Patents

Literature

107results about How to "Reduce power input" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

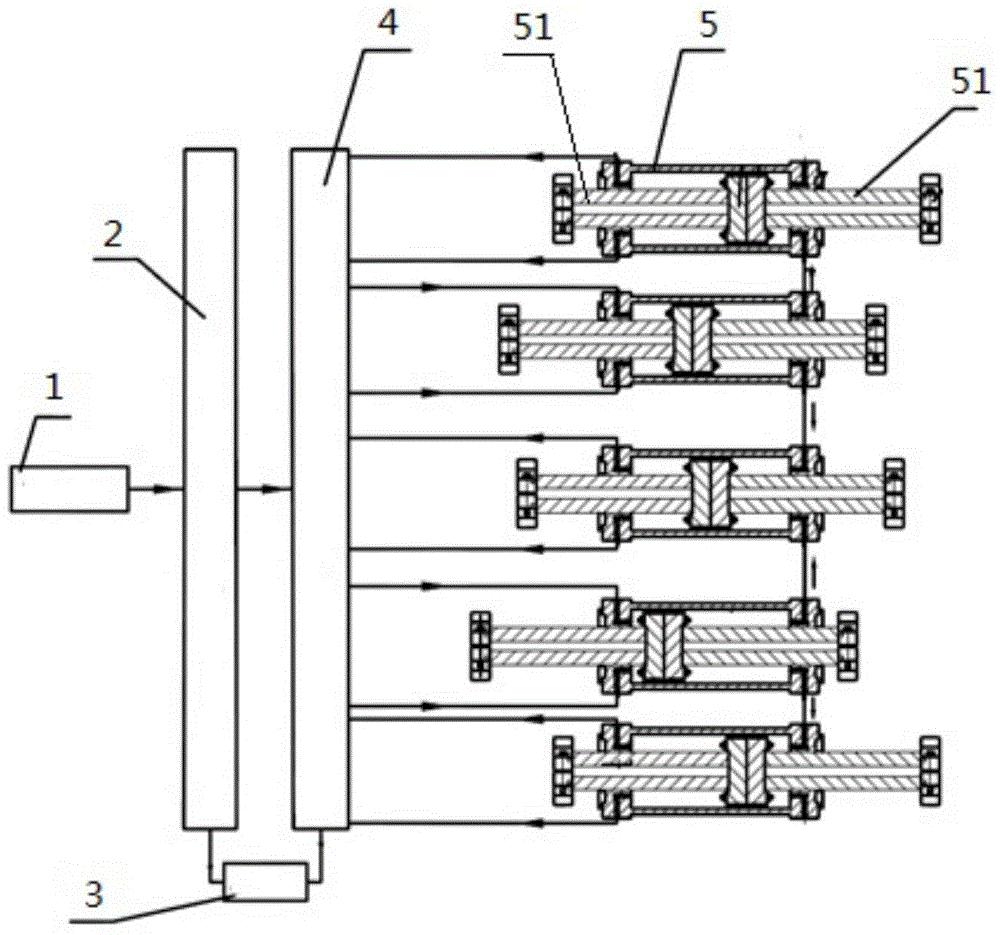

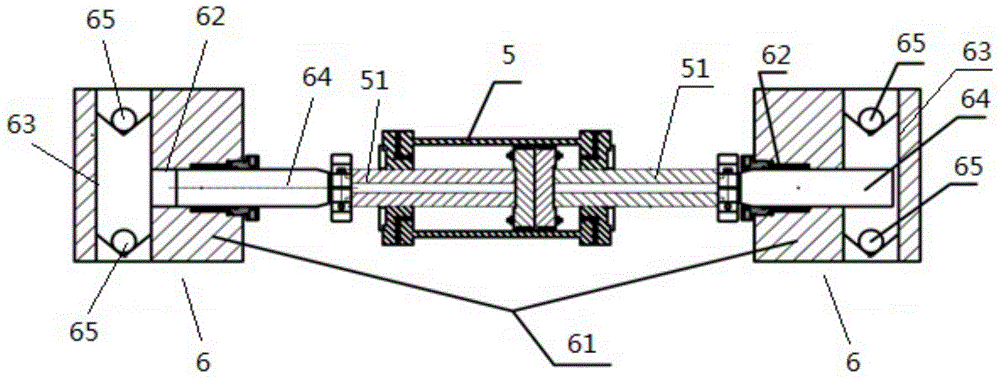

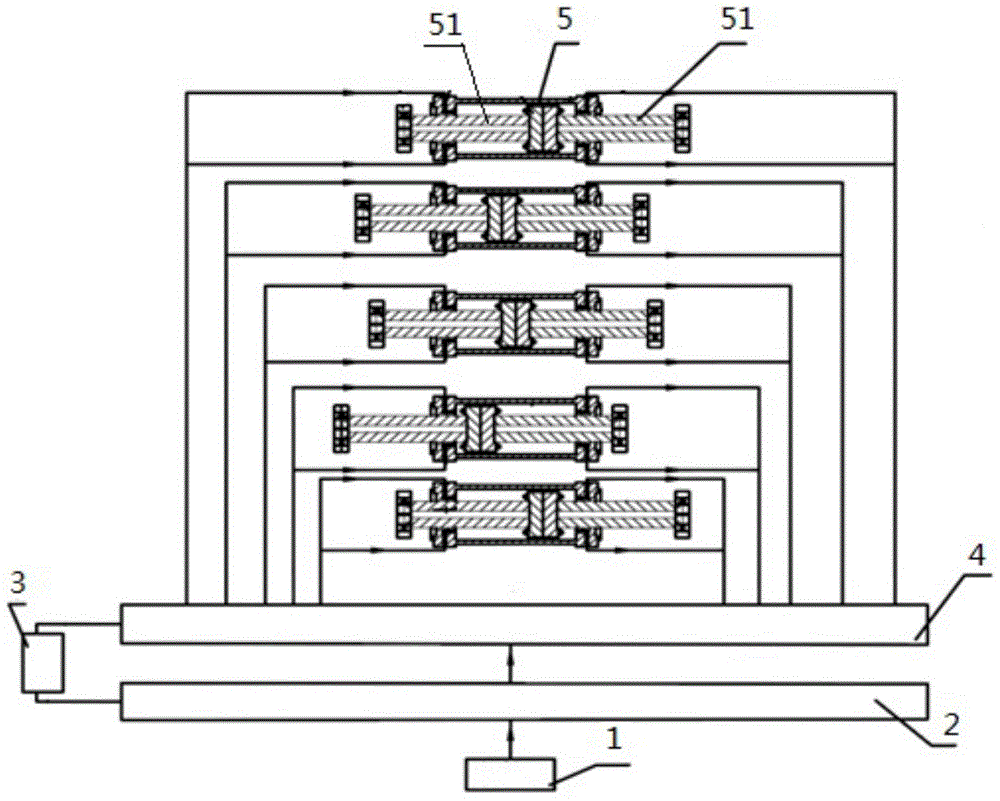

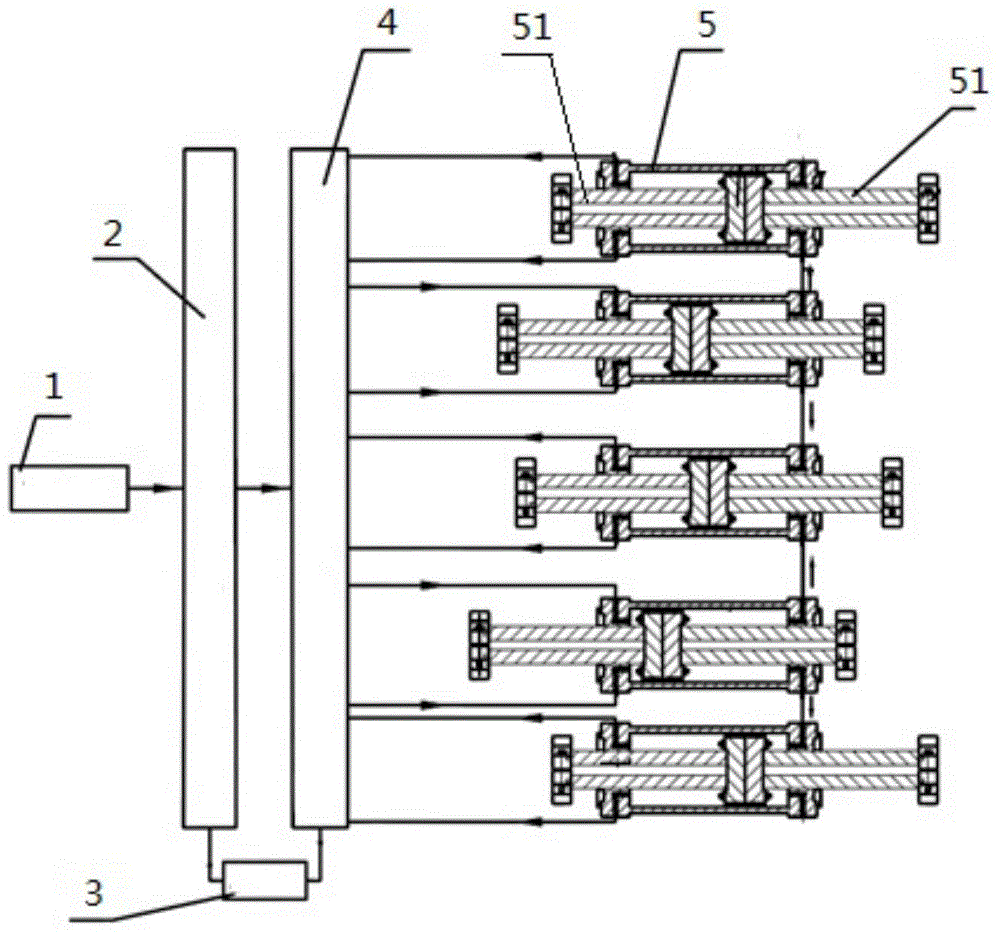

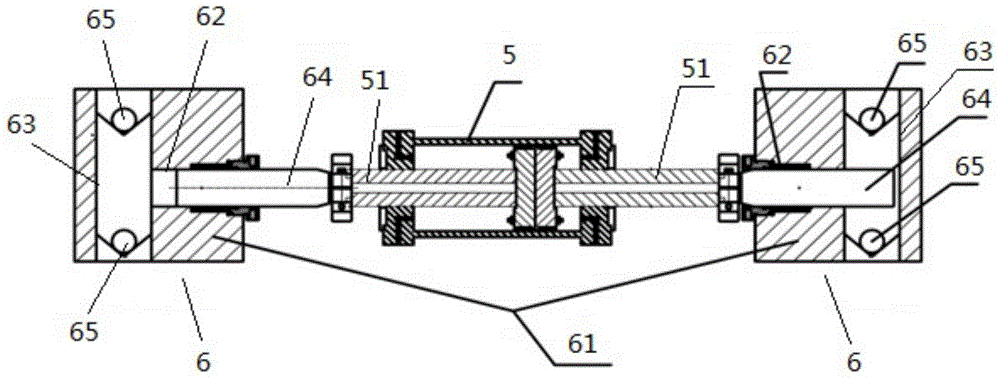

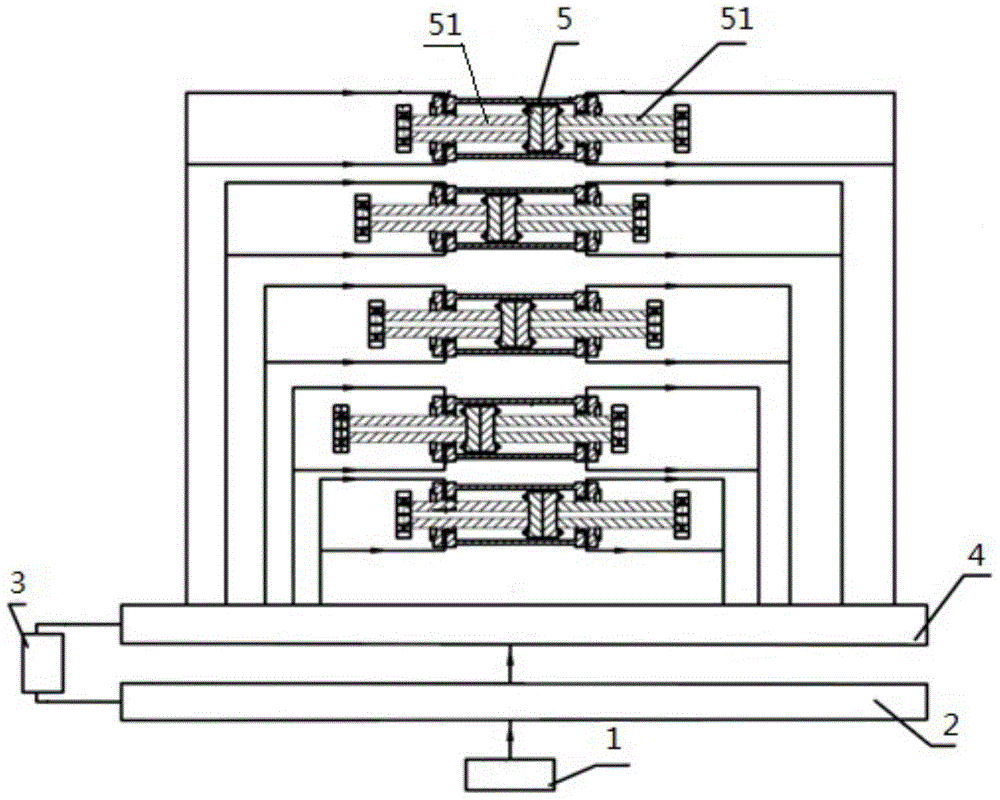

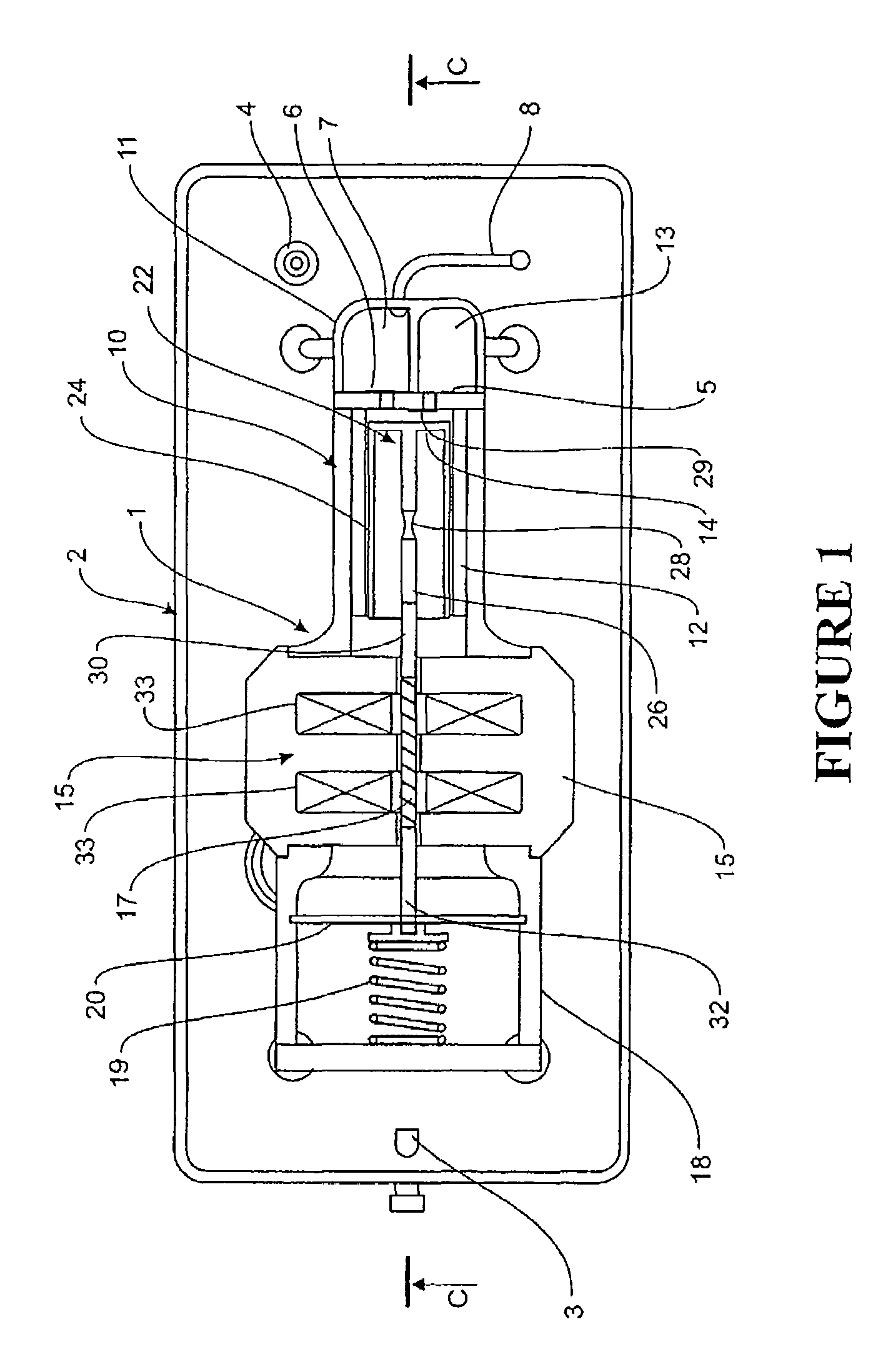

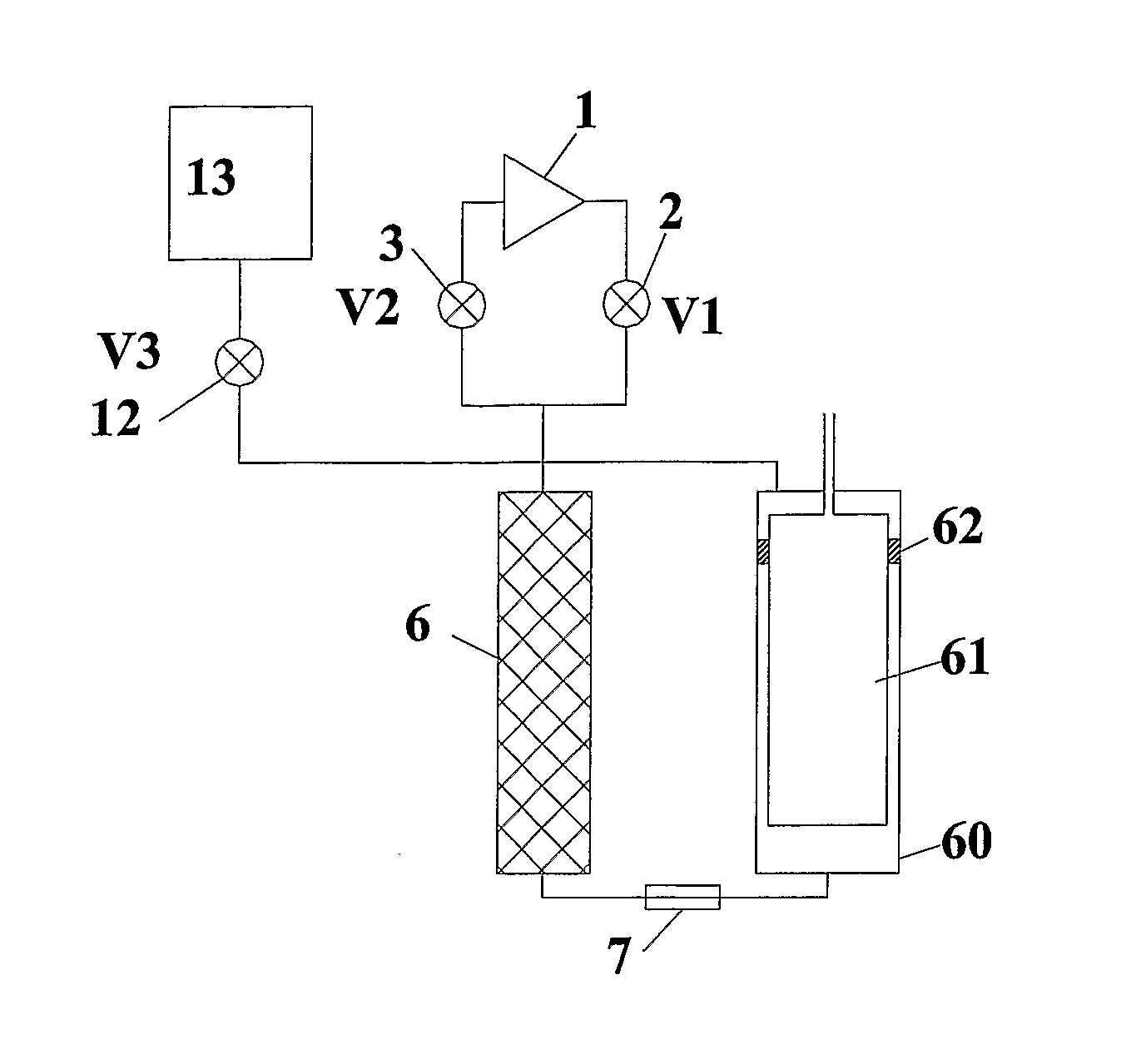

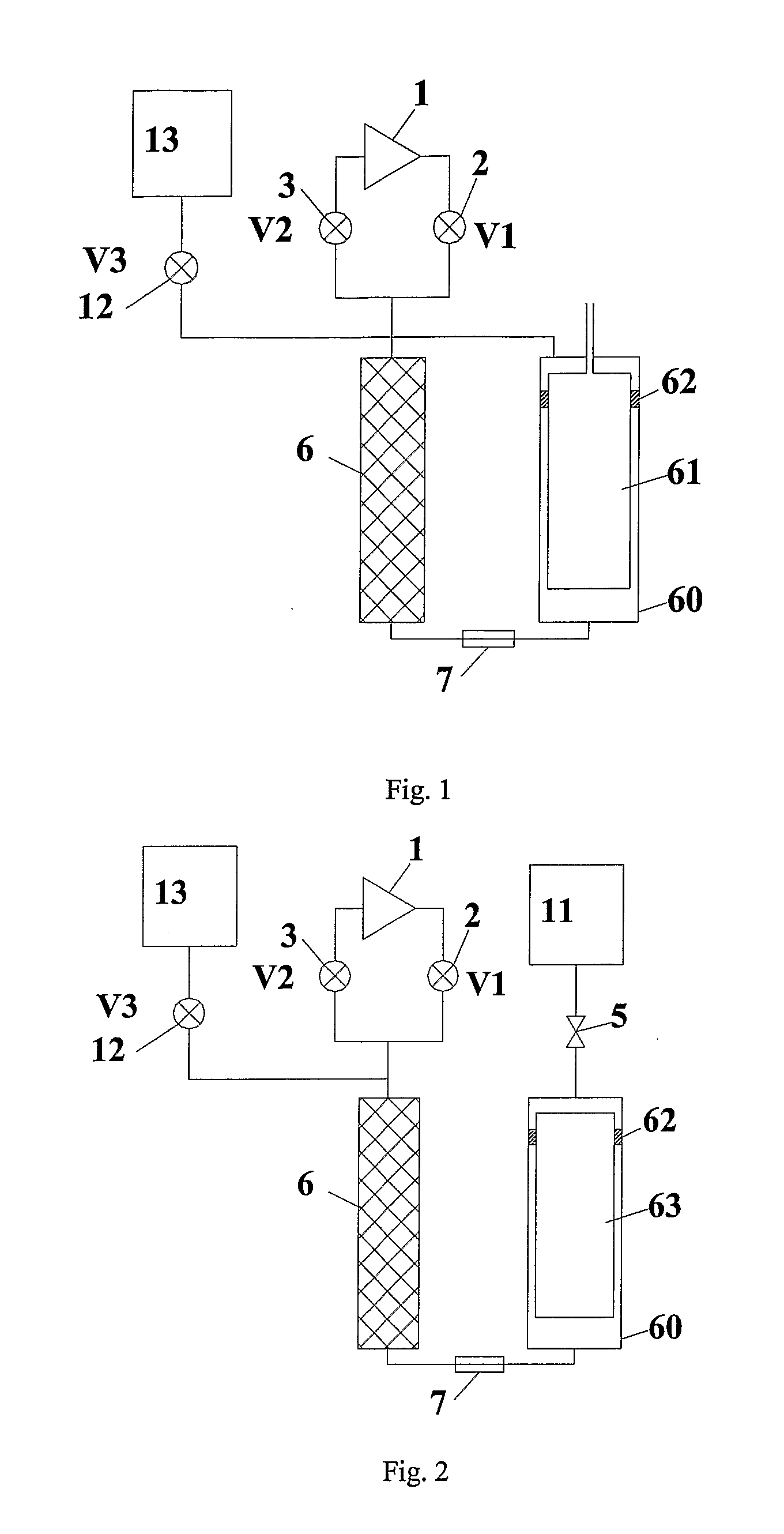

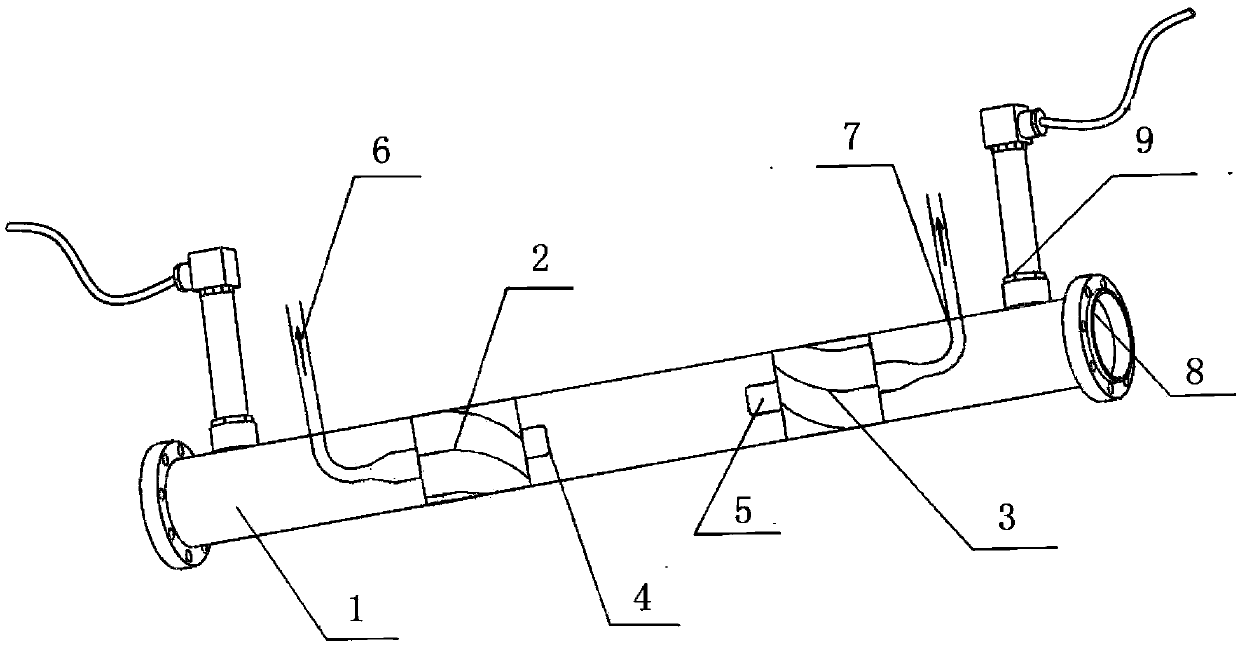

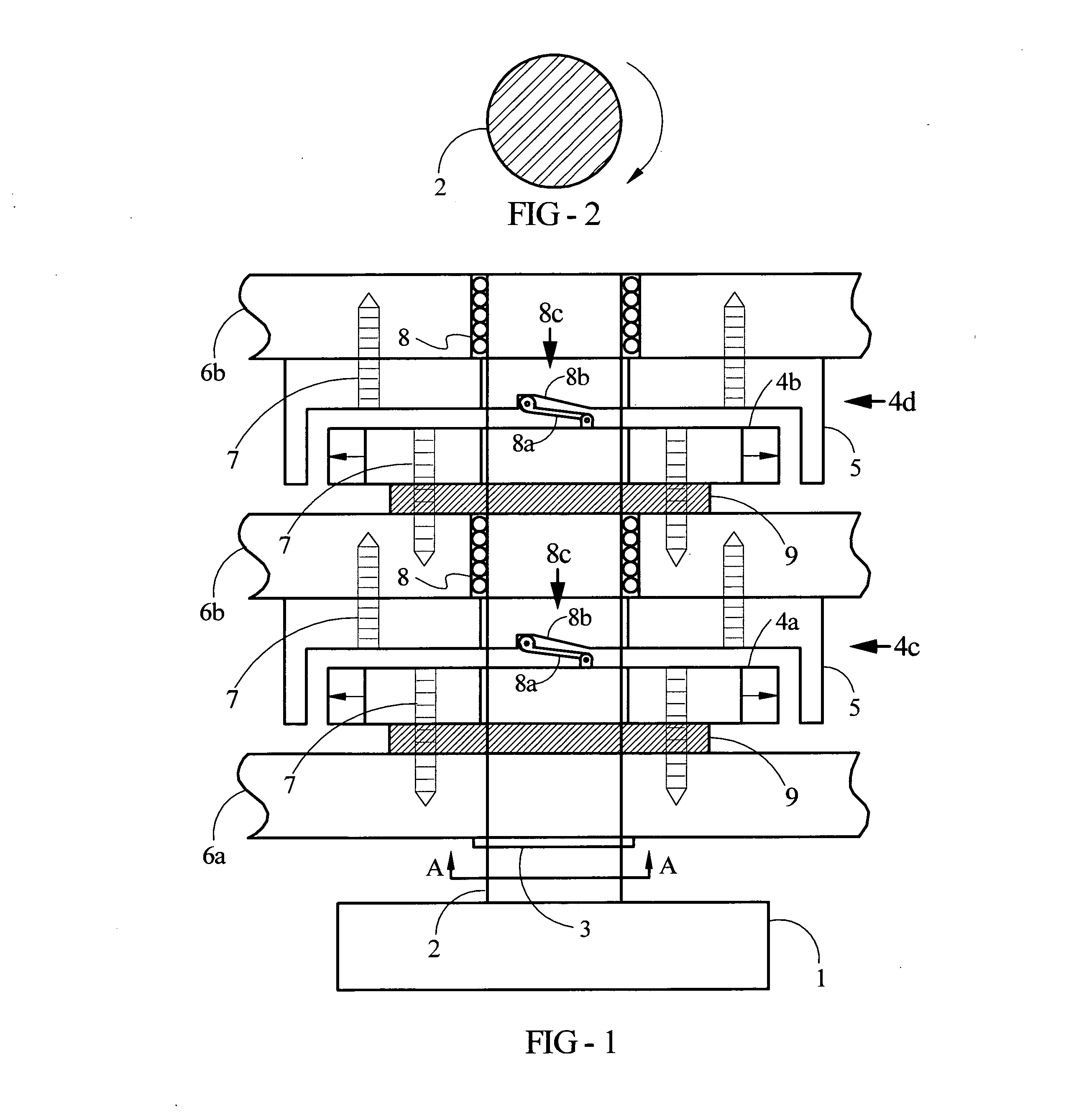

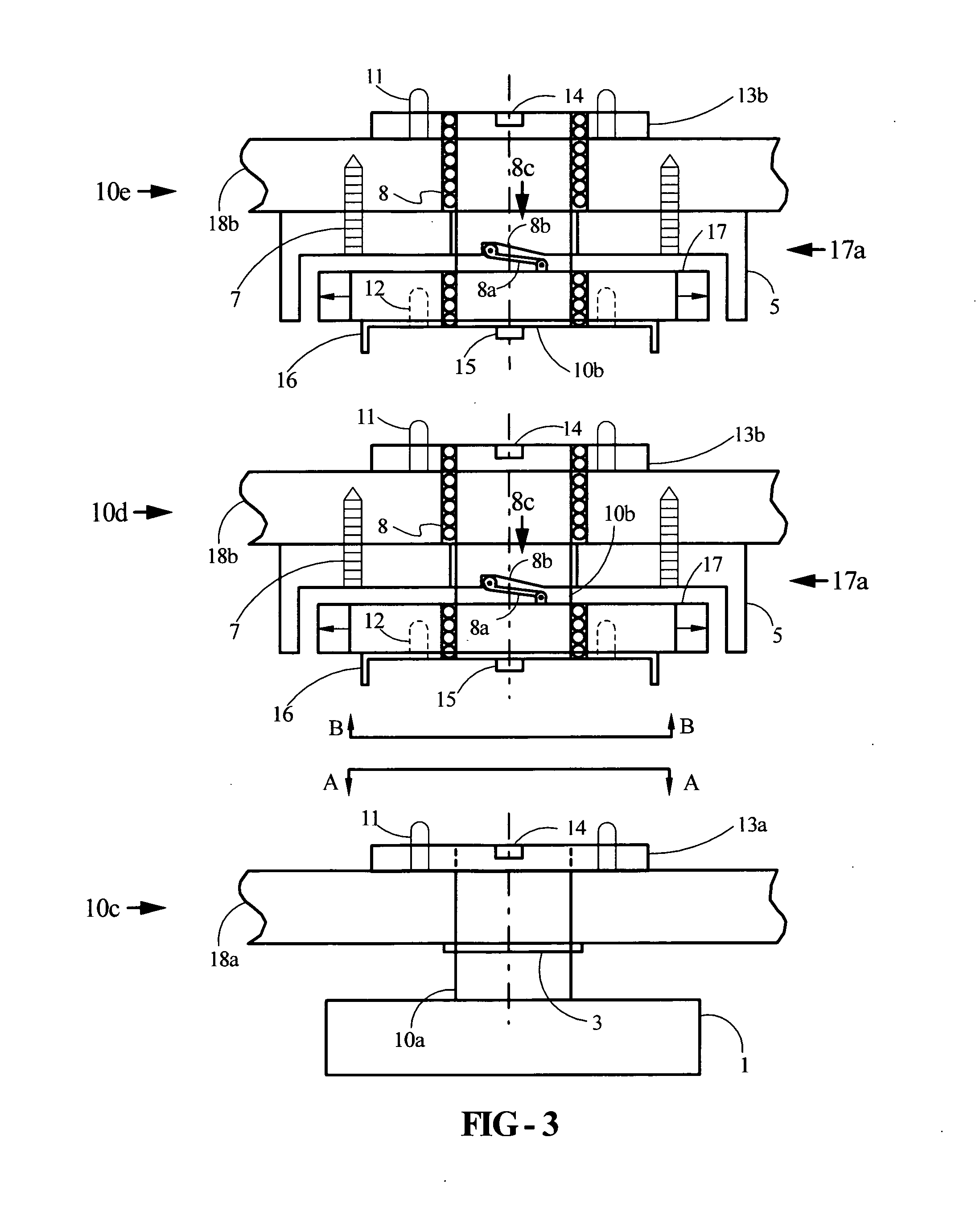

Hydraulic bidirectional pumping device

ActiveCN104612928AExtended service lifeImprove suction efficiencyPiston pumpsPositive-displacement liquid enginesHydraulic cylinderMotor drive

The invention relates to a hydraulic bidirectional pumping device which comprises a prime motor, a hydraulic oil pump, a hydraulic oil tank, a control valve, a double-action hydraulic cylinder and plunger pumps. The prime motor drives the hydraulic oil pump. The hydraulic bidirectional pumping device utilizes the double-action hydraulic cylinder to drive the plunger pumps on both sides; the cylinder number is increased; stroke times are reduced; the service lives of easily damaged parts are prolonged; the coverage range of flow is effectively enlarged; suction efficiency of fracturing fluid is effectively improved; complexity of the integral structure is reduced; cost of manufacturing, maintenance and the like is reduced; the requirements on a lubricating system are lowered; the double-action hydraulic cylinder reciprocates to do work, so that working efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

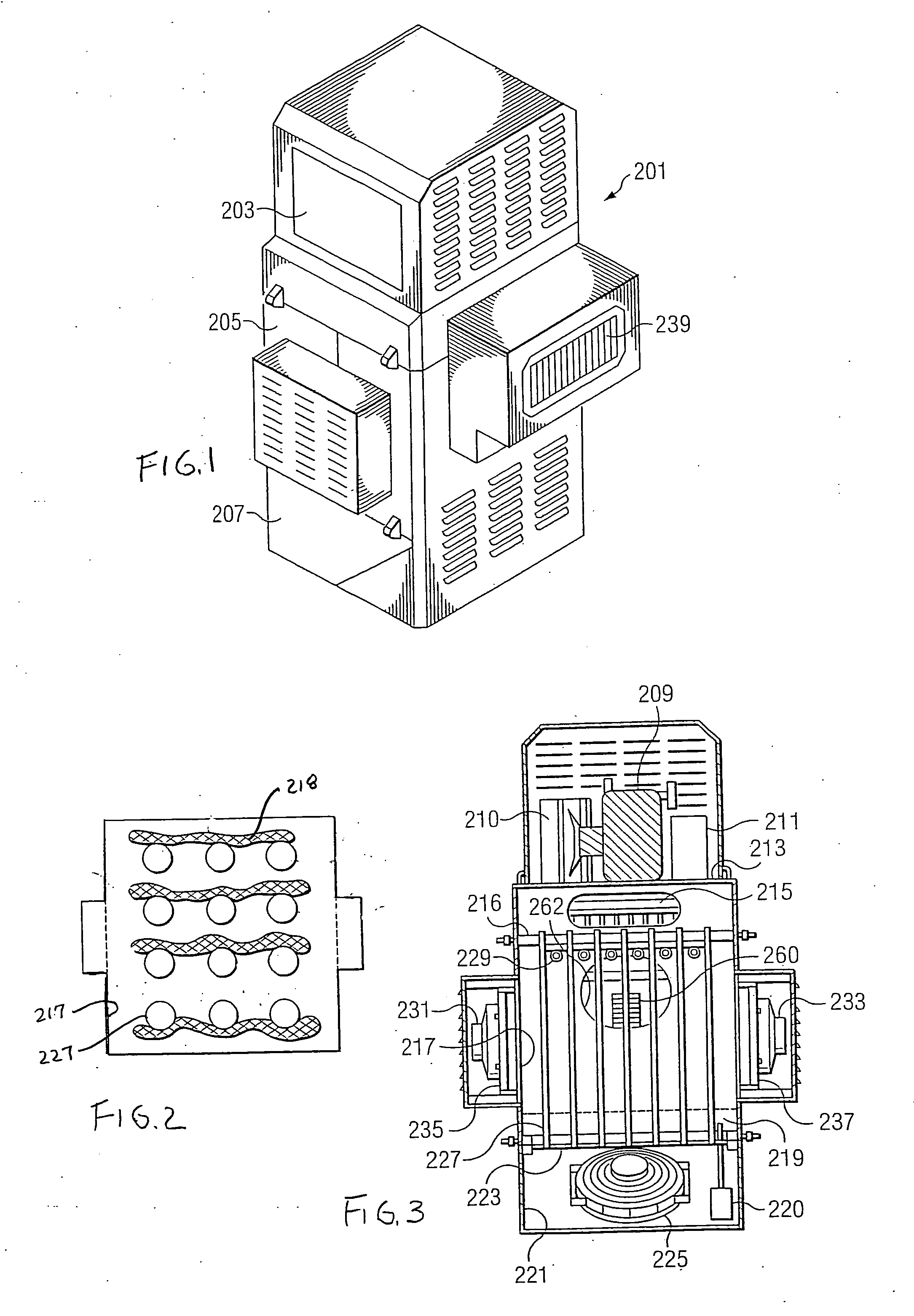

Hydraulic double acting pumping unit

ActiveCN104612928BExtended service lifeImprove suction efficiencyPiston pumpsPositive-displacement liquid enginesHydraulic cylinderMotor drive

