Patents

Literature

568 results about "Atmospheric-pressure plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Atmospheric-pressure plasma (or AP plasma or normal pressure plasma) is a plasma in which the pressure approximately matches that of the surrounding atmosphere – the so-called normal pressure.

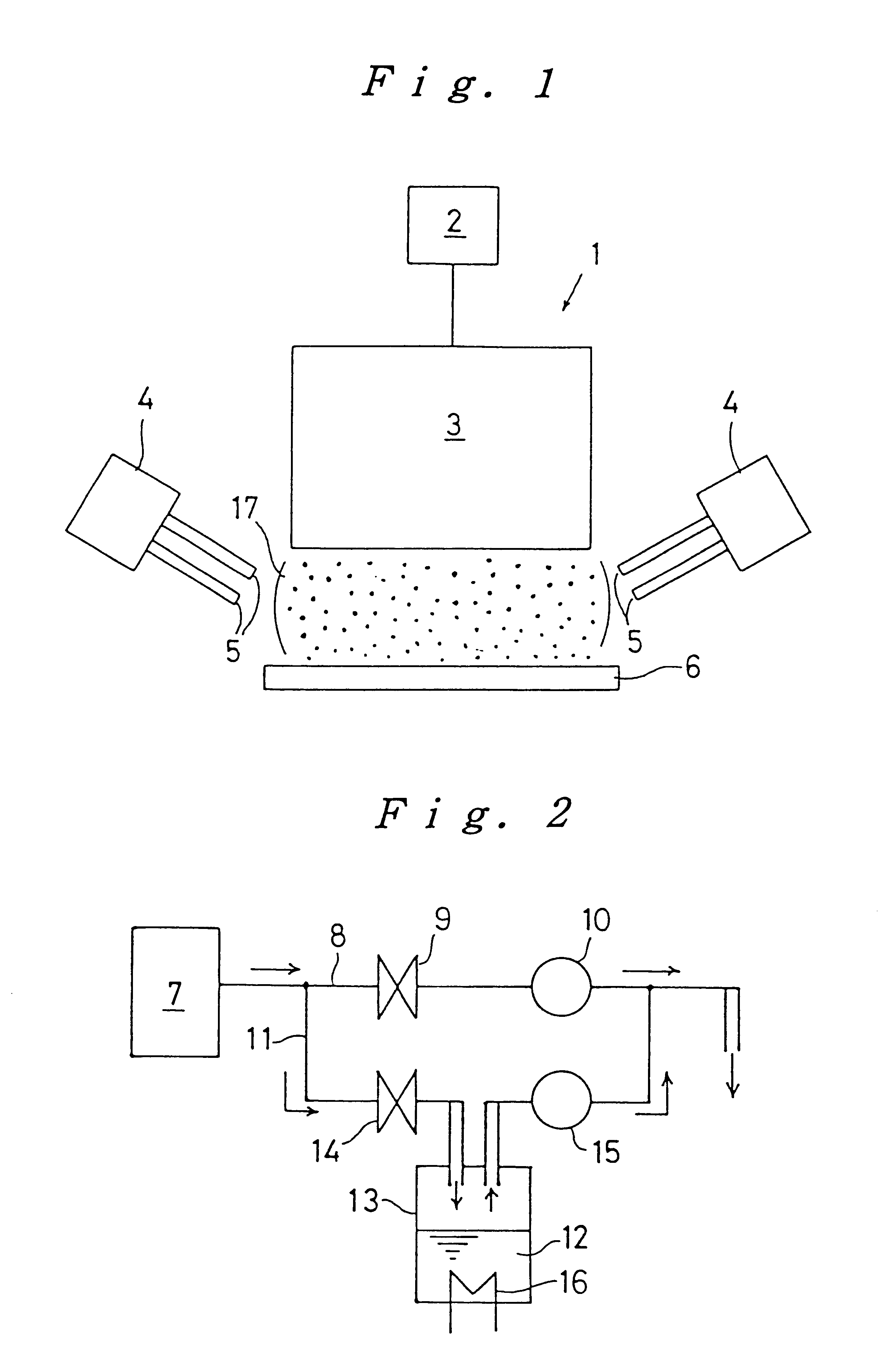

Method and apparatus for atomic layer deposition using an atmospheric pressure glow discharge plasma

InactiveUS20100255625A1Comparable and good performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPlasma generatorProduct gas

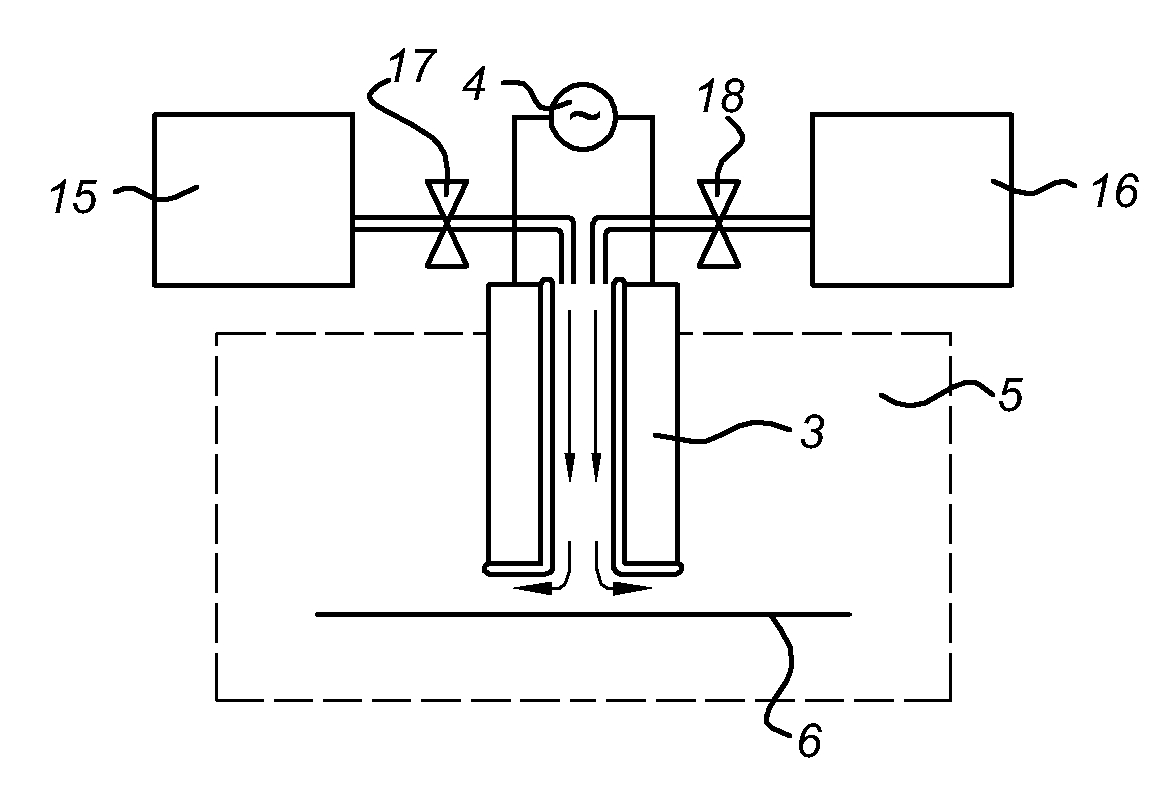

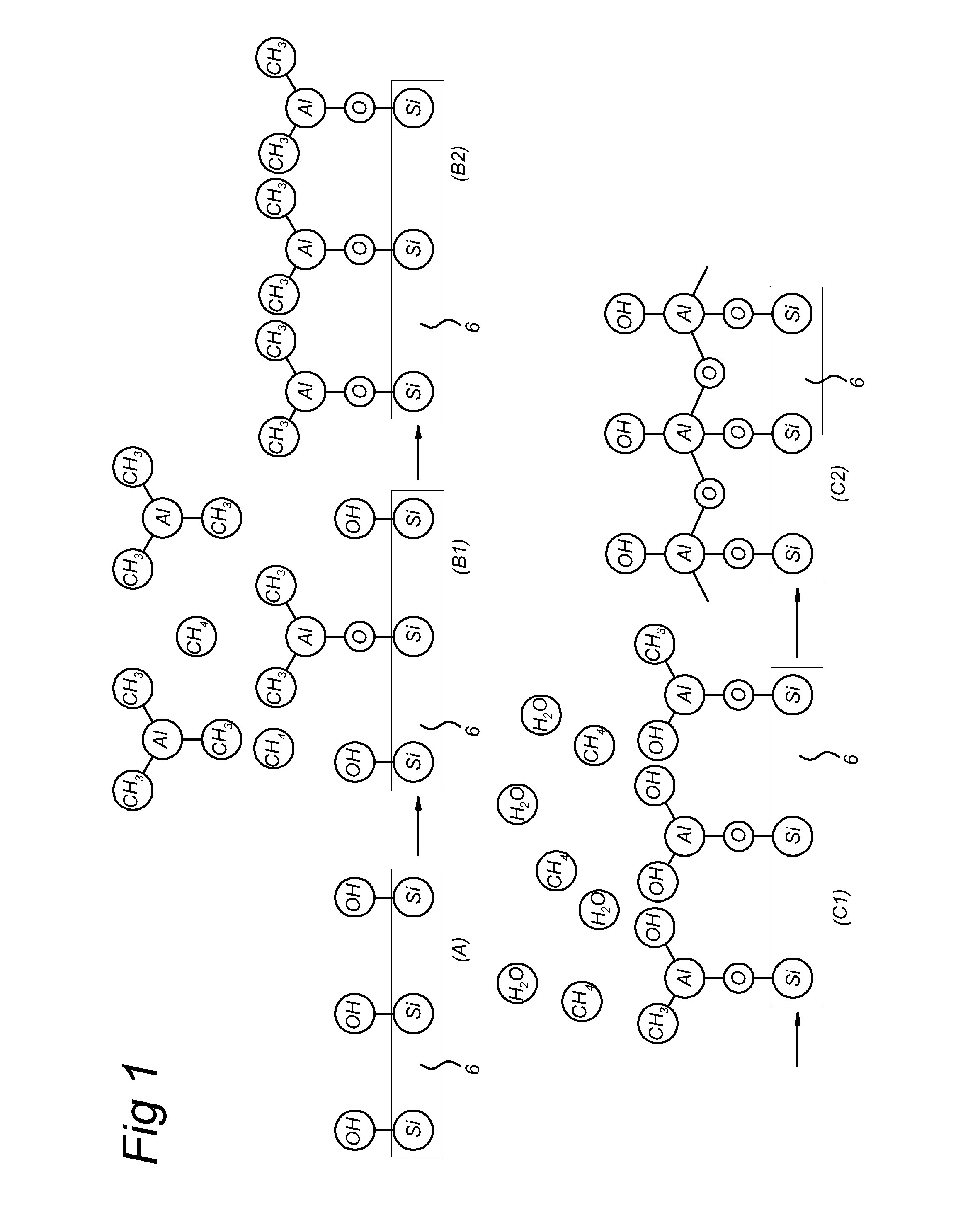

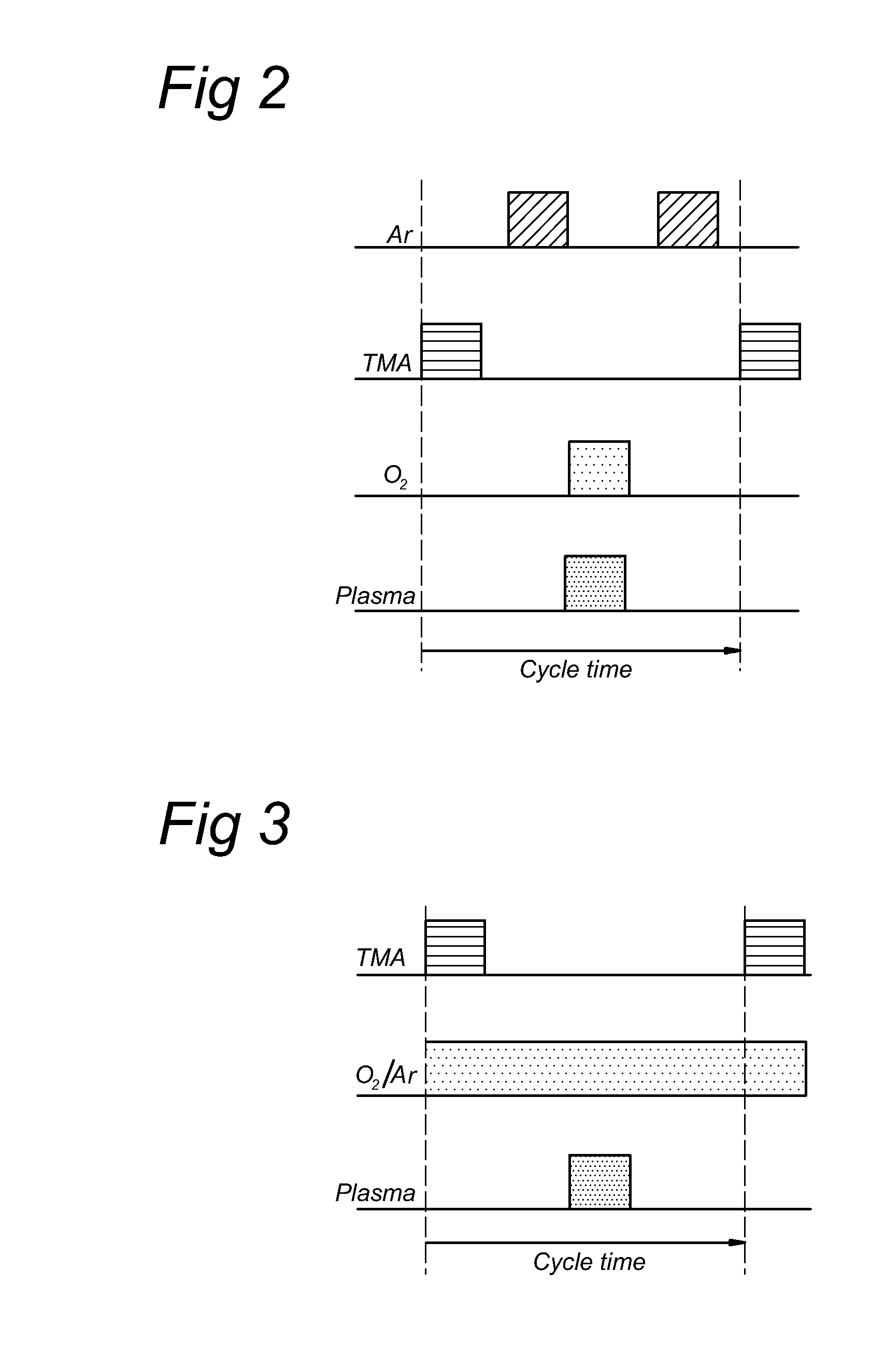

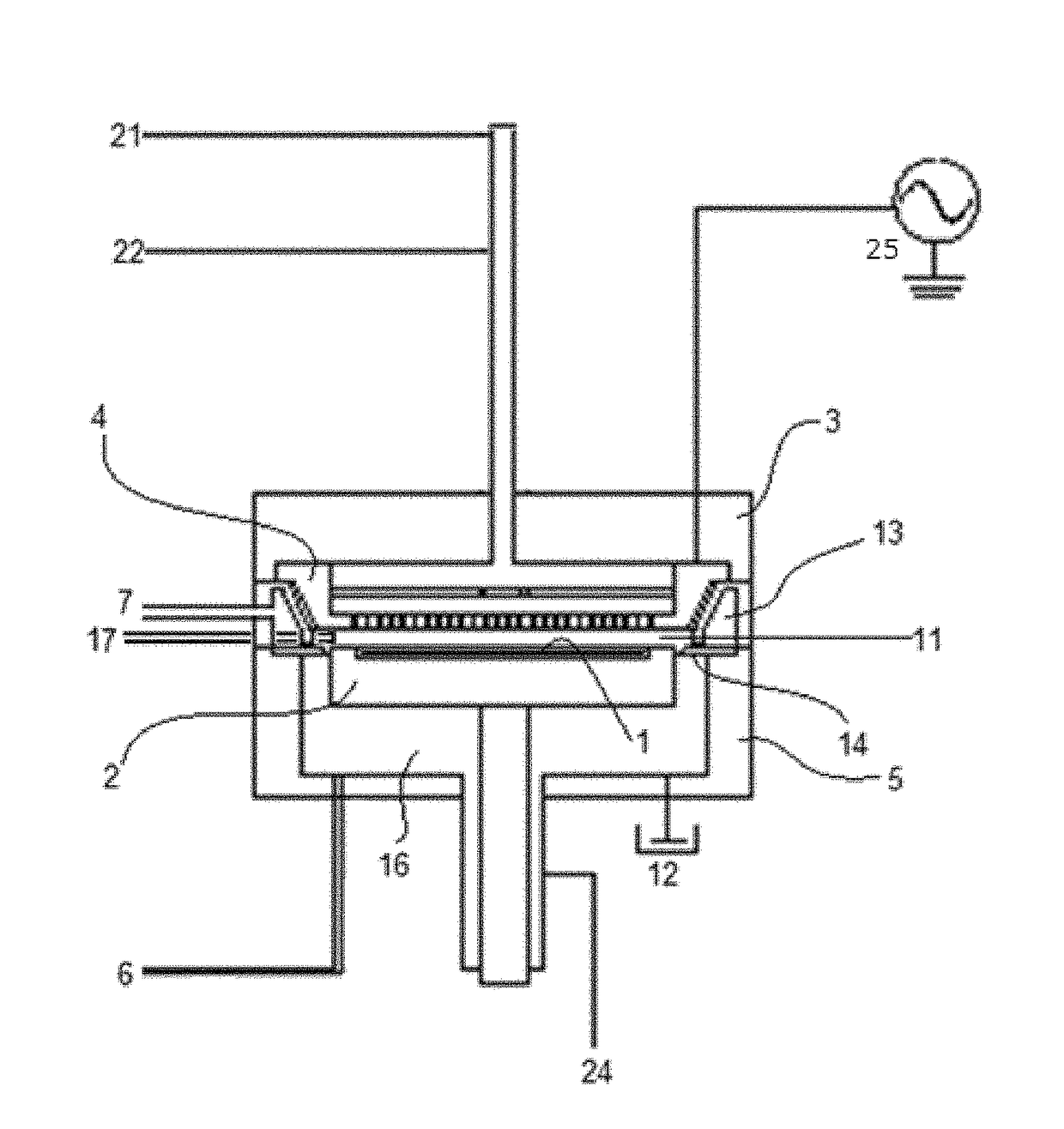

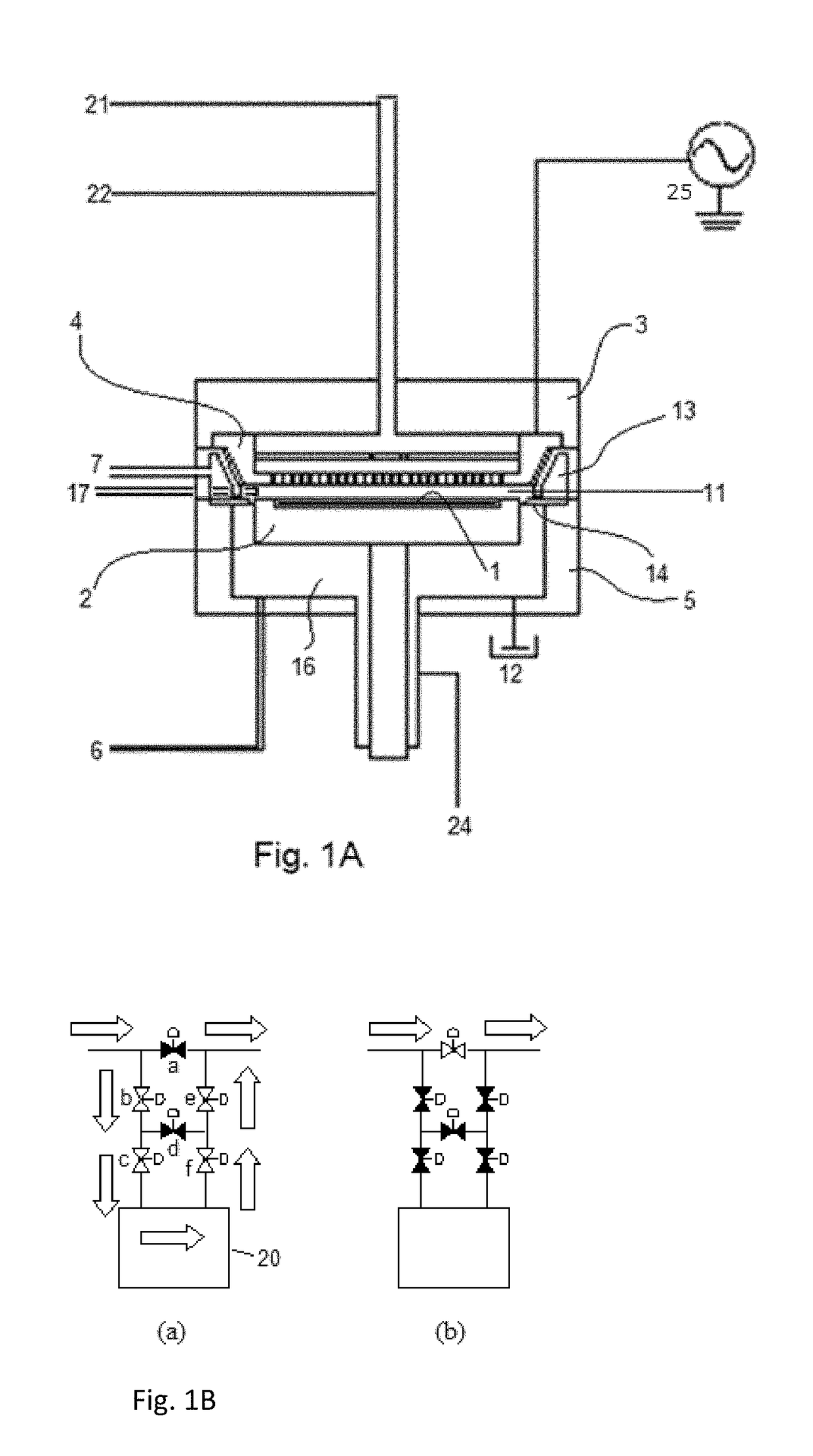

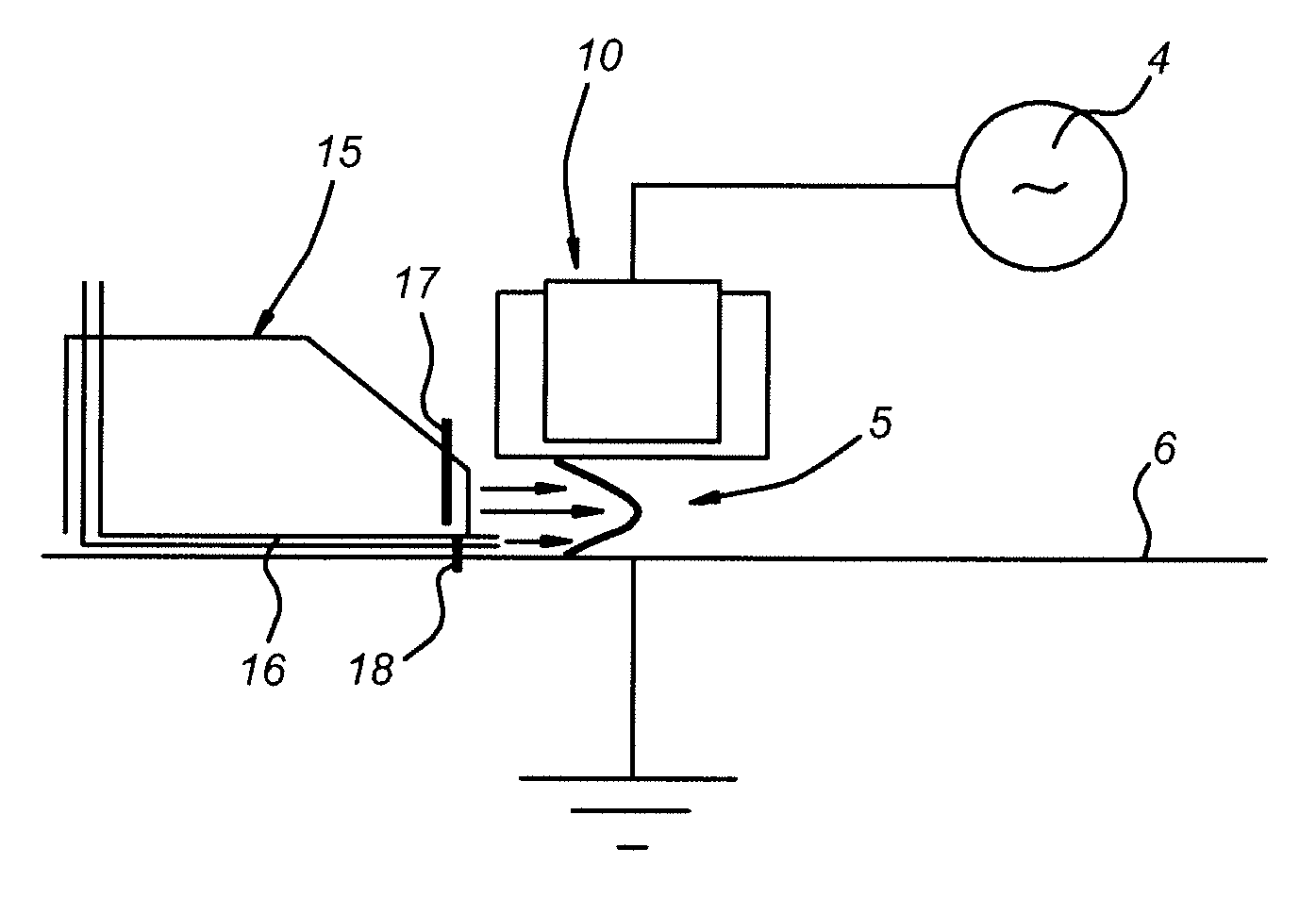

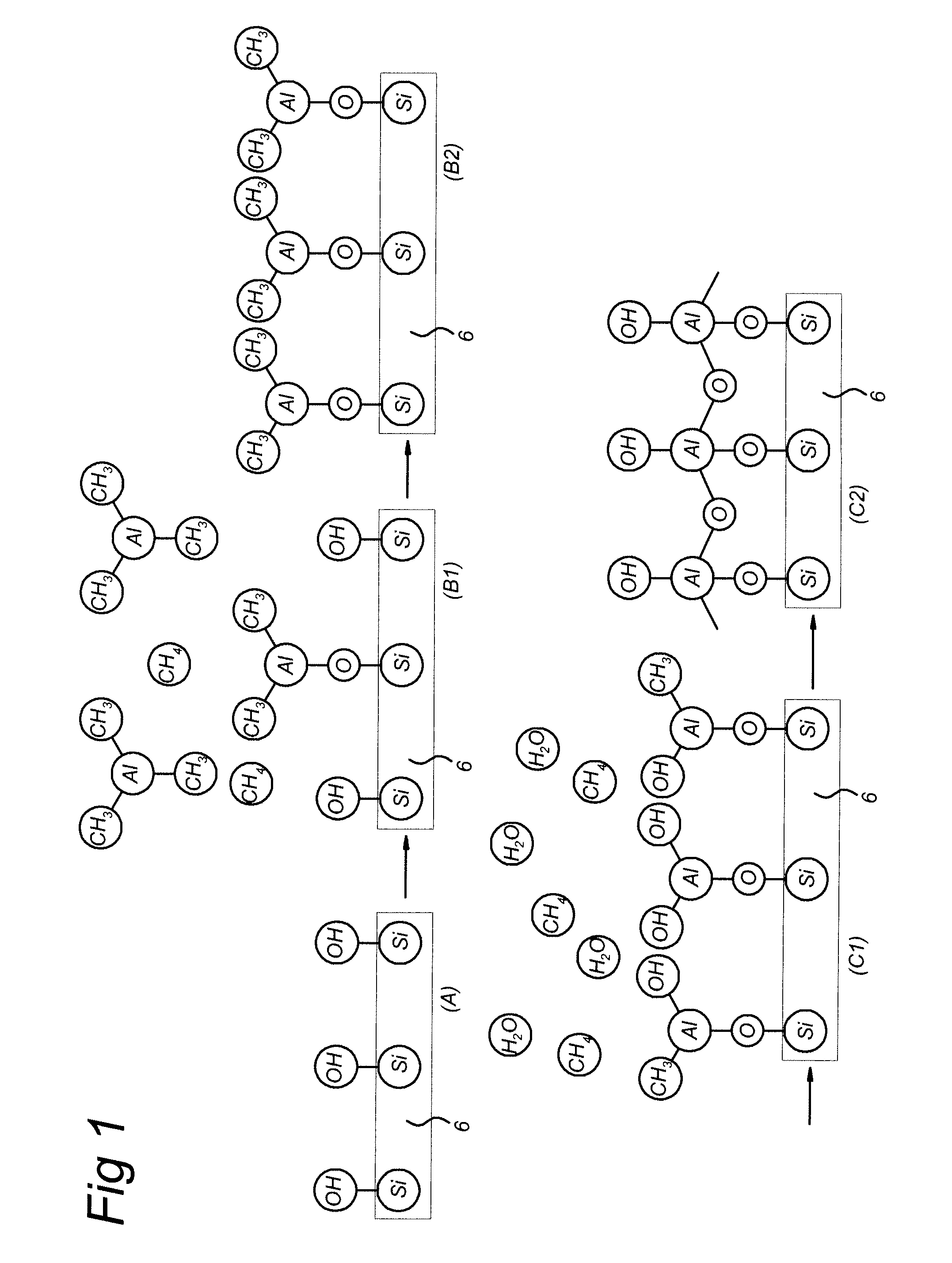

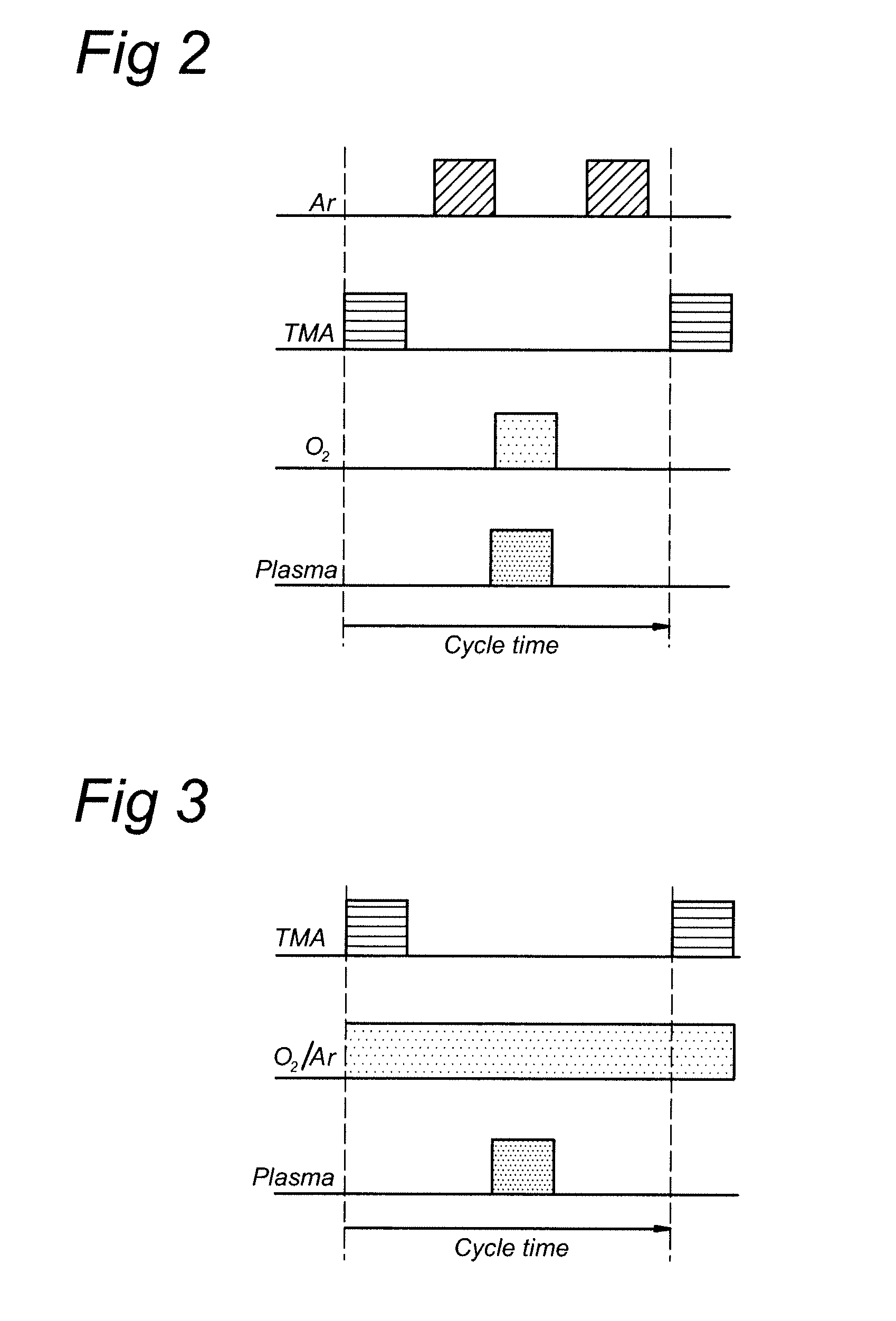

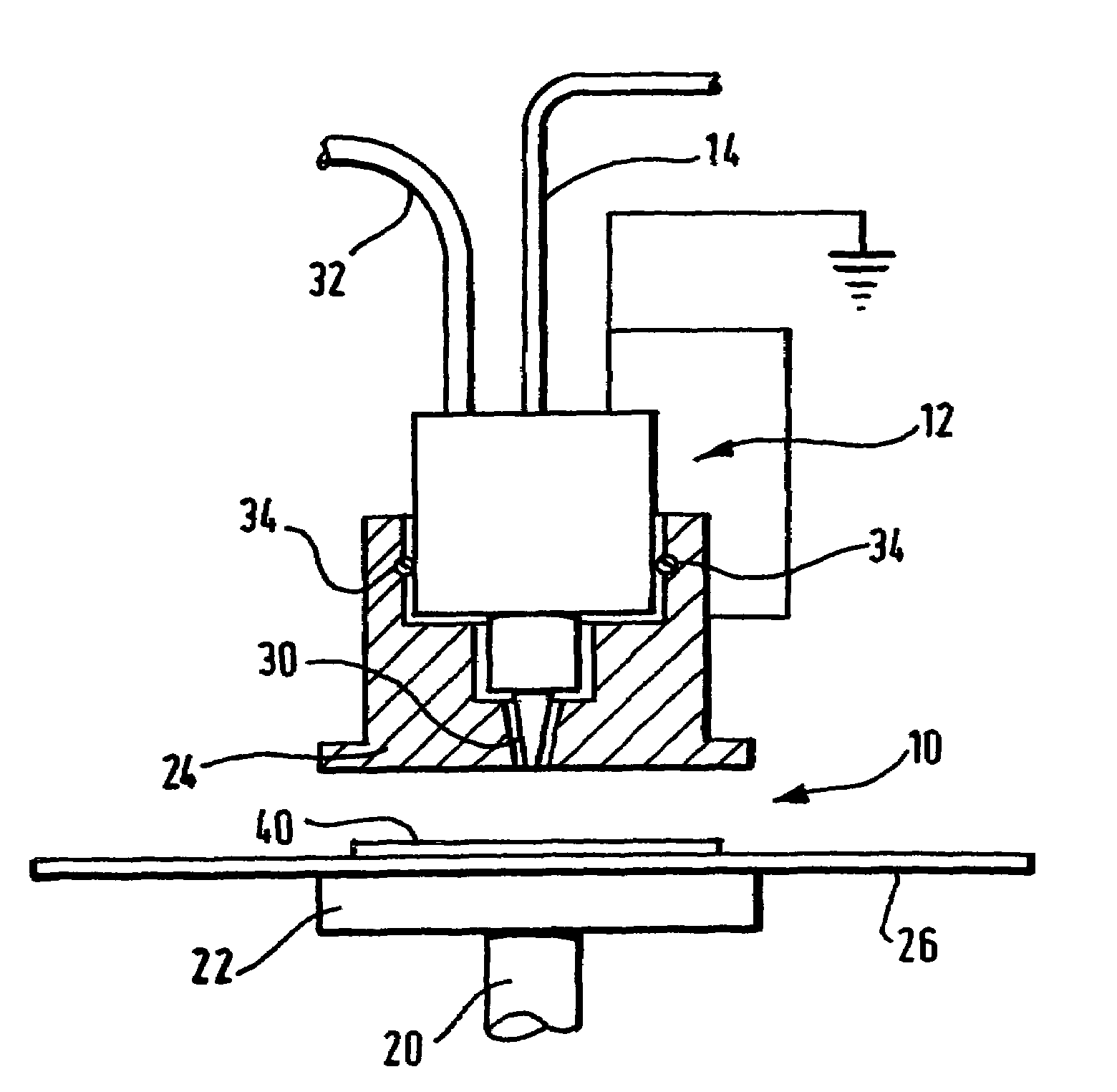

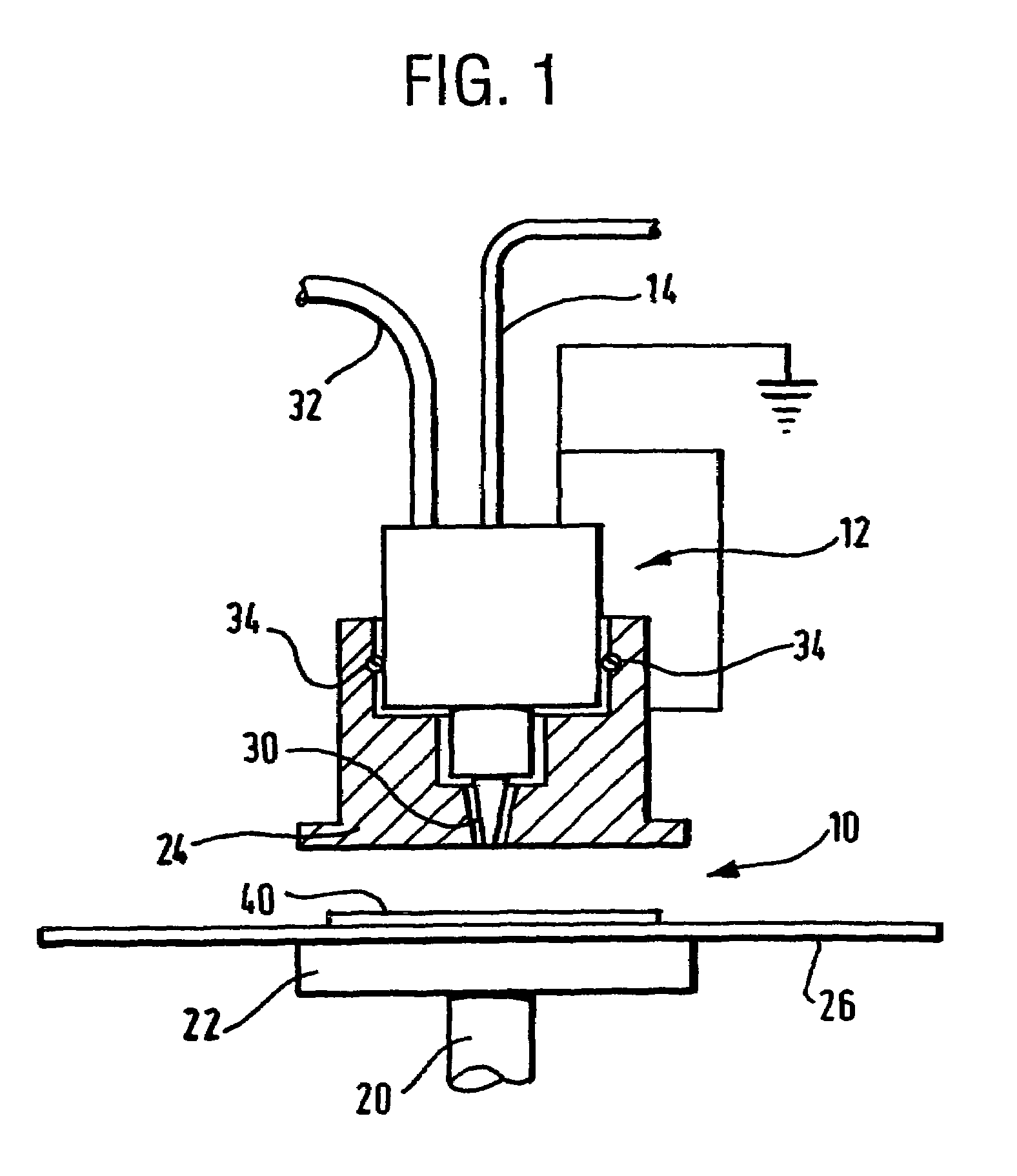

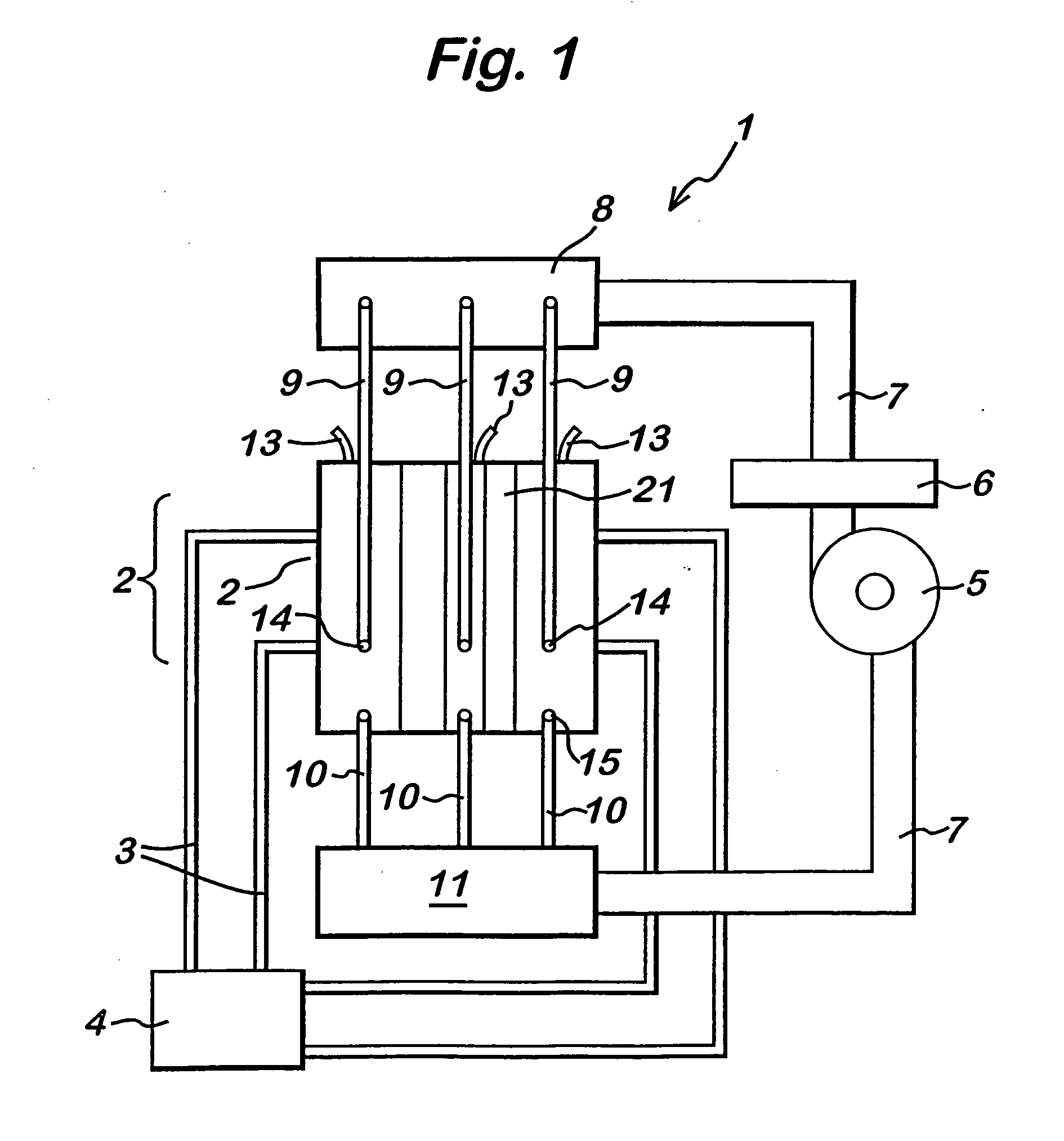

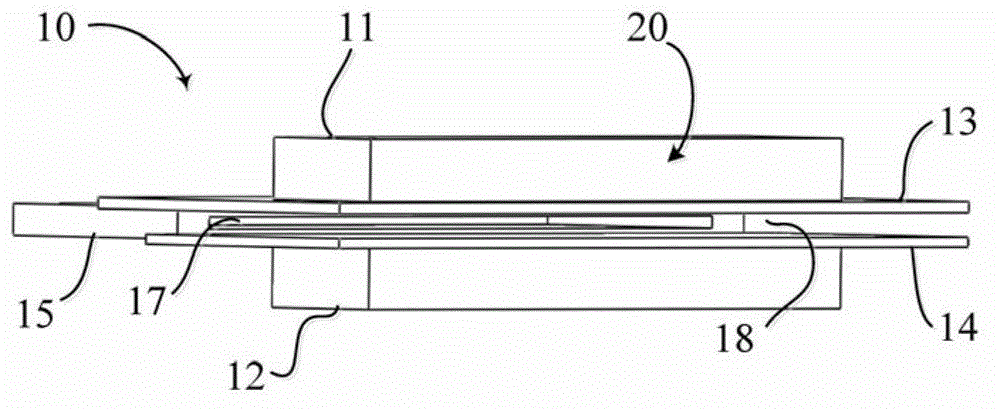

Apparatus and method for atomic layer deposition on a surface of a substrate (6) in a treatment space. A gas supply device (15, 16) is present for providing various gas mixtures to the treatment space (1, 2). The gas supply device (15, 16) is arranged to provide a gas mixture with a precursor material to the treatment space for allowing reactive surface sites to react with precursor material molecules to give a surface covered by a monolayer of precursor molecules attached via the reactive sites to the surface of the substrate. Subsequently, a gas mixture comprising a reactive agent capable to convert the attached precursor molecules to active precursor sites is provided. A plasma generator (10) is present for generating an atmospheric pressure plasma in the gas mixture comprising the reactive agent, the plasma generator being arranged remote from the treatment space (1, 2).

