Straw-excrement microbial silage fertilizer and preparation method thereof

A technology of straw and manure, applied in the field of straw-manure micro-storage fertilizer and its preparation, can solve the problems of high cost of straw leaving the field and decline of farmland soil fertility, achieve a good decomposing environment, low environmental requirements, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

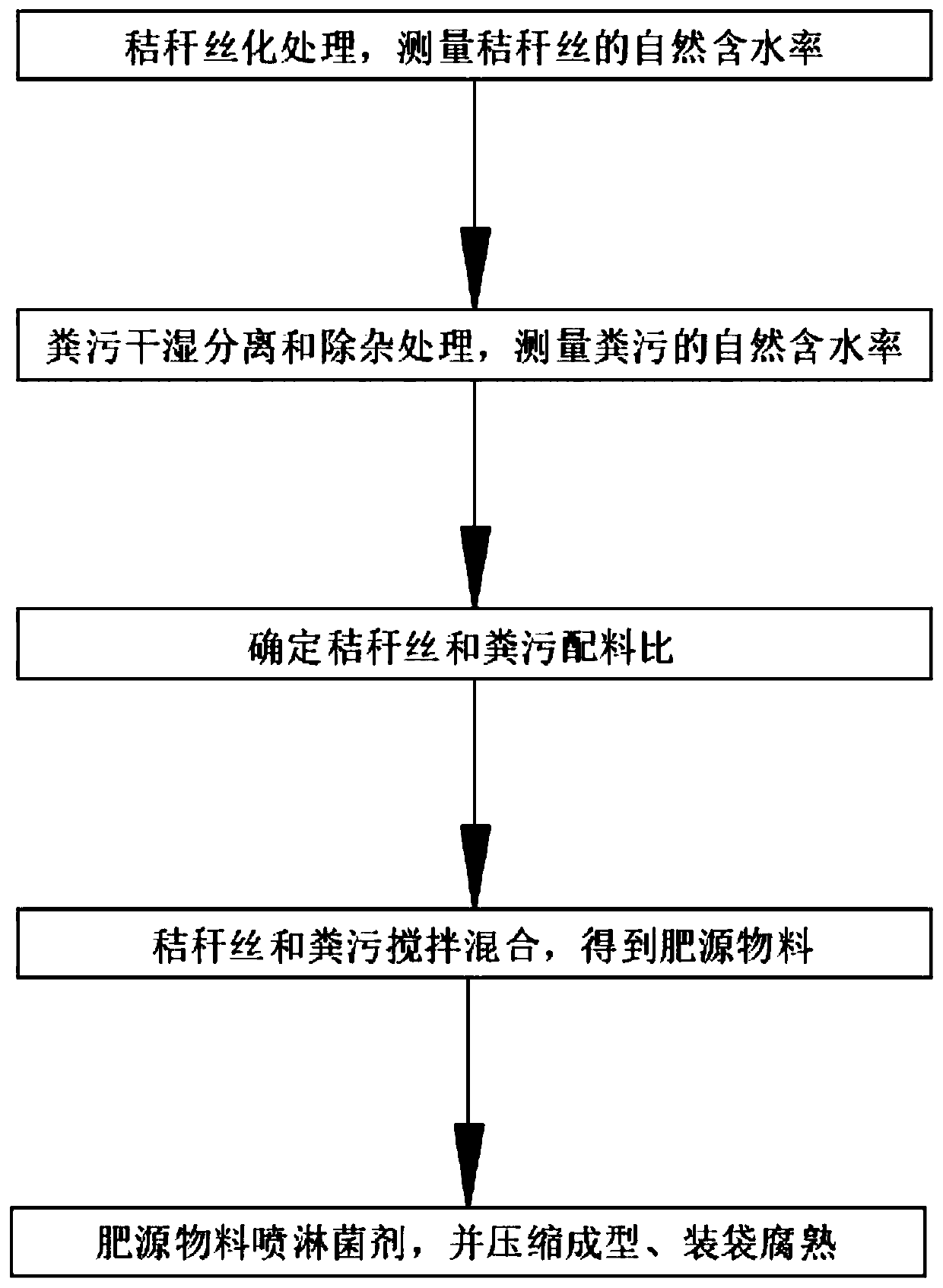

[0046] Such as figure 1 Shown, the first aspect of the present invention provides a kind of preparation method of stalk-manure micro-storage fertilizer, it may further comprise the steps:

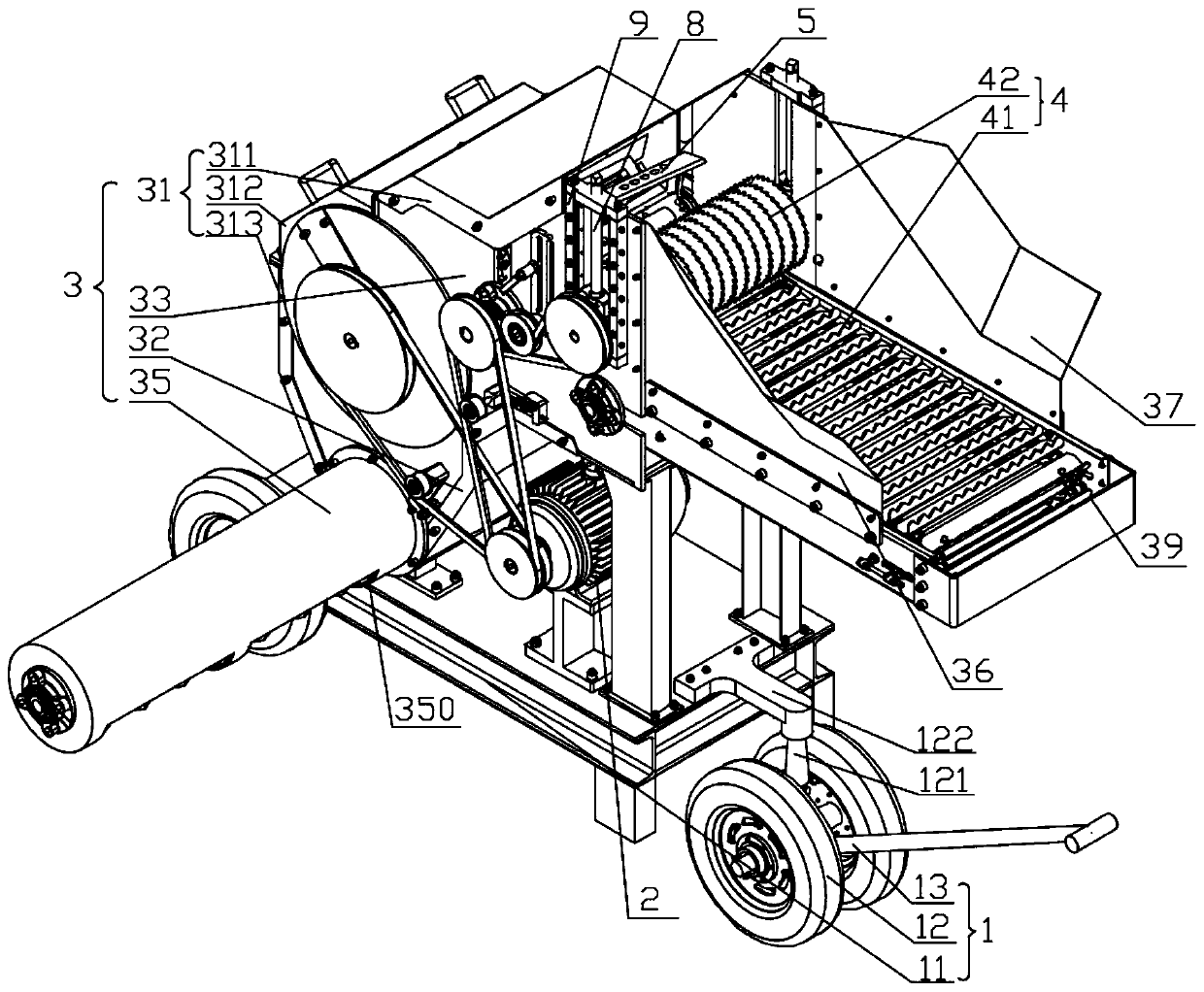

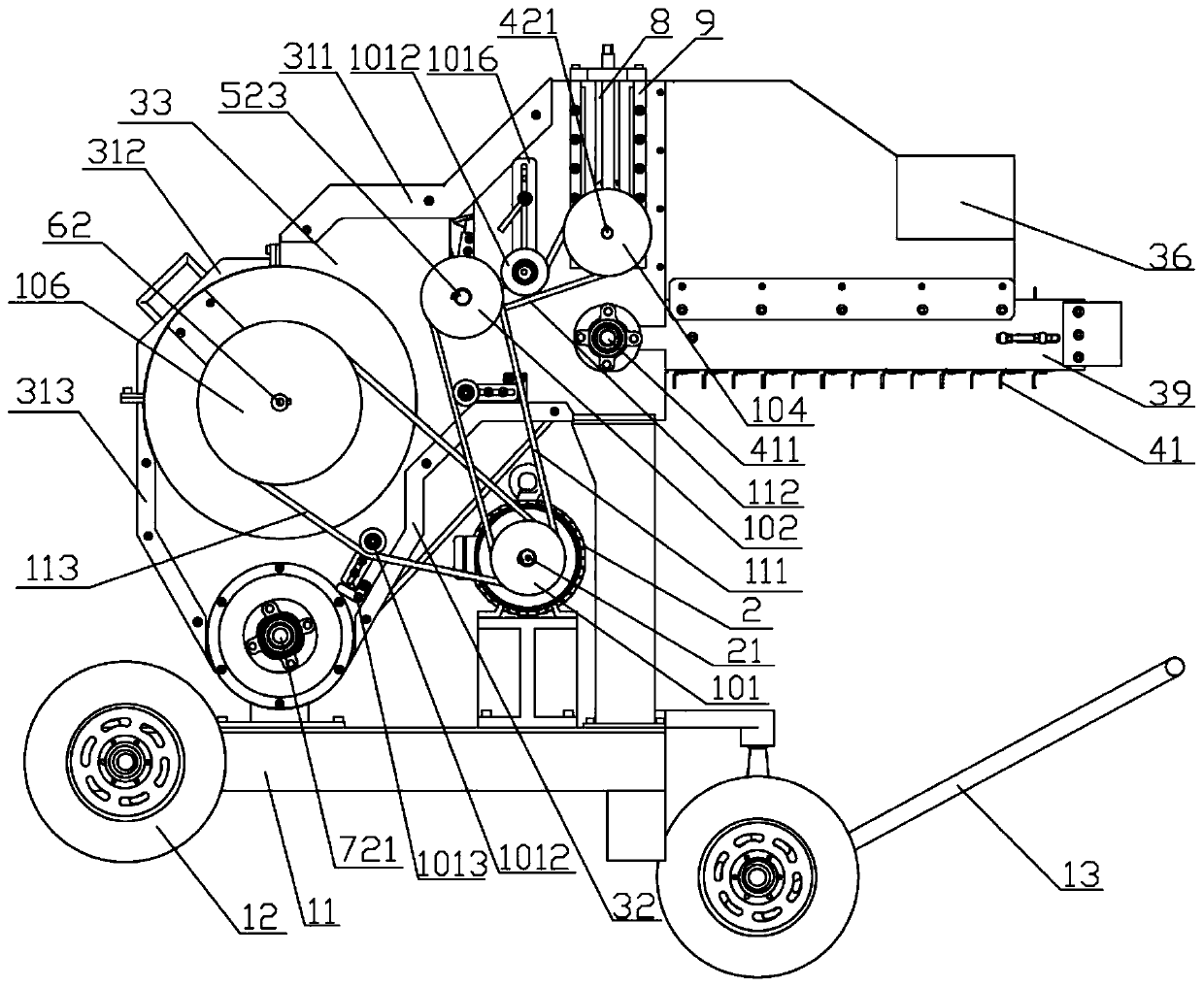

[0047] 1) The straw silkizing machine 100 is used to process the straw on the spot to obtain straw silk, and measure the natural moisture content of the straw silk. The straw silk is composed of water and dry matter of the straw silk.

[0048] 2) Dry-wet separation and impurity removal are carried out on the feces, and the dry matter and wet matter of the feces are separated, and the natural moisture content of the manure is measured. The manure is composed of dry matter and wet matter of the manure. The mass of impurities in the medium is negligible; The manure in the subsequent steps refers to the manure after impurity removal, including manure dry matter and manure wet matter;

[0049] 3) According to the preset moisture content requirements of the fertilizer source material and the...

Embodiment 1

[0063] 1) The corn stalks are silked in situ by a straw silking machine to obtain corn stalk silk, and the natural moisture content of the corn stalk silk is measured to be 60%;

[0064] 2) Cow dung is subjected to dry-wet separation and impurity removal treatment, and the dry matter and wet matter of cow dung are obtained by separation, and the natural moisture content of cow dung is measured to be 60%;