The invention relates to a hydraulic bidirectional pumping device which comprises a prime motor, a hydraulic oil pump, a hydraulic oil tank, a control valve, a double-action hydraulic cylinder and plunger pumps. The prime motor drives the hydraulic oil pump. The hydraulic bidirectional pumping device utilizes the double-action hydraulic cylinder to drive the plunger pumps on both sides; the cylinder number is increased; stroke times are reduced; the service lives of easily damaged parts are prolonged; the coverage range of flow is effectively enlarged; suction efficiency of fracturing fluid is effectively improved; complexity of the integral structure is reduced; cost of manufacturing, maintenance and the like is reduced; the requirements on a lubricating system are lowered; the double-action hydraulic cylinder reciprocates to do work, so that working efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

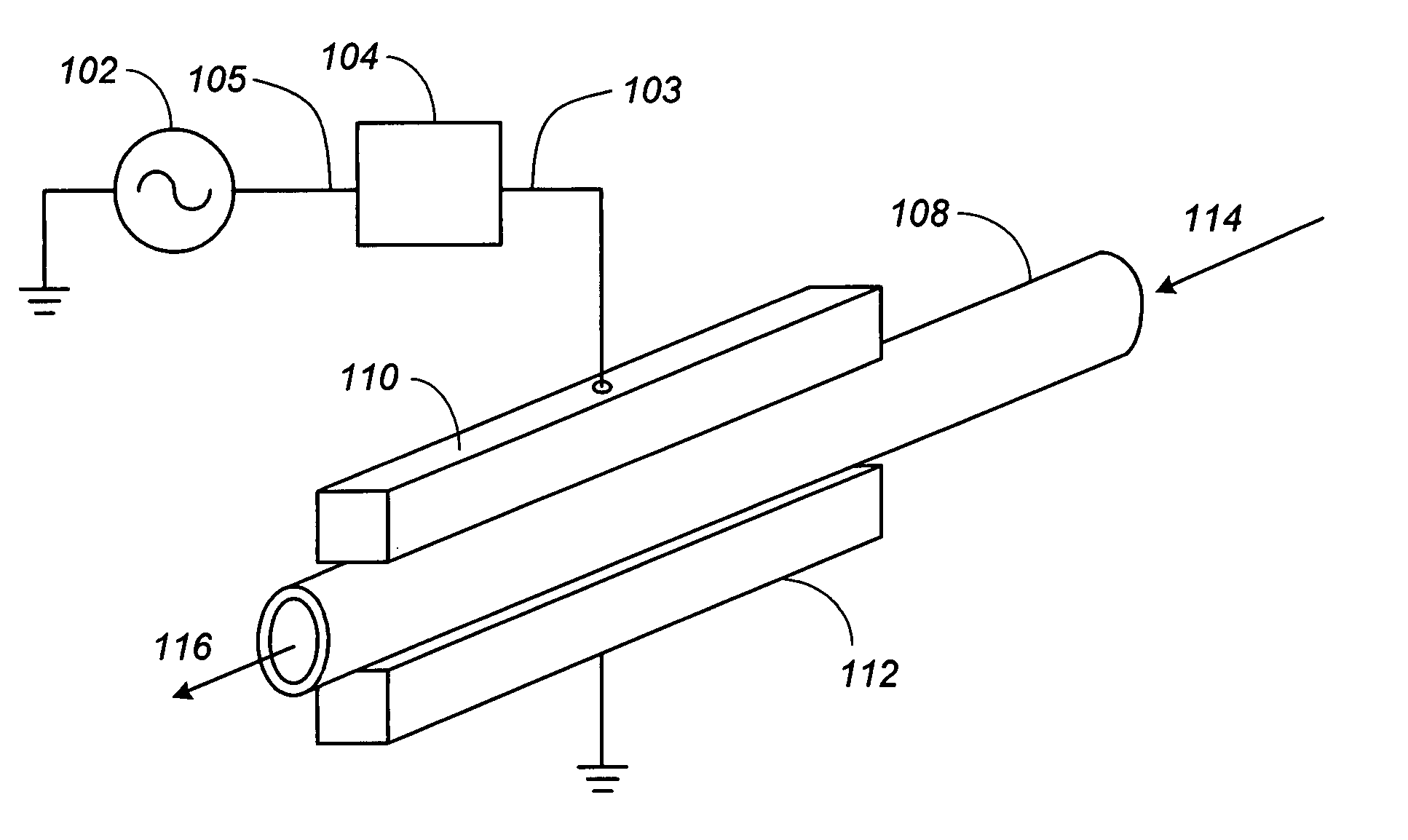

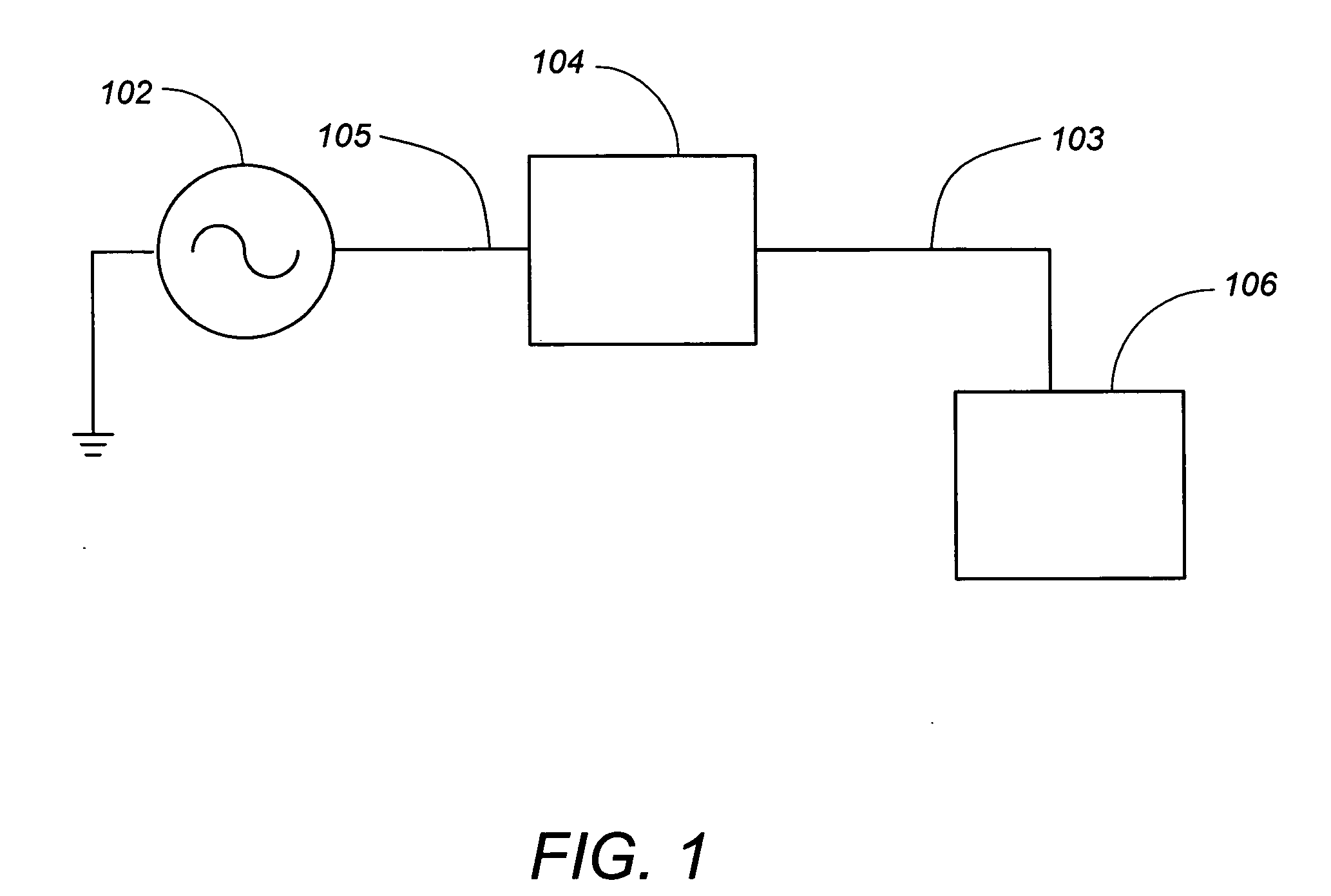

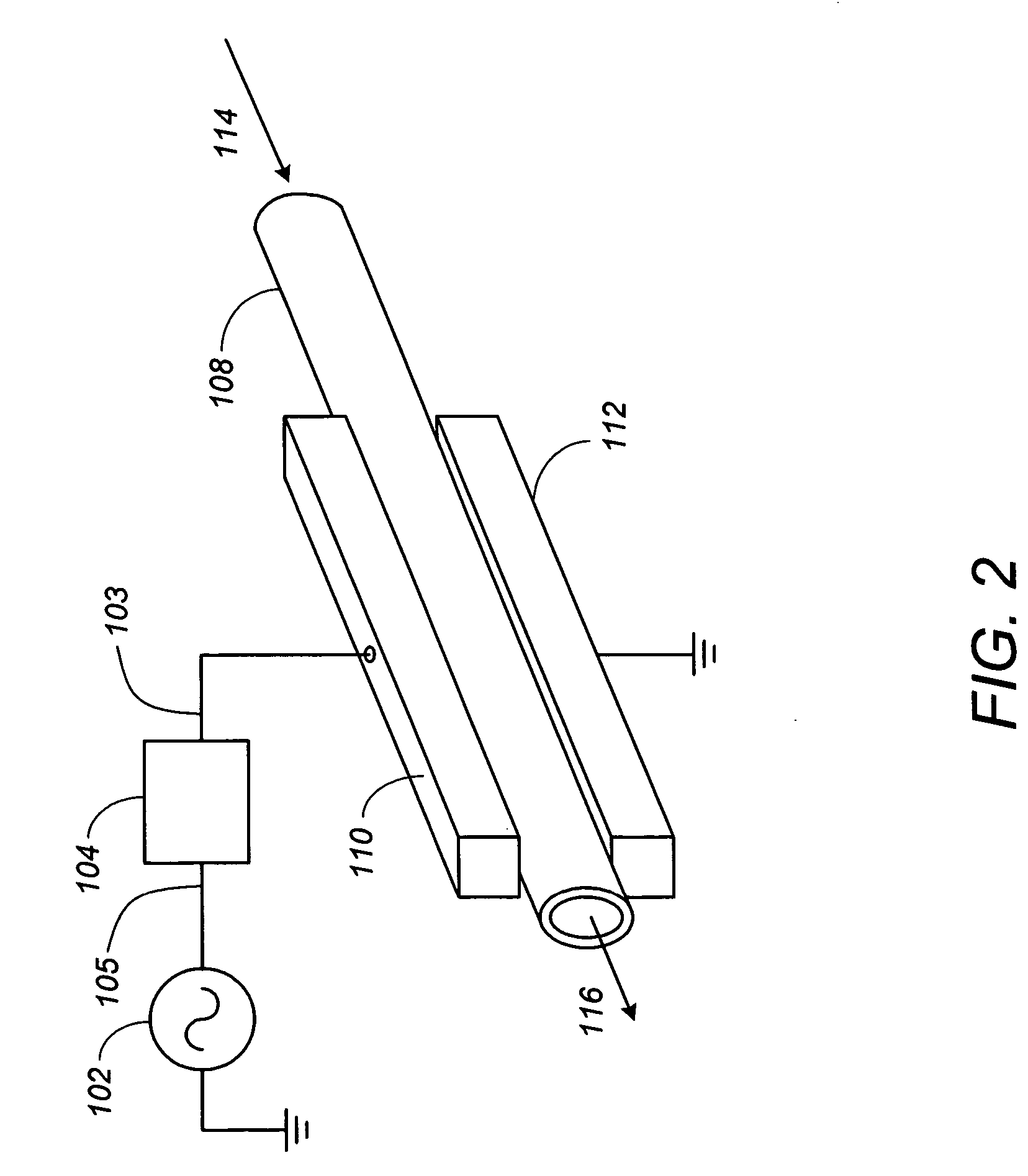

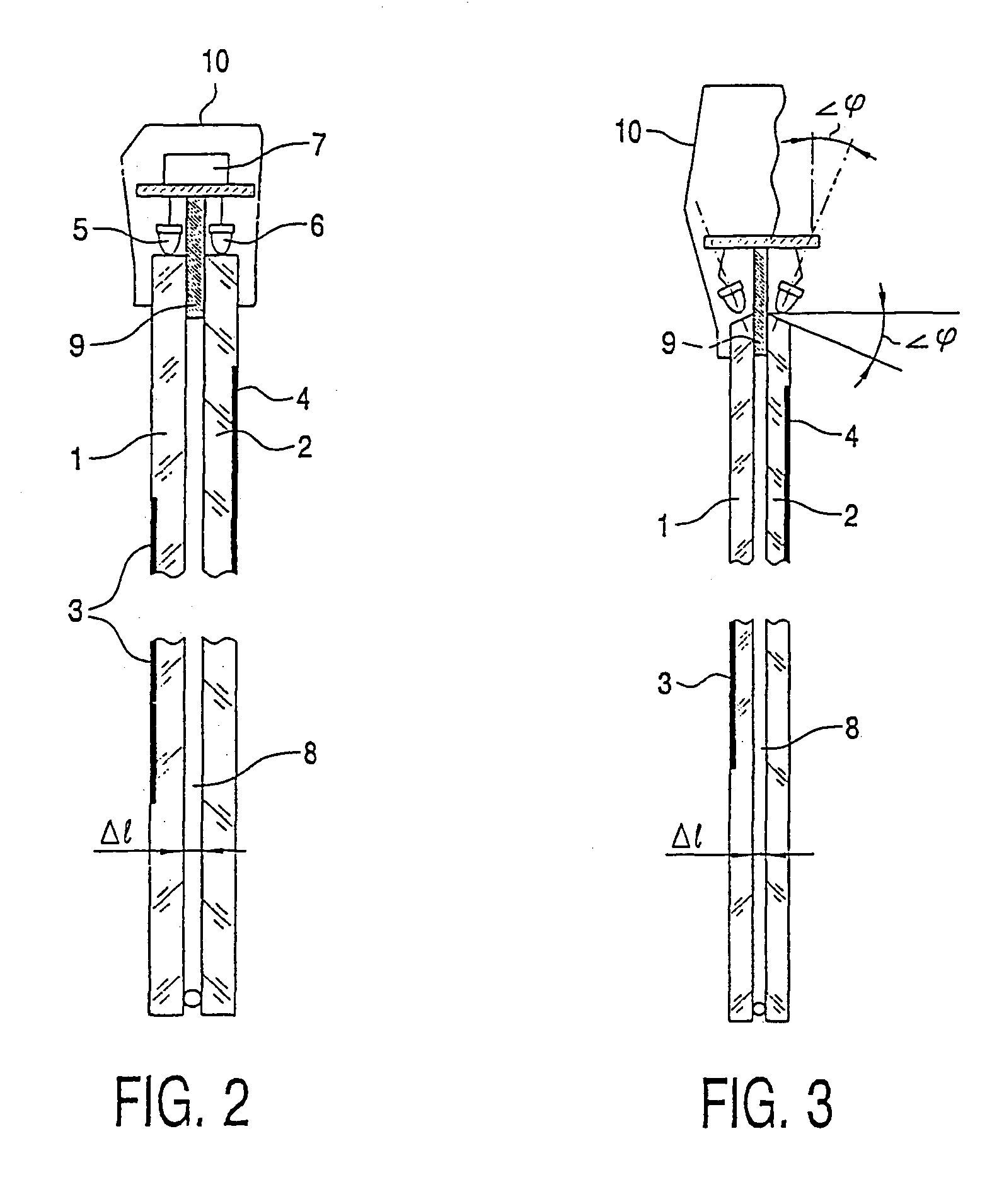

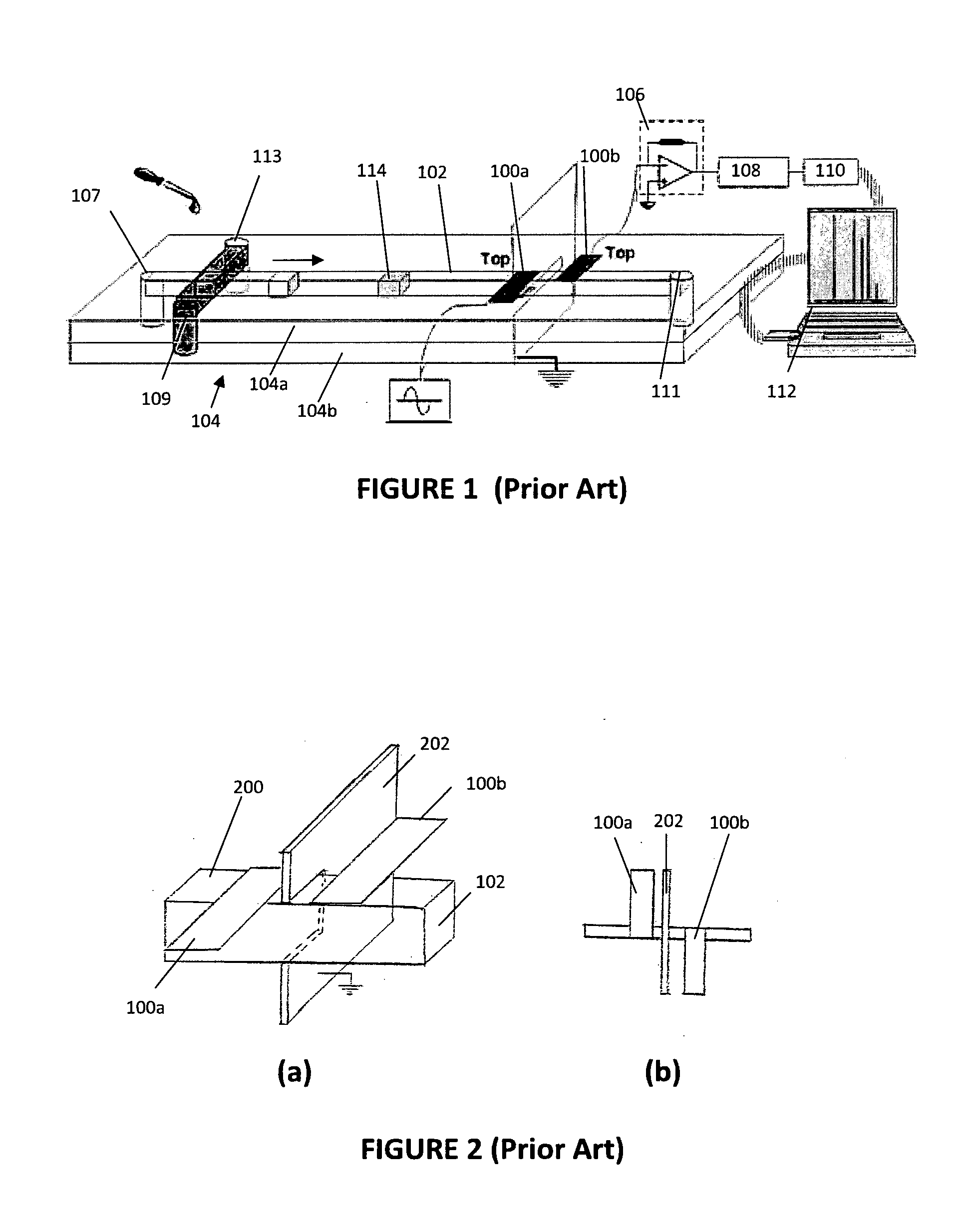

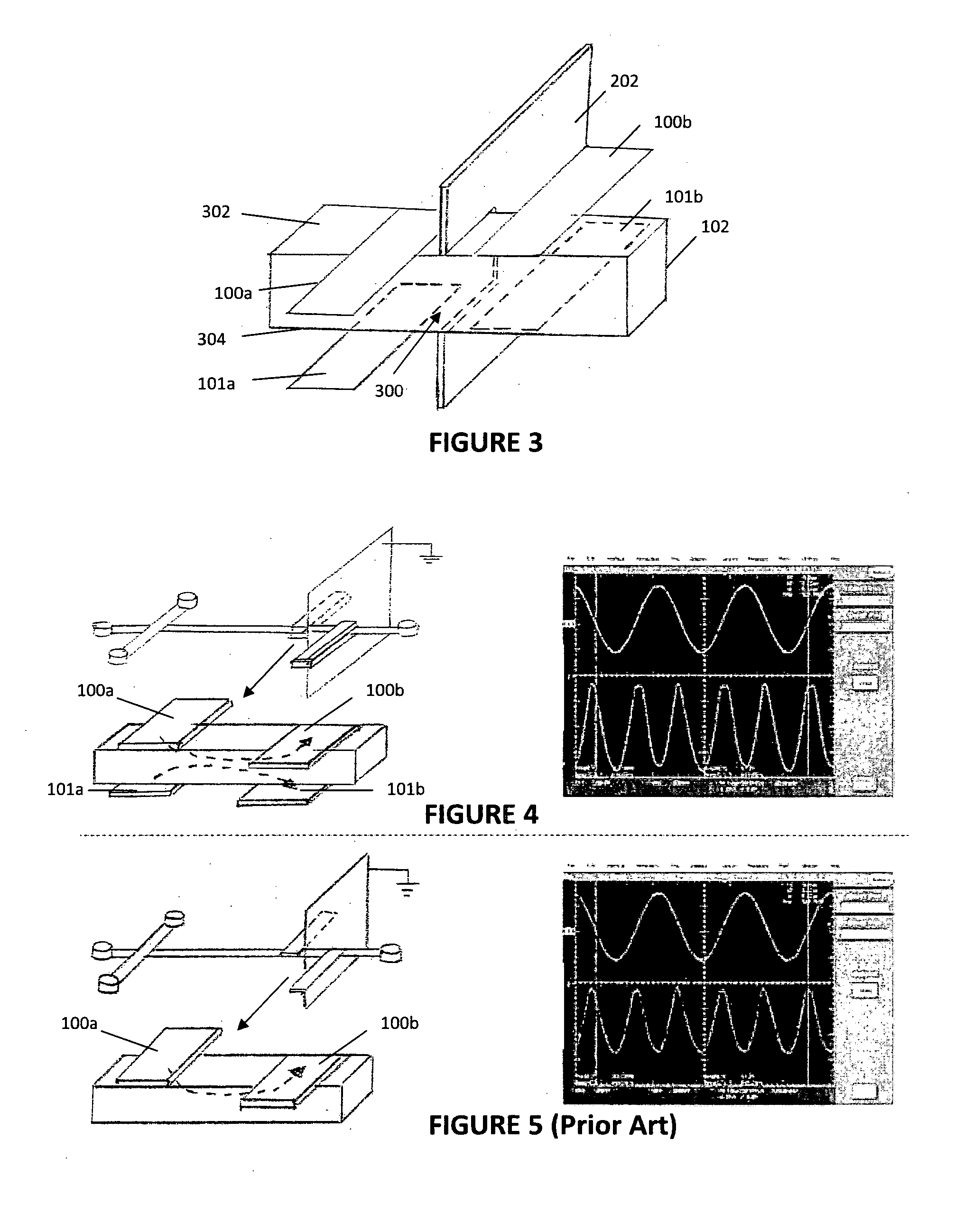

Low temperature, atmospheric pressure plasma generation and applications

InactiveUS20060156983A1Efficient couplingReduce power inputSemiconductor/solid-state device manufacturingDisinfectionEtchingHigh frequency power

Devices and methods for generating a low temperature atmospheric pressure plasma are disclosed. A method of generating a low temperature atmospheric pressure plasma that comprises coupling a high-frequency power supply to a tuning network that is connected to one or more electrodes, placing one or more non-conducting housings between the electrodes, flowing gas through the one or more housings, and striking and maintaining the plasma with the application of said high-frequency power is described. A technique for the surface treatment of materials with said low temperature atmospheric pressure plasma, including surface activation, cleaning, sterilization, etching and deposition of thin films is also disclosed.

Owner:SURFX TECH

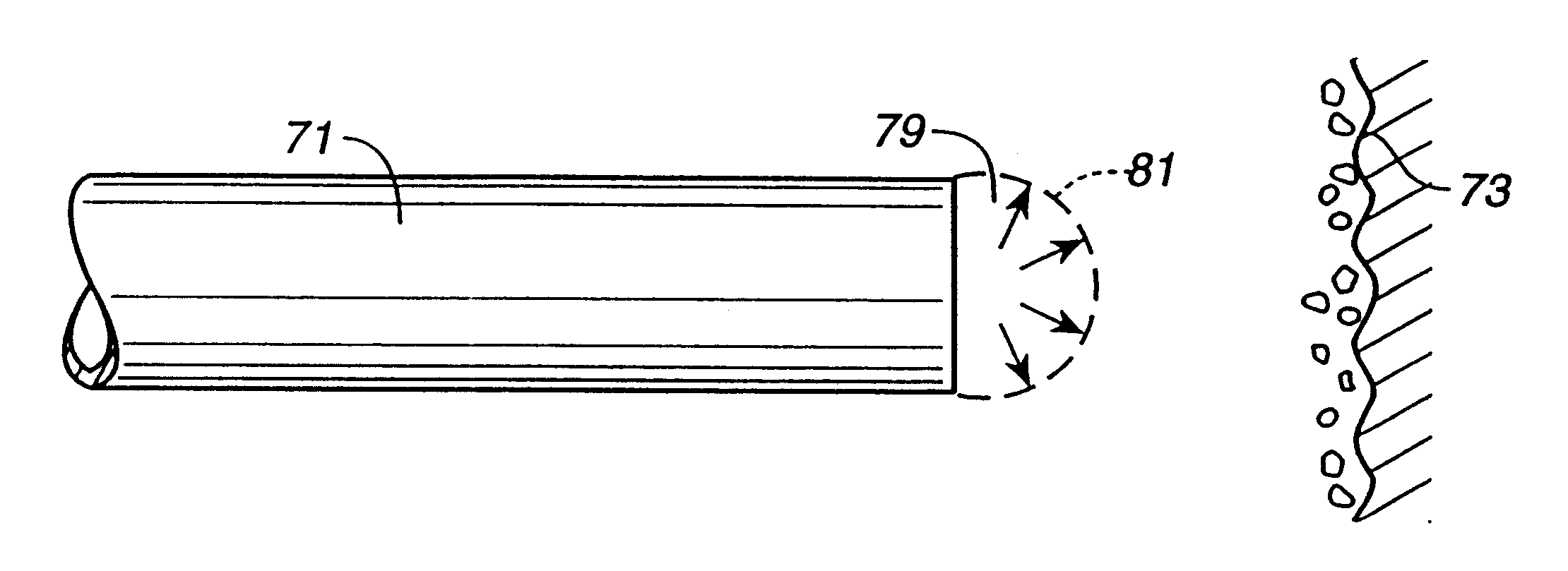

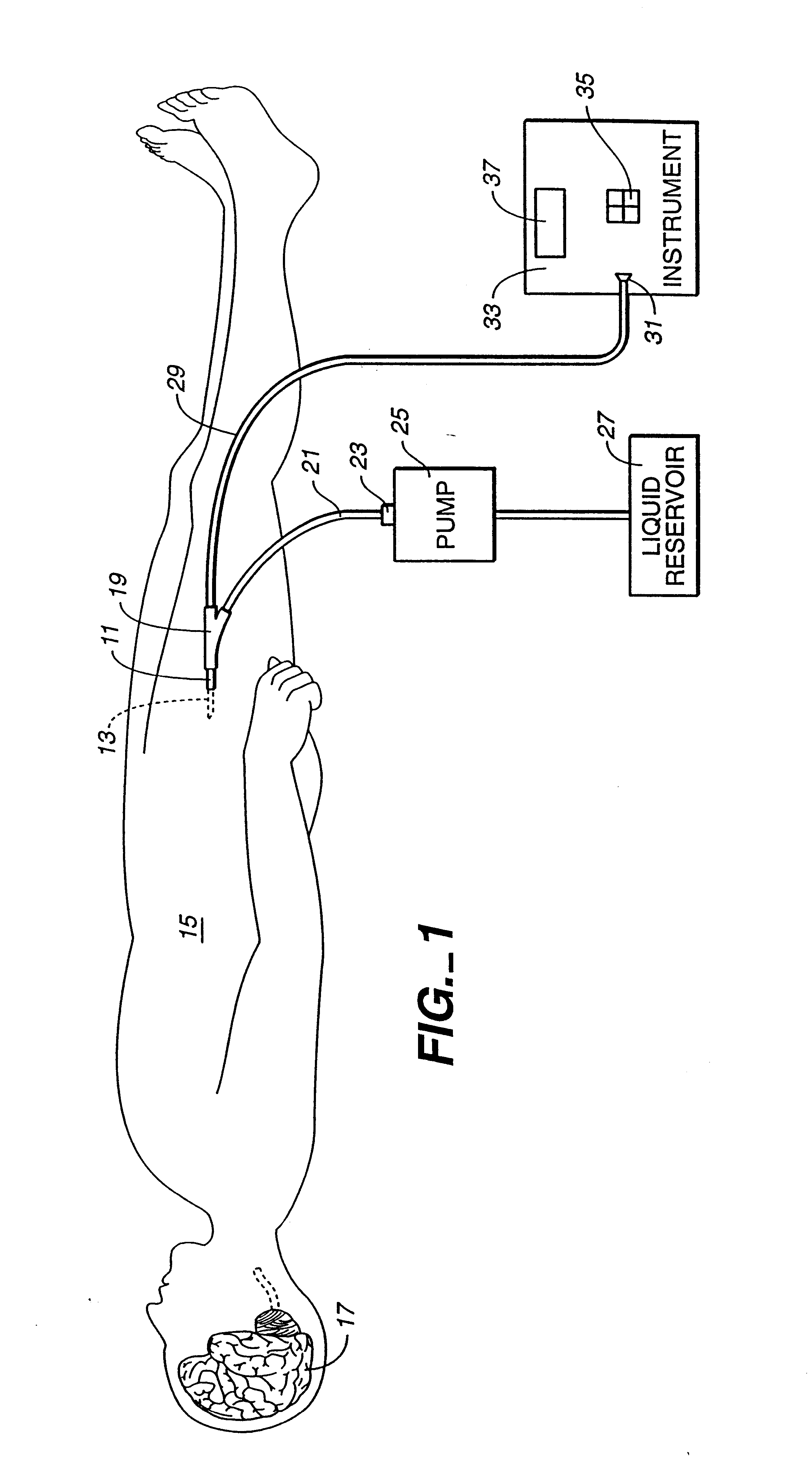

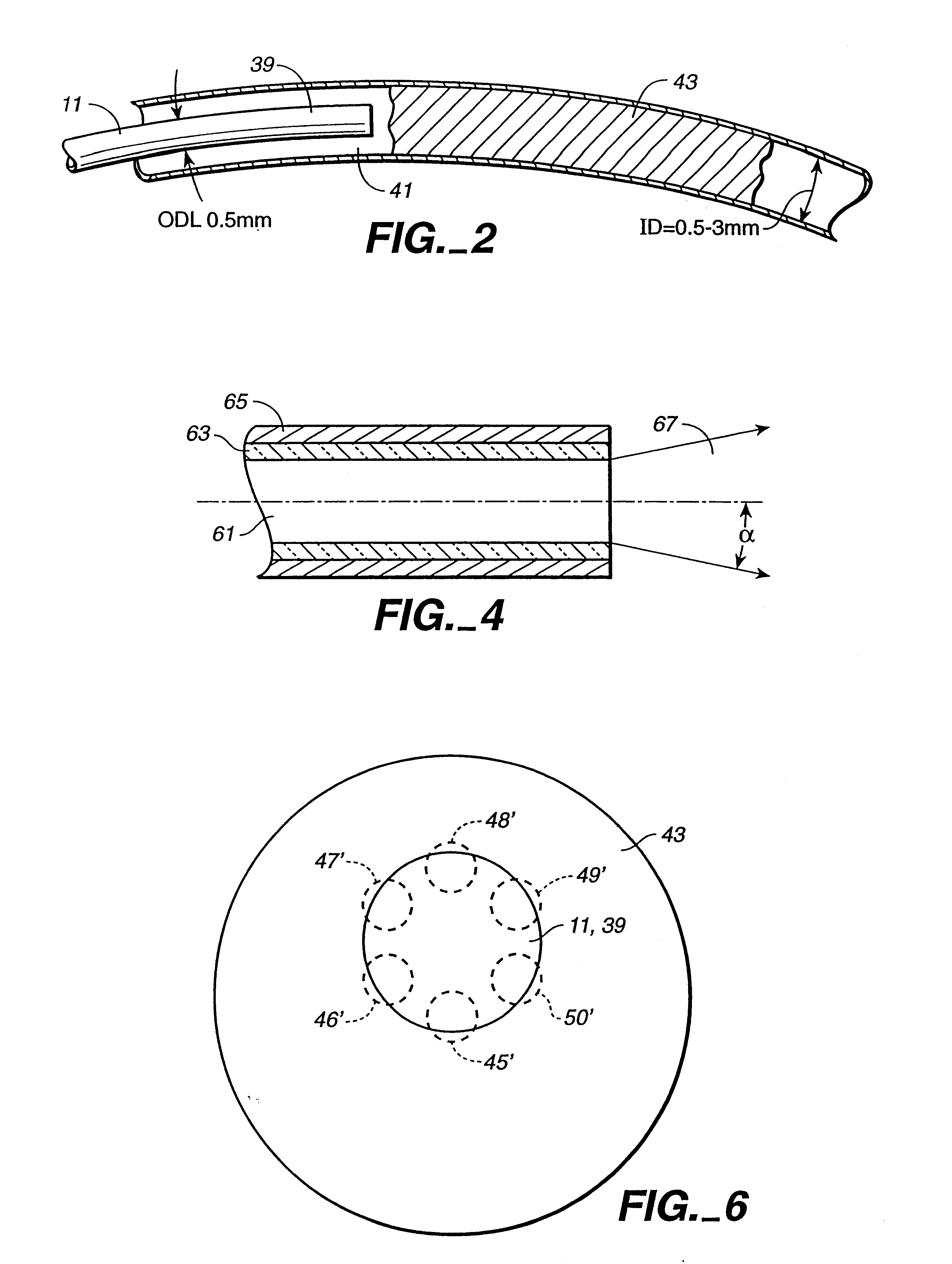

Photoacoustic removal of occlusions from blood vessels

Partial or total occlusions of fluid passages within the human body are removed by positioning an array of optical fibers in the passage and directing treatment radiation pulses along the fibers, one at a time, to generate a shock wave and hydrodynamic flows that strike and emulsify the occlusions. A preferred application is the removal of blood clots (thrombi and emboli) from small cerebral vessels to reverse the effects of an ischemic stroke. The operating parameters and techniques are chosen to minimize the amount of heating of the fragile cerebral vessel walls occurring during this photoacoustic treatment. One such technique is the optical monitoring of the existence of hydrodynamic flow generating vapor bubbles when they are expected to occur and stopping the heat generating pulses propagated along an optical fiber that is not generating such bubbles.

