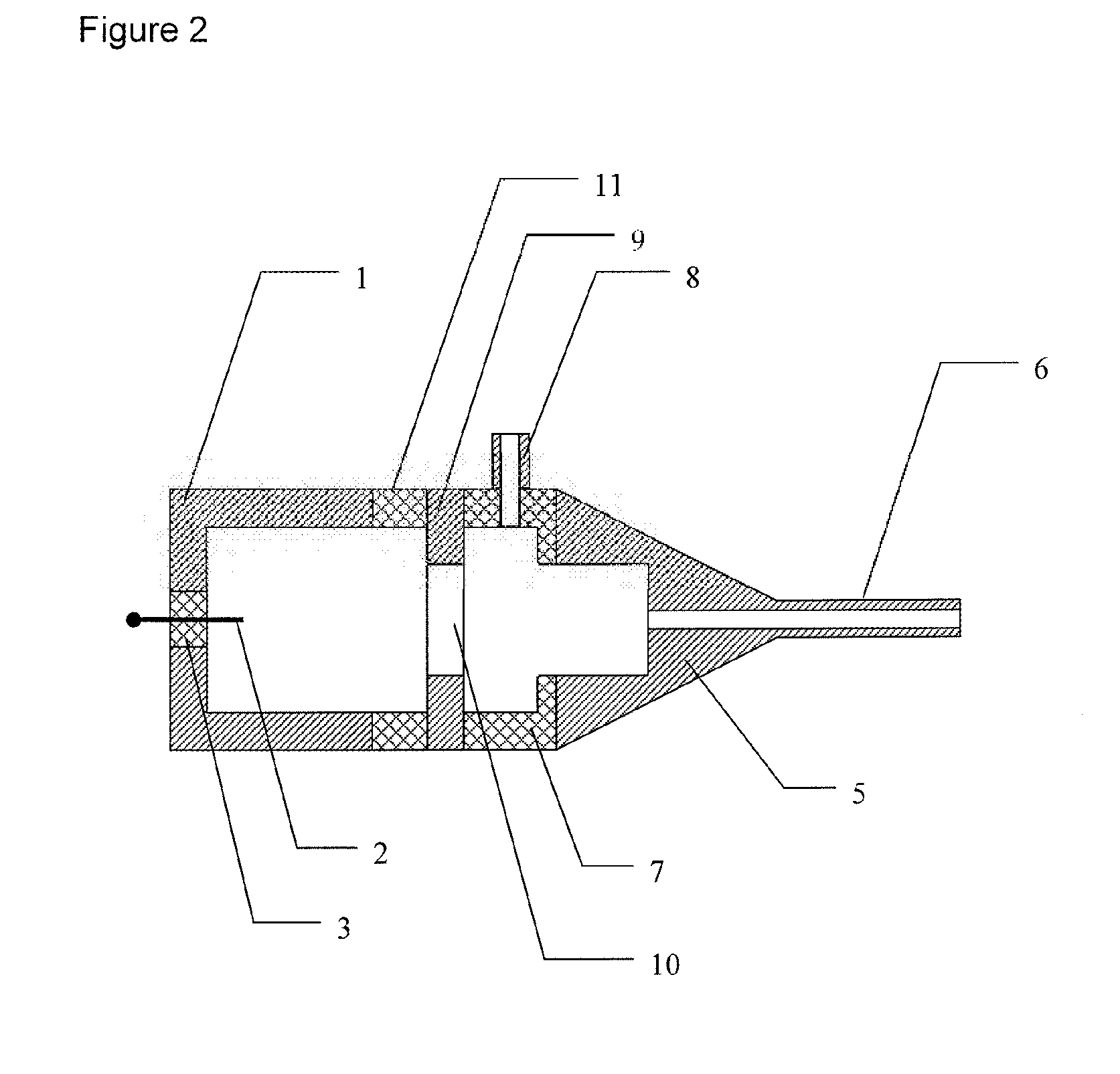

Apparatus for charging or adjusting the charge of aerosol particles

InactiveUS20160126081A1Corona discharge reductionImprove performanceMaterial analysis by optical meansIon sources/gunsCorona dischargeHigh voltage

The invention provides an apparatus for charging or altering the charge of gas-entrained particles in an aerosol, the apparatus comprising:(a) an ion generating chamber (1) containing a first electrode (2) for generating a corona discharge, the first electrode (2) being connected to a power supply of sufficiently high voltage to create the corona discharge; the ion generating chamber (1) having an ion outlet (10) through which ions generated by the corona discharge can leave the chamber (1);(b) a particle charging chamber (5) in which charging or altering the charge of gas-entrained particles in an aerosol takes place, the particle charging chamber (5) being in fluid communication with the ion generation chamber (1) and having an inlet and an aerosol outlet; and(c) an electrically non-conductive interface body (7) positioned between the aerosol particle charging chamber (5) and the ion generating chamber (1), the interface body (7) having a hollow interior which is in fluid communication with the ion generating chamber (1) and the aerosol particle charging chamber, and having a gas inlet (8) through which a stream of gas can be introduced into the hollow interior of the interface body (7).

