Plasma catalytic fuel injector for enhanced combustion

a catalytic fuel and injector technology, applied in the direction of solid fuel combustion, fuels, lighting and heating apparatus, etc., can solve the problems of increasing demands, increasing detonation pressure, and related increase in detonation pressure, and achieve the effect of increasing the efficiency of combustion processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

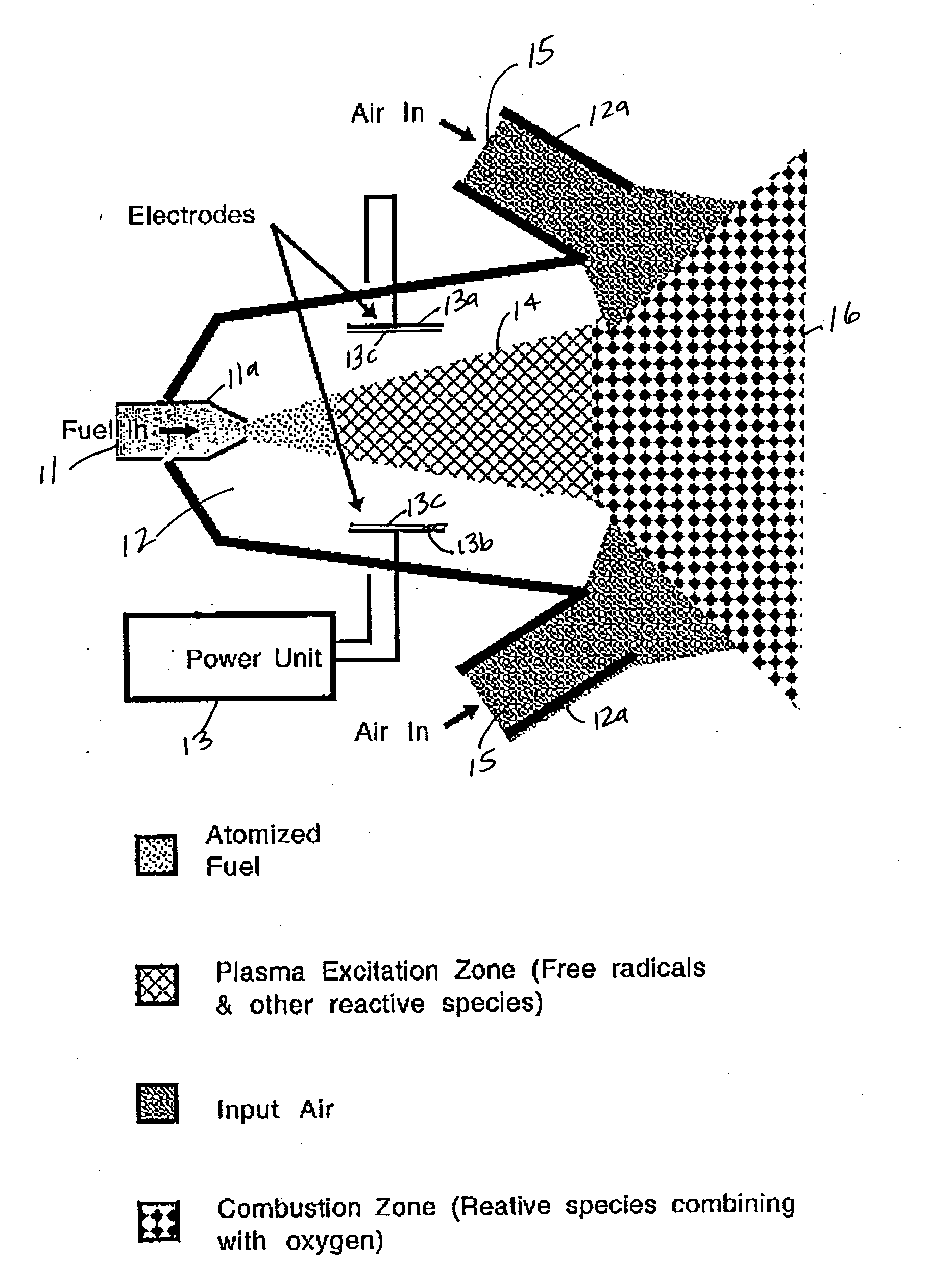

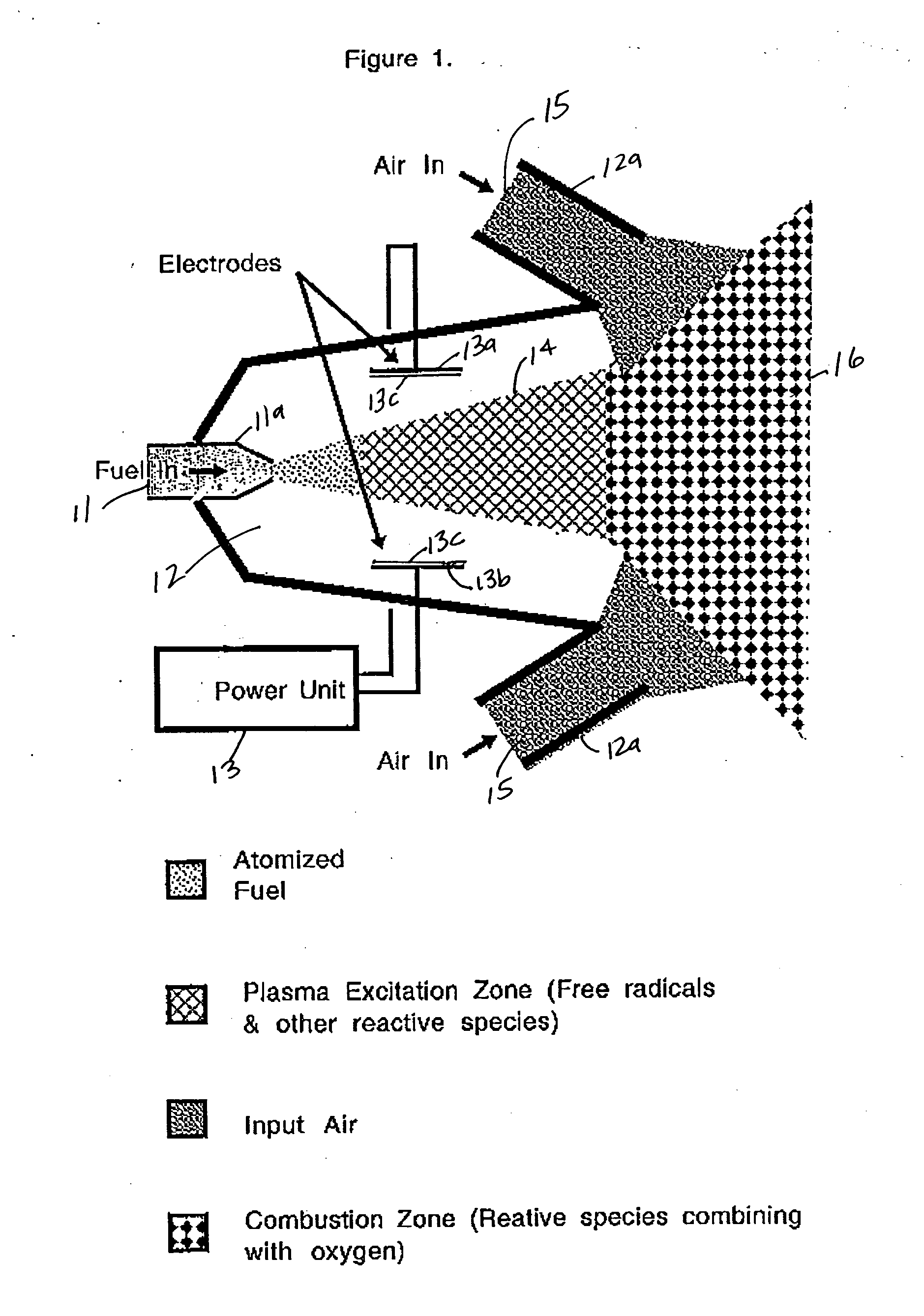