Owner:SELVA MEDICAL +2

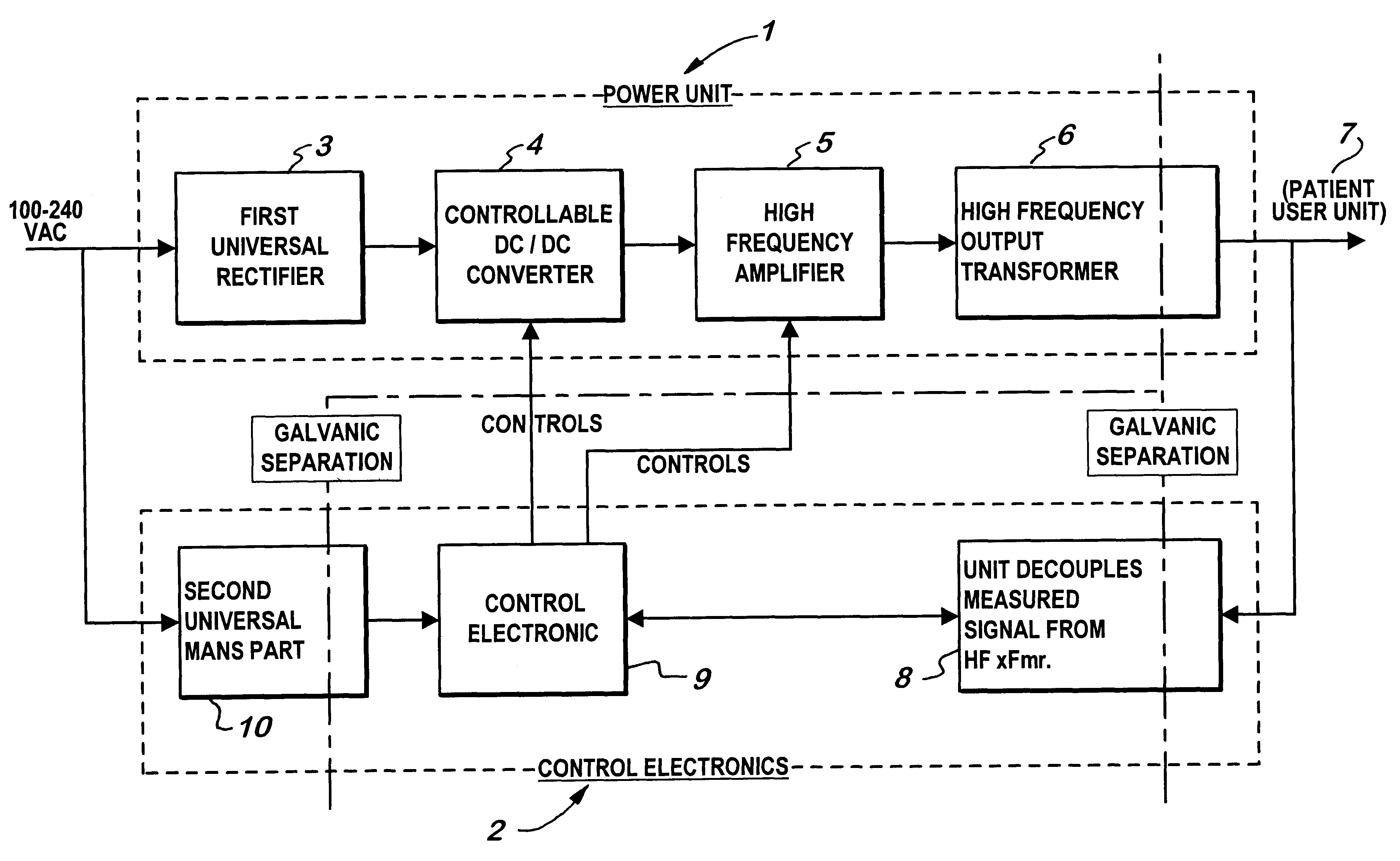

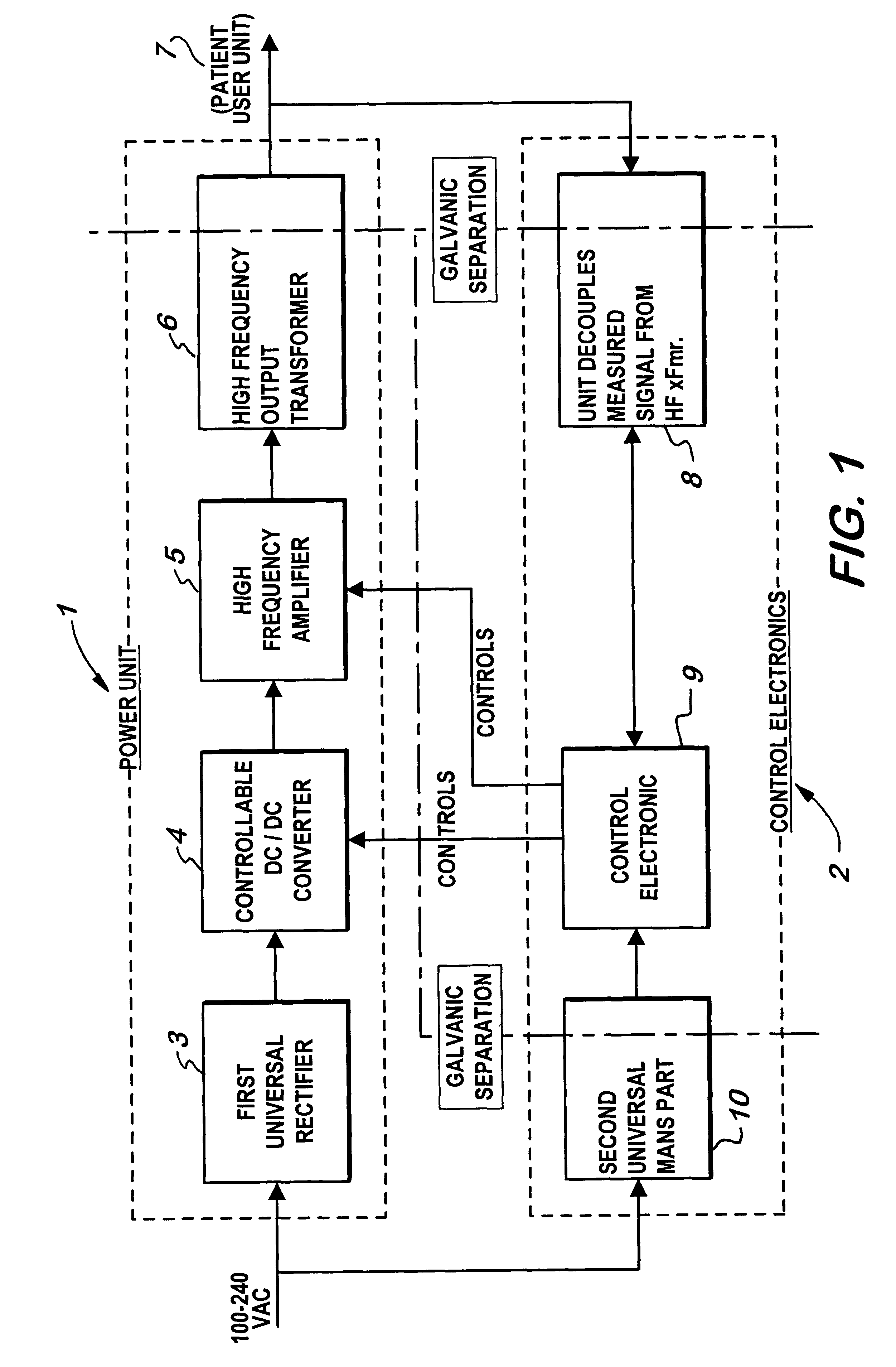

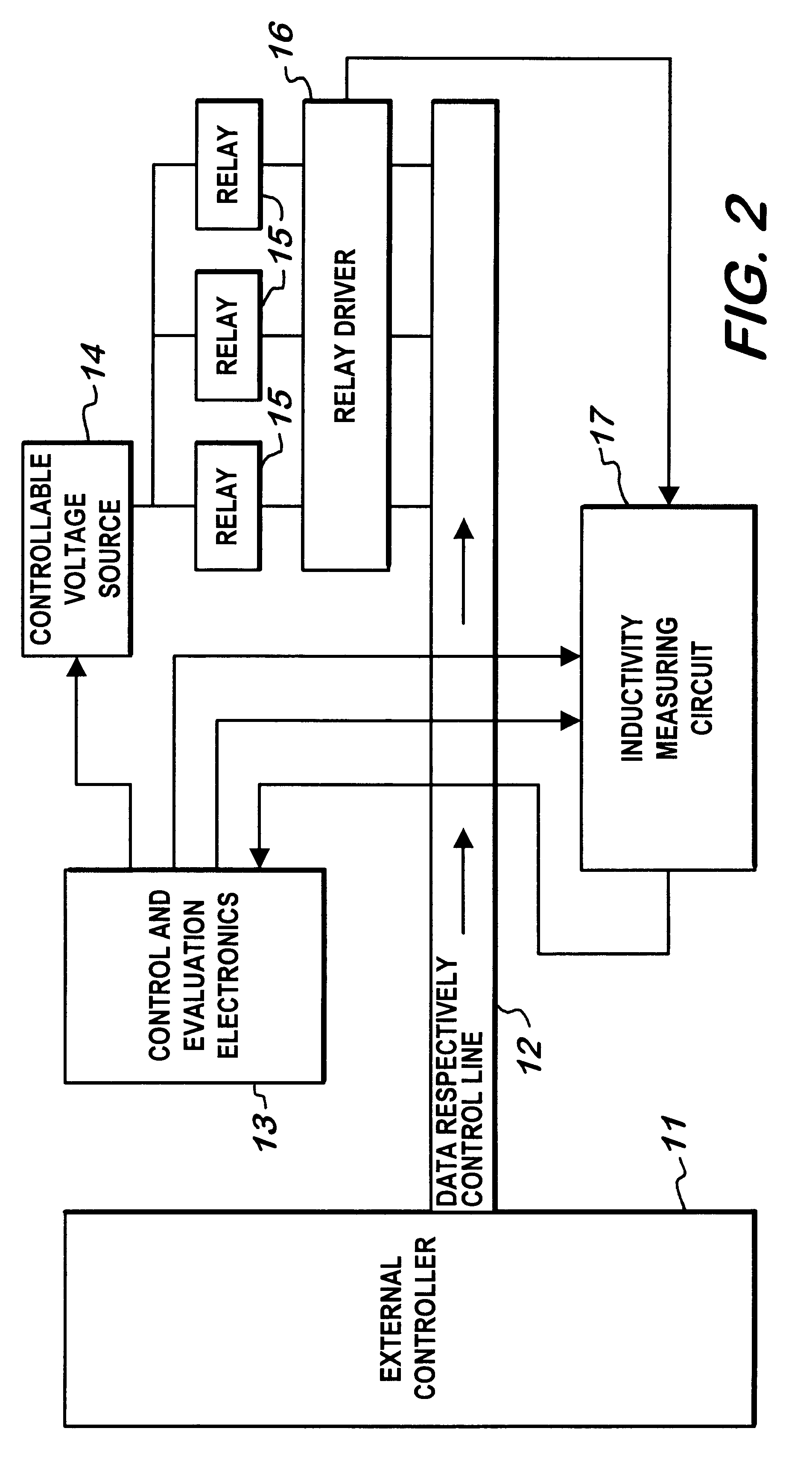

High-frequency surgical device and operation monitoring device for a high-frequency surgical device

InactiveUS6261285B1Reduce power inputSafer designSurgical instruments for heatingControl electronicsTransformer

A high-frequency surgical device encompassing control electronics that control a power unit which utilizes a high-frequency transformer that is the only galvanic separation between the supply voltage and the patient / user unit.

Owner:STORZ ENDOSKOP

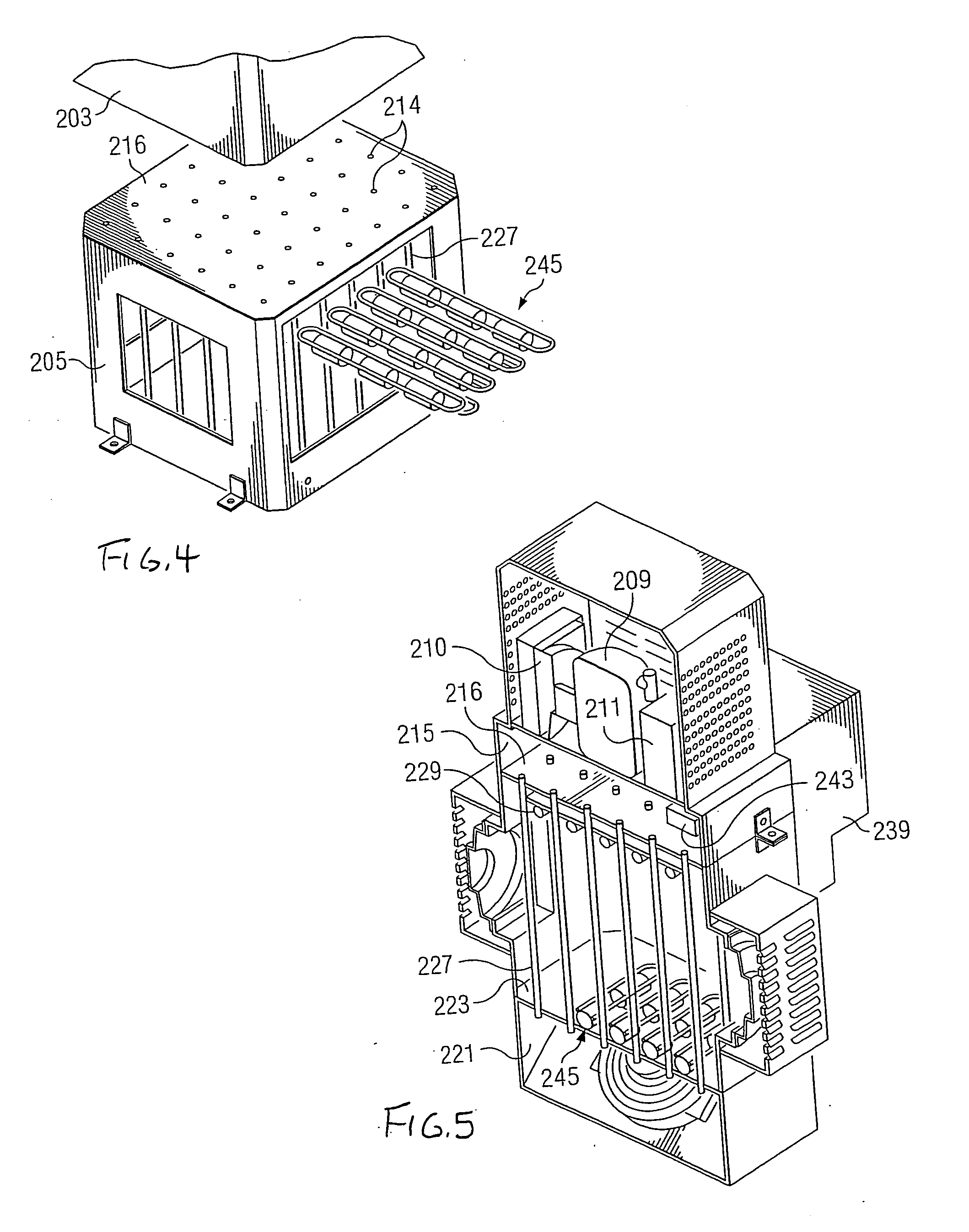

Method and apparatus for generating drinking water by condensing air humidity

InactiveUS20070175234A1Efficient workIdeal for useSteam/vapor condensersStationary conduit assembliesElectricityRural location

A system and method are shown which utilize a hybrid mechanical and evaporative air conditioning system to produce potable drinking while cooling an enclosure. The system operates on direct current, making it suitable for use in areas effected by natural disaster, power outage, or simply rural locations without access to electricity. The conditioning system includes both evaporative air conditioning and mechanical air conditioning functioning components to produce a water discharge. The system is operated to cool an enclosure. A portion of the water discharge is then drawn off and purified for use as drinking water.

Owner:GPM INC

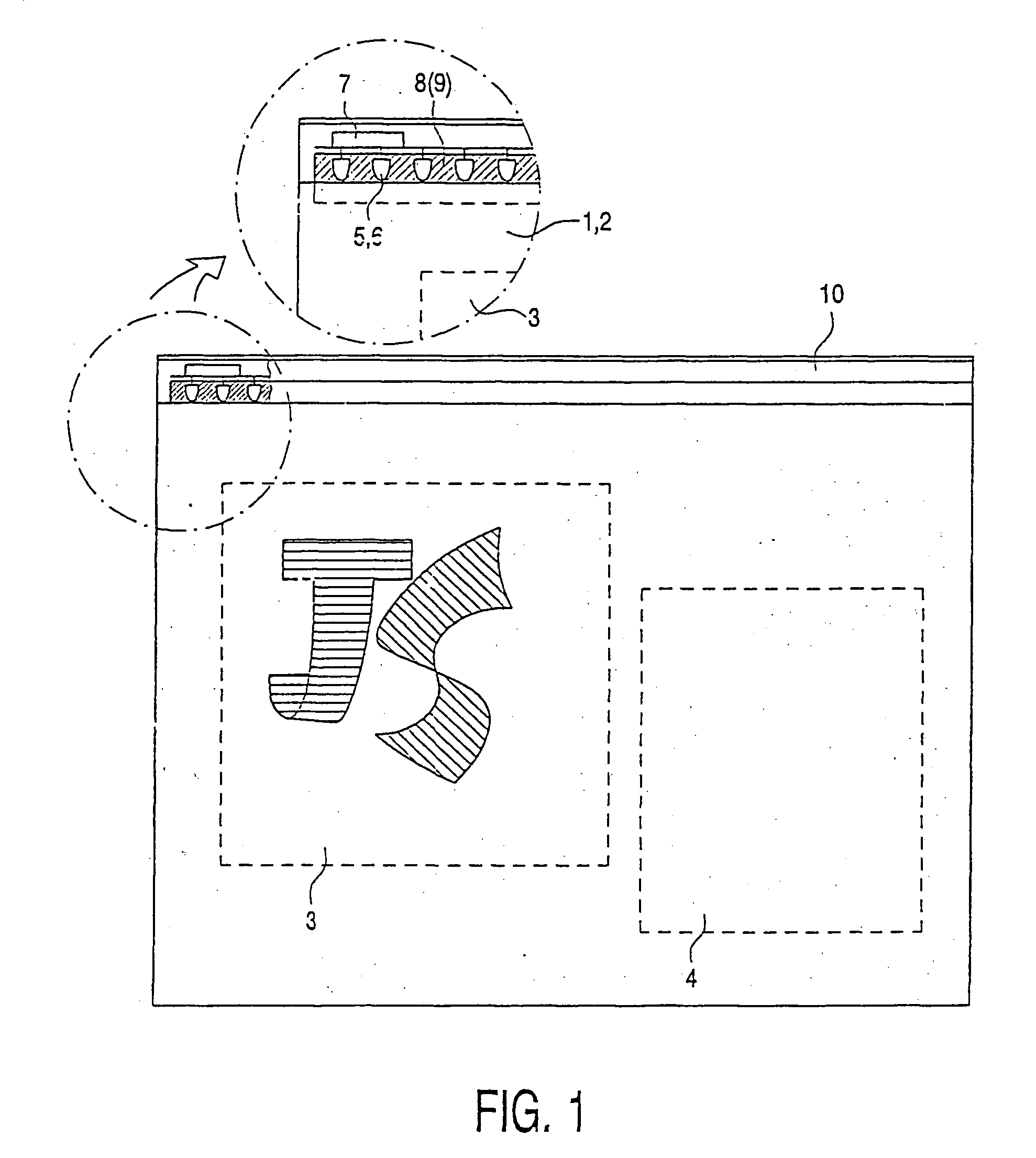

Data display device

InactiveUS7246932B2Enhanced informationEfficient illuminationMechanical apparatusMeasurement apparatus componentsData displayLight guide

A data display device including a light-guide element made of an optically transparent material having at least two polished surfaces faced to one another, whereby at least one surface contains at least one gravure forming a diffuse-reflective character, and a light source arranged close to the light-guide element to illuminate said character.

Owner:ESTRAKON

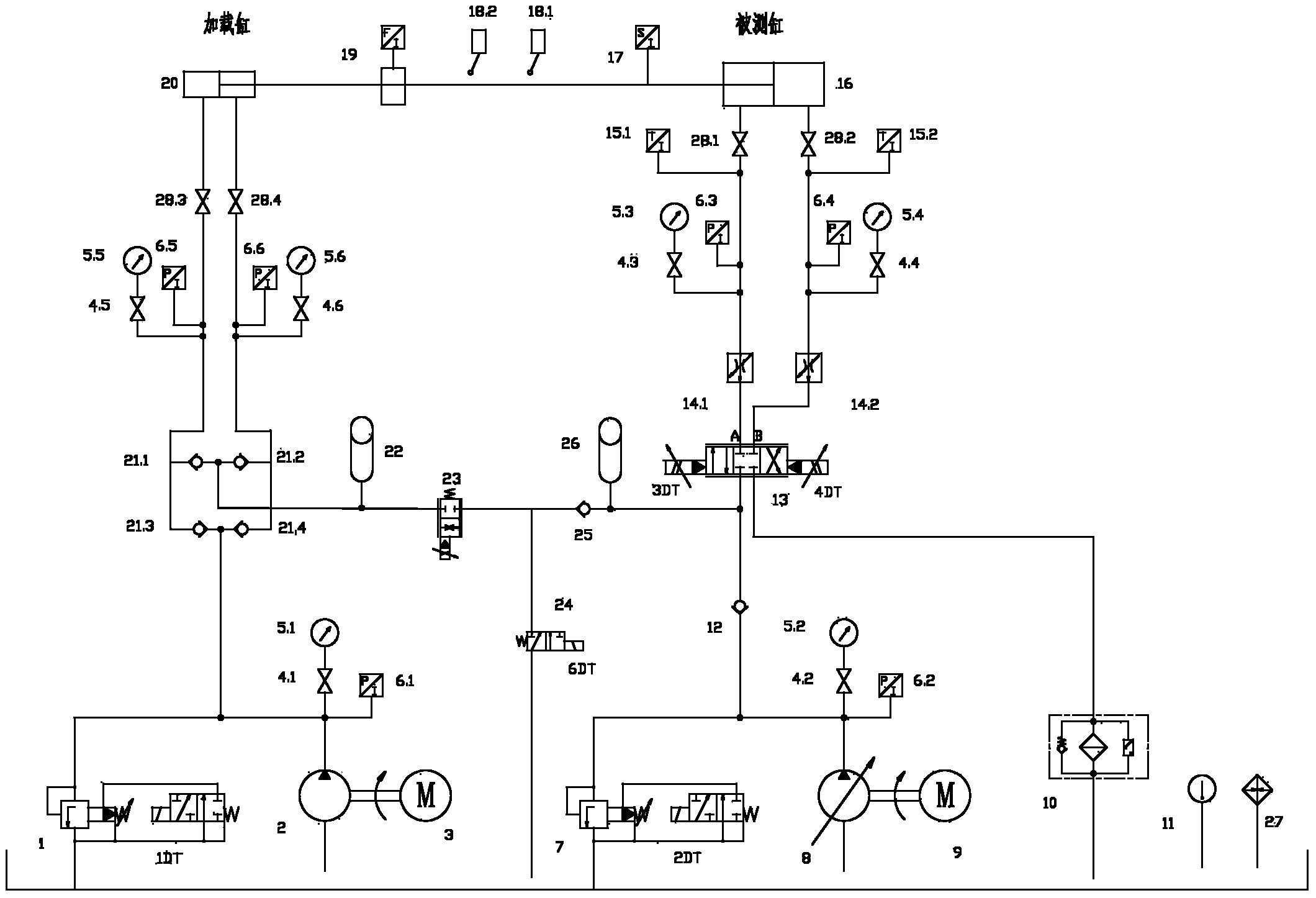

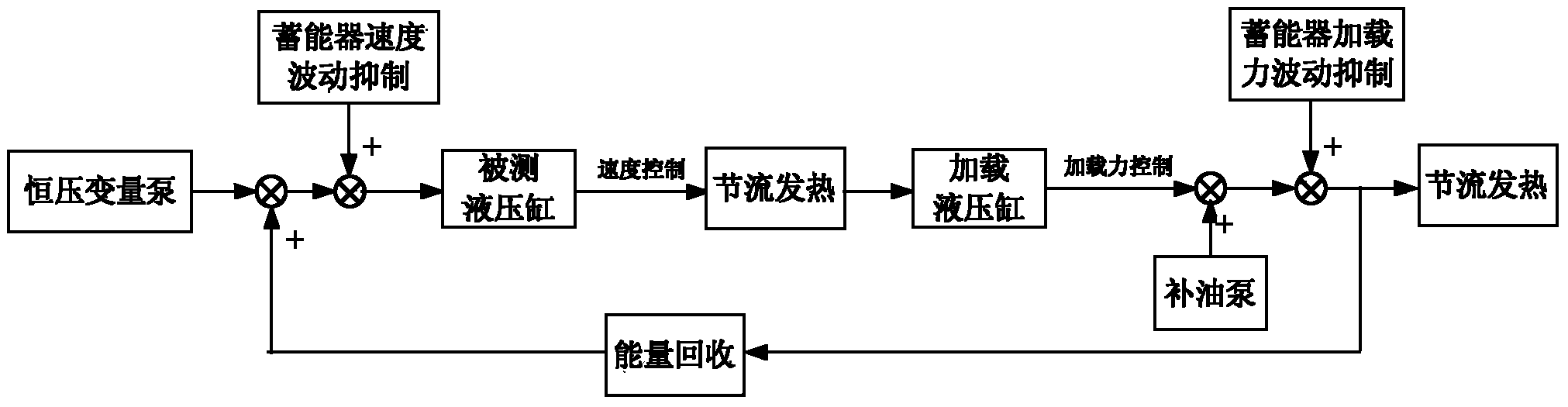

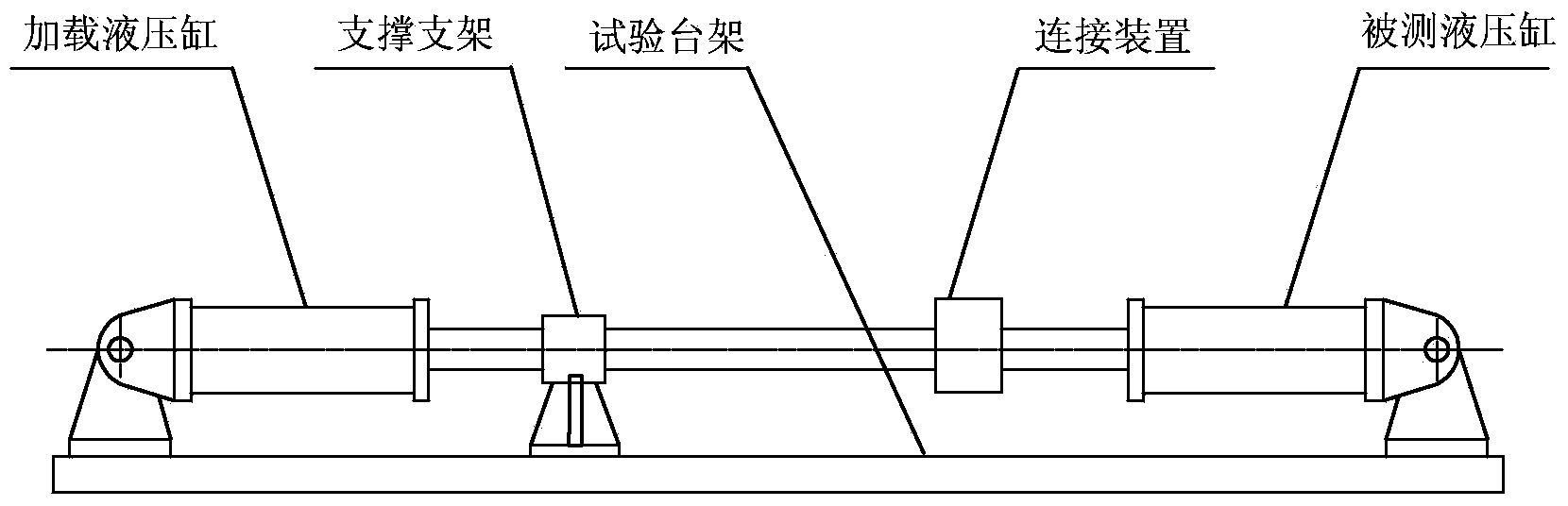

Energy-conservation and low-impact hydraulic cylinder test testbed hydraulic control system

InactiveCN103644151AStable energyRealize full working condition simulationFluid-pressure actuator testingLiquid temperatureFuel tank

The invention discloses an energy-conservation and low-impact hydraulic cylinder test testbed hydraulic control system. The system comprises a constant pressure variable pump, two electromotors, two electromagnetic unloading overflow valves, six check valves, two energy accumulators, an electrohydraulic proportional direction valve, two speed regulating valves, four ball valves, an oil supplementing pump, a proportional throttle valve, an electromagnetic reversing valve, a loading hydraulic cylinder, six pressure sensors, two temperature sensors, a displacement sensor, a force sensor, two travel switches, six pressure measuring connectors, six pressure gages, a heater, a liquid level liquid temperature gage, a filter and an oil tank. The energy-conservation and low-impact hydraulic cylinder test testbed hydraulic control system has the advantages that stable energy is provided for low-impact control over the speed of a tested hydraulic cylinder while energy is conserved, low-impact stable control over the loading force is achieved, meanwhile, the actual work condition that loads of the hydraulic cylinder probably change continuously in work can be simulated, all the work conditions of the loads of the hydraulic cylinder can be simulated, and power input is reduced.

Owner:YANSHAN UNIV

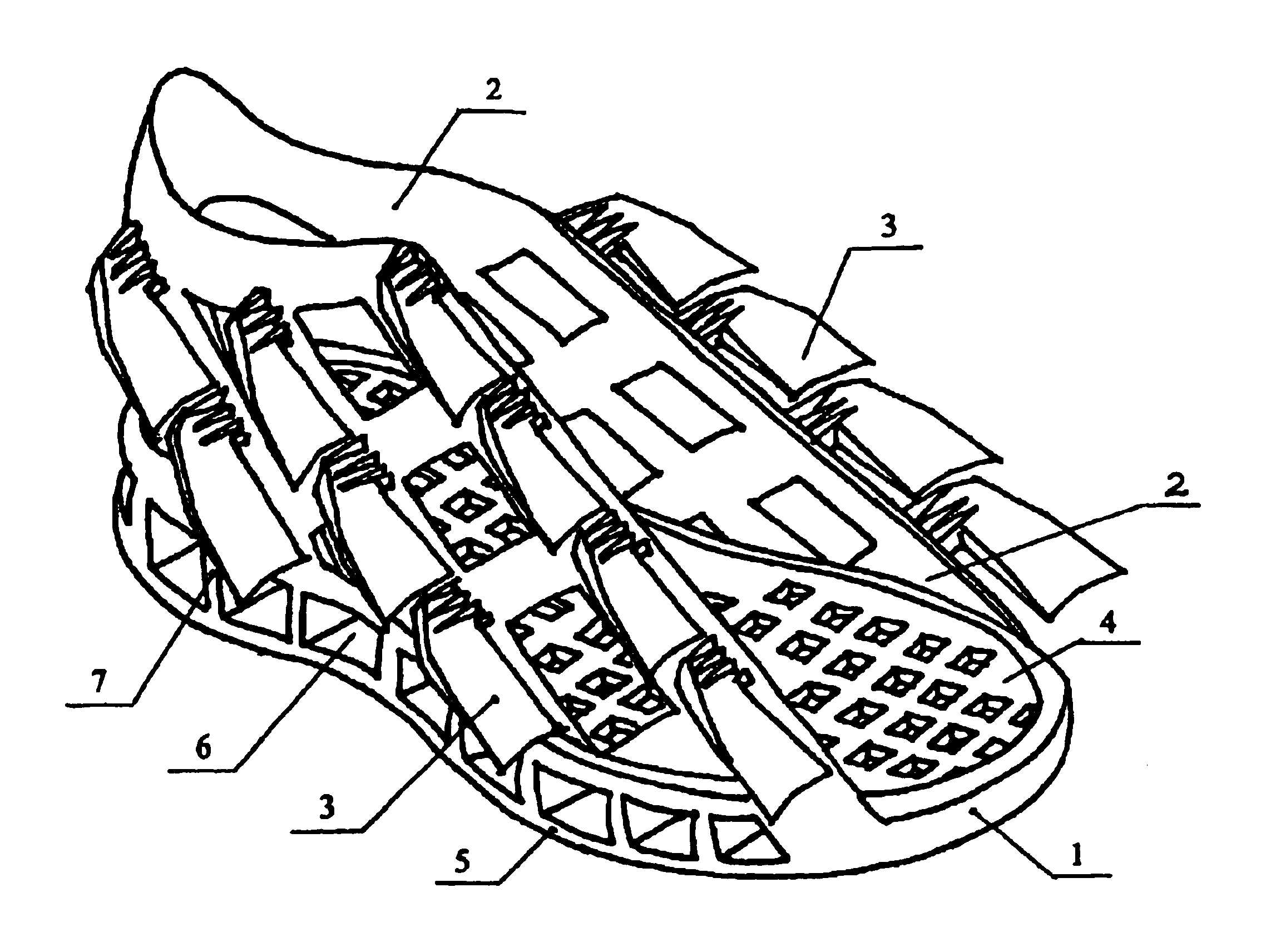

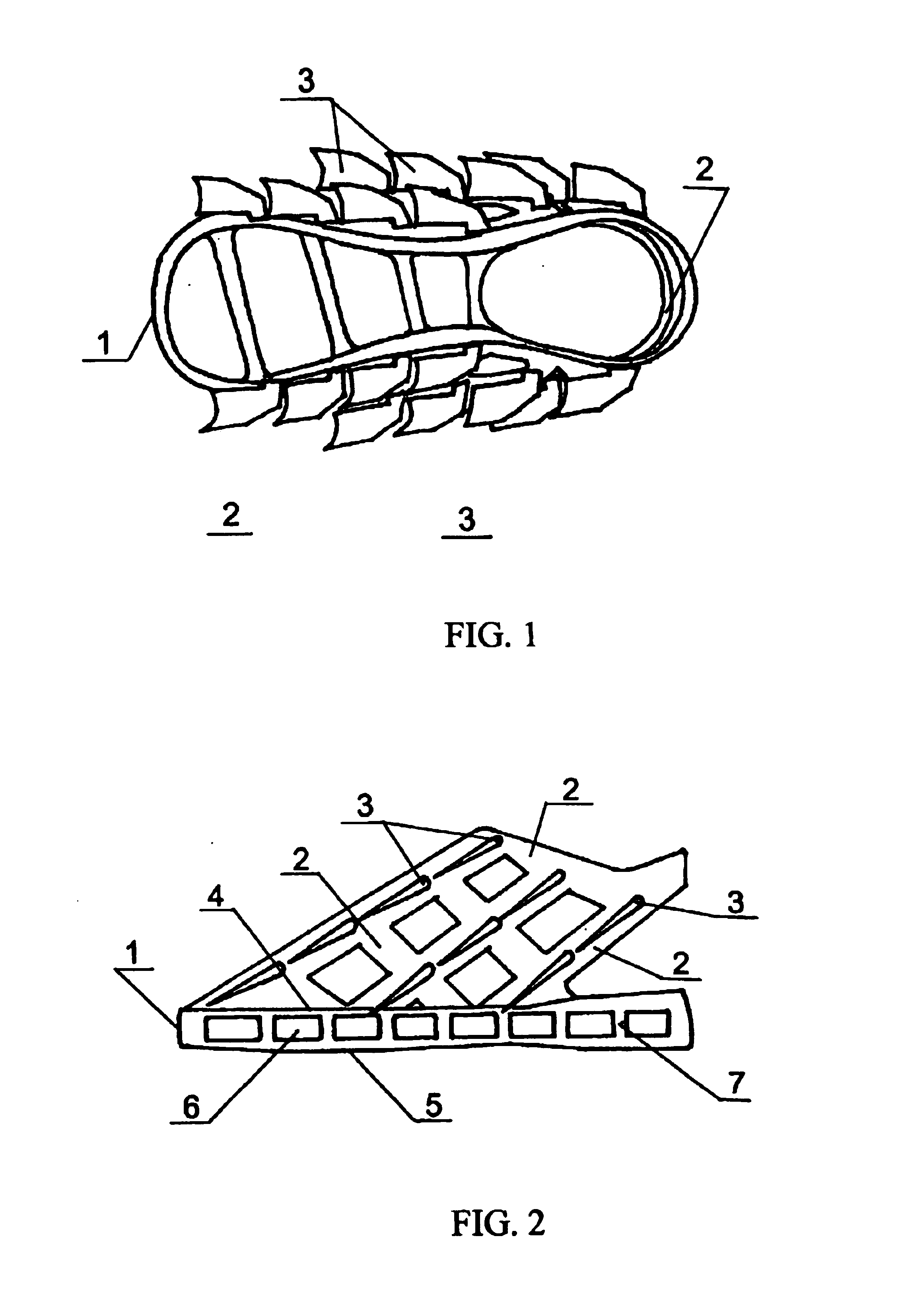

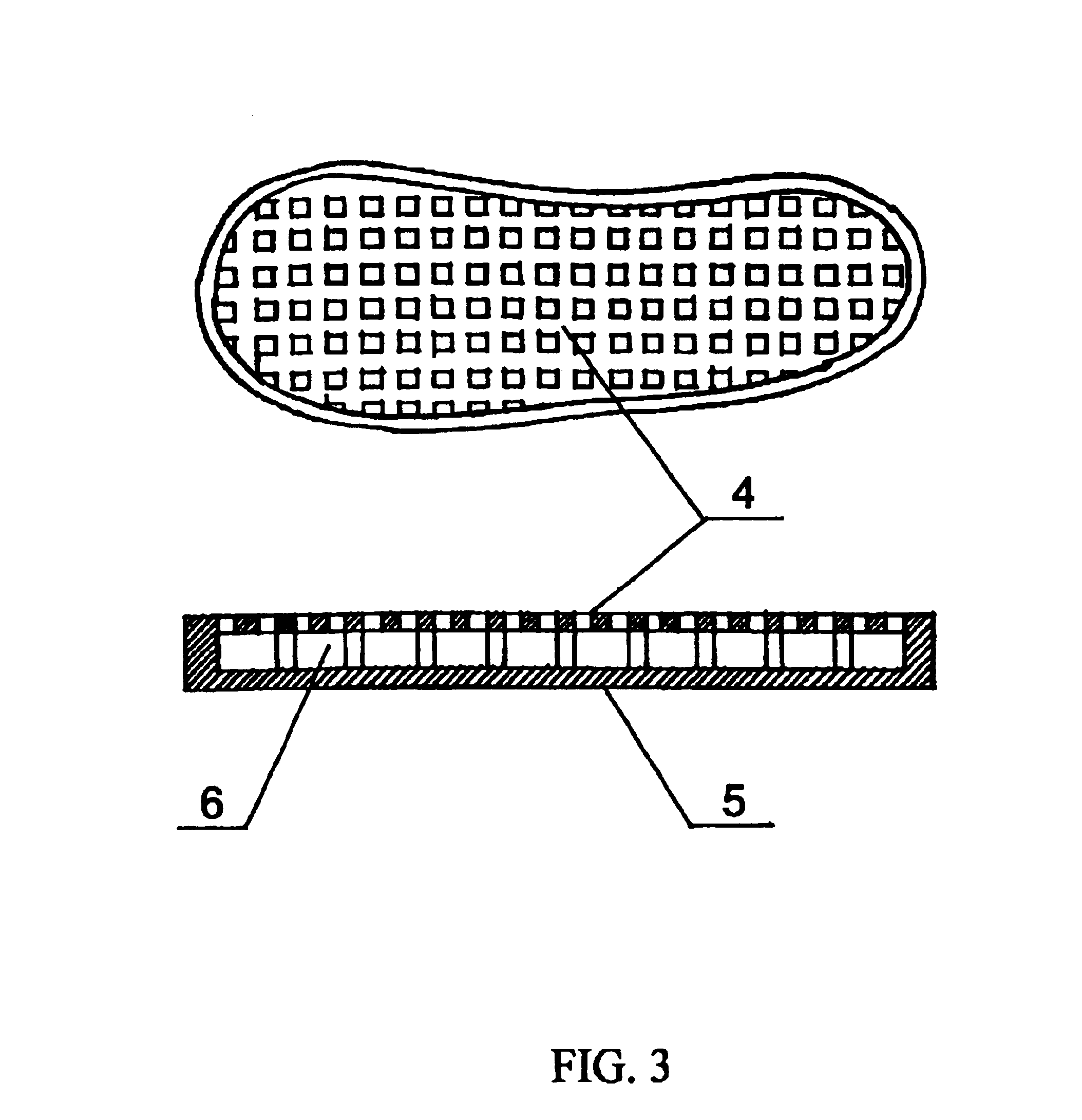

Water shoe

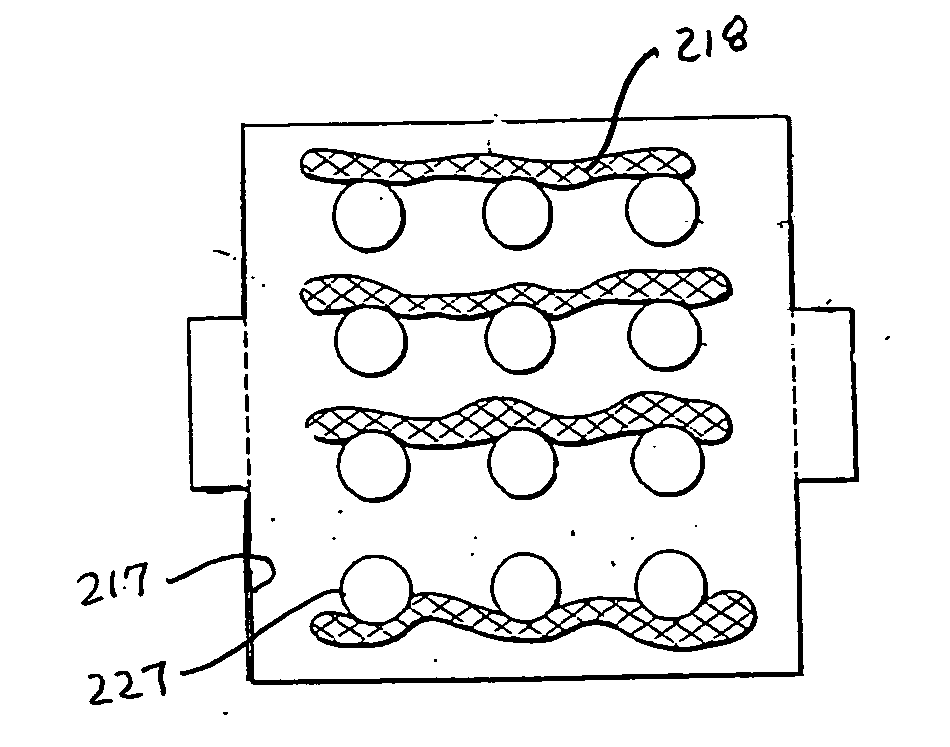

InactiveUS6871420B2Increase ultimate pressureGreat tractionSwim finsFootwearEngineeringTractive force

My invention is unification of shoe and swimming enforcing elements comprising water shoe to assure unconstrained and protected walking and promotion for swimming due to generating of additional tractive force in consequence of foot swimming motions. A flexible slip protected spatial internally partitioned sole, with upper reticulated surface and perforated side wall with outlet holes jointly provide free drainage of water and sand from a shoe upper body. For its turn upper body is also reticulated, of flexible hard enough material fixed on the spatial lower sole. Few ranges of swimming elements, angle shaped fins, are immovably fixed on both lateral sides of the shoe upper body in such away that are paralleled to each other and upper body's top surface.

