Straw filamentation machine

A straw and protective mechanism technology, applied in agricultural machinery and tools, cutting equipment, applications, etc., can solve the problems of poor applicability, small power input, and easy material accumulation of whole straw and bundled straw, and meet the needs of decentralized operations The effect of small demand, small power input, and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

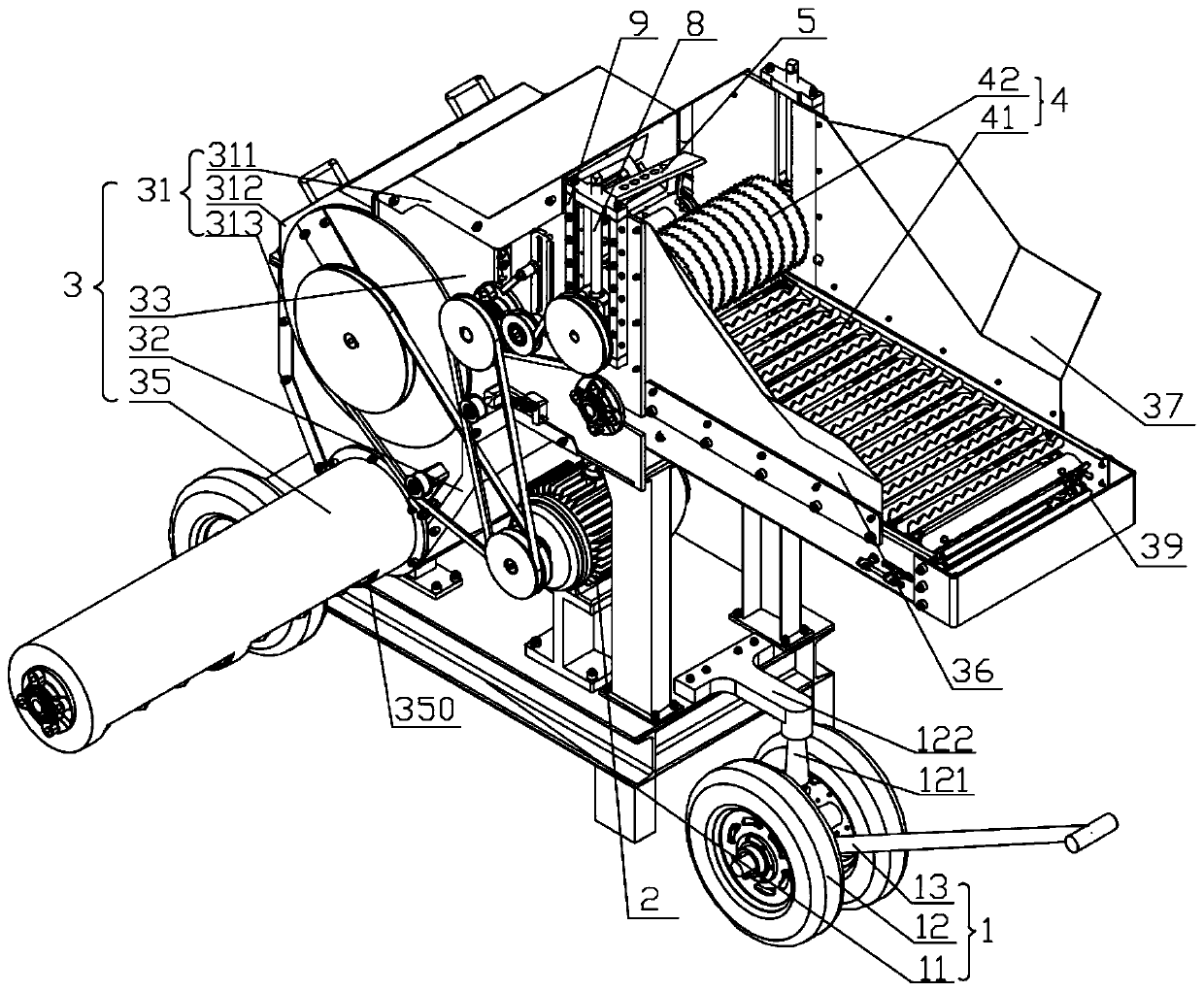

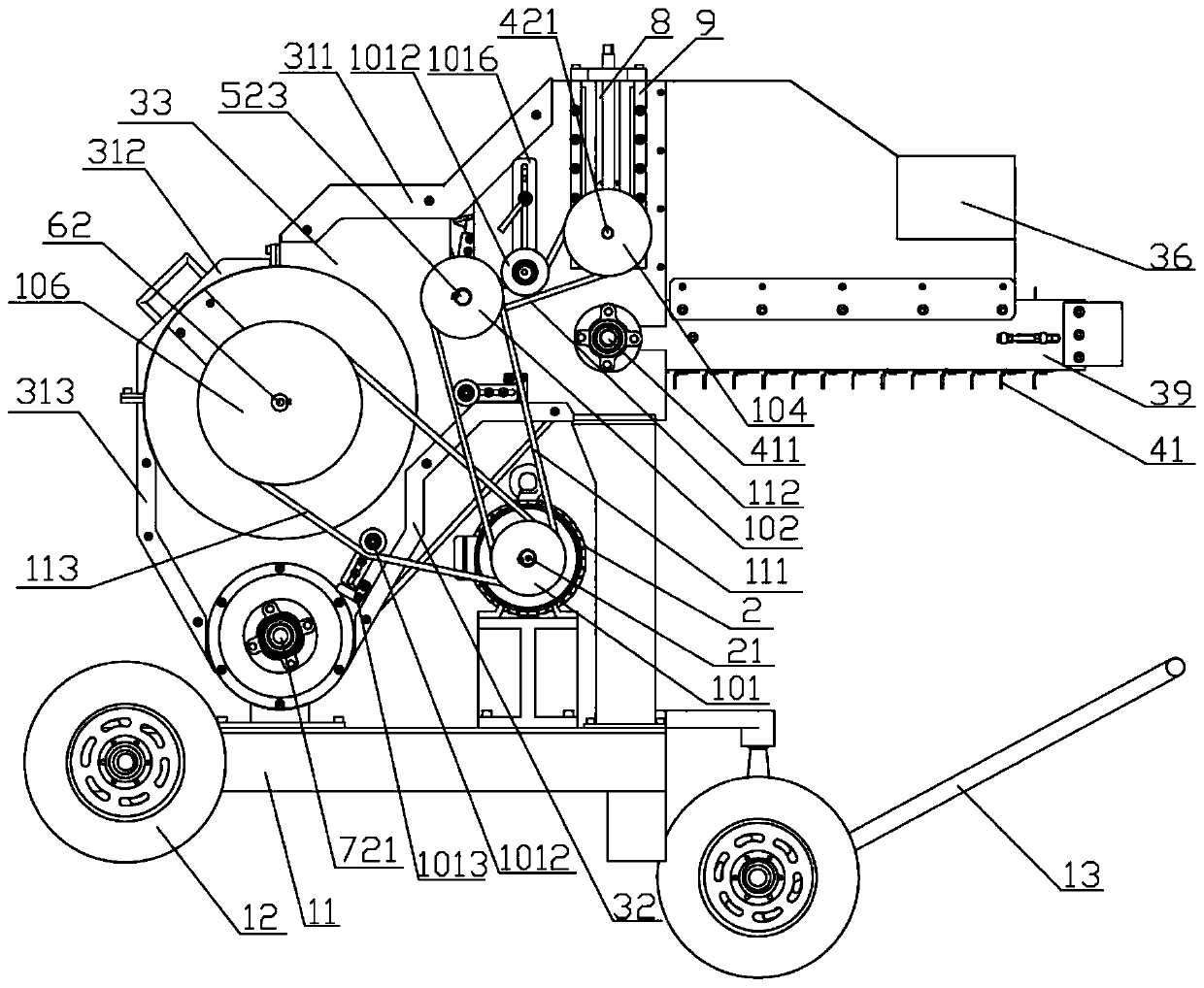