Owner:PARTICLE MEASURING SYST

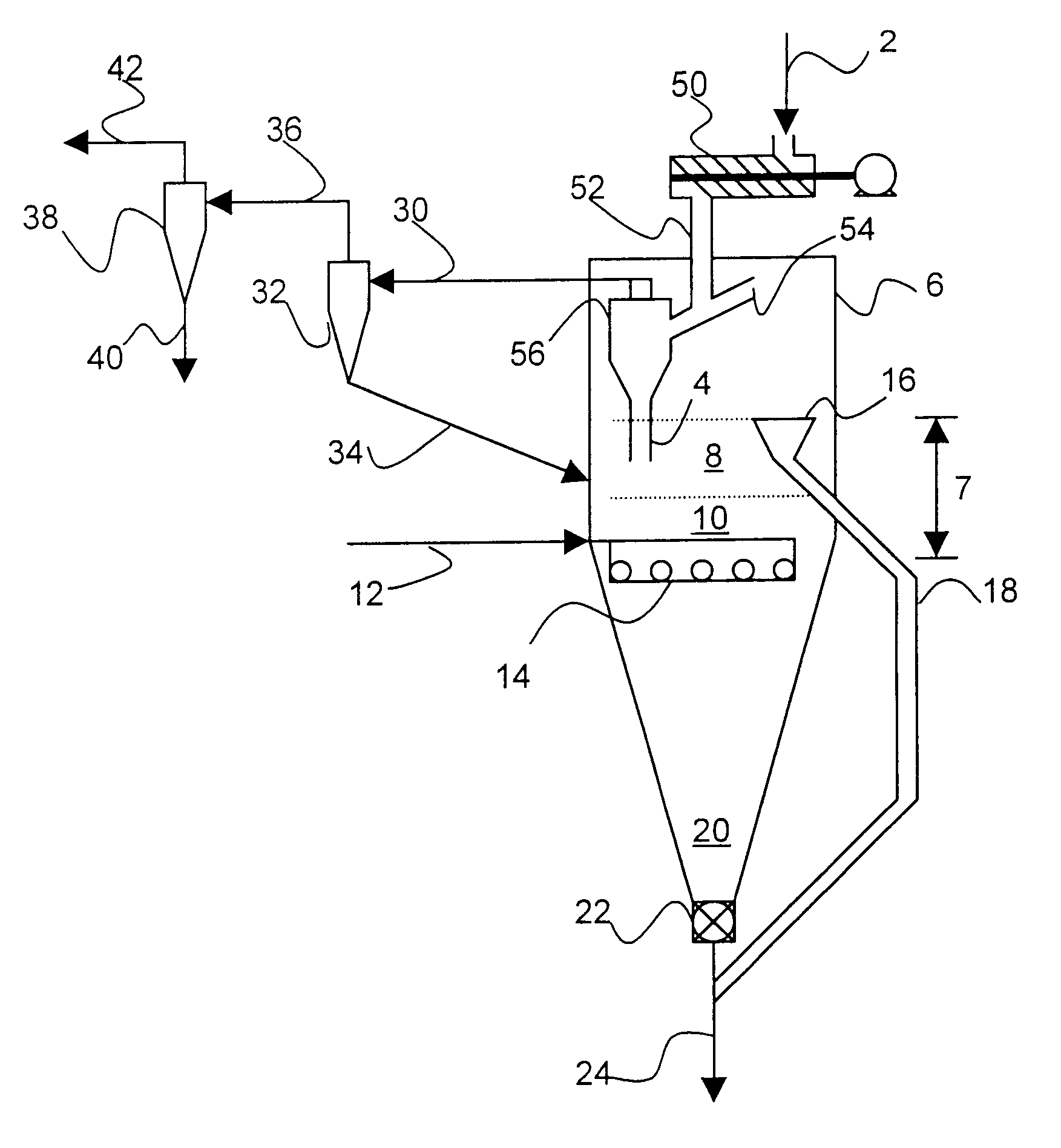

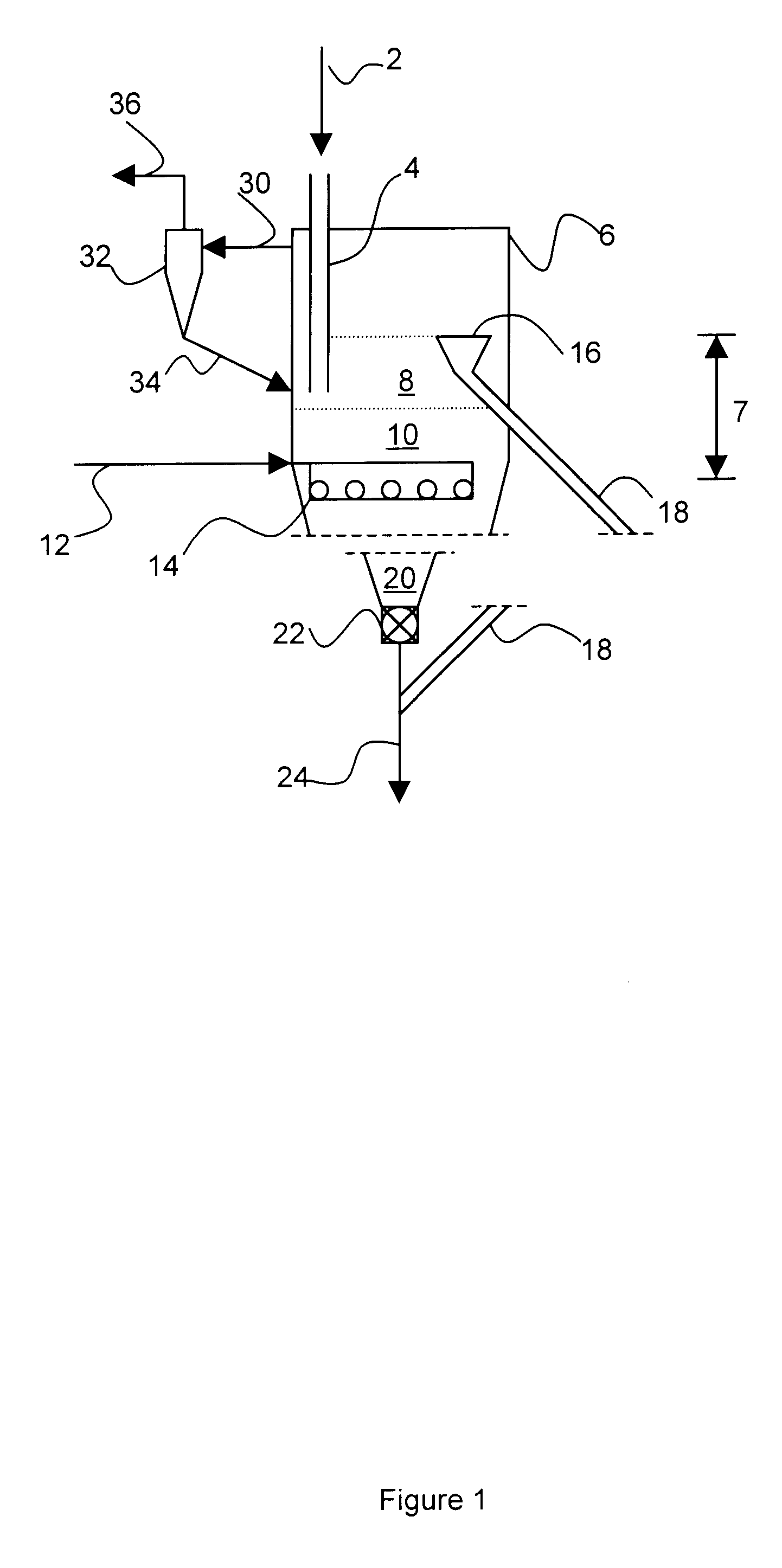

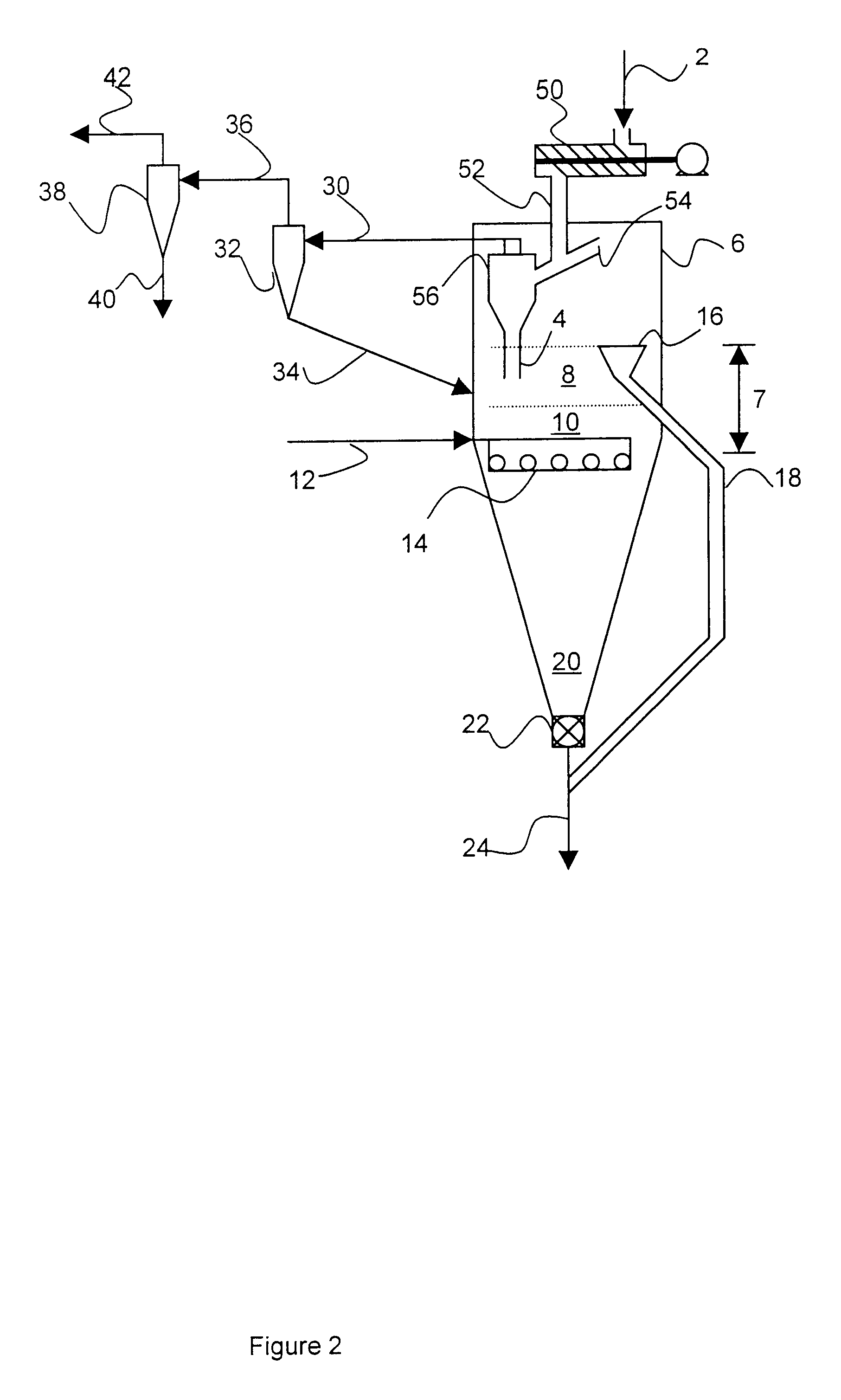

Method and apparatus for reducing iron-oxides-particles having a broad range of sizes

InactiveUS6224649B1Slight loss of efficiencyIncrease chanceExhaust gas handlingFluidised-bed furnacesHydrogenSingle chamber

Methods and apparatus for the reduction into metallic iron of iron-oxides-containing particles having a broad range of sizes. Particles, typically within a broad range of sizes of about 0.1 mm to about 50 mm, are reduced by contact with a hot reducing gas, preferably from a horizontal gas distributor which defines the bottom of the reduction zone by supplying a uniform upflow of gas mainly composed of hydrogen (and / or carbon monoxide) within a temperature range of 650° C. to 1050° C. and at a velocity of about 0.5-0.7 m / s to fluidize at least some of the particles of a size of about 1.0 mm or less (when present). The reducing gas flows upwardly through a descending moving bed of coarser particles and forms thereabove a fluidized bed of fines, all in a single chamber in a reduction reactor, where the particles charged to the reactor are fed into the fluidized bed, preferably at the lower portion thereof at or near the interface with the moving bed, and the lighter reduced fluidized fines are withdrawn from the reactor from the upper portion of the fluidized bed. The spent reducing gas from the reactor passes through at least one cyclone separator with the fines entrained therein being normally returned to the reactor or optionally being subjected to a lower velocity fluidization in a separate reduction chamber of the reactor.