Owner:SHIKHASHVILI GEORGE

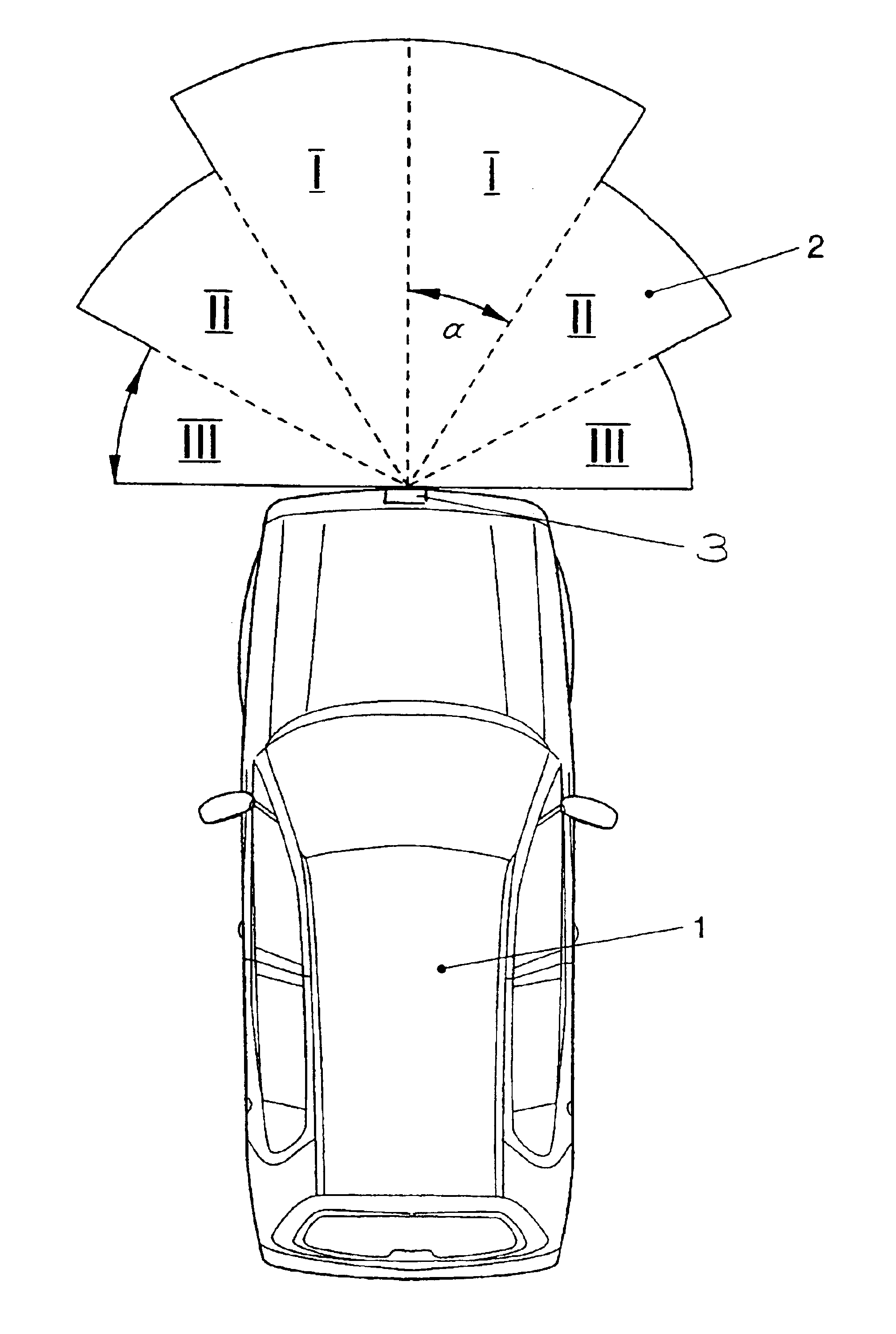

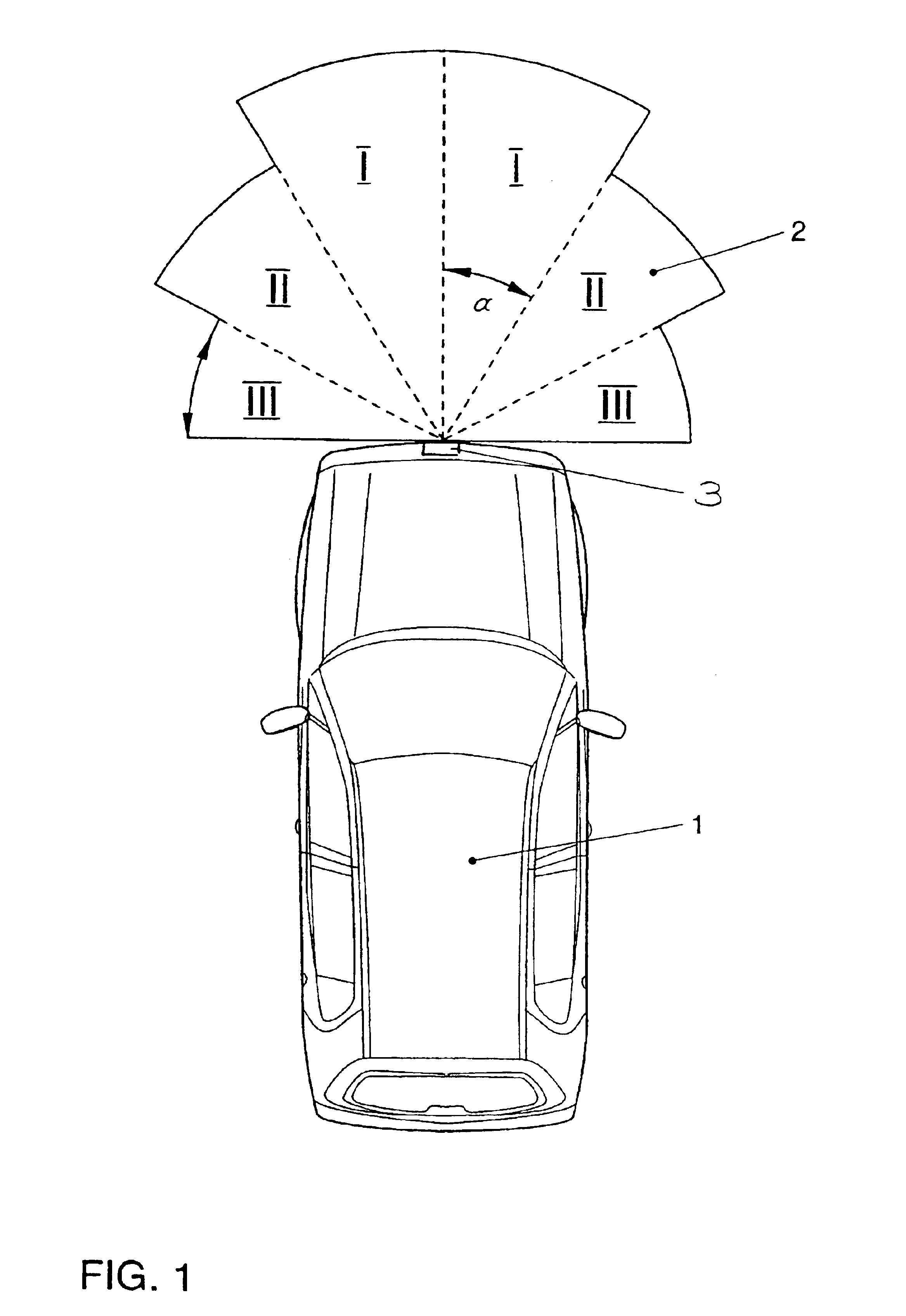

Device with at least one laser sensor and method of operating a laser sensor

InactiveUS6856919B1Extended service lifeImprove securityAnti-collision systemsMaterial analysis by optical meansMobile vehicleOptoelectronics

A device for a motor vehicle includes at least one laser sensor. The laser sensor includes a device configured to sweep a scanning area with at least one laser beam emitted by the laser sensor and a power supply device for the laser sensor. In a method for operating a laser sensor in a scanning area with at least one laser beam, the power of the laser beam emitted by the laser sensor is varied in accordance with its direction of radiation.

Owner:VOLKSWAGEN AG

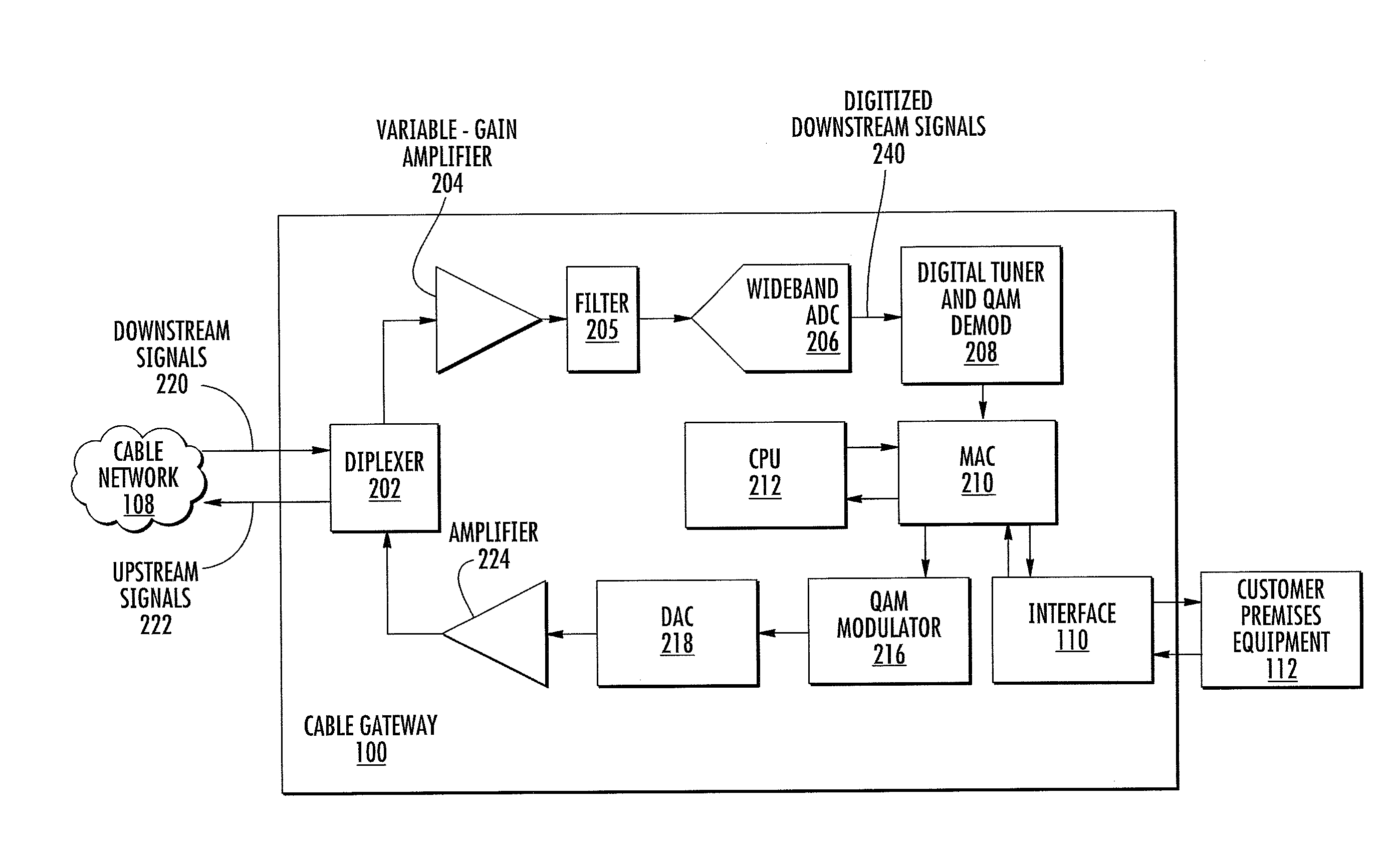

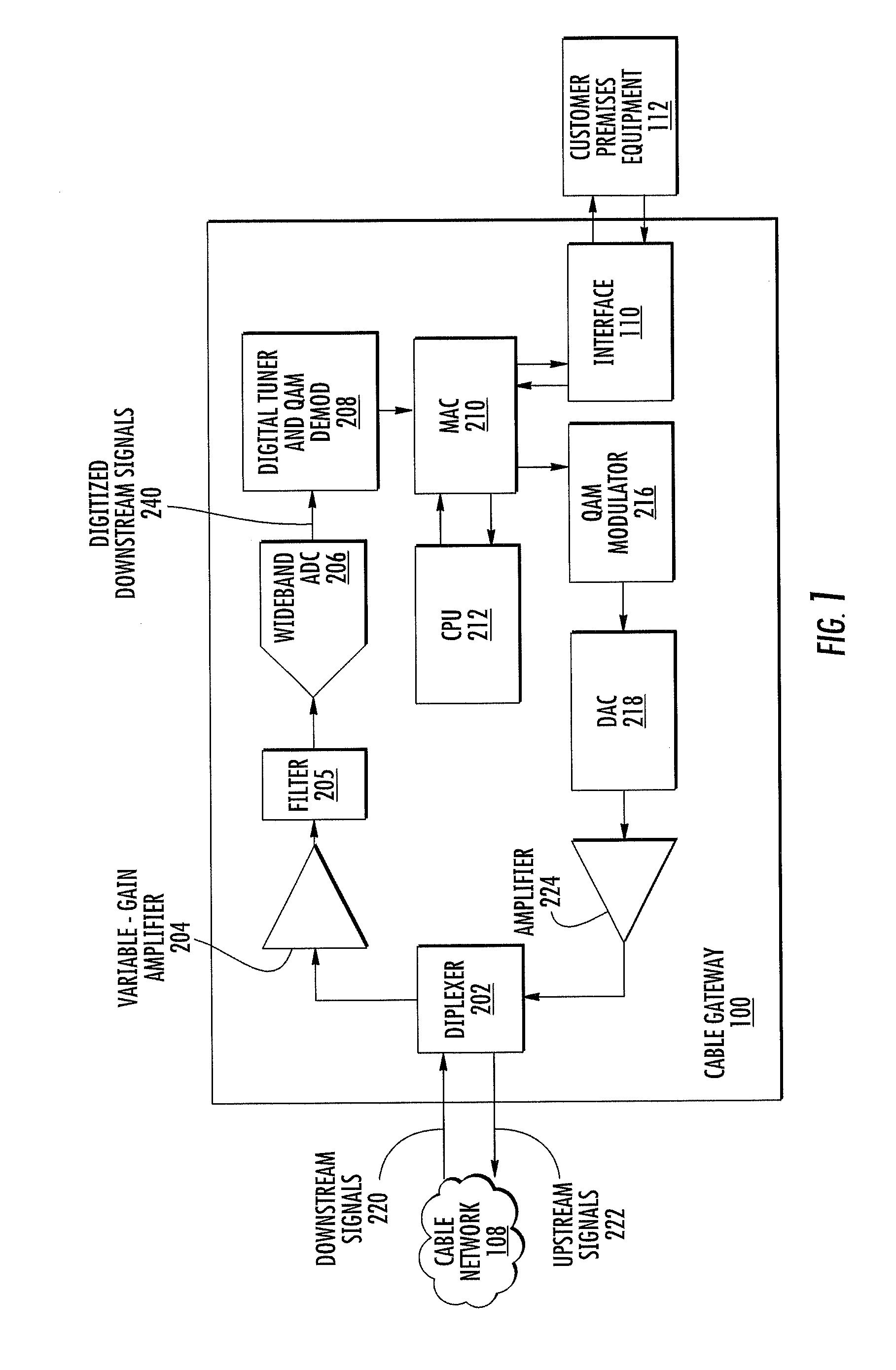

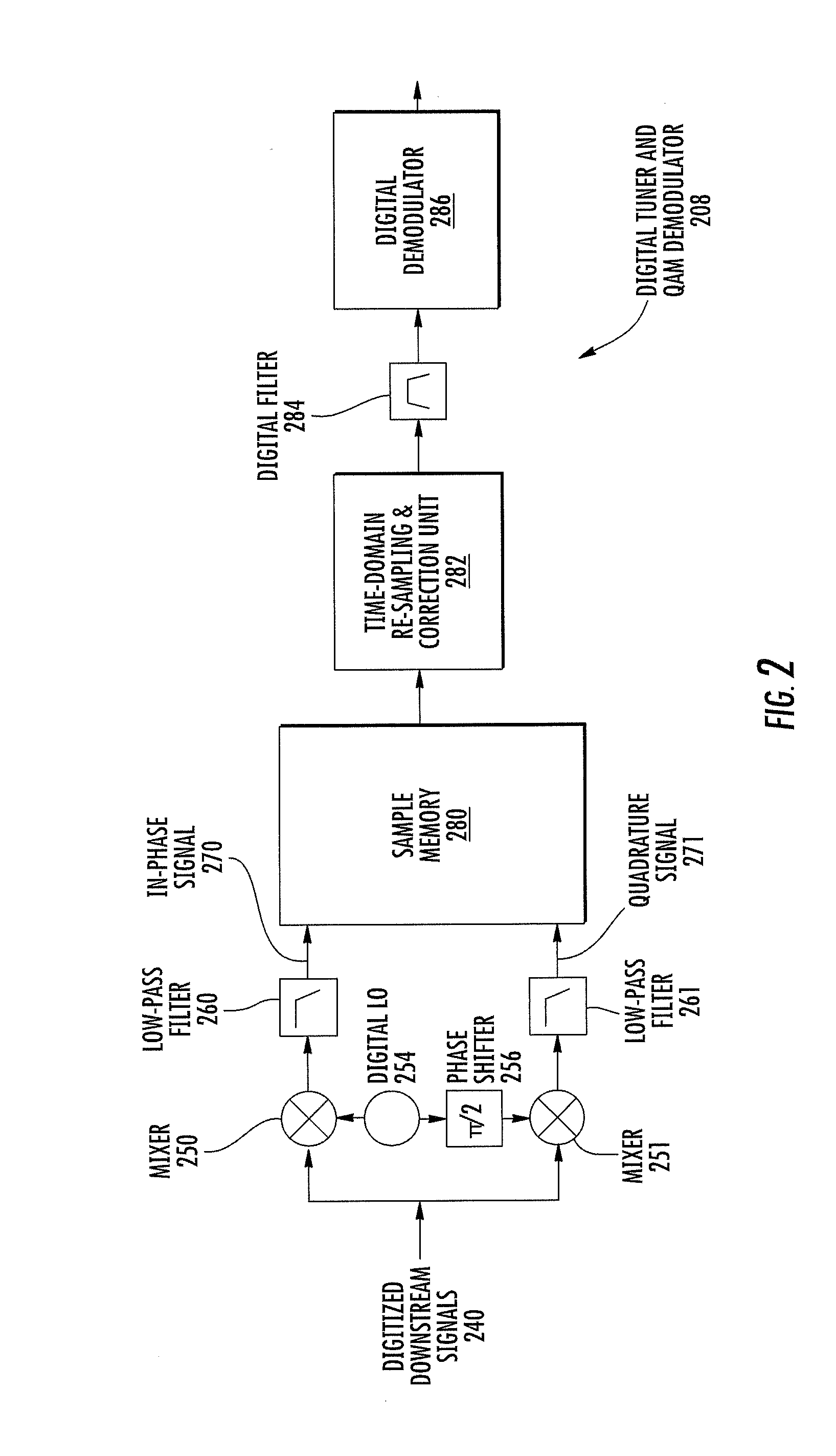

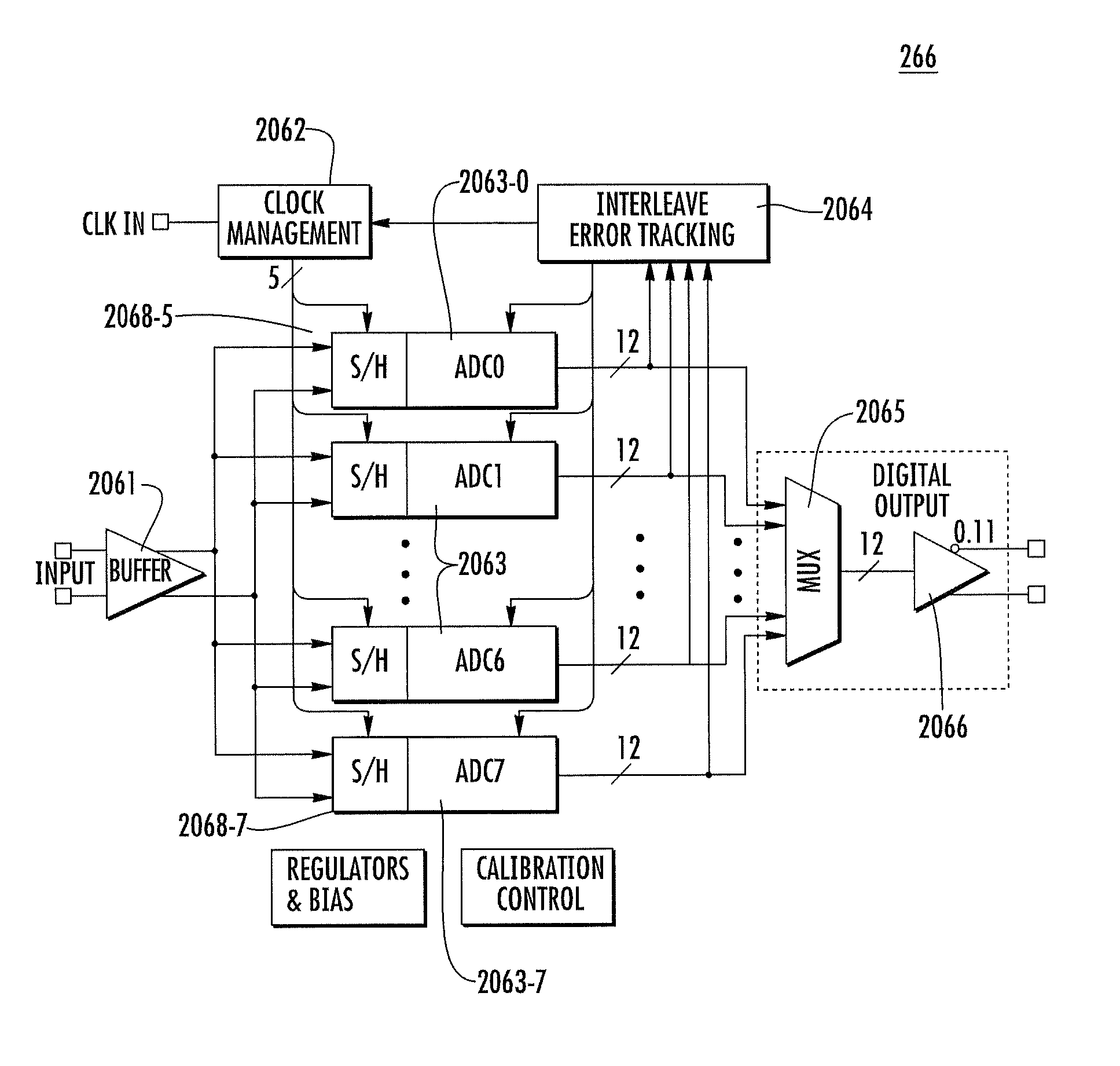

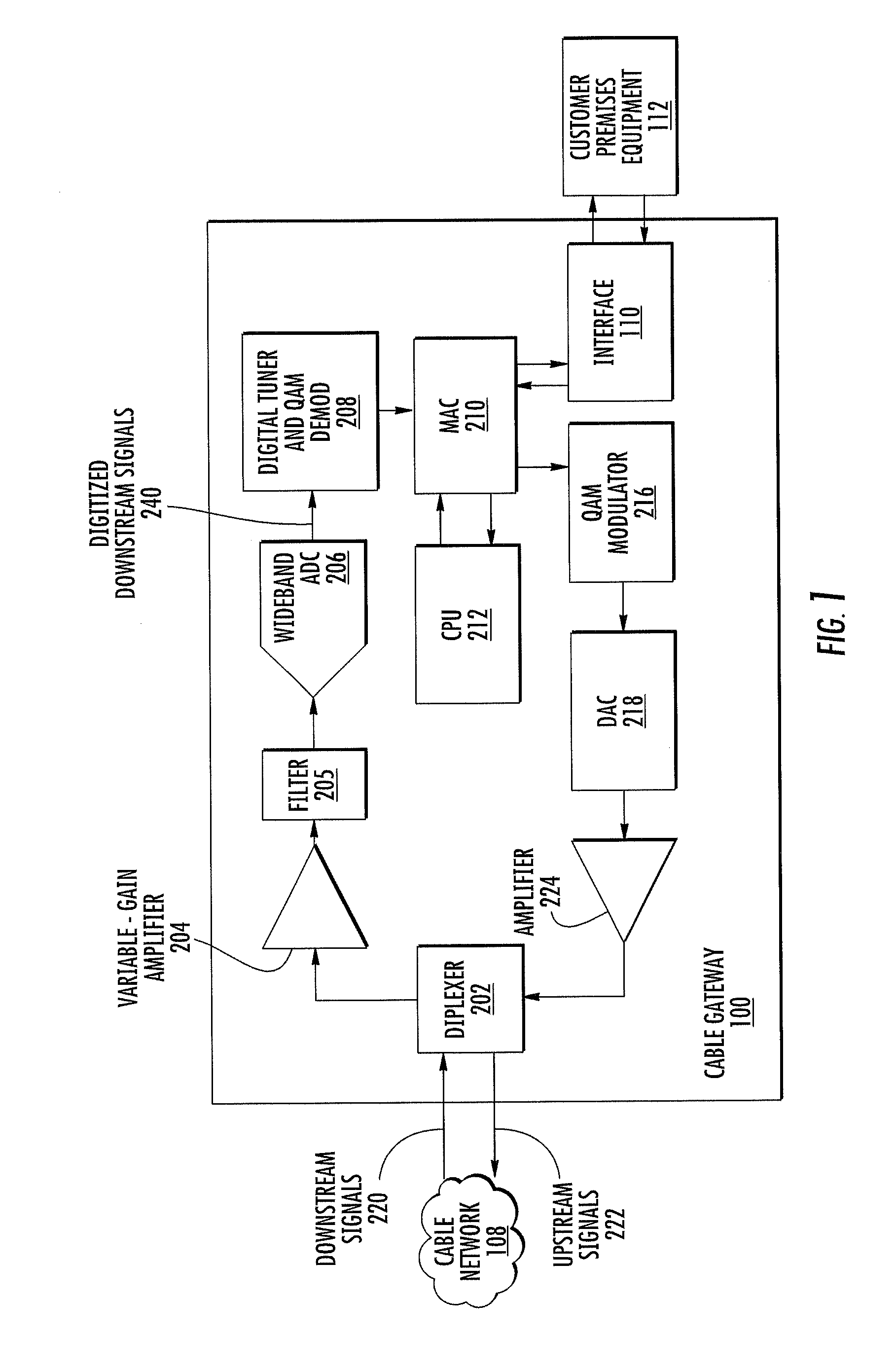

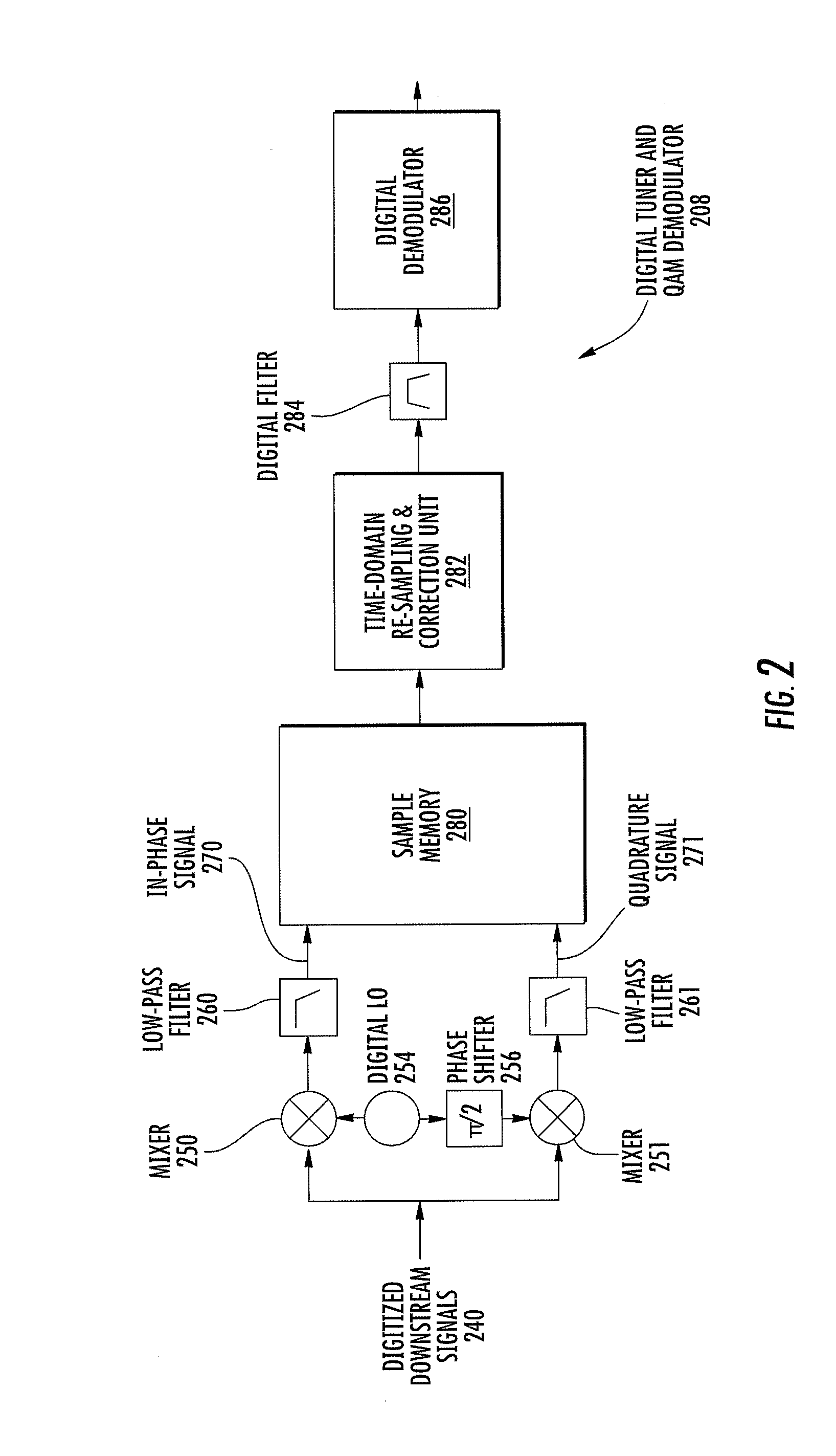

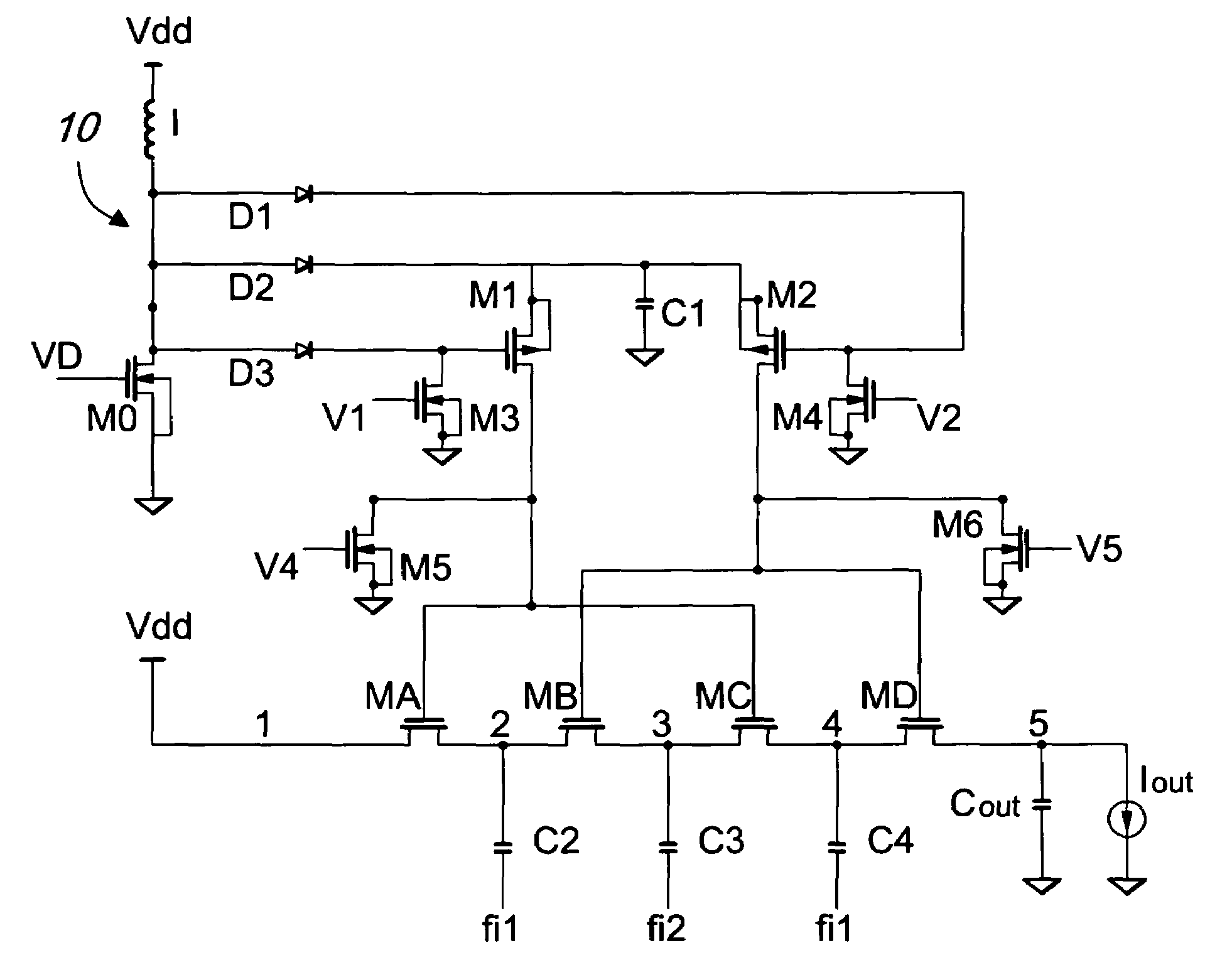

Sampling Method For Time-Interleaved Data Converters In Frequency-Multiplexed Communications Systems

ActiveUS20110128175A1Improve fidelityReduce power inputElectric signal transmission systemsAnalogue-digital convertersFrequency reuseCommunications system

A wide band analog-to-digital converter used in a frequency multiplexed communication system. The converter includes a plurality, M, of time-interleaved analog-to-digital converter subunits (ADC subunits). The sampling rate, FS1, of the M ADC subunits is selected to locate one or more integer multiples of a Nyquist frequency of a respective subunit ADC in one or more guard bands, and / or such that one or more integer multiples of FS1 are also located in the guard bands.

