Washing machine dewatering device and washing machine

A drainage device and washing machine technology, applied in the washing machine field, can solve the problems of increasing the energy consumption of the washing machine, affecting the life of the washing machine, loud noise, etc., and achieve the effects of avoiding bacterial growth, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

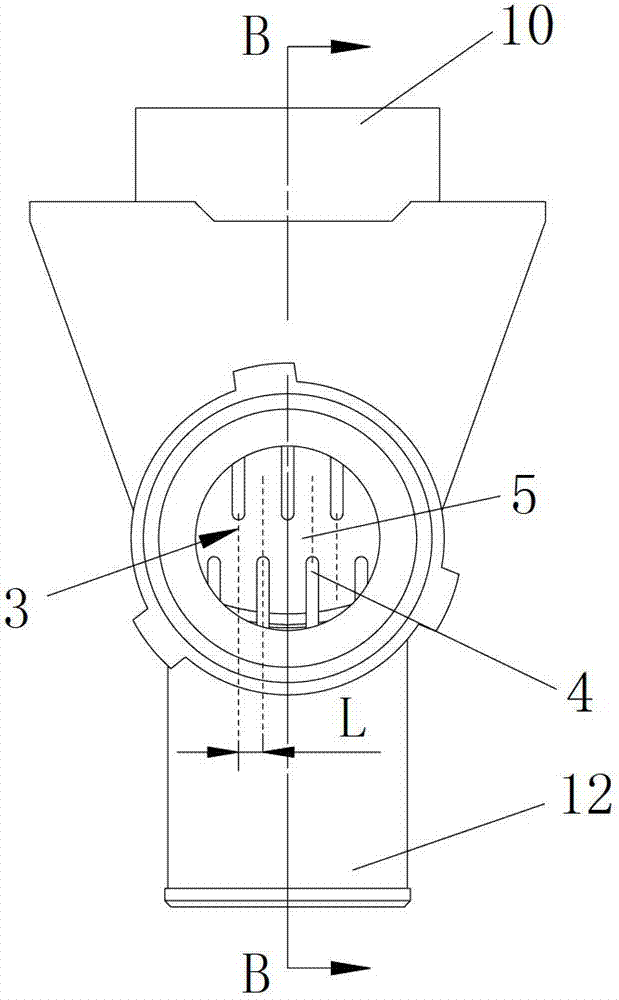

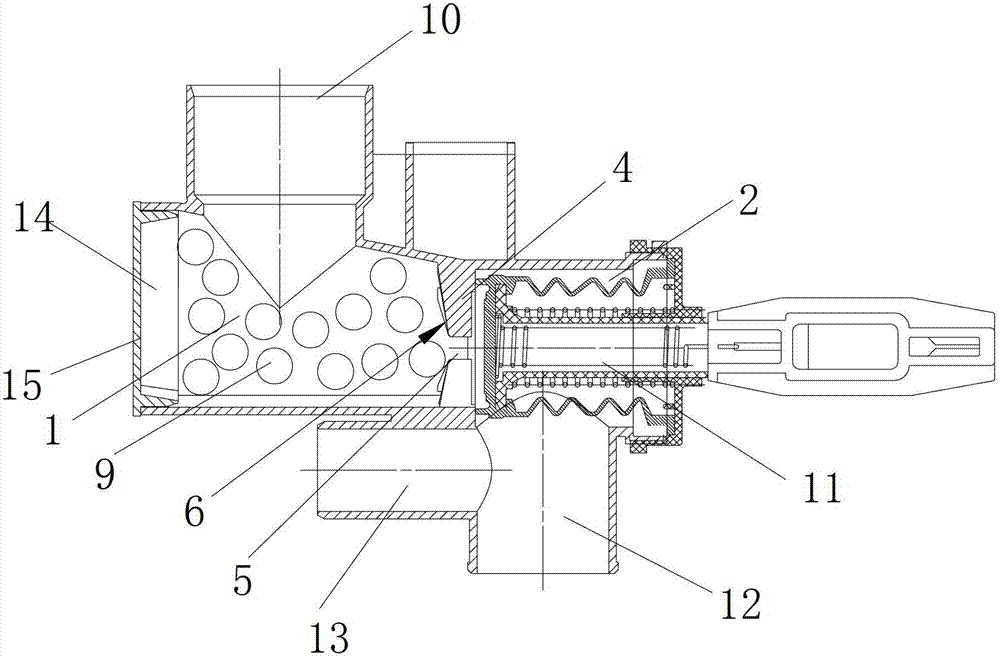

[0037] Such as figure 2 As shown, the two sets of comb structures described in this embodiment are arranged up and down oppositely, with a transverse fracture 5 between them, and the extension line of the retaining ribs 4 of the upper set of comb structures and the retaining ribs 4 of the lower comb structure in turn Alternate vertically, the straight lines where the retaining ribs 4 of the two sets of comb structures are parallel, and the distance L between two adjacent straight lines is the same. The fracture of this structure is set in the middle, which is not only beneficial for the scraps scraped by the retaining ribs to slide and slide through with the drainage water flow, but also facilitates the passage of flakes such as coins.

Embodiment 2

[0039] The retaining ribs described in this embodiment are inclined or curved from the edge of the barrier to the fracture along the water outlet direction, and all the inclined or arc-shaped bending of the retaining ribs constitute a concave diversion structure for the filter facing the drainage chamber. The retaining rib described in this embodiment is an inclined or arc-shaped curved structure as a whole.

Embodiment 3

[0041] Such as Figure 3 to Figure 5 As shown, the ribs described are sheet-like structures, and the width of the side walls along the water flow direction is greater than the width of the side walls of the corresponding particle storage chamber, and all the ribs correspond to the side walls of the particle storage chamber from the edge of the barrier to the The fracture is inclined or curved to form a diversion structure that is concave toward the drainage chamber of the filter. The side wall of the retaining rib in this embodiment close to the particle storage chamber is an inclined or arc-shaped curved structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com