Owner:FUJIFILM MFG EURO

Surface coating method for hydrophobic and superhydrophobic treatment in atmospheric pressure plasma

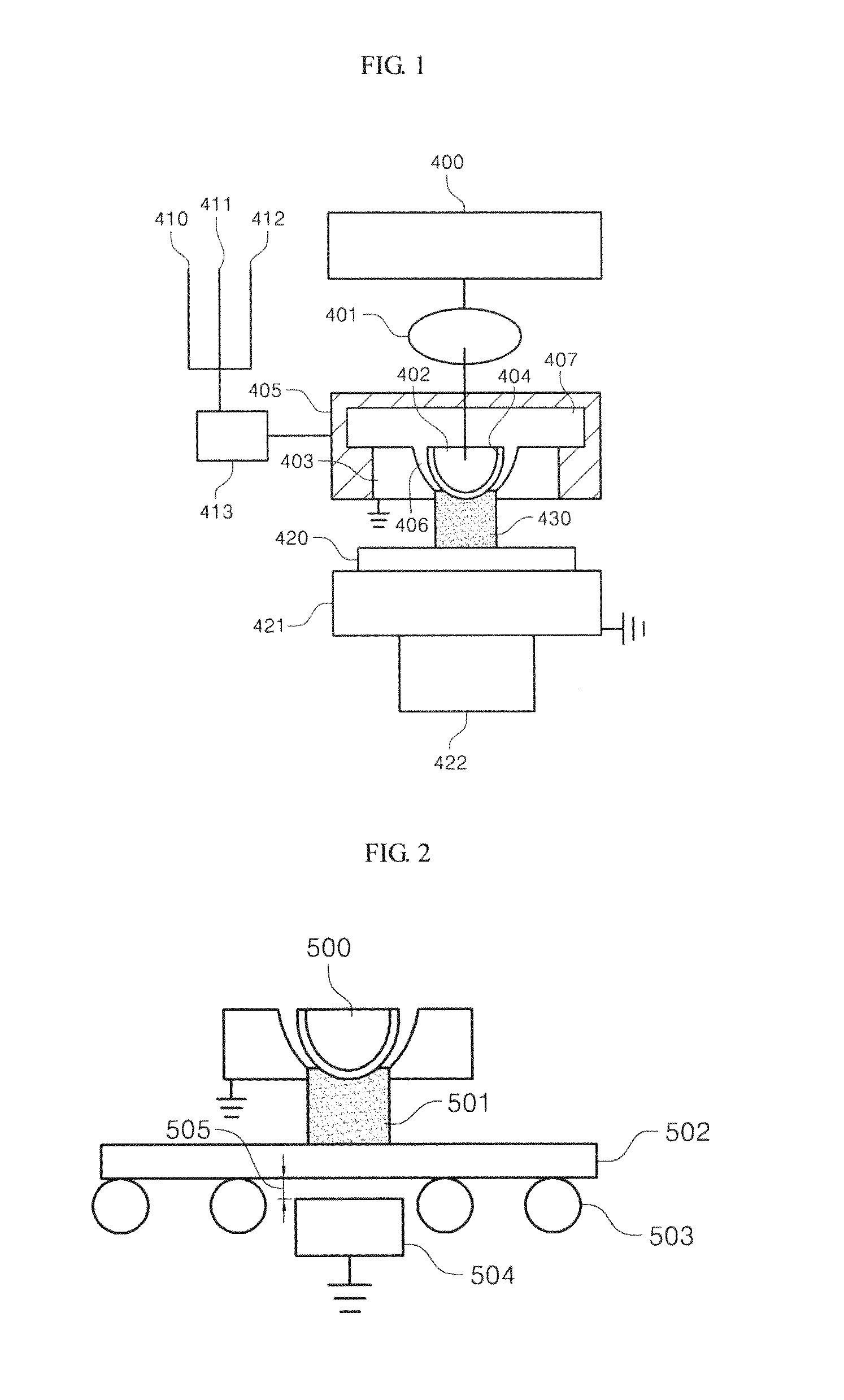

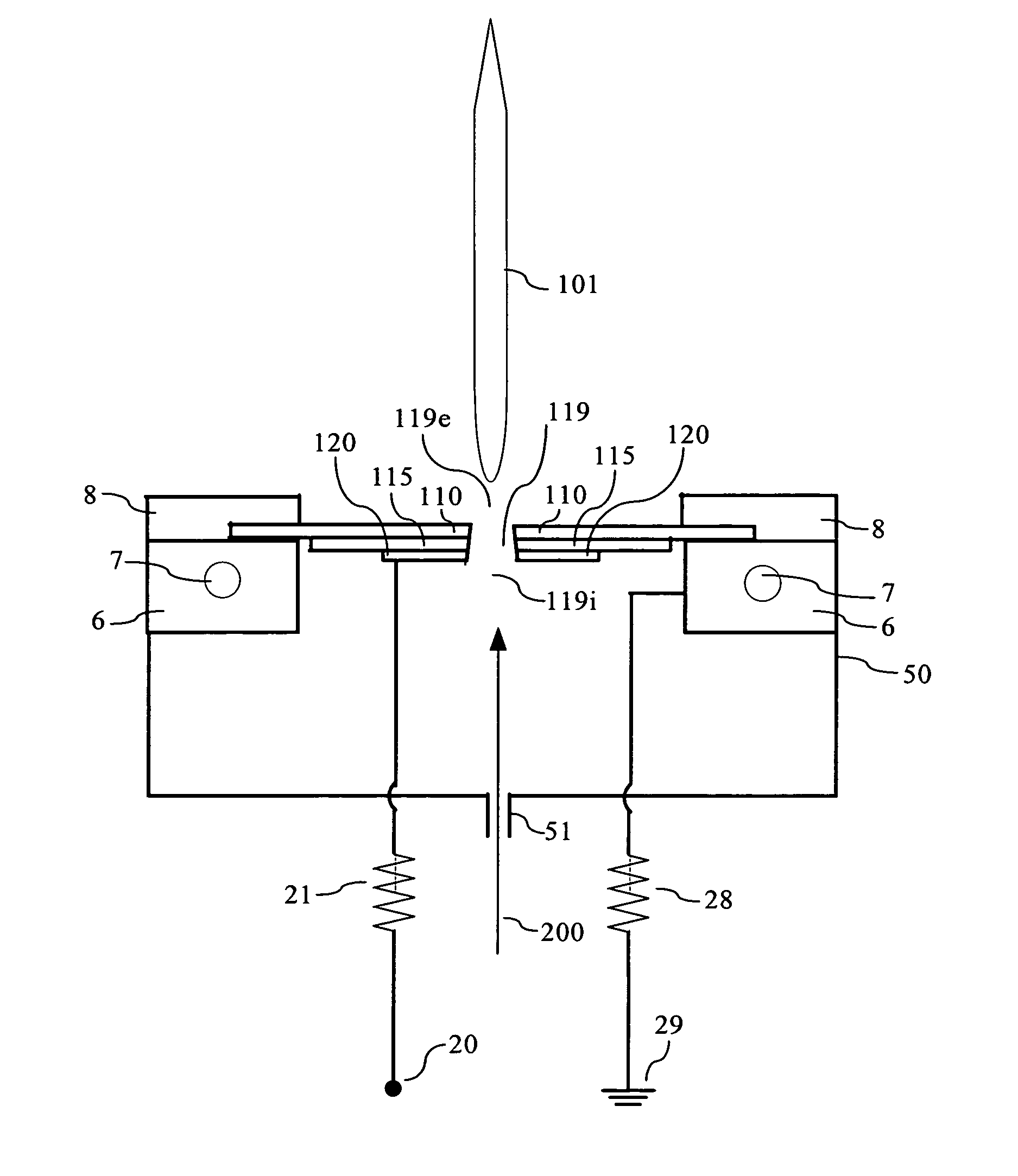

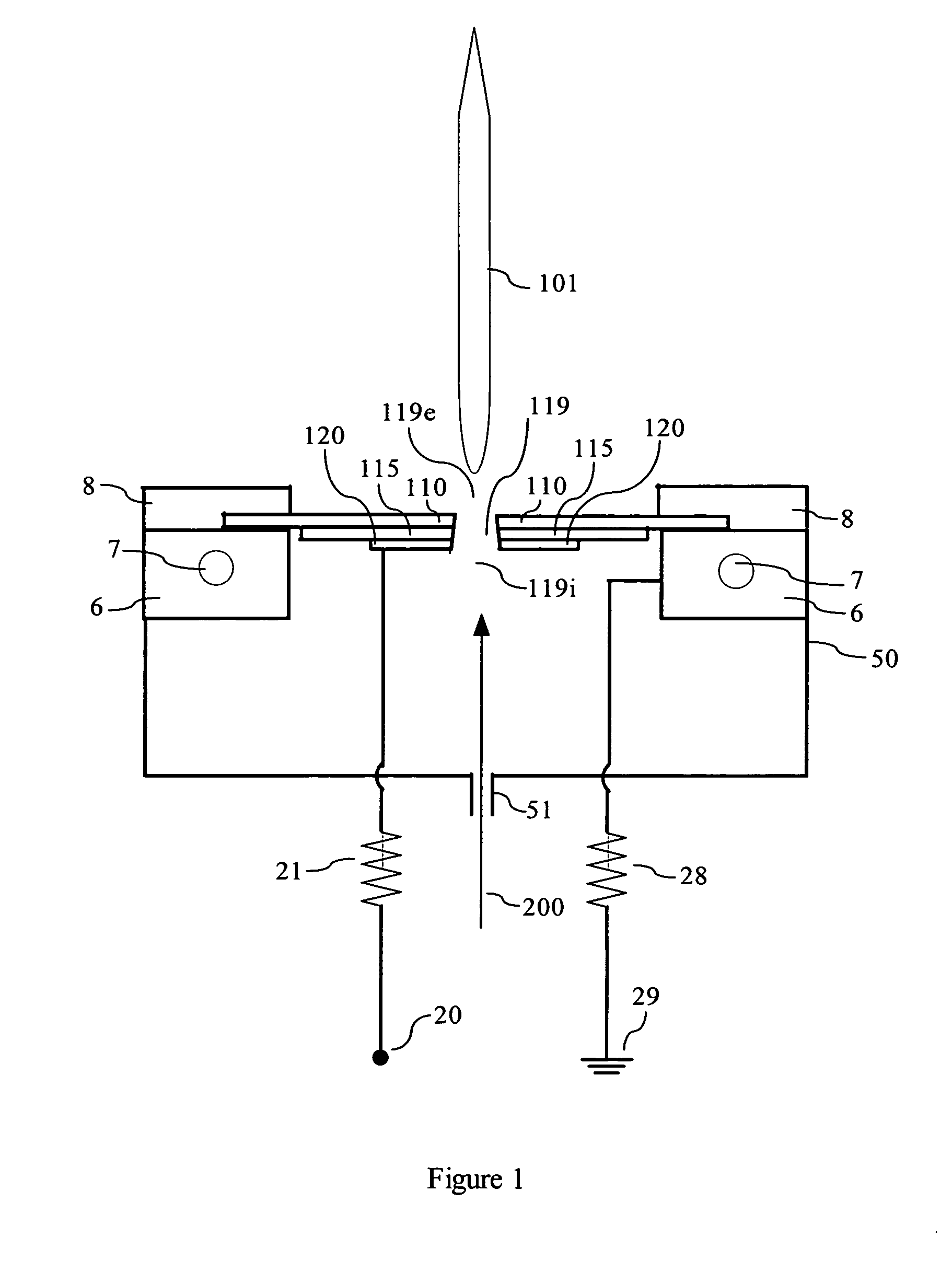

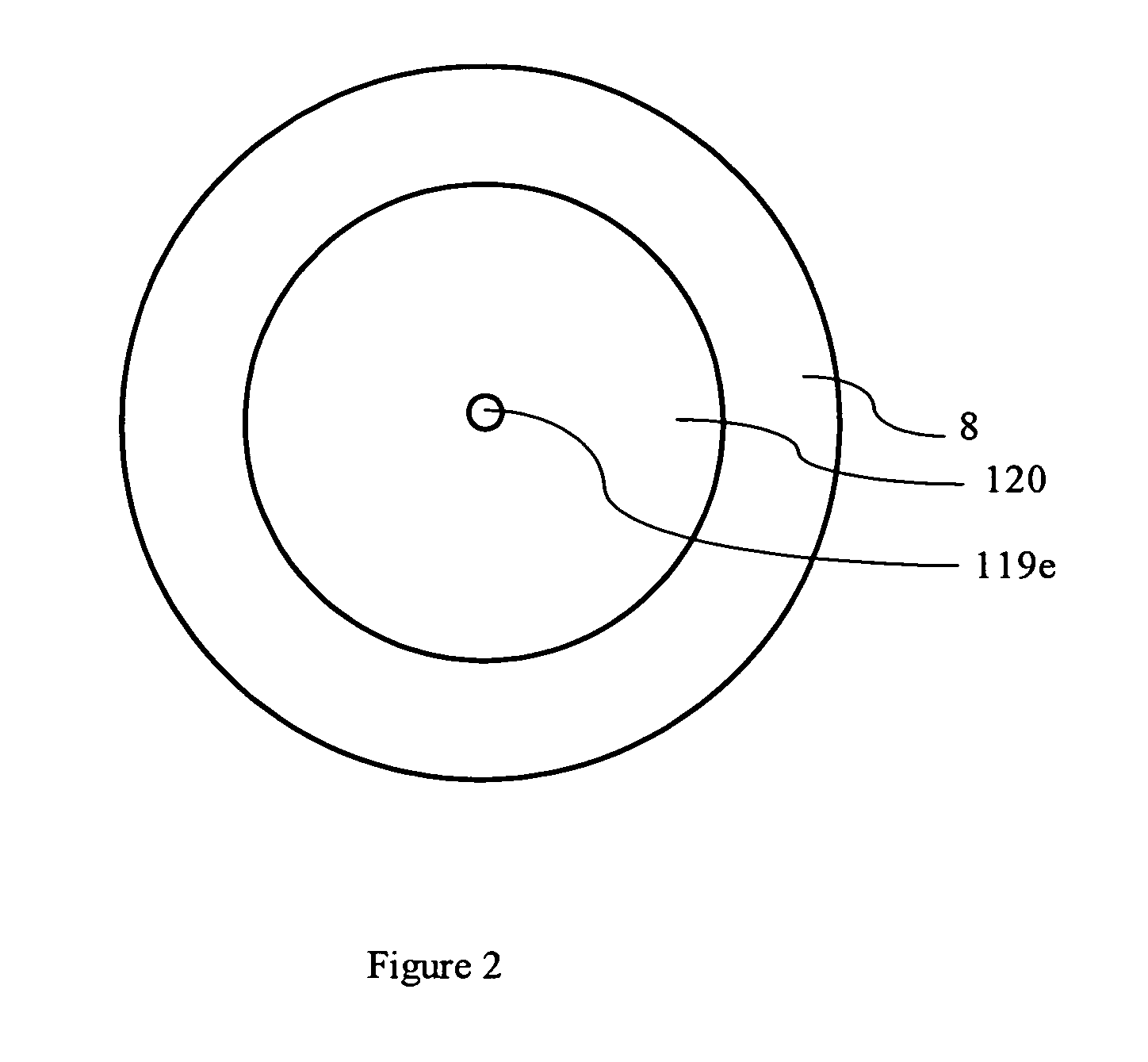

The present invention relates to a method of coating fluorocarbon or hydrocarbon on the surface of a workpiece using atmospheric pressure plasma. More particularly, the present invention relates to a method of coating hydrocarbon or fluorocarbon on the surface of a workpiece using plasma generated under atmospheric pressure such that the workpiece can have a hydrophobic or super-hydrophobic surface.The method of coating a surface of a workpiece with fluorocarbon to be hydrophobic or super-hydrophobic according to the present invention comprises the steps of generating first atmospheric pressure glow plasma by supplying a reaction gas into a discharge space formed between a first electrode and a second electrode, the reaction gas containing hydrogen gas, fluorocarbon gas and inert gas, the first and second electrodes being connected to an RF power supply of an atmospheric pressure plasma generator; and approaching the workpiece to the first electrode downstream of a reaction gas flow passing through the discharge space, such that the plasma created in the discharge space is transferred into a space between the first electrode and the workpiece to generate a second atmospheric pressure glow plasma therein, whereby a fluorocarbon coating layer can be formed on the surface of the workpiece.

Owner:KANG BANG KWON

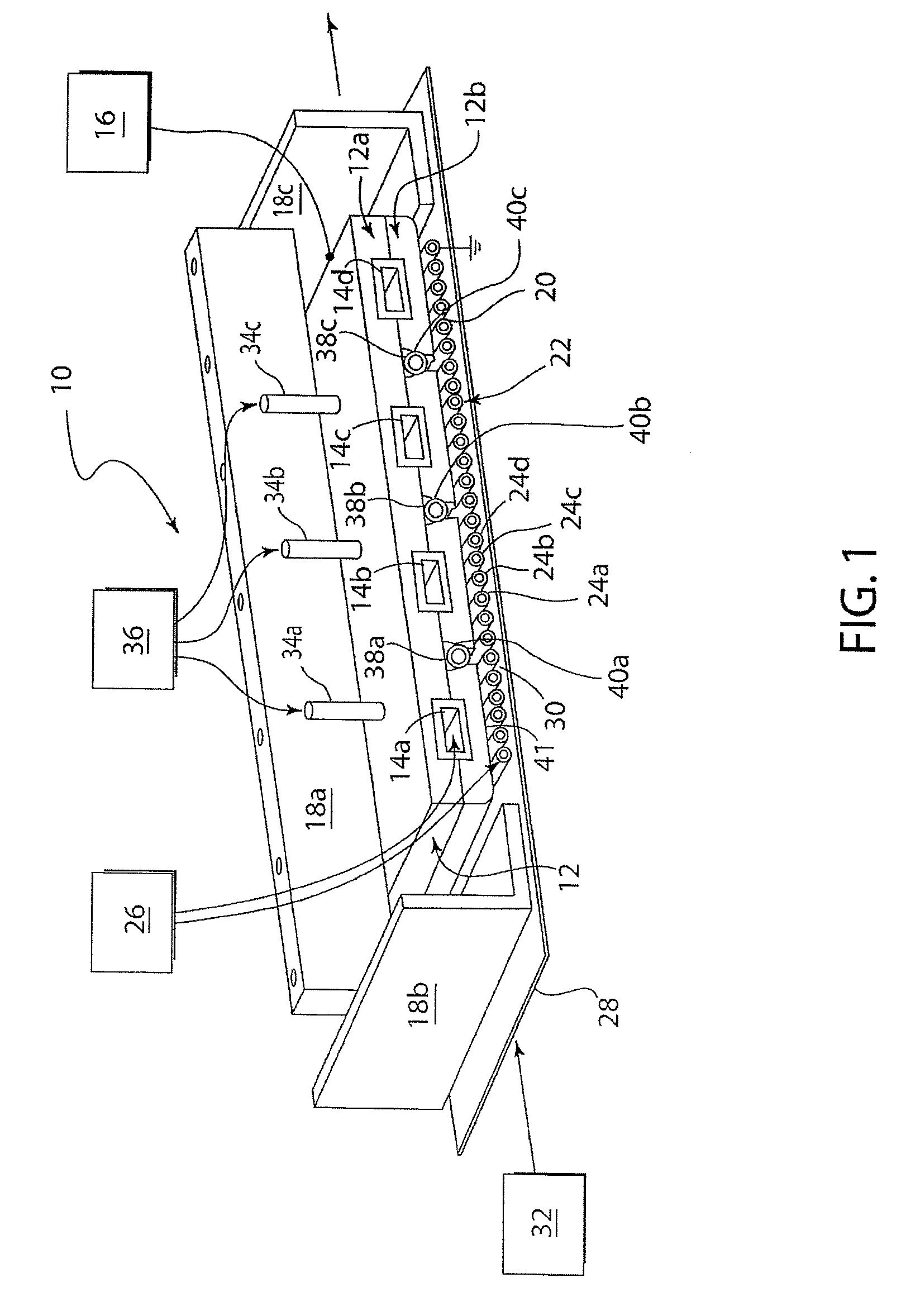

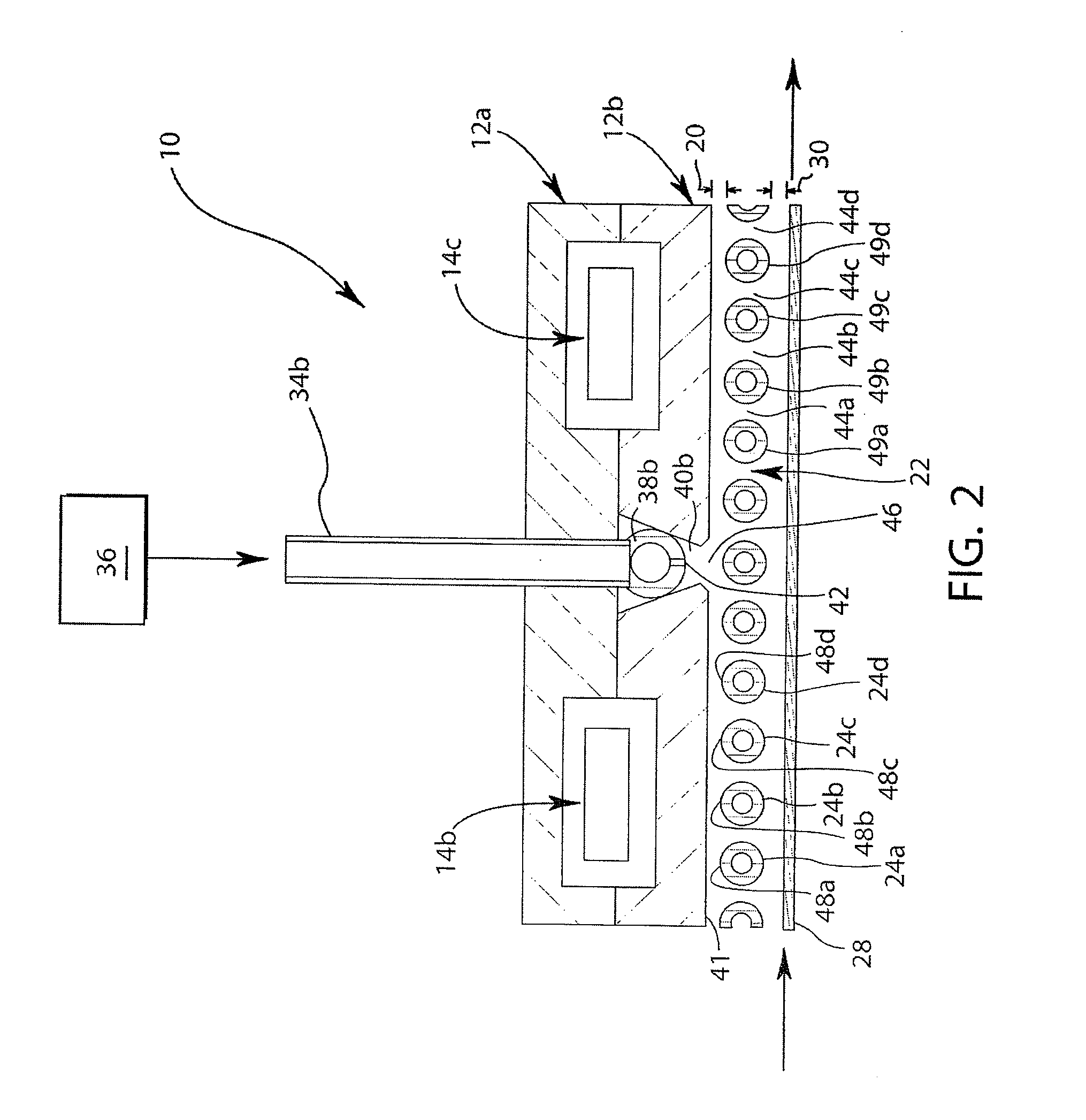

Atmospheric-pressure plasma processing apparatus and method

ActiveUS20140076861A1Faster plasma processing speedMinimum distanceChemical fixing of textilesArc welding apparatusEngineeringAtmospheric pressure