Owner:INTERSIL INC

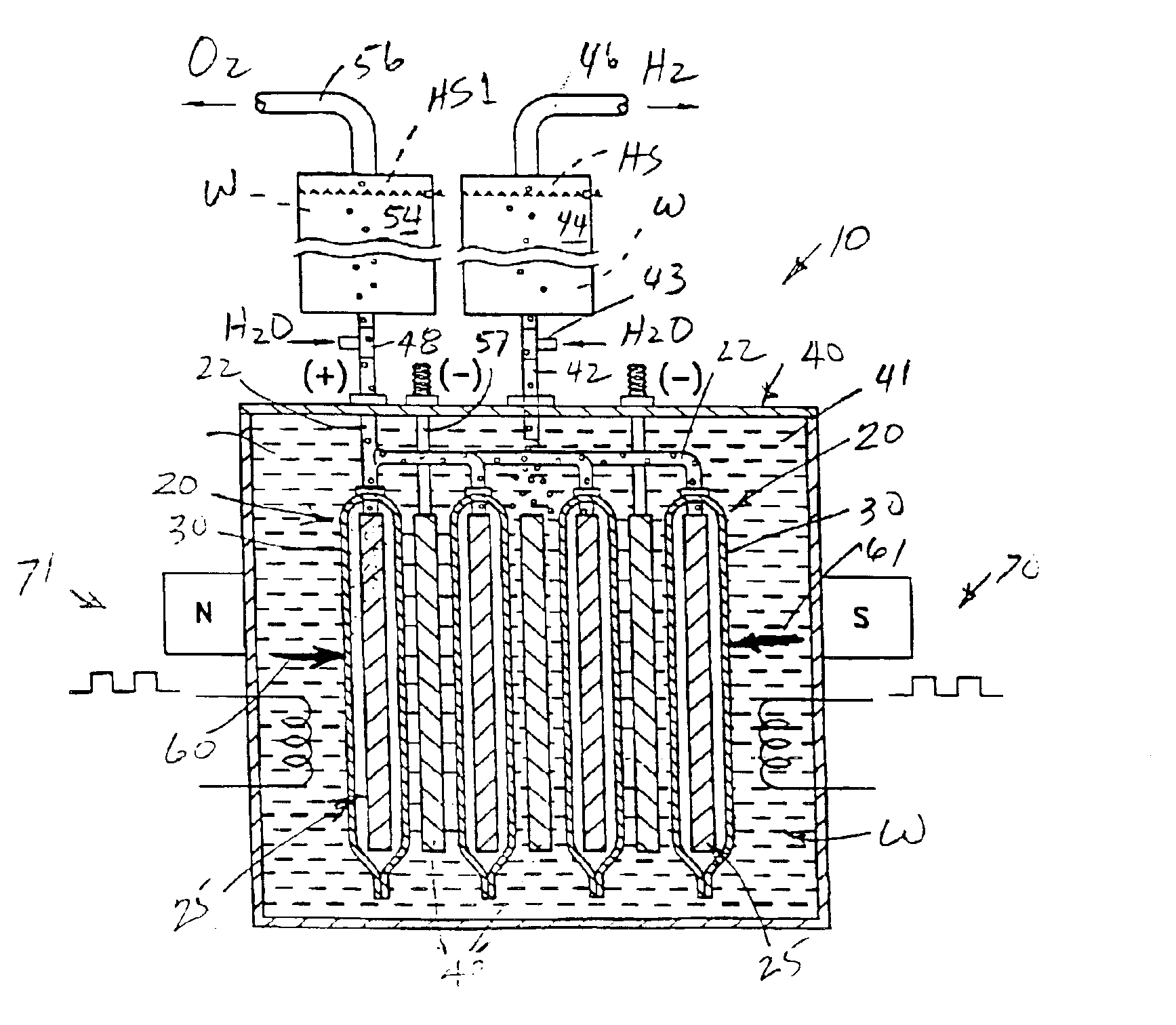

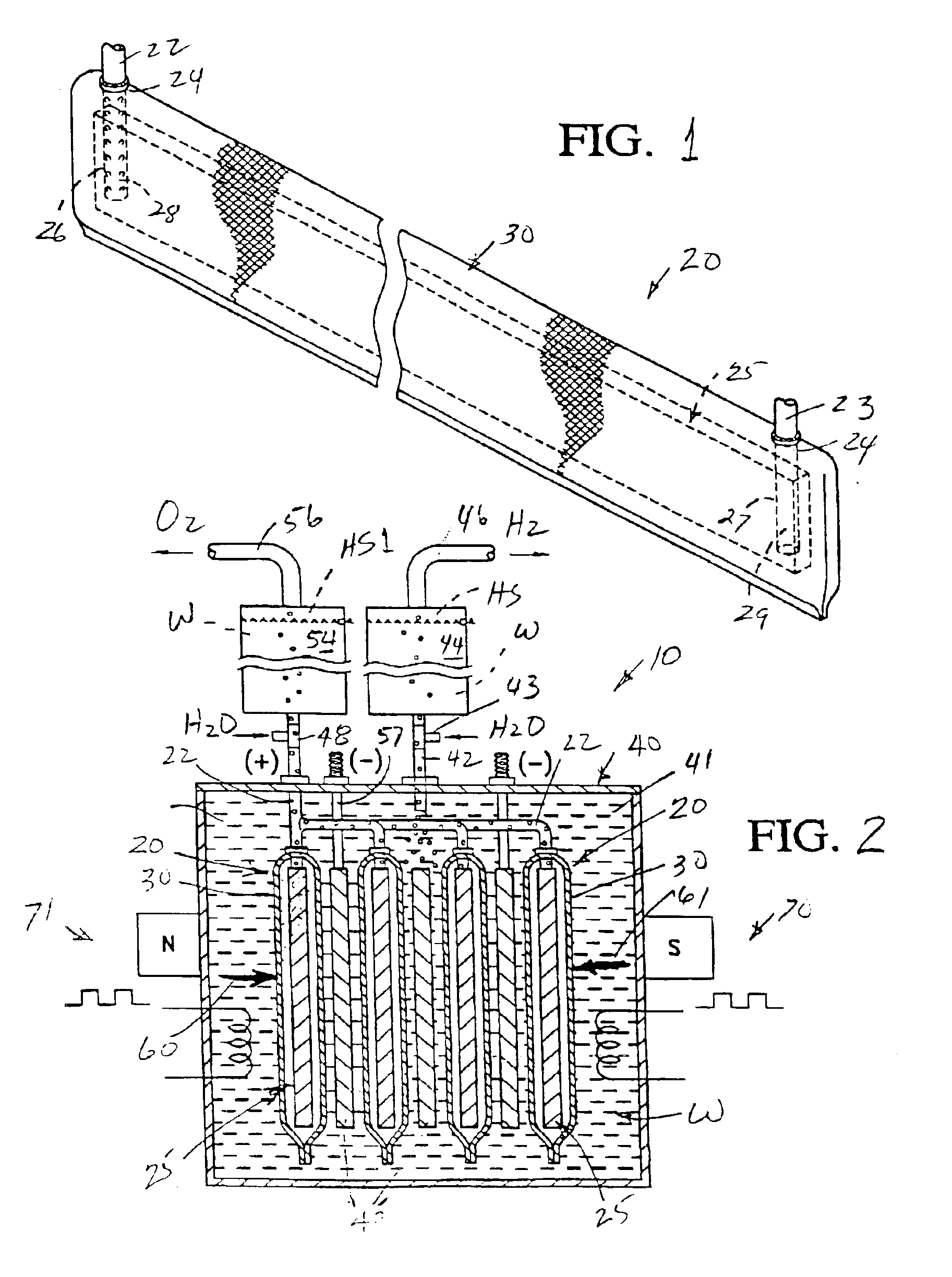

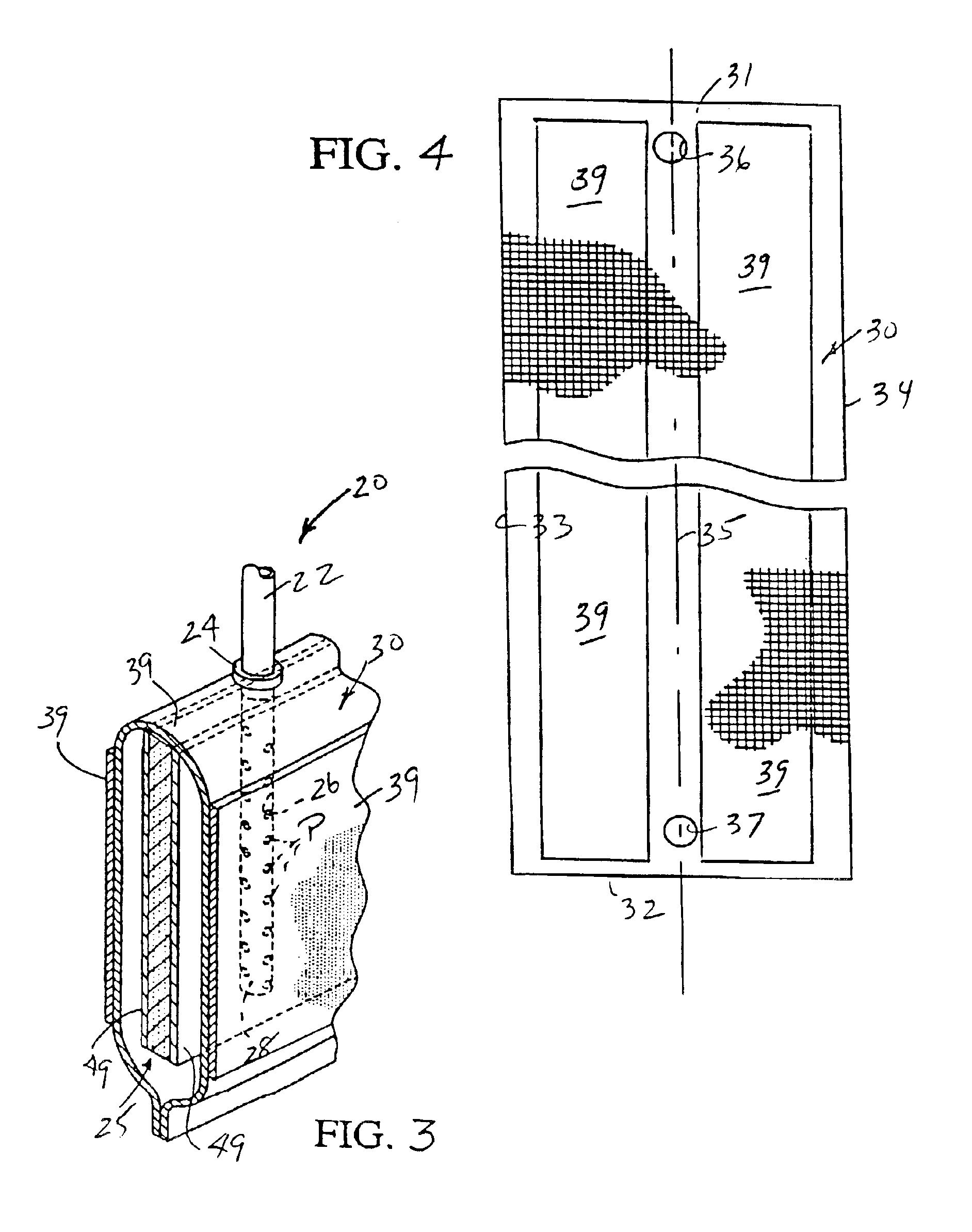

Apparatus for converting a fluid into at least two gasses through electrolysis

InactiveUS6890410B2Reduce manufacturing costSignificantly reduces anode/cathode arcingCellsElectrode shape/formsElectricityElectrolysis

An electrolysis conversion system for converting liquid to gas, such as water into hydrogen and oxygen, includes a housing in which are housed encapsulated and non-encapsulated electrodes in any one of side-by-side, rolled or folded relationship. The electrodes are immersed in an electrolyte, water or the like and are appropriately electrically connected to positive and negative sides of an energy source. The encapsulation material of the encapsulated electrodes can be substantially conductive or non-conductive to either ion flow or electron flow and either substantially non-porous or porous to gas bubbles with the option of utilizing spacers to prevent arcing and thereby generate hydrogen and oxygen from the water / electrolyte. The encapsulating media is either a folded flexible sheet heat sealed along three edges, two sheets heat sealed along four edges, a tube heat sealed along opposite axial edges or a coating dip-coated, electro-deposited, silk screen coated or similarly applied to the electrode which is preferably porous and can either be rigid or relatively bendable / flexible.

Owner:SULLIVAN JOHN T

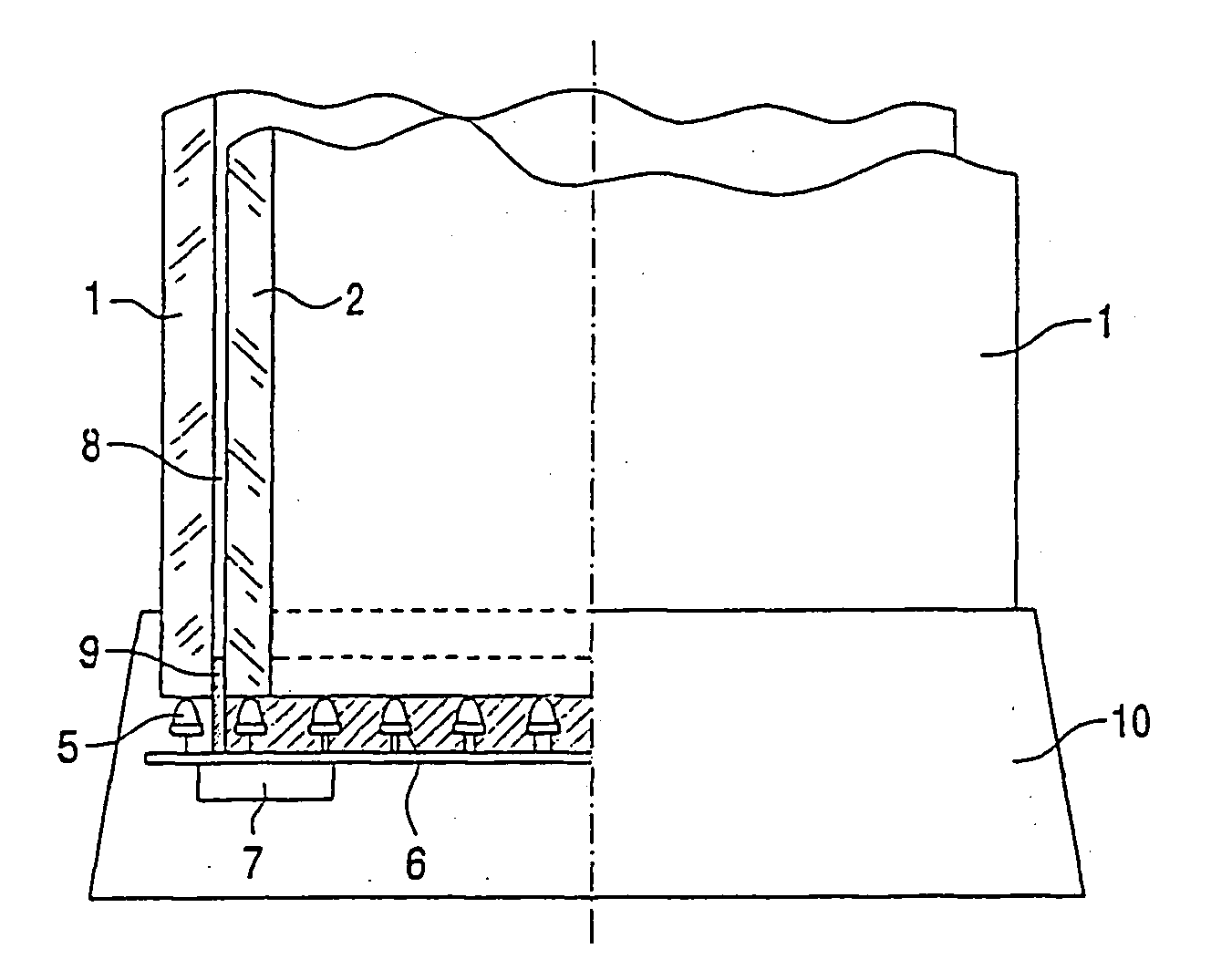

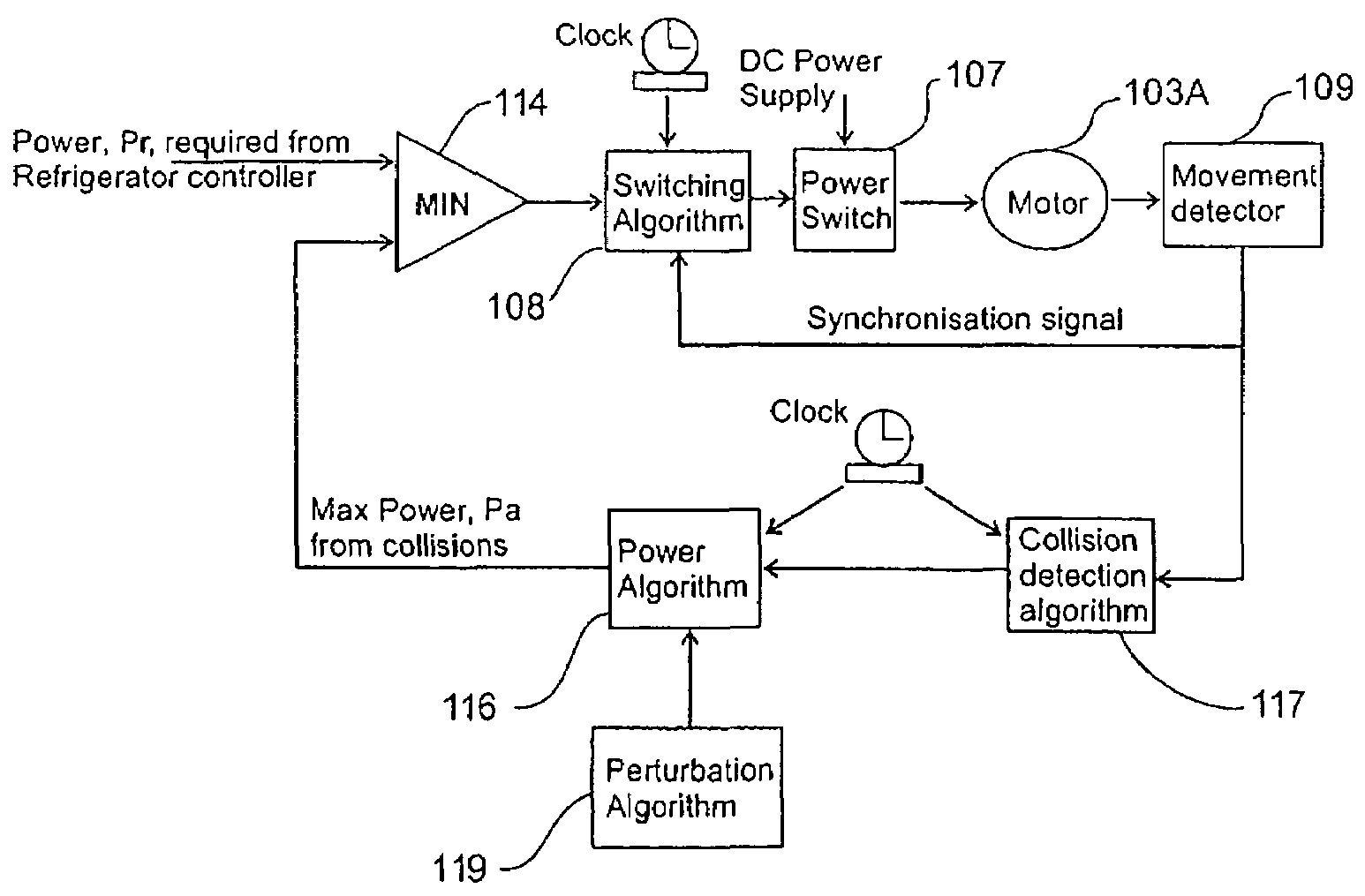

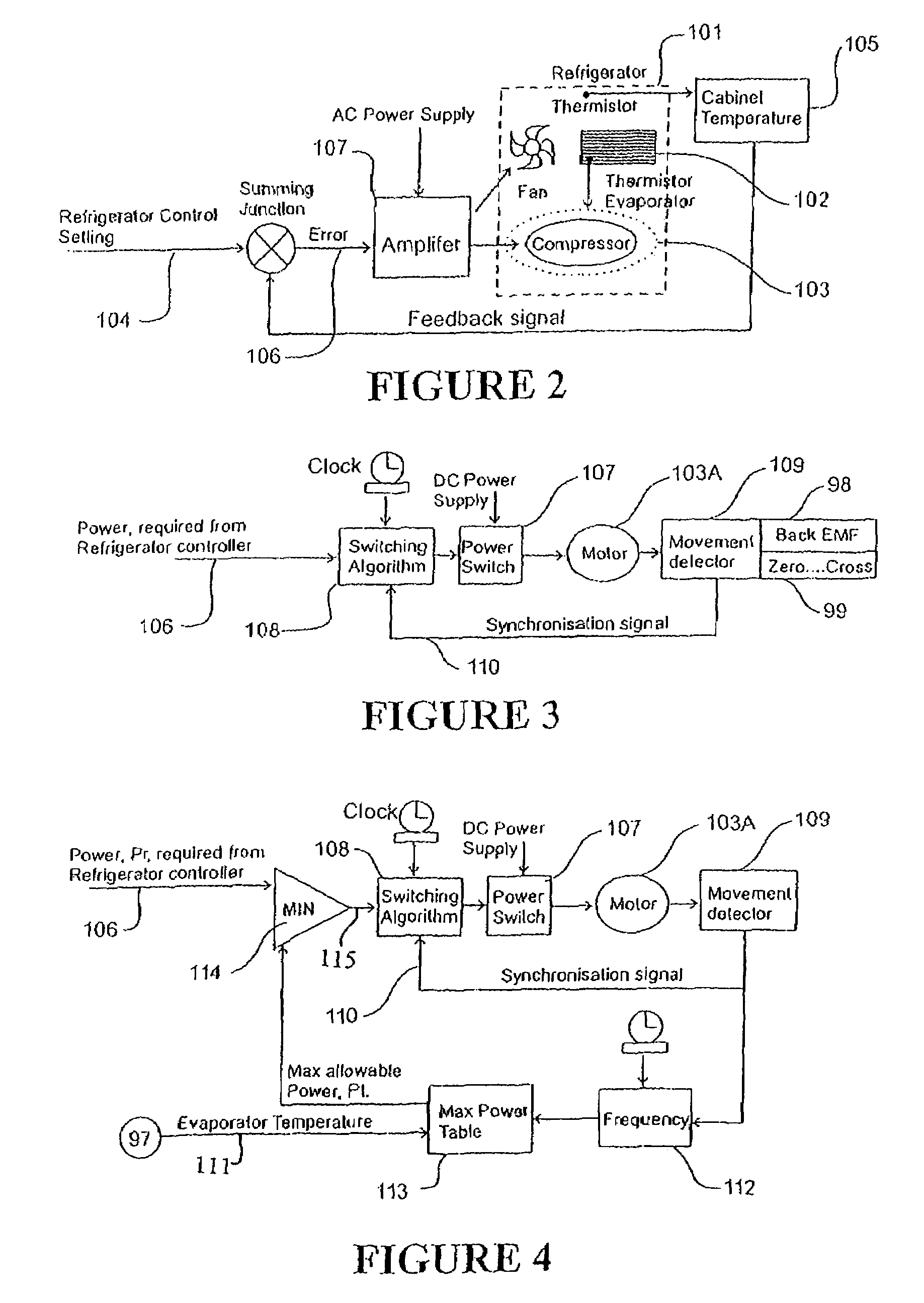

Linear compressor controller

InactiveUS7618243B2High operating requirementsIncrease inputEngine fuctionsCompression machines with non-reversible cycleEnergy collisionLinear compressor

A free-piston linear compressor (1) controlled to achieve high volumetric efficiency by a controller including an algorithm (116) for ramping up input power until piston-cylinder head collisions are detected using a detection algorithm (117 / 118) which then decrements power input whereupon input power is again ramped up by algorithm (116). Non-damaging low energy collisions are achieved by the controller including a perturbation algorithm (119) which perturbates the input power ramp with periodic transient pulses of power to ensure piston collisions are provoked during the transient power pulses.

Owner:FISHER & PAYKEL APPLIANCES LTD

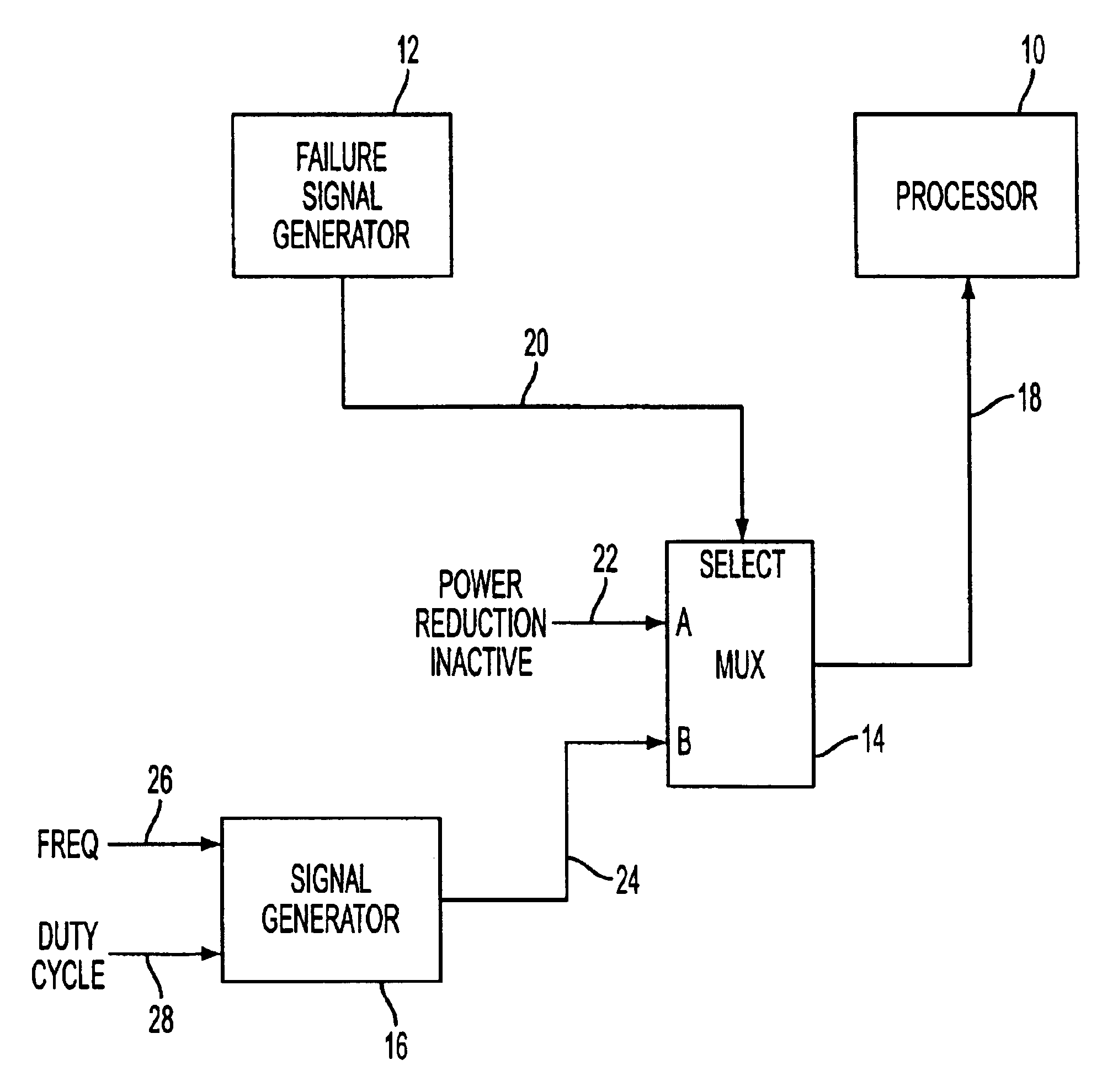

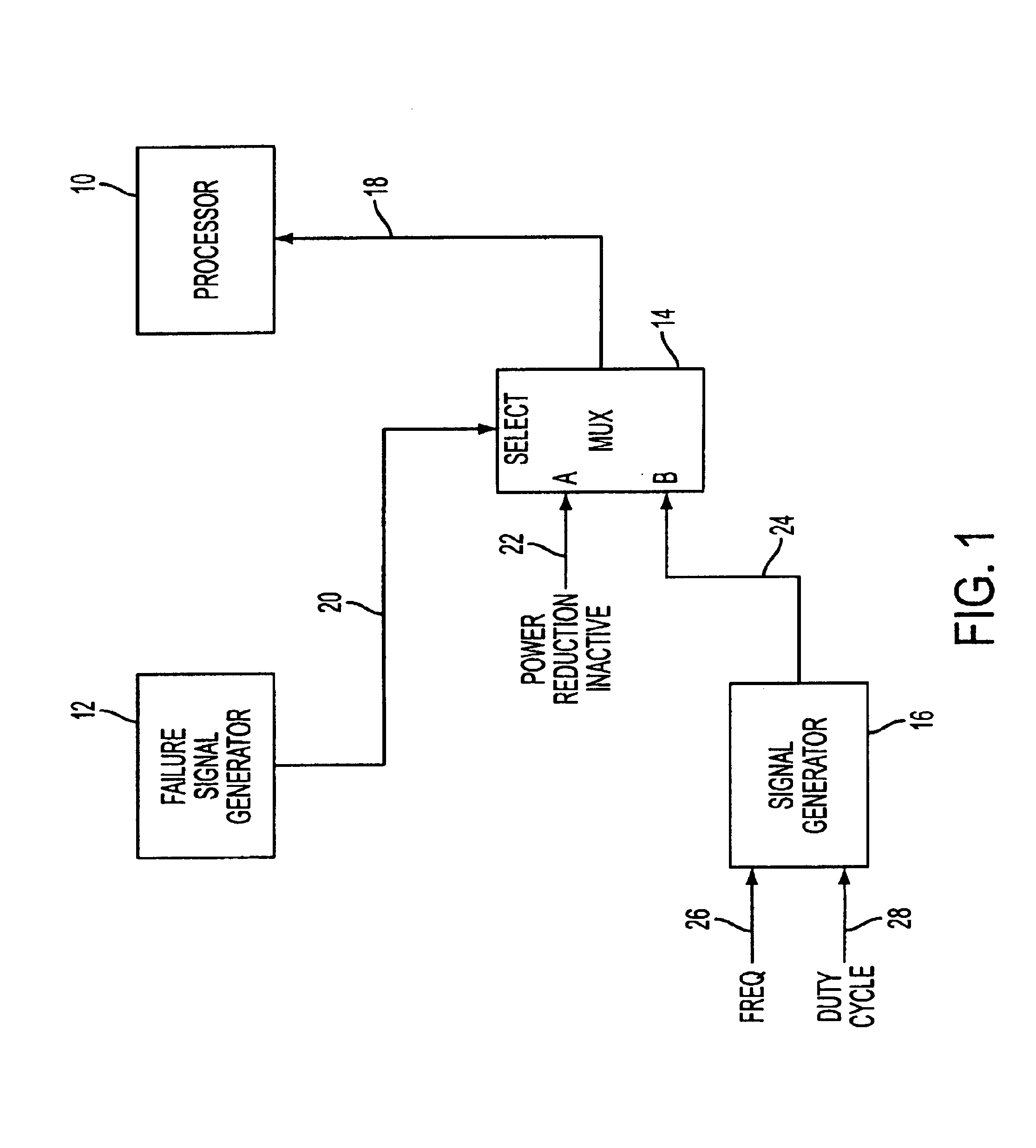

Apparatus, method and computer system for reducing power consumption of a processor or processors upon occurrence of a failure condition affecting the processor or processors

InactiveUS6909922B2Reduce power inputReduce power consumptionReliability increasing modificationsEnergy efficient ICTComputerized systemComputer science

An apparatus, a method and a computer system can be used to reduce power consumption of one or more processors in response to a failure condition such as an overtemperature condition affecting the processor or processors. A signal is provided which indicates a failure condition affecting the processor such as an overtemperature condition or a failure or reduction in performance of a cooling mechanism. In response to the signal, a power consumption of the processor is periodically reduced. This can be accomplished by providing a periodic signal to an input of the processor (e.g., a stop clock input or a processor enable input). The processor reduces power consumption by stopping an internal clock of the processor, for example. The periodic signal can be provided to the input of the processor to periodically reduce power consumption. In this manner, power consumption of the processor may be reduced without shutting down the processor entirely, while maintaining some processor functions and without missing the receipt of any signals corresponding to vital functions of the processor system while the power consumption of the processor is reduced.

Owner:INTEL CORP

Sampling method for time-interleaved data converters in frequency-multiplexed communications systems

ActiveUS8310387B2Improve fidelityReduce power inputElectric signal transmission systemsAnalogue-digital convertersFrequency reuseCommunications system

A wide band analog-to-digital converter used in a frequency multiplexed communication system. The converter includes a plurality, M, of time-interleaved analog-to-digital converter subunits (ADC subunits). The sampling rate, FS1, of the M ADC subunits is selected to locate one or more integer multiples of a Nyquist frequency of a respective subunit ADC in one or more guard bands, and / or such that one or more integer multiples of FS1 are also located in the guard bands.

Owner:INTERSIL INC

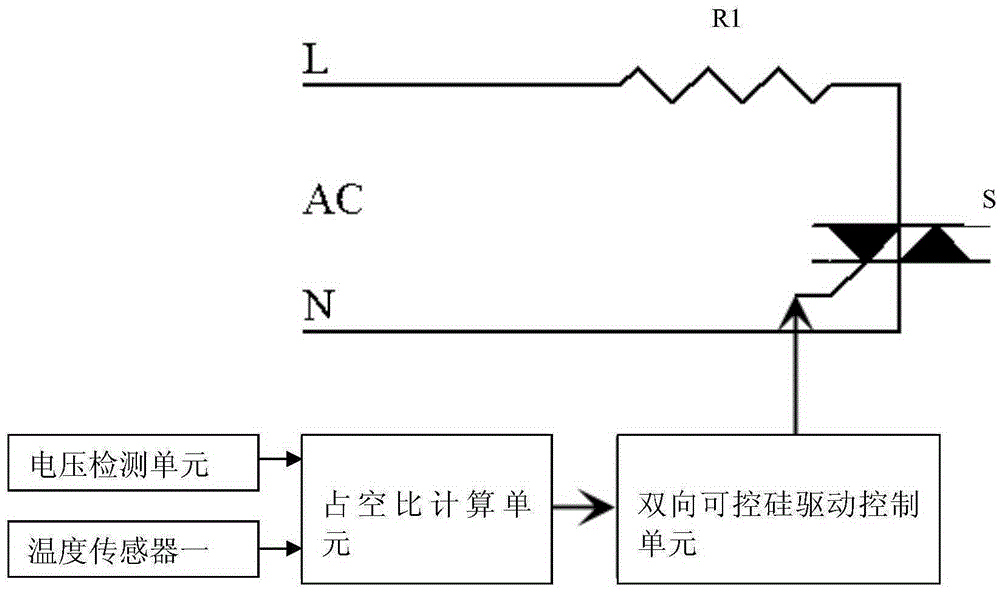

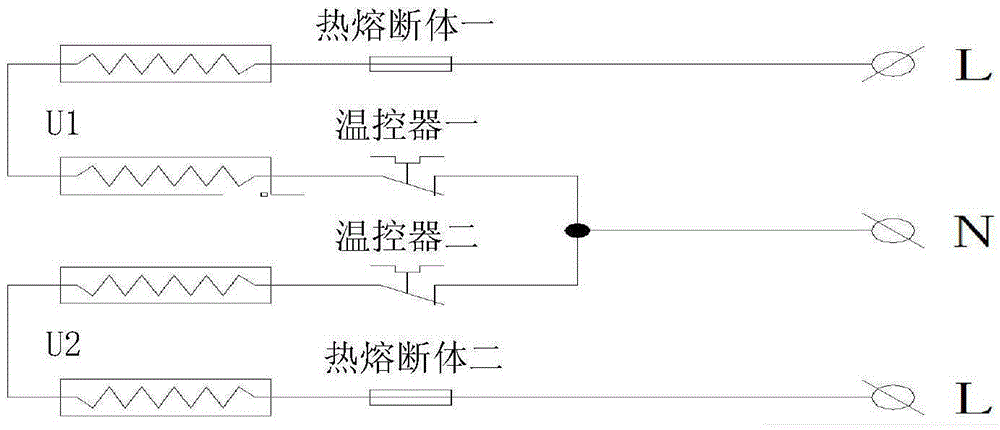

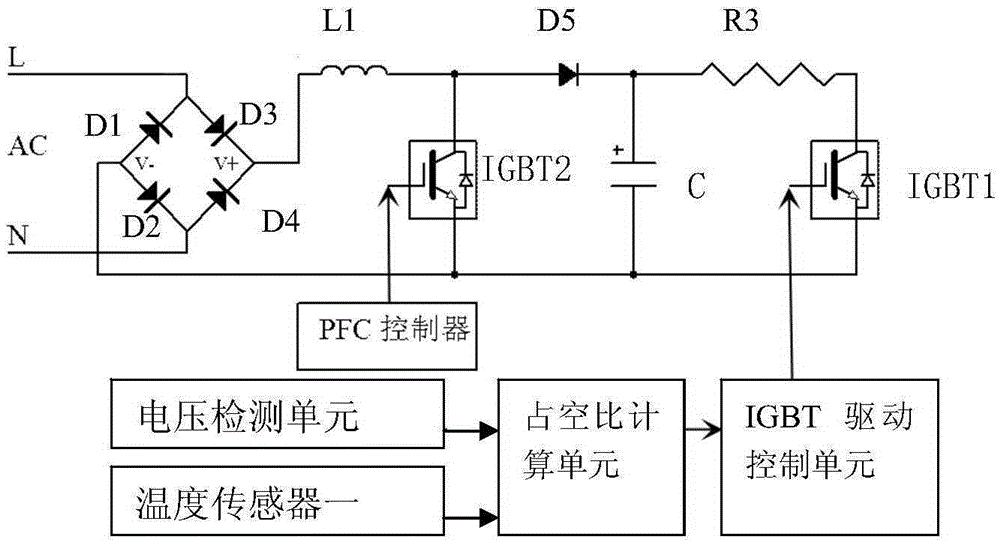

Electric heating system with continuously adjustable power and control method of electric heating system

ActiveCN105423513AIncrease duty cycleThe duty cycle reachesLighting and heating apparatusElectric heatingElectricityUser input

The invention relates to an electric heating device and provides an electric heating control method with continuously adjustable power. The method comprises the following steps: firstly, a system receives a target temperature input by a user and calculates target power according to the target temperature, and the target temperature is in direct proportion to the target power; then the system detects real-time input voltage value, calculates the real-time power difference according to the real-time input voltage value and the target power and calculates the real-time duty cycle according to the real-time power difference, and the real-time power difference is in direct proportion to the real-time duty cycle; finally, the system modulates the output power of a power module according to the real-time duty cycle. The power output of the heating device is adjusted in real time according to the difference change of the current temperature and the target temperature, so that the effects of improving the heating comfort, improving the energy efficiency of an air conditioner, prolonging the service life of the product and reducing the energy consumption are realized, and the method is applicable to air conditioners, electric heaters and electric blankets.