Owner:HYLSA SA DE CV

Fine particle removal method and device

ActiveCN102836779AReduce volumeImprove applicabilityExternal electric electrostatic seperatorElectrode constructionsElectricityFine particulate

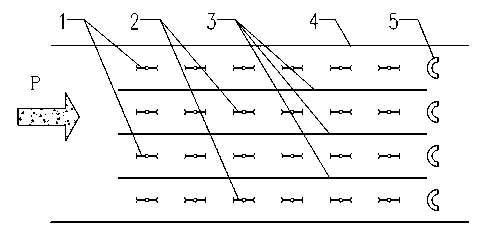

The invention discloses a fine particle removal method which comprises the steps that fine particles enter a plurality of charged channels that are adjacent and parallel to one another along with air flow and are charged with positive charge and negative charge in every two adjacent charged channels respectively; and the fine particles charged in the charged channels pass through a plurality of particle channels for communicating every two adjacent charged channels and are collided, coagulated, and then trapped by a trapping device. In addition, the invention further provides a fine particle removal device which comprises a plurality of grounding electrode plates that are arranged in parallel to one another, a plurality of channels and the trapping device, wherein through holes are uniformly and densely distributed in the grounding electrode plates; a plurality of discharging wires are arranged in each of the channels in the length direction of each channel; the discharging wires in every two adjacent channels are connected with a positive output power supply and a negative output power supply respectively; and the trapping device is arranged at the back of the tail ends of the channels.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Equipment and method for generating nm particles charged negatively

A device and method for generating negatively charged nm particles is disclosed. Said device is composed of superfine electronic emitting electrode and control package. Under the action of power supply and control package and according to the material, shape, size and purpose of electrode, the superfine electronic emitting electrode is relatively at negative 2-29 KV potential to generate tunnel-effect field electron emitting. When the generated high-density electrons are collided with particles in air sol, their energy is regulated to make the electrons be attached to the nm particles.