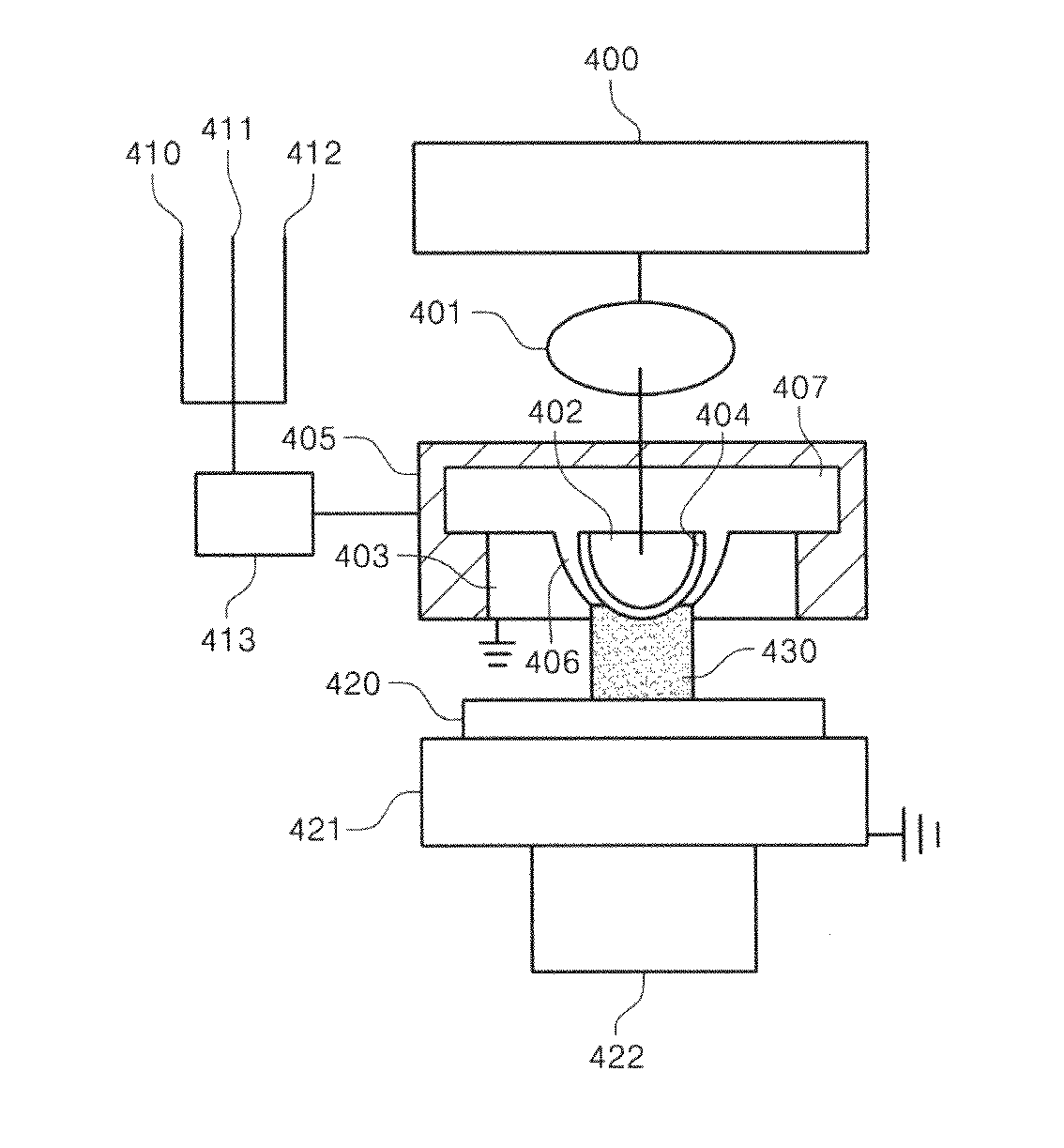

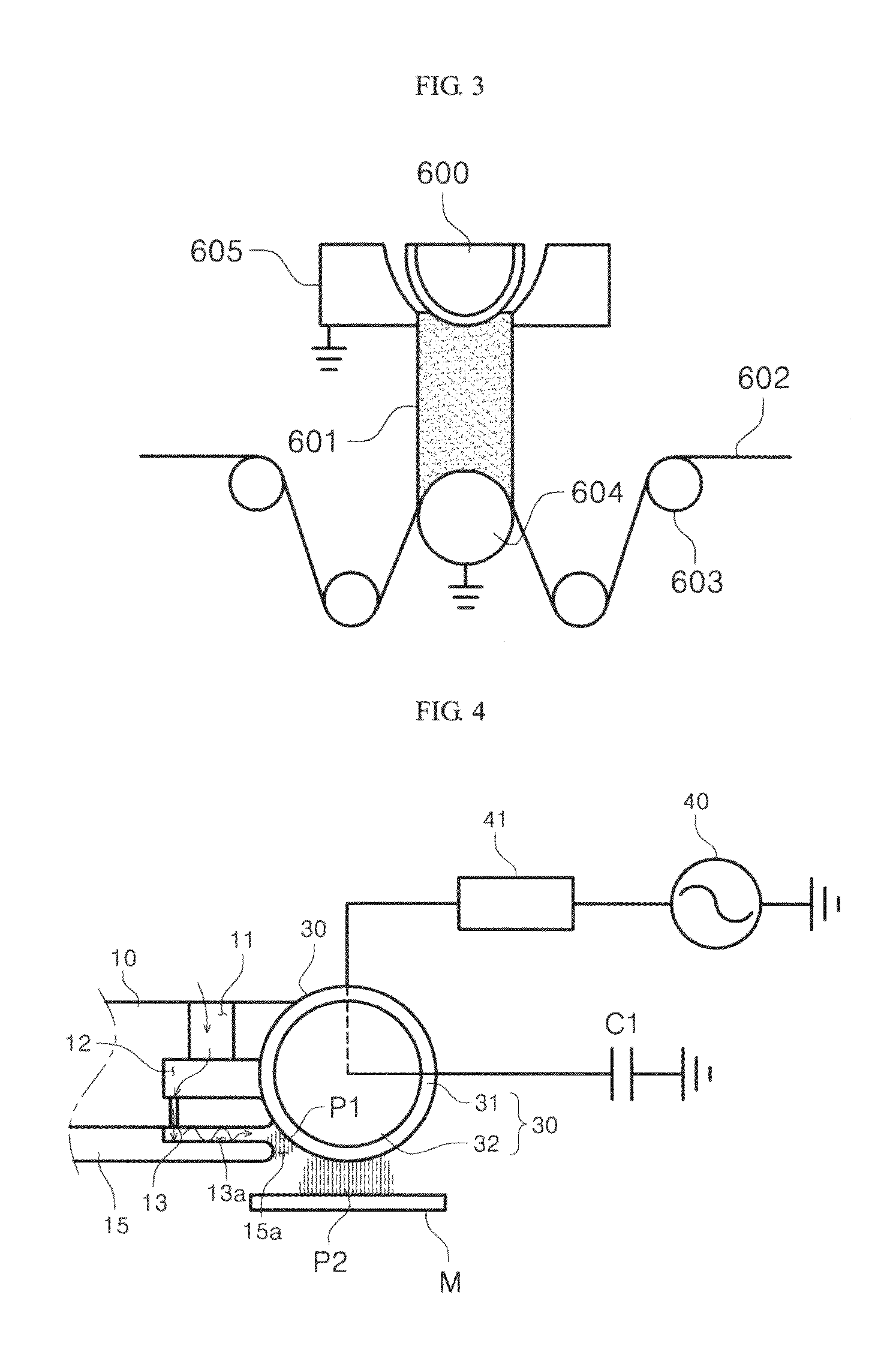

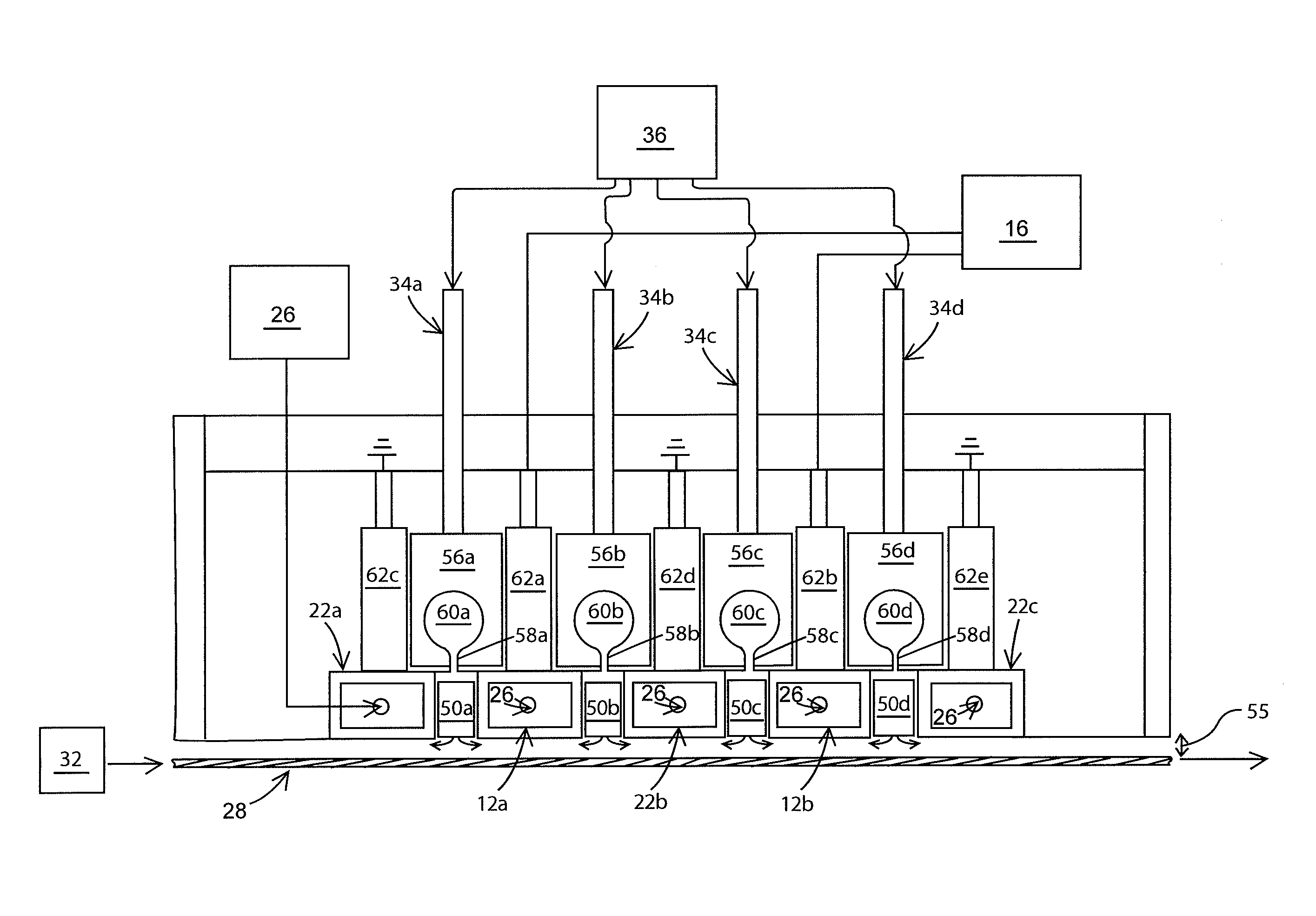

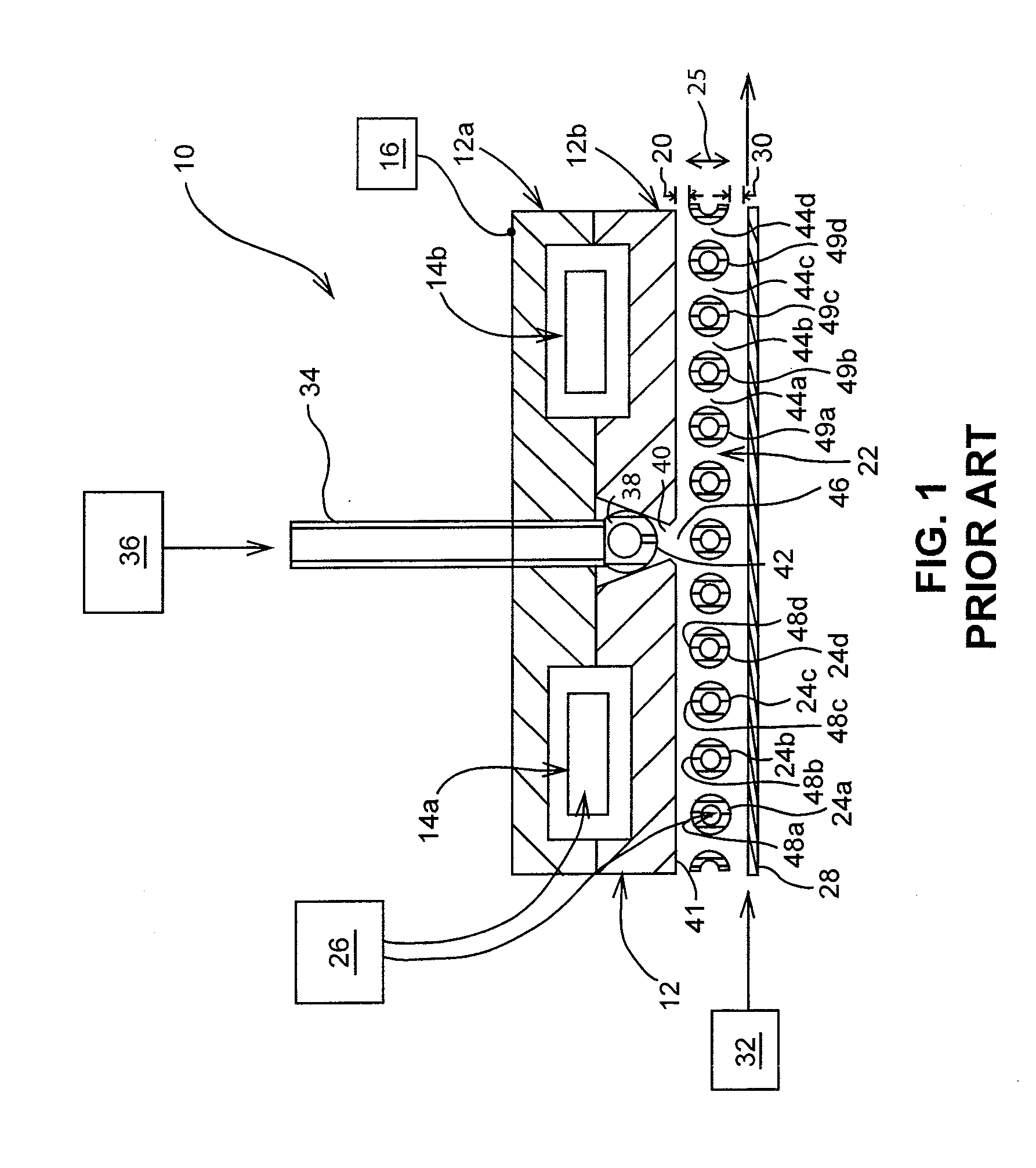

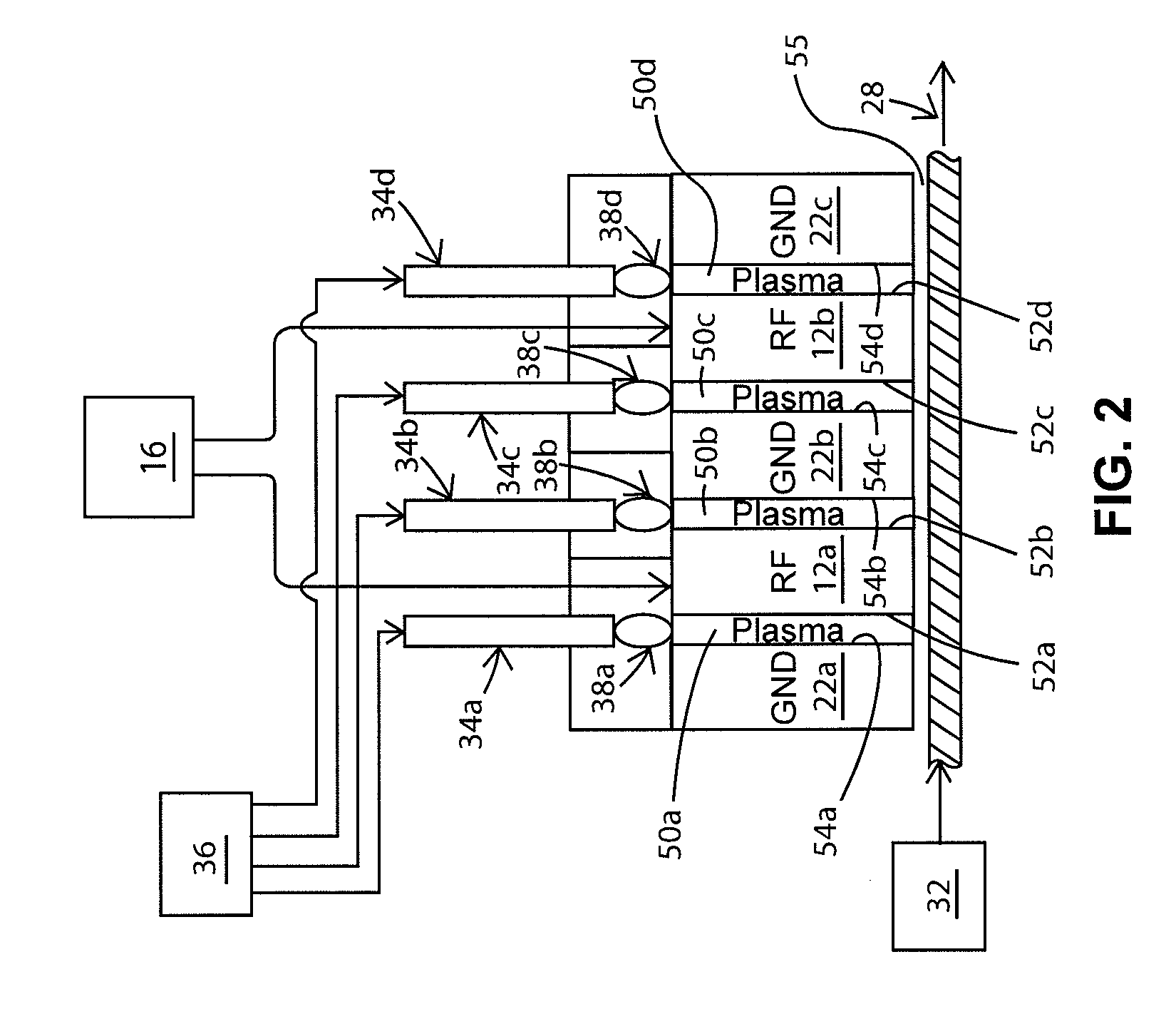

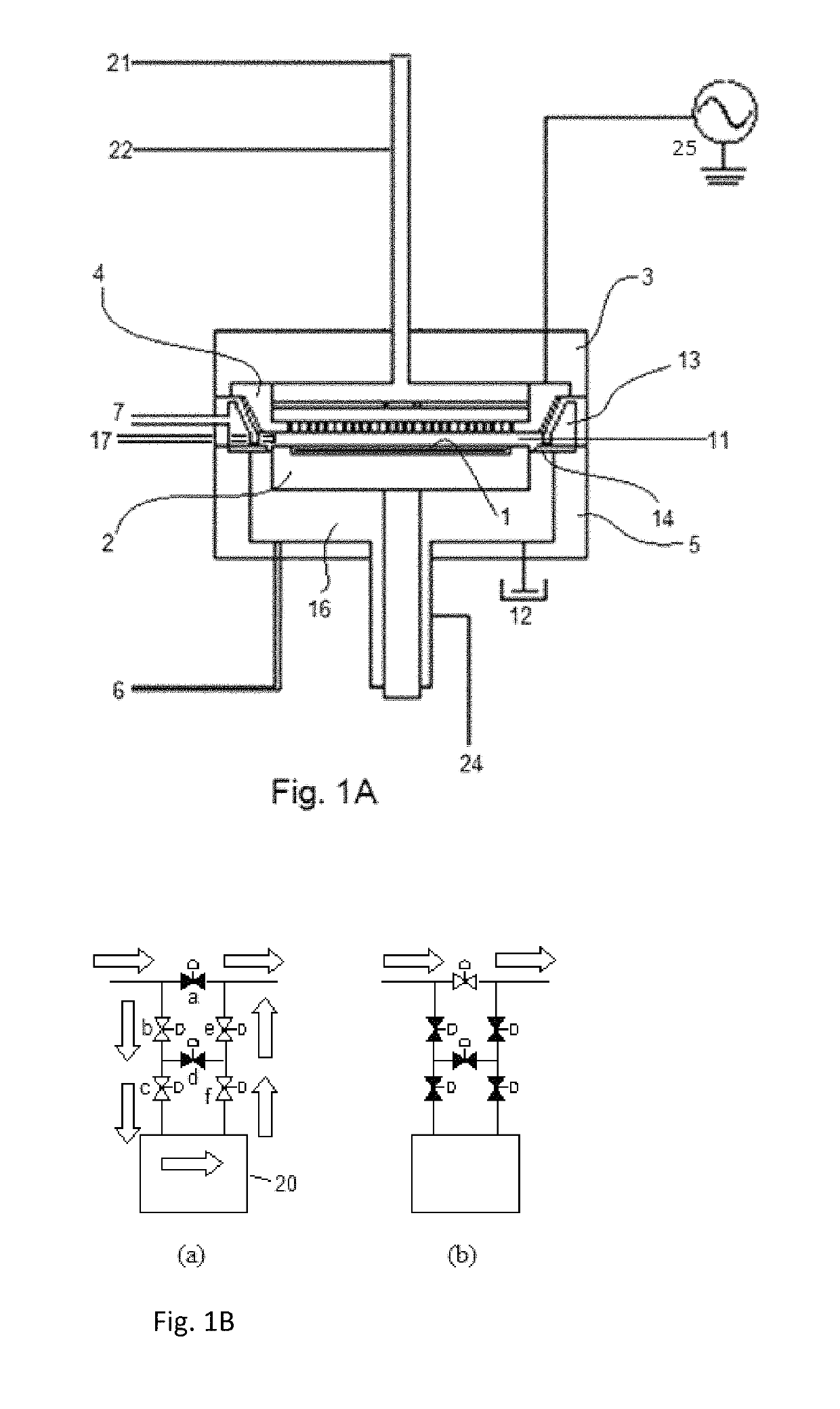

A plasma processing apparatus including powered electrodes having elongated planar surfaces; grounded electrodes having elongated planar surfaces parallel to and coextensive with the elongated surfaces of the powered electrodes, and spaced-apart a chosen distance therefrom, forming plasma regions, is described. RF power is provided to the at least one powered electrode, both powered and grounded electrodes may be cooled, and a plasma gas is flowed through the plasma regions at atmospheric pressure; whereby a plasma is formed in the plasma regions. The material to be processed may be moved into close proximity to the exit of the plasma gas from the plasma regions perpendicular to the gas flow, and perpendicular to the elongated electrode dimensions, whereby excited species generated in the plasma exit the plasma regions and impinge unimpeded onto the material.

Owner:APJET INC

Method of subatmospheric plasma-enhanced ald using capacitively coupled electrodes with narrow gap

ActiveUS20180119283A1Poor conformalityGood shape retentionElectric discharge tubesChemical vapor deposition coatingCapacitanceParallel plate

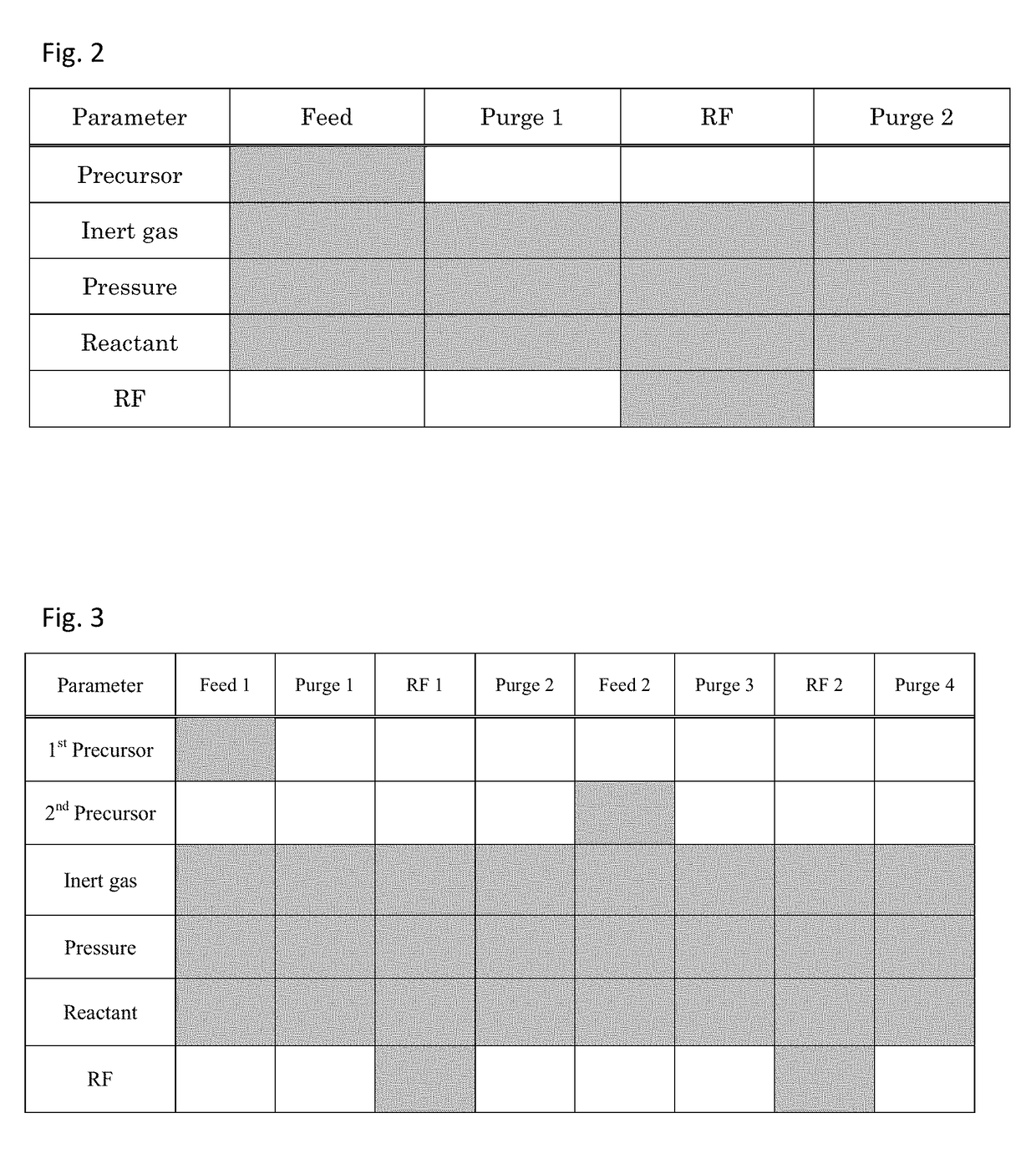

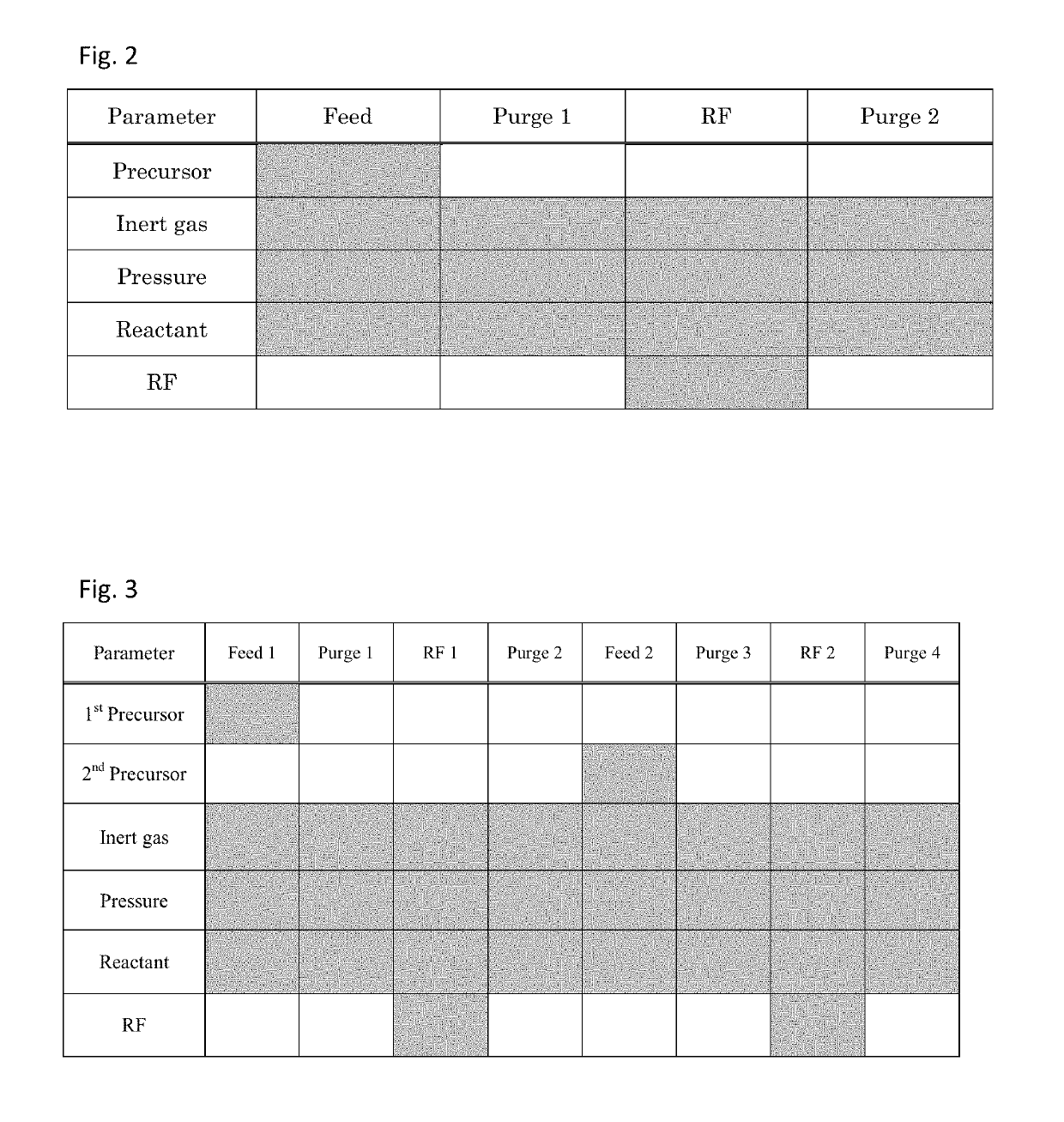

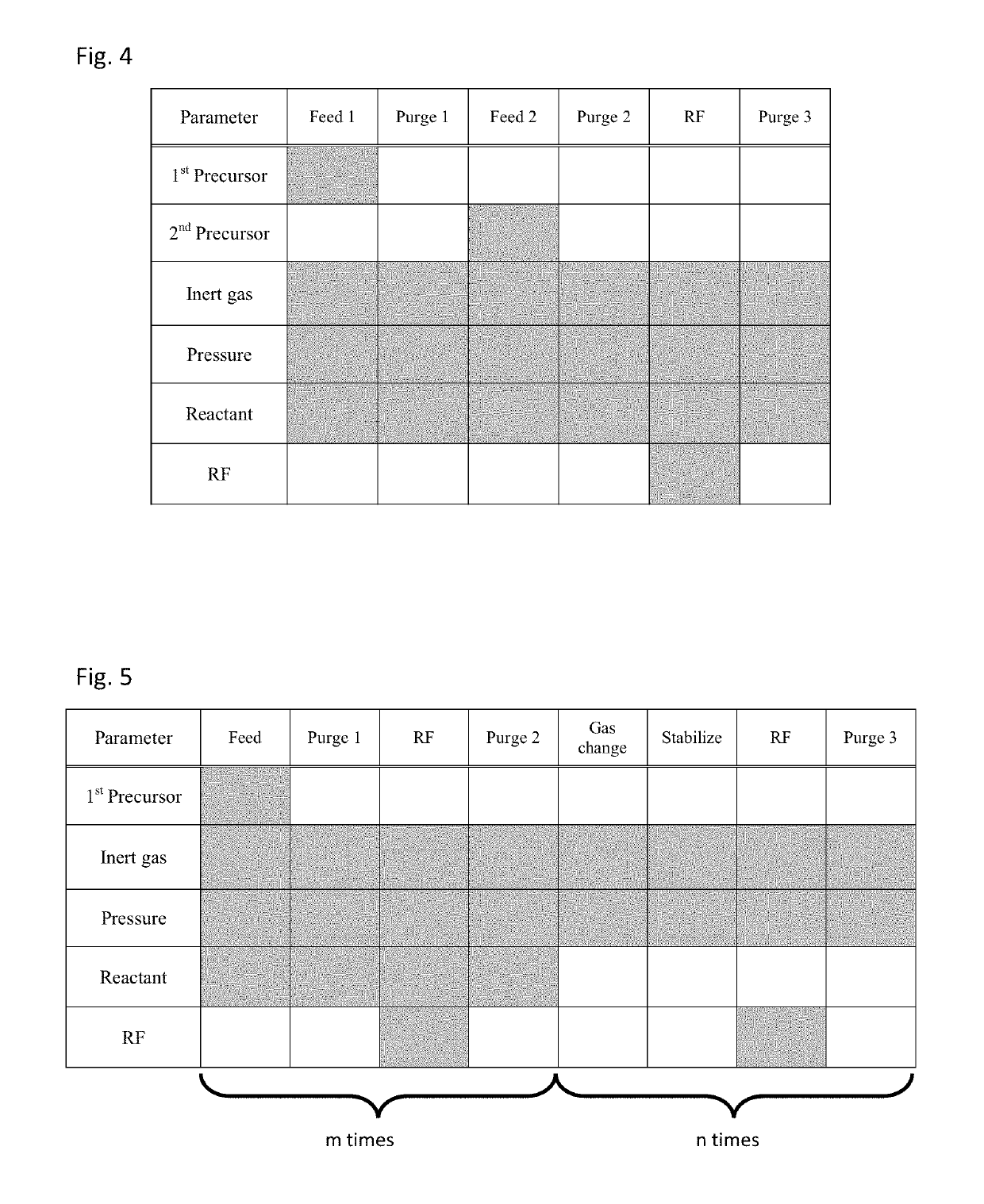

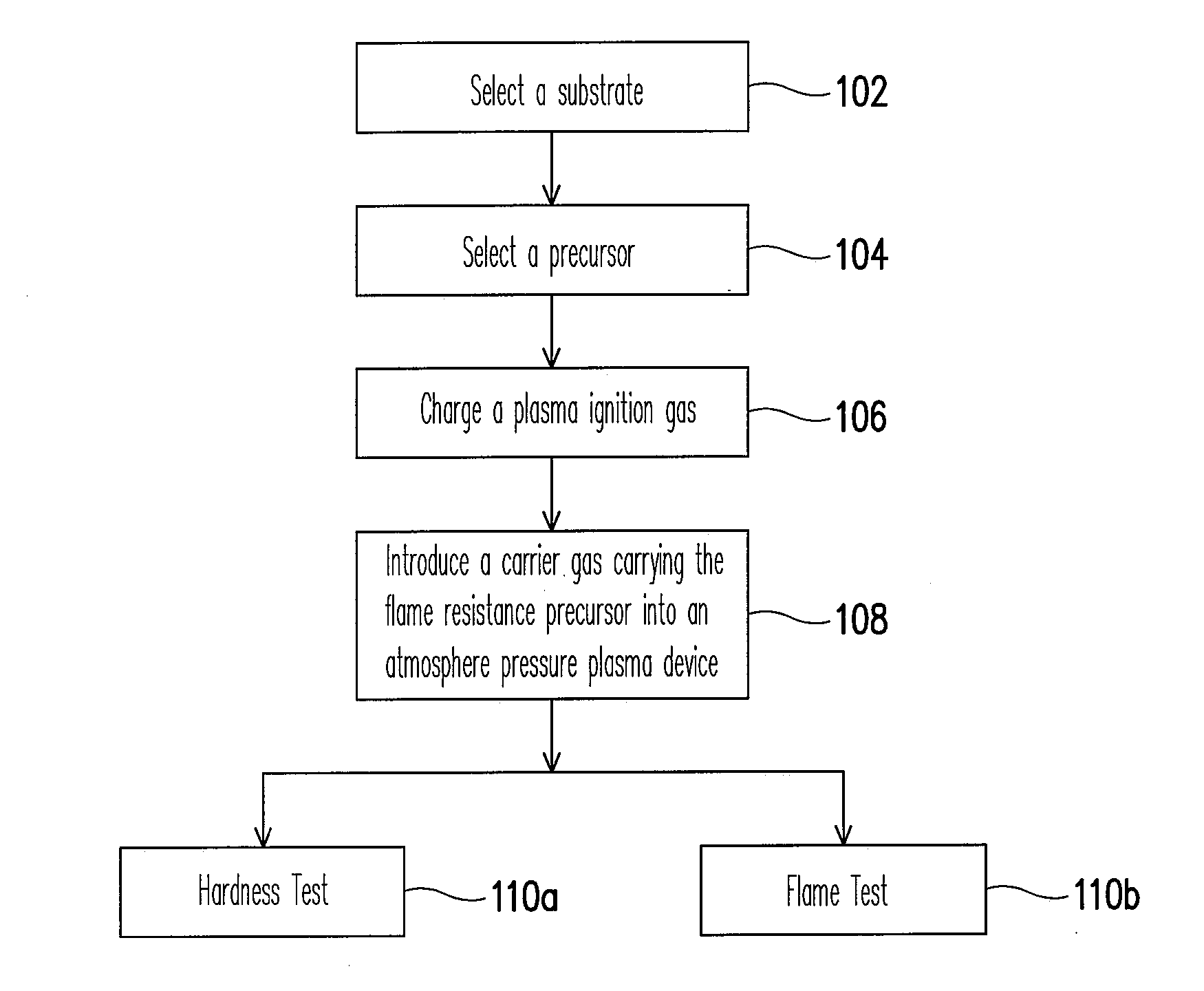

A method for depositing a film by plasma-enhanced subatmospheric-pressure atomic layer deposition (subatmospheric PEALD) is conducted using capacitively coupled parallel plate electrodes with a gap of 1 mm to 5 mm, wherein one cycle of subatmospheric PEALD includes: supplying a precursor in a pulse to the reaction chamber; continuously supplying a reactant to the reaction chamber; continuously supplying an inert gas to the reaction chamber; continuously controlling a pressure of the reaction chamber in a range of 15 kPa to 80 kPa; and applying RF power for glow discharge in a pulse to one of the parallel plate electrodes.

Owner:ASM IP HLDG BV

Method and apparatus for atomic layer deposition using an atmospheric pressure glow discharge plasma

InactiveUS20090324971A1Increase response rateImprove productivitySynthetic resin layered productsChemical vapor deposition coatingPlasma generatorProduct gas

Apparatus and method for atomic layer deposition on a surface of a substrate (6) in a treatment space. A gas supply device (15, 16) is present for providing various gas mixtures to the treatment space. The gas supply device (15, 16) is arranged to provide a gas mixture with a precursor material to the treatment space for allowing reactive surface sites to react with precursor material molecules to give a surface covered by a monolayer of precursor molecules attached via the reactive sites to the surface of the substrate. Subsequently, a gas mixture comprising a reactive agent capable to convert the attached precursor molecules to active precursor sites is provided. A plasma generator (10) is present for generating an atmospheric pressure plasma in the gas mixture comprising the reactive agent.

Owner:FUJIFILM MFG EURO

Method of subatmospheric plasma-enhanced ALD using capacitively coupled electrodes with narrow gap

ActiveUS10435790B2Poor conformalityGood shape retentionElectric discharge tubesChemical vapor deposition coatingCapacitanceParallel plate

A method for depositing a film by plasma-enhanced subatmospheric-pressure atomic layer deposition (subatmospheric PEALD) is conducted using capacitively coupled parallel plate electrodes with a gap of 1 mm to 5 mm, wherein one cycle of subatmospheric PEALD includes: supplying a precursor in a pulse to the reaction chamber; continuously supplying a reactant to the reaction chamber; continuously supplying an inert gas to the reaction chamber; continuously controlling a pressure of the reaction chamber in a range of 15 kPa to 80 kPa; and applying RF power for glow discharge in a pulse to one of the parallel plate electrodes.

Owner:ASM IP HLDG BV

Method of improving surface flame resistnace of substrate

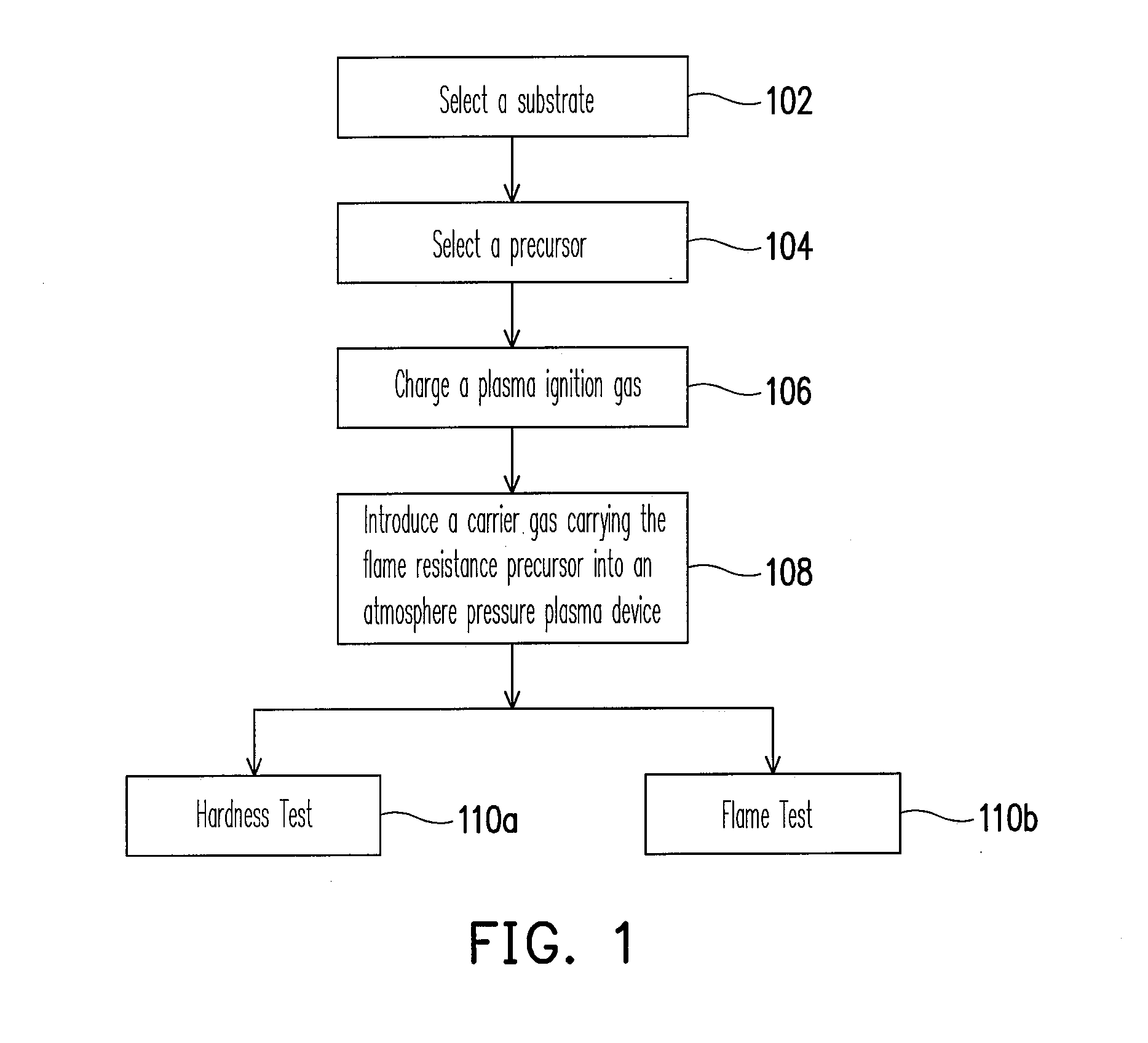

InactiveUS20080105276A1Improve flame retardant performanceSurface cleaningElectrostatic cleaningChemical vapor deposition coatingPlasma ignitionAtmosphere

A method of improving surface flame resistance of a substrate is provided. A substrate is provided. An atmosphere pressure plasma process is performed on the surface of the substrate to form an inorganic film layer on the surface of the substrate, wherein a process gas of the atmosphere plasma process includes a flame resistance precursor, a carrier gas, and a plasma ignition gas. Particularly, the flame resistance precursor is selected from a siloxane compound, an inorganic alkoxide compound and a combination thereof. The siloxane compound has a formula of Si(OCnH2(n+1))4, n=1˜5, and the inorganic alkoxide compound has a formula of A(OCmH2m+1)4, where A represents Sn, Ti, Zr, Ce and m=2.

Owner:IND TECH RES INST

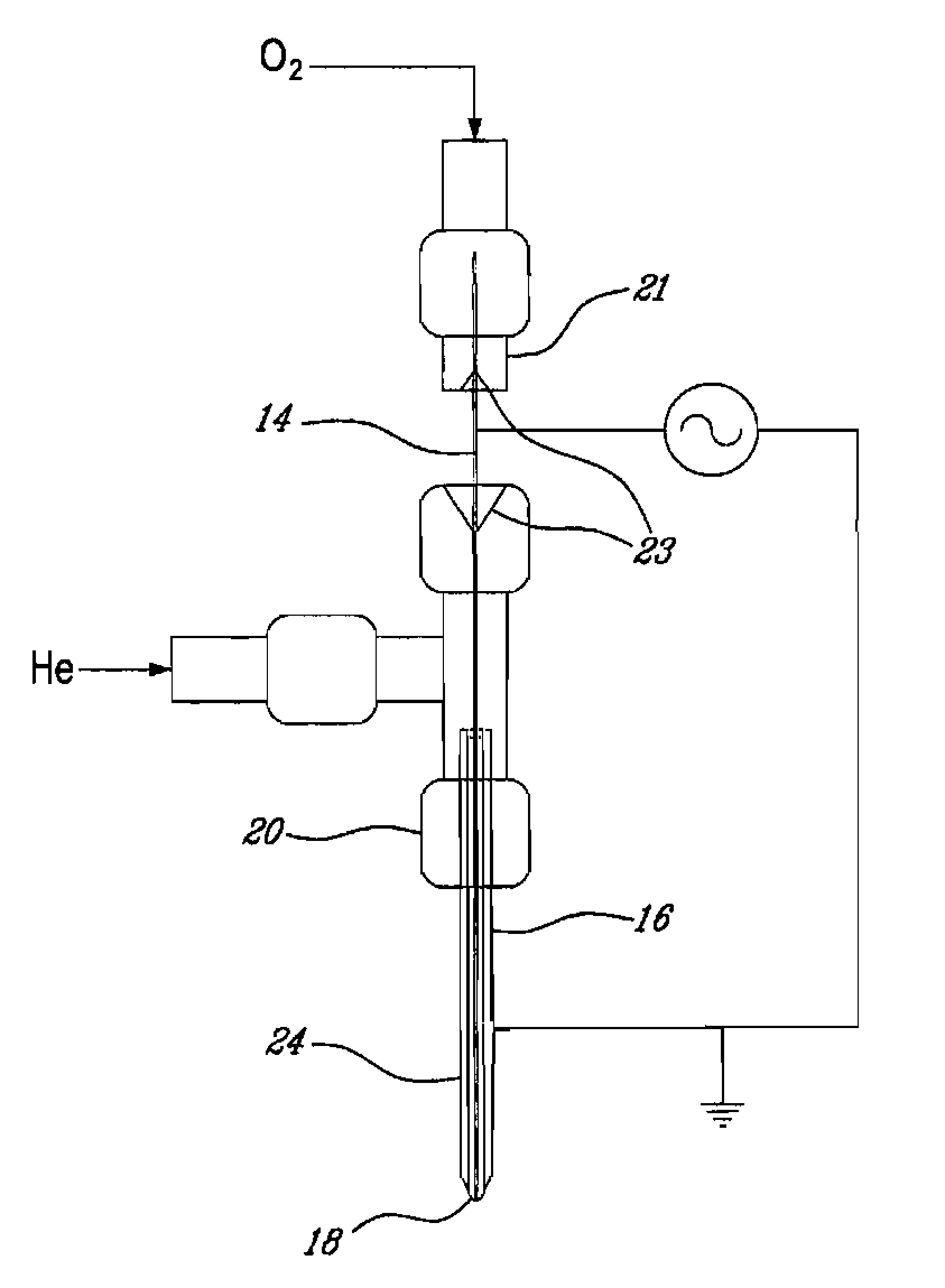

Plasma source and applications thereof

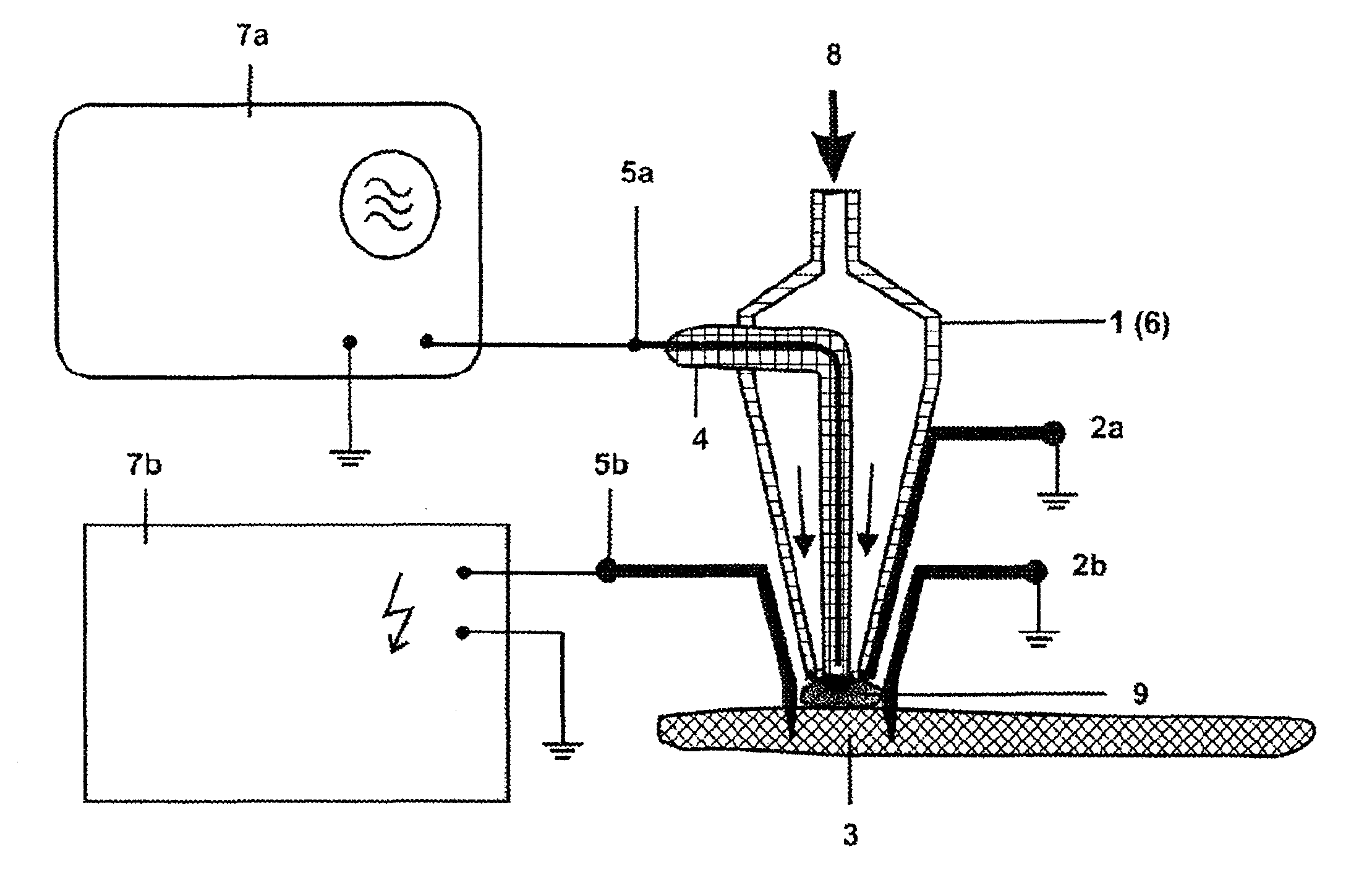

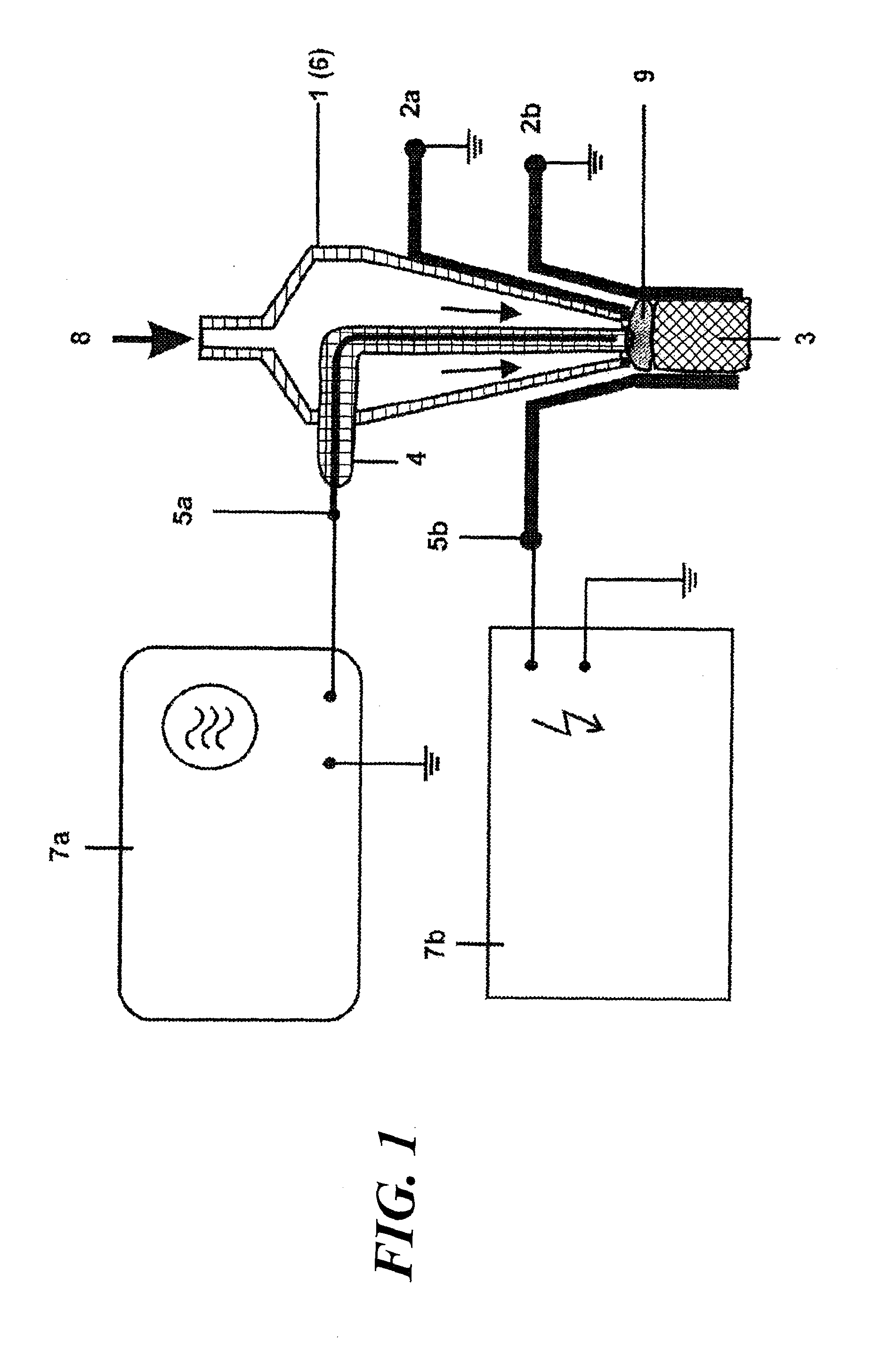

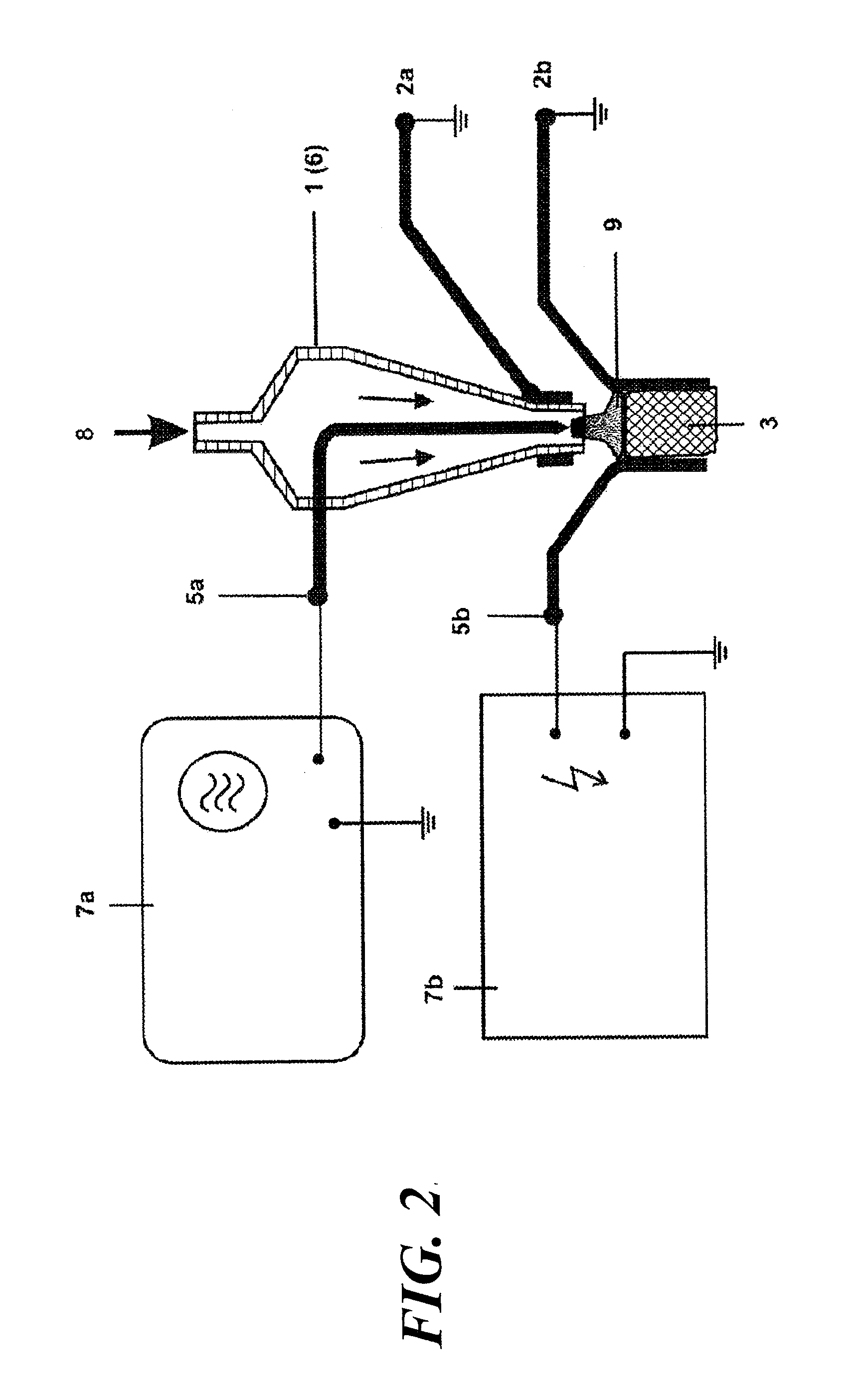

A low-power atmospheric pressure plasma source, comprising a plasma-forming region for injection of a plasma-forming gas; an excitation region for injection of a source reactive species downstream of the plasma-forming region; and a narrow converging plasma exit for producing a narrow plasma jet, the source being electrically decoupled from a substrate under treatment by the plasma jet. The present source may found applications for example for skin treatment, etching of skin cancer cells, detachment of cells, removal of skin pigmentation and deposition of temporary organic films.