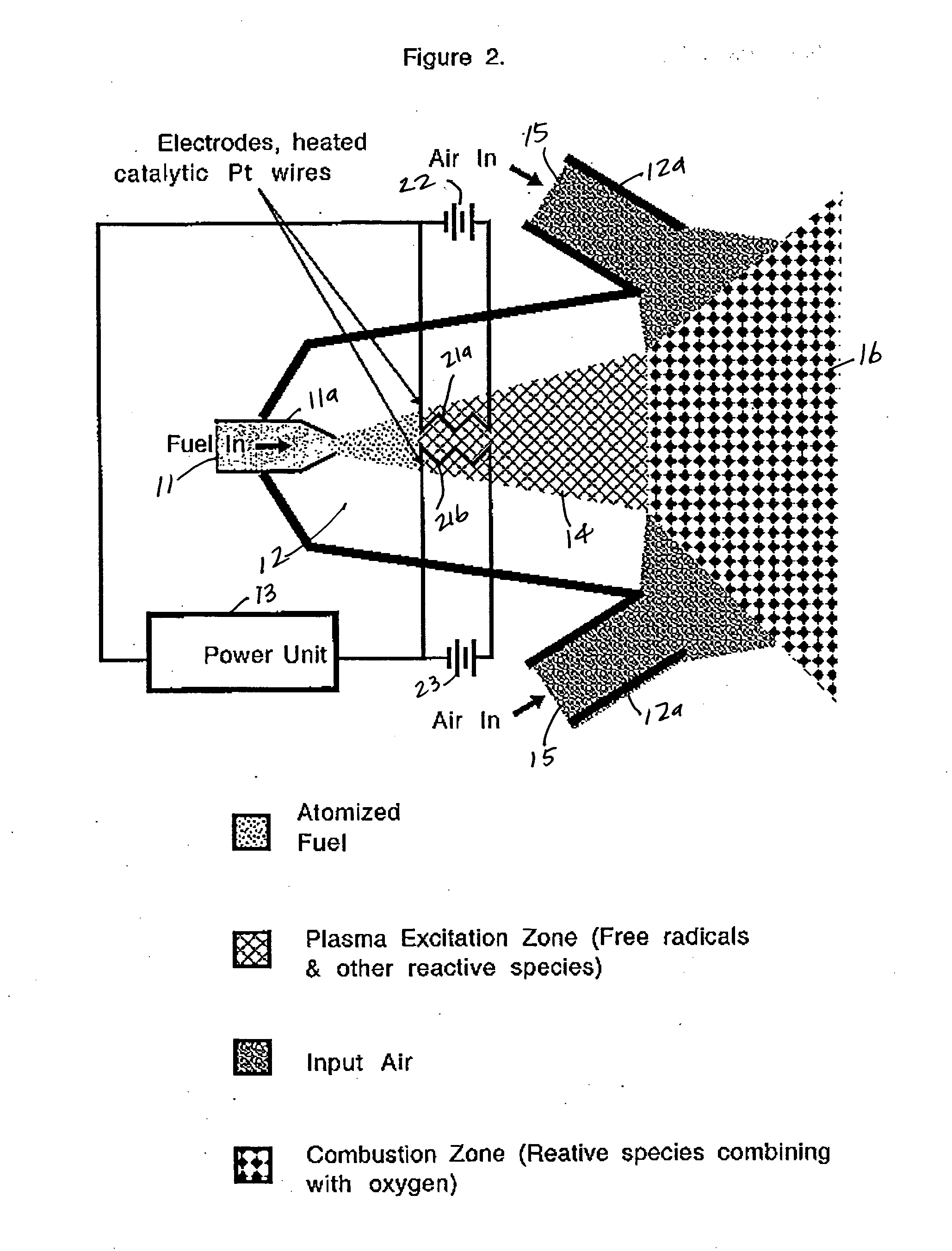

The present invention converts liquid or gaseous fuels into reactive species on a continuous basis, so that the combustion process does not rely solely on the self-generation of reactive species. The understanding of the invention can be aided through reference to the drawings.

In FIG. 1, a schematical illustration of one embodiment of the invention is shown where fuel gas 11 is introduced into volume 12 through fuel nozzle 11a. If fuel gas 11 is initially in liquid form, such as all hydrocarbon fuels, oxygenated hydrocarbon fuels and other functionalized fuels, fuel oils, diesel fuels, kerosene fuels including usual jet fuels such as Jet A, Jet B, JP-10, crude oil, and kerosene, it is atomized in the manner of conventional fuel injectors before being introduced into volume 12. If the fuel gas 11 is a gas, such as propane, natural gas, butane, propene, pure methane, ethylene, ethane and related fuels, it is passed directly through nozzle 11a to meter the flow. The present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com