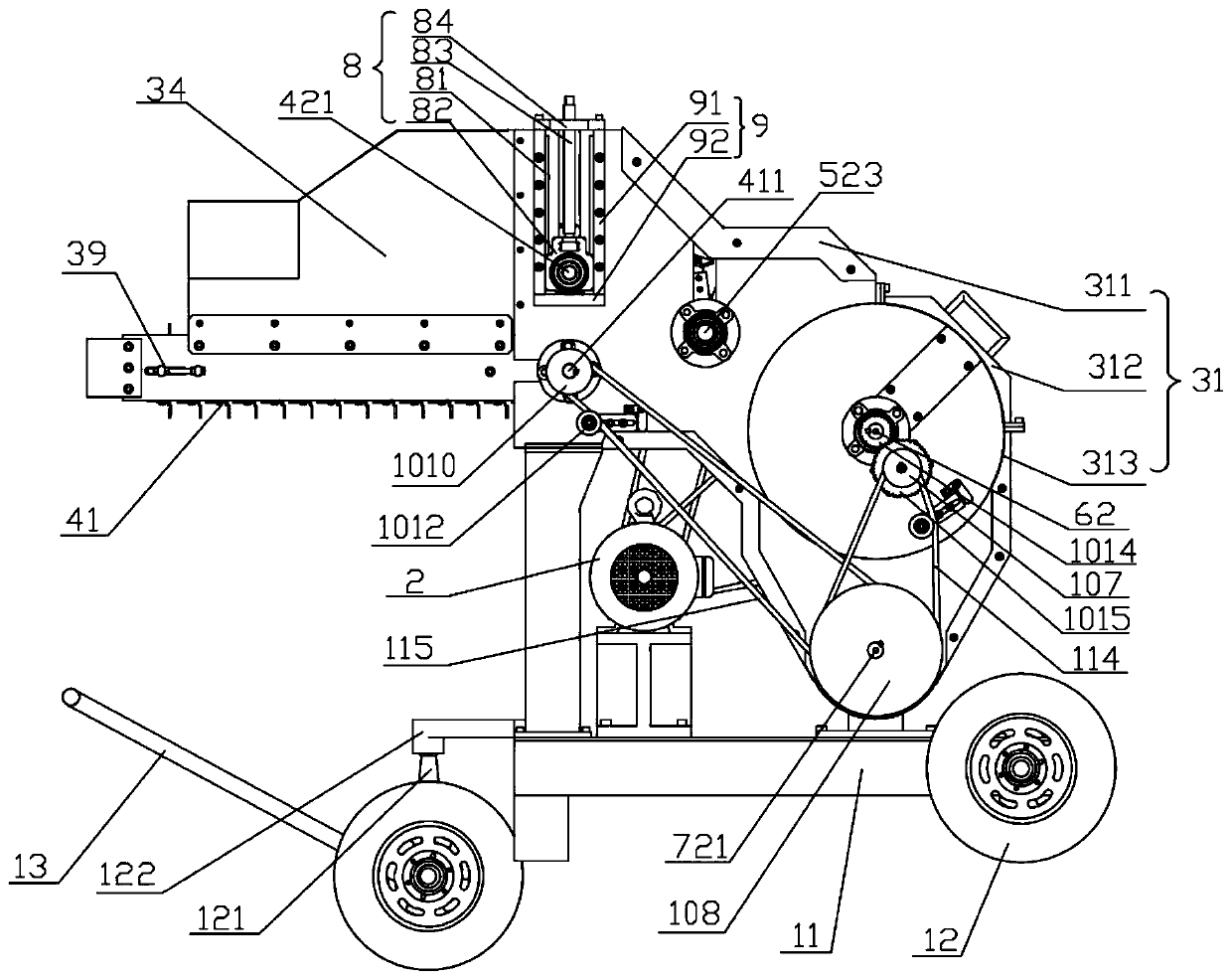

[0046] The straw silking machine provided by the present invention will be explained and described in detail below in conjunction with the accompanying drawings of the description.

[0047] Such as Figure 1~5 As shown, this embodiment specifically discloses a straw silk machine, which includes a support mechanism 1 and a drive mechanism 2 arranged on the support mechanism 1, a protection mechanism 3, a feeding mechanism 4, and a shredding mechanism 5 , knead silk mechanism 6 and discharge mechanism 7. The protection mechanism 3 forms the feeding port, the movement channel and the discharge port of the straw, the feeding mechanism 4 is fixed at the feeding port, the chopping mechanism 5 and the kneading mechanism 6 are arranged in the straw movement channel, and the discharging mechanism 7 is connected with the straw The moving passages are connected, and the straw silkized in the straw moving passage is sent out of the straw silking machine through the discharge port. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com