Owner:四川长虹空调有限公司

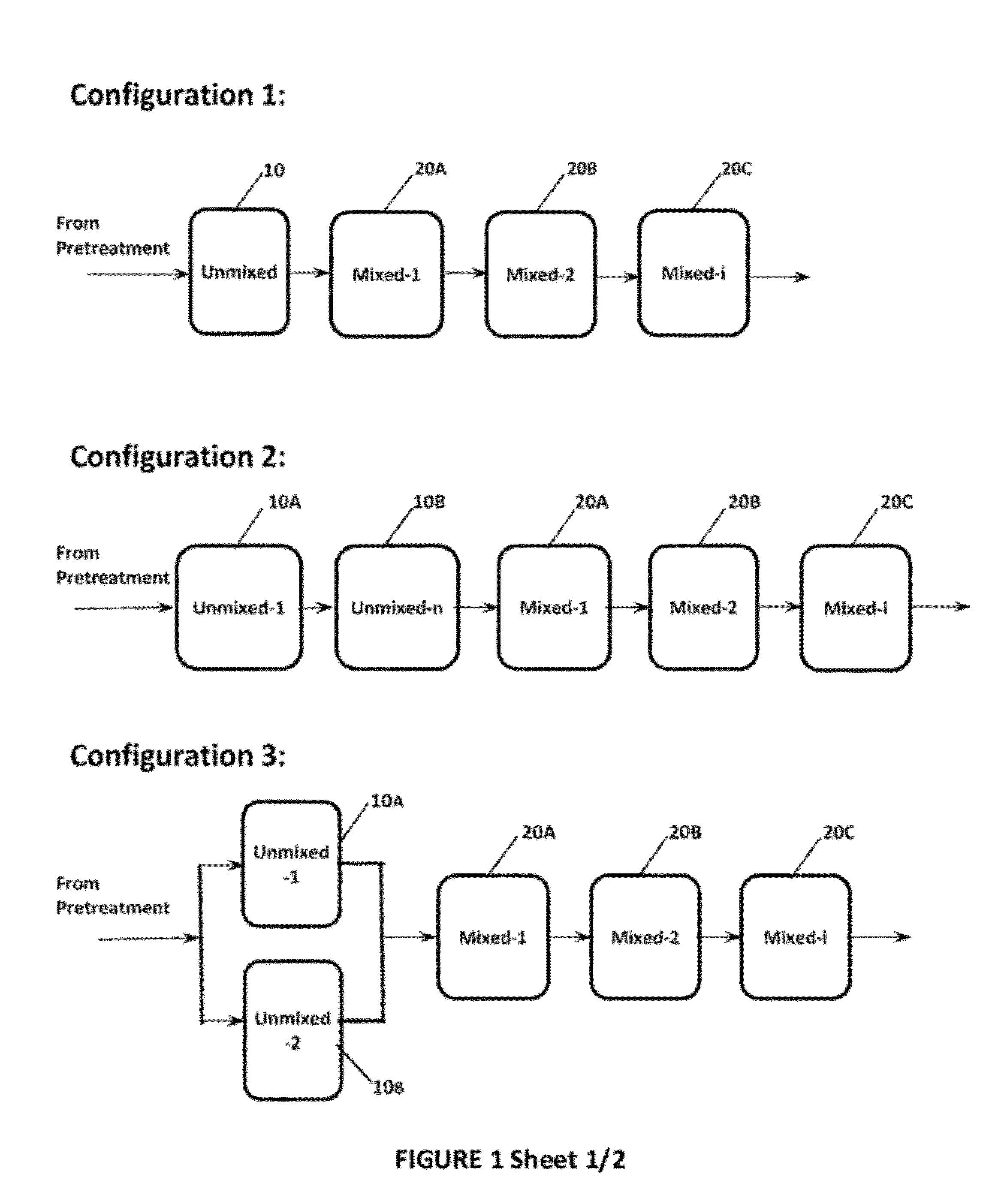

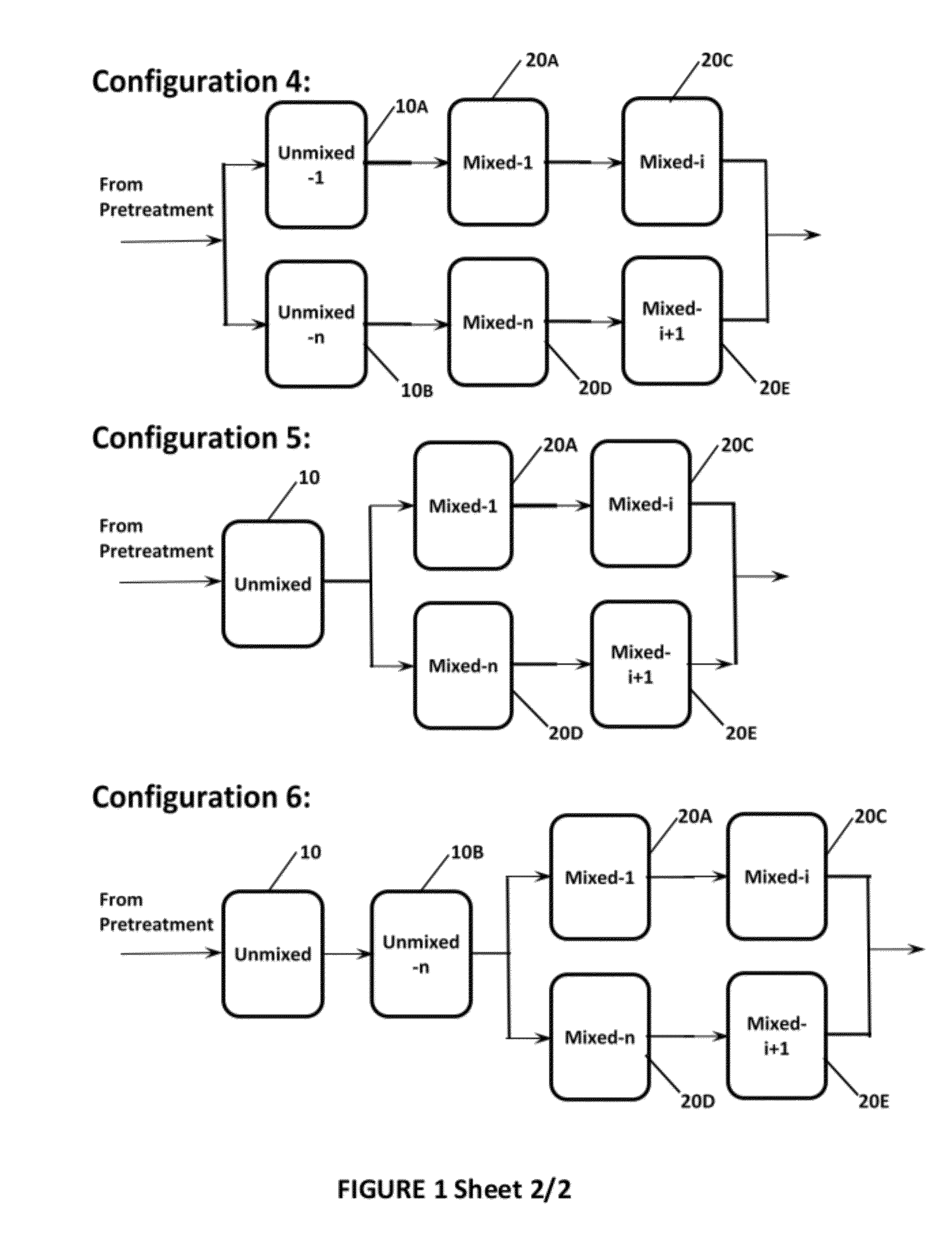

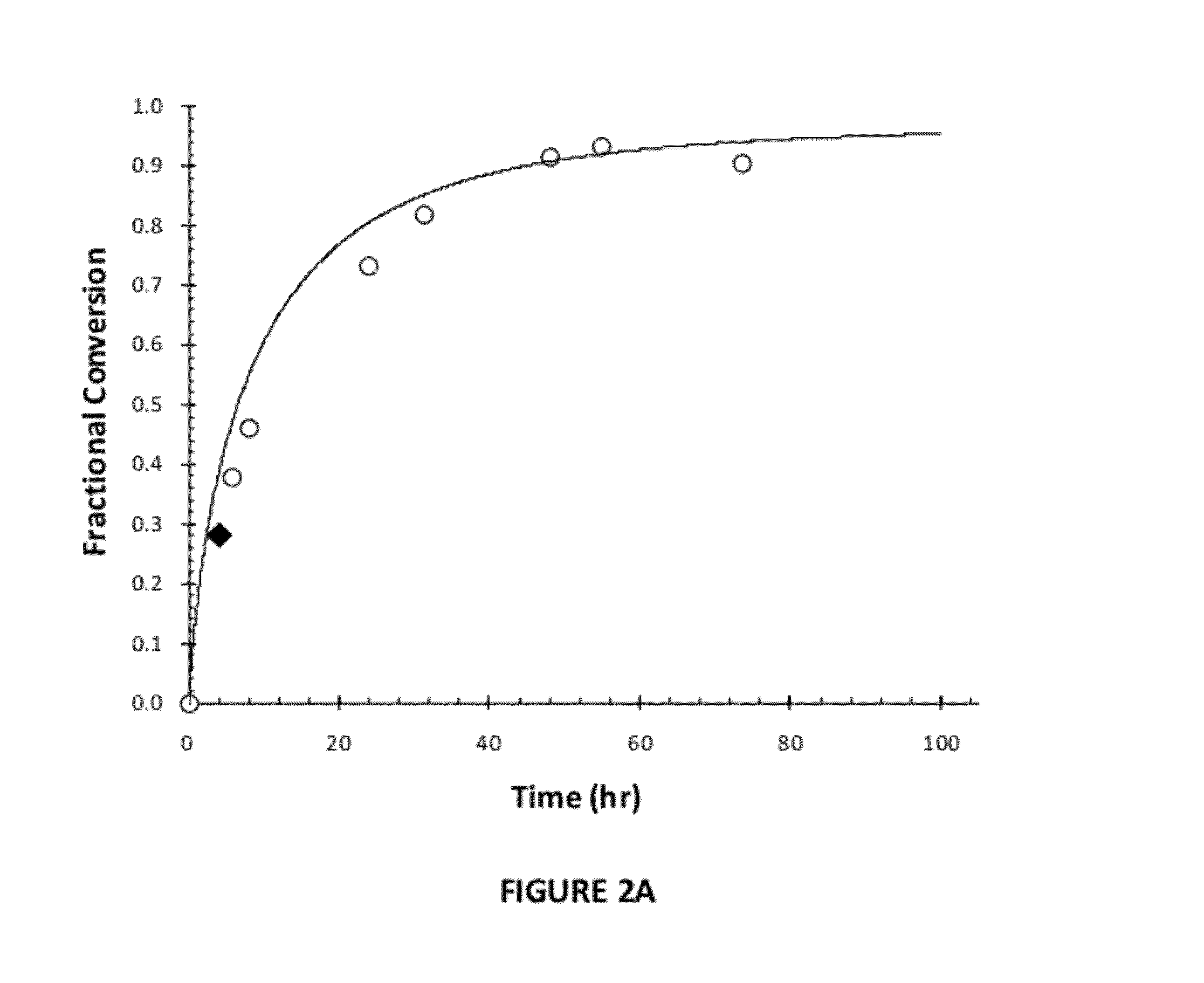

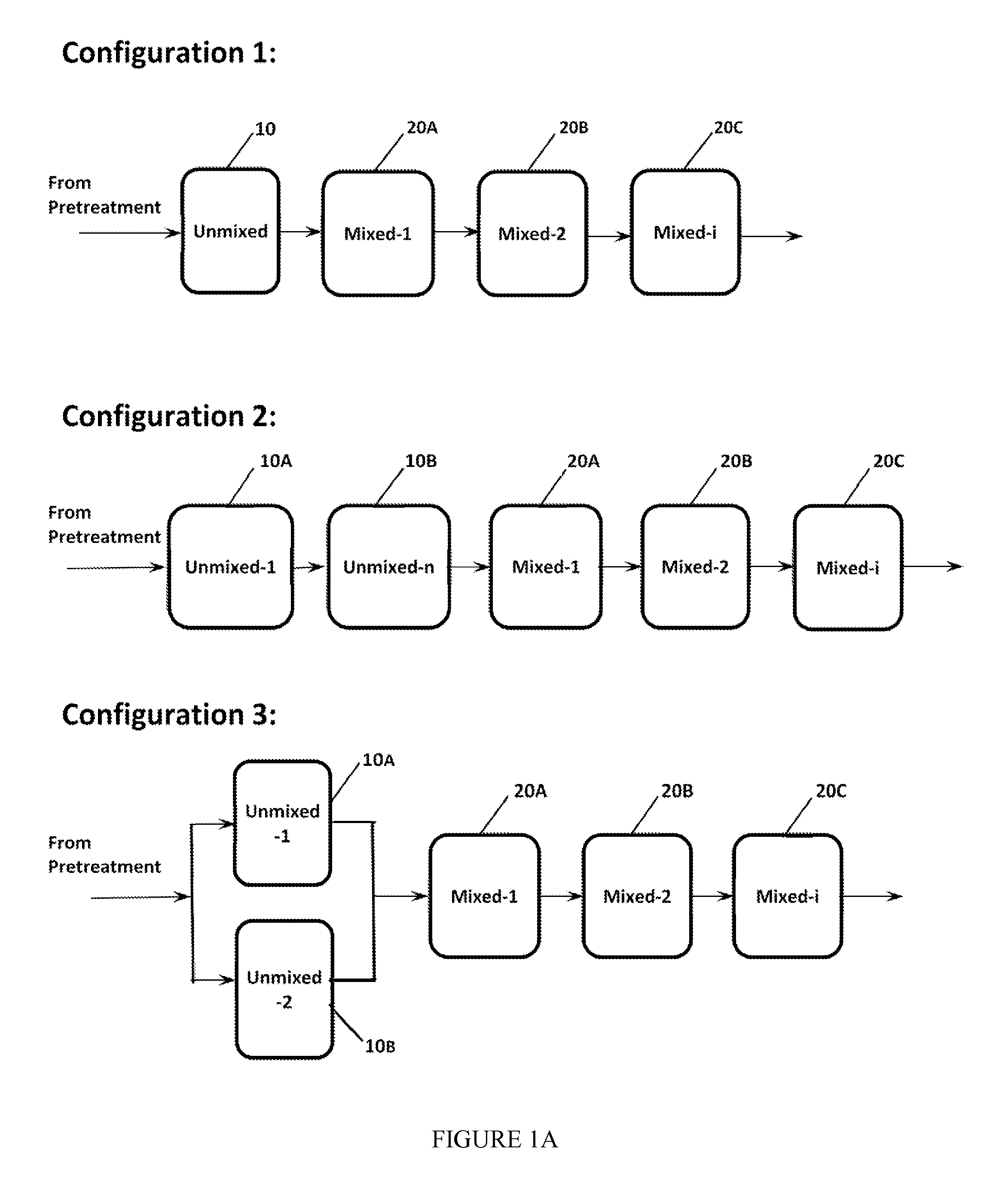

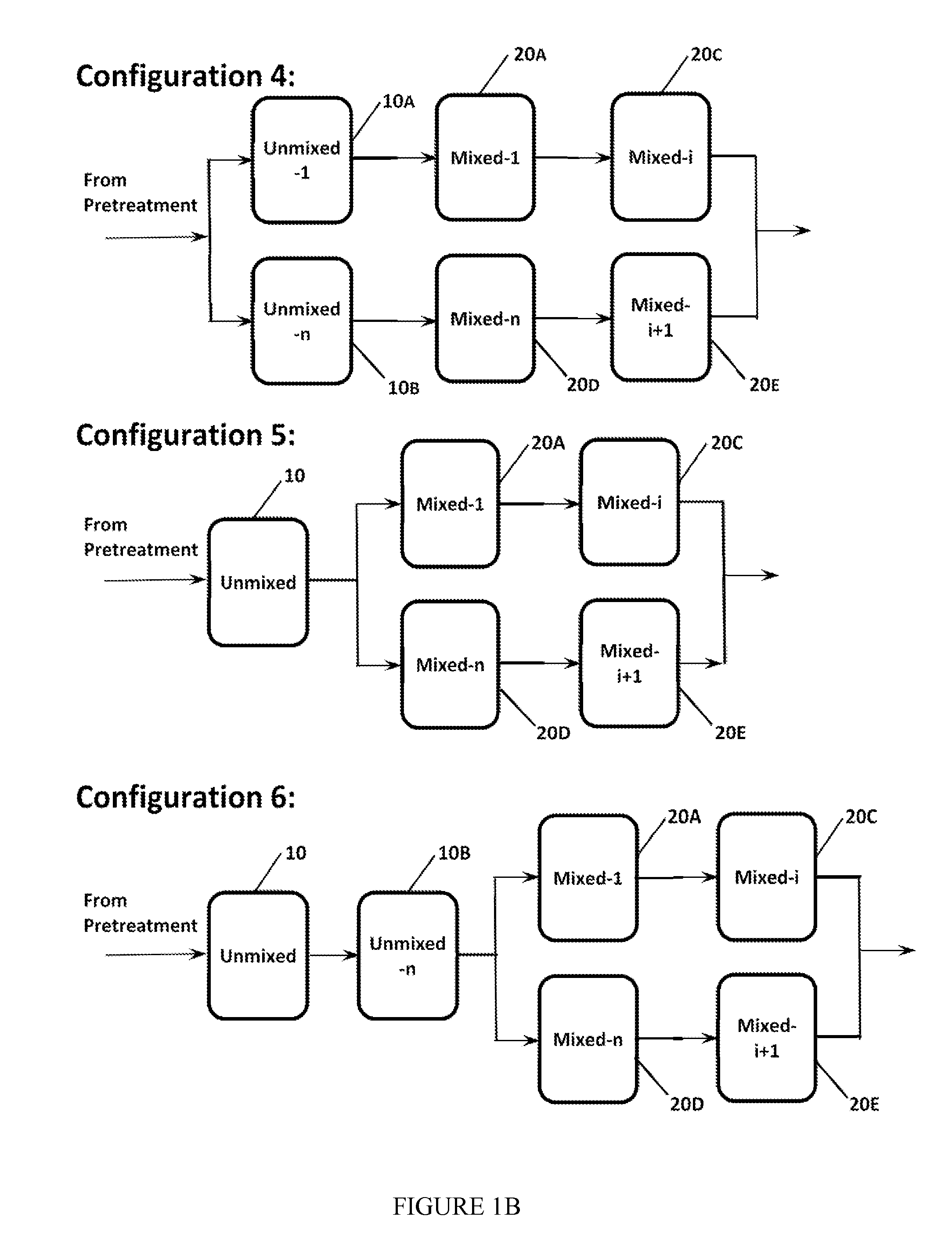

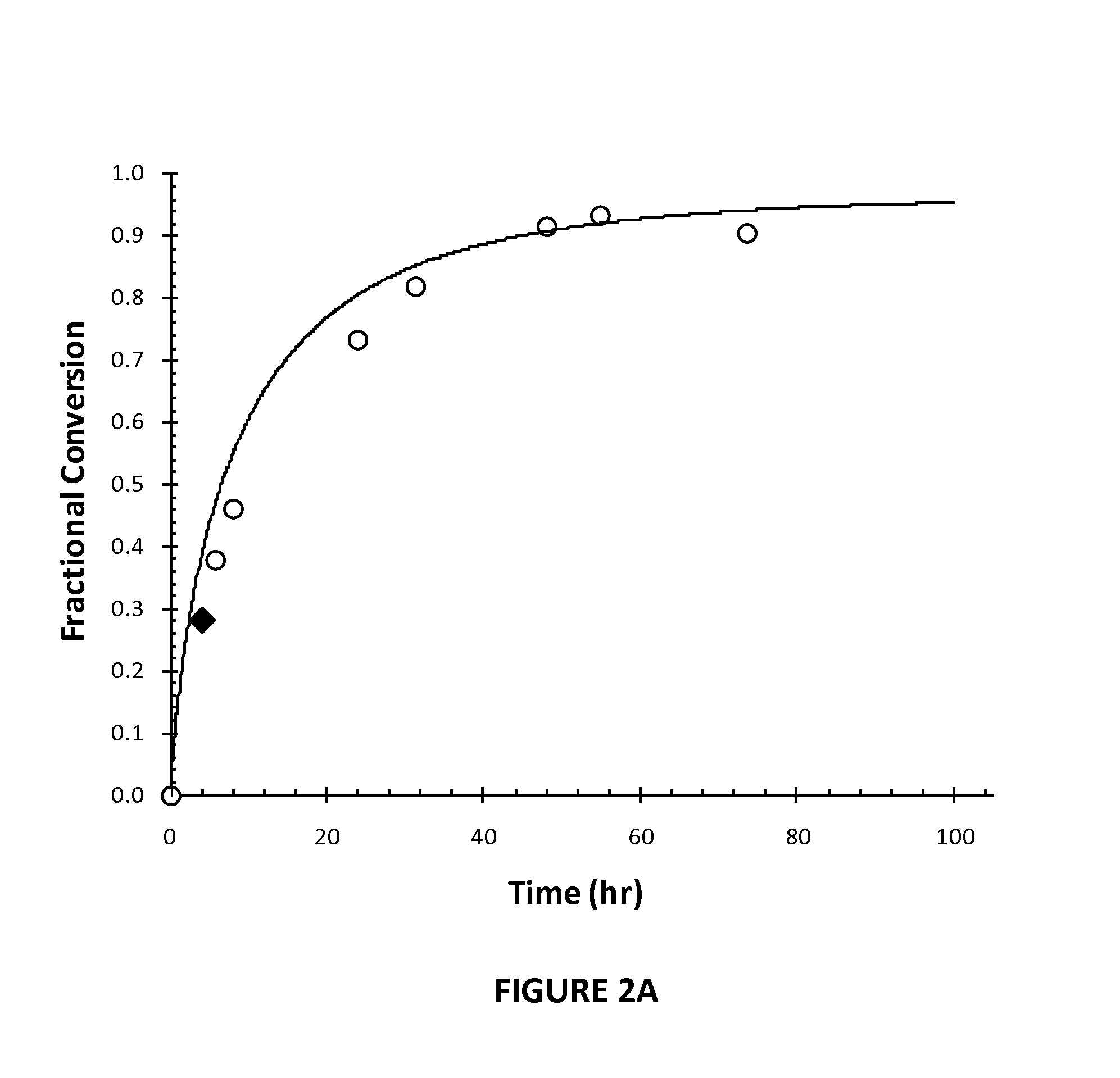

Process for improving the hydrolysis of cellulose in high consistency systems

ActiveUS20120052534A1Low viscosityReduce power inputBioreactor/fermenter combinationsBiological substance pretreatmentsWater contentAcid hydrolysis

Provided is a process for the enzymatic hydrolysis of cellulose to produce glucose from a pretreated cellulosic feedstock. The process comprises providing an aqueous slurry of the pretreated cellulosic feedstock that has a water content that is less than about 140% of the maximum water holding capacity of the pretreated cellulosic feedstock. The aqueous slurry of the pretreated cellulosic feedstock is fed to one or more unmixed hydrolysis reactors and hydrolyzed with cellulase enzymes therein. In the unmixed hydrolysis reactor(s), the cellulase enzymes hydrolyze a portion of the cellulose to produce soluble sugars, thereby producing a mixture of partially hydrolyzed cellulose containing soluble sugars. The hydrolysis of the cellulose to glucose is continued by feeding the mixture of partially hydrolyzed cellulose to one or more mixed hydrolysis reactors. Also provided are systems for carrying out the foregoing enzymatic hydrolysis.

Owner:IOGEN ENERGY CORP

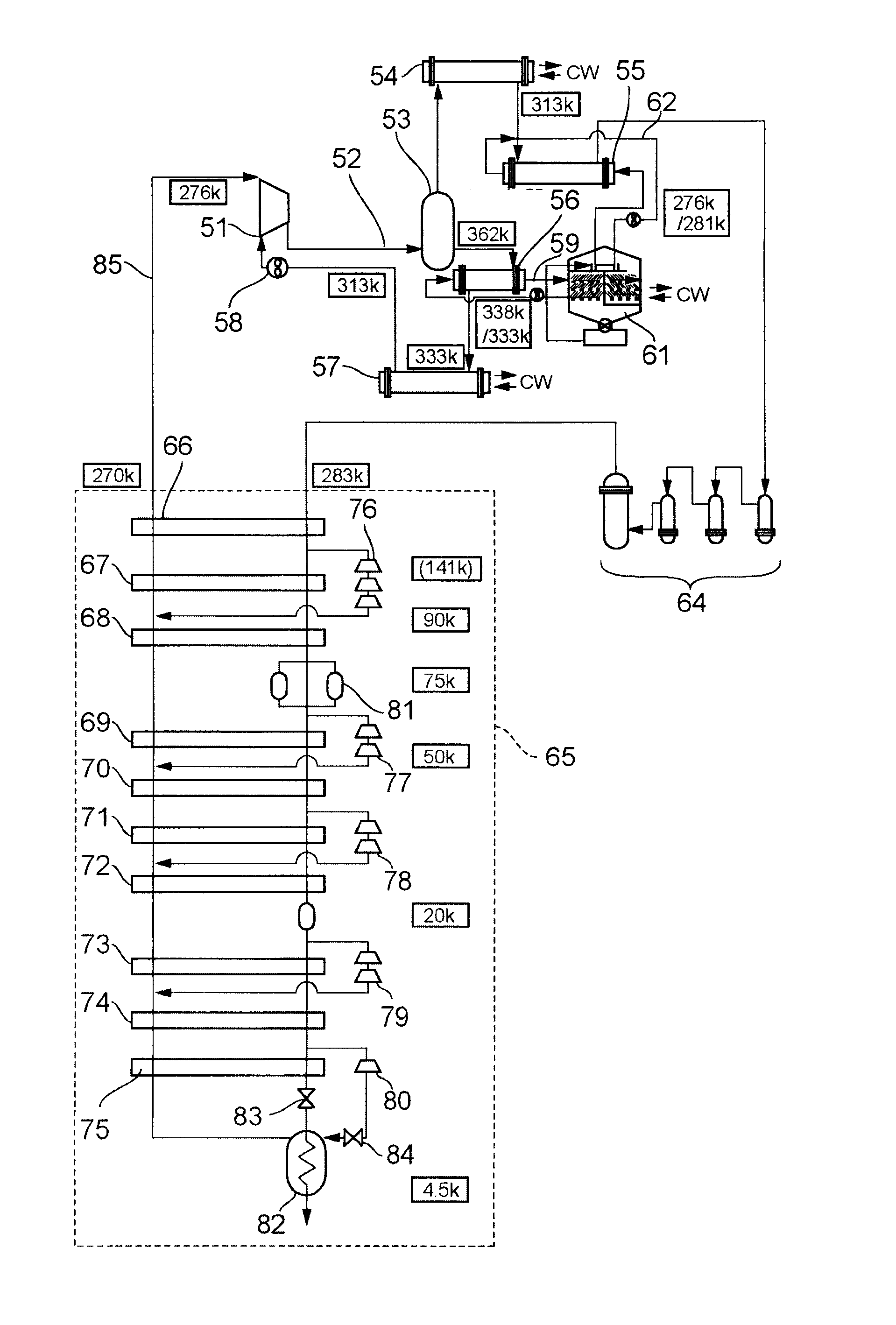

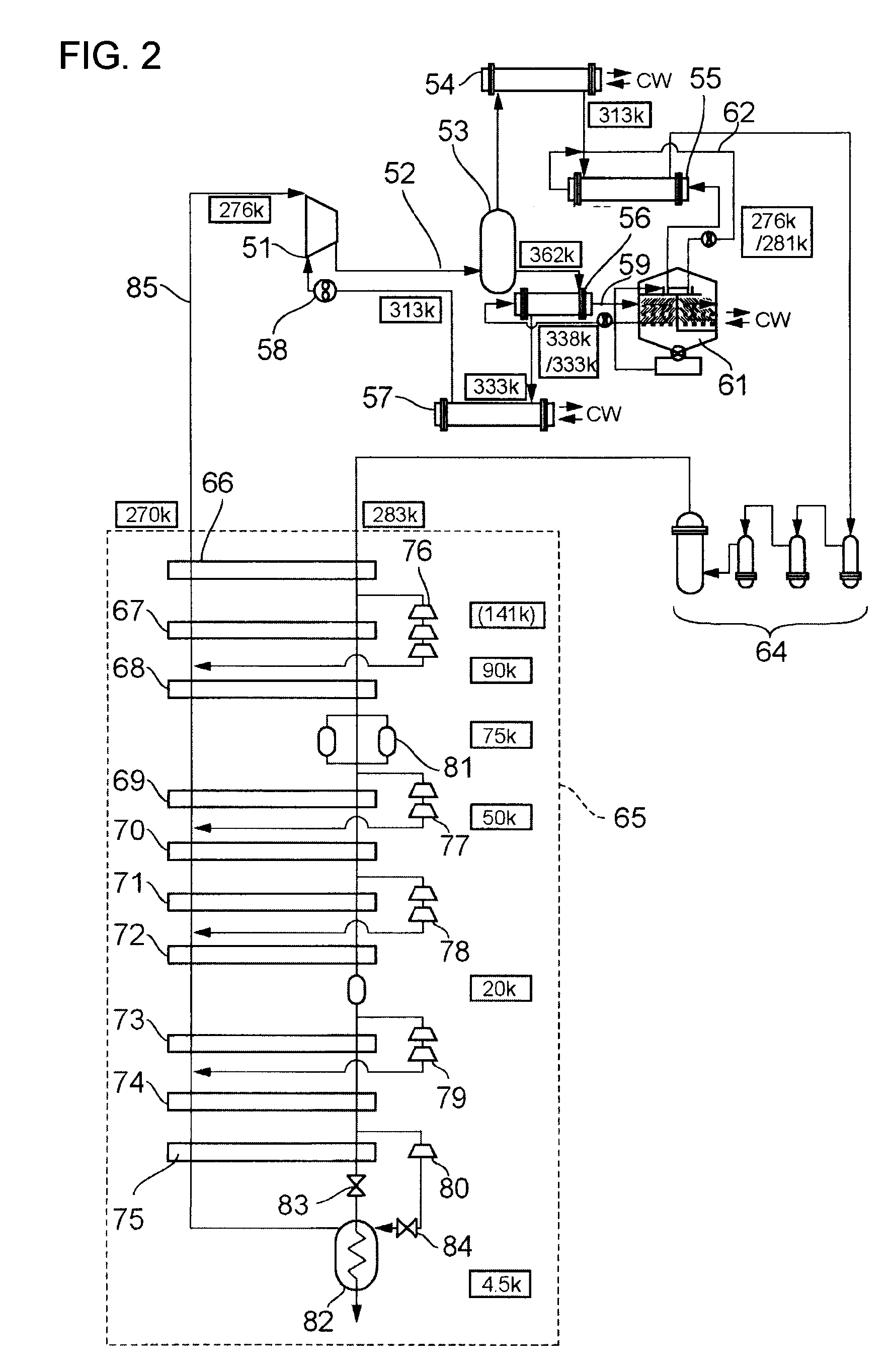

Reduced Input Power Cryogenic Refrigerator

InactiveUS20080092588A1Reduce pressure drop lossReduce gas volumeSolidificationLiquefactionReflux valveNuclear engineering

Owner:SUMITOMO HEAVY IND LTD +1

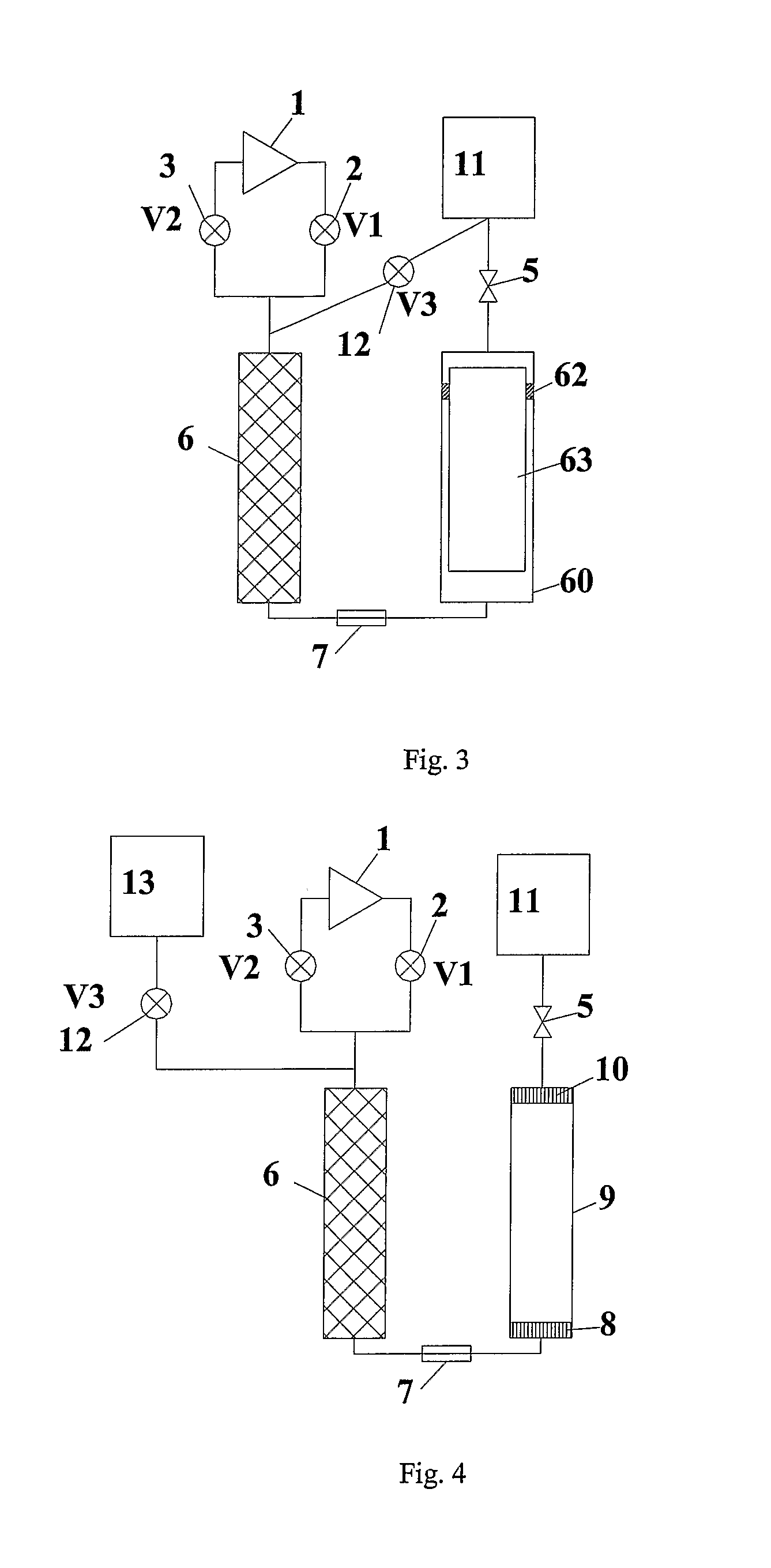

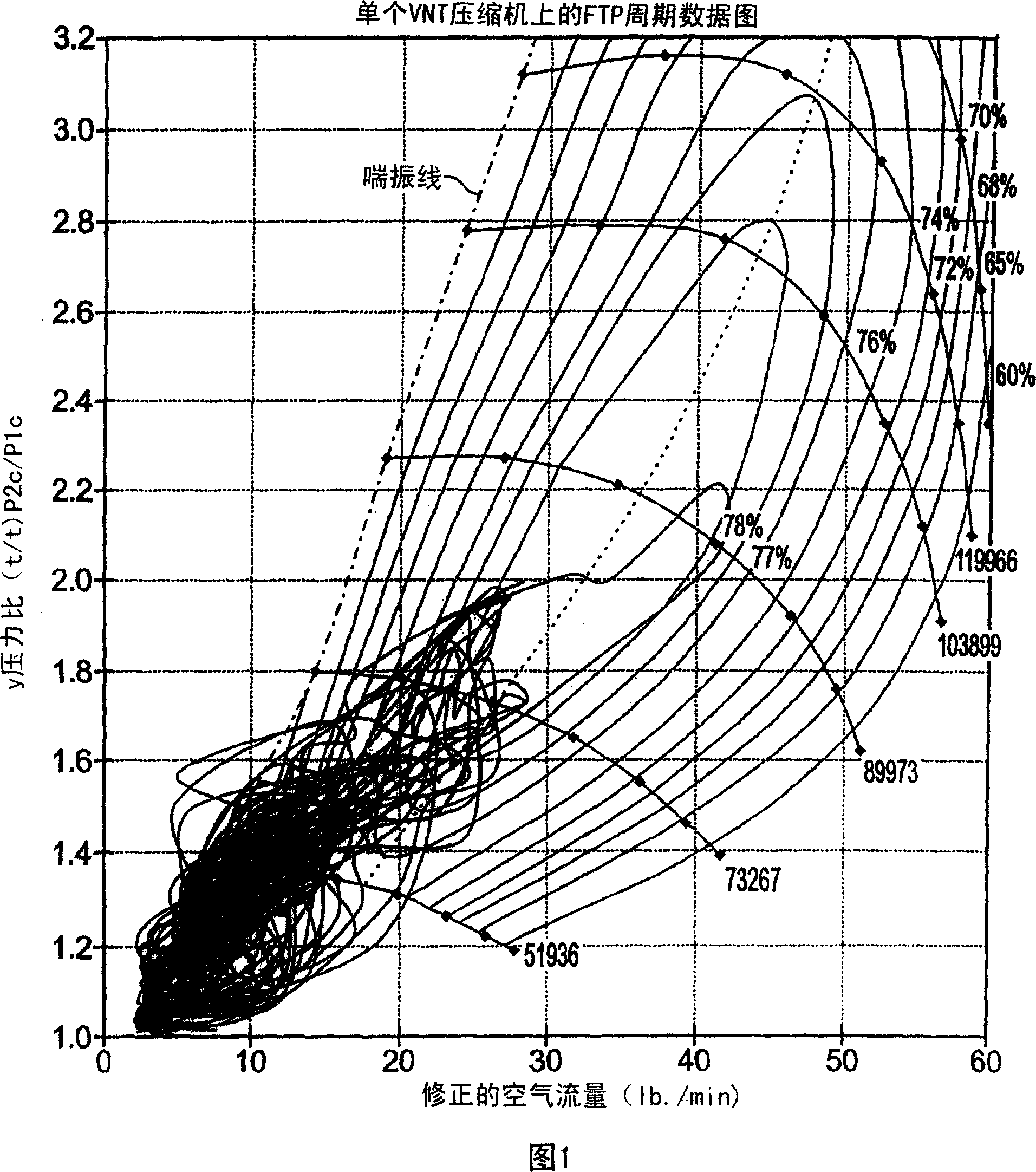

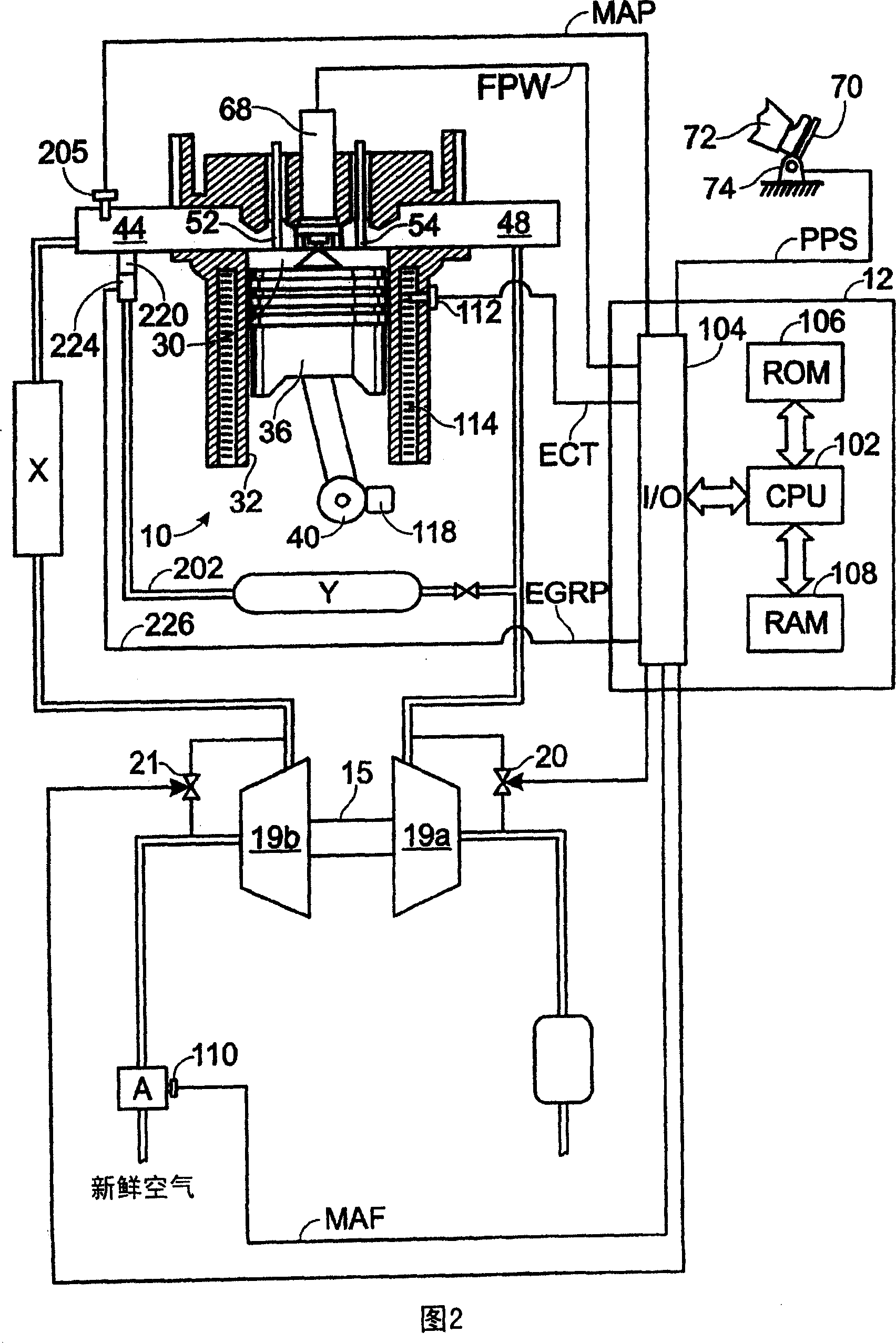

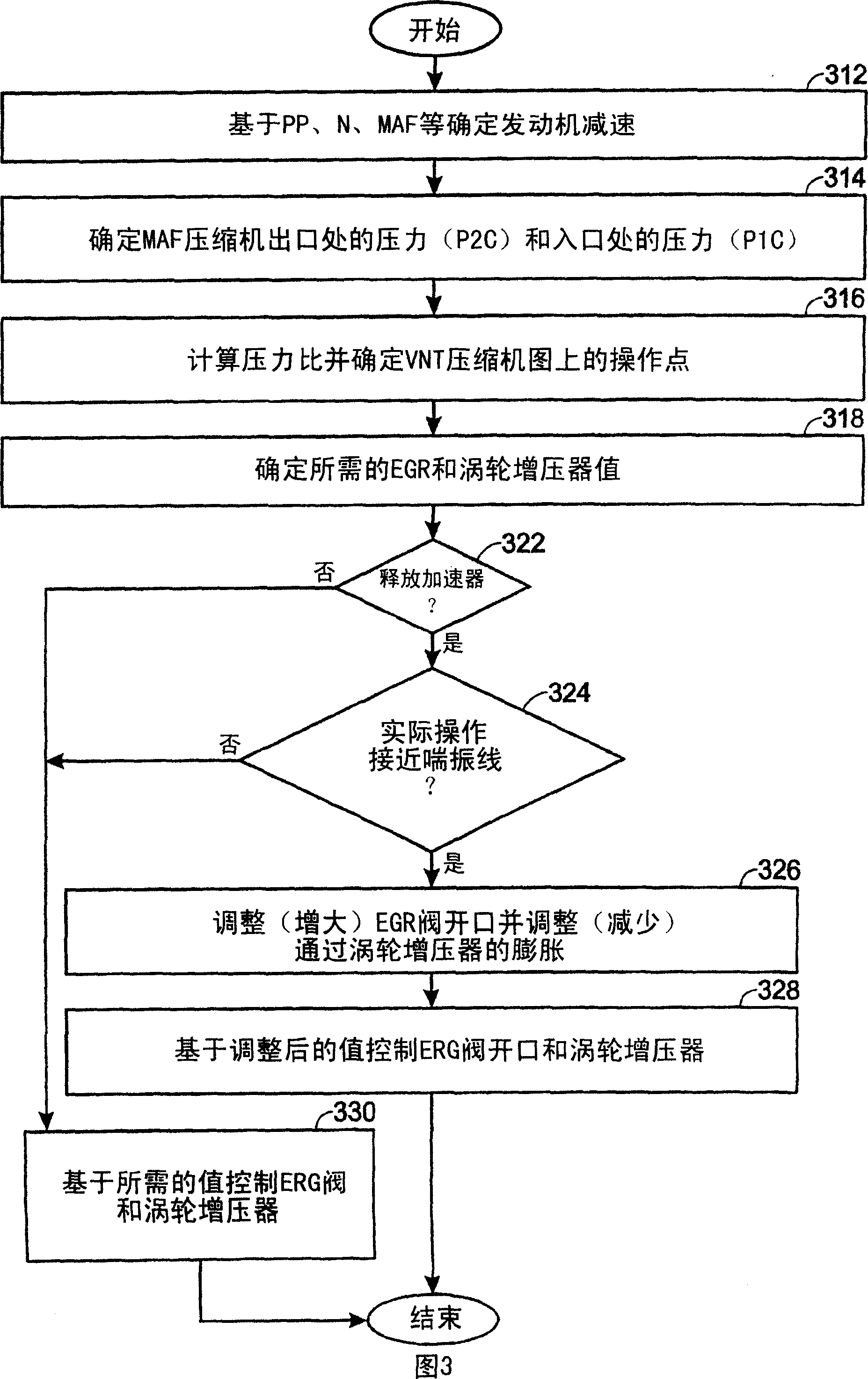

System and method for reducing surge

InactiveCN1940262AReduce bloatReduce power inputInternal combustion piston enginesTurbochargerDropout voltage

A method of controlling an engine having an intake manifold and an exhaust manifold, wherein an exhaust gas recirculation path having a valve is provided between the intake and exhaust manifolds, and the engine has a turbocharger ; the method comprising increasing the opening of the exhaust gas recirculation valve when there is at least one condition of reduced engine output; and adjusting exhaust gas expansion through the turbocharger turbine to reduce expansion through the turbocharger. Reducing turbocharger expansion will reduce the power input to the compressor and slow down the compressor. At the same time, the pressure differential between the intake and exhaust manifolds increases due to the reduced pressure on the exhaust manifold side (because of the reduced expansion). Therefore, more airflow from the intake side can flow into the exhaust side for efficient exhaust to the intake manifold. As a result, the pressure at the outlet of the compressor is further reduced. Thus, such manipulation can reduce the likelihood of surge through the synergistic effect of the two actions.