Owner:方墨希 +1

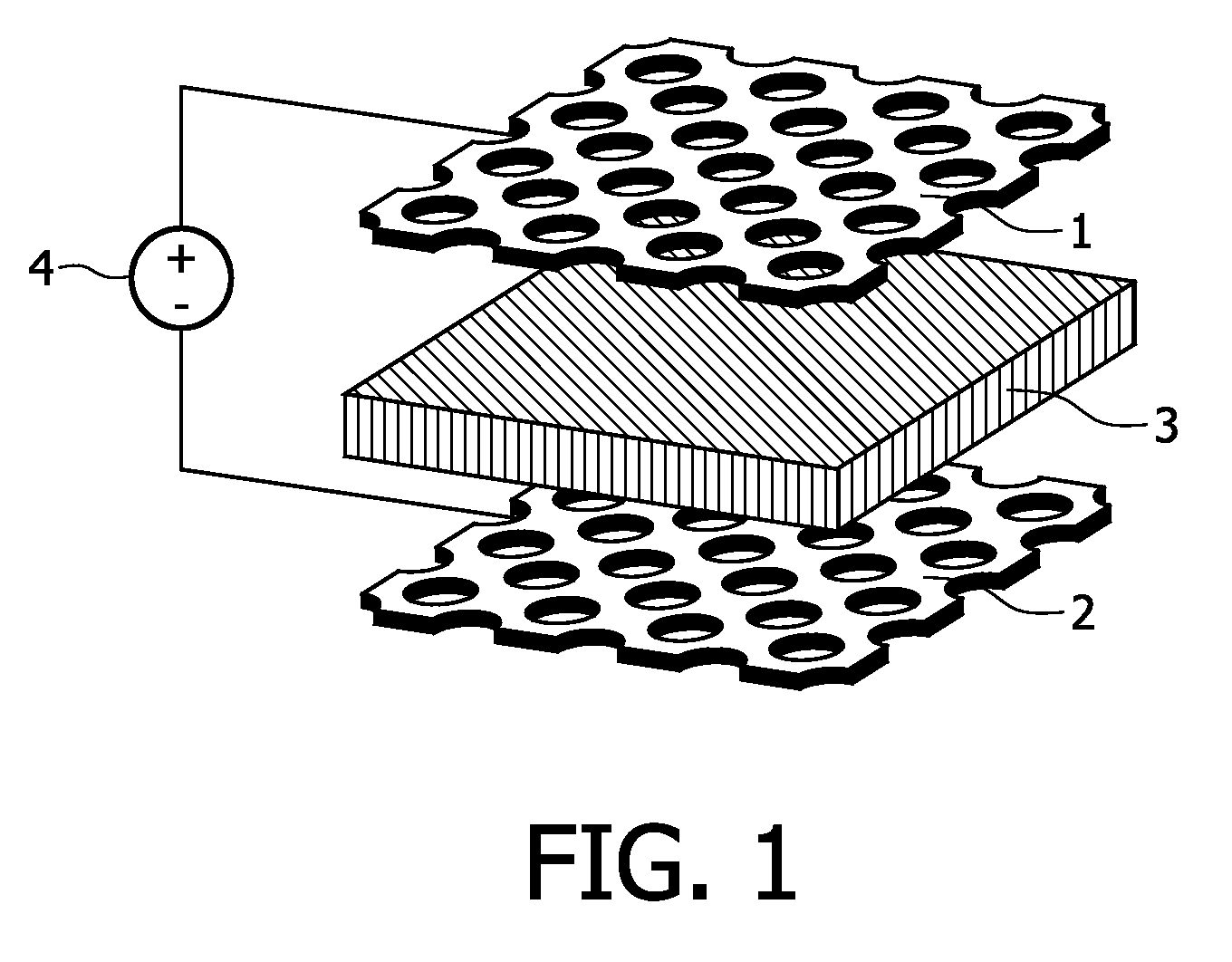

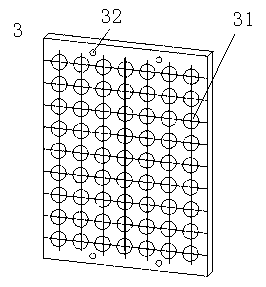

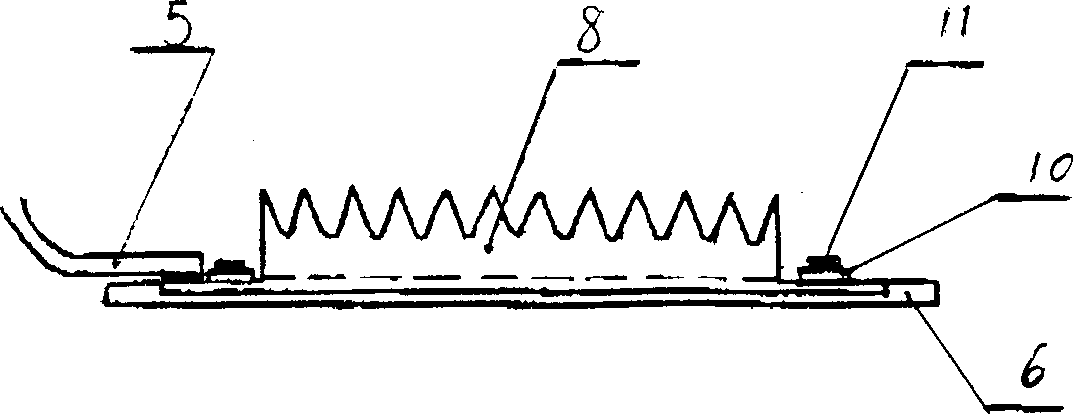

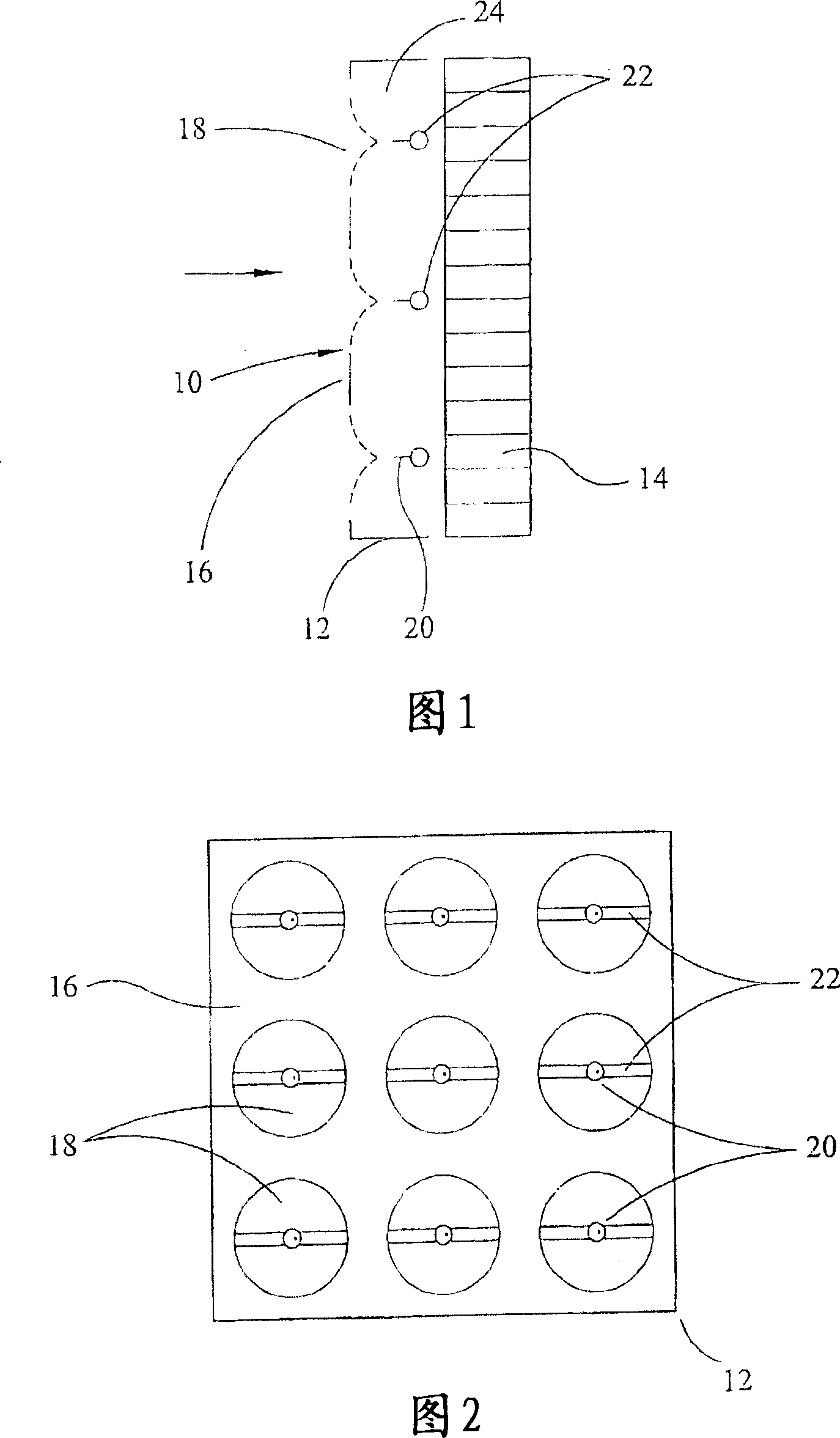

Device for air cleaning

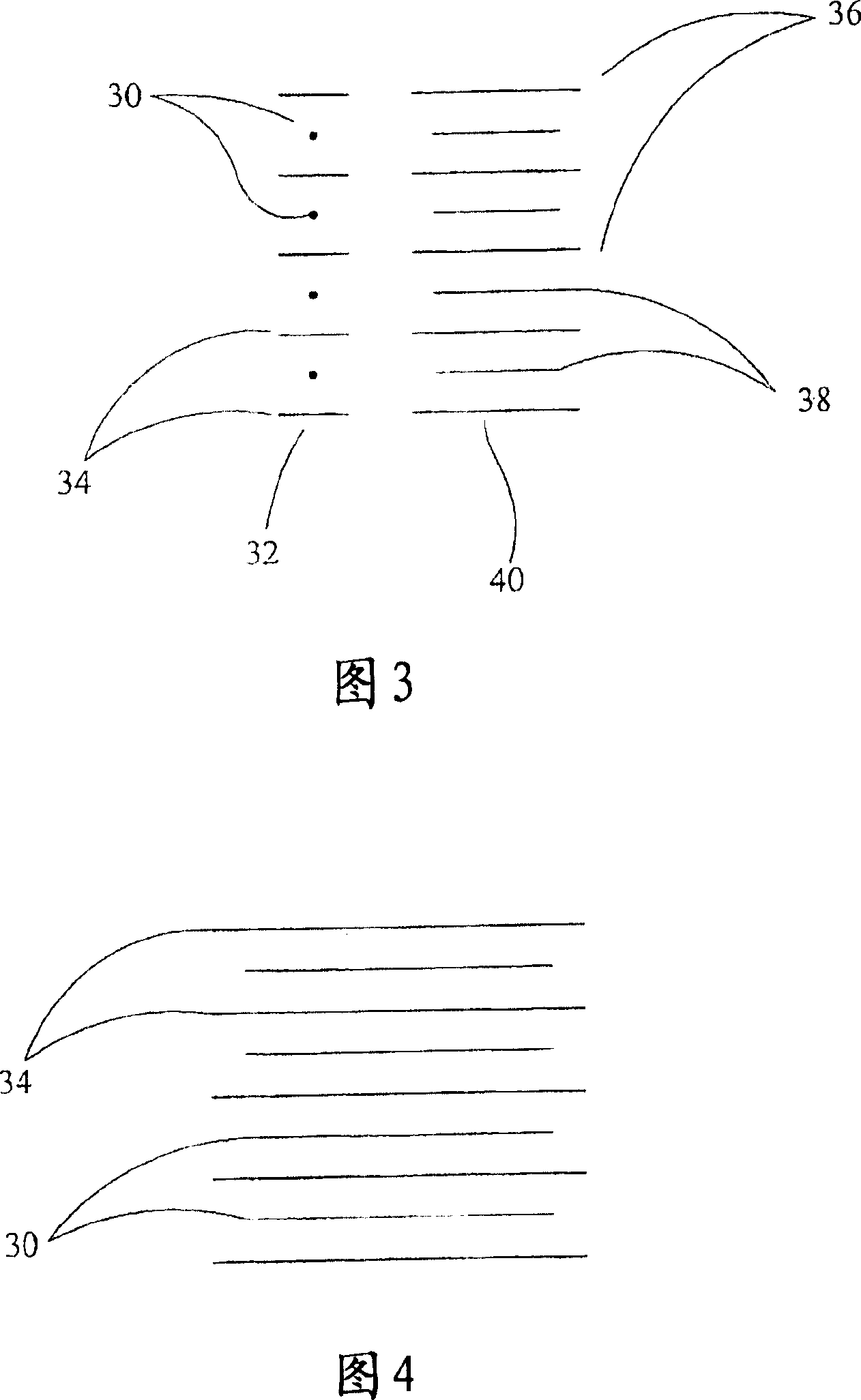

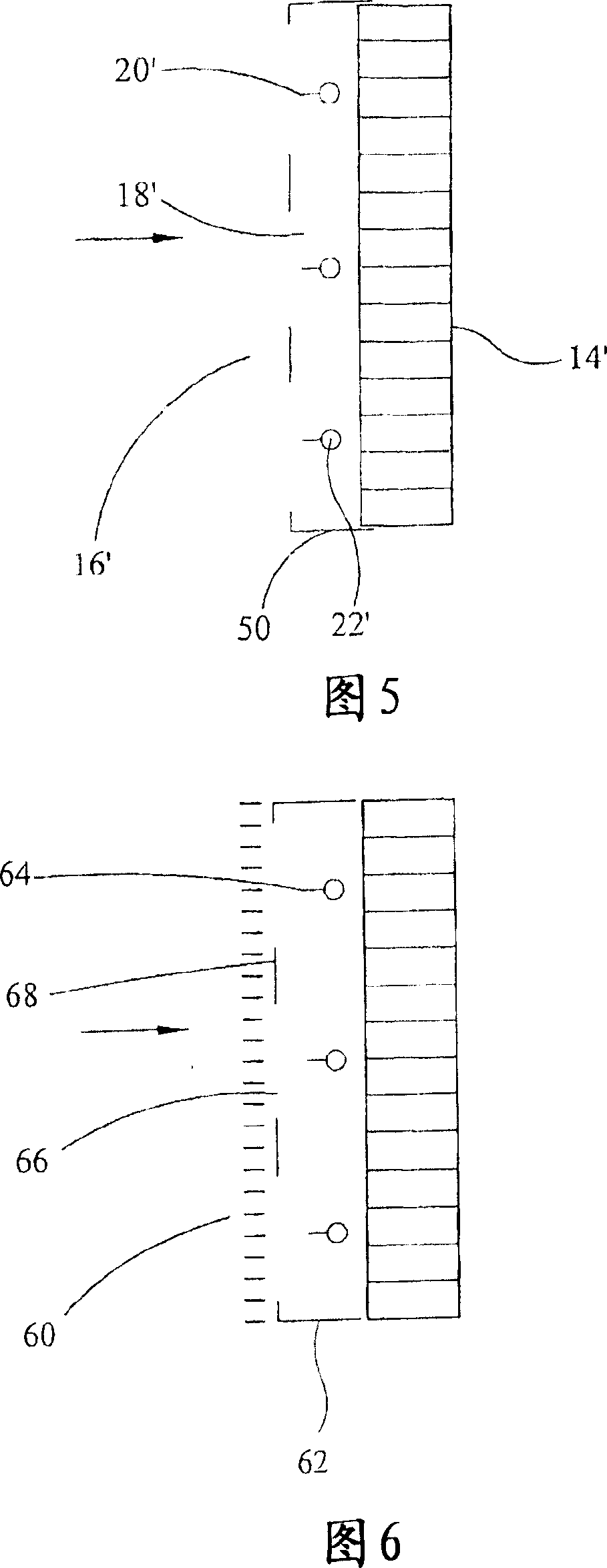

An air cleaning device (10) has a particle charging zone (12) comprising a conducting sheet (16) having a plurality of apertures (18), through which air can be passed, and a plurality of corona emitters (22) each associated with an aperture, and a filter (14).