[0065] 3) According to the preset fertilizer source material moisture content of 60% and the preset ingredient ratio of straw dry matter to manure dry matter of 2:3, combined with the natural moisture content of corn straw silk measured in step 1) and step 2) The measured natural moisture content of cow dung determines the amount of corn stalks and cow dung;

[0066] 4) Weighing 40 kg of corn stalks and 60 kg of cow dung respectively, and stirring and mixing the corn stalks and cow dung to obtain fertilizer source materials;

[0067] 5) Spray Bacillus licheniformis on the f...

Embodiment 2

[0069] 1) The corn stalks are processed into silk by using a straw silking machine to obtain corn stalk silk, and the natural moisture content of the corn stalk silk is measured to be 50%;

[0070] 2) The cow dung is subjected to dry-wet separation and impurity removal treatment, and the dry matter of cow dung and the wet matter of cow dung are separated, and the natural moisture content of the cow dung is measured to be 50%;

[0071] 3) According to the preset fertilizer source material moisture content of 50% and the preset ingredient ratio of straw dry matter to manure dry matter of 3:2, combined with the natural moisture content of corn straw silk measured in step 1) and step 2) The measured natural moisture content of cow dung determines the amount of corn stalks and cow dung;

[0072] 4) Weighing 30 kg of corn stalks and 20 kg of cow dung respectively, and stirring and mixing the corn stalks and cow dung to obtain fertilizer source materials;

[0073] 5) Spray Bacillus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com