Owner:FORD GLOBAL TECH LLC

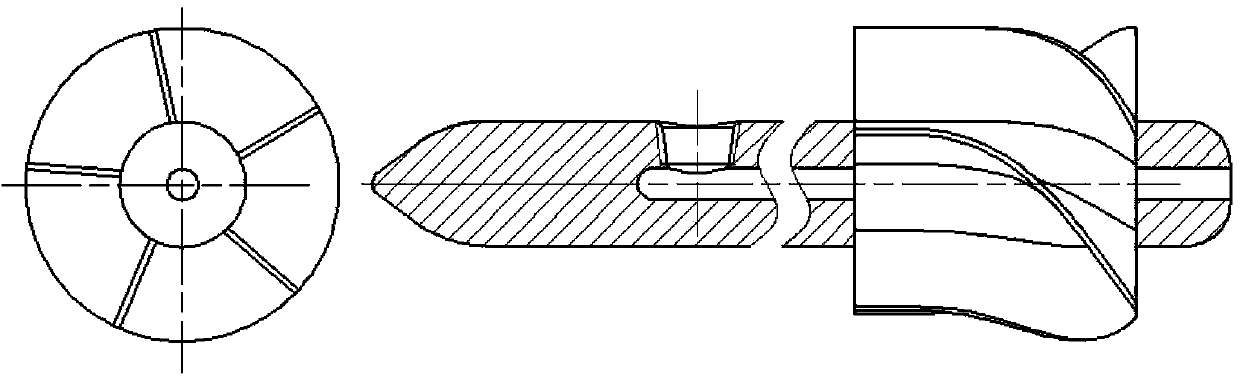

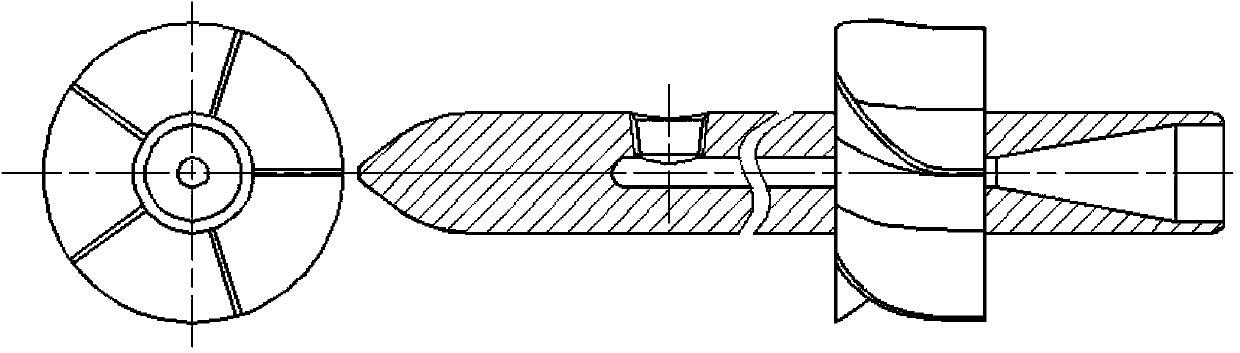

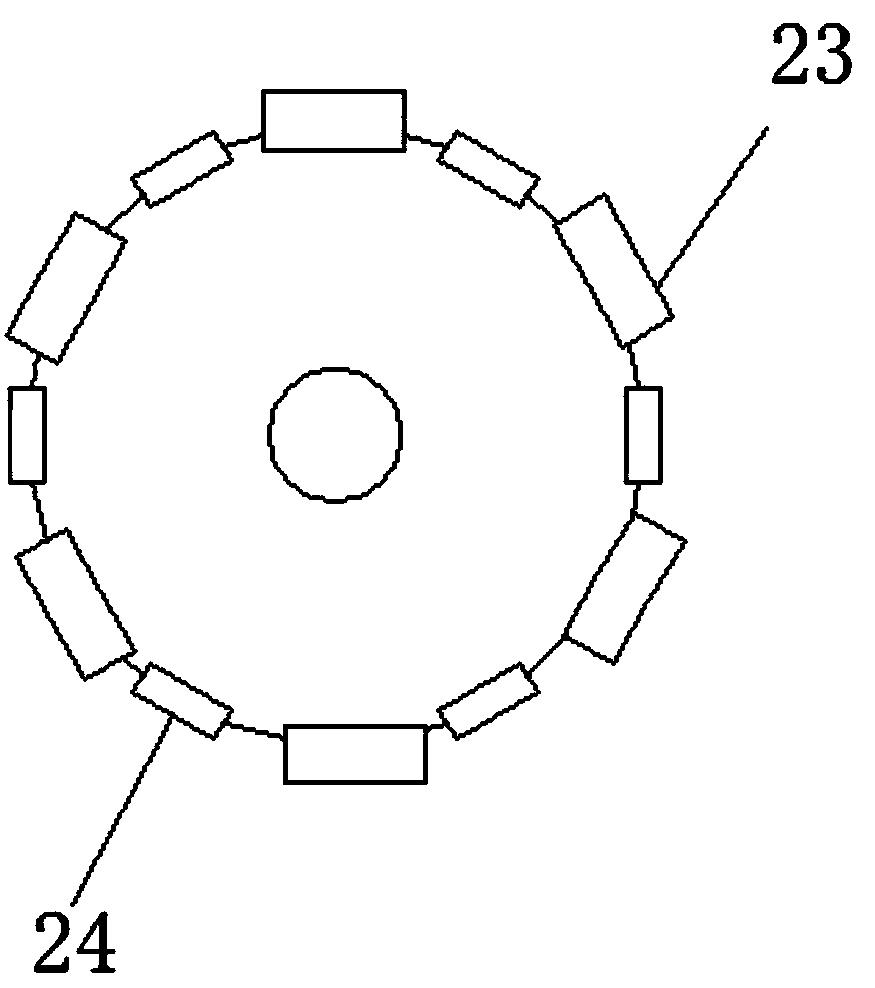

Spiral blade type small-size air bubble separation device

InactiveCN103394213AEfficient separationReduce power inputLiquid degasificationNuclear energy generationImpellerAir bubble

The invention aims to provide a spiral blade type small-size air bubble separation device which comprises a cylindrical barrel body, wherein a front air discharging pipe is arranged at the front end of the barrel body; a rear air discharging pipe is arranged at the rear end of the barrel body; a stirring blade wheel and a recovering blade wheel are respectively arranged in the barrel body; the stirring blade wheel comprises stirring blades and a stirring blade wheel shaft; the recovering blade wheel comprises recovering blades and a recovering blade wheel shaft; center holes are formed in both the stirring blade wheel shaft and the recovering blade wheel shaft; inlets of the two center holes are opposite; an air outlet of the center hole in the stirring blade wheel shaft is communicated with the front air discharging pipe; an air outlet of the center hole in the recovering blade wheel shaft is communicated with the rear air discharging pipe. The spiral blade type small-size air bubble separation device can realize the high-efficiency separation of small air bubbles and can work in a wide air content range and a wide liquid flow range; the recovering blade wheel at the tail has a function of partially recovering the pressure, so that the power investment in the equipment running process is effectively reduced, and the equipment running cost can be reduced.

Owner:HARBIN ENG UNIV

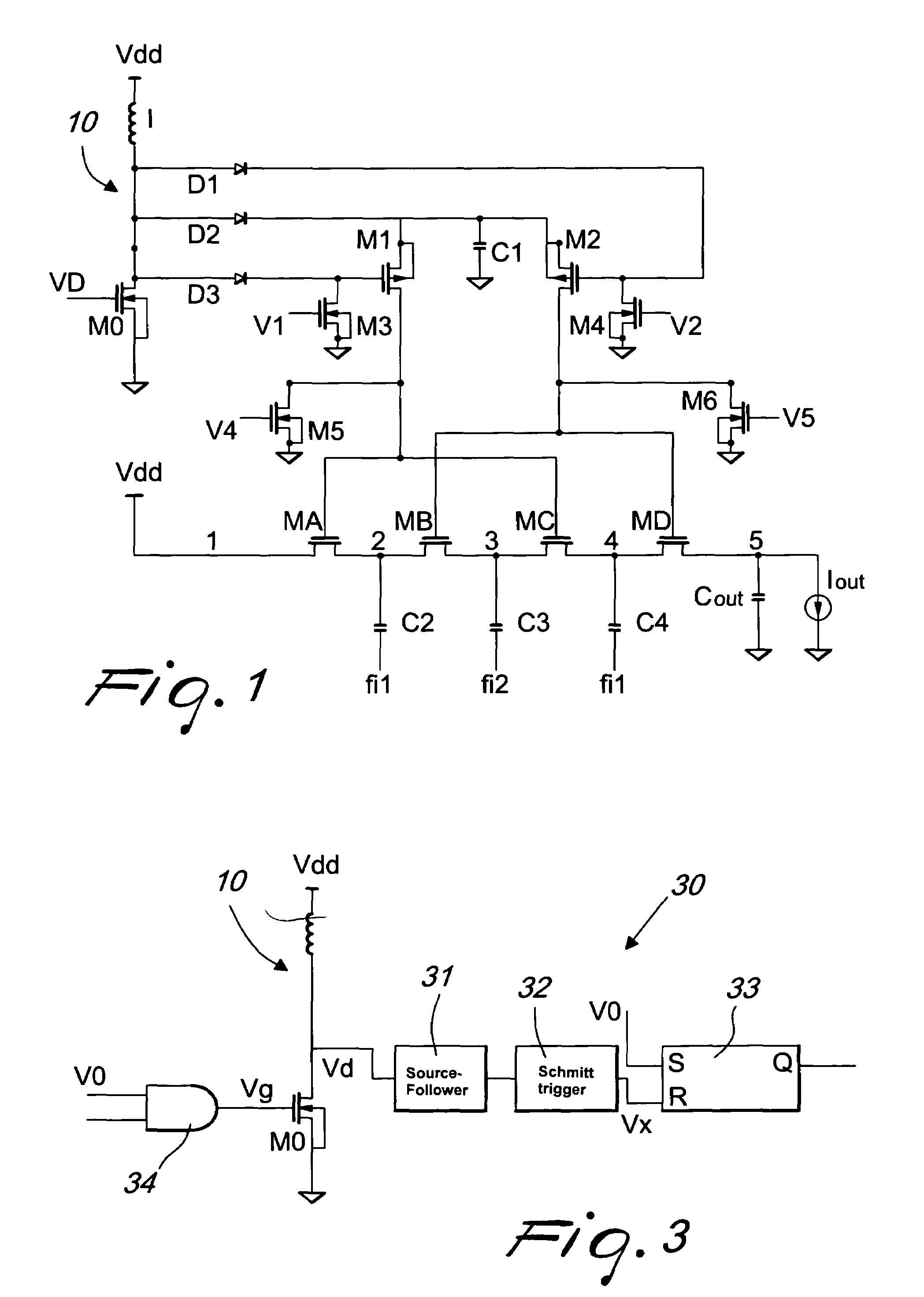

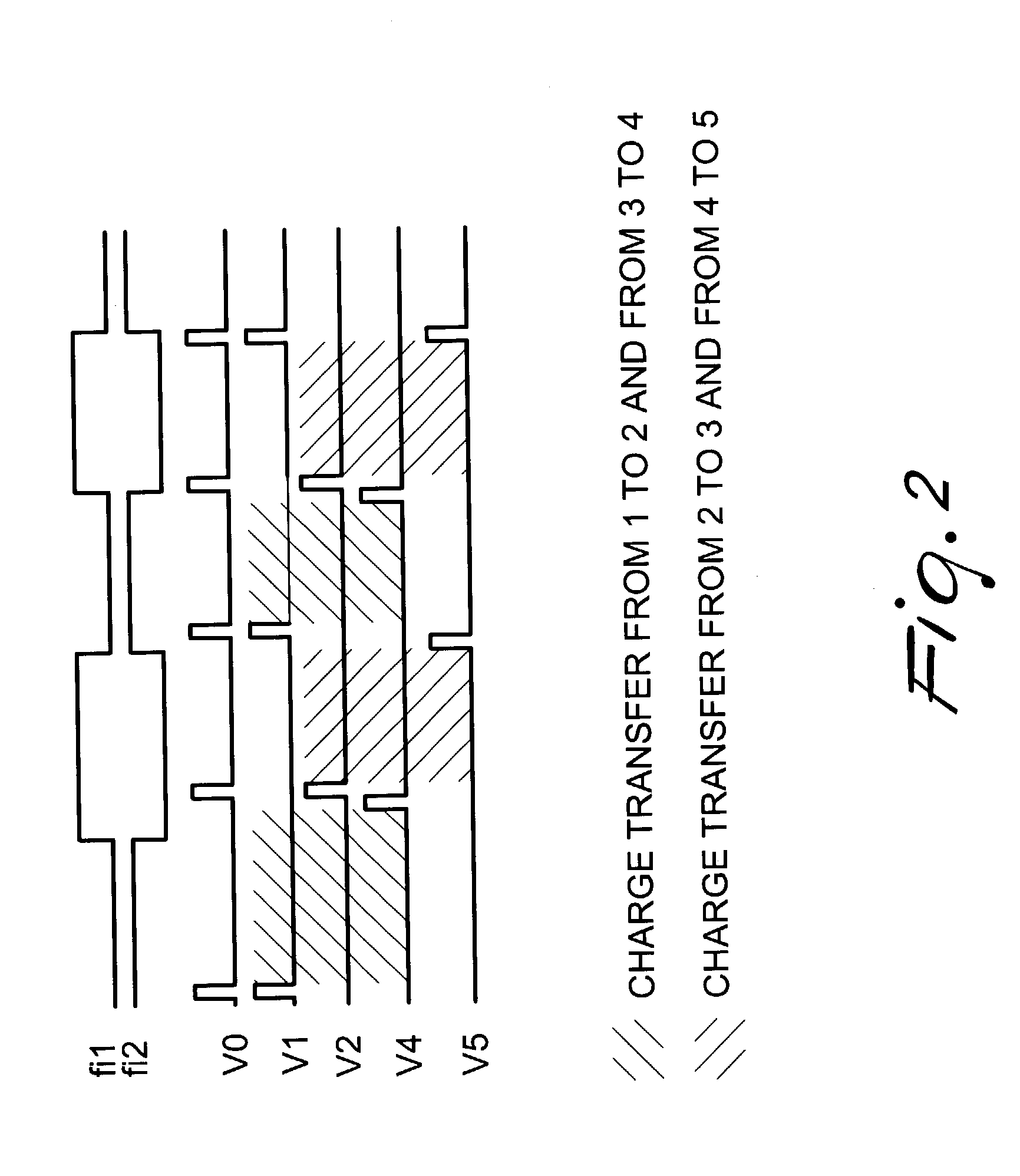

Hybrid inductive-capacitive charge pump with high diode driving capability

InactiveUS7034601B2High diode driving capabilityAvoid threshold lossAc-dc conversionApparatus without intermediate ac conversionSnubber capacitorEngineering

A hybrid inductive-capacitive charge pump provided with a driving stage that comprises a step-up converter and a buffer capacitor, and a cascade of charge pump stages; the first stage of the stage cascade is connected to a power supply and the last stage of the stage cascade is connected to an output of the charge pump circuit; the charge pump circuit comprises elements for activating alternately the charge pump stages, transferring charge from one stage of the cascade to the next stage of the cascade, each stage of the cascade of charge pumping stages comprising a pass transistor and a capacitor.

Owner:STMICROELECTRONICS SRL

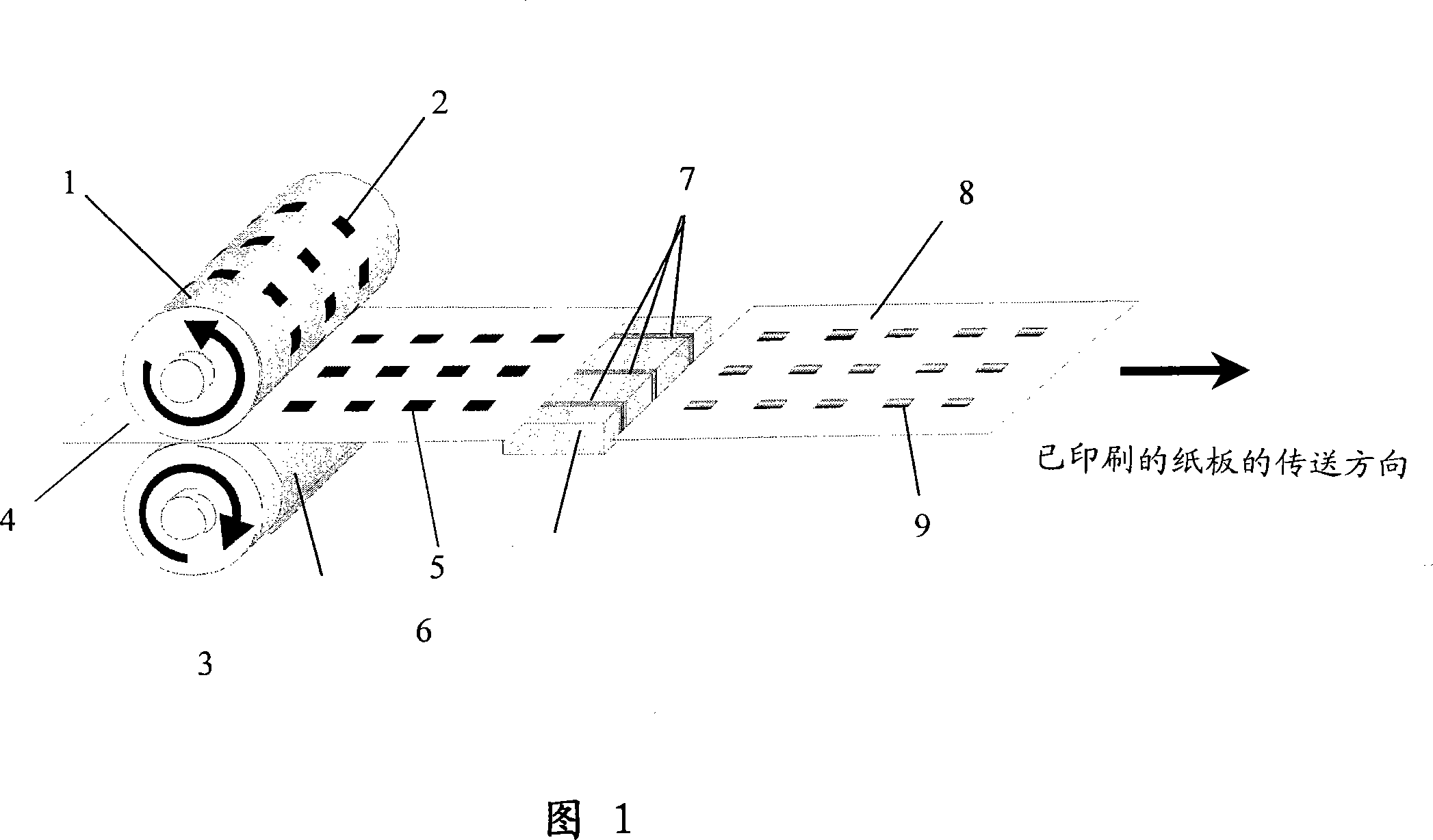

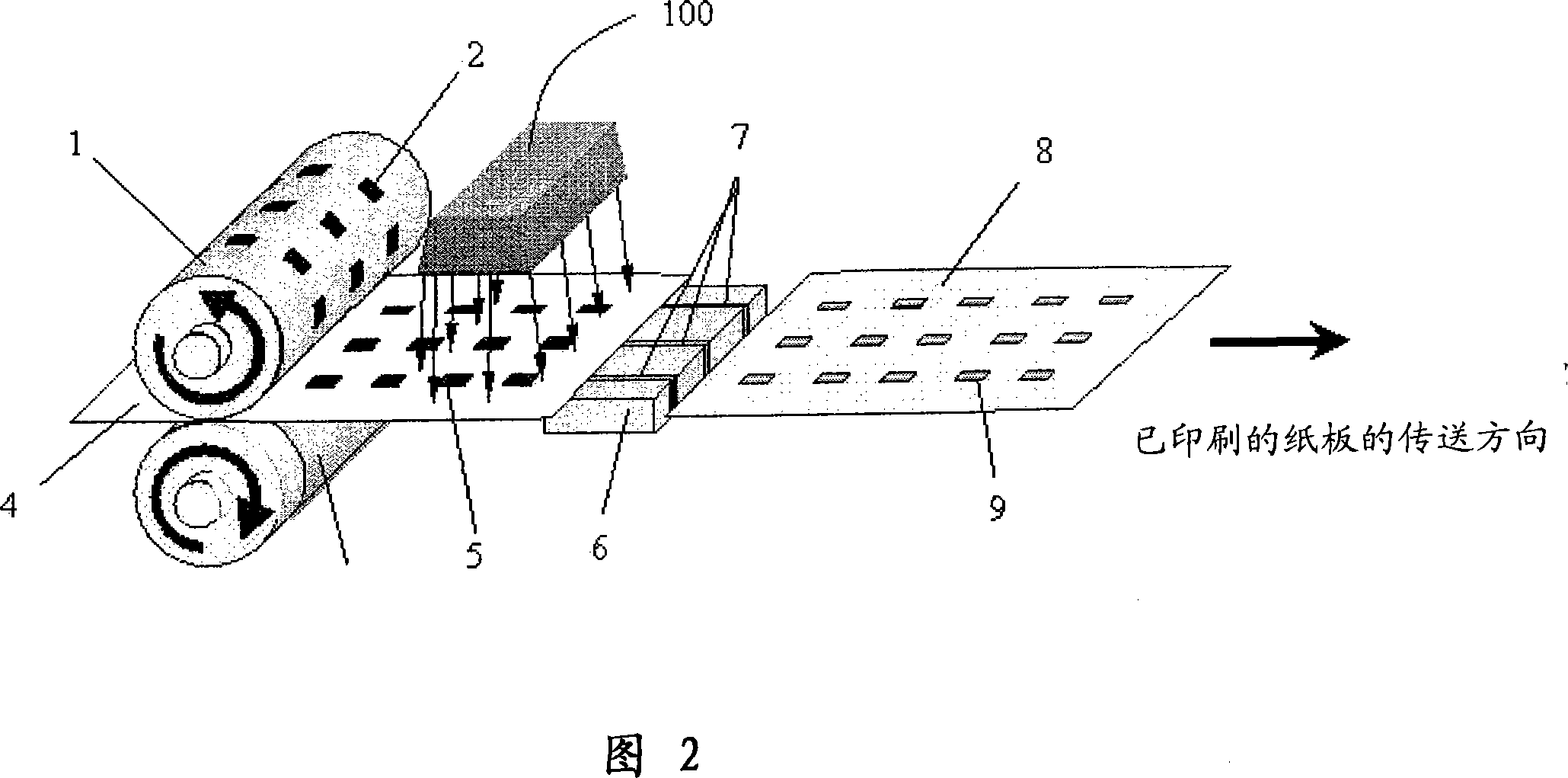

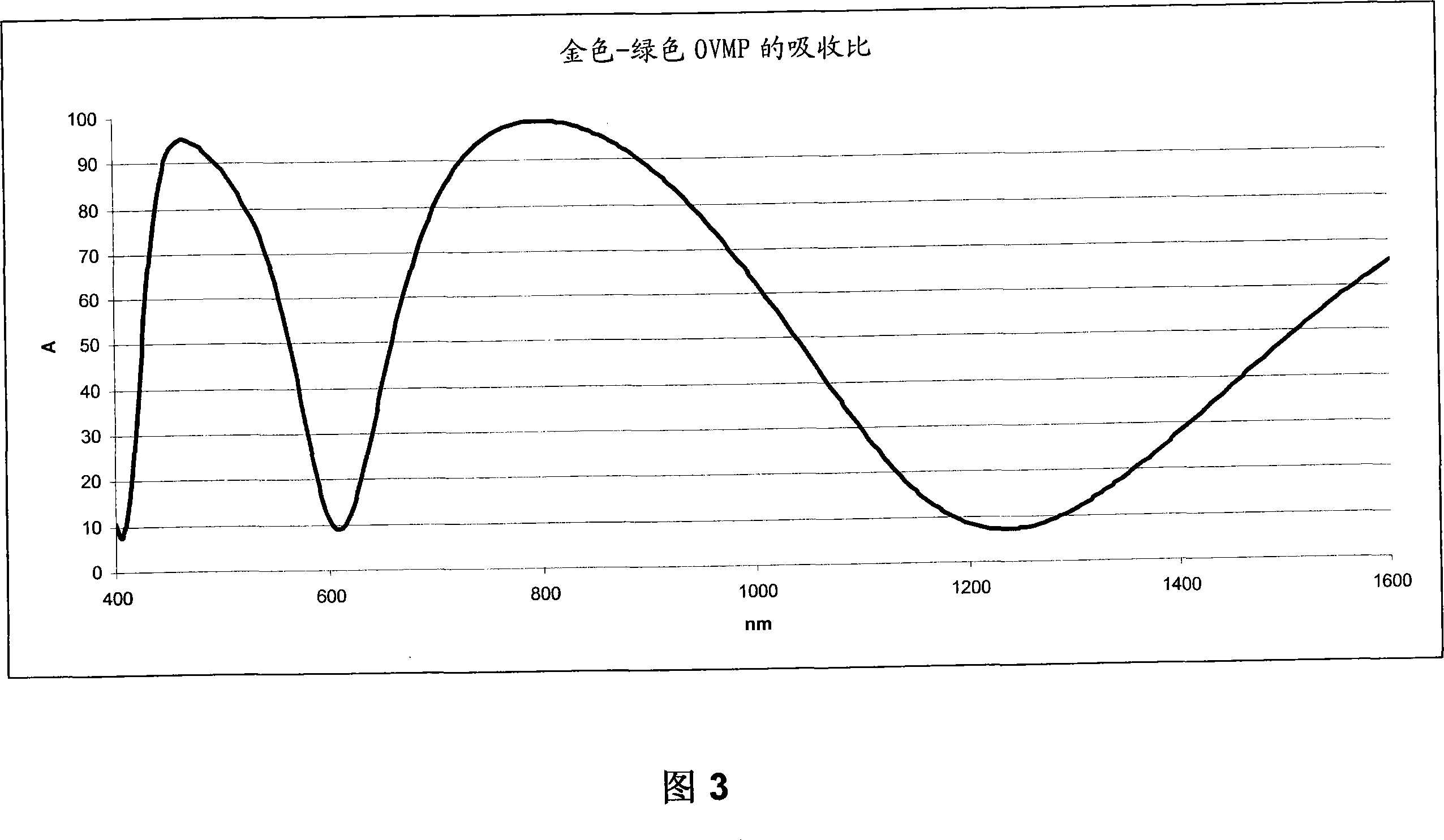

Heating magnetically orientable pigment in a printing process

InactiveCN101073958AProperly heatedReduce power inputMagnetic paintsPretreated surfacesLight beamOptical power

A printing apparatus and method for aligning special effect flakes is disclosed. The flakes field orientable and have an absorption band of wavelengths and a reflection band of wavelengths and are dispersed within in a viscous paste-like ink. The absorption band of the flakes is more absorbing than reflecting and the reflecting band is more reflecting than absorbing. A laser diode array is provided for generating beams of light positioned to irradiate the paste-like ink coating on the substrate so as to lessening the viscosity of the paste like ink by irradiating with light. Preferably at least 45% of the optical power of the one or more beams of light is in the absorption band of the flakes. After the flakes are heated to lessen the viscosity of the ink, a magnetic field is applied so as to orient the flakes within the ink.

Owner:JDS UNIPHASE CORP

Process for improving the hydrolysis of cellulose in high consistency systems using one or more unmixed and mixed hydrolysis reactors

ActiveUS8709770B2Low viscosityReduce power inputBioreactor/fermenter combinationsBiological substance pretreatmentsEnzymatic hydrolysisSlurry

Provided is a process for the enzymatic hydrolysis of cellulose to produce glucose from a pretreated cellulosic feedstock. The process comprises providing an aqueous slurry of the pretreated cellulosic feedstock that has a water content that is less than about 140% of the maximum water holding capacity of the pretreated cellulosic feedstock. The aqueous slurry of the pretreated cellulosic feedstock is fed to one or more unmixed hydrolysis reactors and hydrolyzed with cellulase enzymes therein. In the unmixed hydrolysis reactor(s), the cellulase enzymes hydrolyze a portion of the cellulose to produce soluble sugars, thereby producing a mixture of partially hydrolyzed cellulose containing soluble sugars. The hydrolysis of the cellulose to glucose is continued by feeding the mixture of partially hydrolyzed cellulose to one or more mixed hydrolysis reactors. Also provided are systems for carrying out the foregoing enzymatic hydrolysis.

Owner:IOGEN ENERGY CORP

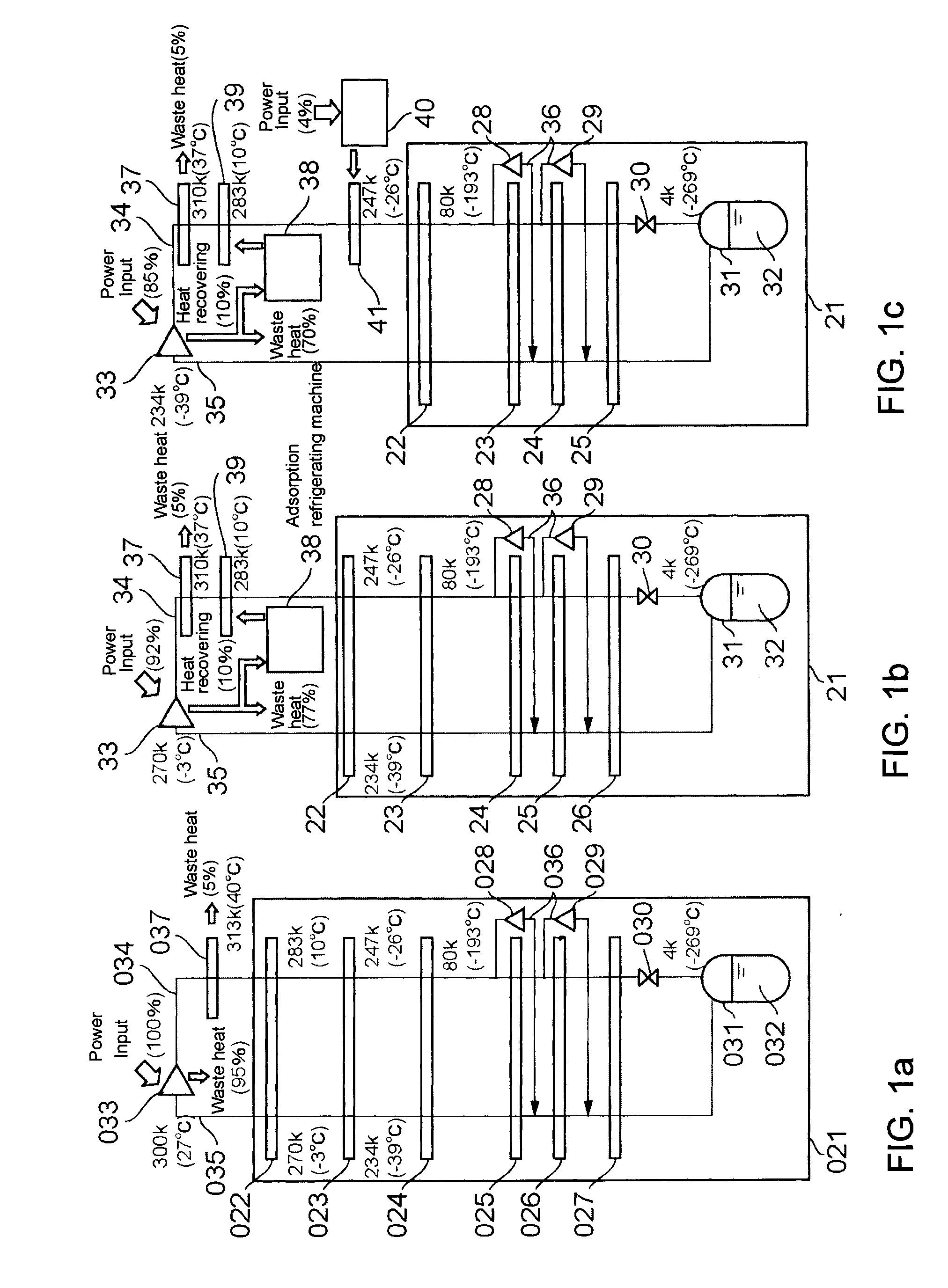

Cryogenic liquefying/refrigerating method and system

InactiveUS20070251266A1Reduced power inputIncrease thermal efficiencySolidificationLiquefactionProcess engineeringChiller

Cryogenic liquefying / refrigerating method and system, wherein temperature of gas-to-be-liquefied at the inlet of the compressor for compressing the gas is reduced by cooling the gas discharged from the compressor using a high-efficiency chemical refrigerating machine and vapor compression refrigerating machine before the gas is introduced to a multiple stage heat exchanger thereby reducing power input to the compressor and improving liquefying / refrigerating efficiency. Gas-to-be-liquefied compressed by a compressor is cooled by aftercooler, and further cooled by an adsorption refrigerating machine which utilizes waste heat generated in the compressor and by an ammonia refrigerating machine 40, then the high pressure gas is introduced to a multiple-stage heat exchanger where it is cooled by low pressure low temperature gas separated from a mixture of liquid and gas generated by adiabatically expanding the high pressure gas through an expansion valve 30 and returning to the compressor, and a portion of the high pressure gas is expanded adiabatically by expansion turbines in mid-course of flowing of the high pressure gas through the stages of the heat exchanger to be joined with the low pressure low temperature gas returning to the compressor.