Owner:MCGILL UNIV

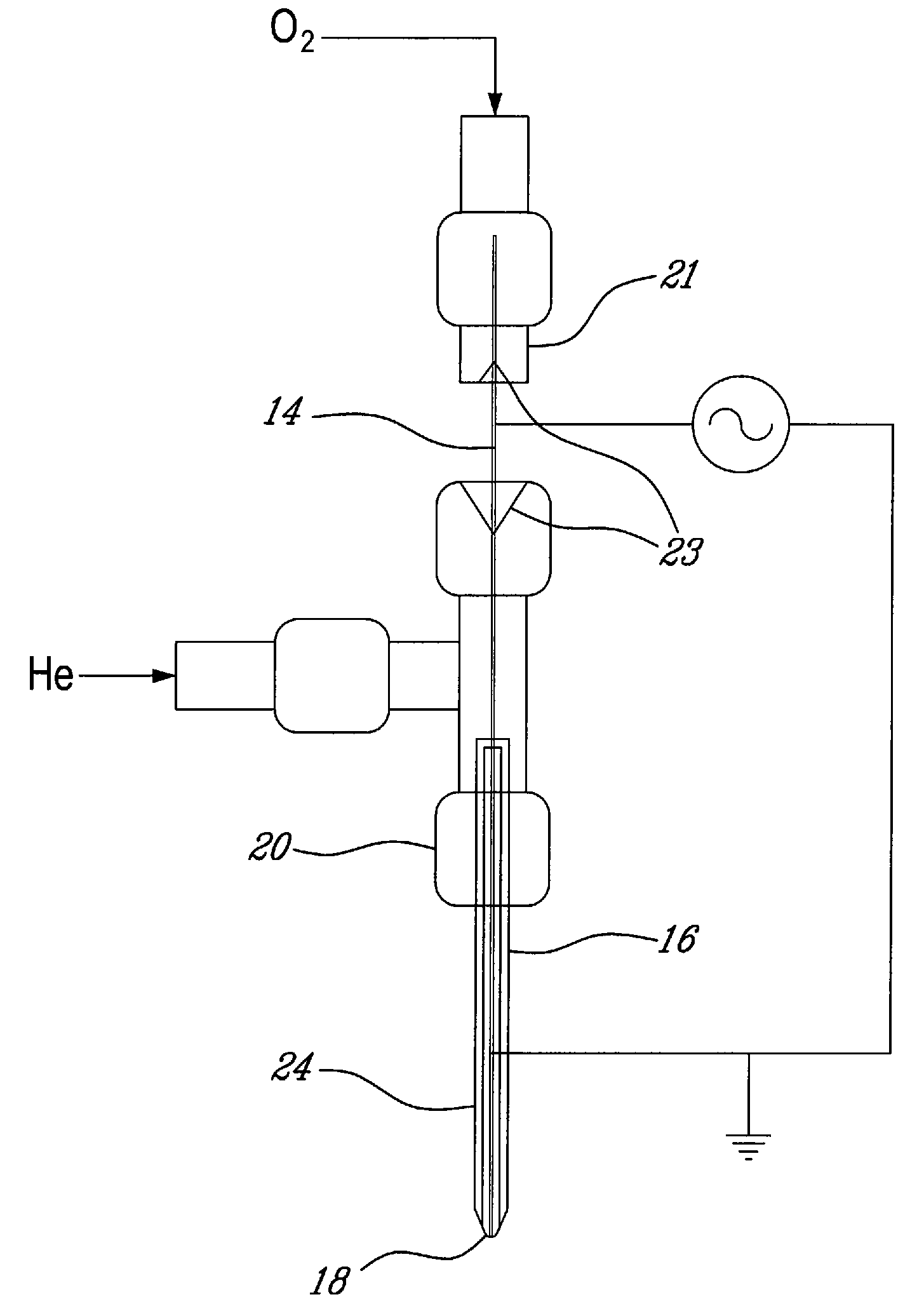

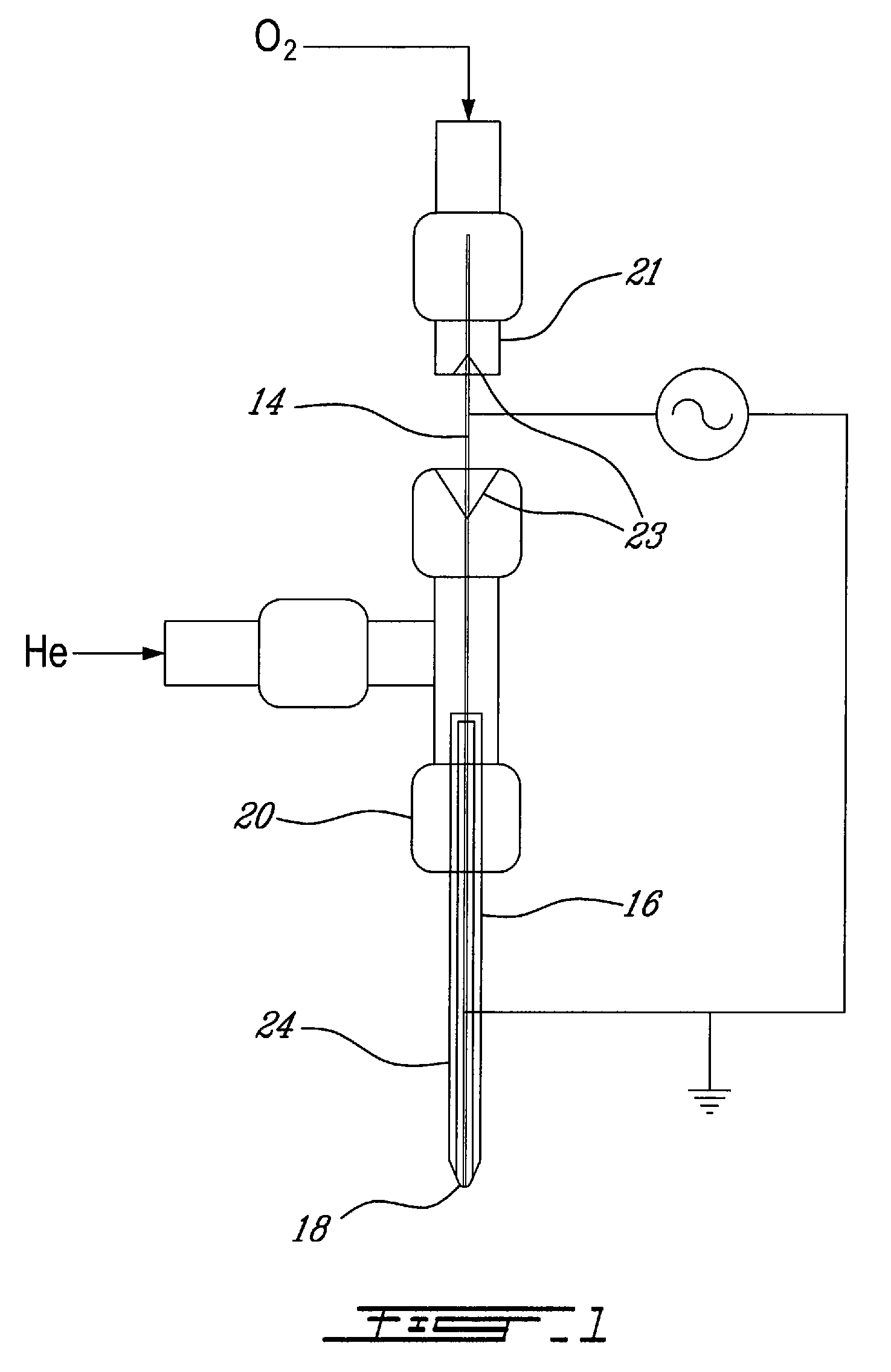

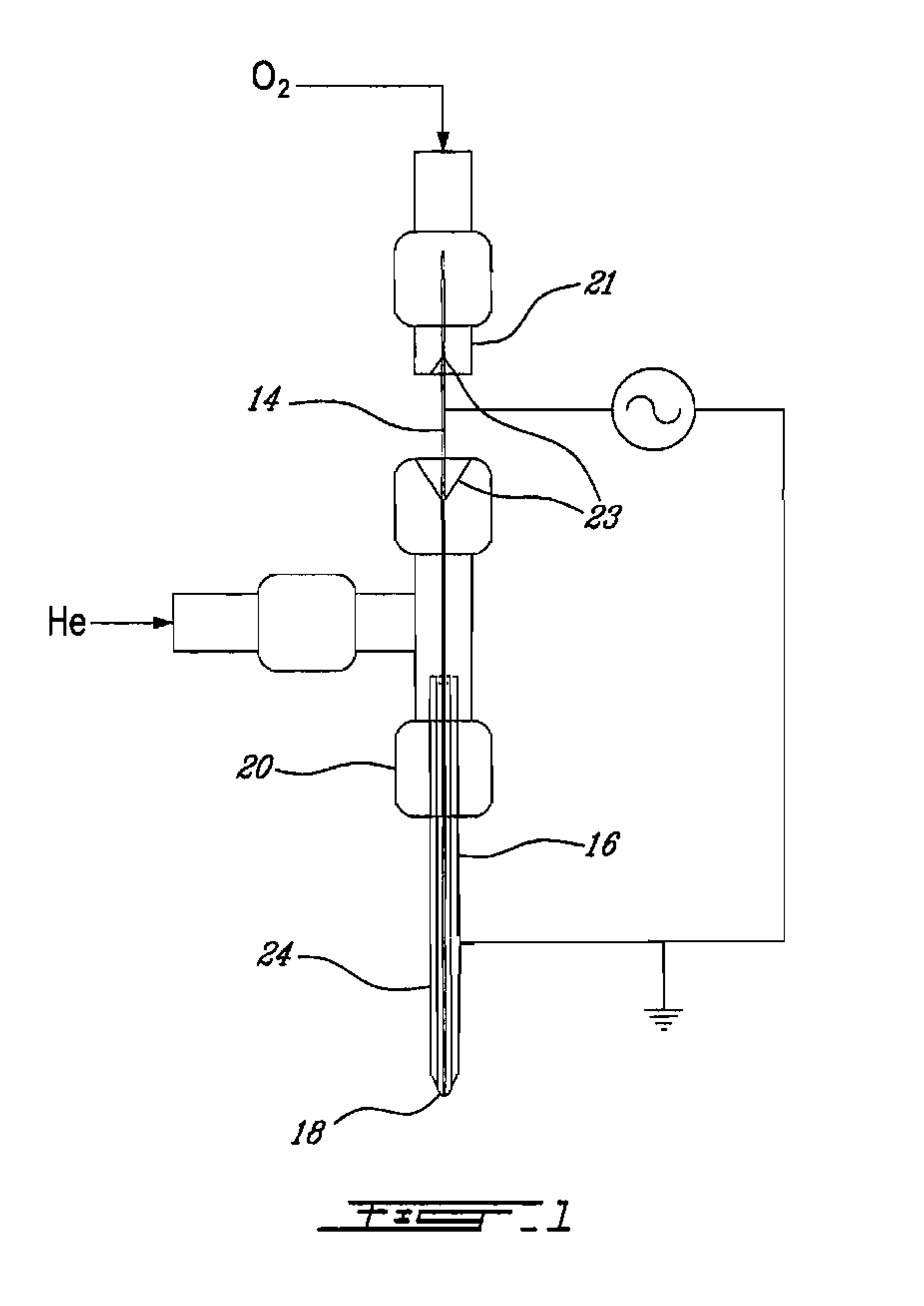

Low temperature, atmospheric pressure plasma generation and applications

InactiveUS20060156983A1Efficient couplingReduce power inputSemiconductor/solid-state device manufacturingDisinfectionEtchingHigh frequency power

Devices and methods for generating a low temperature atmospheric pressure plasma are disclosed. A method of generating a low temperature atmospheric pressure plasma that comprises coupling a high-frequency power supply to a tuning network that is connected to one or more electrodes, placing one or more non-conducting housings between the electrodes, flowing gas through the one or more housings, and striking and maintaining the plasma with the application of said high-frequency power is described. A technique for the surface treatment of materials with said low temperature atmospheric pressure plasma, including surface activation, cleaning, sterilization, etching and deposition of thin films is also disclosed.

Owner:SURFX TECH

Plasma source and applications thereof

A low-power atmospheric pressure plasma source, comprising a plasma-forming region for injection of a plasma-forming gas; an excitation region for injection of a source of reactive species downstream of the plasma-forming region; and a narrow converging plasma exit for producing a narrow plasma jet, the source being electrically decoupled from a substrate under treatment by the plasma jet. The present source may find applications for example for skin treatment, etching of skin cancer cells, detachment of cells, removal of skin pigmentation and deposition of temporary organic films.

Owner:MCGILL UNIV

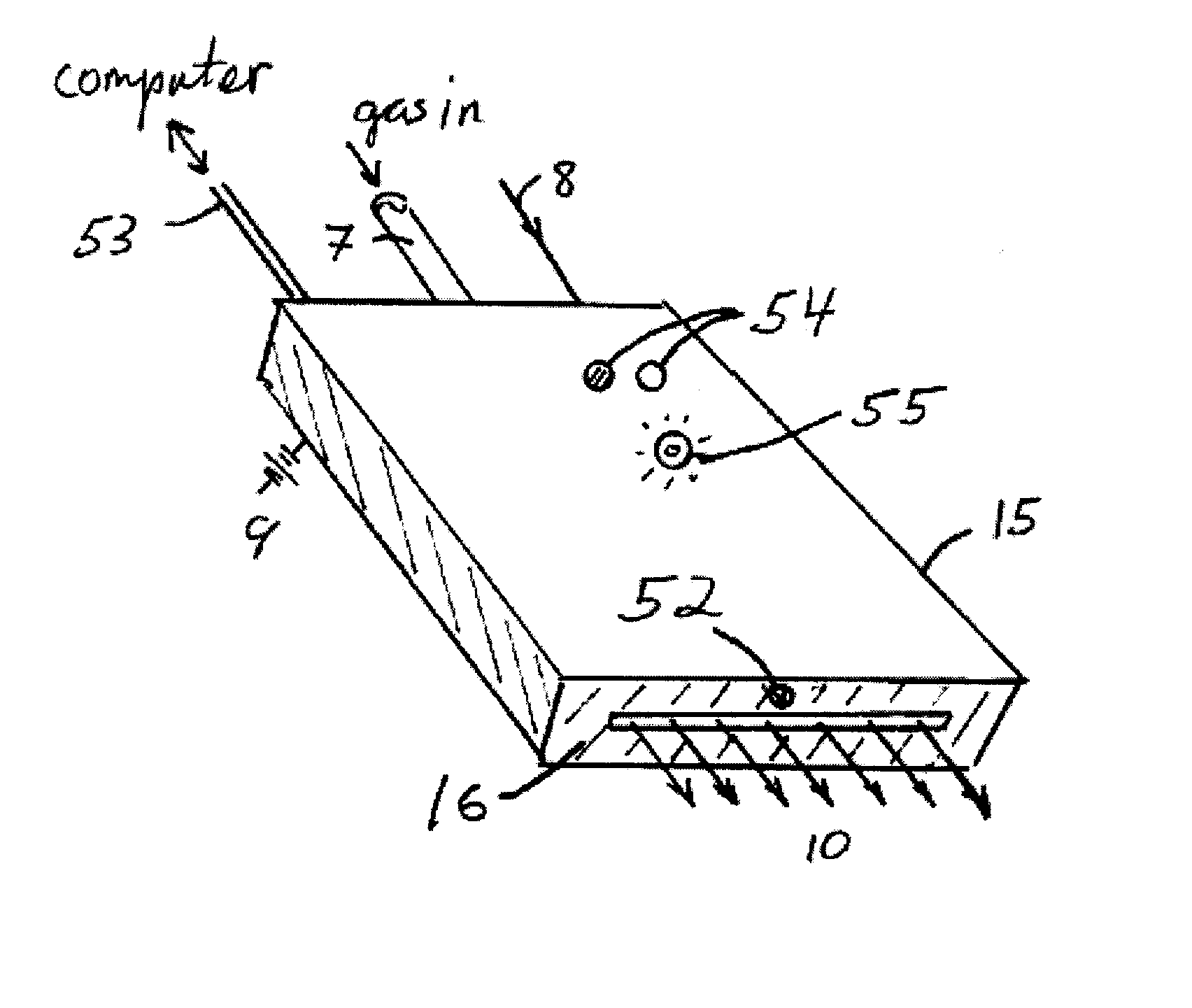

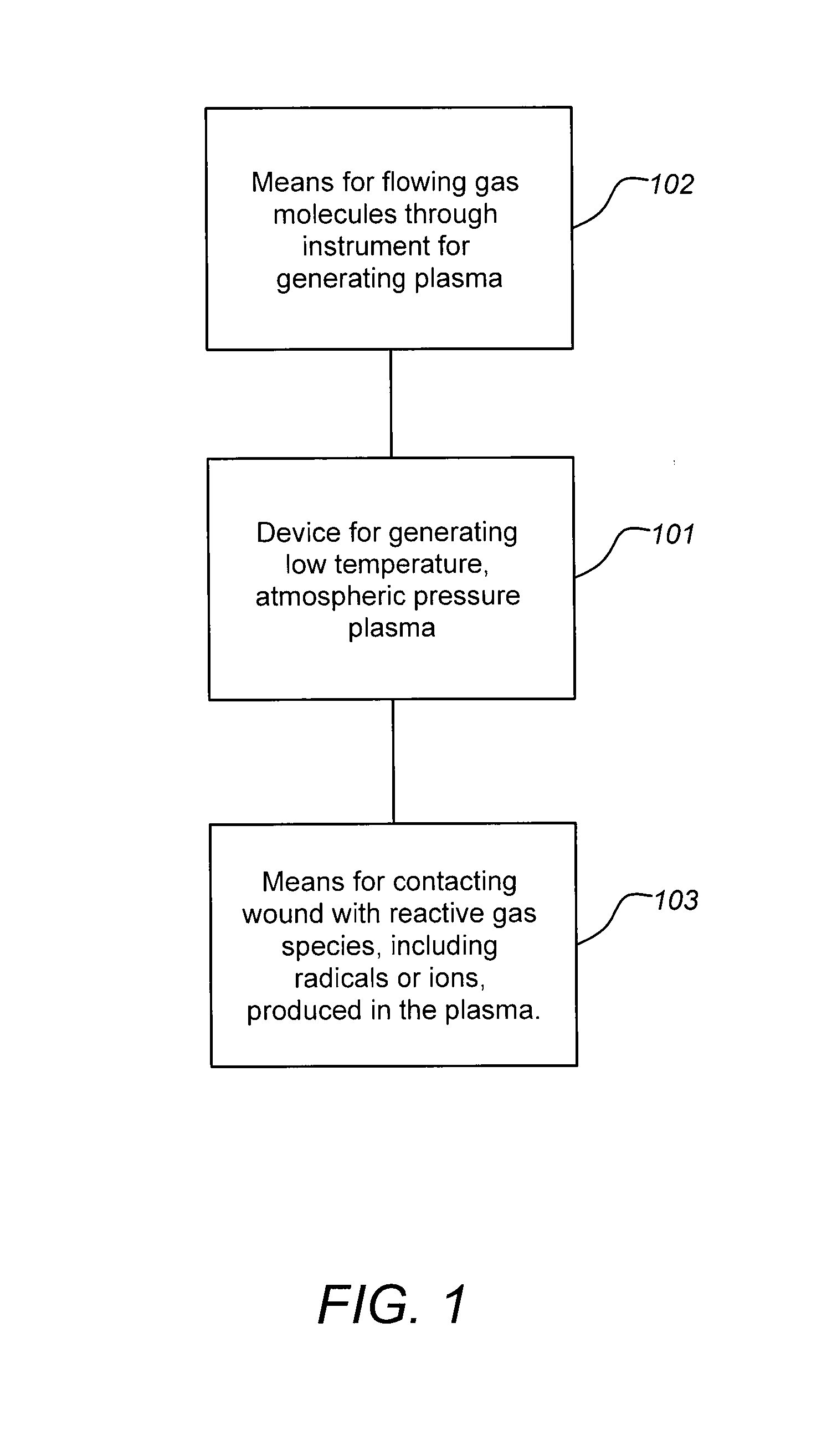

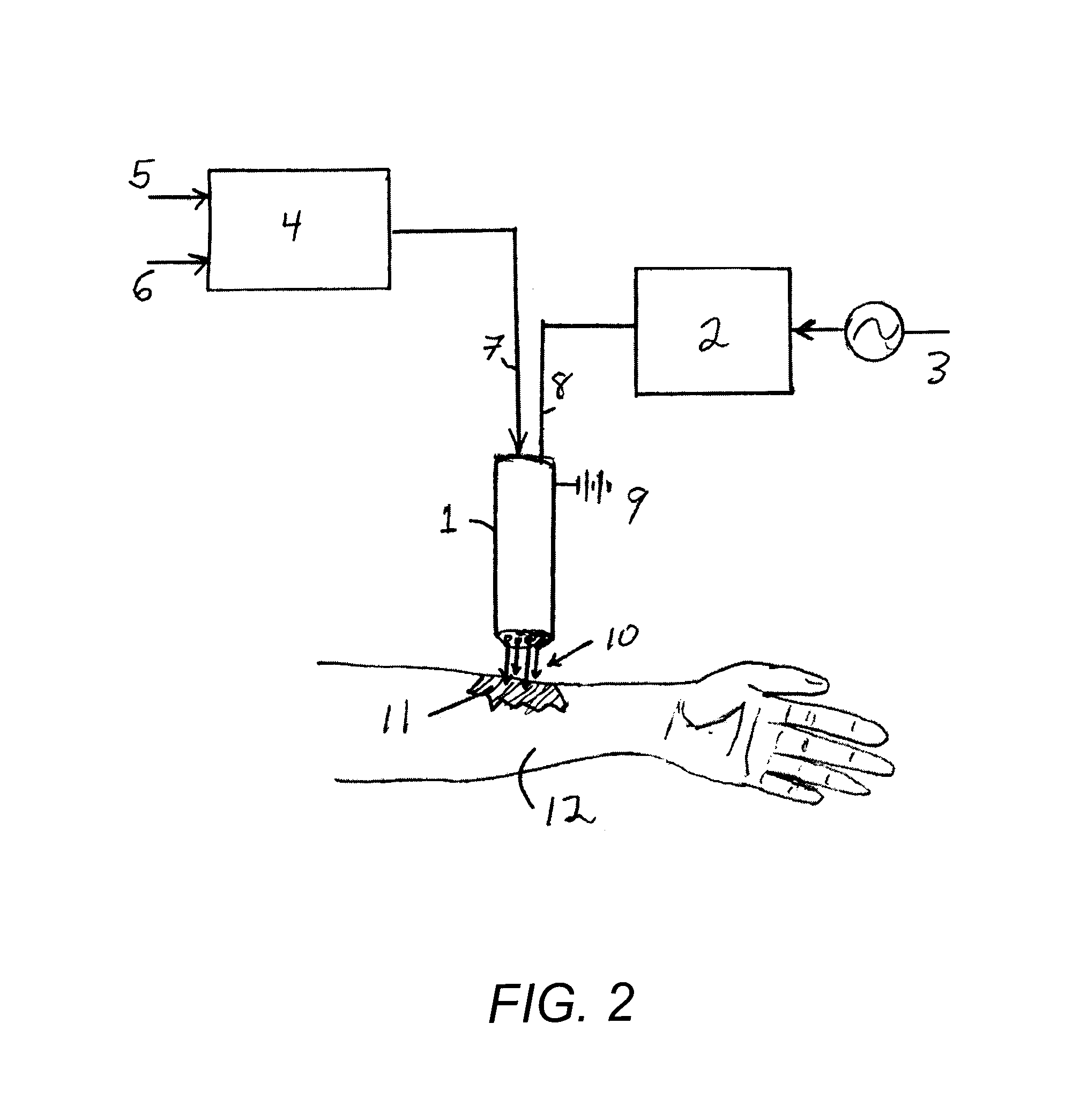

Wound treatment apparatus and method

ActiveUS8267884B1Promote healingEasy to operateElectric discharge tubesDiagnosticsMedicineReactive gas

Apparatuses and methods for treating wounds are disclosed. An apparatus for treating wounds is disclosed comprising an instrument for generating a low temperature, atmospheric pressure plasma, a means of flowing gas through the instrument, and a means of contacting the wound with the reactive gases flowing out of the instrument. A method for treating wounds using reactive gases is disclosed. The use of atmospheric pressure plasmas for treating wounds is also disclosed.

Owner:SURFX TECH

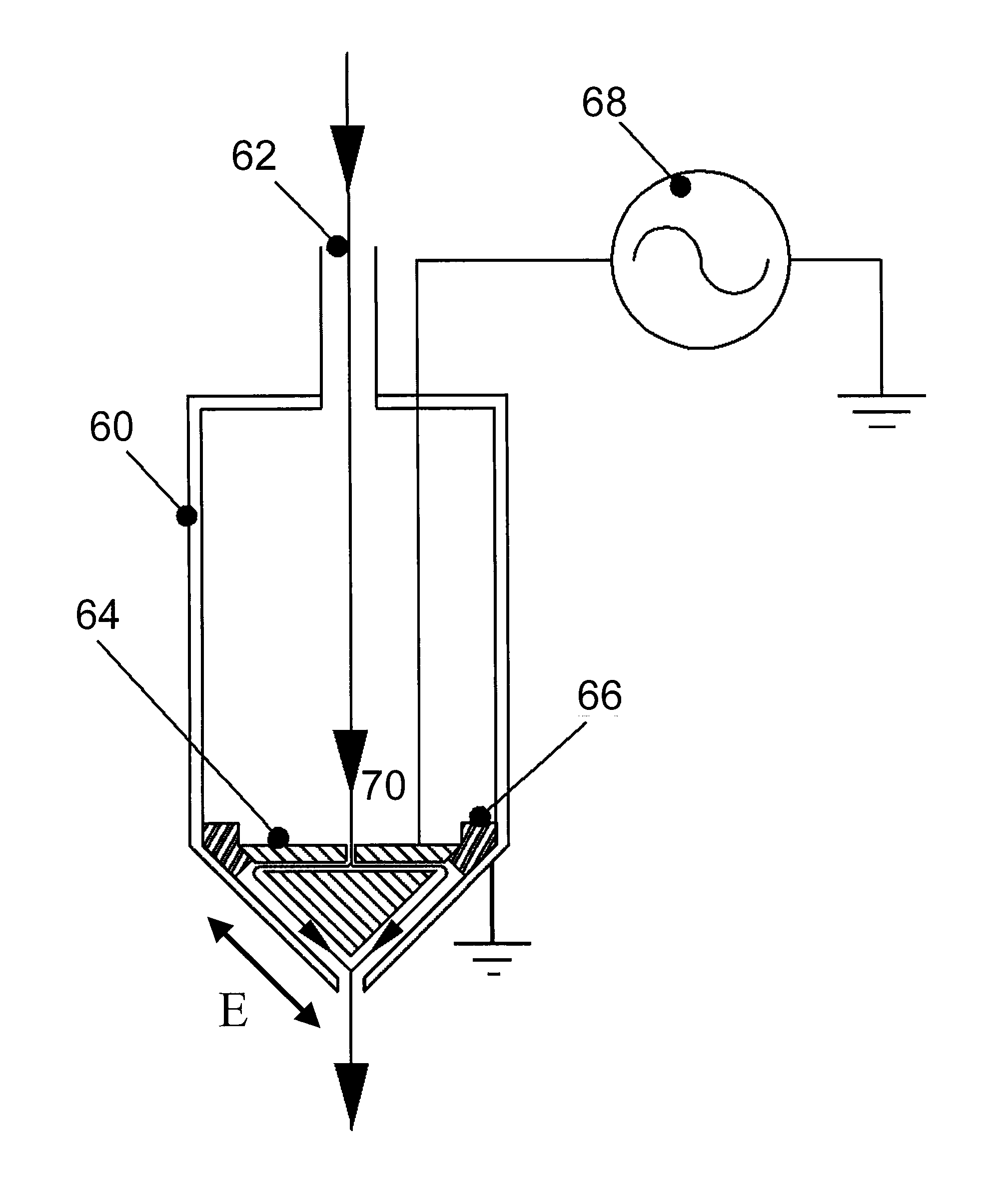

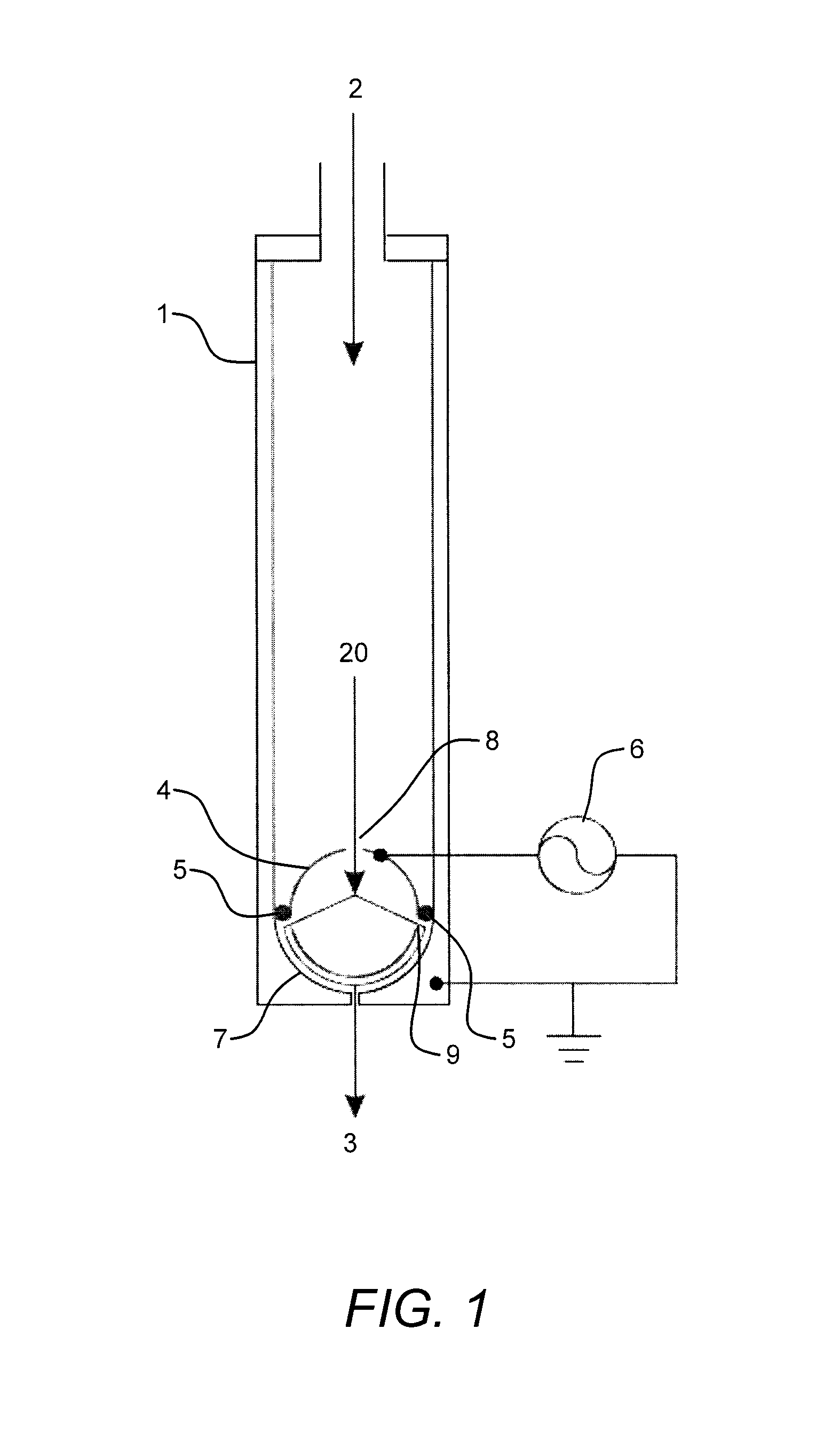

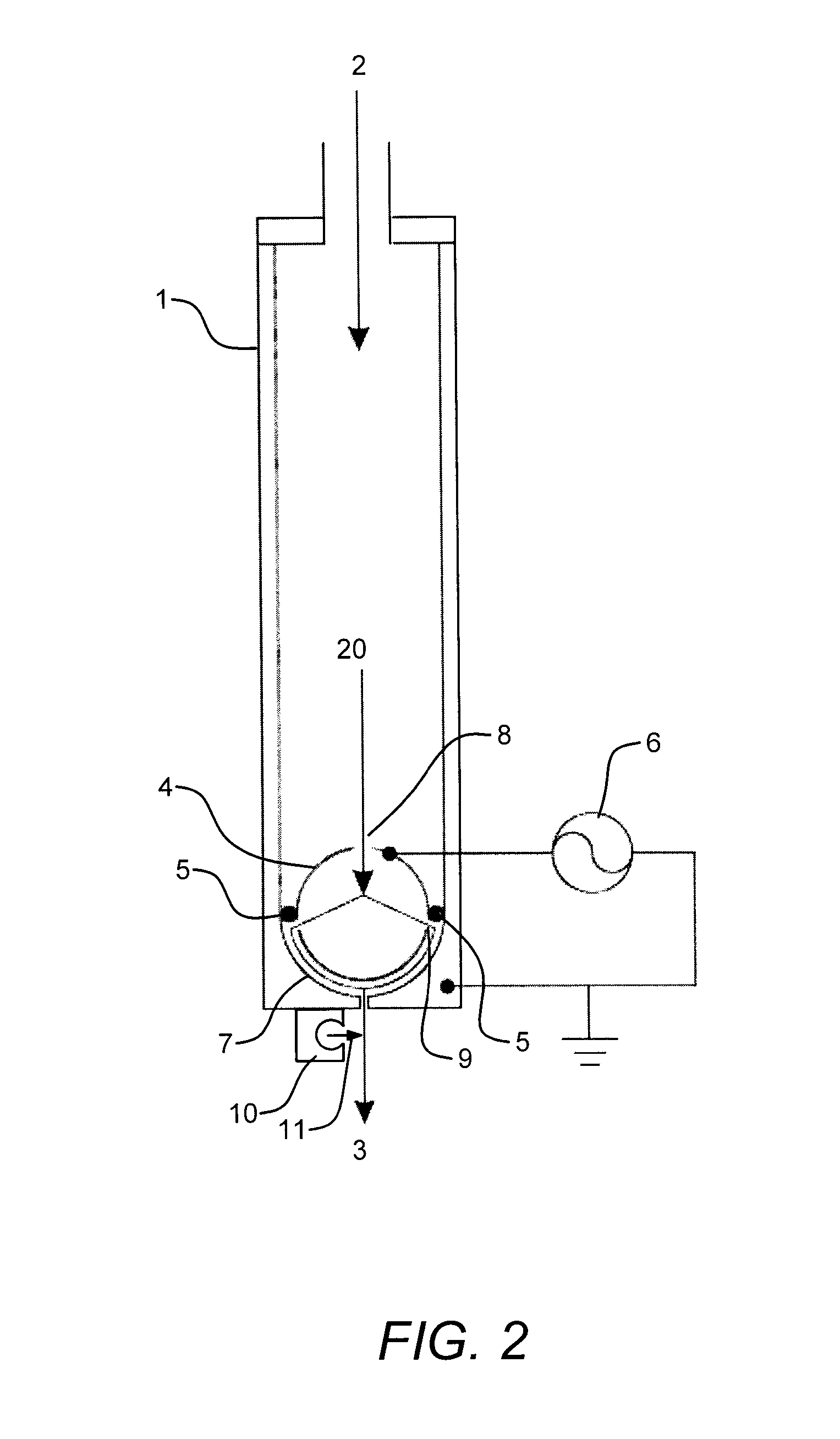

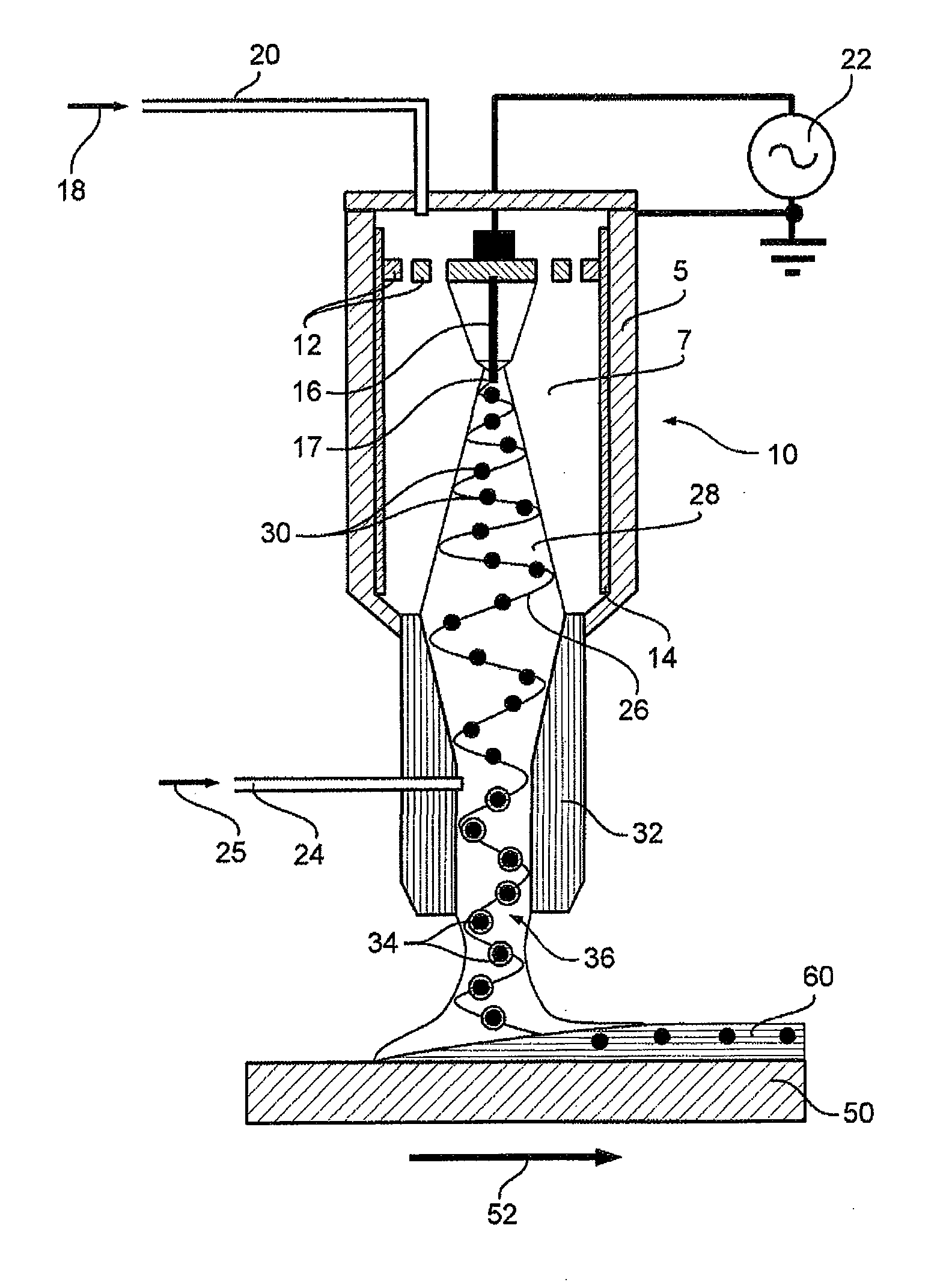

Low-temperature, converging, reactive gas source and method of use

ActiveUS8328982B1Electric discharge tubesSemiconductor/solid-state device manufacturingEtchingReactive gas