Owner:DARWIN TECH

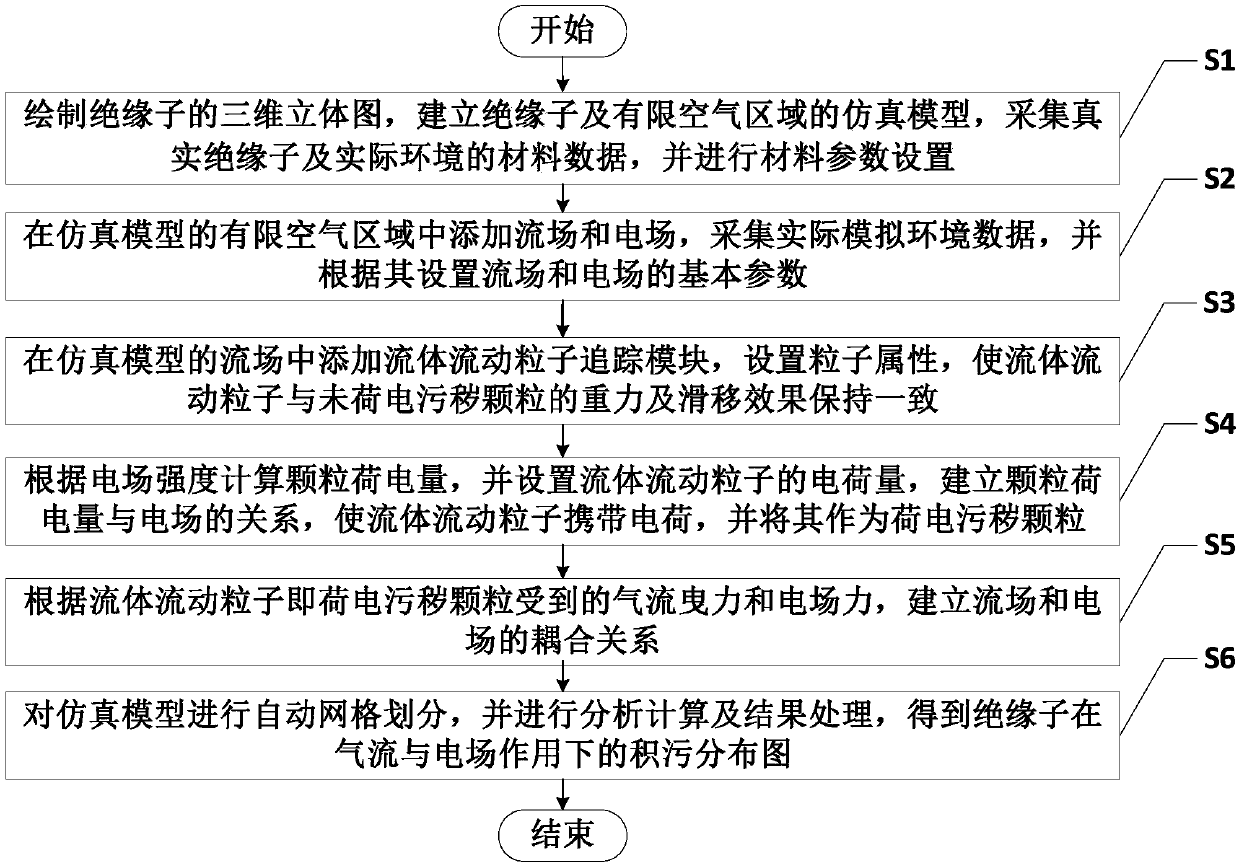

A method for acquiring electrified accumulated dirt distribution of an insulator in a flow field environment

InactiveCN109598065AEasy to getEasy to implementGeometric CADSustainable transportationMultiphysics couplingElectrical field strength

The invention discloses a method for acquiring electrified accumulated dirt distribution of an insulator in a flow field environment, which comprises the following steps of: S1, drawing a three-dimensional stereogram of an insulator, establishing a simulation model of the insulator and a limited air area, acquiring material data of a real insulator and an actual environment, and setting material parameters; S2, adding a flow field and an electric field, and setting basic parameters of the flow field and the electric field; S3, adding a fluid flow particle tracking module in the flow field of the simulation model; S4, calculating the particle charge quantity according to the electric field intensity, setting the charge quantity of fluid flowing particles, and establishing the relation between the particle charge quantity and the electric field; S5, establishing a coupling relationship between the flow field and the electric field; S6, obtaining a dirt accumulation distribution map of the insulator under the action of airflow and an electric field; The method solves the problems that in the prior art, on-site insulator pollution data acquisition is difficult, and an existing numerical method cannot achieve multi-physical-field coupling.