Owner:MAYEKAWA MFG CO LTD

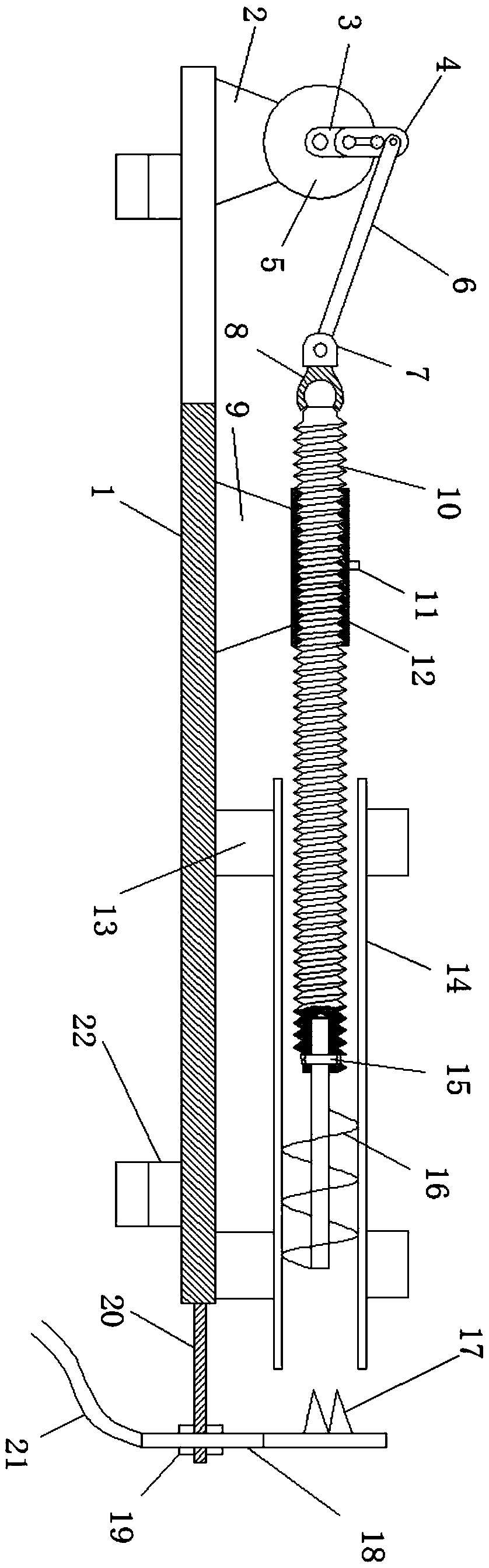

Polishing and grinding device for inner wall of glass pipeline

InactiveCN108044492AGood sandingImprove grinding effectPolishing machinesGrinding drivesWire gauzeReciprocating motion

The invention discloses a polishing and grinding device for the inner wall of a glass pipeline. The device comprises a bottom plate and a lead screw, wherein the lead screw is arranged above the bottom plate in parallel; four mounting legs are rectangularly distributed at the lower end of the bottom plate and are fixedly connected to the bottom plate; a sleeve sleeves the column surface of the lead screw; an inner thread corresponding to an outer thread of the lead screw is arranged on the inner wall of the sleeve; the sleeve is fixedly connected to the bottom plate through a sleeve support; the end, close to the sleeve, of the lead screw is fixedly connected to a joint bearing; the end, far from the lead screw, of the joint bearing is fixedly connected to a connecting block; and a connecting rod is hinged to the connecting block. The device disclosed by the invention is simpler in structure, small in power input and strong in co-movement, and is stronger in co-movement compared with that of an existing device in structure while solving the problem that the manual grinding cost is high. A grinding head also reciprocates in the glass pipeline while rotating. In addition to the action of oilstones and an asbestosed wire gauze, the grinding and polishing effect is better.

Owner:合肥挺泰环保科技有限公司

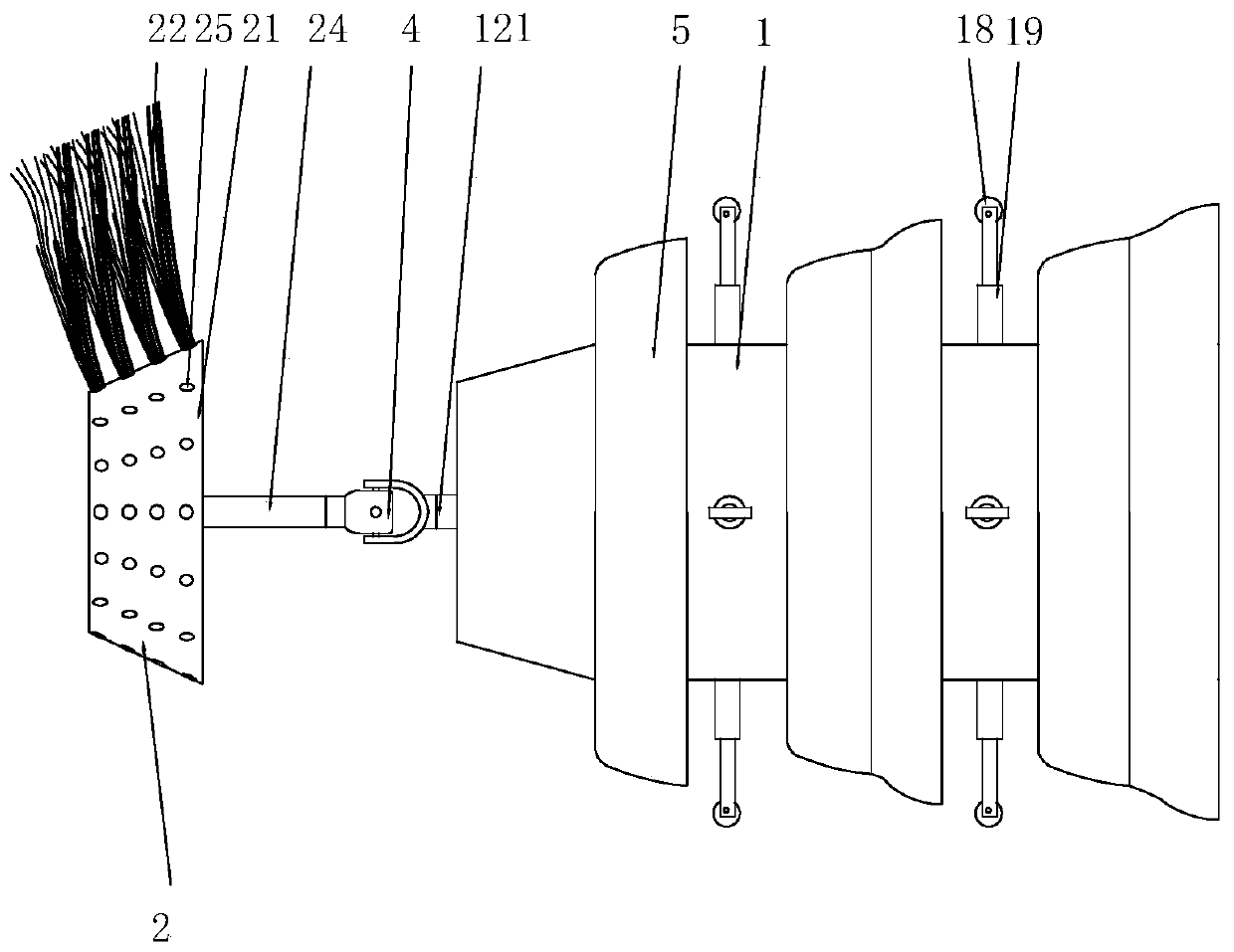

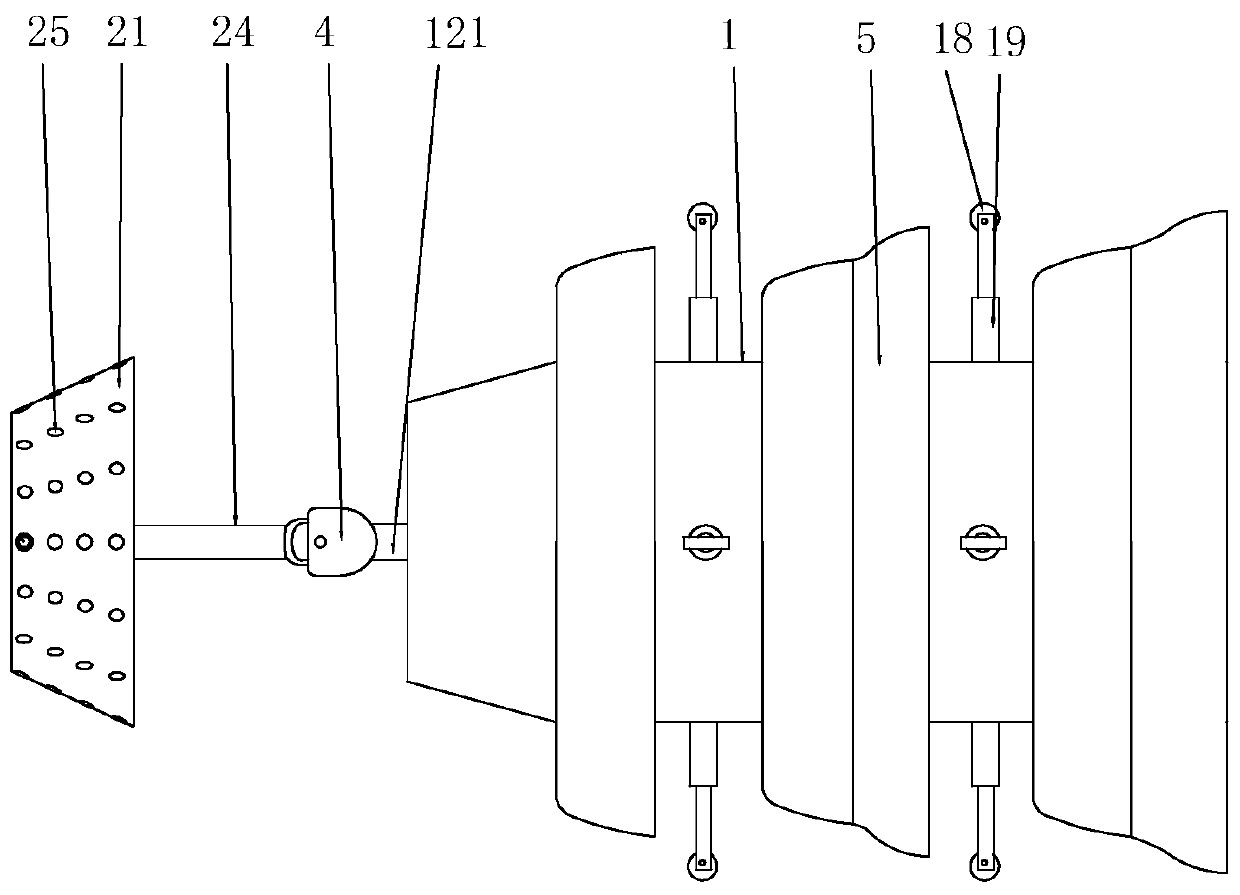

Pipe sweeping device and sweeping system

PendingCN110586587AEfficient cleaningReduce power inputHollow article cleaningPipe fittingUniversal structure

The invention discloses a pipe sweeping device. The pipe sweeping device comprises a propeller and a sweeping head, wherein a backswept-shape conical ring sleeve is arranged on the side wall of the outer ring of the propeller, and the outer edge of the conical ring sleeve can be attached to the inner wall of a pipe fitting; the sweeping head can rotate in the axial direction of the sweeping head so as to sweep the inner wall of the pipe fitting; a flow passing channel is arranged on the propeller, a rotating mechanism is rotatably arranged in the flow passing channel, and the output end of therotating mechanism is movably penetrate through the flow passing channel, is located at one end of the sweeping direction, and is connected with the sweeping head through a universal structure; and when fluid in the pipe fitting passes through the flow passing channel, the fluid can drive the rotating mechanism to rotate, and the rotating mechanism drives the sweeping head to sweep the inner wallof the pipe fitting. According to the pipe sweeping device and the sweeping system, the sweeping head can be forced to automatically rotate and sweep the inner wall of the pipe fitting while the fluid is utilized to drive the whole device to move in the pipe fitting, the structure is simple, and the sweeping effect is good.

Owner:ZHUHAI WINBASE INT CHEM TANK TERMINAL CO LTD

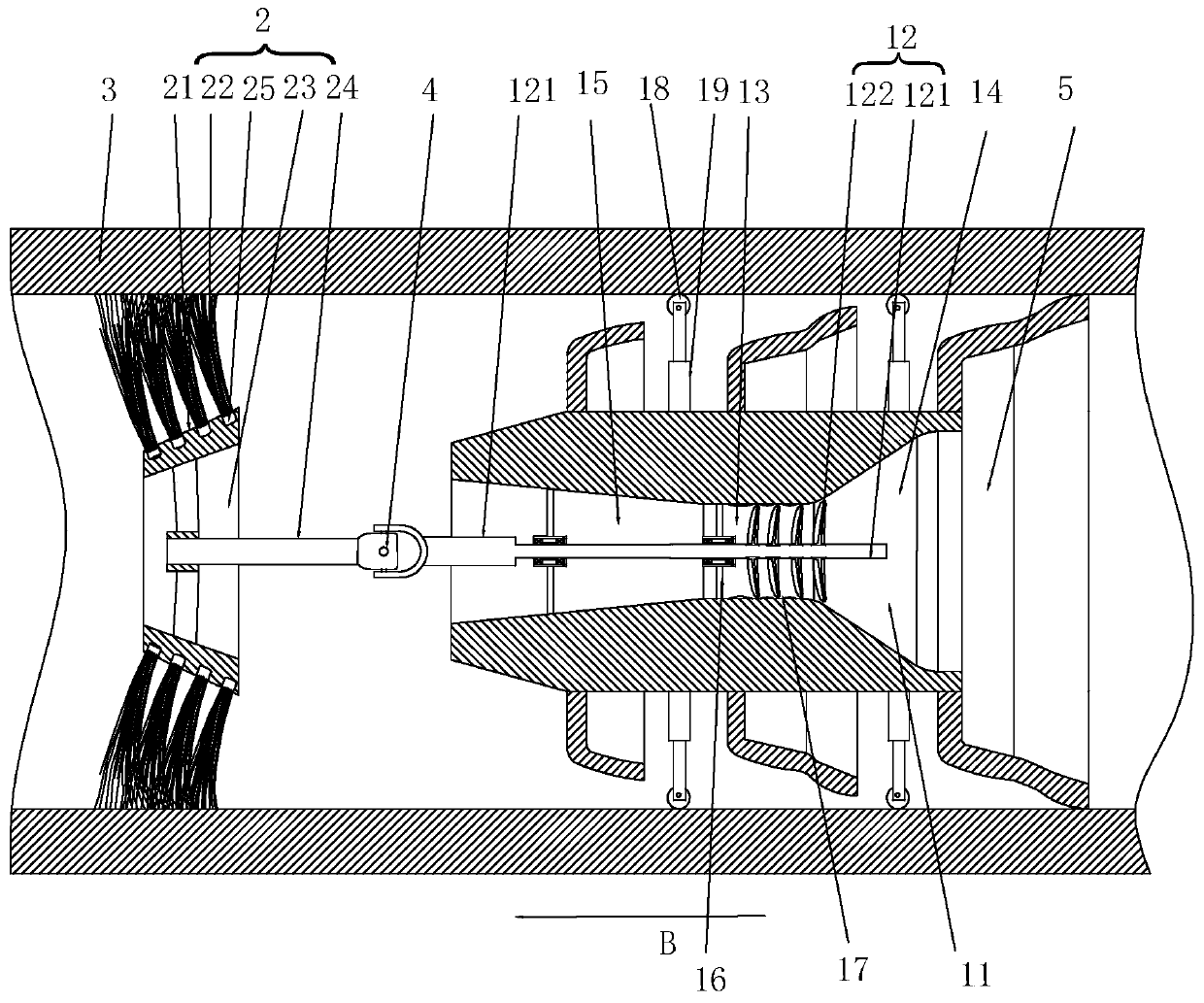

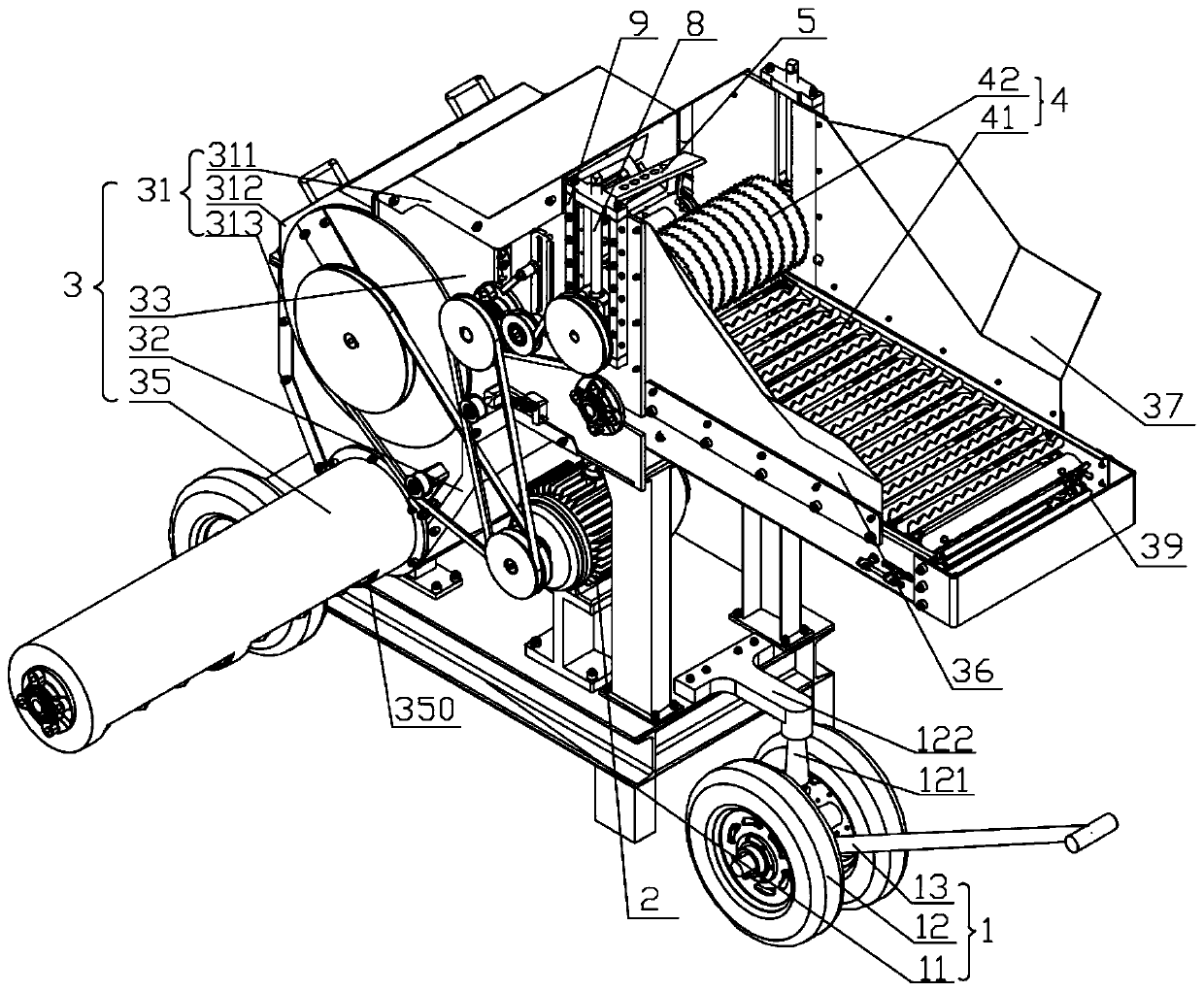

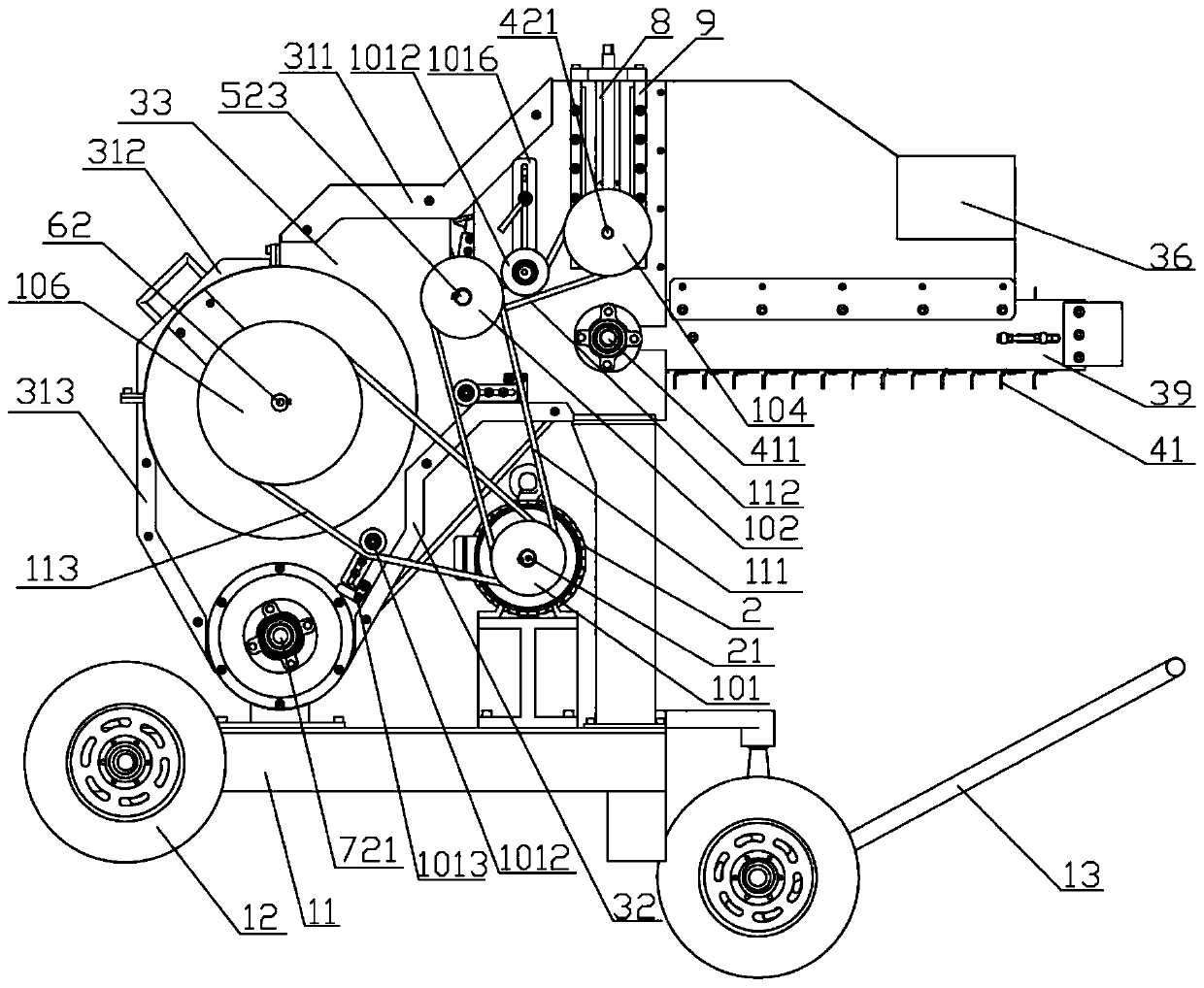

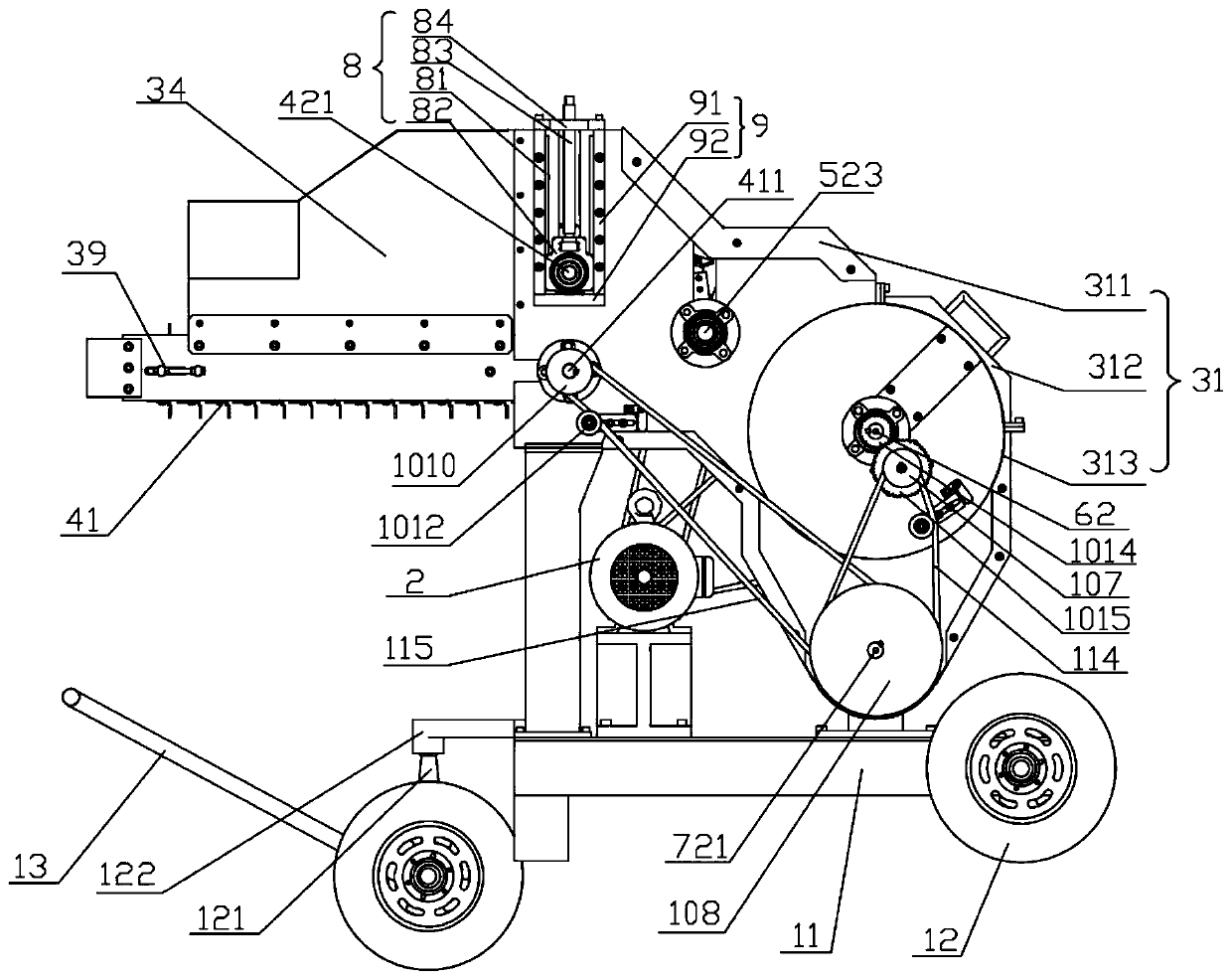

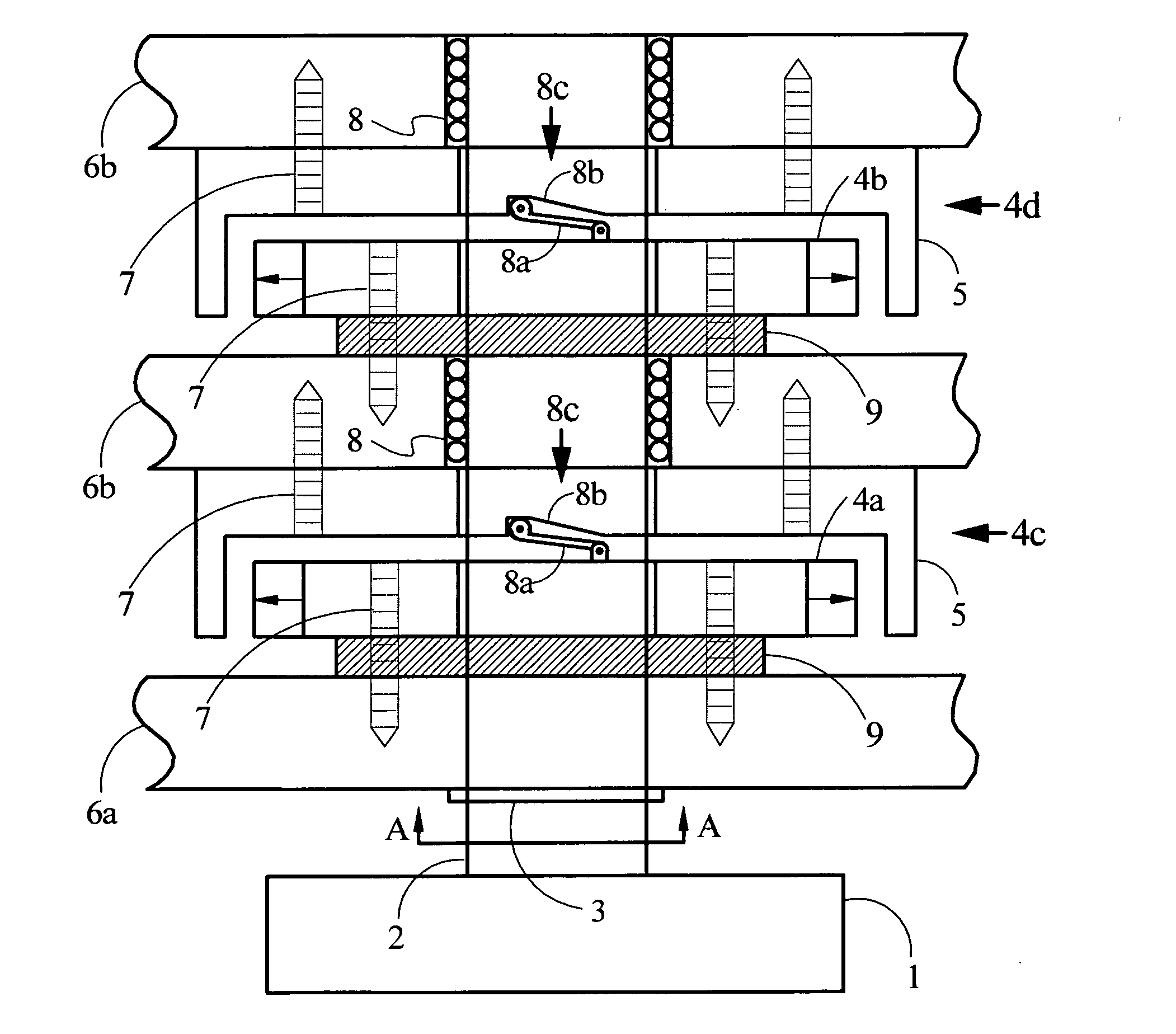

Straw filamentation machine

The invention discloses a straw filamentation machine. The straw filamentation machine comprises a supporting mechanism, a driving mechanism, a protection mechanism, a feeding mechanism, a shredding mechanism, a filament rubbing mechanism and a discharging mechanism, wherein the driving mechanism, the protection mechanism, the feeding mechanism, the shredding mechanism, the filament rubbing mechanism and the discharging mechanism are arranged on the supporting mechanism. A feeding hole, a straw moving channel and a discharging hole are formed in the protection mechanism; the feeding mechanismis located at the feeding hole and includes a conveyor belt and a saw disc knife roller; straw is conveyed to the shredding mechanism after being primarily crushed; the shredding mechanism and the filament rubbing mechanism are located in the straw moving channel; the shredding mechanism comprises a fixed cutter and a hob cutter, and the straw is shredded under the sliding cutting action of the fixed cutter and the hob cutter and is conveyed to the filament rubbing mechanism; the filament rubbing mechanism is used for filamentation of the shredded straw and for conveying straw filaments to thedischarging mechanism; after being screened through the discharging mechanism, the straw filaments are sent out of the machine through the discharging hole. According to the straw filamentation machine, filamentation of the straw is achieved through cooperation of feeding and division, cutting and crushing, hammering and rubbing, the filamentation efficiency is high, material accumulation is avoided, the structure is very simple, and the requirement of decentralized operation of agricultural production is met.

Owner:SHENYANG AGRI UNIV

Multi-stack flywheel energy storage assembly

InactiveUS20140103760A1Reduce power inputLess timeManufacturing dynamo-electric machinesMechanical energy handlingFreewheelFlywheel energy storage

A flywheel based energy storage system which includes multiple flywheels and a motor / generator unit. A single flywheel is fixed to the drive shaft. Multiple additional flywheels are mounted to drive shaft via bearings to allow freewheeling. Fixed flywheel is fully charged before speed activated clutch engages second flywheel. All additional flywheels are started sequentially in like manner. During discharge, charged flywheels engage drive shaft via one-way ratchet type mechanism and non-charged flywheels continue to freewheel. A sectional drive shaft of one embodiment simplifies portability and assembly. A Variable inertia flywheel of another embodiment further reduces charge-up time.

Owner:DUGAS PATRICK J

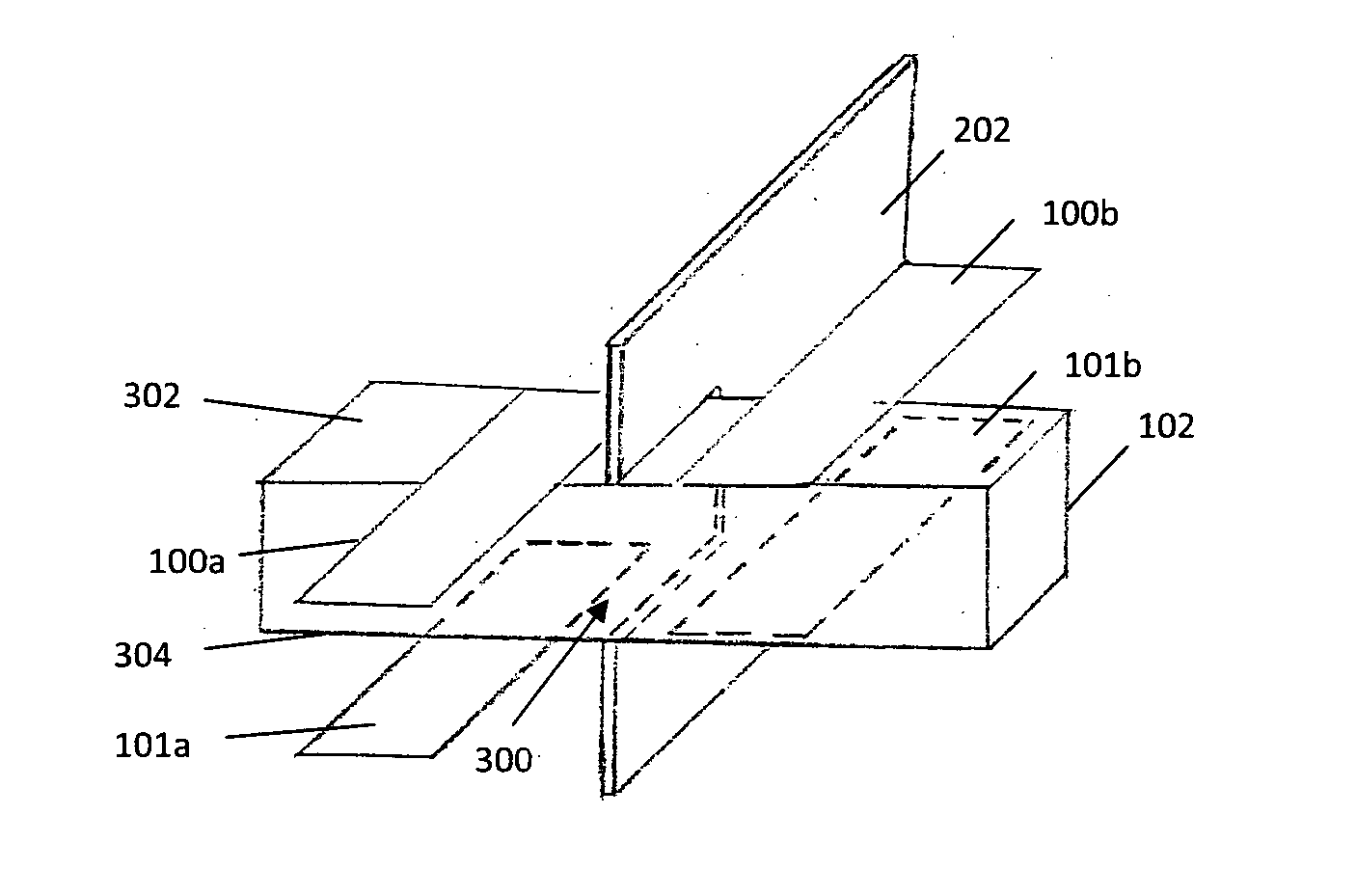

Contactless conductivity detector

InactiveUS20110140721A1High sensitivityImprove detection limitResistance/reactance/impedenceMaterial analysis by electric/magnetic meansEngineeringElectrode

The contactless conductivity detector in one embodiment includes a microfluidic chip having a channel (102) thereon and four detection electrodes: first and second emitting electrodes (100a, 101a), and first and second receiving electrodes (100b, 101b). The channel (102) is defined by channel walls. The first emitting electrode (100a) and the first receiving electrode (100b) are adjacent a first channel wall, and the second emitting electrode (101a) and the second receiving electrode (101b) are adjacent a second channel wall, the second channel wall being opposite the first channel wall.

Owner:AGENCY FOR SCI TECH & RES

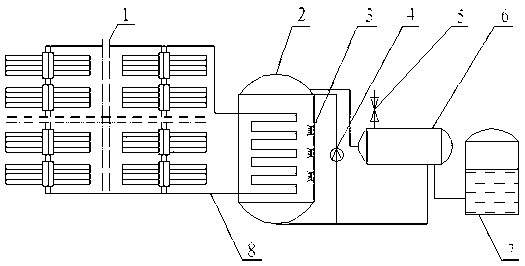

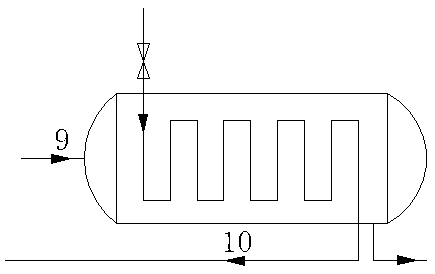

Solar seawater desalting system

InactiveCN103232086AIncrease profitSmall footprintGeneral water supply conservationSeawater treatmentThermal energyExternal energy

The invention relates to a solar seawater desalting system. A solar heat collector array is connected with an oil pipeline in a seawater evaporating tank, the inner side wall of the seawater evaporating tank is provided with an atomizing spray head, the atomizing spray head is connected with an unevaporated seawater outlet on the lower end of the seawater evaporating tank and a cold seawater outlet of a condenser through a cycling pump, and a steam outlet on the upper end of the seawater evaporating tank is connected with a steam inlet of the condenser. A coiled pipe is fully distributed inside the condenser, a water inlet of the coiled pipe is connected with a throttling valve for controlling the cold seawater inlet quantity, and a liquid water outlet on the lower end of the condenser is connected with a fresh water collecting device. The solar seawater desalting system does not need external energy, the radiation energy is converted to the heat for heating the working medium oil through the solar heat collector, and the heat is transferred to the seawater in the evaporating tank through the circulation of the oil inside the pipeline so as to heat the seawater. In addition, the atomizing spray head is also installed inside the evaporating tank, so that the heated area of the seawater is increased, and the evaporation of the seawater can be accelerated. The steam is condensed into the fresh water through the condenser, so that the desalting of the seawater can be realized.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com