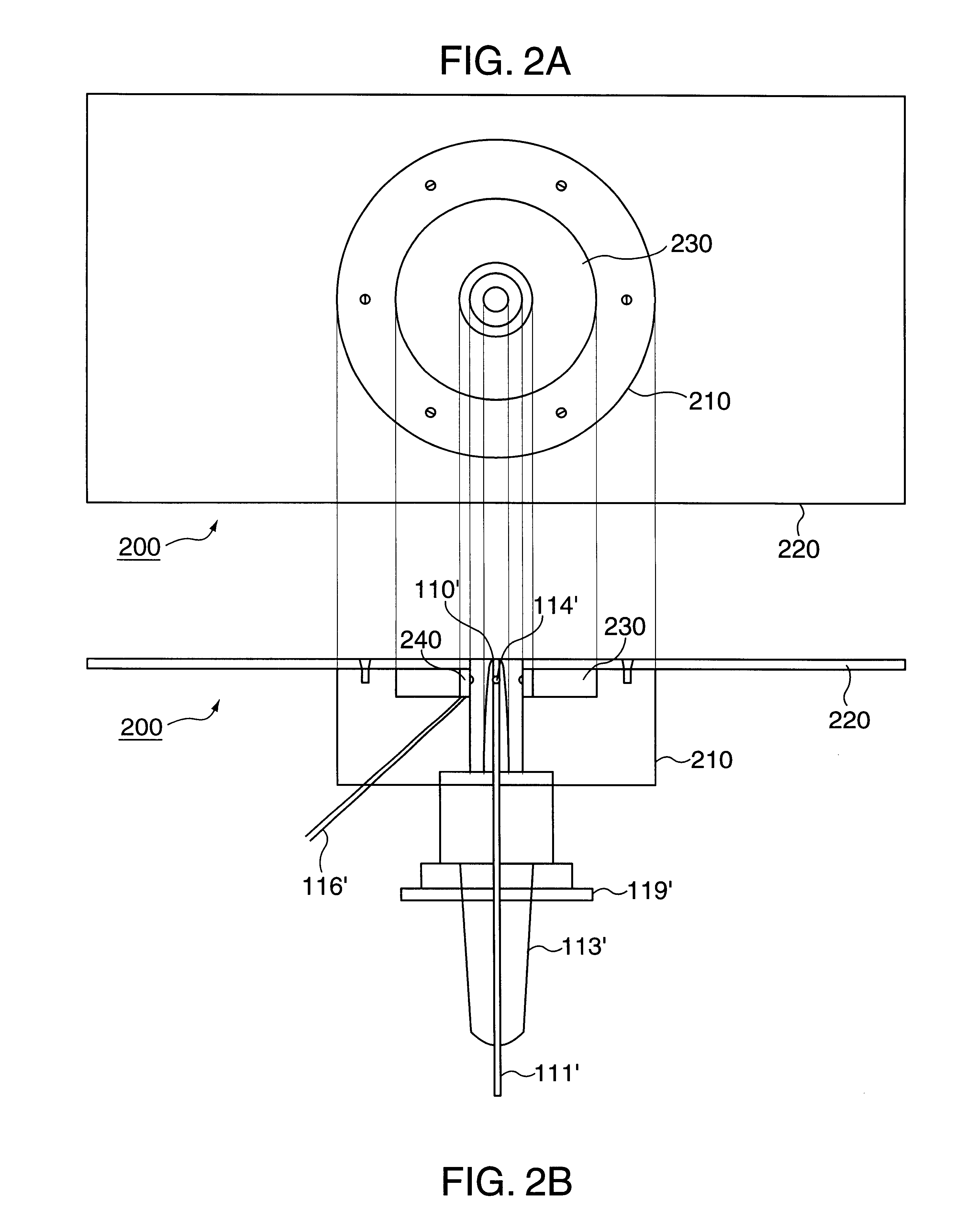

Devices and methods for generating a low-temperature, atmospheric pressure plasma are disclosed. A plasma device may include a first electrode having an inlet for a gas, a second electrode having an outlet for the gas and disposed proximate to the first electrode to form a substantially uniform gap therebetween. The gas flows along the substantially uniform gap and from a plurality of different directions to converge and flow through the outlet. High frequency electrical power is applied between the first electrode and the second electrode to generate a plasma within the gas flow emerging at the outlet. Precursor chemicals are added to the plasma flow at the outlet. Various electrode designs may be implemented and various applications involving surface treatment of materials with the low-temperature atmospheric plasma, including surface activation, cleaning, sterilization, etching and deposition of thin films are disclosed.

Owner:SURFX TECH

Method and apparatus for forming a coating

A method for forming a coating on a substrate using an atmospheric pressure plasma discharge. The method comprises introducing an atomized liquid and / or solid coating-forming material into an atmospheric pressure plasma discharge and / or an ionized gas stream resulting therefrom, and exposing the substrate to the atomized coating-forming material. The application also described a method for polymerizing a polymer forming material, and further to apparatus for forming a coating on a substrate.

Owner:DOW CORNING IRELAND

Methods and apparatus for generating a plasma torch

InactiveUS6329628B1SmallSmall sizeArc welding apparatusPlasma welding apparatusHigh densityVolumetric Mass Density

A modular system for constructing an atmospheric pressure plasma source. A plasma torch module may be constructed by reassembling the structural components of two (2) different models of spark plugs. Each module can produce a plasma torch having a radius of about 1 cm or more, a height of about 6 cm, and a peak density exceeding 1013 cm-3. A set of modules, each connected in series, may be used with a ballasting capacitor such that an array can be operated while sharing a common power supply to produce a plasma having a relatively large volume and a relatively high density. A system having a number of plasma torch modules may be used in applications for absorbing radiation, reducing air drag and igniting fuel.

Owner:POLYTECHNIC INST OF NEW YORK

Inkjet recording method and inkjet recording apparatus

ActiveUS20090290007A1Quality improvementIncrease drying speedDuplicating/marking methodsInksPolymer scienceOrganic chemistry

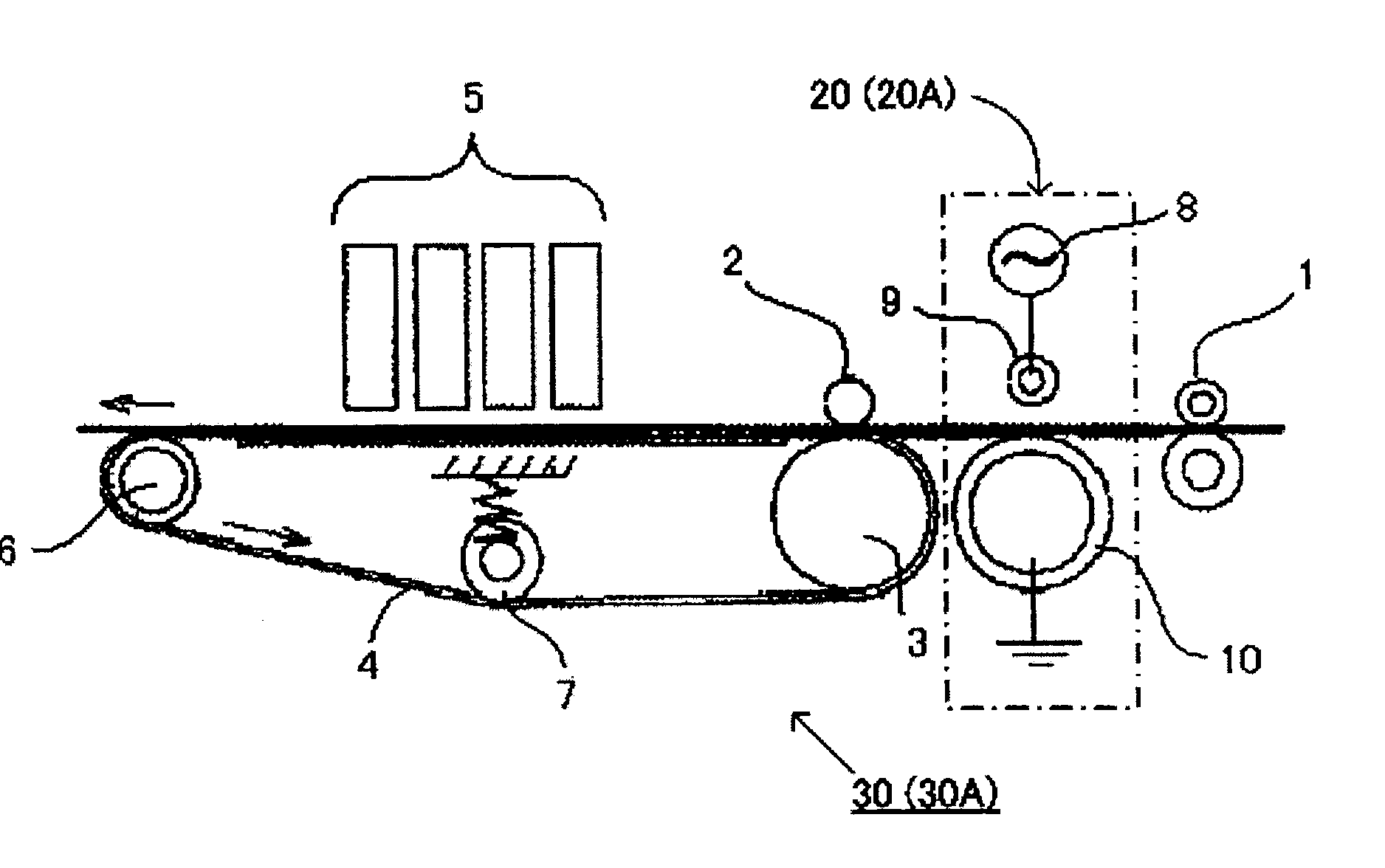

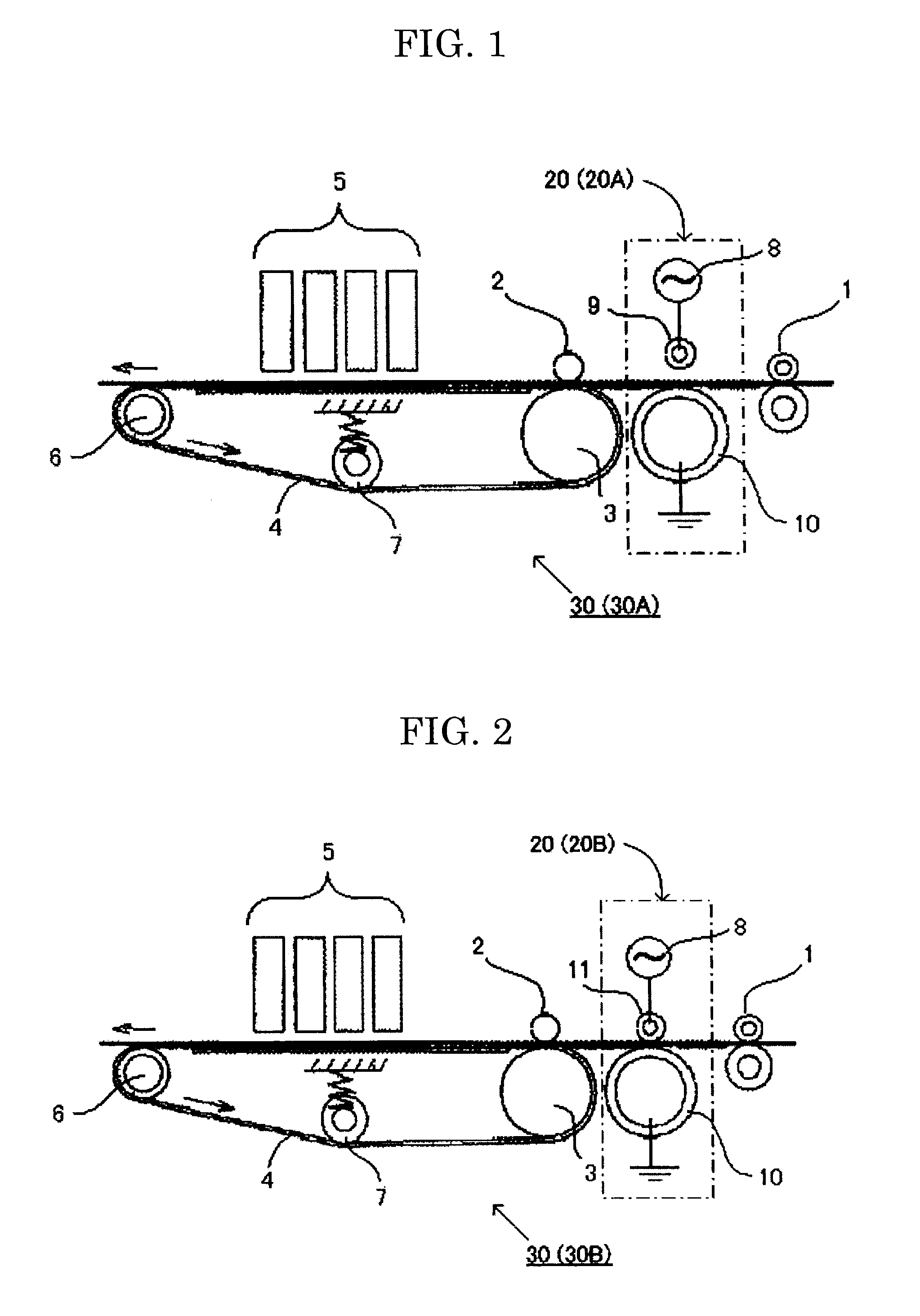

An inkjet recording method including: (i) exposing a surface of a recording medium to non-thermal atmospheric pressure plasma so as to hydrophilize the surface of the recording medium, and (ii) applying a stimulus to an ink composition so as to eject the ink composition to form an image on the recording medium, wherein the ink composition contains at least one of a pigment / water-dispersible resin particle mixture in which a pigment is dispersed along with water-dispersible resin particles and colored water-dispersible resin particles each of which is a water-dispersible resin particle which is colored.

Owner:RICOH KK

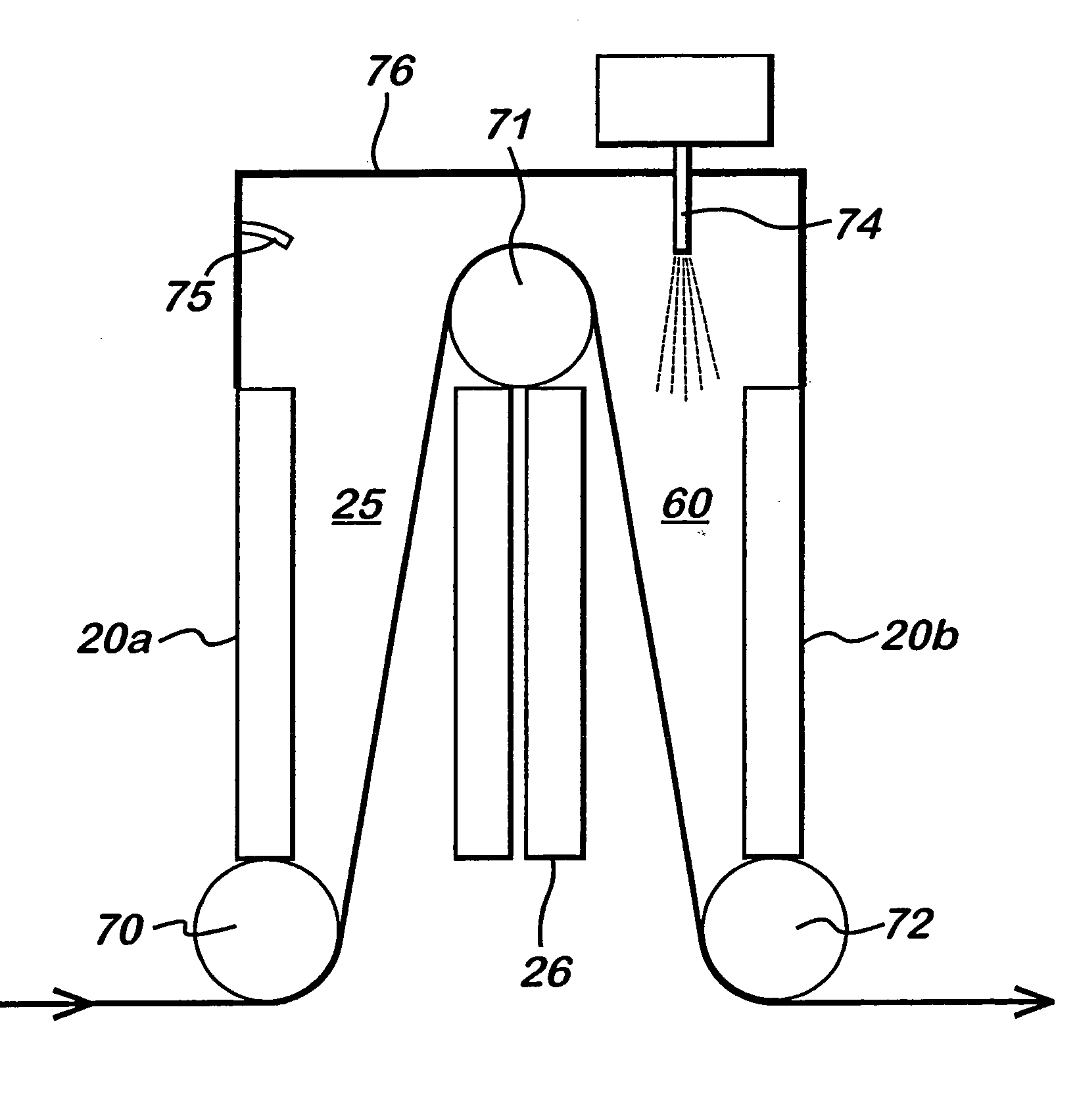

Atmospheric pressure plasma assembly

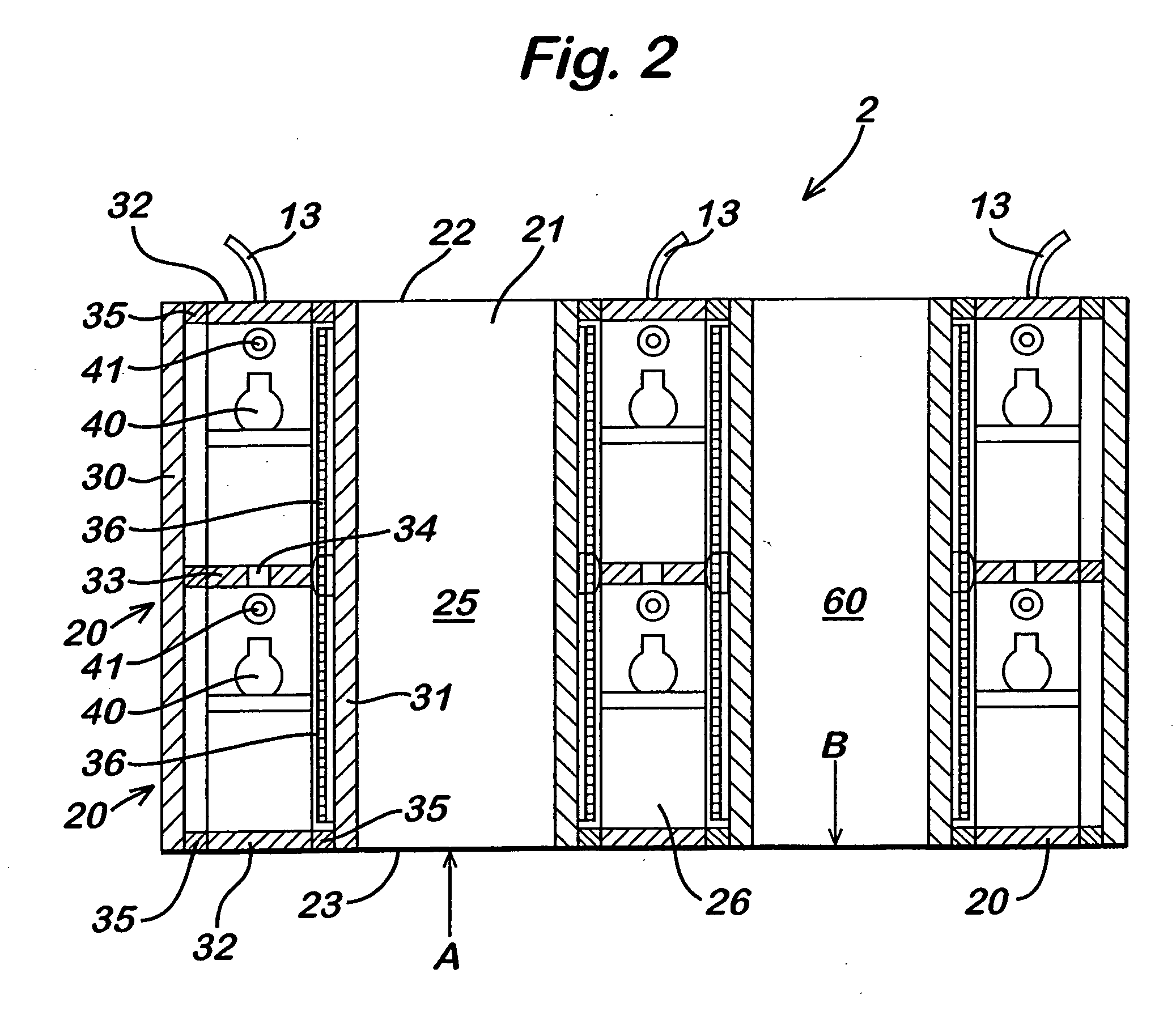

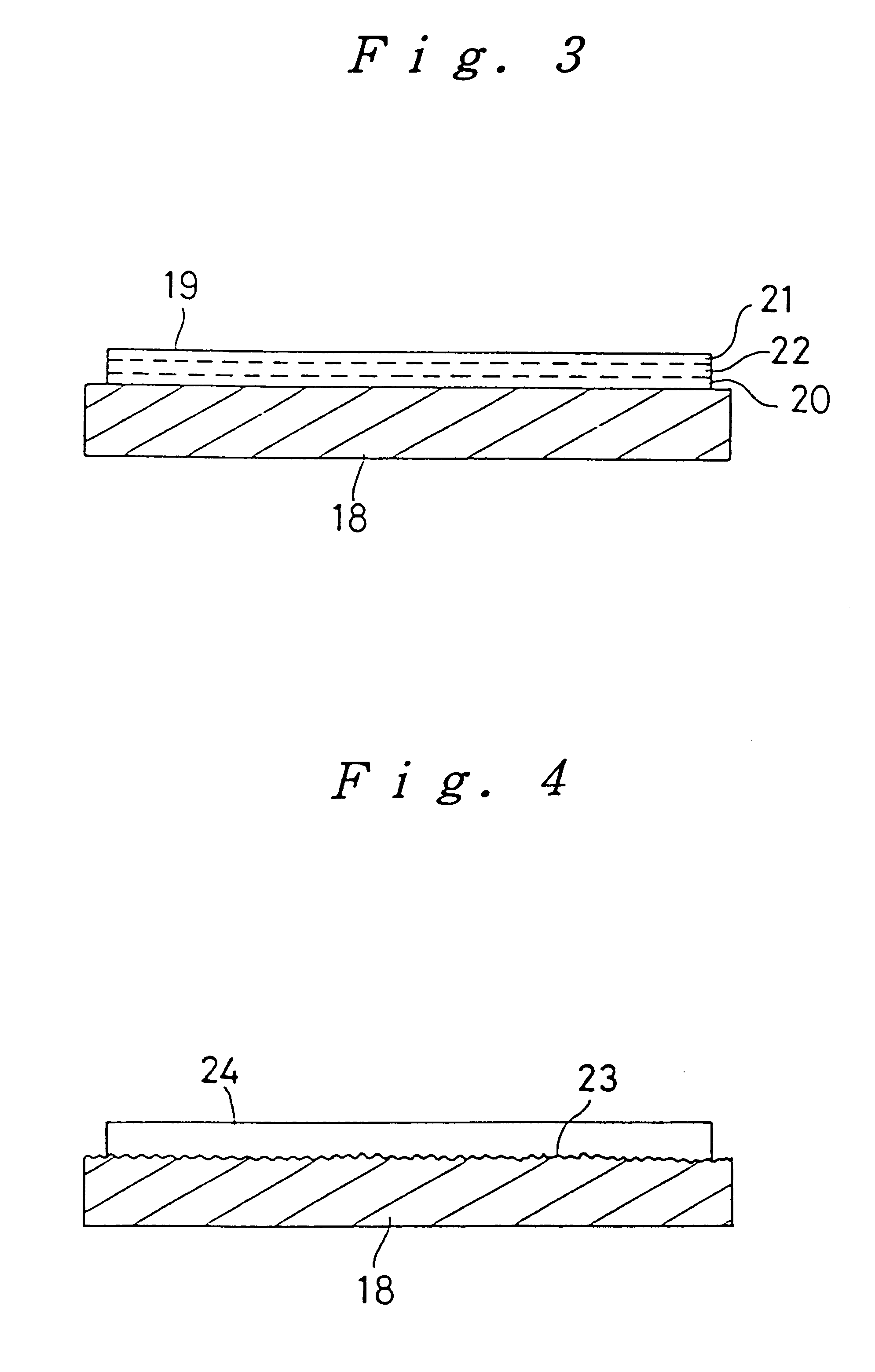

InactiveUS20050178330A1Efficient cooling agentEfficient electrodeElectric discharge tubesSurgeryPlanar electrodeDielectric plate

An atmospheric pressure plasma assembly (1) comprising a first and second pair of vertically arrayed, parallel spaced-apart planar electrodes (36) with at least one dielectric plate (31) between said first pair, adjacent one electrode and at least one dielectric plate (31) between said second pair adjacent one electrode, the spacing between the dielectric plate and the other dielectric plate or electrode of each of the first and second pairs of electrodes forming a first and second plasma regions (25,60) characterised in that the assembly further comprises a means of transporting a substrate (70,71,72) successively through said first and second plasma regions (25,60) and an atomiser (74) adapted to introduce an atomised liquid or solid coating making material into one of said first or second plasma regions.

Owner:DOW CORNING IRELAND

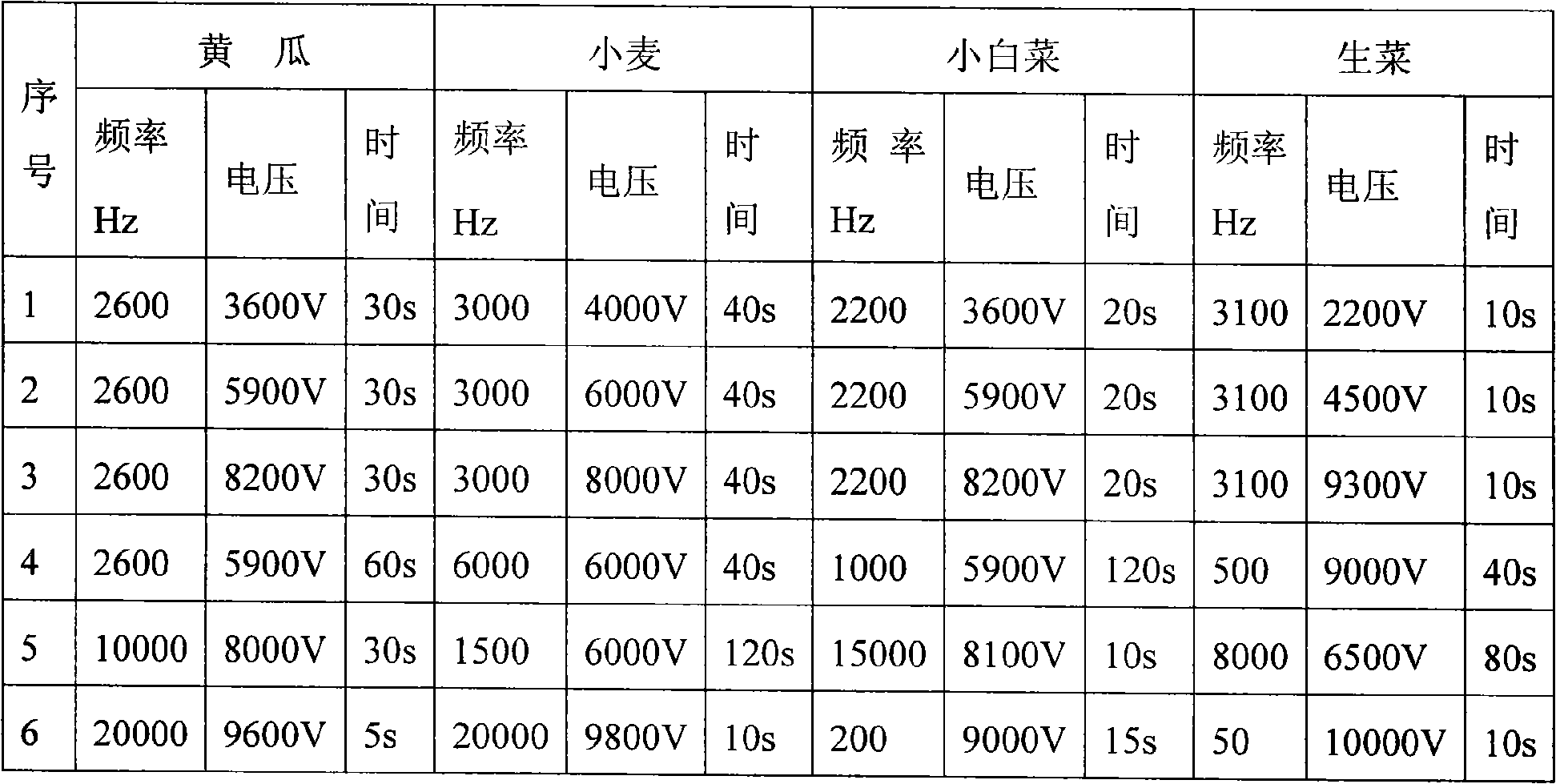

Method for treating plant seeds by plasmas and device for realizing method

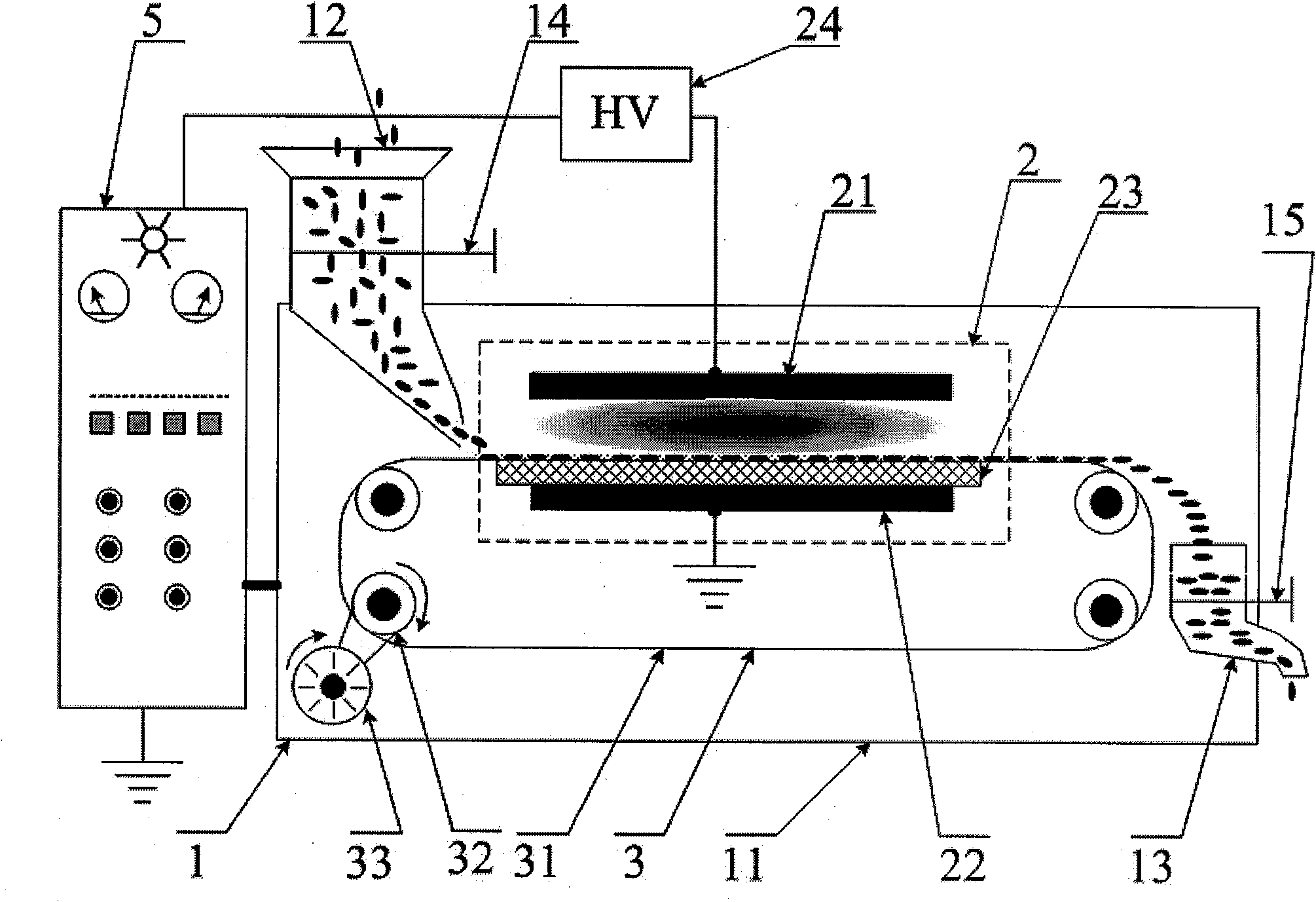

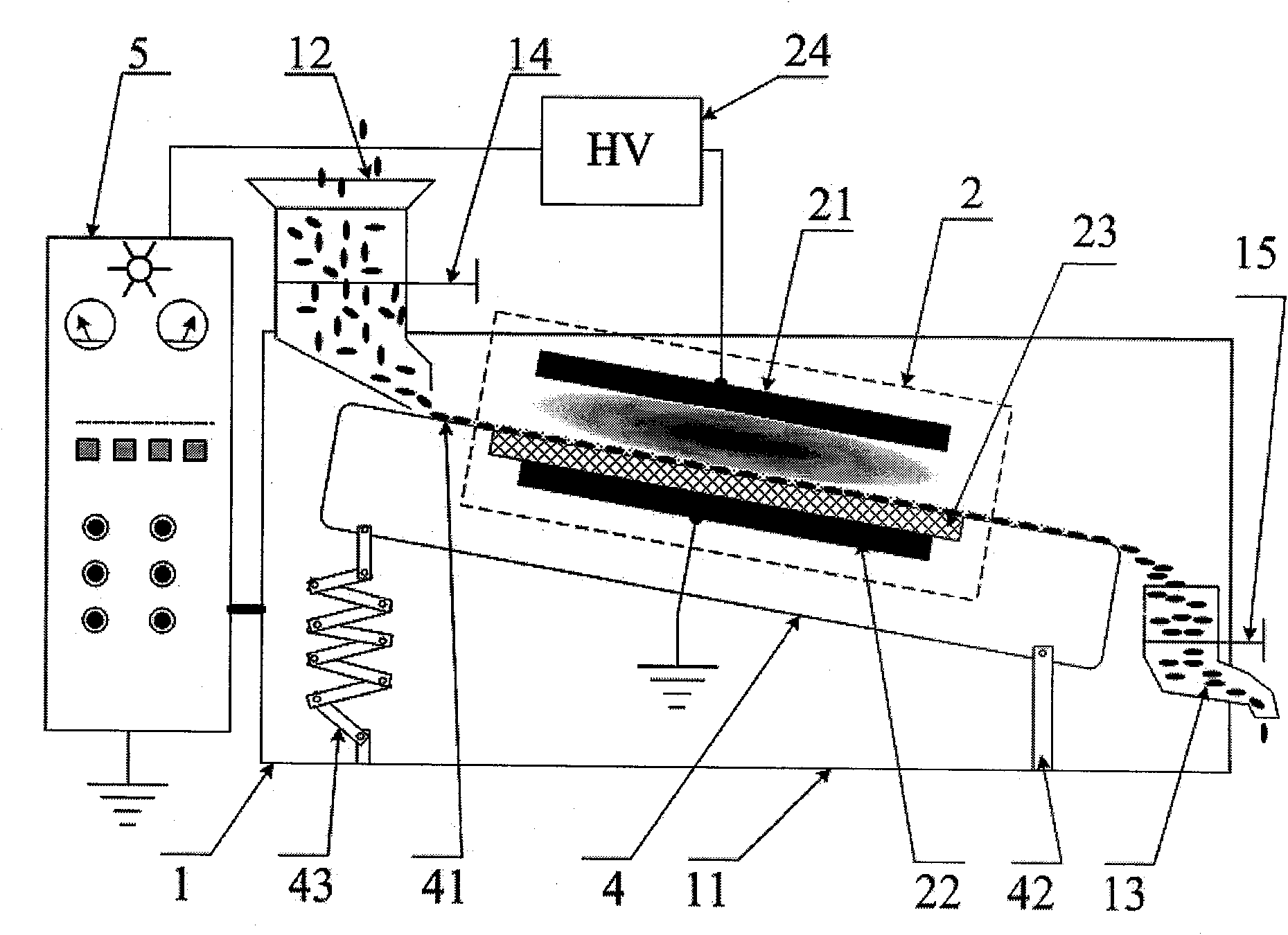

InactiveCN101669416AIncrease vitalityPromote germinationHorticulture methodsPlasma techniqueRetention timePlanting seed

The invention relates to a method for treating plant seeds by plasmas and a device for realizing the method. The plasmas of the invention are cold plasmas generated by dielectric barrier discharge under the atmospheric pressure, wherein the cold plasmas are generated in the air; the working air pressure is the atmospheric pressure; an electric source for the dielectric barrier discharge is a high-frequency and high-voltage electric source with the frequency range from 50 Hz to 20 kHz and the voltage range from 1 kV to 10 kV; and the plant seeds are treated by the plasmas for 5 to 129 sec. Thedevice for realizing the seed treating method of the invention comprises a seed treating cavity, a plasma generator for generating the plasmas in the seed treating cavity and a transmitting device capable of controlling the retention time of the seeds in the seed treating cavity. The treating operation on the plant seeds by using the atmospheric-pressure plasmas does not refer to DNA recombination, does not relate to structural genovariation of the plant seeds, and cannot cause hazards. The method only denatures the plant seeds to make the advantages become more prominent.