Owner:SOUTHWEST JIAOTONG UNIV +1

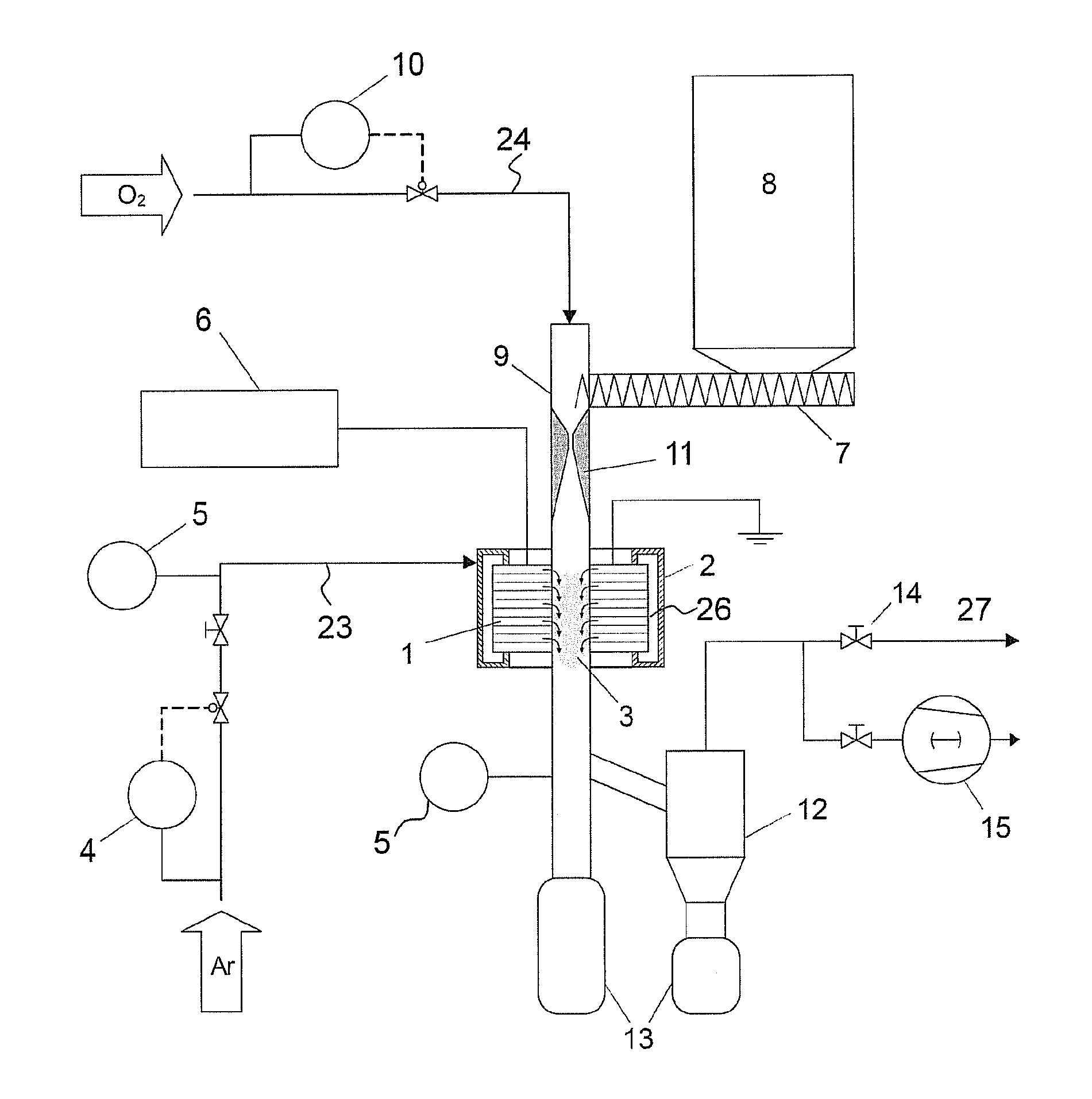

Remote non-thermal atmospheric plasma treatment of temperature sensitive particulate materials and apparatus therefore

InactiveUS20110039036A1Molten spray coatingChemical vapor deposition coatingParticulatesSystem pressure

The present invention relates to a novel process for the remote plasma surface treatment of substrate particles at atmospheric pressure. The invention is motivated by the urge to overcome major drawbacks of particle treatment in low pressure plasmas and in-situ particle treatment at atmospheric pressure. The former requires complex and mostly expensive vacuum installations and vacuum locks usually prohibiting continuous processing. Independent of the system pressure, in-situ plasma treatment causes particle charging and therefore undesirable interaction with the electric field of the discharge, which is seen to contribute to the process of reactor clogging. Additionally, the filamentary discharges modes of atmospheric pressure plasmas are inflicted with inhomogeneous surface treatment. Furthermore, short radical lifetimes at elevated pressures complicate a remote plasma treatment approach as widely used in low pressure applications. The key-element of the invention is that by reducing the dimension of the atmospheric discharge arrangement to the micrometer range, transonic flow conditions can be achieved in the discharge zone while maintaining moderate flow rates. The resulting superimposition of high drift velocity in the gas flow and the inherent diffusion movement is to prolong the displacement distance of activated species, thus making a remote plasma treatment of substrate particles feasible and economically interesting. The circumferential arrangement of e.g. micro discharge channels around the treatment zone of variable length allows a remote plasma treatment independently of the discharge mode and benefits additionally from the aerodynamic focusing of a particle-gas stream to the centre, reducing reactor clogging. Furthermore, taking advantage of non-thermal discharges, there is no restriction of the concept of the outlined invention in the material properties of the particulate solids especially not with regard to the treatment of temperature sensitive materials as often encountered in polymer or pharmaceutical industries. In conclusion, atmospheric pressure plasma treatment close to ambient gas temperature as well as continuous processing is a specialty of the invention disclosed here.

Owner:ETH ZZURICH

Display apparatuses and methods of driving the same

InactiveUS20100091049A1Improve response speedCathode-ray tube indicatorsNon-linear opticsElectrical polarityOptoelectronics

A pixel of a display apparatus includes at least a first transistor and at least a second transistor. A cell of transparent fluid including particles charged to have different polarities from each other is arranged between a pixel electrode and a common electrode. The first and second transistors are connected to the pixel electrode. The pixel is drivable according to pulse amplitude modulation (PAM) and pulse width modulation (PWM) such that a frame of an image is displayable using a single field.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com