Owner:杨思泽

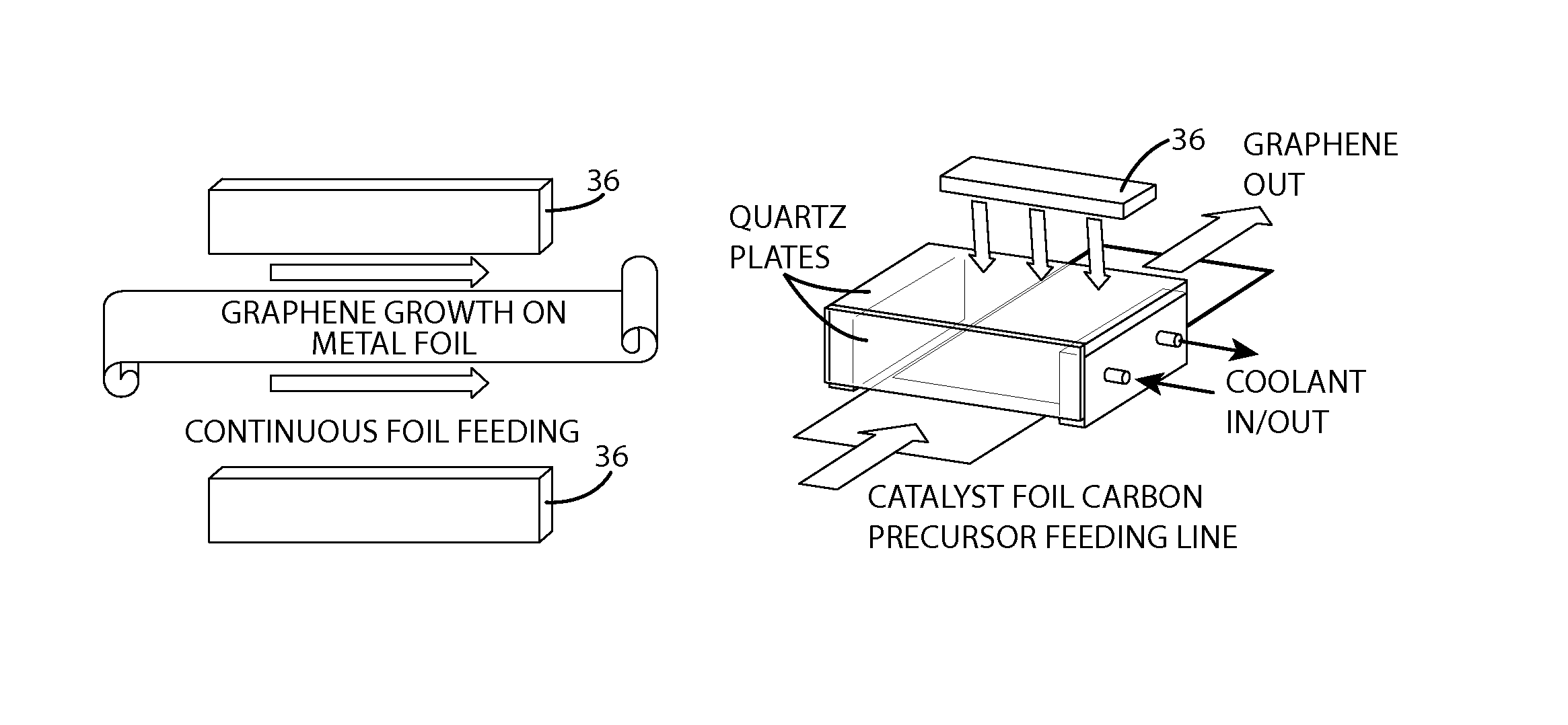

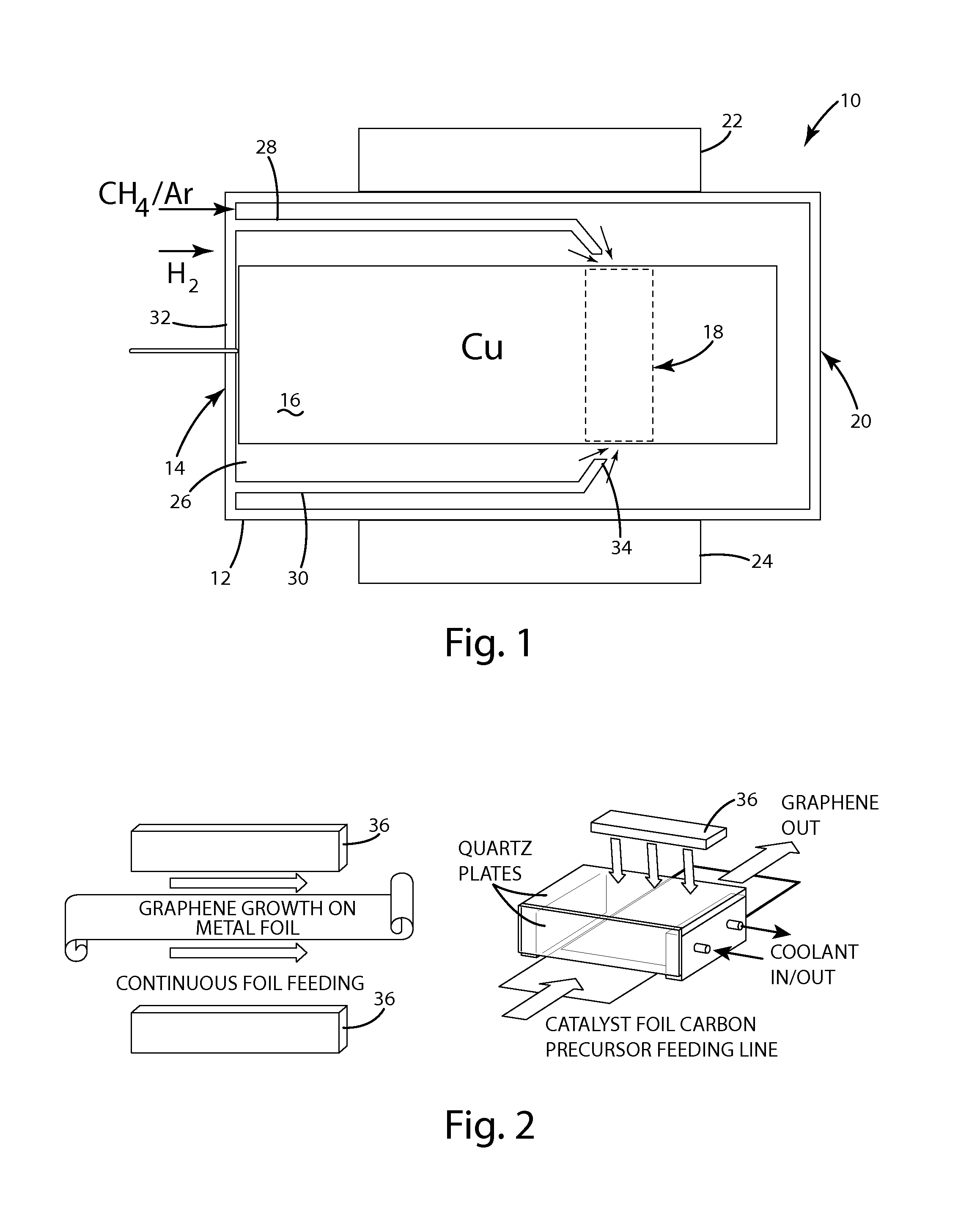

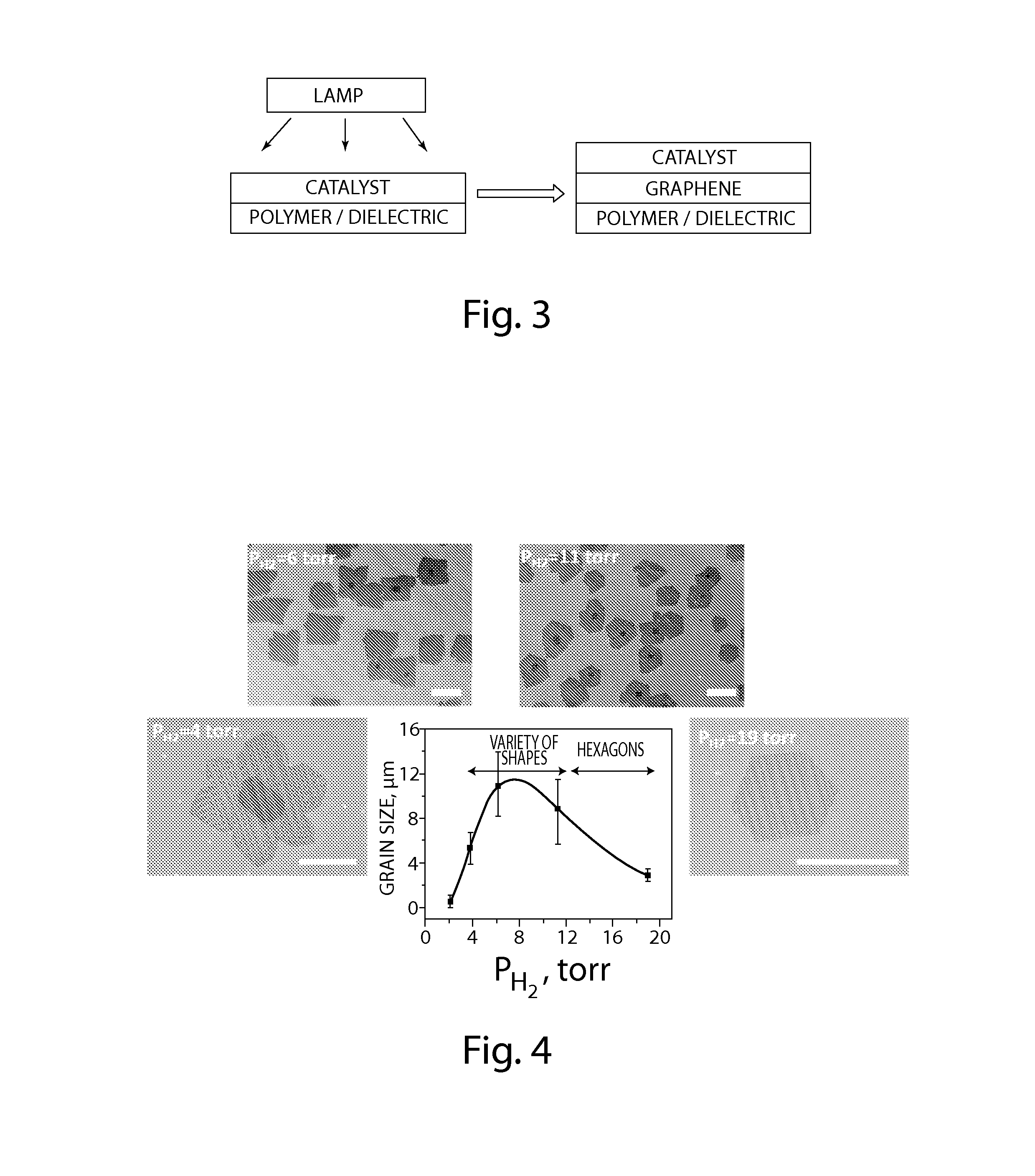

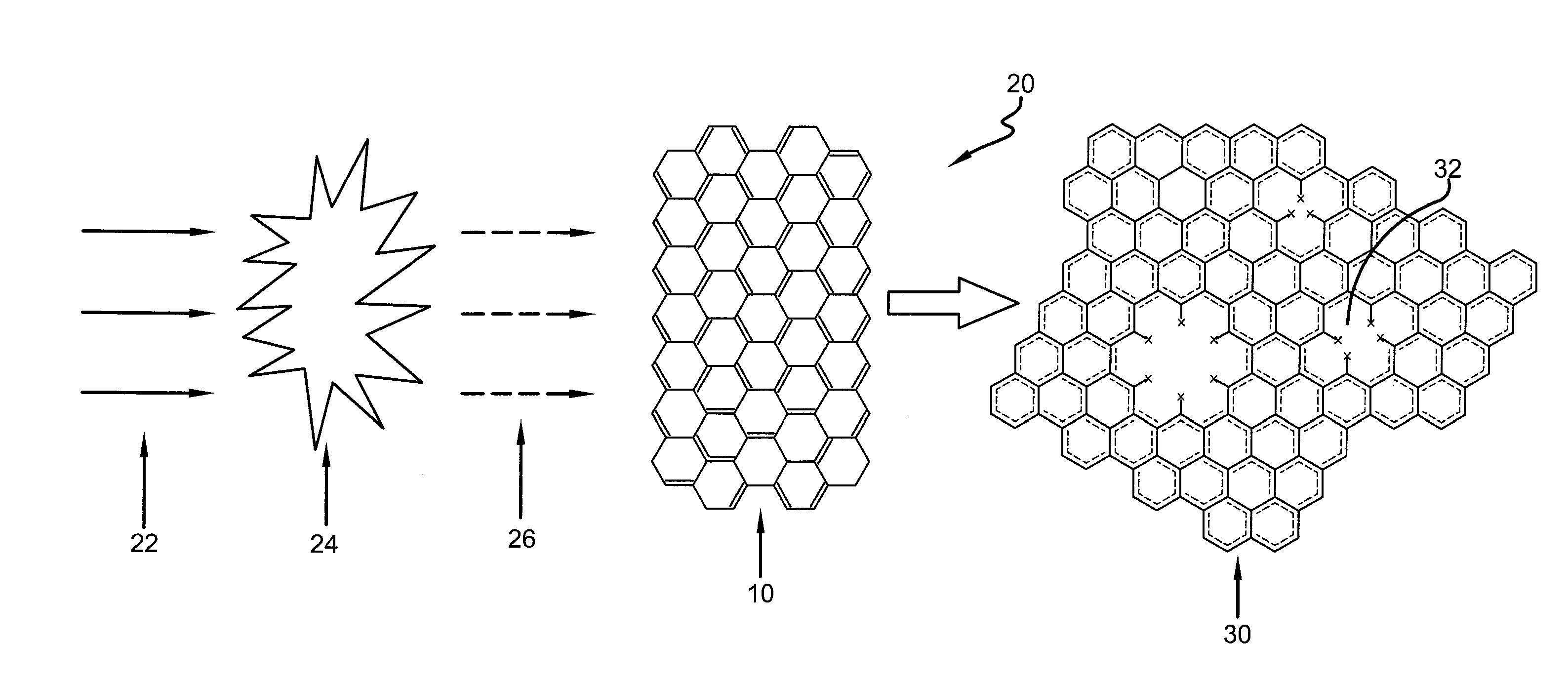

High quality large scale single and multilayer graphene production by chemical vapor deposition

ActiveUS20130174968A1Reduce manufacturing costShorten production timeMaterial nanotechnologySingle layer grapheneNoble gasGas phase

Systems and methods for synthesizing continuous graphene sheets are provided. The systems and methods include passing a catalyst substrate through a heated chemical vapor deposition chamber and exposing the substrate to a reaction gas mixture of hydrogen and hydrocarbon at a preselected location within the chamber. The reaction gas mixture can include hydrogen having a partial pressure of between about 0 Torr and 20 Torr, hydrocarbon having a partial pressure of between about 20 mTorr and about 10 Torr, and one or more buffer gases. The buffer gases can include argon or other noble gases to maintain atmospheric pressure within the chemical deposition chamber. The resulting graphene can be made with continuous mono and multilayers (up to six layers) and have single crystalline hexagonal grains with a preselected nucleation density and domain size for a range of applications.

Owner:UT BATTELLE LLC

Method and device for creating a micro plasma jet

ActiveUS20060028145A1Reduce the possibilityIncrease electron densityElectric arc lampsArc welding apparatusDielectricPlasma jet

A microhollow cathode discharge assembly capable of generating a low temperature, atmospheric pressure plasma micro jet is disclosed. The microhollow assembly has at two electrodes: an anode and a cathode separated by a dielectric. A microhollow gas passage is disposed through the three layers, preferably in a taper such that the area at the anode is larger than the area at the cathode. When a potential is placed across the electrodes and a gas is directed through the gas passage into the anode and out the cathode, along the tapered direction, then a low temperature micro plasma jet can be created at atmospheric pressure.

Owner:MOHAMED ABDEL ALEAM H +2

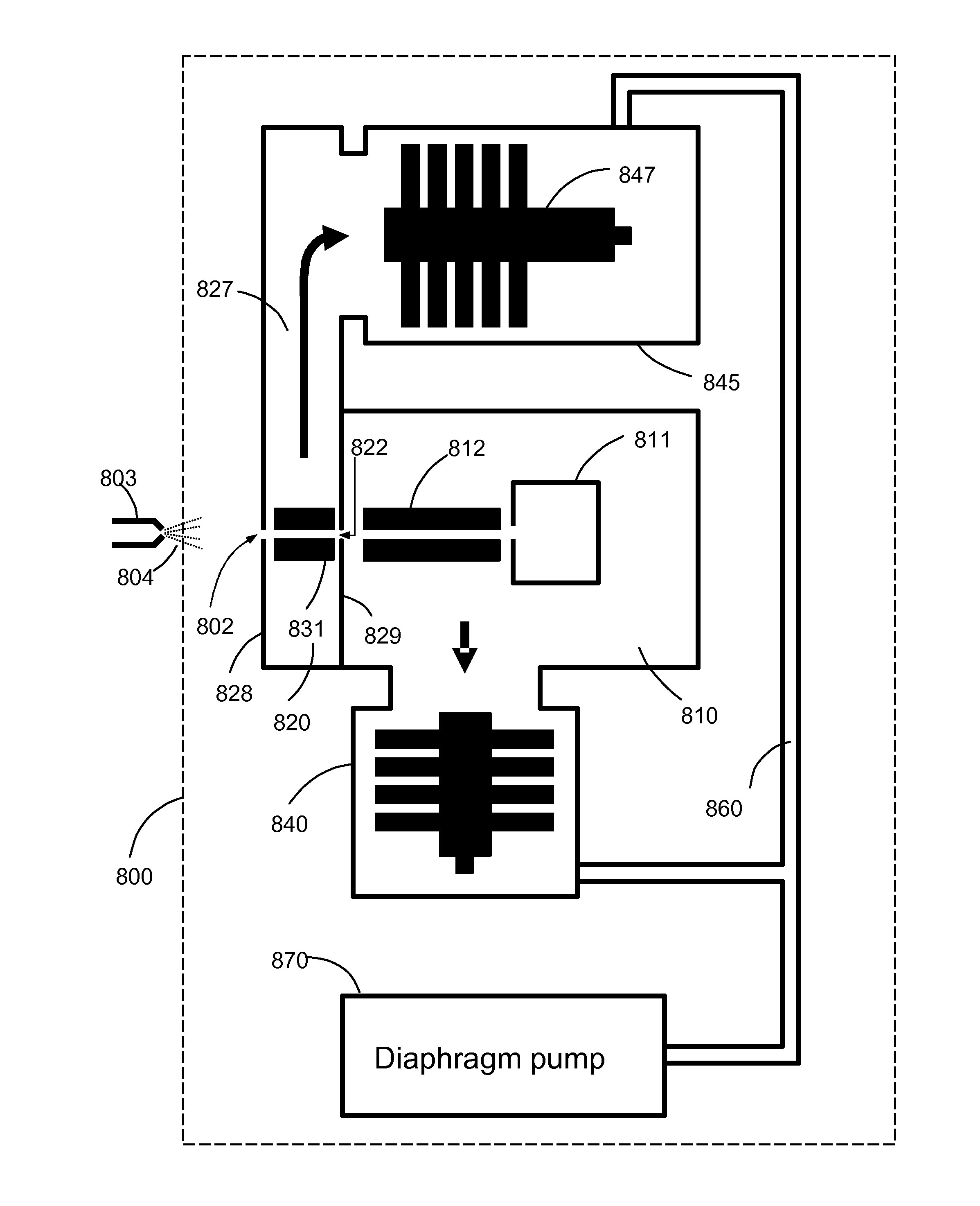

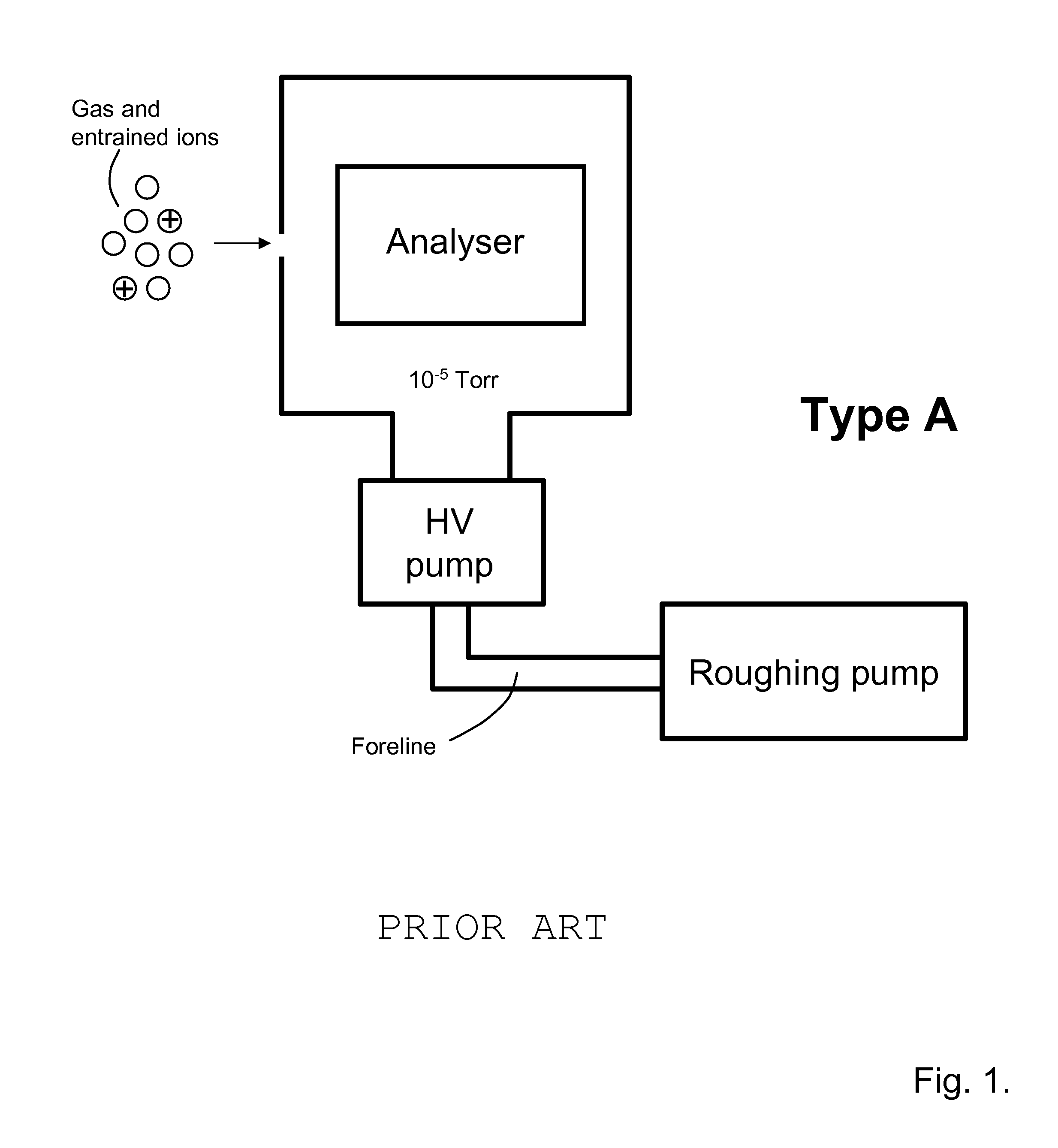

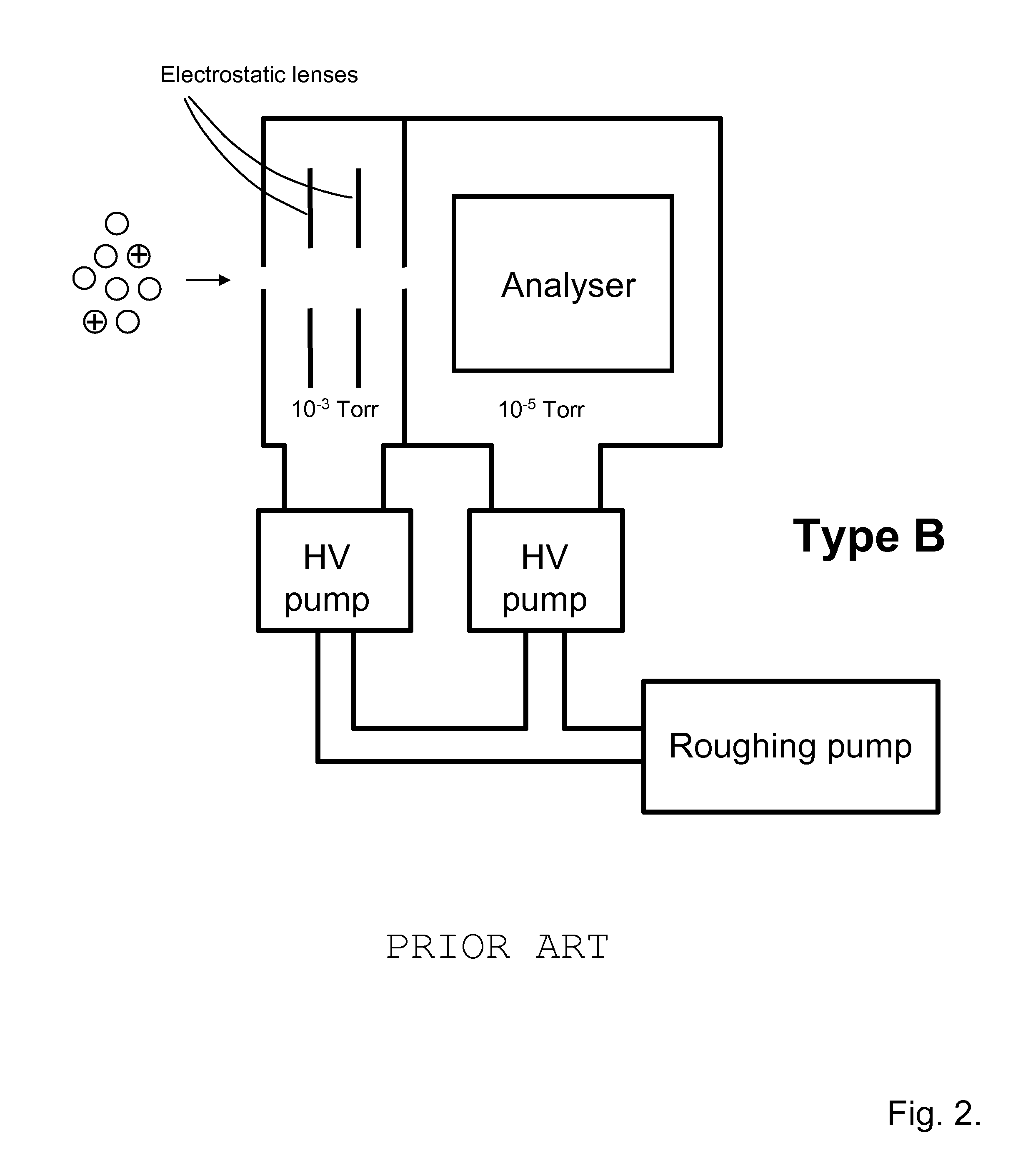

Miniature mass spectrometer system

ActiveUS20120138790A1Small sizeReduce weightMiniaturised spectrometersIsotope separationIon beamMass analyzer

A miniature mass spectrometer that may be coupled to an atmospheric pressure ionisation source is described. Ions pass through a small orifice from a region at atmospheric pressure or low vacuum, and undergo efficient collisional cooling as they transit a very short, differentially pumped ion guide. A narrow beam of low energy ions is passed through a small aperture and into a separate chamber containing the mass analyser.

Owner:MICROSAIC SYST

Method and apparatus for atmospheric pressure plasma surface treatment, method of manufacturing semiconductor device, and method of manufacturing ink jet printing head

InactiveUS6342275B1Improve adhesionSafely mixedLiquid surface applicatorsSemiconductor/solid-state device detailsRoom temperatureHardness

Gas discharge is caused in a predetermined discharging gas at atmospheric pressure or a pressure close to atmospheric pressure, and an organic material which is liquid at room temperature and which is previously contained in the discharging gas or applied to a surface of a treated member is dissociated or excited by a plasma caused by the gas discharge to generate activated species. By using these excited activated species, a polymerized film of organic material is formed on the surface of the treated member. By variously selecting the organic material or the kind of the discharging material and variously combining them, a water repellent film, a hydrophilic film or a film having a high hardness can easily be formed on the surface of the treated member according to use, or the polymerization speed of the organic material can be increased, or the polymerization can be limited. Further, the adhesion of an organic polymerized film essentially low can be improved with respect to a treated member formed of an inorganic material such as glass or some inactive organic material if the organic material or the kind of gas is used while being changed.

Owner:SEIKO EPSON CORP

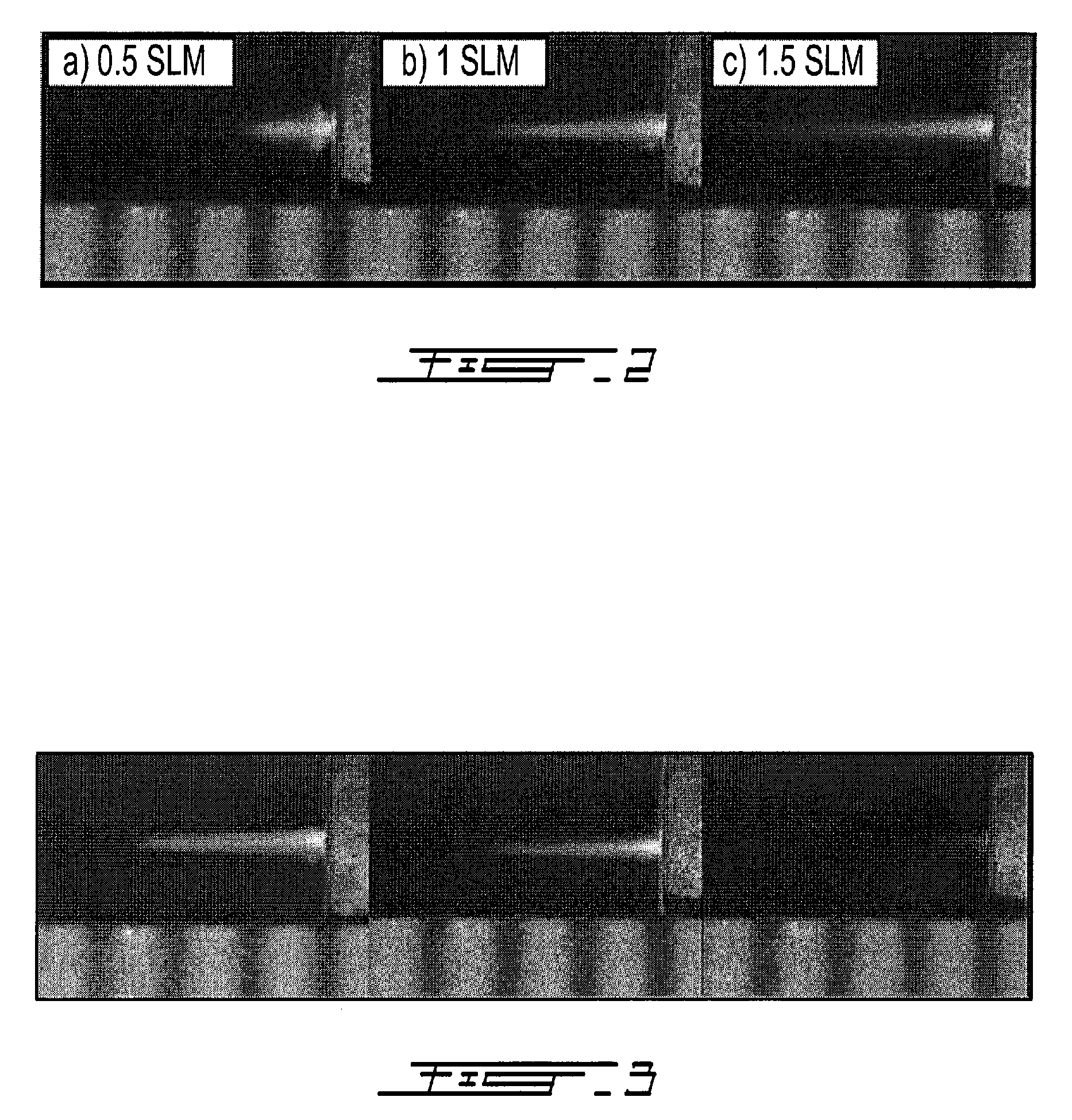

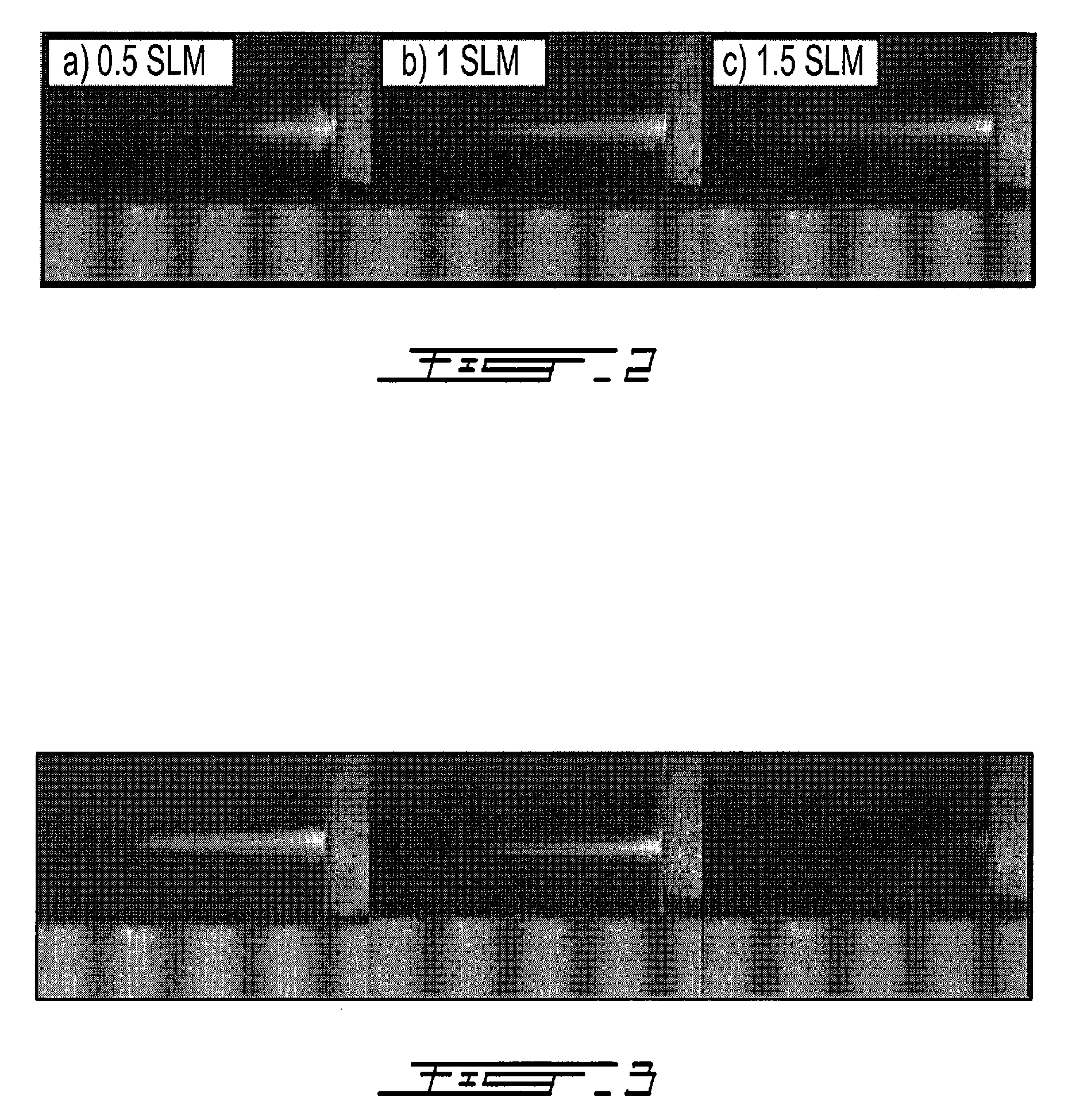

Methods for perforating graphene using an activated gas stream and perforated graphene produced therefrom

InactiveUS20130249147A1Reliably allow passage of certain nano-sized componentMaterial nanotechnologyGrapheneContact timeProduct gas

Graphene sheets having a plurality of holes in their basal planes are described herein. Methods for making the graphene sheets can involve contacting graphene sheets with an activated gas that has contacted a helium or argon atmospheric pressure plasma. The size and / or number of holes introduced can be altered by changing the contact time, the stand-off distance, the activated gas concentration, and / or the plasma power. Polymer composites containing the perforated graphene sheets are also described.

Owner:LOCKHEED MARTIN CORP

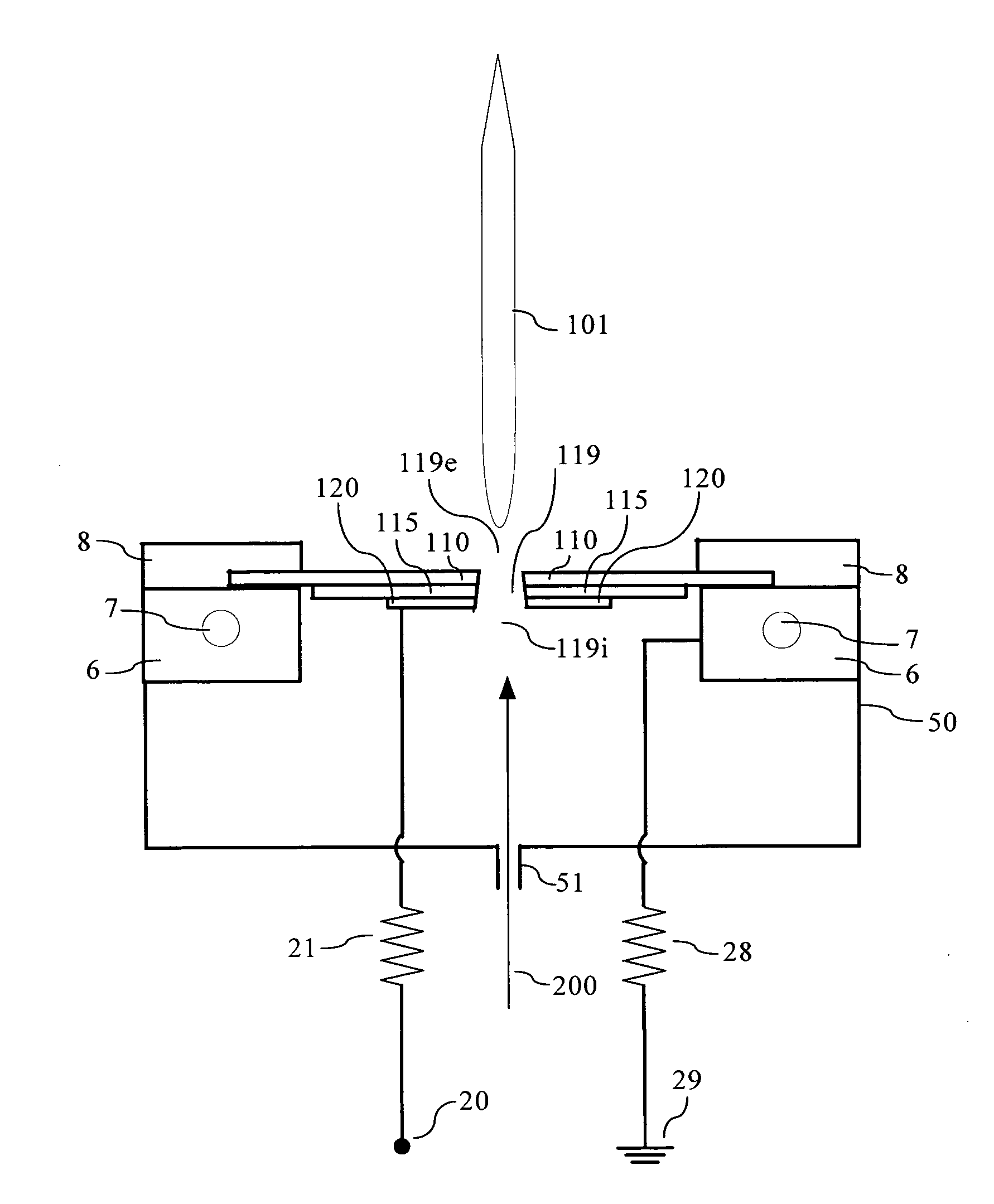

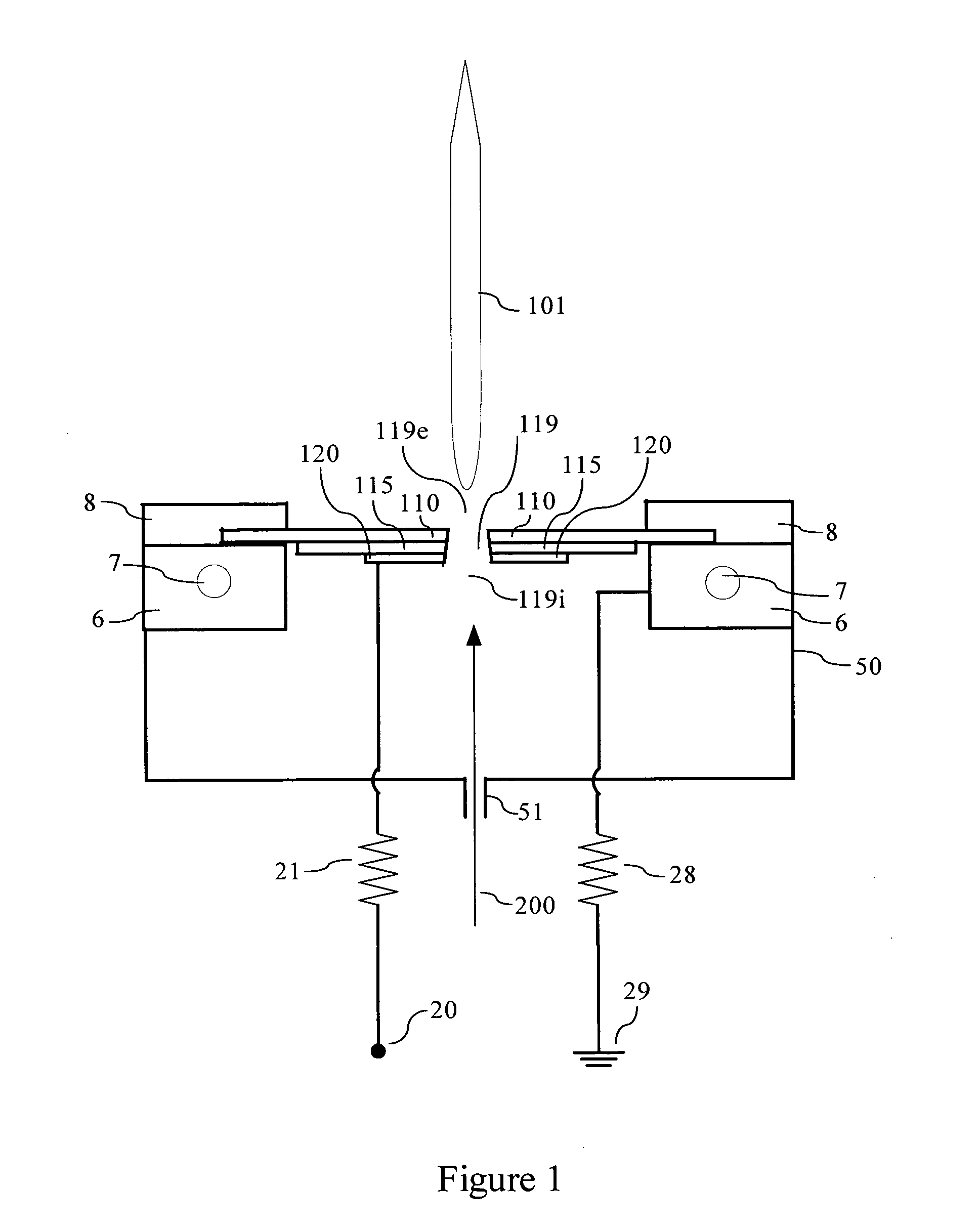

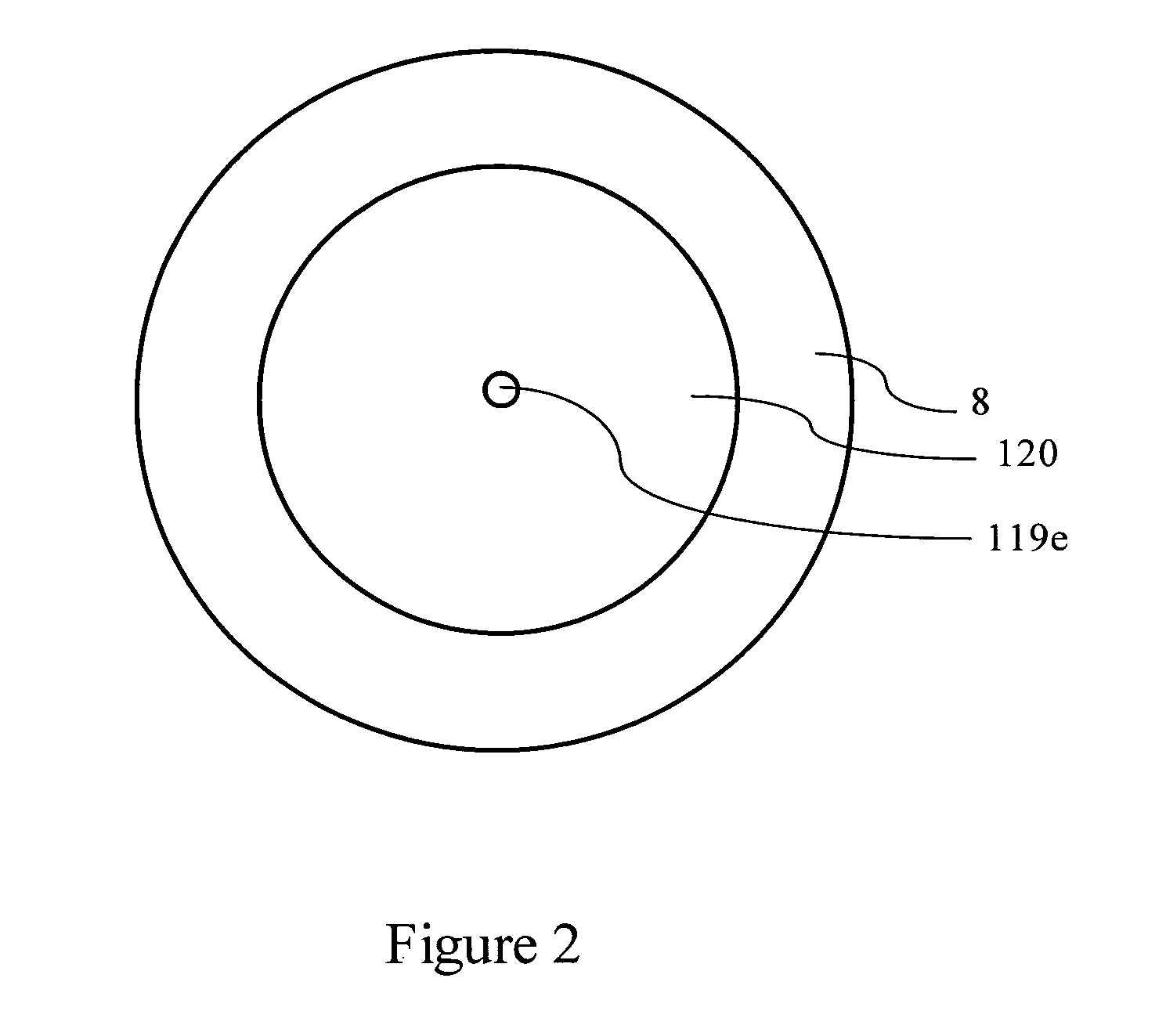

Plasma device for selective treatment of electropored cells

InactiveUS20110112528A1Increased cell absorptionMinimal scarringBioreactor/fermenter combinationsElectrotherapyCancer cellMedicine

A method and device for treatment of living cells with cold atmospheric pressure plasma while simultaneously applying selective electroporation of the cells are provided. The method is useful for the local selective killing of cancer cells, improvement of wound treatment and sterilization or decontamination of objects.

Owner:LEIBNIZ INST FUR PLASMAFORSCHUNG & TECH

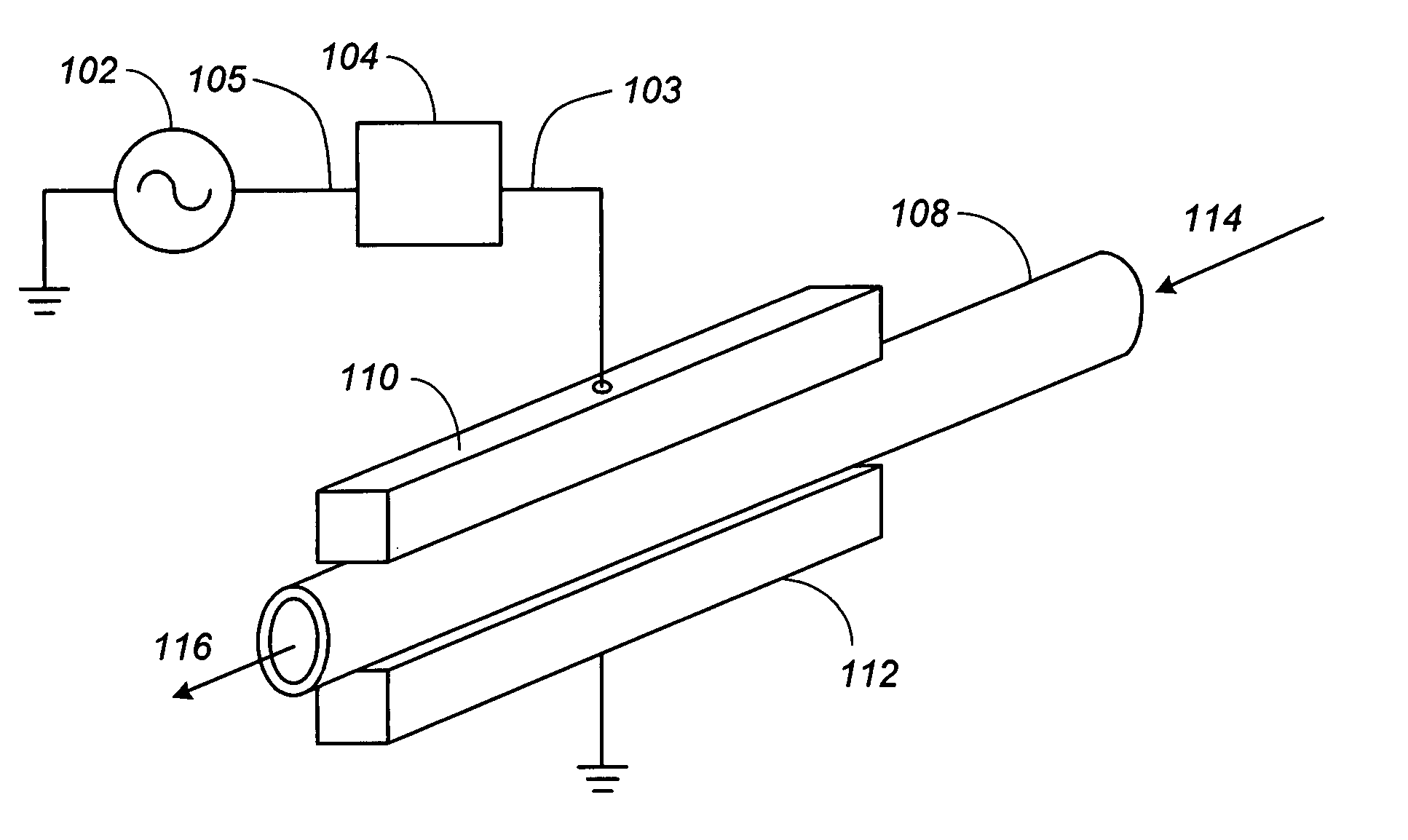

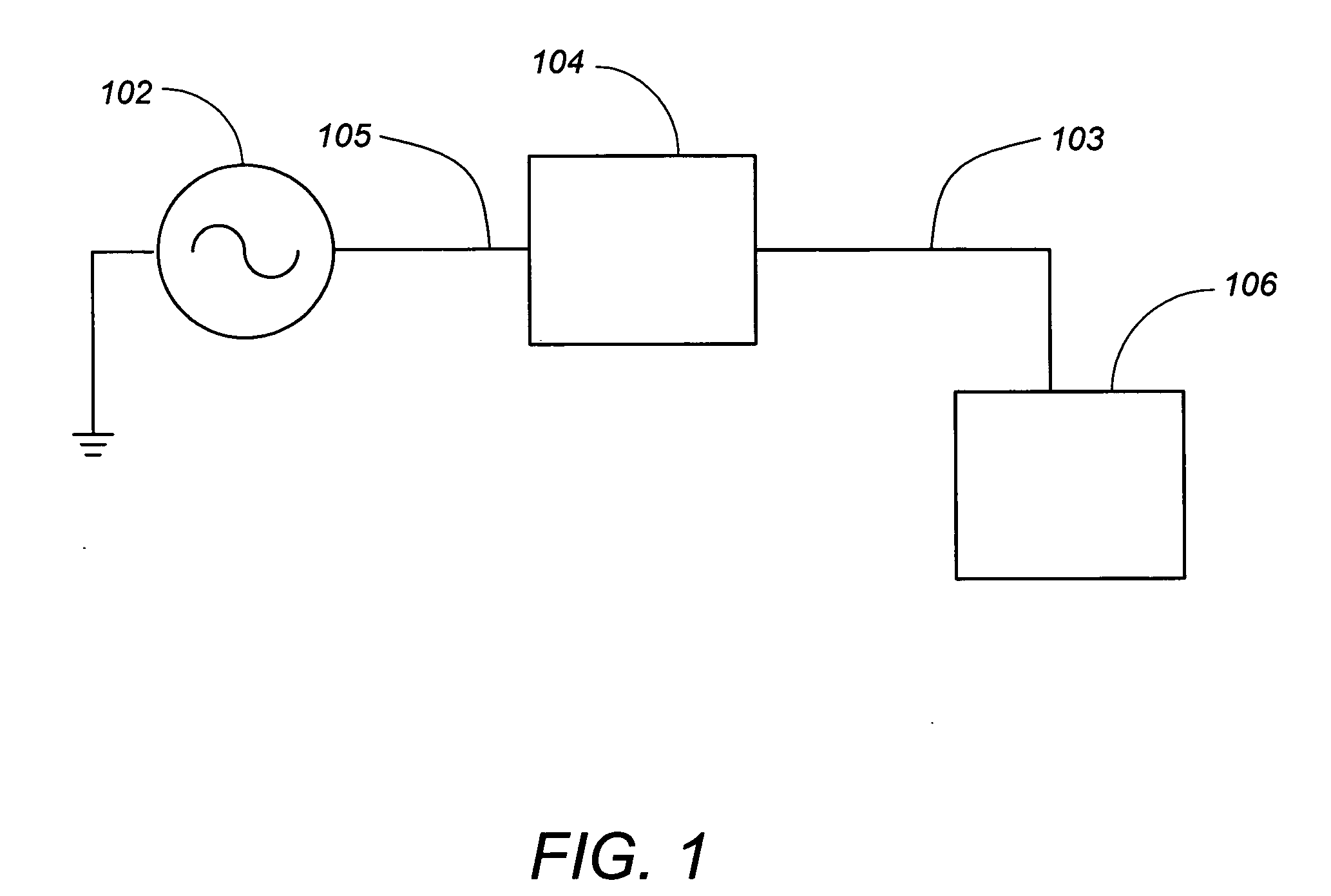

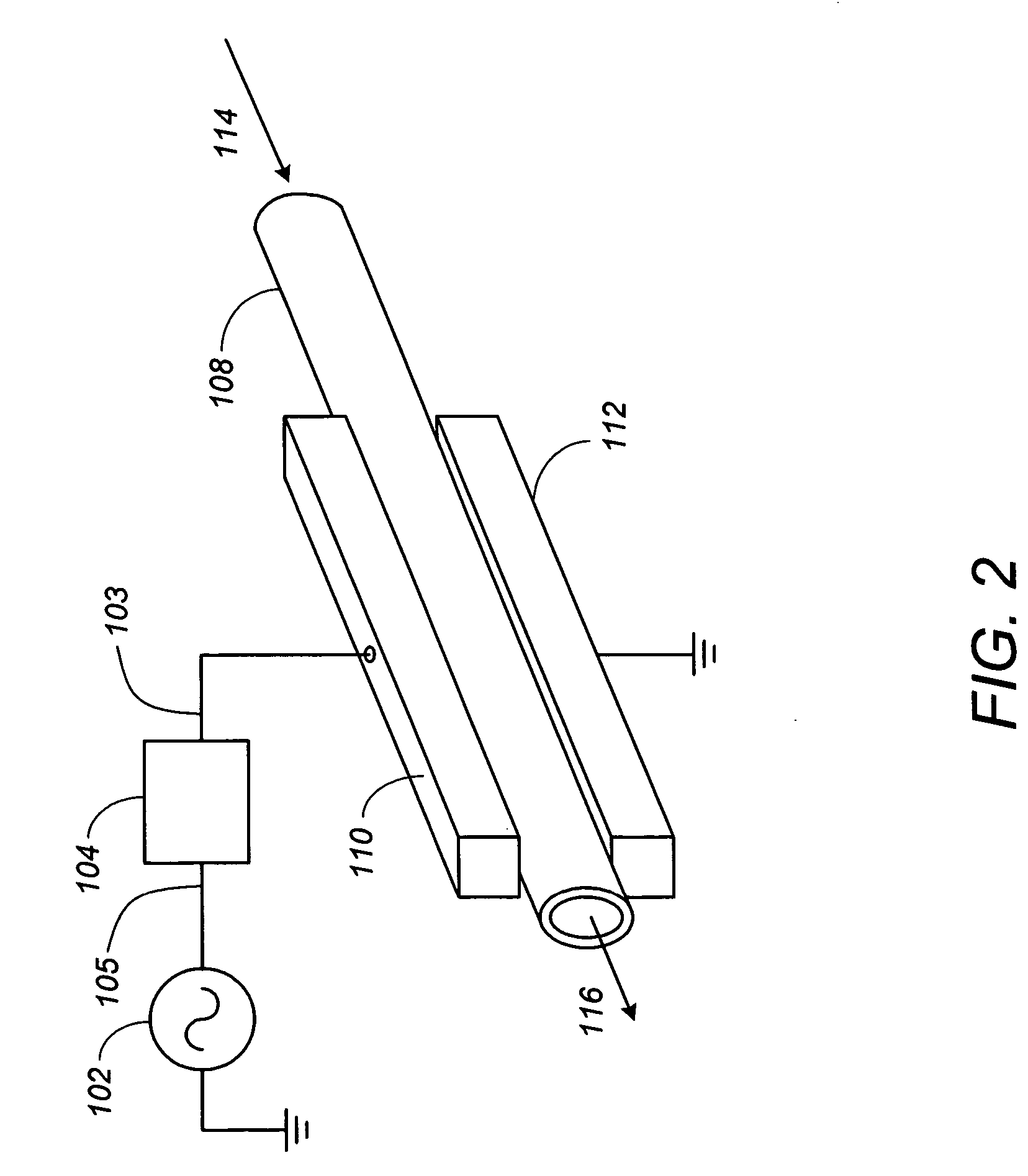

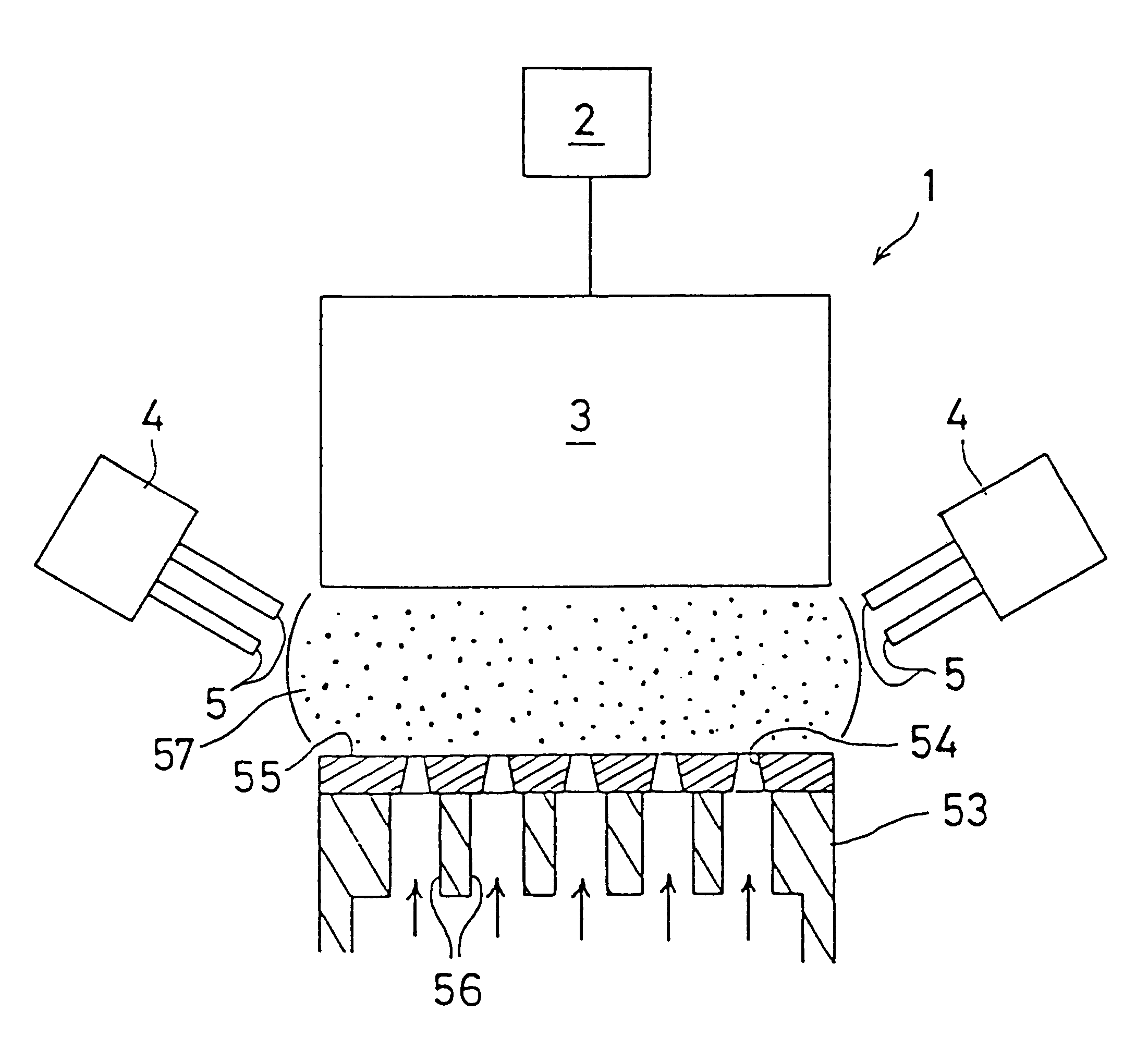

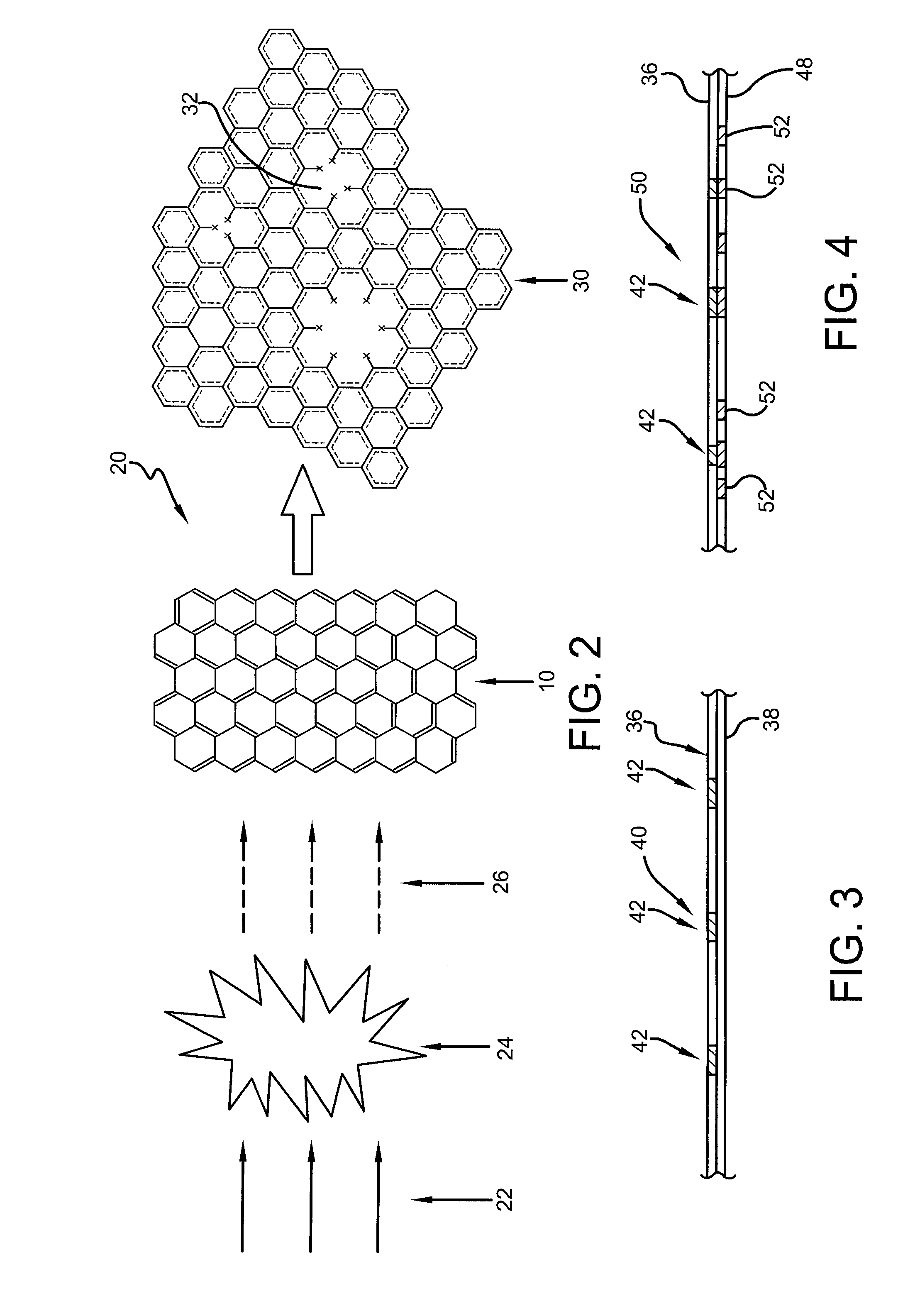

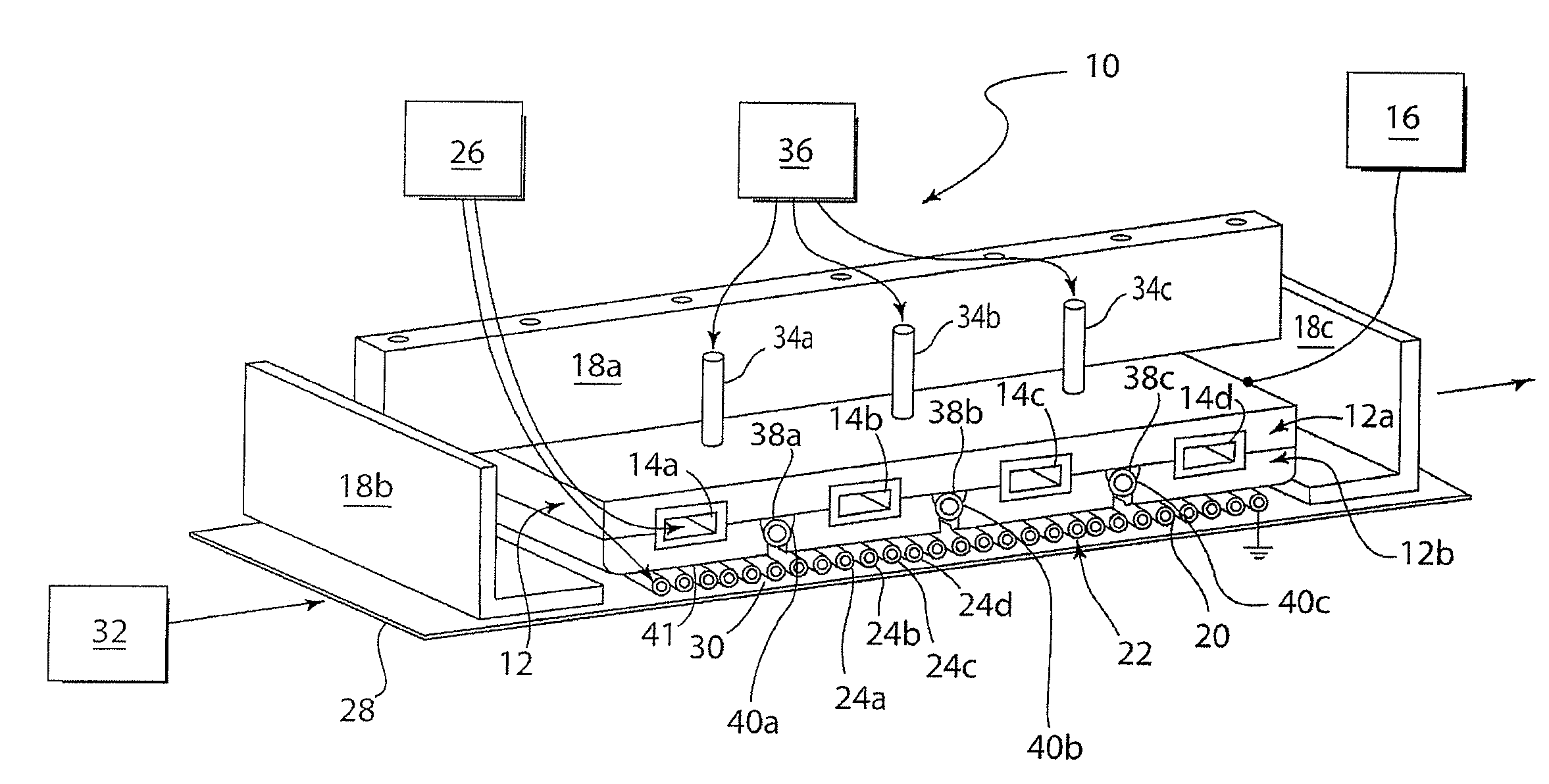

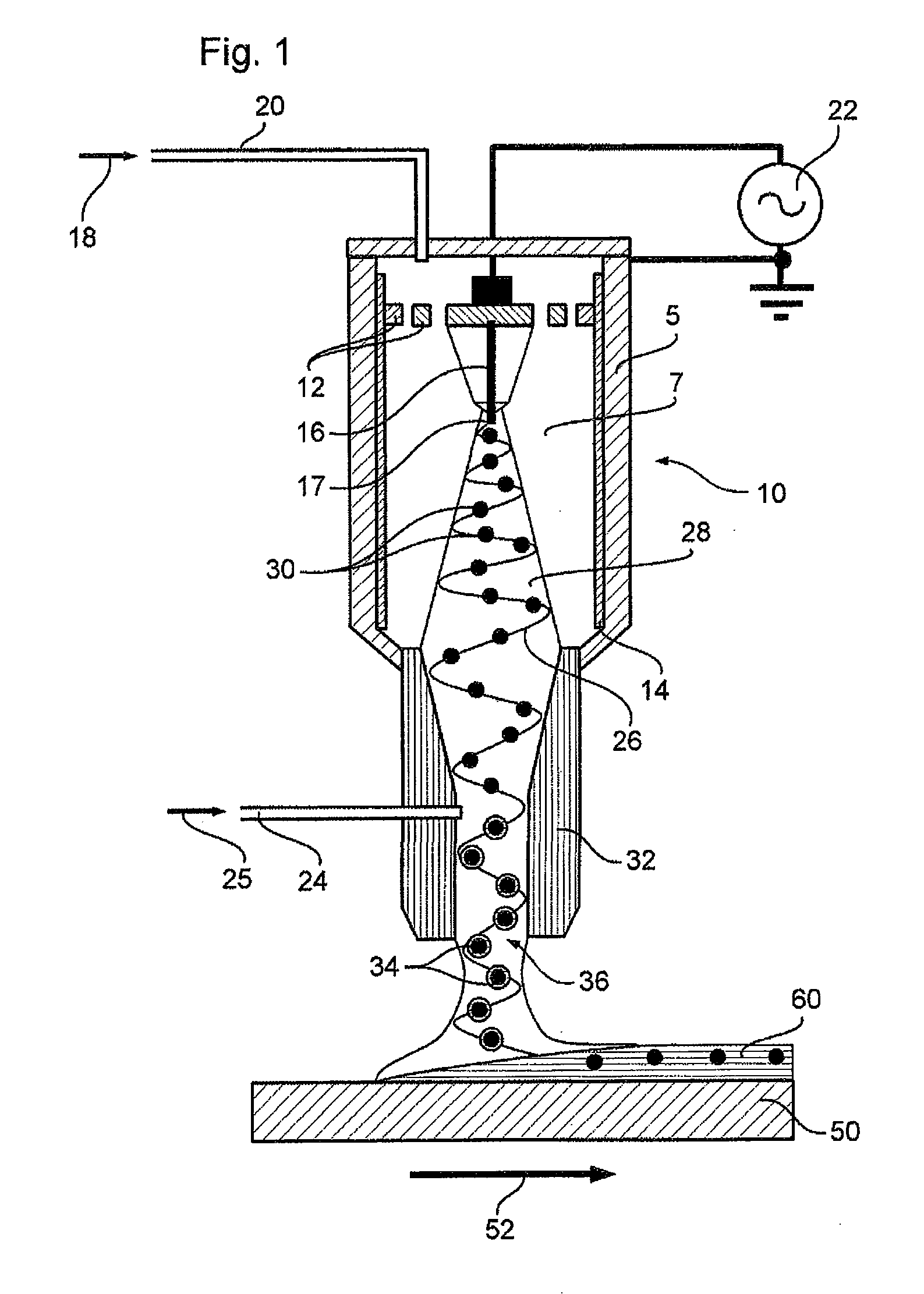

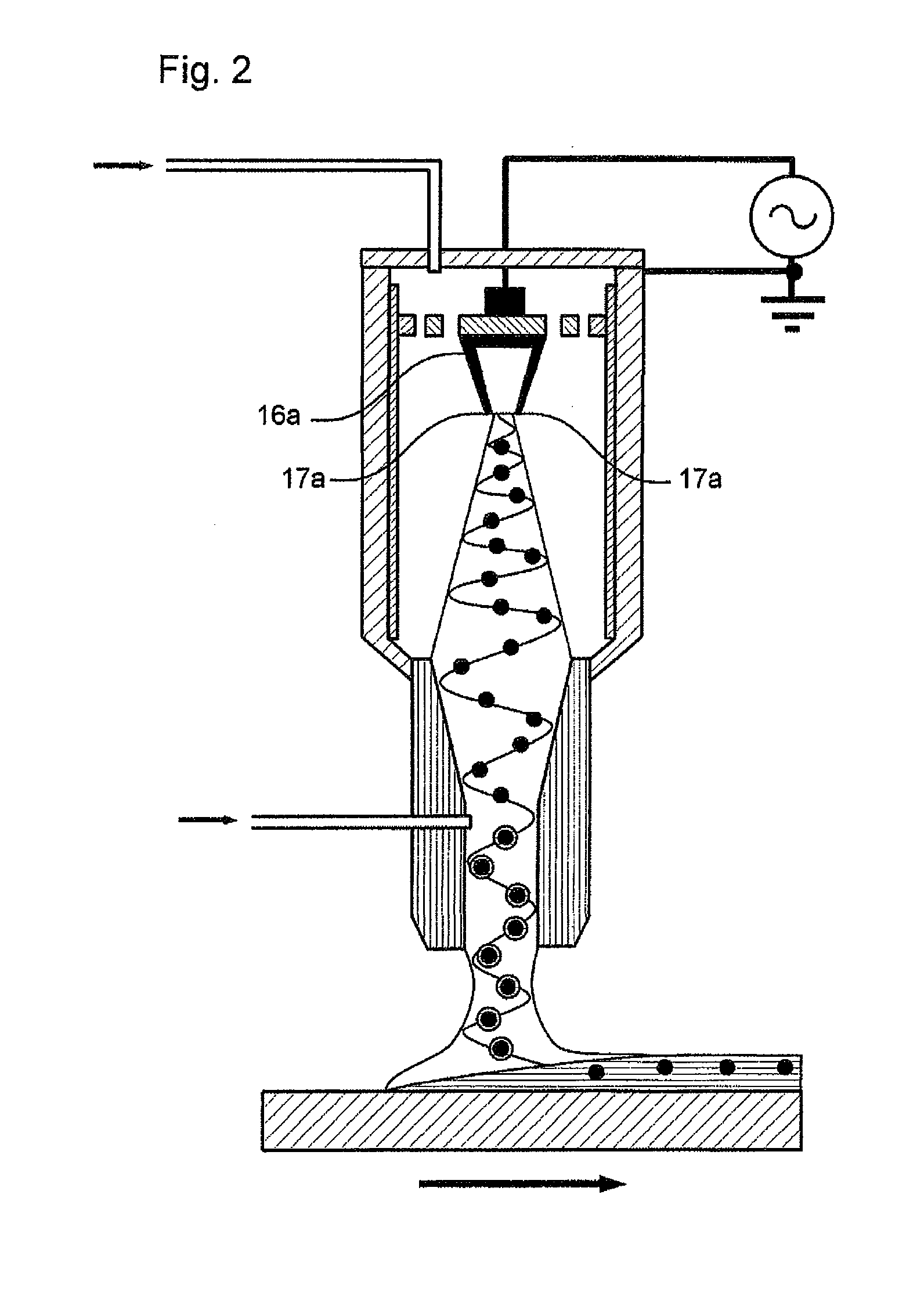

Large area, atmospheric pressure plasma for downstream processing

InactiveUS20090200948A1Uniform surface treatmentPromote resultsElectric discharge tubesElectric arc lampsEtchingDownstream processing

An arcless, atmospheric-pressure plasma generating apparatus capable of producing a large-area, temperature-controlled, stable discharge at power densities between about 0.1 W / cm3 and about 200 W / cm3, while having an operating gas temperature of less than 50° C., for processing materials outside of the discharge, is described. The apparatus produces active chemical species, including gaseous metastables and radicals which may be used for polymerization (either free radical-induced or through dehydrogenation-based polymerization), surface cleaning and modification, etching, adhesion promotion, and sterilization, as examples. The invention may include either a cooled rf-driven electrode or a cooled ground electrode, or two cooled electrodes, wherein active components of the plasma may be directed out of the plasma and onto an external workpiece without simultaneously exposing a material to the electrical influence or ionic components of the plasma.

Owner:APJET INC

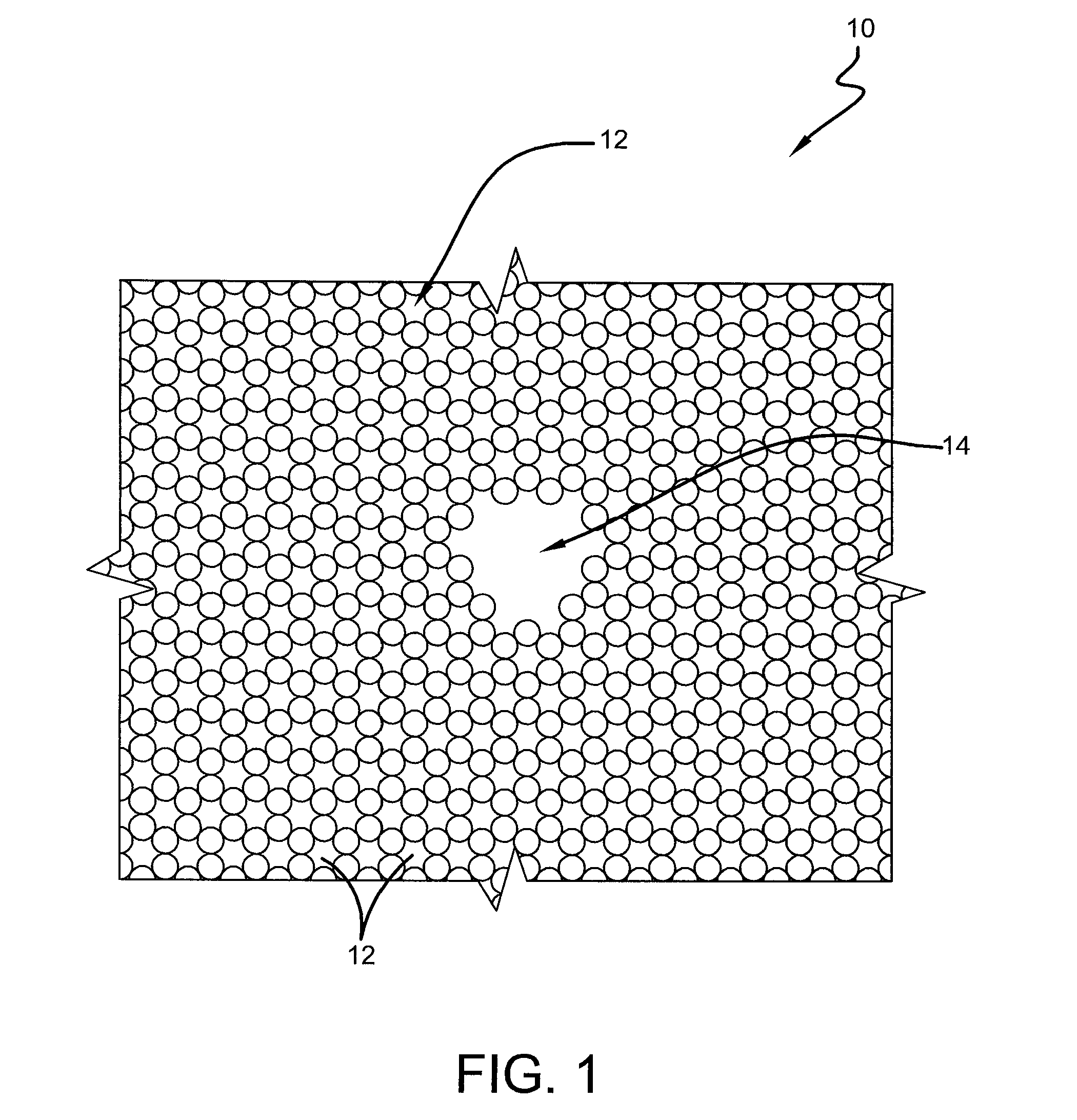

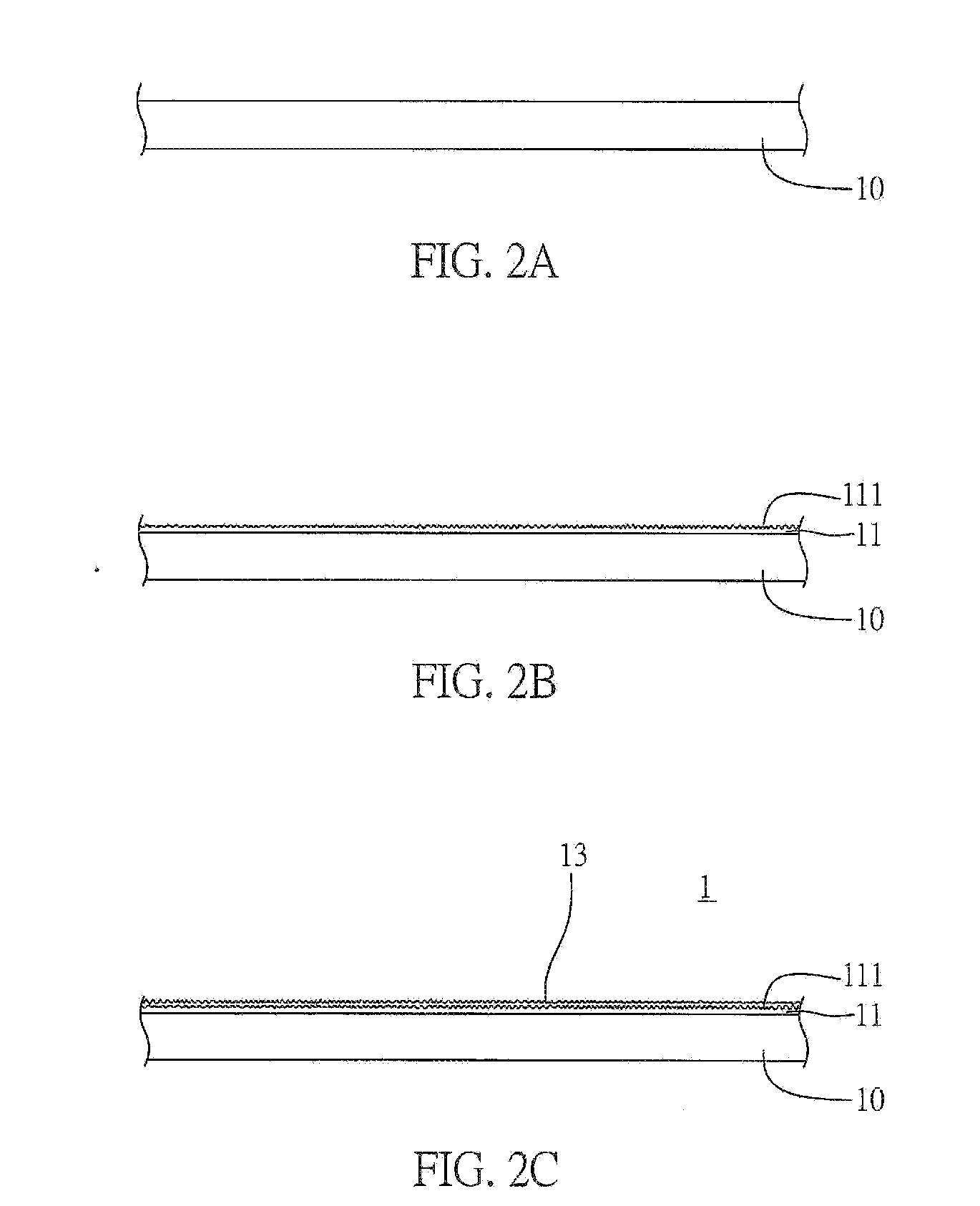

Water-Repellent Structure and Method for Making the Same

InactiveUS20070148407A1Reduce thicknessHigh transparencyRecord information storageMagnetic recordingRough surfaceHard water

A water-repellent structure and a method for fabricating the same are provided. The method adopts an atmospheric pressure plasma deposition (APPD) technique to form a hardened coating having a rough surface on a substrate, and form a water-repellent coating on the rough surface. Because the water-repellent structure includes the hardened coating and the water-repellent coating, hardness, abrasion-resistance, transparency and hydrophobicity of the water-repellent structure are improved. The hard water-repellent structure protects the substrate from friction. Moreover, because the present invention adopts the APPD technique to form the water-repellent structure, the cost of production is reduced dramatically. Thus, the present invention can solve drawbacks of prior art.

Owner:IND TECH RES INST

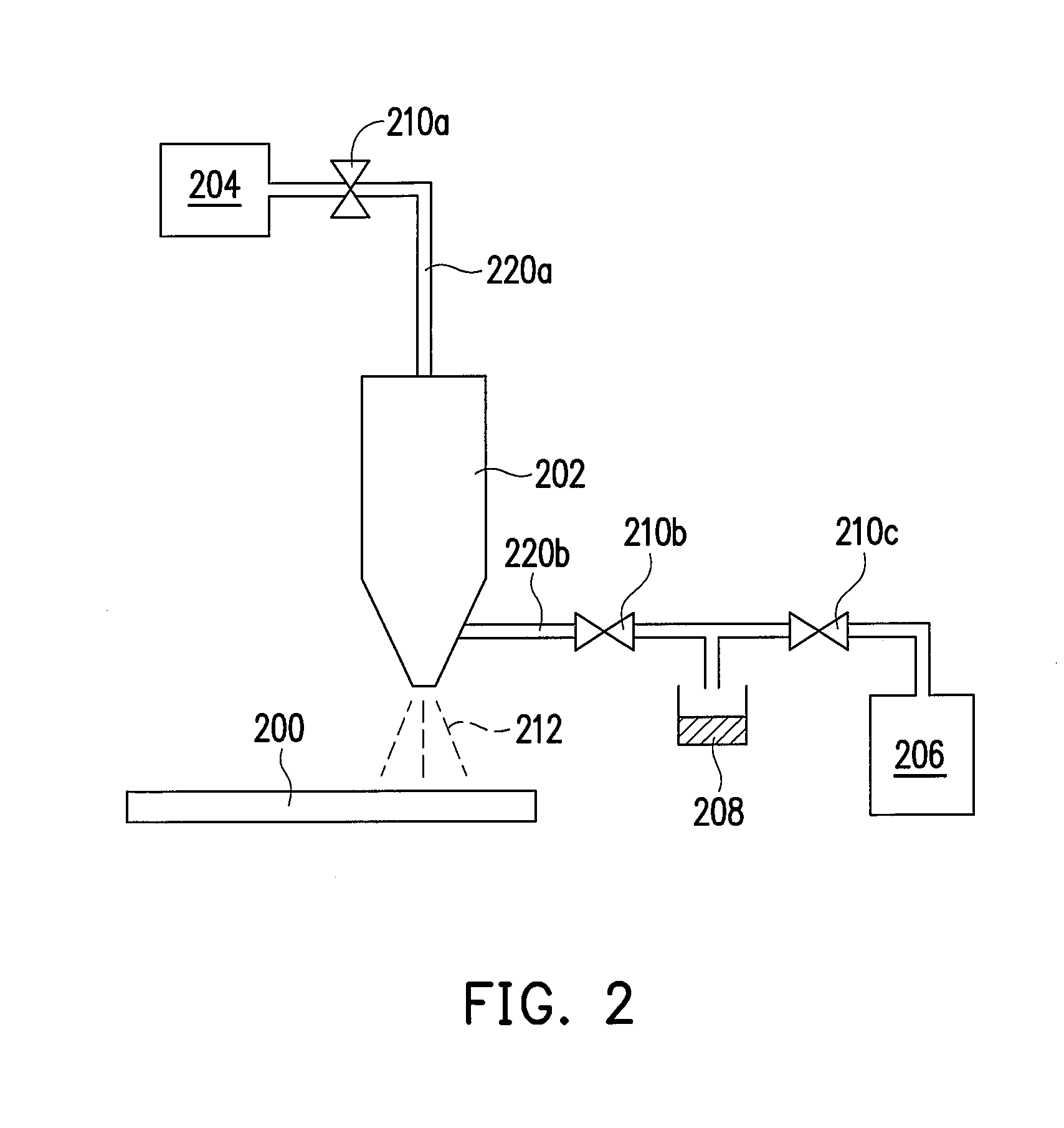

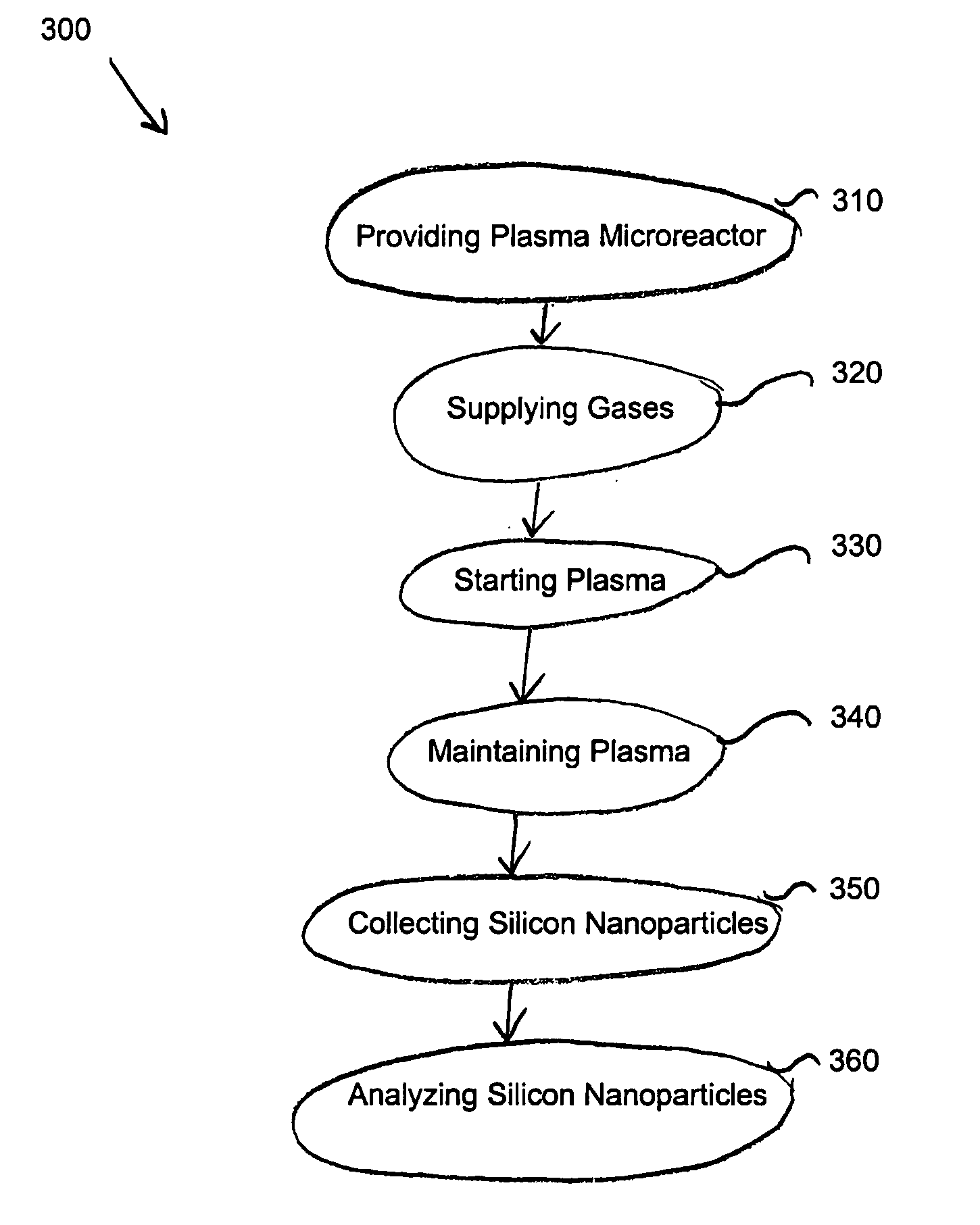

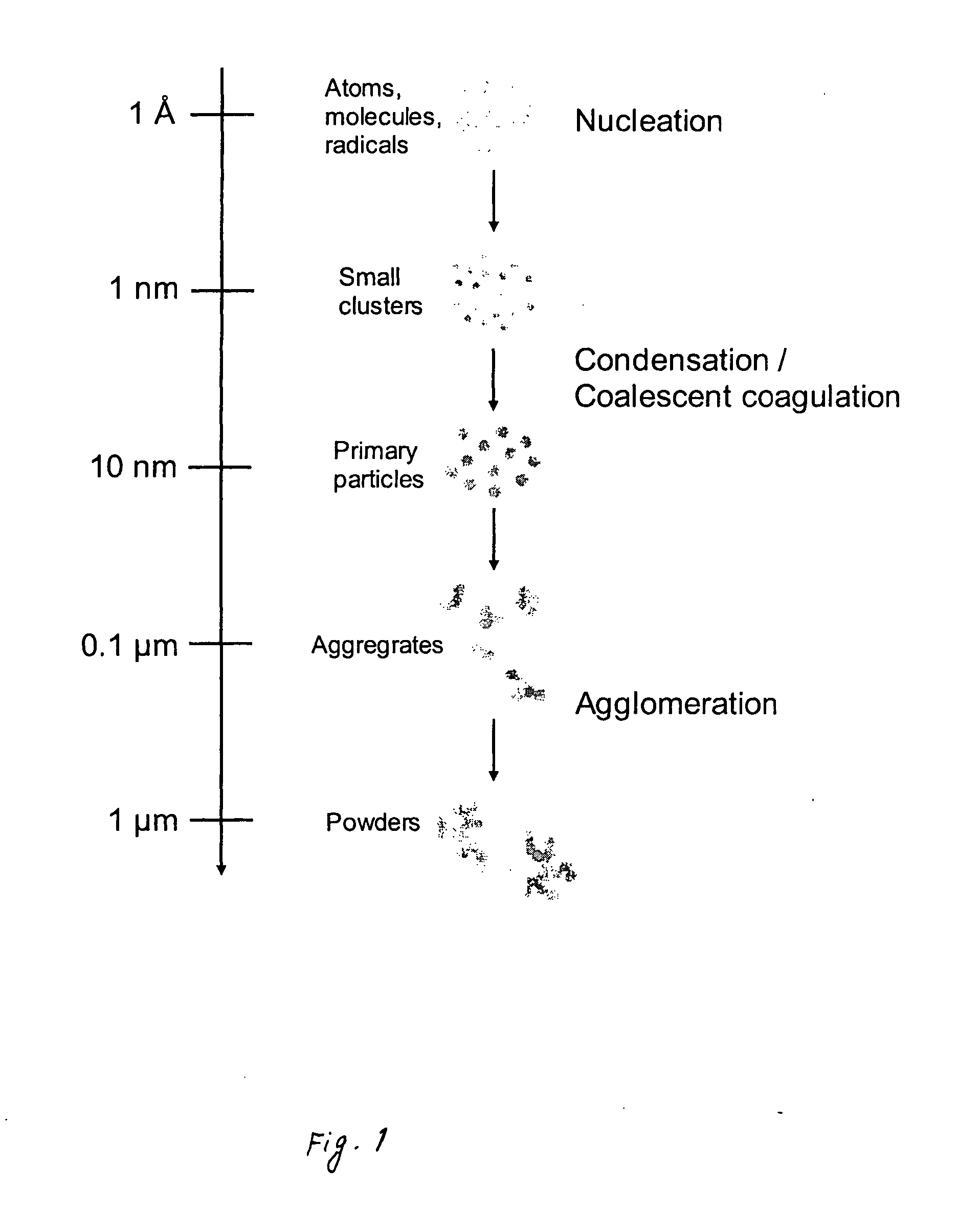

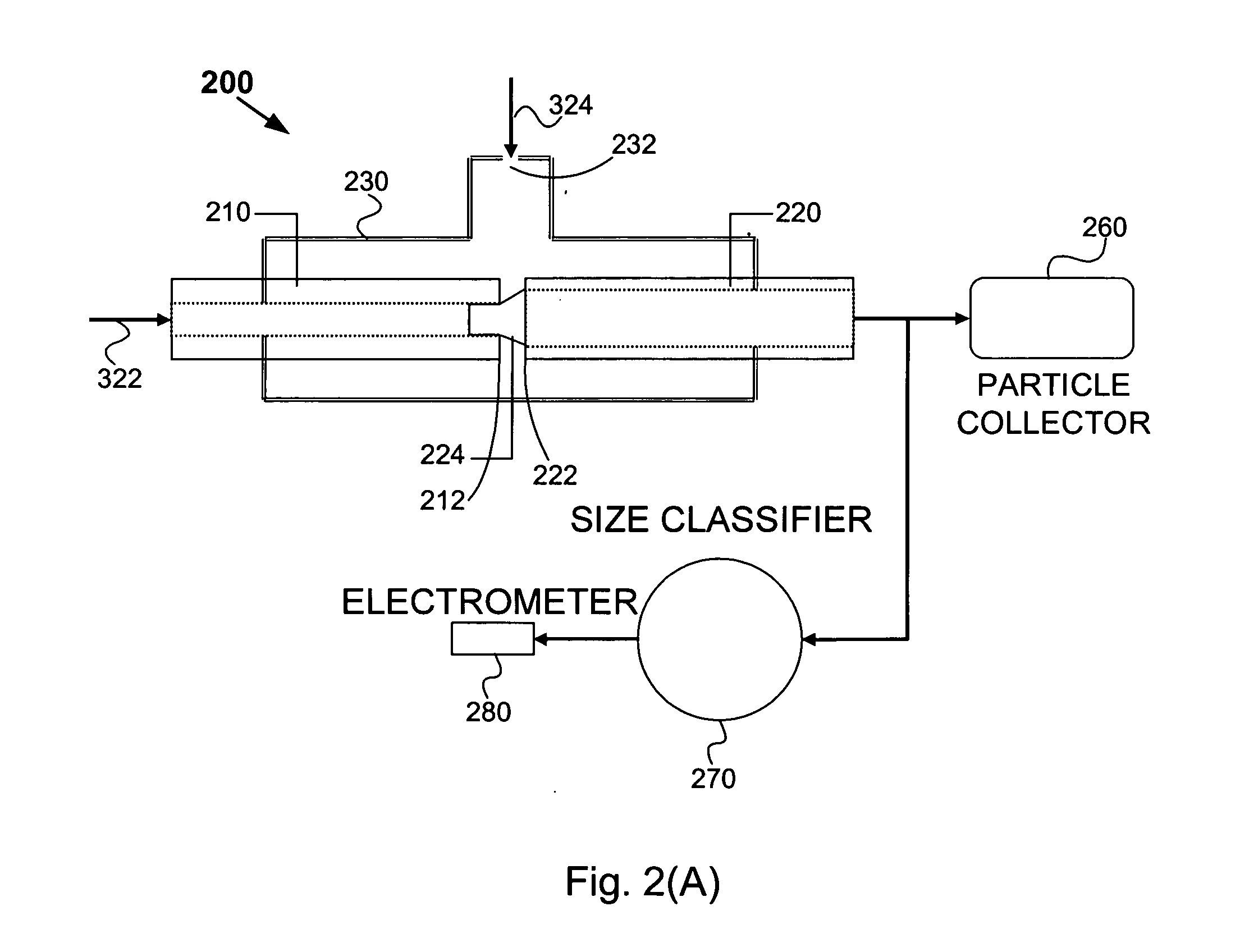

System and method for making nanoparticles using atmospheric-pressure plasma microreactor

InactiveUS20060042414A1Prevent coagulationAccelerate particle growthNanotechChemical/physical/physico-chemical microreactorsMicroreactorNanoparticle

A system and method for making nanoparticles. The system includes a first cathode including a first metal tube associated with a first end and a second end, a first anode including a second metal tube associated with a third end and a fourth end, and a first container including a first gas inlet. The first end and the third end are located inside the first container. The first end and the third end are separated by a first gap, the first metal tube is configured to allow a first gas to flow from the second end to the first end, and the first container is configured to allow a second gas to flow from the first gas inlet into the second metal tube through at least a first part of the first gap.

Owner:CALIFORNIA INST OF TECH

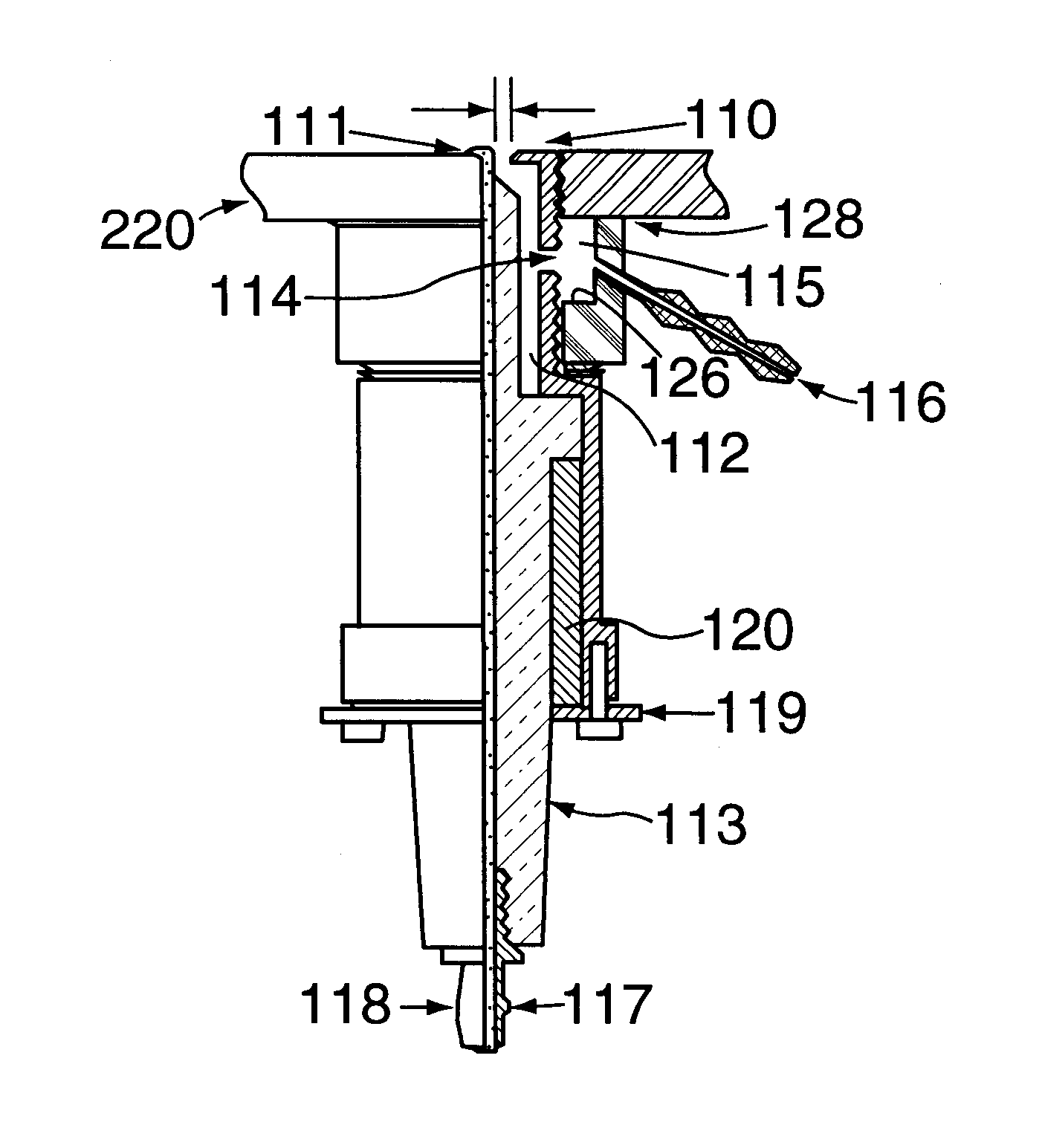

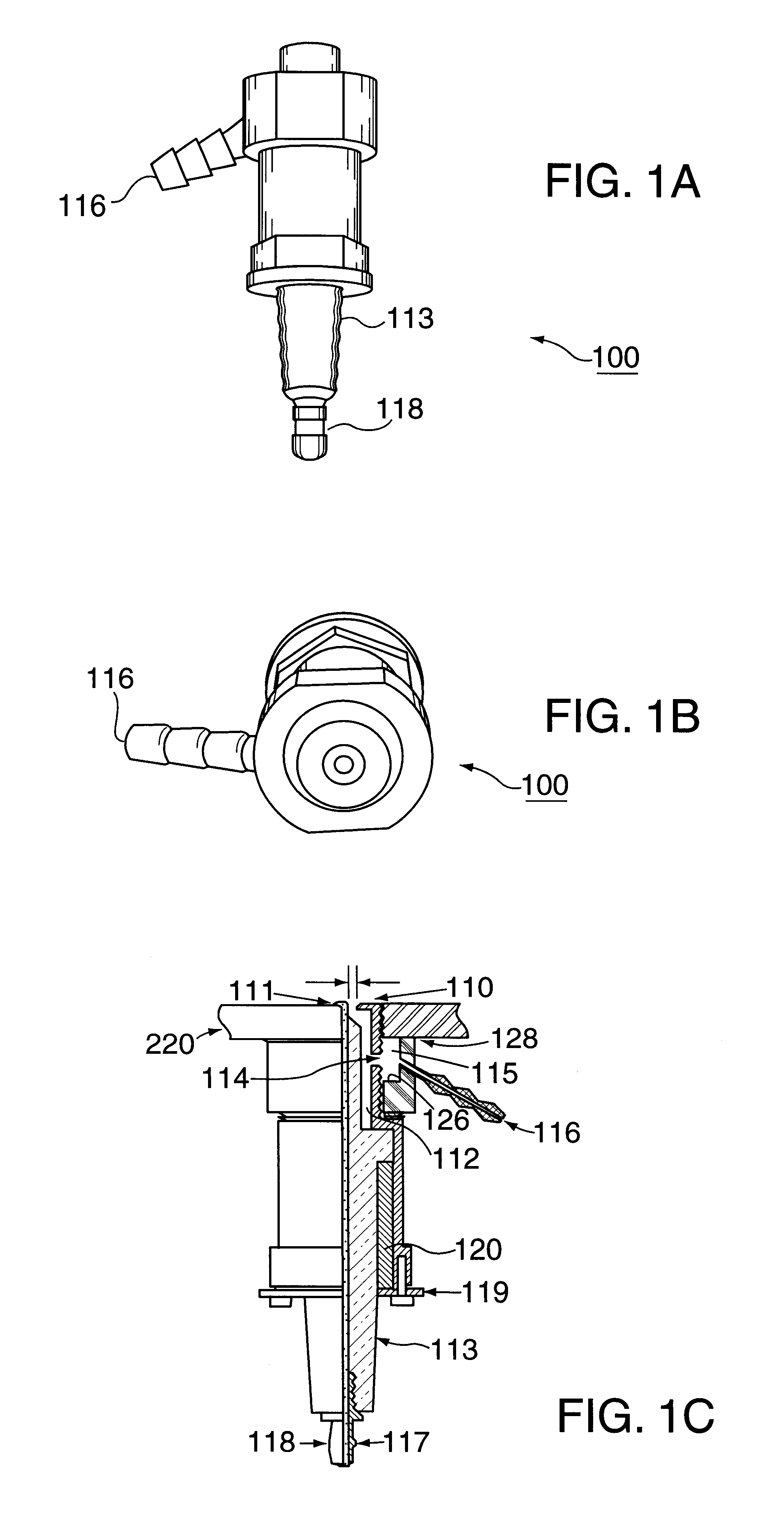

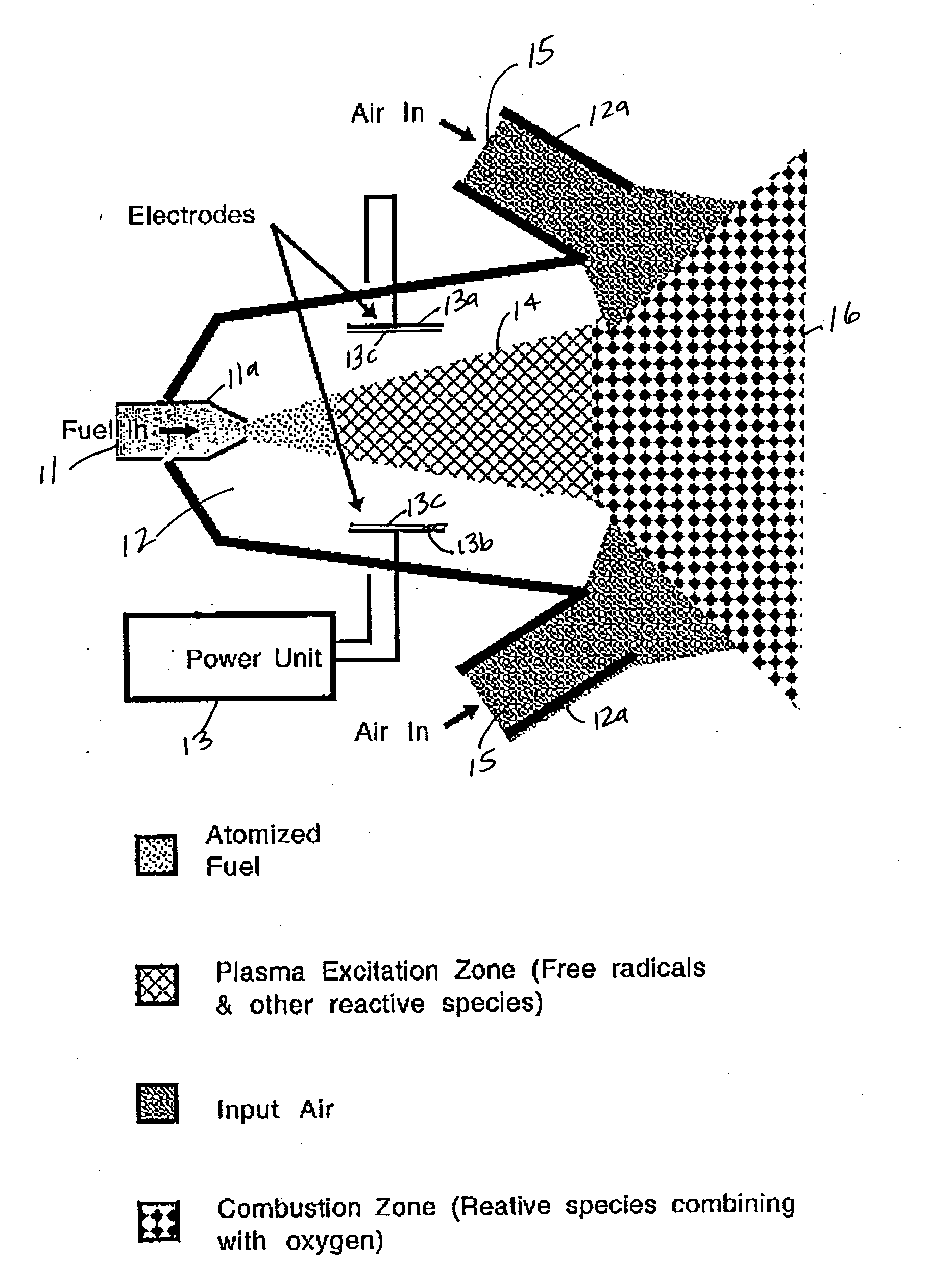

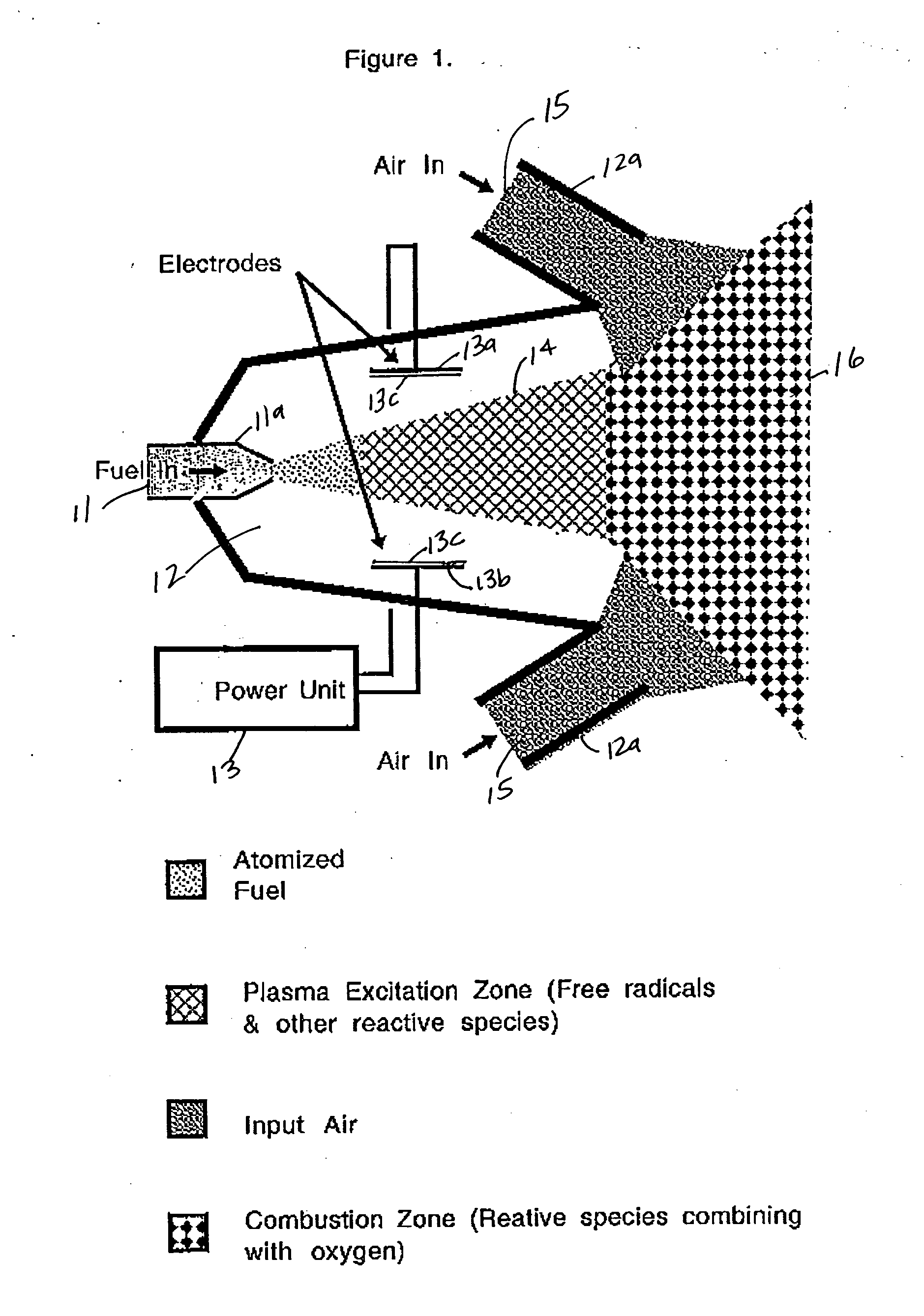

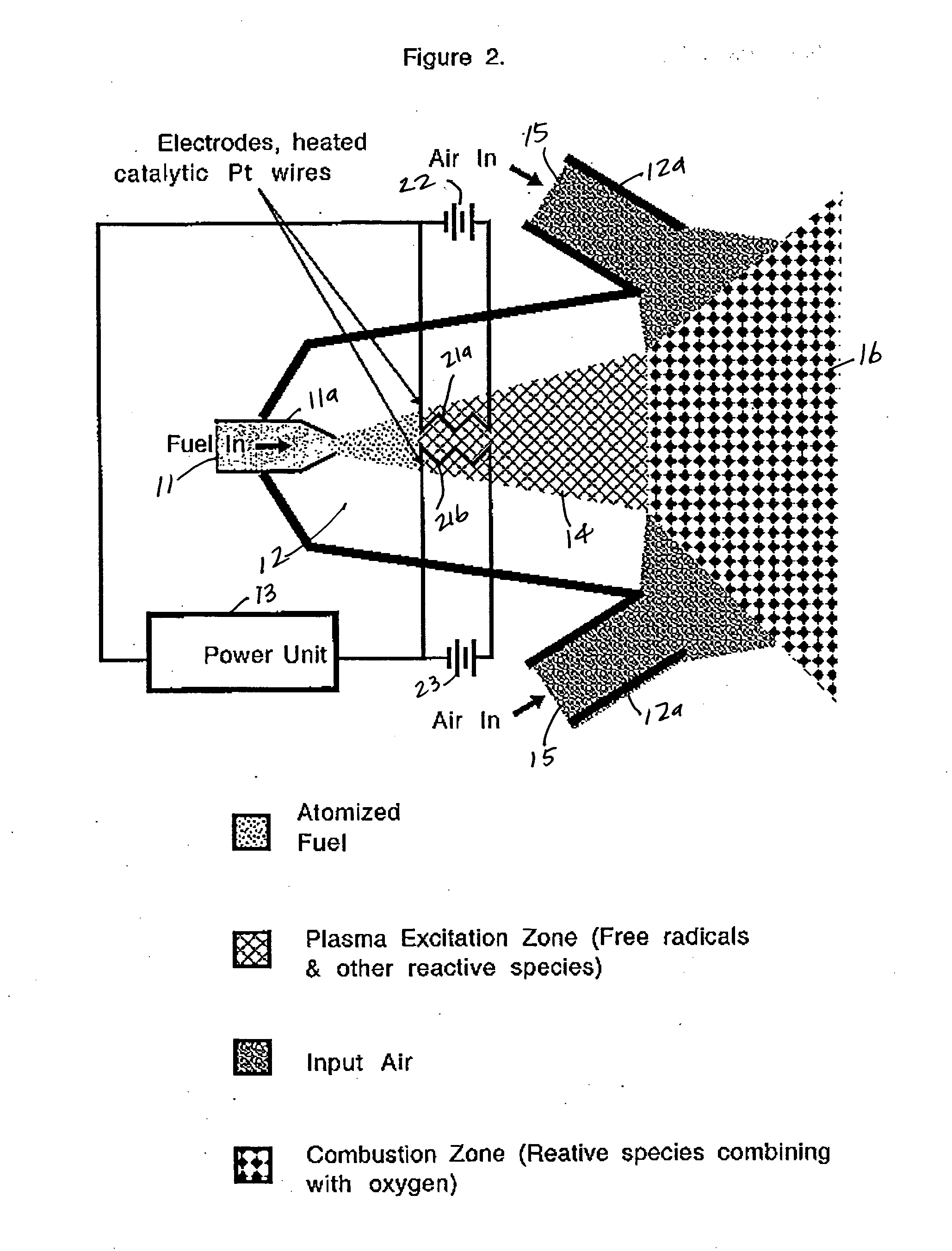

Plasma catalytic fuel injector for enhanced combustion

InactiveUS20050019714A1Improve efficiencyPromote combustionLiquid fuel feeder/distributionGaseous fuel feeder/distributionEngineeringElectric power

Apparatus and method for enhancing combustion comprises an enclosure defining an opening for introduction of a gas and openings for the introduction of air, with a nozzle in the opening for introduction of a fuel gas into the enclosure. First and second electrodes are located in the enclosure, the first and second electrodes being coated with dielectric material, and being connected to an electrical power supply. With electrical power applied to the first and second electrodes and with the fuel gas sprayed into the enclosure, an atmospheric pressure plasma created by a dielectric barrier discharge is produced in the enclosure that cracks the fuel gas prior to its mixing with air introduced through the openings for the introduction of air.

Owner:RGT UNIV OF CALIFORNIA

Atmospheric pressure plasma method for producing surface-modified particles and coatings

InactiveUS20120261391A1Easy to produceTransportation and packagingVacuum evaporation coatingSpray nozzleMaterials science

Disclosed is a method for producing surface-modified particles in atmospheric pressure plasma, and a method for producing a coating with particles dispersed therein using an atmospheric pressure plasma. The plasma is produced by a discharge between electrodes in a process gas. In both methods one of the electrodes is a sputter electrode, which sputters the particles due to the discharge. Also disclosed are methods for producing composite material, with which surface-modified particles are built in a matrix, and to said composite materials. Also disclosed are plasma nozzles and devices containing said nozzles for producing surface-modified particles and coatings with the particles dispersed therein.

Owner:PLASMATREAT GMBH

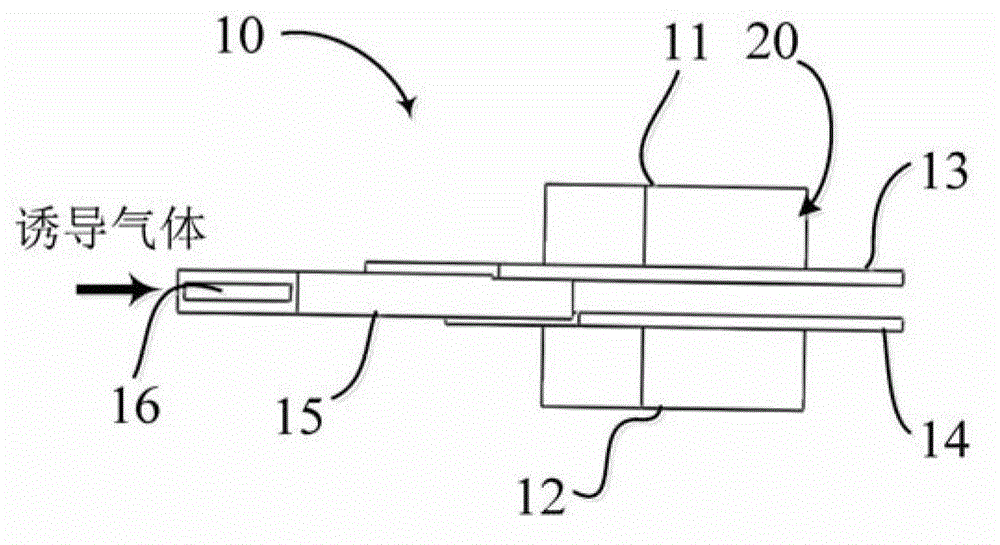

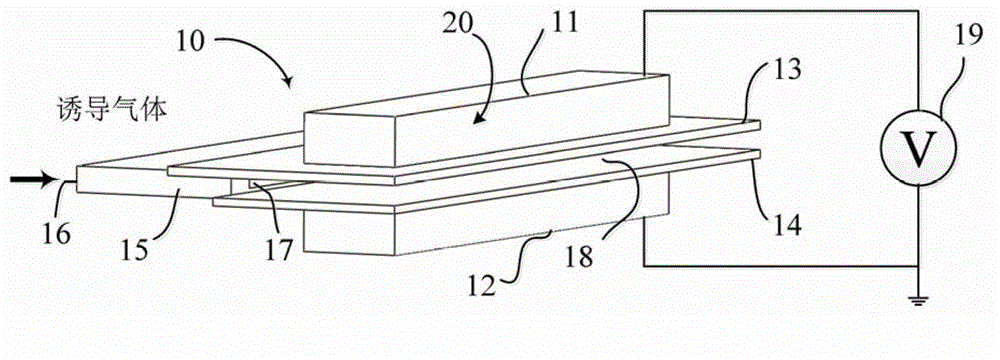

Atmospheric pressure induced air dielectric barrier discharge (DBD) low temperature plasma generation device

The invention aims to provide an atmospheric pressure induced air dielectric barrier discharge (DBD) low temperature plasma generation device. The device comprises a discharge unit provided with a DBD electrode structure and a narrow slit cavity body connected to the front end of the discharge unit, wherein the discharge unit comprises two oppositely-arranged plate electrodes; an insulation medium plate used for limiting a discharge current between the two plate electrodes is fixedly arranged on the plane of the inner side of a high voltage electrode; a sample to be processed, which is plate-shaped, is movably mounted on the plane of the inner side of a grounding electrode in a manner of being parallel and opposite to the insulation medium plate; the narrow slit cavity body is provided with a gas inlet port used for connecting induced gas into the narrow slit cavity body, and a narrow-slit-shaped gas outlet port; and the gas outlet port is embedded between the insulation medium plate and the sample to be processed. The plasma generation device provided by the invention can produce evenly-dispersed plasma; and the plasma is rich in active species such as metastable-state nitrogen molecules, hydroxyl radicals and oxygen atoms, and can be used for conducting material surface modification, sterilization, disinfection, and the like.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Cold air atmospheric pressure micro plasma jet application nethod and device

ActiveUS20090121638A1Reduce the possibilityIncrease electron densityElectric arc lampsArc welding apparatusPlasma jetCold air

A microhollow cathode discharge assembly capable of generating a low temperature, atmospheric pressure plasma micro jet is disclosed. The microhollow assembly has at two electrodes: an anode and a cathode separated by a dielectric. A microhollow gas passage is disposed through the three layers, preferably in a taper such that the area at the anode is larger than the area at the cathode. When a potential is placed across the electrodes and a gas is directed through the gas passage into the anode and out the cathode, along the tapered direction, then a low temperature micro plasma jet can be created at atmospheric pressure. Selection of gas microhollow geometry and operational characteristics enable the application of the assembly to low temperature treatments, including the treatment of living tissue.

Owner:PRICE ROBERT O +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com